System and method for removing heavy metal chromium, dyes and short wool fibers in leather wastewater

A technology for leather wastewater and heavy metals, which is applied in chemical instruments and methods, water pollutants, animal processing wastewater treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. Material properties

[0056] (1) Leather wastewater containing heavy metals, dyes, and short-haired fibers: The tanning and dyeing wastewater of a tannery has a solid particle content of 600 mg / L and a heavy metal ion chromium concentration of 120 mg / L, both exceeding the standard. The waste water treatment capacity of the side line experiment is 40L / h at room temperature.

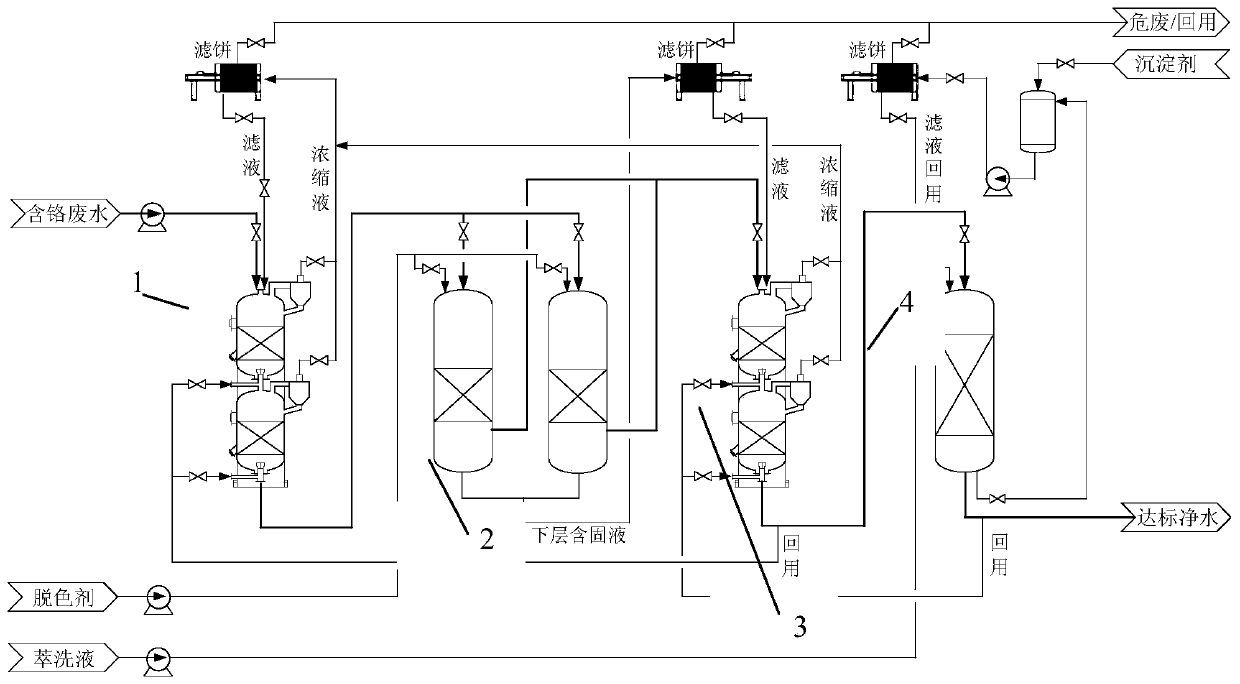

[0057] (2) Separation and adsorption medium: The granular bed separator group uses modified carbon ball particles as the separation medium; the dual-function adsorption tower uses D001 resin pellets as the adsorbent.

[0058] 2. Process flow

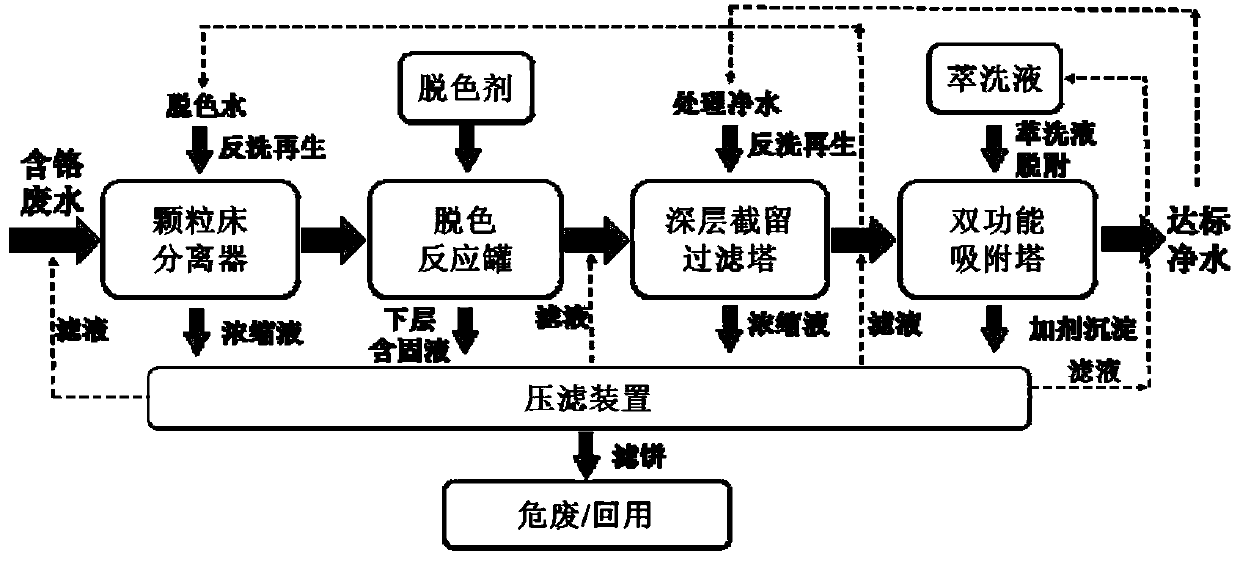

[0059] In view of the high content of dyes, short-haired fibers and heavy metals in leather wastewater, choose the following figure 1system shown. The waste water first passes through the particle bed separator to remove short-haired fibers and some dyes in the water; the waste water treated by the self-cleaning particle bed is placed in a liquid storage...

Embodiment 2

[0066] 1Material properties

[0067] (1) Wastewater containing heavy metal chromium, dyes, and short-haired fibers: The wastewater discharged from a leather factory has a solid particle content of 430mg / L and a heavy metal ion chromium concentration of 105.6mg / L, exceeding the standard. The waste water treatment capacity of the side line experiment is 80L / h at room temperature.

[0068] (2) Separation and adsorption medium: The particle bed separator group uses modified coal particles as the separation medium; the dual-function adsorption tower uses D401 porous resin pellets.

[0069] 2. Process flow

[0070] In view of the characteristics that leather wastewater contains more heavy metals, dyes and fibers, choose as attached figure 1 Process flow shown. The leather wastewater first passes through the particle bed separator to remove short-haired fibers and other impurity solid particles in the wastewater; then add Fenton’s reagent and other decolorizers to decompose the dy...

Embodiment 3

[0077] 1Material properties

[0078] (1) Wastewater containing heavy metal chromium and dyes: The wastewater discharged from a tannery has a solid particle content of 8.9mg / L, a heavy metal ion chromium concentration of 146.2mg / L, and a chroma of 3300. Both heavy metals and chroma exceed the standard. The waste water treatment capacity of the side line experiment is 40L / h at room temperature.

[0079] (2) Adsorption medium: The dual-function adsorption tower uses 732-type porous resin pellets.

[0080] 2 process flow

[0081] In view of the characteristics of leather wastewater containing heavy metals and more dyes, choose the following figure 1 Process flow shown. First add an appropriate amount of ozone decolorizer to the leather wastewater, stir until fully mixed and then let it stand for 30 minutes, then the supernatant is pressurized by the pump to the deep interception filter tower to remove the solid particles produced by the decolorization reaction, and finally use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com