Treatment method of dyestuff wastewater containing heavy metals

A dye wastewater and treatment method technology, which is applied in textile industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of not considering the removal effect of heavy metal salts, achieve simple operation, reduce treatment cost, The effect of simple reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 100mL and contain 100mg / L Cu 2+ ions and 50mg / L methylene blue mixed solution, adding a certain amount of ferrous sulfate to it to make Fe in the mixed solution 2+ The concentration of the mixture is 300mg / L, stirring at a certain speed (200r / min) at 70°C, adjusting the pH to 6 with NaOH, and reacting for 5min. After sampling through a 0.45 μm filter membrane, the concentration of methylene blue in the solution was measured by an ultraviolet spectrophotometer, and the concentration of Cu and Fe ions in the mixed solution was measured by ICP-OES.

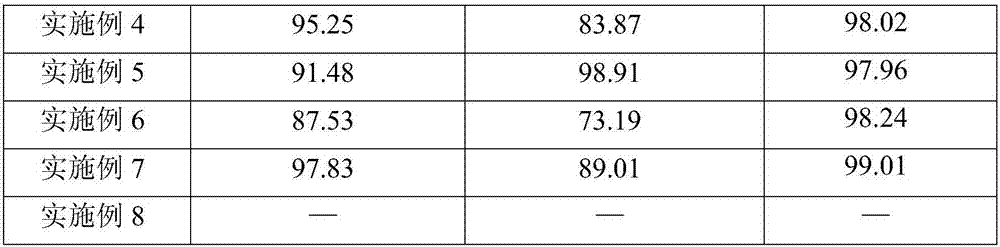

[0026] The measurement results are shown in Table 1.

Embodiment 2

[0028] Take 100mL while containing 550mg / L Mn 2+ ions and 200mg / L of tartrazine mixed solution, adding a certain amount of ferrous sulfate to it to make Fe in the mixed solution 2+ The concentration of the mixture is 1200mg / L, stirred at a certain speed (250r / min) at 20°C, adjusted to pH 7 with KOH, and reacted for 15min. After magnetic separation, pass through a 0.45 μm filter membrane, and use an ultraviolet spectrophotometer to measure the concentration of methylene blue in the solution. The concentrations of Mn and Fe ions in the mixed solution were measured by ICP-OES.

[0029] The measurement results are shown in Table 1.

Embodiment 3

[0031] Take 100mL and contain 1200mg / L Cu 2+ ion and 200mg / L of crystal violet mixed solution, adding a certain amount of ferrous chloride to it to make Fe in the mixed solution 2+ The concentration of the mixture is 1200 mg / L, stirring at a certain speed (200 r / min) at 15°C, adjusting the pH to 9 with KOH, and reacting for 15 minutes. After centrifugation, pass through a 0.45 μm filter membrane, and measure the concentration of methylene blue in the solution with an ultraviolet spectrophotometer. The concentrations of Cu and Fe ions in the mixed solution were measured by ICP-OES.

[0032] The measurement results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com