Device and method for removing and recovering cationic heavy metals in organic acid wastewater by using aerobic granular sludge

An aerobic granular sludge and organic acid technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, aerobic process treatment, etc., can solve the problem of increasing the manufacturing and operating costs of reactors and not having recycling Value, increase process complexity and other issues, to achieve the effect of further degradation, reduce the risk of re-release, and reduce bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

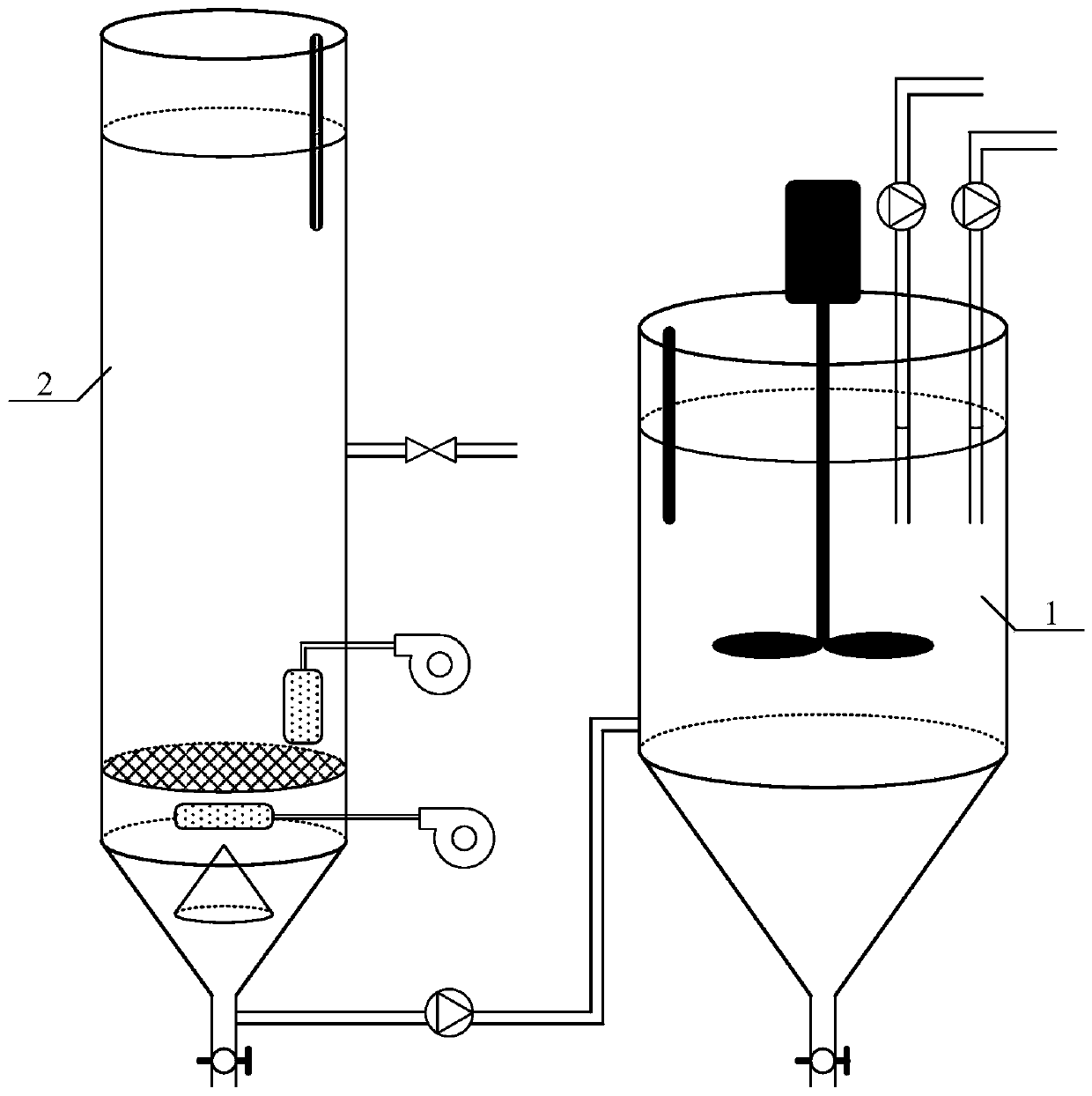

[0036] Such as figure 2 As shown, a device for removing and recovering cationic heavy metals in organic acid wastewater by using aerobic granular sludge in this embodiment mainly includes two parts: a regulating tank 1 and a reaction tank 2 .

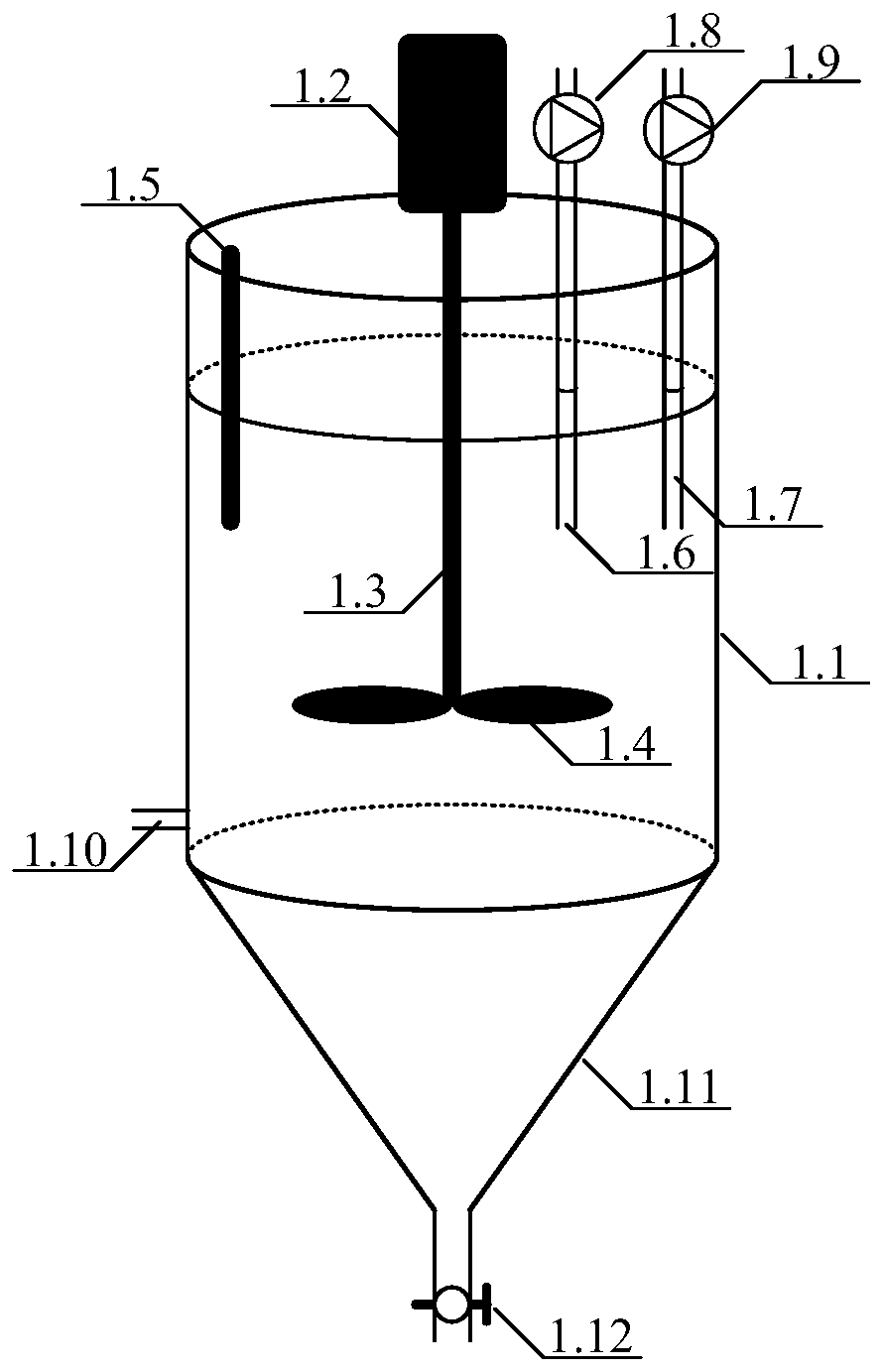

[0037] Such as image 3 As shown, the main body of the regulating tank 1 is the regulating tank body 1.1, and the upper end of the regulating tank body 1.1 is provided with a stirring motor 1.2, a regulating tank pH electrode 1.5, an alkali liquid inlet pipe 1.6, and a regulating tank water inlet pipe 1.7. The output shaft of the stirring motor 1.2 is connected to the stirring paddle 1.4 through the stirring rod 1.3, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com