Patents

Literature

135results about How to "Reduced chromium content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water soluble humic acid multi-element solid fertilizer and production method thereof

InactiveCN101570456ADissolve fastNot easy to agglomerateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSoil scienceWater soluble

The invention discloses a water soluble fertilizer and a production method thereof, in particular to a water soluble humic acid multi-element solid fertilizer and a production method thereof. The water soluble humic acid multi-element solid fertilizer is made by mixing water soluble humic acid, water soluble nitrogenous fertilizer, water soluble phosphorous fertilizer, water soluble potassic fertilizer and water soluble complex trace elements. Compared with the prior art, the water soluble humic acid multi-element solid fertilizer can reduce the transporting and packing cost, can be rapidly dissolved without agglomeration when in use, is applied along with water, and has the advantages of strong points, high nutrient content, complete nutrition, good water-solubility, combination of organic and inorganic matters as well as high effect of fertilizer and utilization rate. The utilization rate of product nitrogen reaches 60%, the utilization rate of phosphorus is 30-35%, and the utilization rate of potassium is 60-70%, so that the fertilizer application utilization rate is increased by more than 10% compared with the conventional fertilizer.

Owner:新疆三赢农业科技发展有限公司

Wear-resisting white cast iron and preparation method thereof

The invention provides a wear-resisting white cast iron and a preparation method thereof, and belongs to the technical field of wear-resisting materials. The liquid wear-resisting white cast iron is smelted in an electric furnace at first, and the liquid iron is composed of 2.9-3.3% of C, 4.5-5.5% of Mn, 6.0-7.2% of Cr, 0.45-0.70% of B, 0.50% of Si<, 0.05% of S<, 0.05% of P< and the balance of Fe by mass fraction. Modification treatment is performed on the wear-resisting white cast iron by adding a compound modificator to a casting ladle, wherein the addition amount of the compound modificator accounts for 1.8-3.0% of the mass fraction of the liquid iron in the casting ladle; besides, the wear-resisting white cast iron has excellent properties after being quenched by air cooling at a temperature ranging from 950 to 1000 DEG C and tempered at a temperature ranging from 280 to 320 DEG C.

Owner:BEIJING UNIV OF TECH

Environment-friendly type crust leather production method

ActiveCN103060488AEmission reductionCreate pollutionTanning treatmentPre-tanning chemical treatmentChromiumIon

The invention discloses an environment-friendly type crust leather production method, and aims at solving the problems that in a crust leather production method using conventional chrome tanning as basis, plenty of chromium ions are contained in waste water and cannot be effectively processed, plenty of leather wastes with chrome are also generated, and the environment is seriously polluted. The production method comprises the following steps of non-pickling tanning, retanning filling, dyeing fat liquoring and chrome retanning. The method adopts non-pickling non-chrome tanning technology, so solid wastes with the chrome cannot be generated. At the same time, through mutual matching with other procedures, finished leather shrinkage temperature and performance can be effectively improved so as to meet demands of leather production. At the last, the chrome retanning is adopted, only a path of waste water with the chrome is generated, waste water quantity is small, and the waste water is easy to recover and process. Therefore, compared with an existing crust leather production method using a chrome tanning method as basis, cleaning degree is high, the waste water quantity with the chrome can be effectively reduced, and the waste water is convenient to recover and process. At the same time, the leather wastes with the chrome cannot be produced, and the method is environment-friendly.

Owner:四川亭江新材料股份有限公司 +1

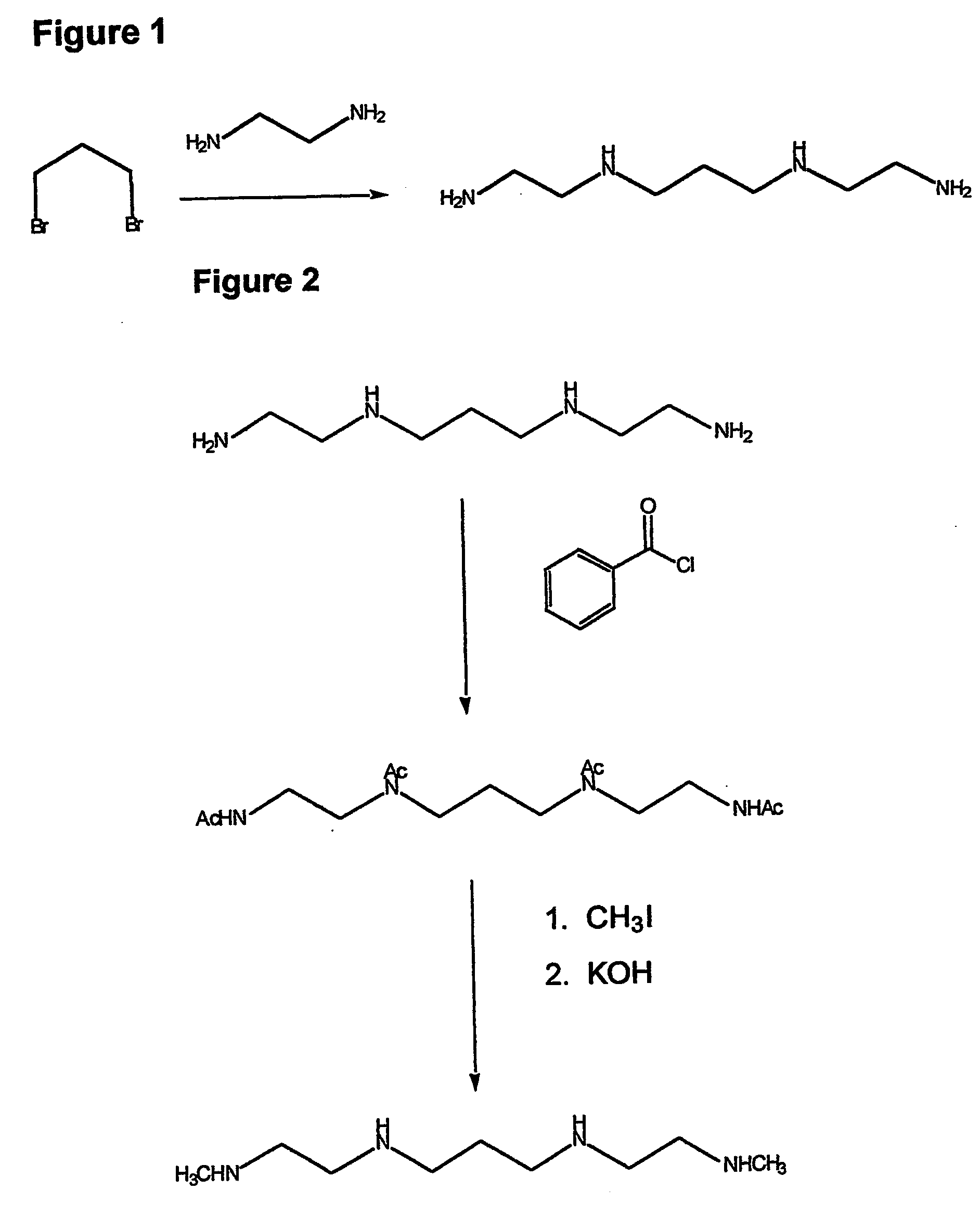

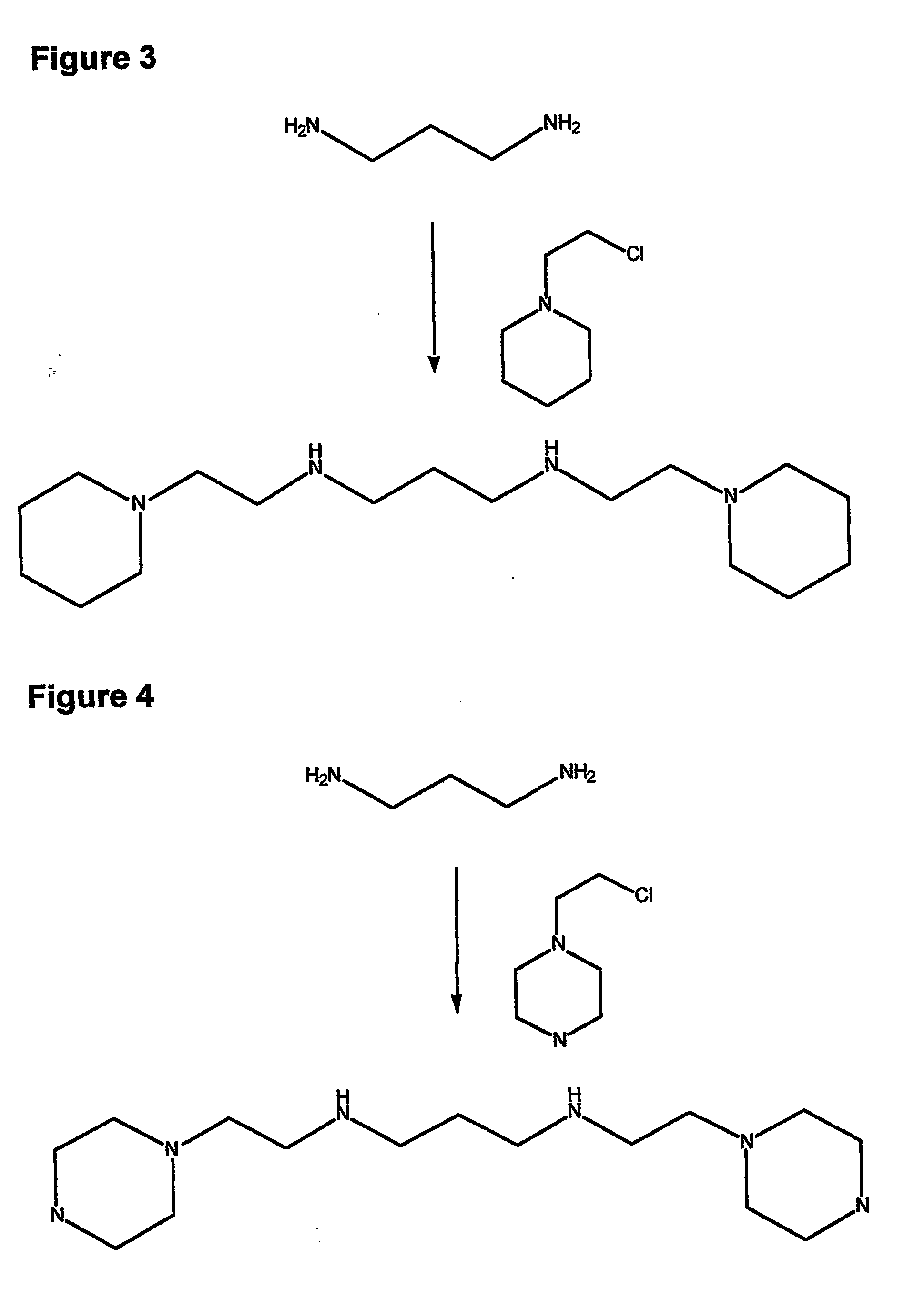

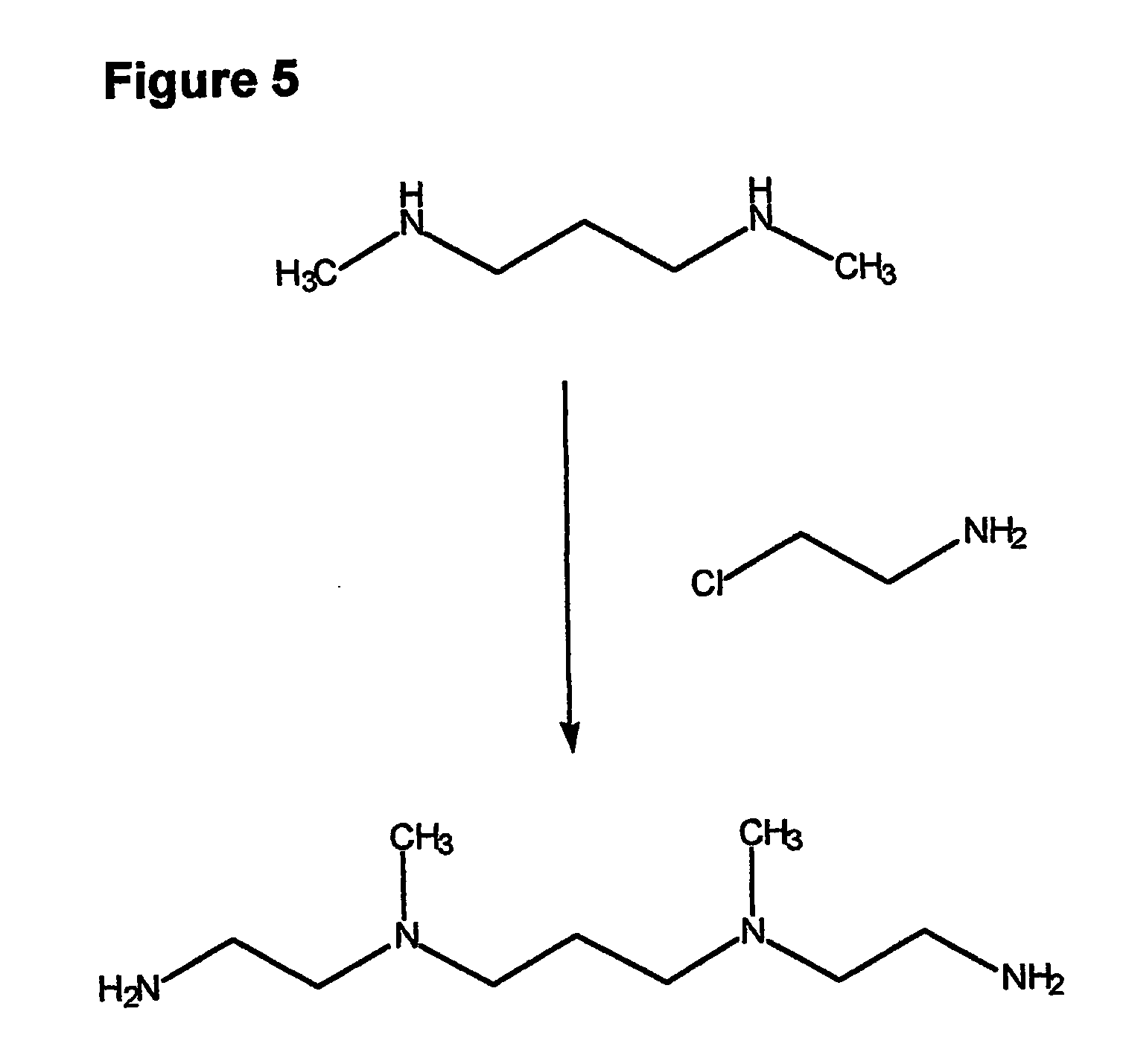

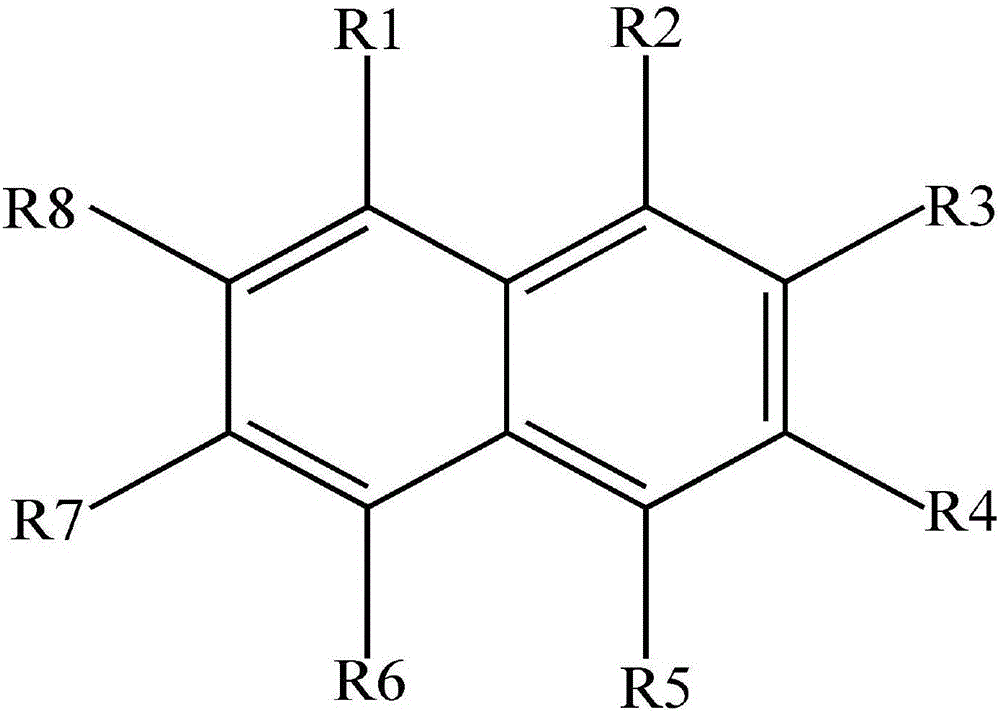

Composition, synthesis and therapeutic applications of polyamines

InactiveUS20050085555A1Chromium concentration were decreasedIncrease excretionBiocideGroup 5/15 element organic compoundsAntidoteRisk stroke

This invention relates to a process of synthesis and composition of open chain (ring), closed ring, linear branched and or substituted polyamines, polyamine derived tyrosine phosphatase inhibitors and PPAR partial agonists / partial antagonists via a series of substitution reactions and optimizing the bioavailability and biological activities of the compounds. Polyamines prevent the toxicty of neutoxins and diabetogenic toxins including paraquat, methyphenyl pyridine radical, rotenone, diazoxide, streptozotocin and alloxan. These polyamines can be to treat neurological, cardiovascular, endocrine acquired and inherited mitochondrial DNA damage diseases and other disorders in mammalian subjects, and more specifically to the therapy of Parkinson's disease, Alzheimer's disease, Lou Gehrig's disease, Binswanger's disease, Olivopontine Cerebellar Degeneration, Lewy Body disease, Diabetes, Stroke, Atherosclerosis, Myocardial Ischemia, Cardiomyopathy, Nephropathy, Ischemia, Glaucoma, Presbycussis, Cancer, Osteoporosis, Rheumatoid Arthritis, Inflammatory Bowel Disease, Multiple Sclerosis and as Antidotes to Toxin Exposure.

Owner:MURPHY MICHAEL A

Leather retanning method

InactiveCN102517409AHigh fullnessImprove firmnessTanning treatmentPre-tanning chemical treatmentIndustrial waste waterElectrical energy consumption

The invention relates to a leather retanning method. The method comprises the following steps of: water washing, rewetting to soften, retanning with chrome, neutralization, dyeing to fill, adding grease, dyeing in set and the like; and finally, drying, finishing and coating to obtain the finished product, i.e. leather. In the invention, the process of retanning with chrome is adjusted and a proper environment-friendly tanning agent is adopted, so the content of chrome in chrome liquid can be reduced, the fullness and the toughness of the leather is effectively improved, dyed color is uniform,the heat and humidity resistant stability of the leather can be improved, the physical performances of the leather are uniform, and the finished leather is soft and bend-resistant and is high in tensile strength; the amount of used water in the processing process is small, and the generated industrial waste water is little, so environment protection is facilitated; and the process period is relatively short, so the electric energy consumption is low, the cost is low, and the method has a better economic benefit.

Owner:郑州科信化工有限公司

Super-hard middle-chrome cast grinding ball and production process thereof

InactiveCN103060667ARefined grain sizeReduce in quantityFurnace typesQuenching agentsRare earthManganese

The invention discloses a super-hard middle-chrome cast grinding ball which consists of the following chemical ingredients: 1.8-3.0% of carbon, 0.3-1.5% of silicon, 0.2-1.5% of manganese, 7.0-10.0% of chrome, 0.02-0.1% of phosphorus, 0.02-0.1% of sulfur, 0.02-0.1% of copper, 0.02-0.1% of molybdenum, 0.02-0.1% of nickel, 0.02-0.1% of tungsten, 0.1-0.2% of rare earth yttrium and 80.1-87.2% of iron. The rare earth yttrium is adopted for evolution inoculation treatment, so that a carbide is changed in shape and distribution, furthermore a net is broken, and meanwhile crystal grains are refined, the texture is compact and the flexibility is improved. By adopting an oil medium annealing and tempering thermal treatment process, eutectic carbide with martensite with the broken net is obtained, the hardness of the middle-chrome grinding ball is HRC60-69, and the toughness and the abrasion resistance of a high-chrome grinding ball are remarkably improved. On premise that the abrasion resistance and the crushing resistance of the grinding ball are further improved, the content of the noble metal chrome is reduced, and relatively the manufacturing cost of the grinding ball is lowered, and significant social benefits are achieved.

Owner:NINGGUO ZHONGYI WEAR RESISTANT MATERIALS

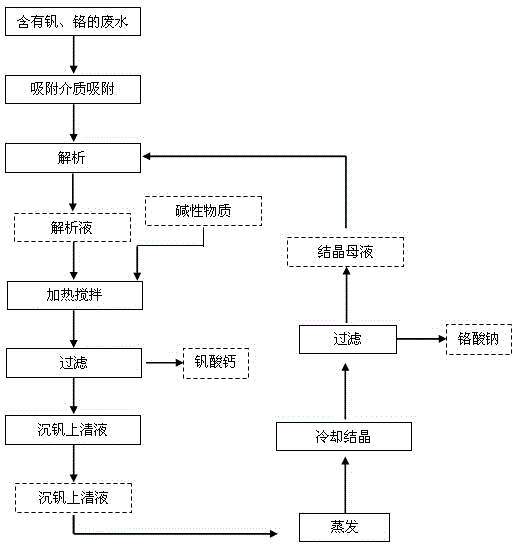

Method for treating waste water containing vanadium and chromium

ActiveCN104556522AHigh adsorption rateEfficient separationMultistage water/sewage treatmentChromates/bichromatesDesorptionWastewater

The invention relates to a method for treating waste water containing vanadium and chromium. The method comprises the following steps of: (1) adsorption: adopting an adsorbing medium to adsorb vanadium and chromium ions in the waste water containing vanadium and chromium; (2) desorption: adding a desorption agent into the adsorbing medium containing vanadium and chromium ions obtained in the step (1) to carry out desorption; (3) vanadium precipitation: adding alkaline substances into desorption solution, stirring to be uniform, and then filtering to obtain a calcium-vanadate product and vanadium-precipitated supernant; (4) chromium crystallization: carrying out evaporating concentration and cooling crystallization on the vanadium-precipitated supernant to obtain a sodium-chromate crude product and crystallizing mother liquor; (5) recrystallization: heating and dissolving the sodium-chromate crude product, and carrying out cooling crystallization to obtain a sodium-chromate product and cooling-crystallizing mother liquor; and (6) returning of the crystallizing mother liquor: returning the crystallizing mother liquor to the step (2) as the ingredient of the analysis solution to be repeatedly utilized. The method has the advantages that the recovery rate for the vanadium and chromium elements in the waste water reaches 99.9% or higher, simultaneously high-purity calcium vanadate and sodium chromate are obtained, and no waste water and waste residue are generated in the whole process.

Owner:HEBEI IRON AND STEEL

Processing method of leather semi-finished product

InactiveCN102517407AIncrease elasticityImprove breathabilityTanning treatmentPre-tanning chemical treatmentIndustrial waste waterEconomic benefits

The invention relates to a processing method of a leather semi-finished product. The method comprises the steps of pre-soaking, main soaking, liming, washing, pre-deliming, deliming, softening, pickling, tanning and the like. By adjusting the processing technology and adopting proper auxiliaries, the method provided by the invention can reduce the chromium content in a chromium solution, remove barilla in lime pelt, eliminate scurf, and improve the elasticity, air permeability and smooth grain side of the leather. According to the invention, preparation is made for the tanning operation, the contraction temperature of leather can be increased, the heat / humidity resistance stability is high, and thus the leather is soft and full and has excellent corrosion resistance. The leather processing method provided by the invention uses a relatively small amount of water, generates little industrial waste water, is favorable for environmental protection, and has a relatively short technologicalperiod, low power consumption, low cost and relatively good economic benefits.

Owner:郑州科信化工有限公司

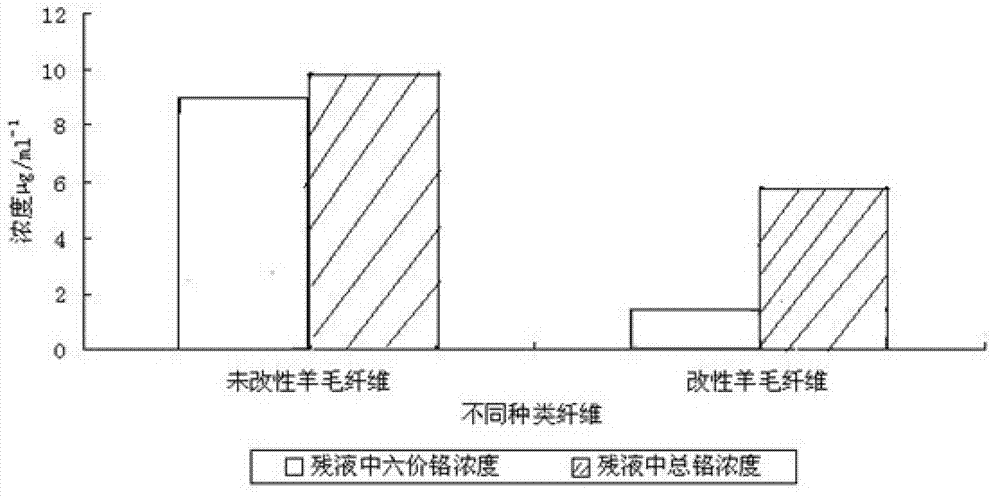

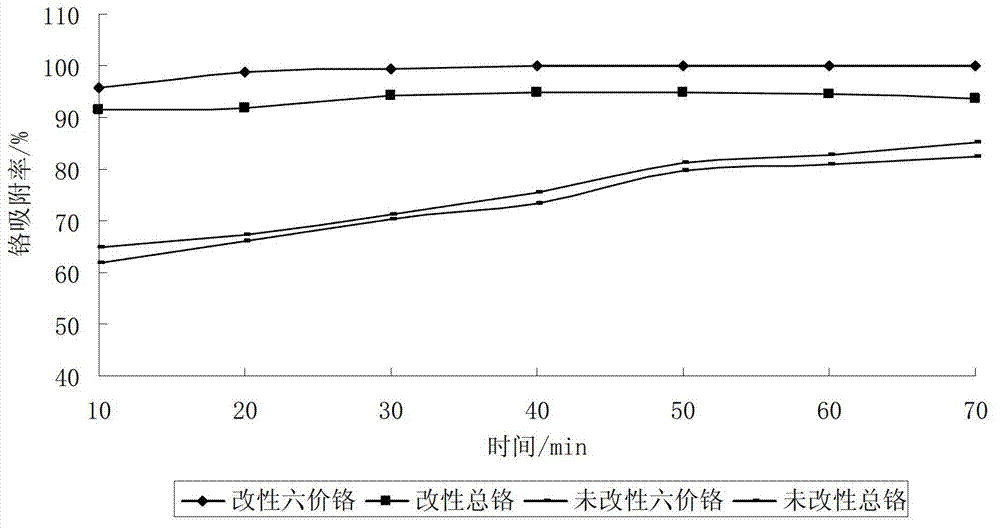

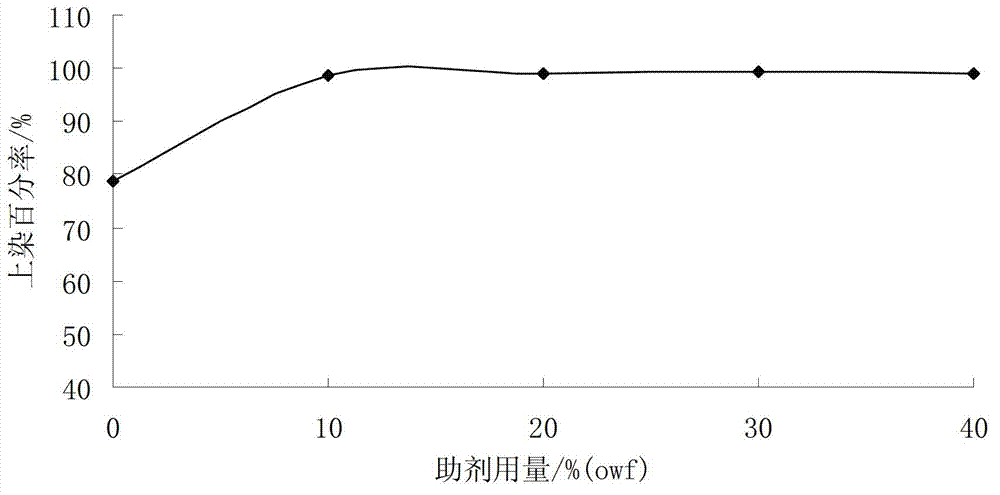

Preparation method and application method of low-temperature low-chromium dyeing auxiliary agent of acidic medium dye for wool

InactiveCN102817251AEfficient reuseReduce pollutionDepsipeptidesPeptide preparation methodsCross-linkKeratin

The invention discloses a preparation method and an application method of a low-temperature low-chromium dyeing auxiliary agent of an acidic medium dye for wool. The preparation method comprises the steps that: 1, protein powder is prepared by using waste duck feather, wherein (1) the duck feather is subjected to pretreatment; (2) the suck feather is subjected to a dissolving treatment; and (3) duck feather protein powder is prepared; 2, a sodium hydroxide solution is prepared, and the sodium hydroxide solution is used for dissolving the duck feather protein powder; 3, sodium hydroxide, triethanolamine, and epichlorohydrin are adopted for preparing a cationic quaternary ammonium salt cross-linking modification agent WLS; and 4, the low-temperature low-chromium dyeing auxiliary agent for the acidic medium dye is prepared. The auxiliary agent can be used as a wool modification agent. After wool fibers are modified, wool fiber dyeing properties of acidic medium dyes are greatly improved, dye uptake percentage rate can be improved, mordant absorption performance of the dye is improved, chromium pollution in dye wastewater is reduced, wool fiber low-temperature low-chromium dyeing is realized, and waste duck feather keratin is effectively utilized. After modification, the wearability of wool products is improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Production technology for improving smoothness and fineness of grain surface of leather

ActiveCN108977593AImprove grainImprove grain flatnessTanning treatmentPre-tanning chemical treatmentTanninFineness

The invention relates to a technical field of tanning chemistry and engineering, and provides a production technology for improving the smoothness and fineness of the grain surface of leather. According to the production technology, the grain surface of the cow leather obtained through the production technology is smooth, fine, tiny in pores, attractive, elegant, high in product grade, good in physical and mechanical properties, soft and comfortable in hand feeling and good in resilience, and in addition, the production technology is simple and easy to realize, appropriate in production cost and suitable for mass production and use. The production technology for improving the smoothness and fineness of the grain surface of the leather sequentially comprises the following steps of carryingout splitting on limed hide, carrying out deliming, softening and pickling, carrying out tanning, carrying out wringing and shaving, carrying out softening, carrying out retannin, carrying out neutralizing, carrying out filling, carrying out greasing, carrying out overdyeing and carrying out post treatment, wherein the tanning process adopts an aluminum-contained multi-metal tanning agent and a chrome tanning agent for co-tanning, the retanning process adopts a liquid betel nut tannin extract, an aldehyde tanning agent, an amphoteric synthetic tanning agent and the aluminum-contained multi-metal tanning agent for retanning, and the filling process adopts a micromolecular acrylic resin retanning agent, a phenolic condensation compound, a naphthalene sulfonic acid condensation compound, a synthetic greasing agent, sulfonated natural oil and a plant tannin extract for filling.

Owner:XINGYE LEATHER TECH CO LTD

Method for refining sodium sulfate powder from chromium-containing mirabilite

ActiveCN103539164AReduced chromium contentHigh yieldAlkali metal sulfites/sulfatesThenarditeSulfite salt

The invention relates to a method for refining sodium sulfate powder from chromium-containing mirabilite. The method comprises the following steps: a) grinding the chromium-containing mirabilite in the presence of water to prepare water-containing slurry; b) regulating the pH of the water-containing slurry obtained in the step a) with sulfuric acid to 2-3, and then adding sodium sulfite to reduce hexavalent chromium in the water-containing slurry to trivalent chromium, thus obtaining a saturated or over-saturated sodium sulfate water solution; c) stirring and crystallizing the saturated or over-saturated water solution which is obtained after reduction in the step b); d) filtering out crystals obtained in the step c); e) washing the crystals obtained in the step d) with the saturated sodium sulfate water solution; f) re-crystallizing the washed crystals obtained in the step e) with a saturated neutral sodium sulfate water solution to obtain the sodium sulfate powder. According to the method provided by the invention, additional heating is not required, the energy consumption is low, the obtained sodium sulfate powder has high yield and high purity, the content of sodium sulfate can achieve 99.00-99.90wt%, and the chromium content does not exceed 5ppm.

Owner:SICHUAN YINHE CHEM

Original form dechroming method for chrome leather fragment, and application of product thereof in fertilizer aspect

ActiveCN103143551AReduce manufacturing costReduced chromium contentSolid waste disposalPlant growthCalcium oxide

The invention relates to an original form dechroming method for chrome leather fragment, and application of a product thereof in fertilizer aspect. The method comprises the following steps of: adding water and calcium oxide, soaking at 20-40 DEG C for 1-4 days, washing by water and filtering; adding water, acid and salt into the filter residue, dechroming at 20-30 DEG C for 2-4 hours, washing by water and filtering; continuing to add water, salt and alkaline into the filter residue, keeping the temperature and dechroming for 30-60 min, regulating the pH to be neutral, washing by water and filtering; obtaining an original form dechromed product of chrome leather fragment; mixing and crushing the original form dechromed product of chrome leather fragment with plant ash, pelleting, and thus containing an agricultural composite fertilizer. The composite fertilizer not only has low chrome content and is rich of potassium element and organic nitrogen, but also has certain slow release function, and can effectively promote growth of plants.

Owner:王全杰

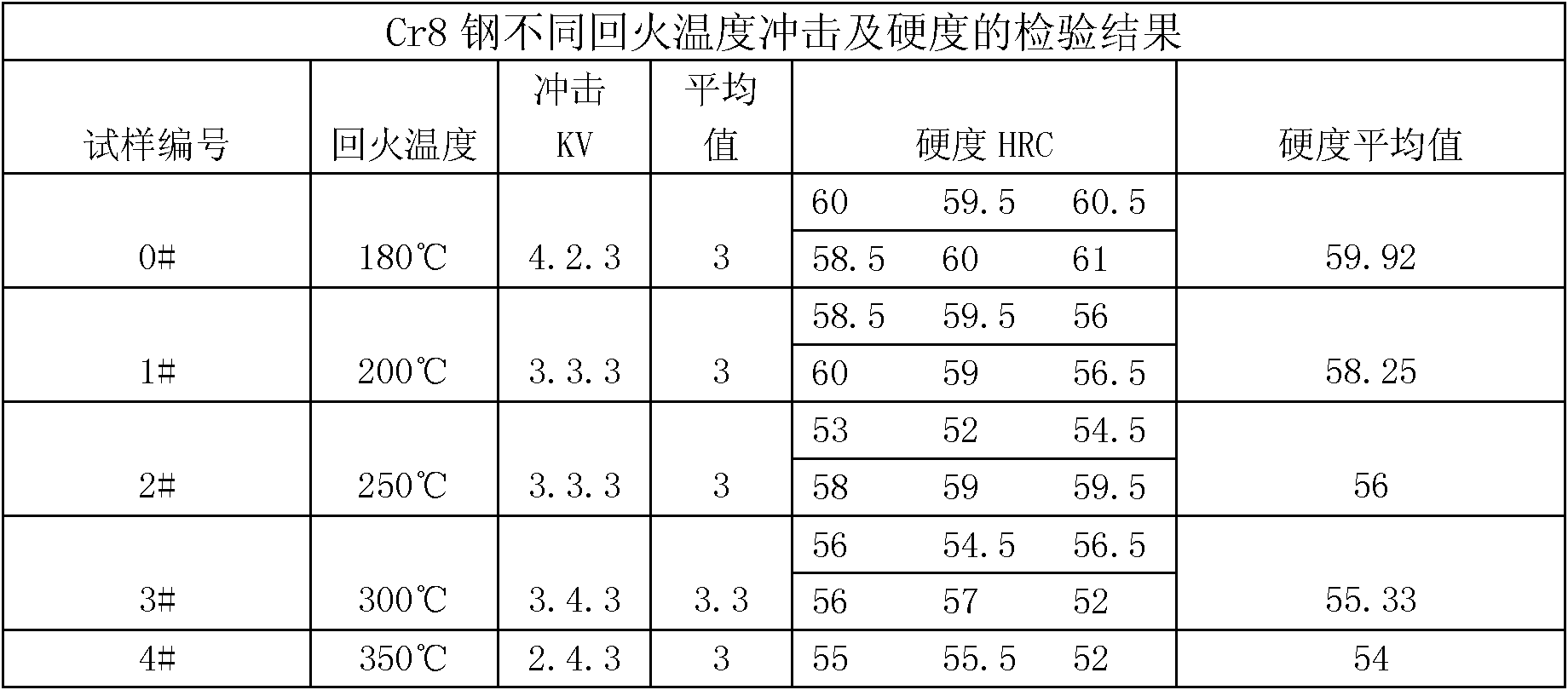

A kind of cold working die steel cr8 and its production method

The invention relates to a cold work die steel Cr8 and a production method thereof. The chemical composition of the cold work die steel Cr8 is as follows according to weight percentage: C: 1.10-1.20%, Mn: 0.30-0.60%, Si≤0.40 %, P≤0.030%, S≤0.030%, Cr: 7.00~8.00%, Cu≤0.25%, and the balance is iron. The production method of cold work die steel Cr8 is carried out according to the following steps: 1) preliminary smelting in an intermediate frequency furnace; 2) tapping; 3) refining in a refining furnace, and then on a continuous casting machine; 4) heating and rolling with heat treatment. The cold working die steel Cr8 of the present invention has the advantages of high hardness, high wear resistance, high hardenability and good toughness, can avoid brittle cracks caused by poor toughness, and has the advantage of low price. The production method has the advantages of simpler process and less time-consuming.

Owner:广东金型重工有限公司

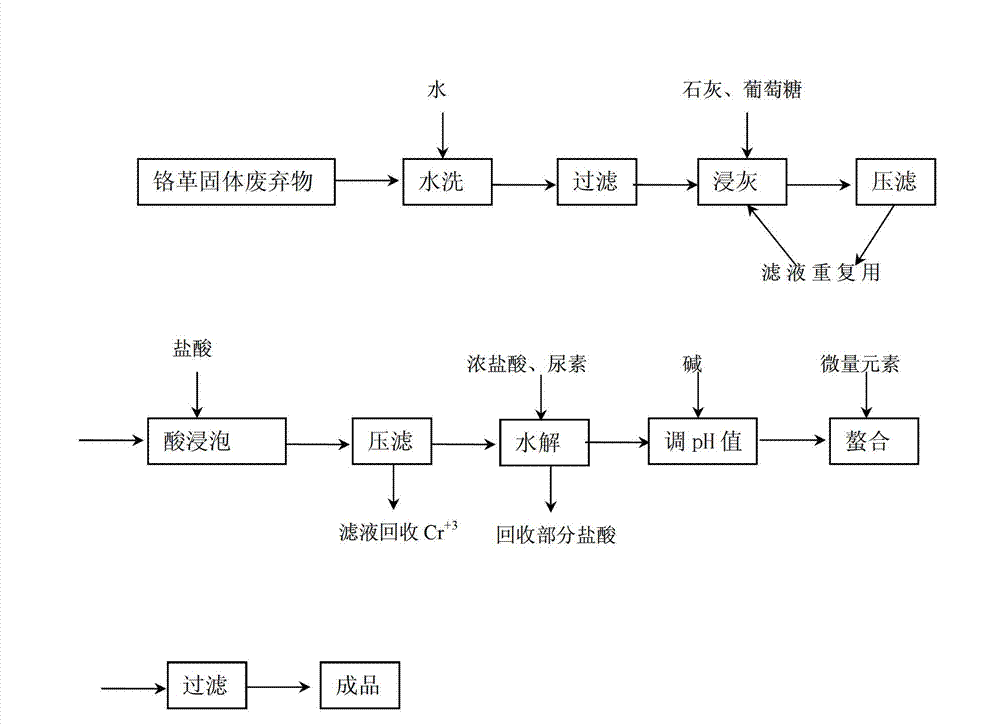

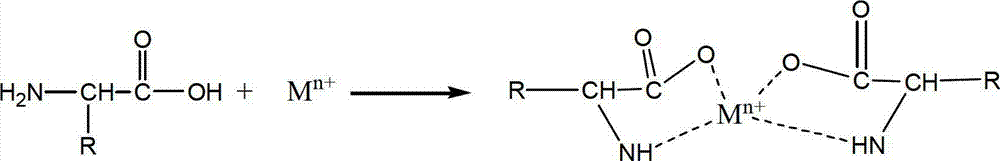

Method for preparing amino acid chelated fertilizer by using chrome leather solid wastes

The invention relates to resource utilization of chrome leather solid wastes, in particular to a method for preparing an amino acid chelated fertilizer by using chrome leather solid wastes. According to the invention, the method comprises the following steps of: using the chrome leather wastes as raw materials, dechroming and hydrolyzing the chrome leather wastes so as to generate an amino acid, and then chelating trace elements so as to prepare the amino acid chelated fertilizer. The method for preparing the amino acid chelated fertilizer by using the chrome leather solid wastes, provided by the invention, has the advantages of simple process and easiness in operation; collagens in the chrome leather solid wastes are completely hydrolyzed to be chelated with the trace elements so as to prepare the chelated fertilizer; the chrome content of the chelated fertilizer is less than national standard; and the chelating rate of the collagens and the trace elements is more than 95%. The chelated fertilizer prepared by using the method provided by the invention can be used for leaf surface spraying, seed soaking and root pouring and has an obvious effect on yield increase of crops.

Owner:罗星 +2

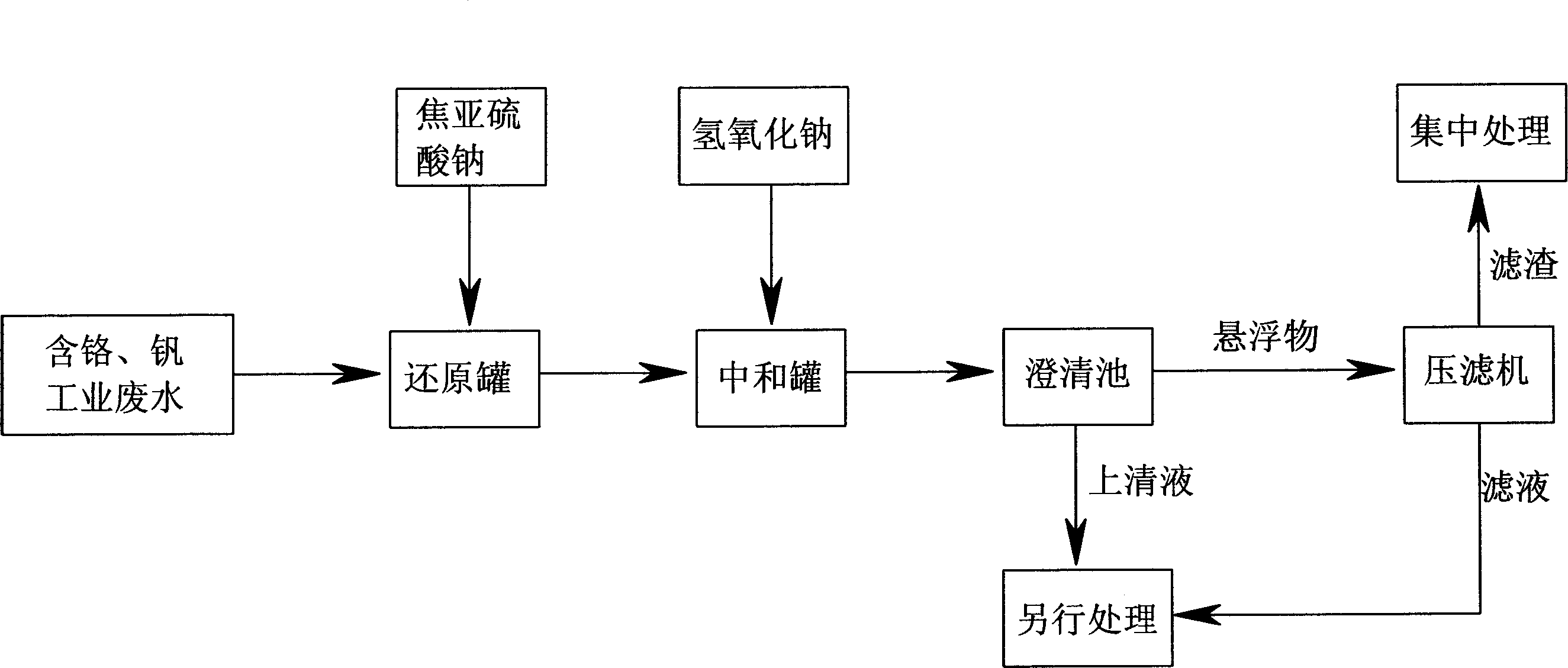

Process for treating industrial waste water containing chromium, vanadium

InactiveCN1724406AReduced chromium contentAvoid pollutionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationIndustrial waste waterSewage

A process for treating the industrial sewage containing Cr and V includes such steps as preparing the solution of sodium pyro-sulfite, proportionally adding it to the sewage in reduction tank, reducing the 6-valence Cr to 3-valence Cr, proportionally adding the solution of sodium hydroxide to the sewage in neutralizing tank for reaction between V2O2 and sodium hydroxide to generate Na2V4O9 * 4H2O, reaction between V4O9 and said 3-valence Cr to generate Cr2(V4O9)3 deposit and changing residual 3-valence Cr to chromium hydroxide deposit, regulating pH=7.5-8.5, clarifying, and press filtering of suspended substance.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Salt-free high-chrome-absorption chrome tanning method for animal skin and application of salt-free high-chrome-absorption chrome tanning method

InactiveCN105063253AImprove overall performanceSimplify alkali extraction operationTanning treatmentPre-tanning chemical treatmentAbsorption rateChemistry

The invention discloses a salt-free high-chrome-absorption chrome tanning method for animal skin and application of the salt-free high-chrome-absorption chrome tanning method. The salt-free high-chrome-absorption chrome tanning method is characterized by comprising the following steps of treating pretreated animal skin by using aromatic sulfonic acid or a low-molecular polycondensate thereof; regulating the pH value of the animal skin to 4.0-6.5 under the condition that no neutral salts such as sodium chloride and sodium sulfate are used; and carrying out chrome tanning under a relatively high initial pH value condition to realize salt-free high-chrome-absorption tanning. By using the salt-free high-chrome-absorption chrome tanning method, the problem that the quality and performances of leather or fur are influenced because the skin possibly has the acid expansion phenomenon under salt-free and acidic tanning conditions, the combination of chrome and the surface of the skin are excessively fast during the tanning, and the chrome cannot permeate the skin easily under the relatively high initial pH value condition is solved; and compared with the conventional chrome tanning method, the chrome tanning method disclosed by the invention is advantaged in that the chrome tanning efficiency is remarkably increased, the consumption of chrome can be reduced by more than 30%, the absorption rate of chrome is up to more than 98%, the concentration of chrome in chrome tanning effluent is reduced to be less than 50mg / L, chrome in wet blue leather is more uniformly distributed, and the chrome tanning effluent can be recycled many times. By using the salt-free high-chrome-absorption chrome tanning method, the chlorine and chrome pollution generated in the leather and fur preparation processes is remarkably reduced.

Owner:SICHUAN UNIV

Method for preparing aldehyde-containing polyurethane-acrylate resin tanning agent

The invention relates to a method for preparing an aldehyde-containing polyurethane-acrylate resin tanning agent. The aldehyde-containing polyurethane-acrylate resin tanning agent is prepared from a polymerizable nonionic polyurethane oligomer and unsaturated aldehyde by carrying out radical copolymerization in distilled water. The tanning agent contains aldehyde group, can be combined with a covalent bond of hide collagen fibers, has obvious tanning function, can make leather obtain higher hydrothermal stability when reducing the use amount of a chrome tanning agent, has excellent selective filling property, can make the leather have soft and plump hand feeling and exquisite grain, can be assorted with the chrome tanning agent to use in the low pH value environment of chrom tanning and chrome retanning, is favorable to adsorption fixation of the chrome tanning agent, can obviously reduce content of chromium salt in chrom tanning liquid waste so as to greatly reduce pollution of the tanning liquid waste to the environment, is a novel multifunctional environment-friendly leather tanning material and is suitable for tanning processing of sofa leather, instep leather, clothing leather and the like.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

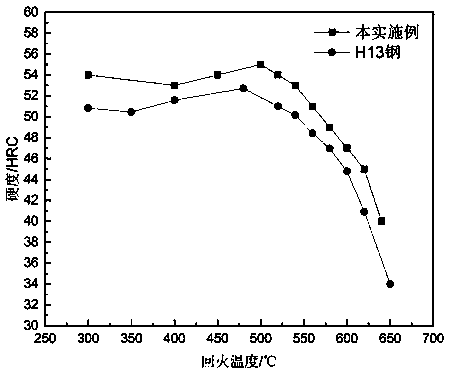

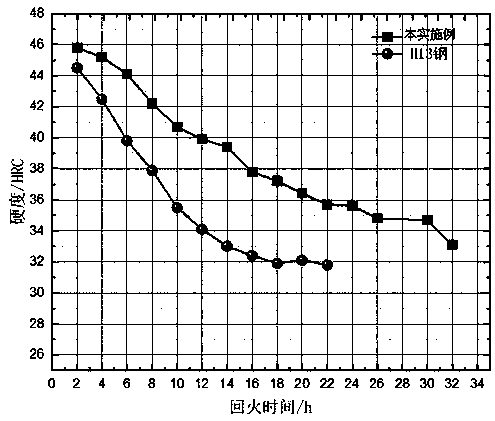

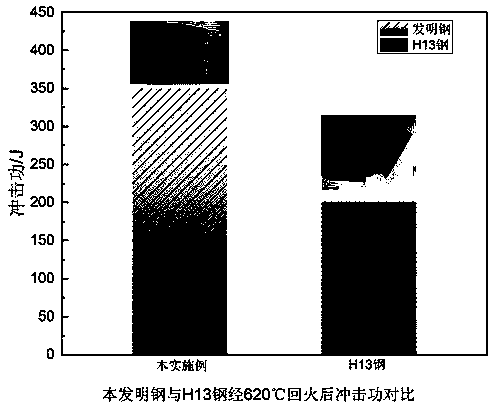

High-manganese low-chromium type hot work die steel and preparation method thereof

The invention relates to high-manganese low-chromium type hot work die steel and a preparation method of the high-manganese low-chromium type hot work die steel, and belongs to the technical field ofhot work die steel. The high-manganese low-chromium type hot work die steel is prepared from, by mass, 0.35-0.45% of C, 0.50-1.20% of Si, 0.60-1.20% of Mn, 3.75-4.50% of Cr, 0.80-1.20% of Mo, 0.30-0.60% of V, 0.50-5.50% of Co, 0.80-3.00% of Ni, less than 0.02% of P, less than 0.02% of S and the balance Fe and inevitable impurities. The high-manganese low-chromium type hot work die steel is prepared through the processes of material preparation, smelting, casting, electroslag remelting, high temperature homogenization treatment, forging, annealing and heat treatment. Compared with existing H13hot work die steel, the high-manganese low-chromium type hot work die steel has higher toughness and higher heat stability.

Owner:KUNMING UNIV OF SCI & TECH

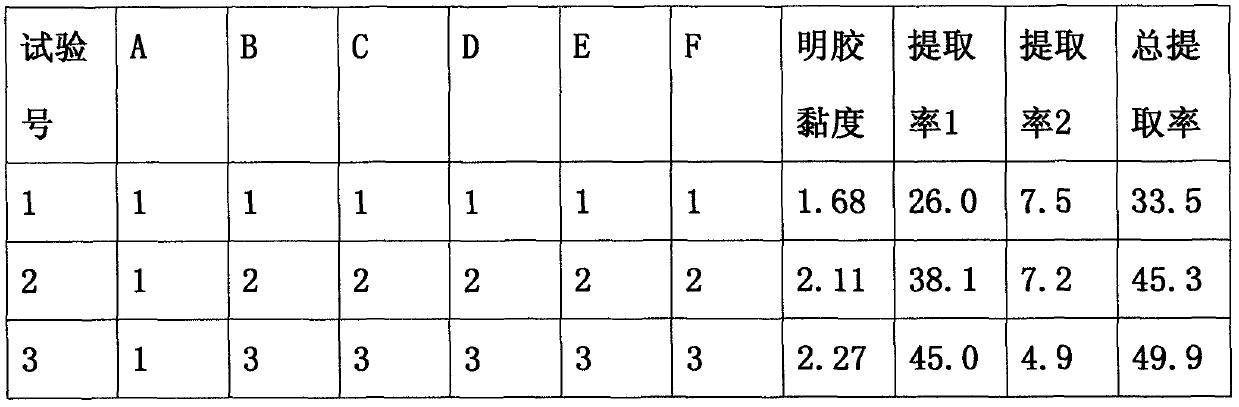

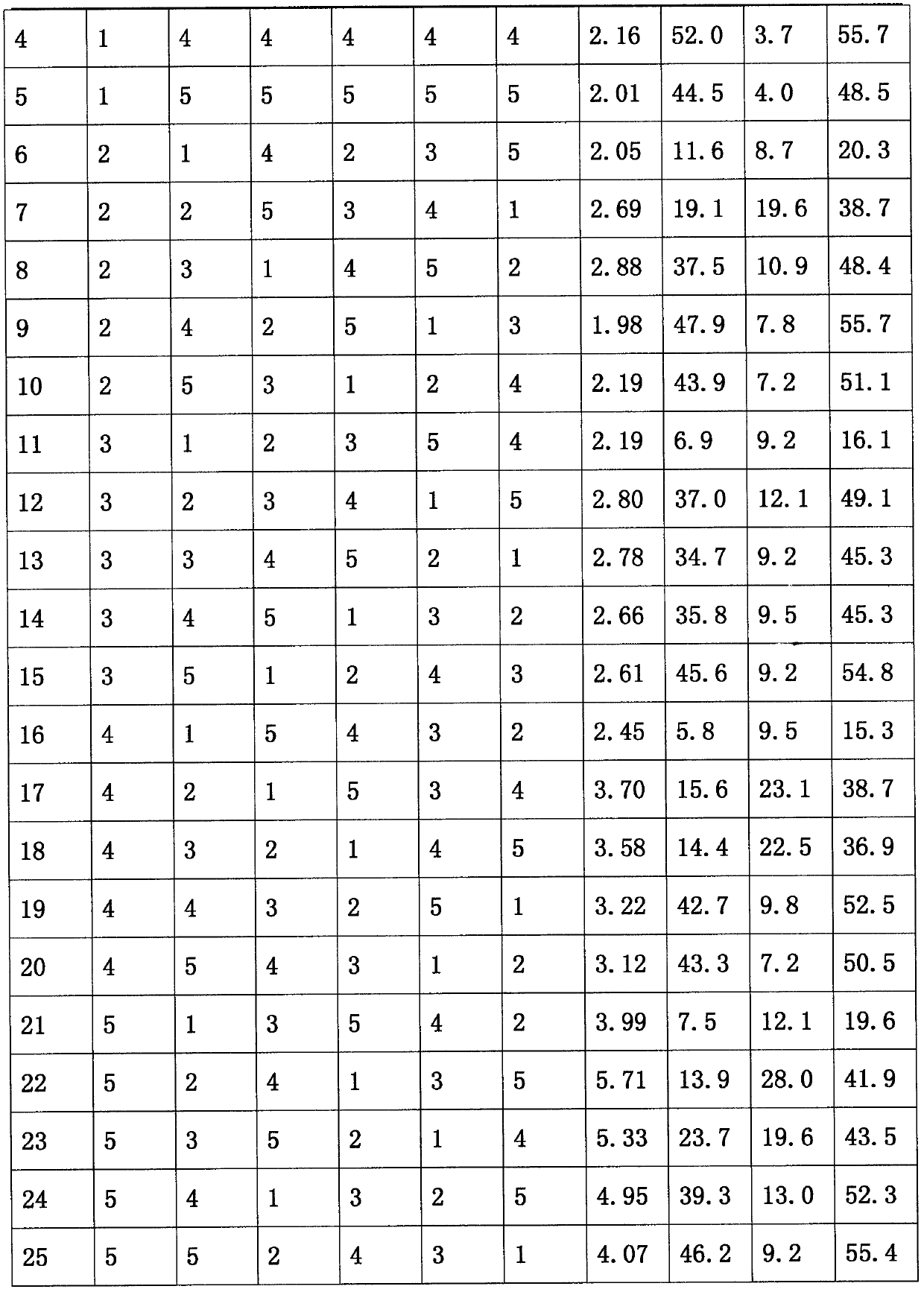

Process of extracting collagen from waste chrome leather scraps

InactiveCN102888434ALow ashReduced chromium contentPeptide preparation methodsFermentationCollagenanGelatin

A process of extracting collagen from waste chrome leather scraps belongs to the extraction technology of collagen. The invention provides the process of extracting collagen from waste chrome leather scraps. The technological process of the invention includes: pretreating the chrome leather scraps, alkaline hydrolyzing, centrifuging to get gelatin and filtrate, desalting and drying the gelatin, hydrolyzing the filtrate with enzyme, and centrifuging to get amino acids, polypeptides and a chrome cake.

Owner:黄义

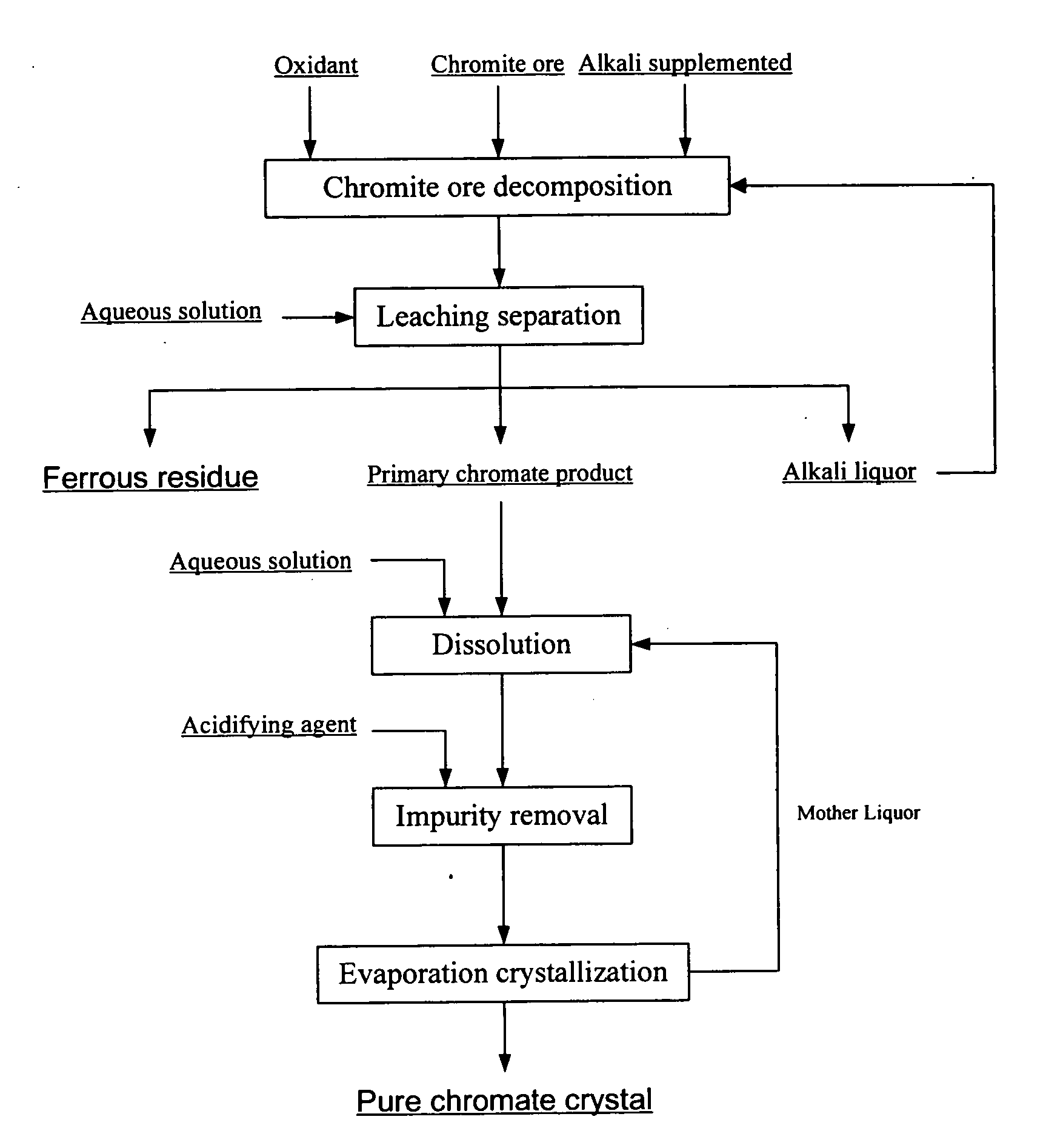

Method for production of alkali metal chromates

InactiveUS20060188419A1Reduce chemical consumptionLow costMolybdeum compoundsChromates/bichromatesChromium CompoundsReaction temperature

This invention relates to a method for producing chromates, especially for producing alkali metal chromates. The method comprises following steps: the obtaining of a mixture of alkali metal hydroxide, alkali metal chromate, and ferrous residue after the reaction of chromite ore with an oxidant in the reactor in the presence of molten salt or in aqueous solution of alkali metal hydroxide, the obtaining of a leaching slurry by leaching the reaction products with aqueous solution of alkali metal hydroxide, the separating of the primary chromate product from the leaching slurry, the obtaining of pure chromate crystal by purifying the primary chromate product. Both the primary chromate product and the pure chromate crystal can be used as the raw materials to manufacture other chromium compounds. Compared with the currently-used roasting method, the method has the advantages of decreasing the reaction temperature by about 700° C., of improving the chromium recovery rate up to nearly 100%, of minimizing the amount of the ferrous residue by not adding calcium-containing auxiliaries, and of completely eliminating the disposal problem of the chromium-containing residue and the environmental pollution due to the addition of calcium-containing auxiliaries, by using ferrous residue as the raw materials for other industries after extraction of magnesium.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Efficient farmland utilization method for cultivating single-season rice, ratoon rice and wild fungi

InactiveCN110122225ASolve the image of food rationsLabor savingCultivating equipmentsMushroom cultivationSoil propertiesWeed

The invention discloses an efficient farmland utilization method for cultivating single-season rice, ratoon rice and wild fungi and mainly solves the technical problem that existing farmland utilization rate is not high, waste straw treatment methods are not environmentally friendly, the economic benefits are not high and the like. The technical scheme is characterized as follows: by cultivating the ratoon rice, labor force output is reduced while the grain yield is guaranteed, first rice straw is crushed and returned to the field, growing of weeds in the rice field can be avoided, the field can be fertilized, cadmium reduction and selenium enrichment measures are taken, low-cadmium and selenium-rich rice is produced, straw after harvesting of the ratoon rice is laid on the field, the wildfungi are planted on the straw, propagation of the wild fungi can accelerate rotting of the straw, after the wild fungi are harvested, the straw further rots to form organic fertilizer, the soil fertility is enhanced, and the soil property of the field is improved.

Owner:邓述东

Process for tanning and softening sheepskin by multi-carboxylic nano compound chrome tanning additive

InactiveCN103509889AFulfil requirementsRequirements meetTanning treatmentPre-tanning chemical treatmentLiquid wasteFiber

The invention belongs to the field of leather tanning process and relates to a process for tanning and softening sheepskin by a multi-carboxylic nano compound chrome tanning additive. In a traditional chrome tanning method, the use of various chemicals in picking and chrome tanning procedures causes damage to the ecological environment. According to leather tanning mechanisms and structural features of collagenous fiber and the multi-carboxylic nano compound chrome tanning additive, the process used for leather tanning and skin softening is characterized in that the shrinkage temperature of blue wet leather can reach 105 DEG C, the grain side is flat and fine, and the requirements of goat skin garment leather can be met; compared with the method that 8 percent of chromium powder is adopted for conventional tanning liquid waste, liquid waste is characterized in that the content of Cr2O3 in the liquid waste is reduced to 172 mg / L from 1,952 mg / L, and the content of chromium in the liquid waste is reduced greatly; compared with the conventional chrome tanned leather, the chrome tanned leather treated through the process has the advantages that excellent effects to follow-up backwater, neutralization, and control to chromium pollution in dying and oiling liquid waste are achieved, the physical and mechanical performance of crust leather is similar, compact hand feeling is achieved, the filling performance and the softness are excellent, and the requirements of the goat skin garment leather can be met.

Owner:SHAANXI UNIV OF SCI & TECH

Grate bar and preparation method thereof

InactiveCN101935805AHigh strengthImprove toughnessProcess efficiency improvementElectric furnaceThermal fatigueEconomic benefits

The invention discloses a grate bar and a preparation method thereof, which belongs to the technical field of heat-resisting materials. The grate bar comprises the following chemical components in percentage by mass: 1.2 to 1.6 percent of C, 15.0 to 20.0 percent of Cr, 2.3 to 2.8 percent of Al, 4.5 to 5.0 percent of Si, 0.05 to 0.15 percent of Ti, 0.05 to 0.15 percent of Nb, 0.08 to 0.20 percent of RE, 0.06 to 0.15 percent of Mg, less than 0.6 percent of Mn, less than 0.04 percent of S, less than 0.05 percent of P and the balance of Fe, wherein the total mass of the Ti and the Nb is more than or equal to 0.20 percent and less than or equal to 0.28 percent. The grate bar of the invention can be produced by electric furnace and is formed by lost foam casting; the grate bar has high strength, high toughness, high inoxidizability and high thermal fatigue resistance, and can be used on large sintering machine trolley for more than 2 years; and when the grate bar is used, the labor intensity of workers can be relieved, the production efficiency of the sintering machine can be improved, and great social and economic benefit can be created.

Owner:BEIJING UNIV OF TECH

Wear-resistant alloy, silicon alloy grinding ball, silicon alloy grinding section and preparation method thereof

InactiveCN102965565AReduced chromium contentBreakage resistantGrain treatmentsSilicon alloyManganese

The invention relates to a wear-resistant alloy, a silicon alloy grinding ball, a silicon alloy grinding section and a preparation method thereof. The wear-resistant alloy comprises the following substances in percentage by weight: 3.30-4.5% of carbon, 1.0-3.20% of silicon, 0.30-1.50% of manganese, 0.10%-1.30% of chromium, 0.006%-0.07% of rare earth, 0.007%-0.08% of magnesium and the balance of iron and inevitable impurities. The wear-resistant alloy provided by the invention has low content of the chromium and has the advantages of excellent resistance to impact fracture, wear resistance, crushing resistance and corrosion resistance.

Owner:清原满族自治县三方耐磨材料有限公司 +2

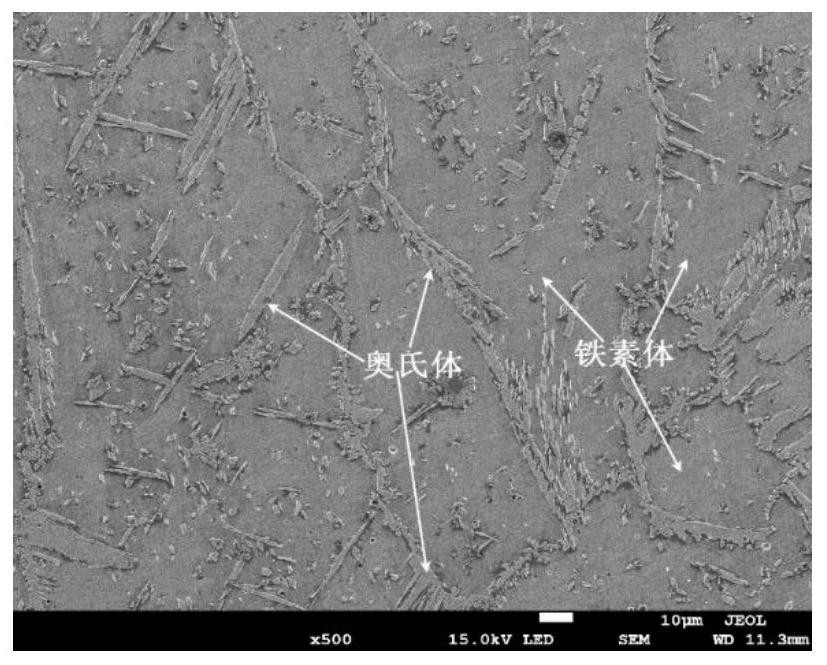

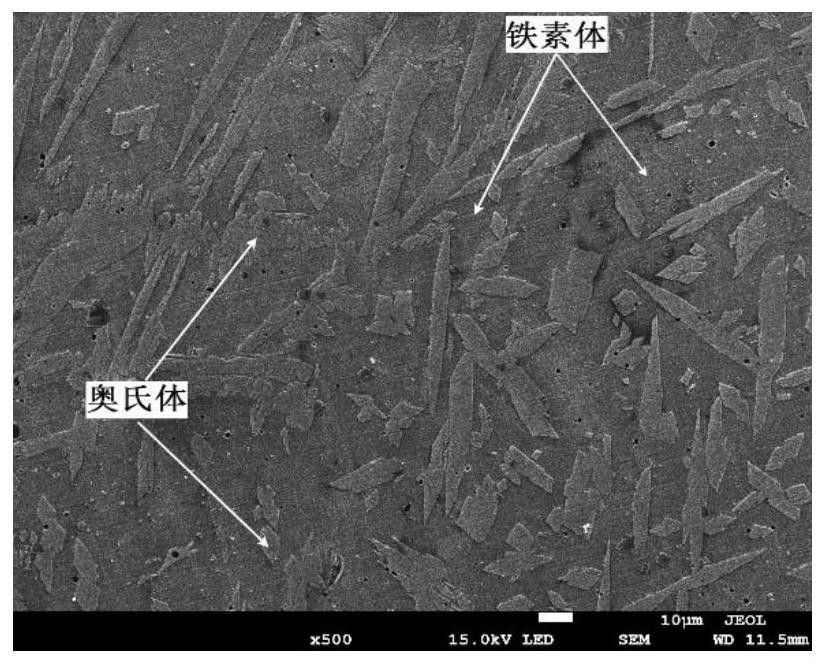

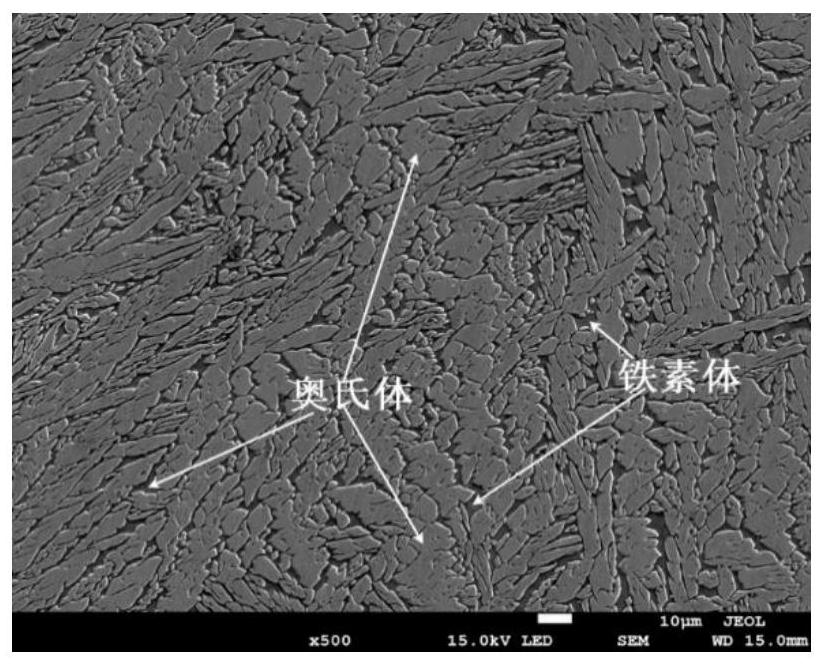

Duplex stainless steel wire material for arc additives and duplex stainless steel member

ActiveCN113369496AImprove corrosion resistanceLow costAdditive manufacturing apparatusIncreasing energy efficiencySS - Stainless steelMetal powder

The invention belongs to the technical field of arc additives, and discloses a duplex stainless steel wire material for arc additives. The duplex stainless steel wire material is composed of a metal powder core and a steel strip, the metal powder core comprises, by mass, 55-90% of chromium powder, 0-5.5% of nickel powder and the balance powder; the invention further discloses a duplex stainless steel member, which is obtained by the duplex stainless steel wire through an arc additive process. By means of the duplex stainless steel wire for the arc additives, the duplex stainless steel member with the austenite content being about 50% and meeting the standard specification can be directly obtained through arc additive manufacturing; the corrosion resistance of the duplex stainless steel member is greatly improved, and the cost of the duplex stainless steel member is obviously reduced; and meanwhile, the duplex stainless steel member which is complex in shape, high in strength and high in corrosion resistance can be produced and manufactured.

Owner:TIANJIN UNIV

Method for preparing semi-chrome tanning addition agent through waste chrome shavings and application method of semi-chrome tanning addition agent

ActiveCN107988443ARealize rational utilizationEco-friendly tanningTanning treatmentPhosphonium saltAcid hydrolysis

The invention relates to the technical field of tanning waste source utilization and provides a method for preparing a semi-chrome tanning addition agent through waste chrome shavings and an application method of the semi-chrome tanning addition agent. Waste chrome shaving resources can be effectively converted into the semi-chrome tanning addition agent so as to be reused in the leather production and preparation processes, and the dual economic benefits of environment-friendly tanning and reduction of tanning cost are achieved. According to the method for preparing the semi-chrome tanning addition agent through the waste chrome shavings, collagen hydrolysate liquor is obtained through acid hydrolysis of the waste chrome shavings and then modified through unsaturated dicarboxylic acid andtetrakis hydroxymethyl phosphonium salt, the semi-chrome tanning addition agent is obtained, carboxyl functional groups of collagens in the semi-chrome tanning addition agent are increased, the jointpoints of proteins in the obtained semi-chrome tanning addition agent and a chrome tanning agent are increased, thus, combination and absorption of leather treated through the obtained semi-chrome tanning addition agent and the chrome tanning agent are promoted, meanwhile, the obtained semi-chrome tanning addition agent has certain tanning performance and filling property, the crust leather contraction temperature can be increased, and the fullness, elasticity and grain surface flatness of crust leather are improved.

Owner:XINGYE LEATHER TECH CO LTD

Environmental protection acid-resisting anti-corrosive paint for mechanical equipment

InactiveCN101125994ALow wear resistanceImprove wear resistanceAnti-corrosive paintsPolyester coatingsMechanical equipmentSolvent

The invention discloses an environmental-friendly, acid resistant and corrosion resistant paint of a mechanical equipment. The components of the environmenta protective acid resistant and corrosion resistant paint used for the mechanical equipment are proportioned according to weight portions of 520 shares of cardanol modified phenolic resin, 230 shares of alkyd resin, 160 shares of rutile titanic dioxide, 73 shares of 200 model solvent oil, 8 shares of wetting agent, 5 shares of anti-sinking dispersant, 2 shares of anti-foam PerenolR, 1.5 shares of high effective compound drier agent and 0.5 shares of anti-skinning agent. The anti-corrosion paint is characterized by environment protective, acid resistance and wearing resistance.

Owner:DAQING PETROLEUM ADMINISTRATION

Method for preparing acid-resistance polyurethane-acrylic resin retanning agent

The invention provides a method for preparing an acid-resistance polyurethane-acrylic resin retanning agent. In the method, acrylic acid or methacrylic acid which accounts for 50 to 80 percent of the total weight of monomers, polymerizable non-ionic polyurethane oligomer which accounts for 15 to 40 percent of the total weight of the monomers and is prepared by a specific method and methyl acrylate or acrylonitrile which accounts for 5 to 30 percent of the total weight of the monomers are dissolved in distilled water in an amount which is 1 to 5 times the total weight of the monomers to form the acid-resistance polyurethane-acrylic resin retanning agent through free radical copolymerization. The retanning agent has high selective fallibility, and offers a soft and full handfeel and fine granular texture to leather. Moreover, the retanning agent can be used in a low pH-value environment in the last stage of chromium tanning or chromium retanning to promote the absorption and fixation ofa chromium tanning and obviously reduce the chromium salt content of chromium tanning waste liquid obviously, and thus the pollution caused by the tanning waste liquid to the environment greatly. Theacid-resistance polyurethane-acrylic resin retanning agent is a novel multifunctional environmentally-friendly leather retanning material and is suitable to be used for the retanning processing of garment leather, shoe upper leather, sofa leather and the like.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

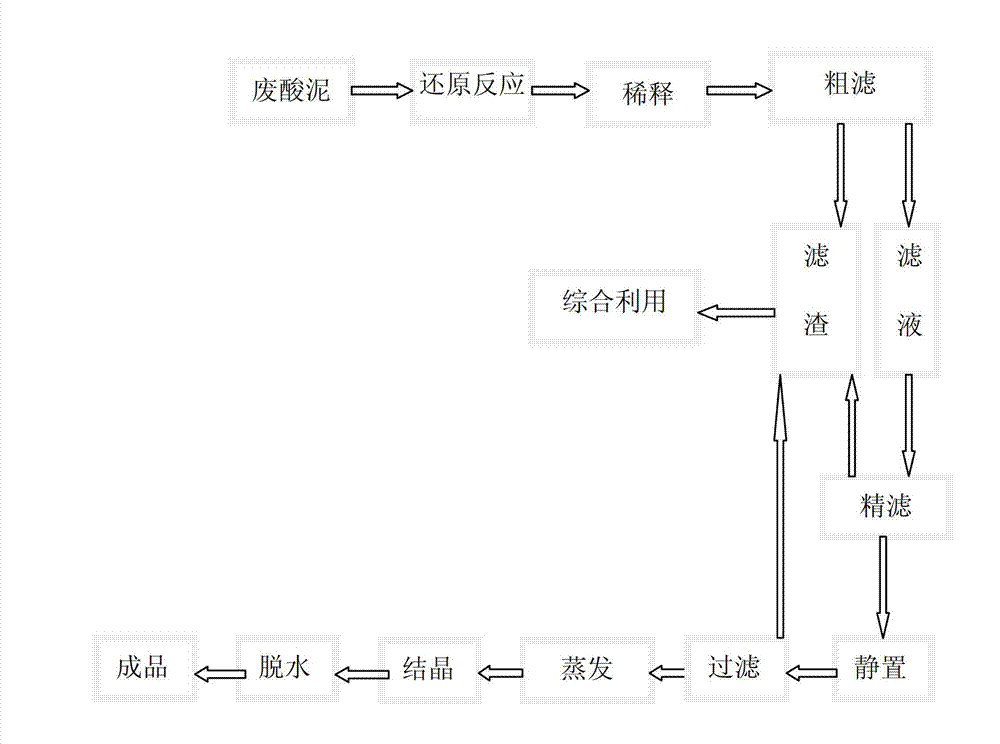

Method for producing sodium hydrogen sulfate and/or hydrate thereof by utilizing side product waste acid residue generated in production of chromic anhydride through sulfuric acid method

ActiveCN102862998AReduced chromium contentHigh puritySulfate/bisulfate preparationSulfate radicalsHydrogen Sulfate

The invention relates to a method for producing sodium hydrogen sulfate and / or hydrate thereof. The method comprises the following steps: (a), waste acid residue with the molar ratio of 0.9:1-1.1:1 of hydrogen ion and sulfate radical ion is provided; (b), the waste acid residue is diluted, precipitator for precipitating trivalent chromium ion is added to the diluted waste acid residue to form precipitation; (c), the precipitation generated in the step (b) is filtered out, filtrate containing sodium hydrogen sulfate is obtained, the filtrate is stilled for 2-80 hours, and the precipitation generated in the stilling process is filtered out; and (d), the stilled filtrate obtained in the step (c) after the precipitation is filtered out is crystallized, and the sodium hydrogen sulfate and / or the hydrate thereof are / is obtained. Through the method, the sodium hydrogen sulfate, sulfuric acid and sodium sulfate in the waste acid residue can be recovered, the total content of chromium in the prepared sodium hydrogen sulfate and / or the hydrate is low, and is generally lower than or equal to 10 ppm. Besides, the method is simple in technique and easy for gaining raw material, and is suitable for industrial production.

Owner:SICHUAN YINHE CHEM

Method for preparing aldehyde-containing polyurethane-acrylate resin tanning agent

The invention relates to a method for preparing an aldehyde-containing polyurethane-acrylate resin tanning agent. The aldehyde-containing polyurethane-acrylate resin tanning agent is prepared from a polymerizable nonionic polyurethane oligomer and unsaturated aldehyde by carrying out radical copolymerization in distilled water. The tanning agent contains aldehyde group, can be combined with a covalent bond of hide collagen fibers, has obvious tanning function, can make leather obtain higher hydrothermal stability when reducing the use amount of a chrome tanning agent, has excellent selective filling property, can make the leather have soft and plump hand feeling and exquisite grain, can be assorted with the chrome tanning agent to use in the low pH value environment of chrom tanning and chrome retanning, is favorable to adsorption fixation of the chrome tanning agent, can obviously reduce content of chromium salt in chrom tanning liquid waste so as to greatly reduce pollution of the tanning liquid waste to the environment, is a novel multifunctional environment-friendly leather tanning material and is suitable for tanning processing of sofa leather, instep leather, clothing leather and the like.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com