A kind of cold working die steel cr8 and its production method

A technology of cold work die steel and production method, applied in the field of iron and steel materials, can solve the problems of easy brittle cracking, poor impact toughness, brittle cracking, etc., and achieve the effects of less surface decarburization, good wear resistance and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

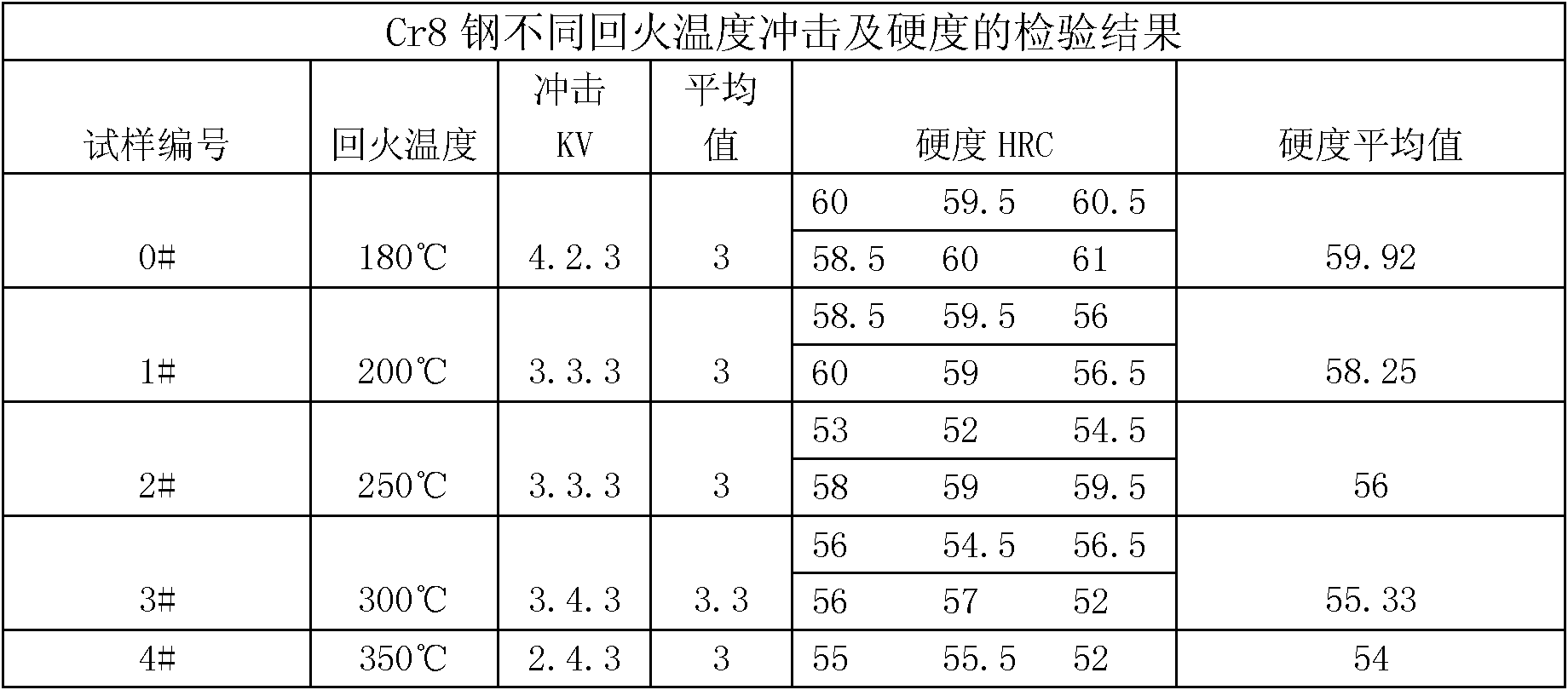

Examples

specific Embodiment 1

[0040] A kind of production method of cold working die steel Cr8, carries out according to the following steps:

[0041] 1) Preliminary smelting in an intermediate frequency furnace:

[0042] 1-1) Tapping capacity of intermediate frequency furnace: 30-32T / furnace, ingredient structure: 4t of Cr-Fe alloy material, 27t of scrap steel material, and 180Kg of high Mn alloy material;

[0043] 1-2) Add part of the scrap steel material in the above batching structure into the intermediate frequency furnace first, then add the waste electrode block with adjusted carbon content into the furnace, and then add scrap steel material to press the waste electrode block until it melts; when the furnace When the molten steel is cleared (scrap steel is converted into molten steel) about 1 / 2, sampling analysis is carried out, and the weight percentage of C in the molten steel in the furnace is adjusted to 1.10% according to the results of the laboratory test sheet. When the weight percentage of C...

specific Embodiment 2

[0054] The characteristics of this embodiment are: in step 3-2), when the temperature is higher than 1500 ° C, sampling and analysis of components, according to the test sheet, the weight percentage of each chemical component in the molten steel in the furnace is adjusted to: C: 1.15 %, Mn: 0.40%, Si: 0.30%, P: 0.020%, S: 0.020%, Cr: 7.50%, Cu: 0.20%, and the balance is iron; others are the same as in Example 1.

specific Embodiment 3

[0055] The characteristics of this embodiment are: in step 3-2), when the temperature is higher than 1500 ° C, sampling and analysis of components, according to the test sheet, the weight percentage of each chemical component in the molten steel in the furnace is adjusted to: C: 1.20 %, Mn: 0.60%, Si: 0.40%, P: 0.030%, S: 0.030%, Cr: 8.00%, Cu: 0.25%, and the balance is iron; others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com