Patents

Literature

35results about How to "Reduce chemical consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

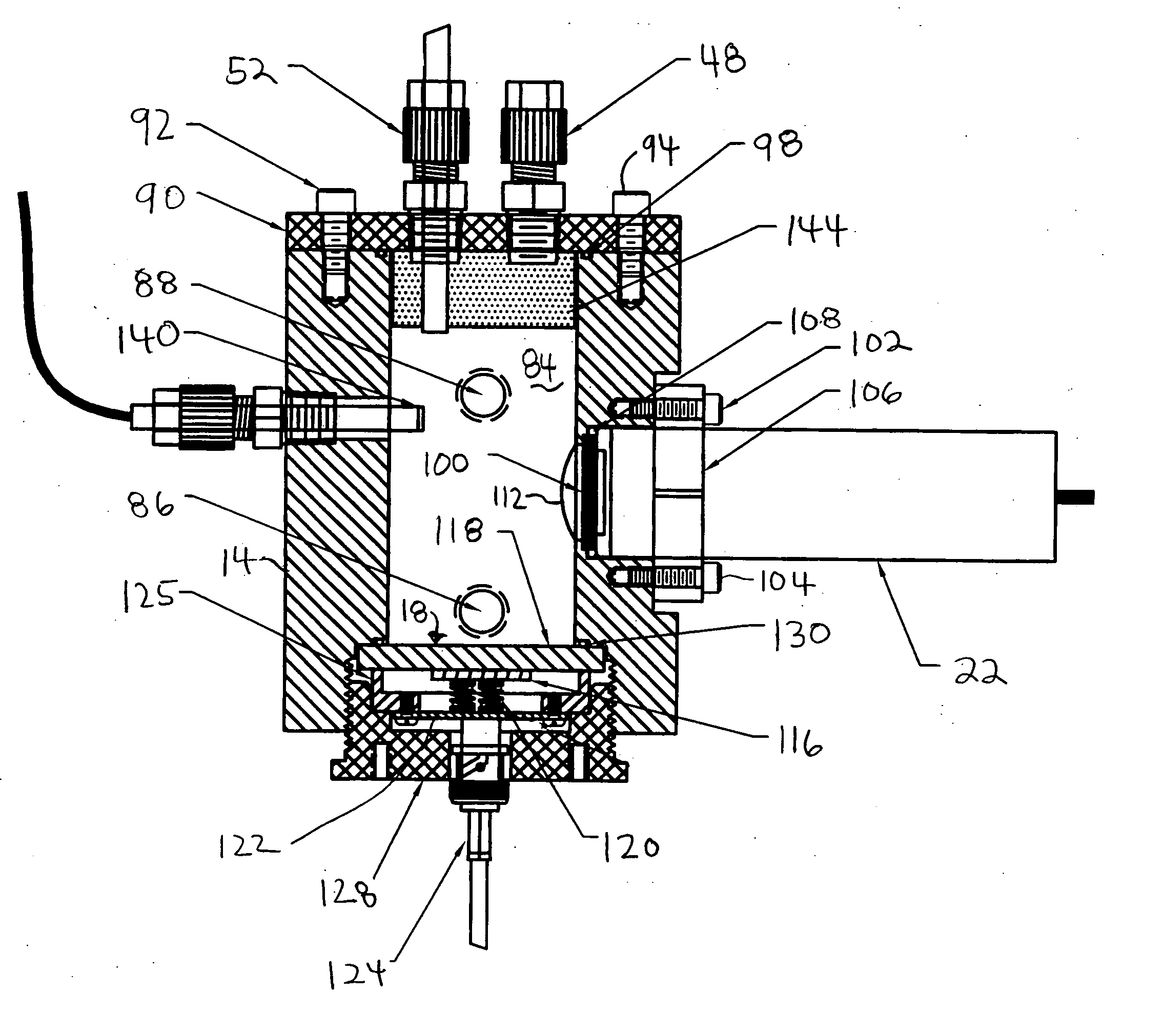

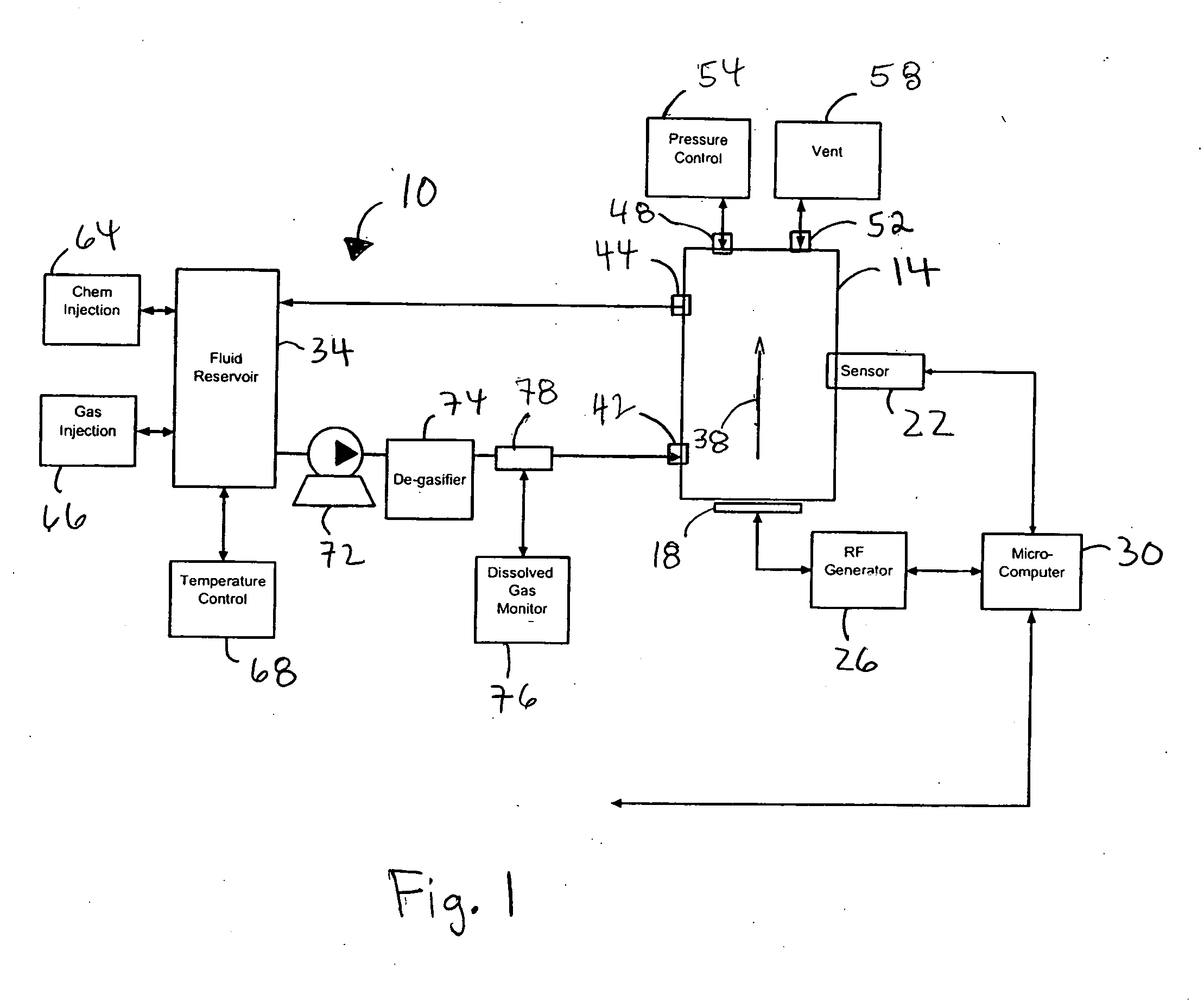

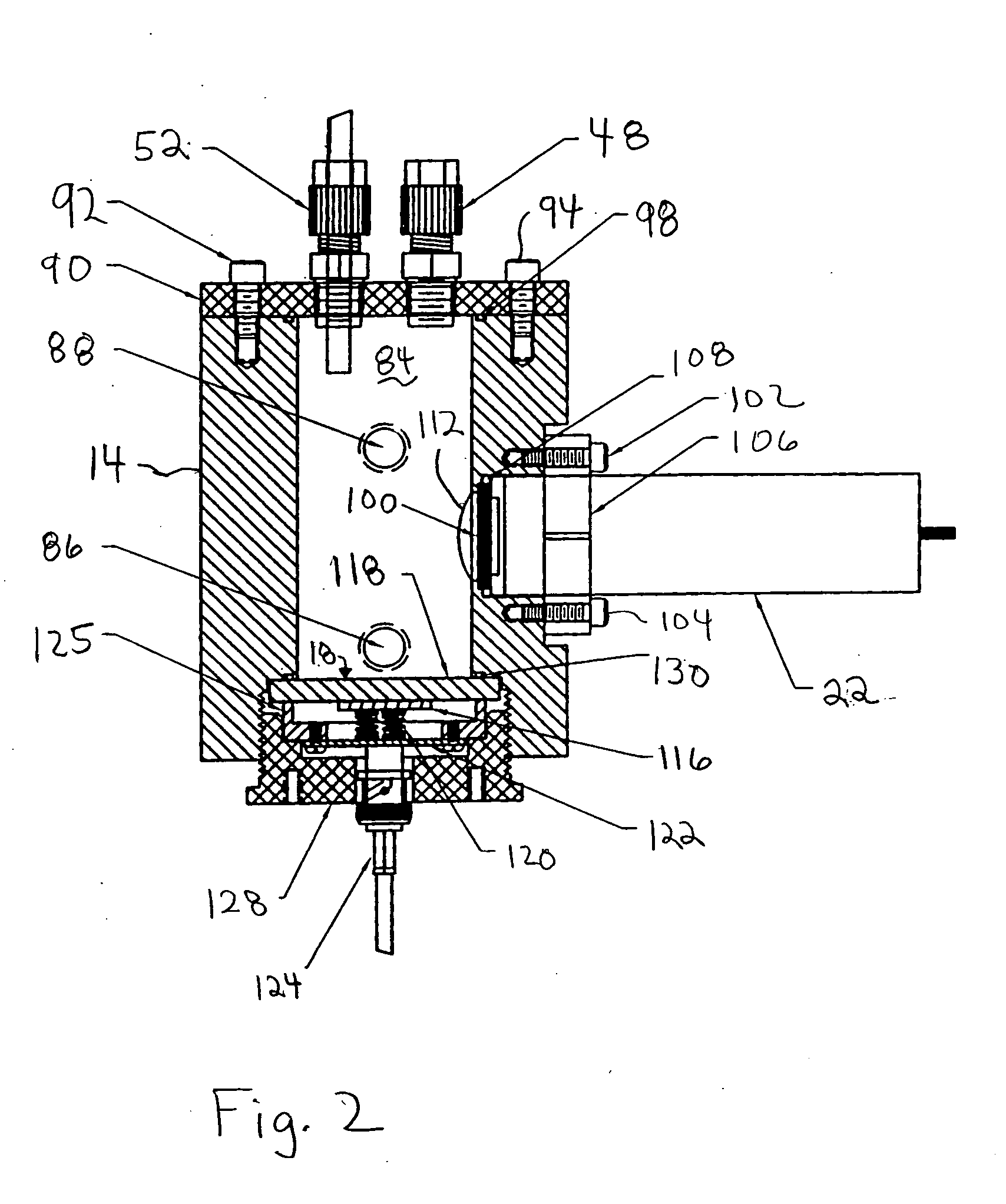

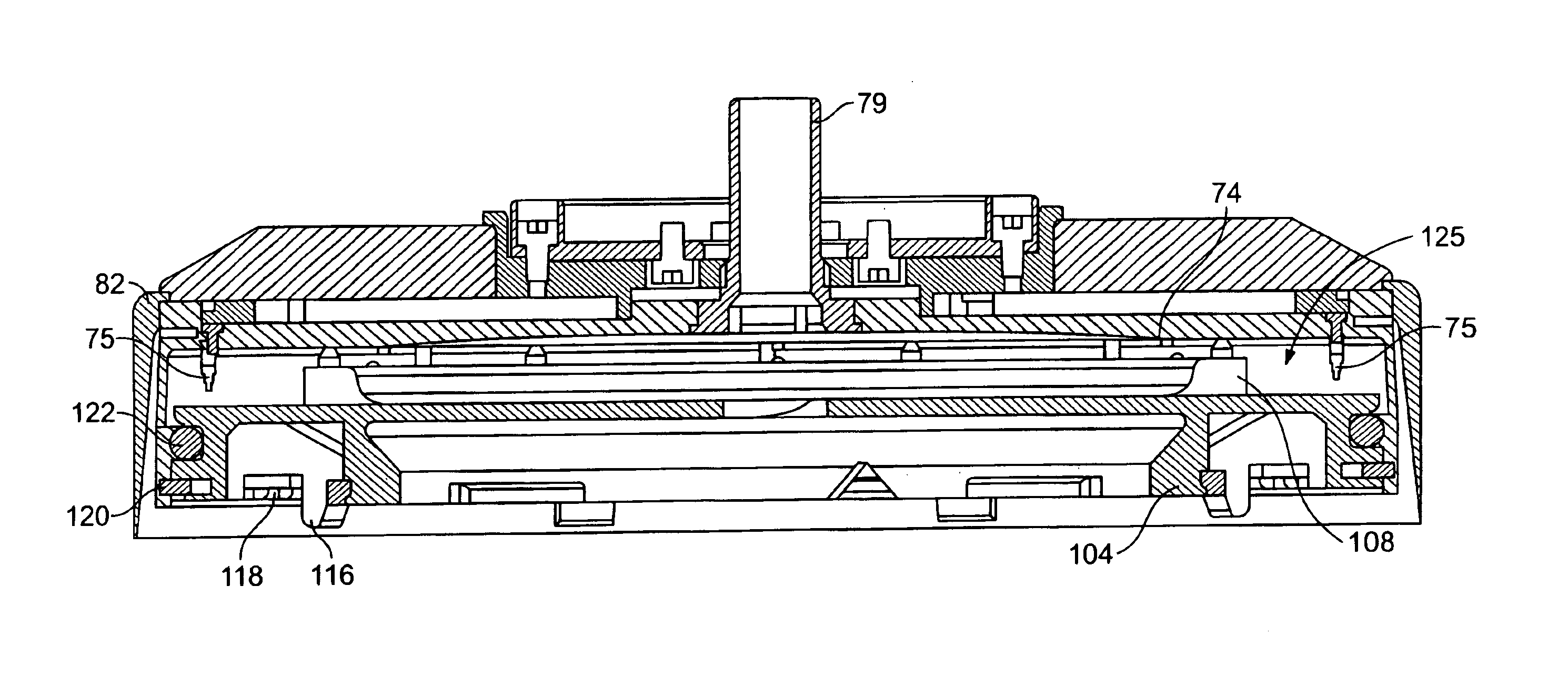

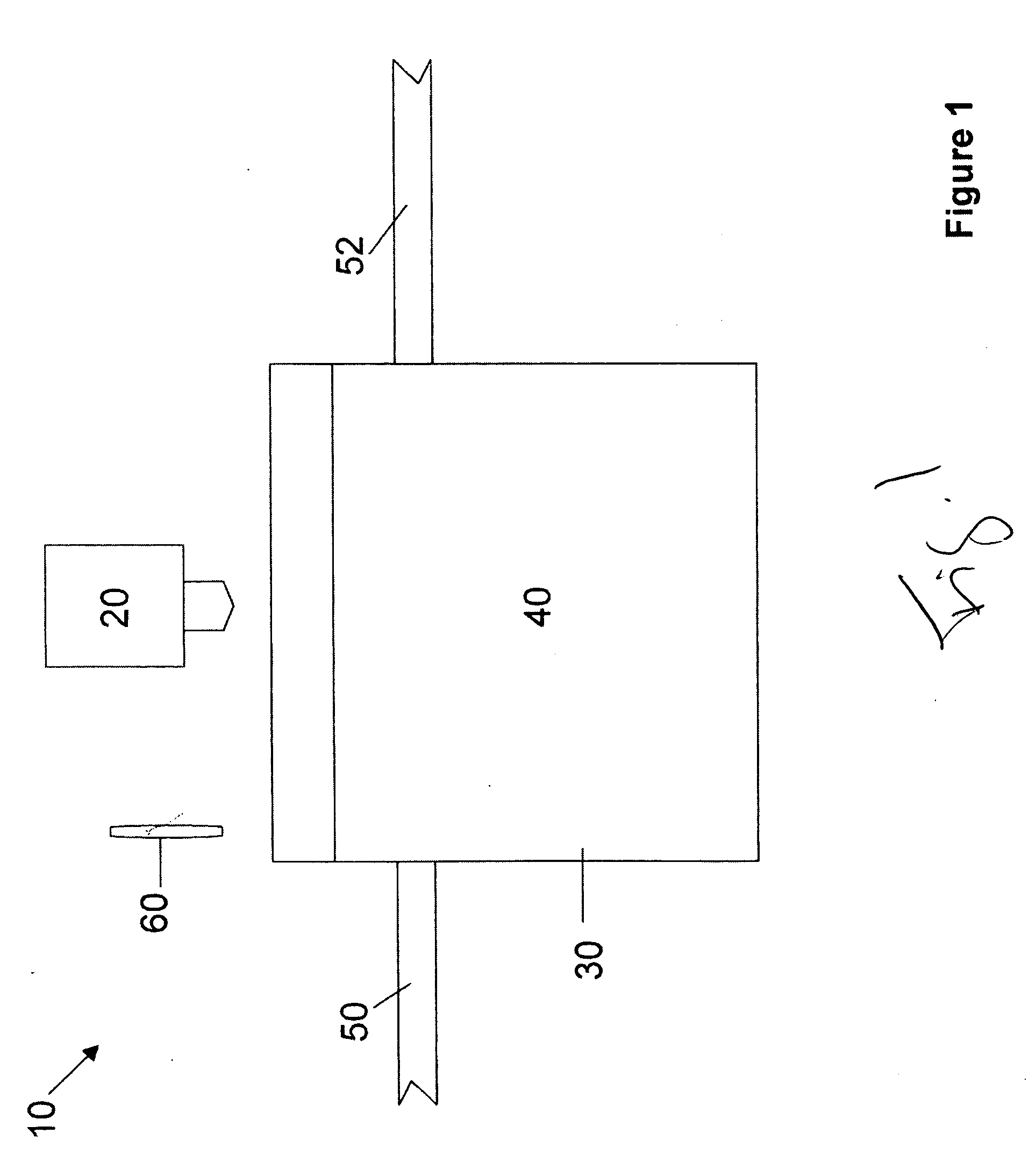

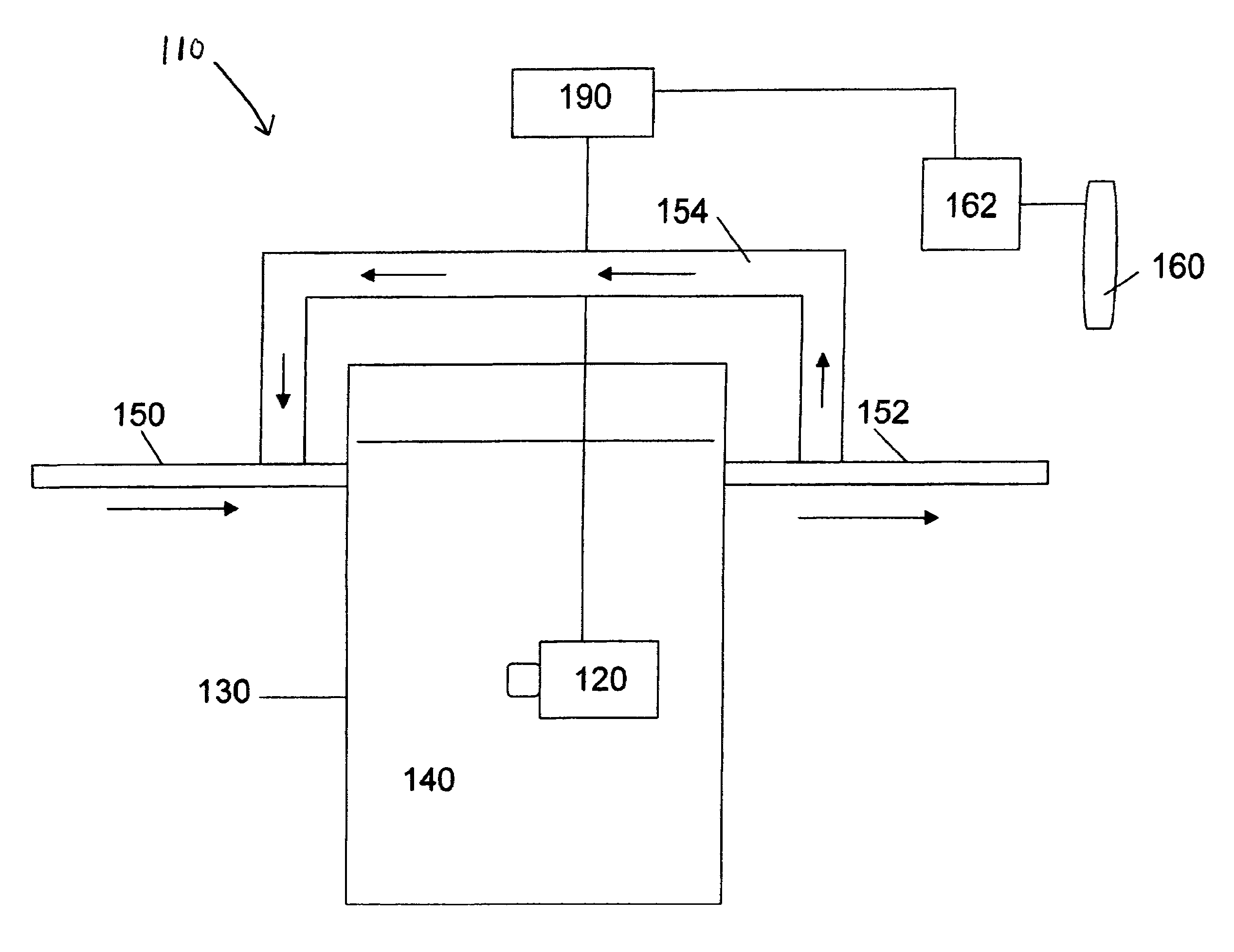

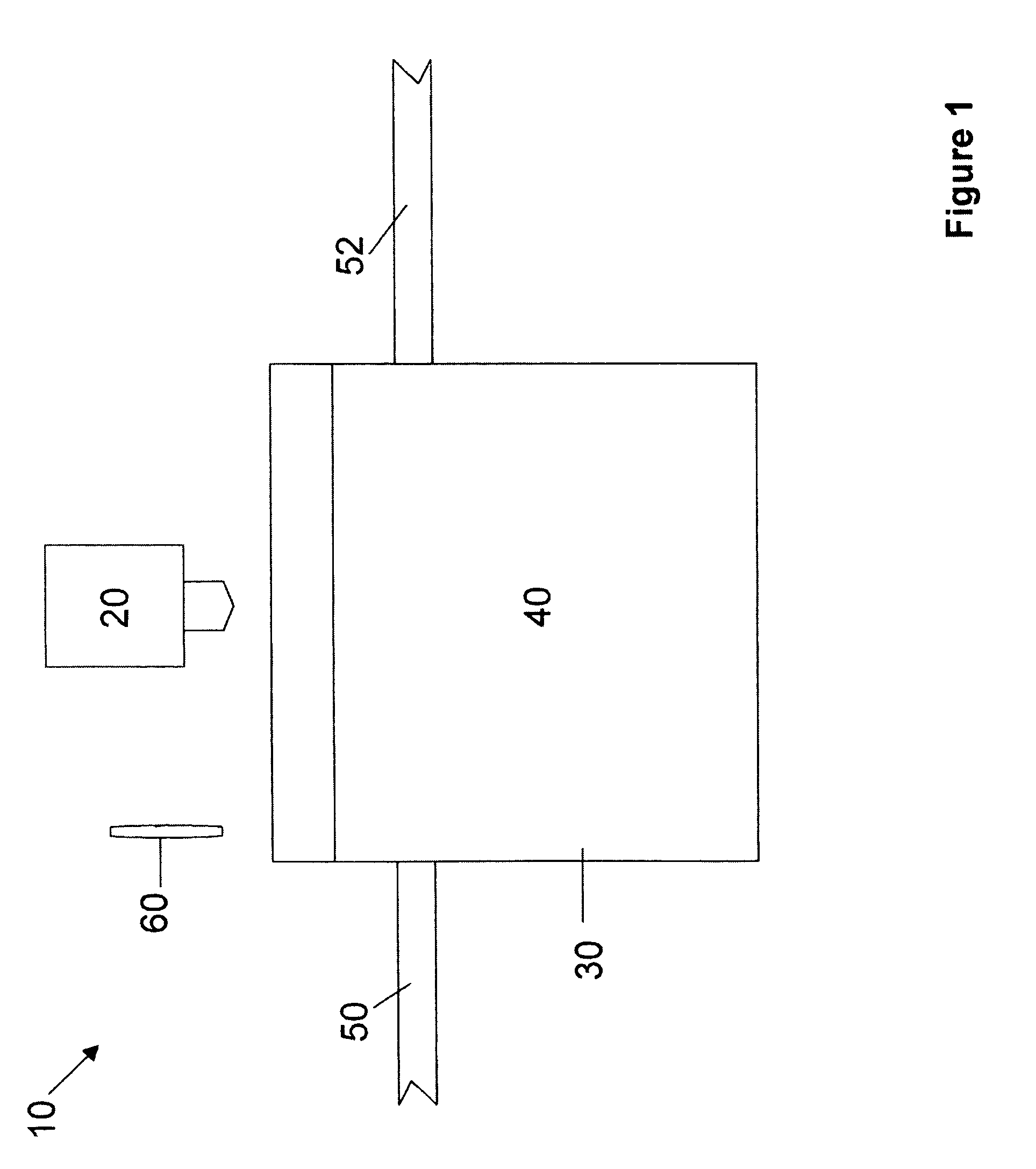

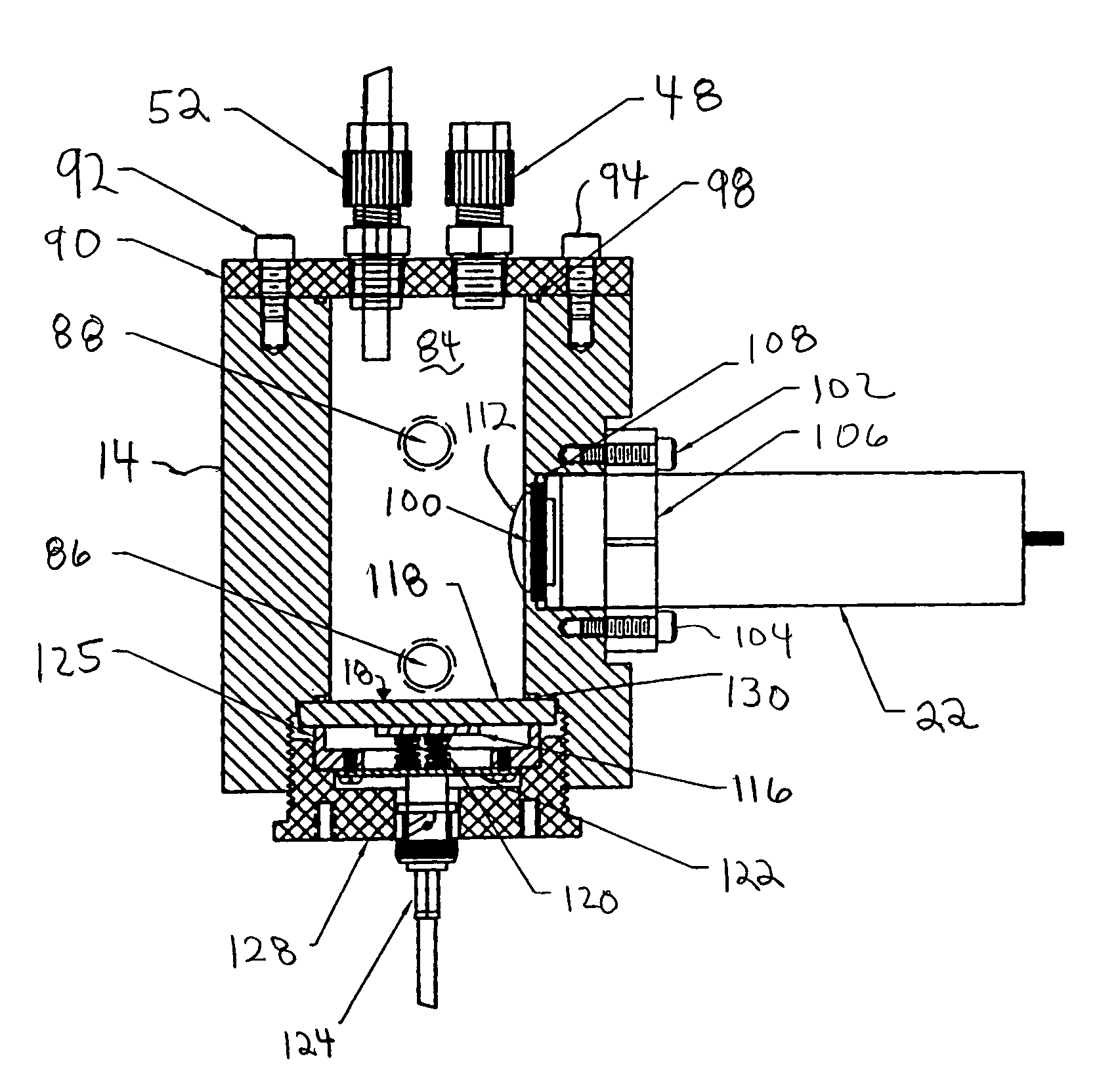

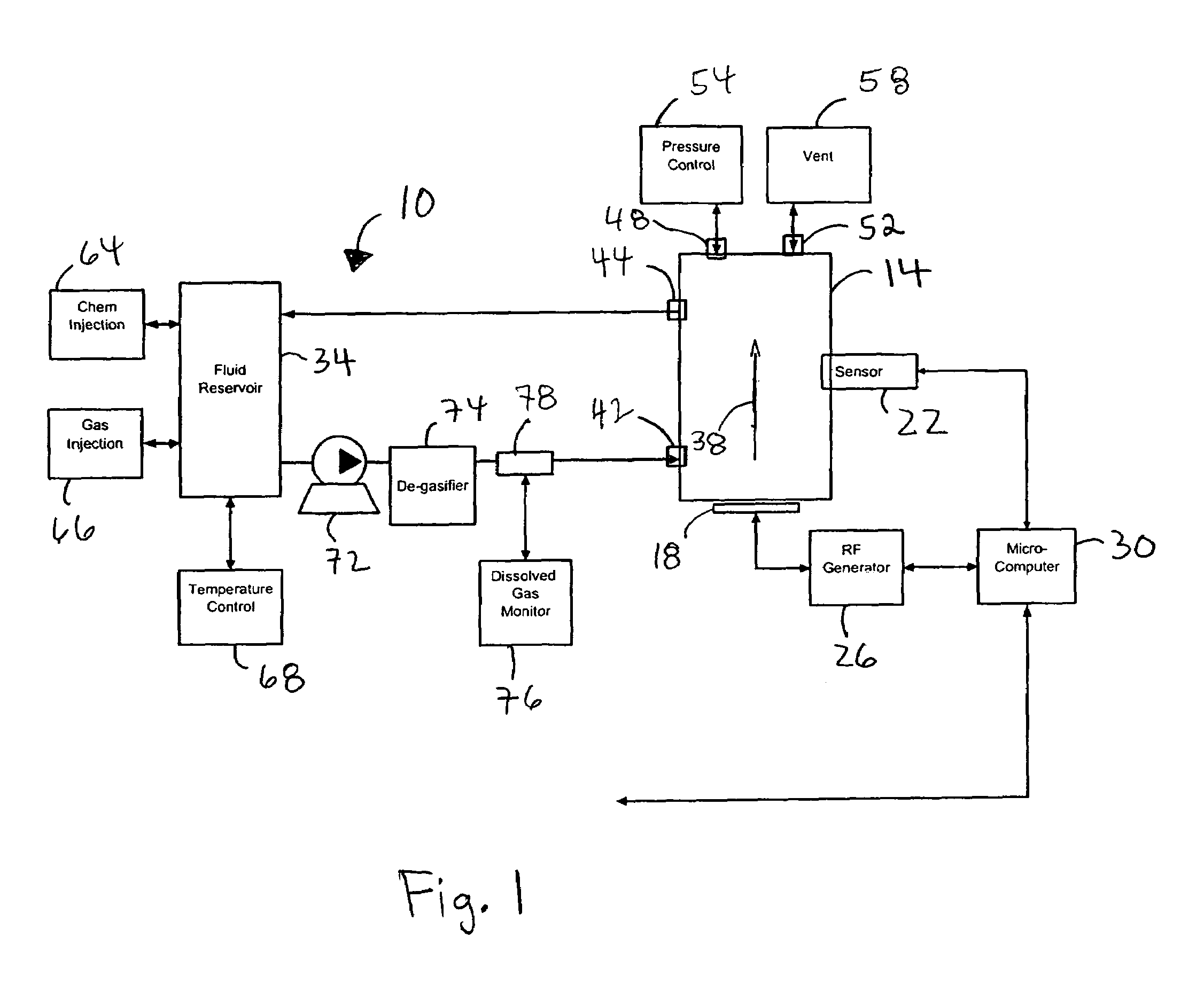

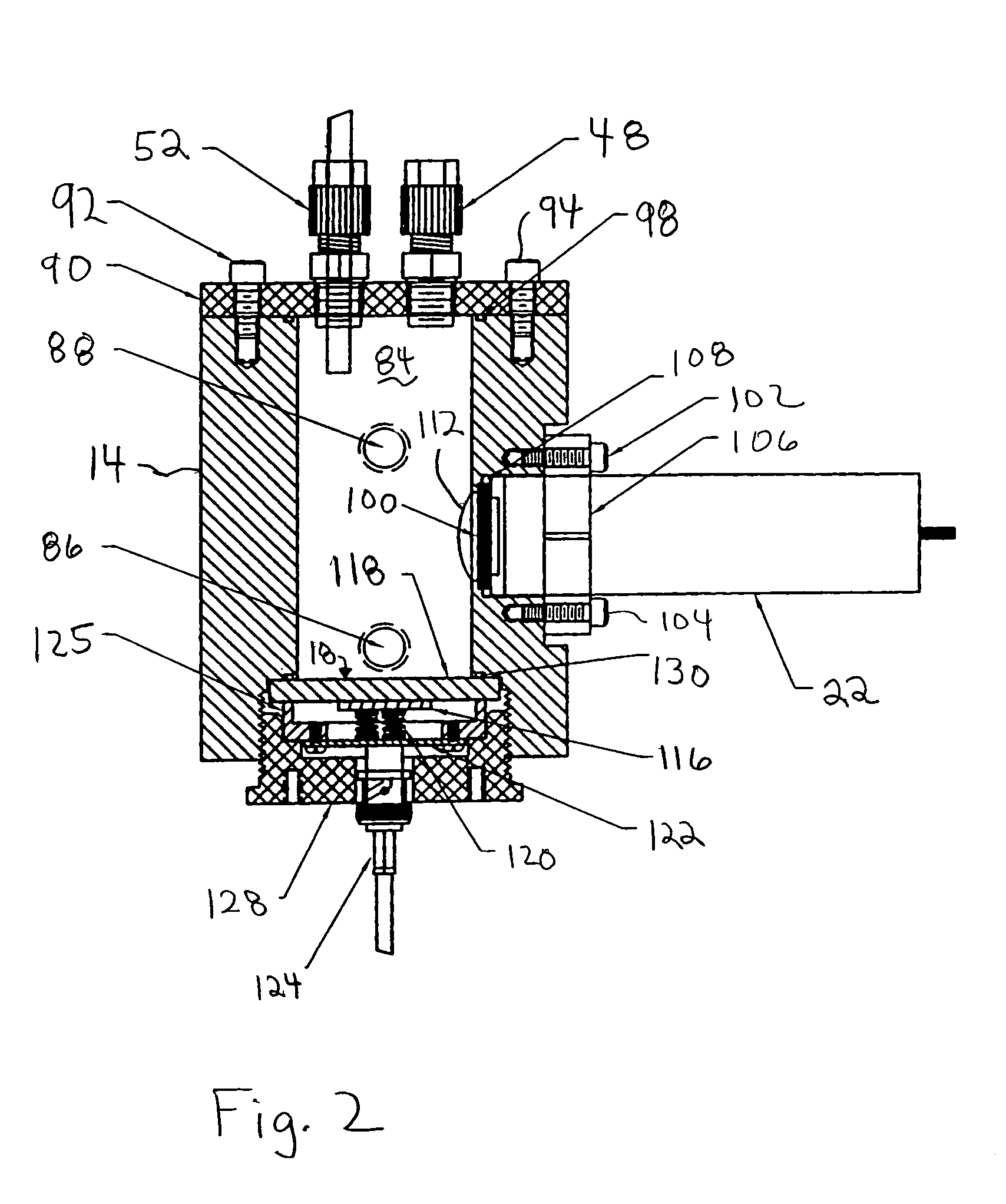

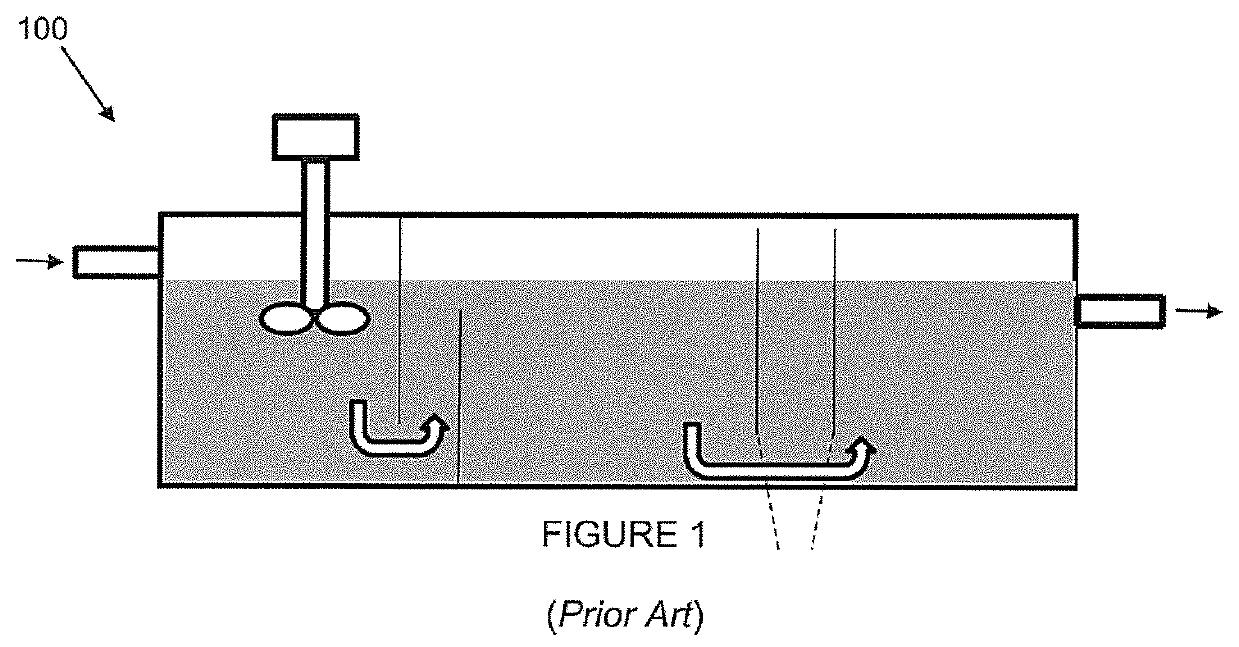

Method and apparatus for cavitation threshold characterization and control

ActiveUS20060061225A1Reduce chemical consumptionAvoid damaging effectsAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidAcoustic energySonoluminescence

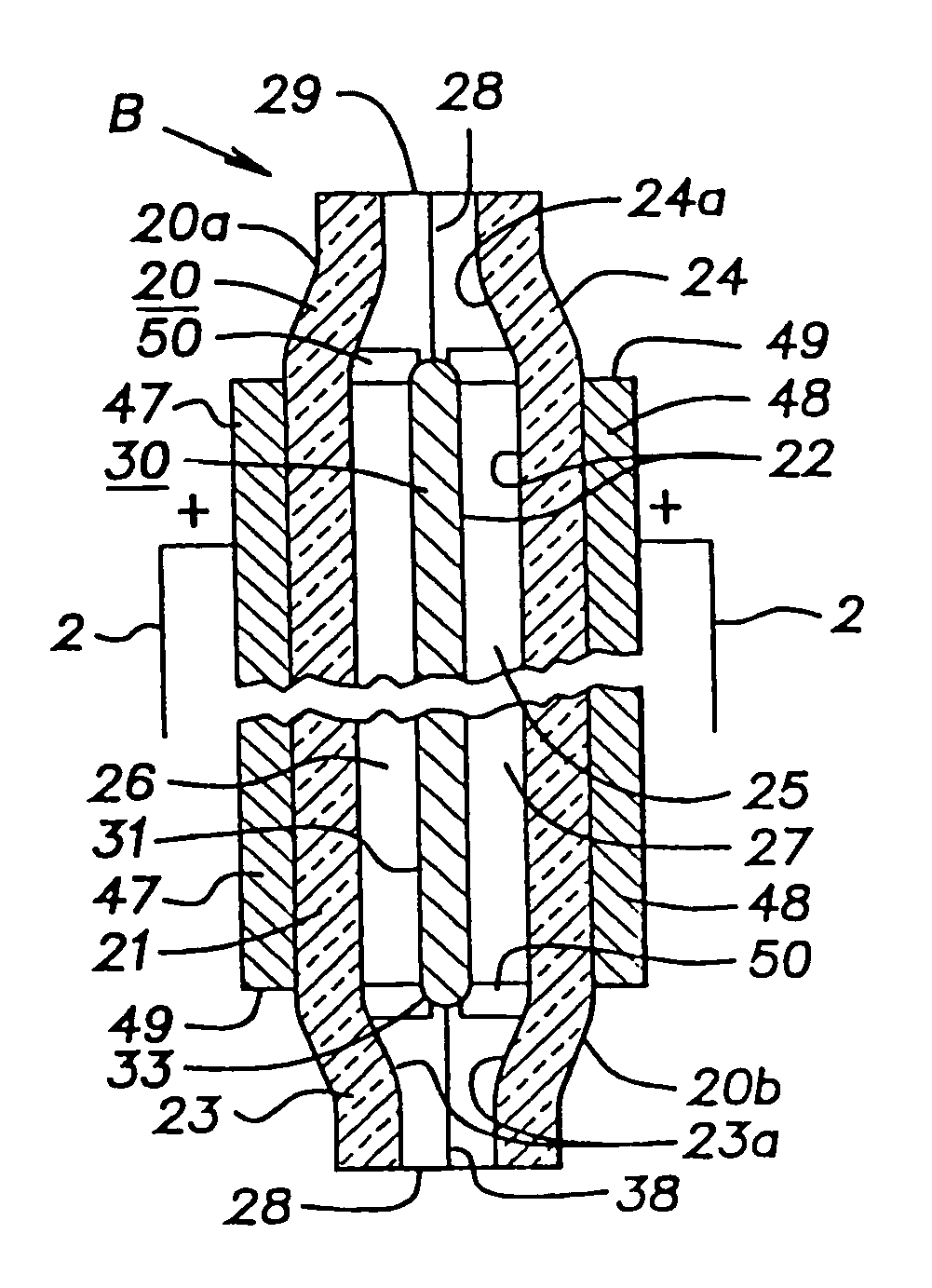

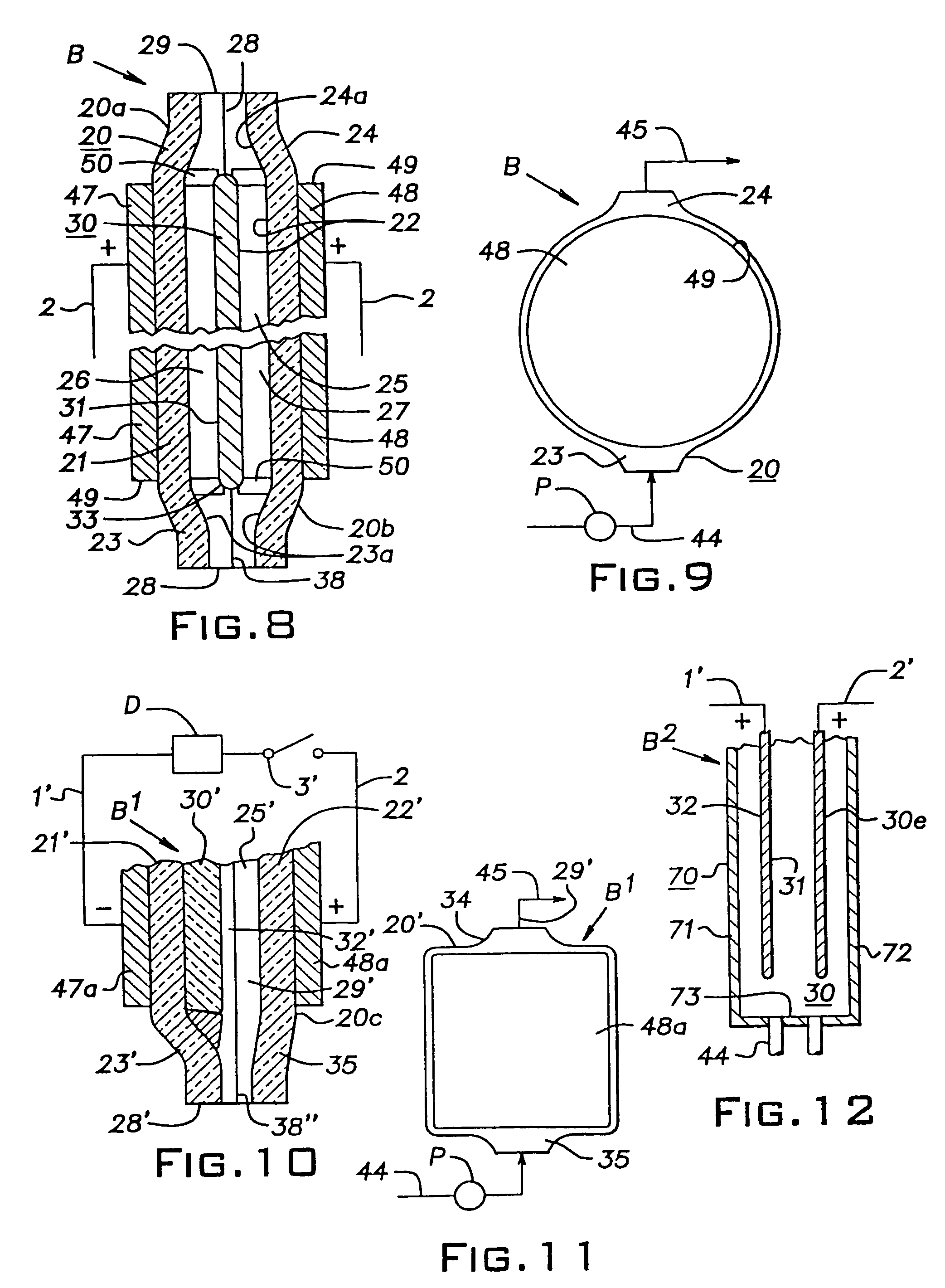

An apparatus and method for characterizing cavitation that occurs in a fluid exposed to acoustic energy. The apparatus comprises a vessel for holding the fluid; an acoustic energy generating means for generating acoustic energy, the acoustic energy generating means being positioned to transmit the acoustic energy into the fluid while the fluid is held in the vessel; and a cavitation detection means for detecting cavitation in the fluid held in the vessel. In a preferred embodiment, the cavitation detection means comprises a light detection means, such as a photomultiplier tube, that detects sonoluminescent emission from the fluid. The method comprises the steps of exposing a volume of process fluid to acoustic energy at a specified power level; measuring the photon output from the fluid over a period of time; and when the photon output deviates from a desired level, initiating a remedial step to bring the photon output back to approximately the desired level.

Owner:PROD SYST

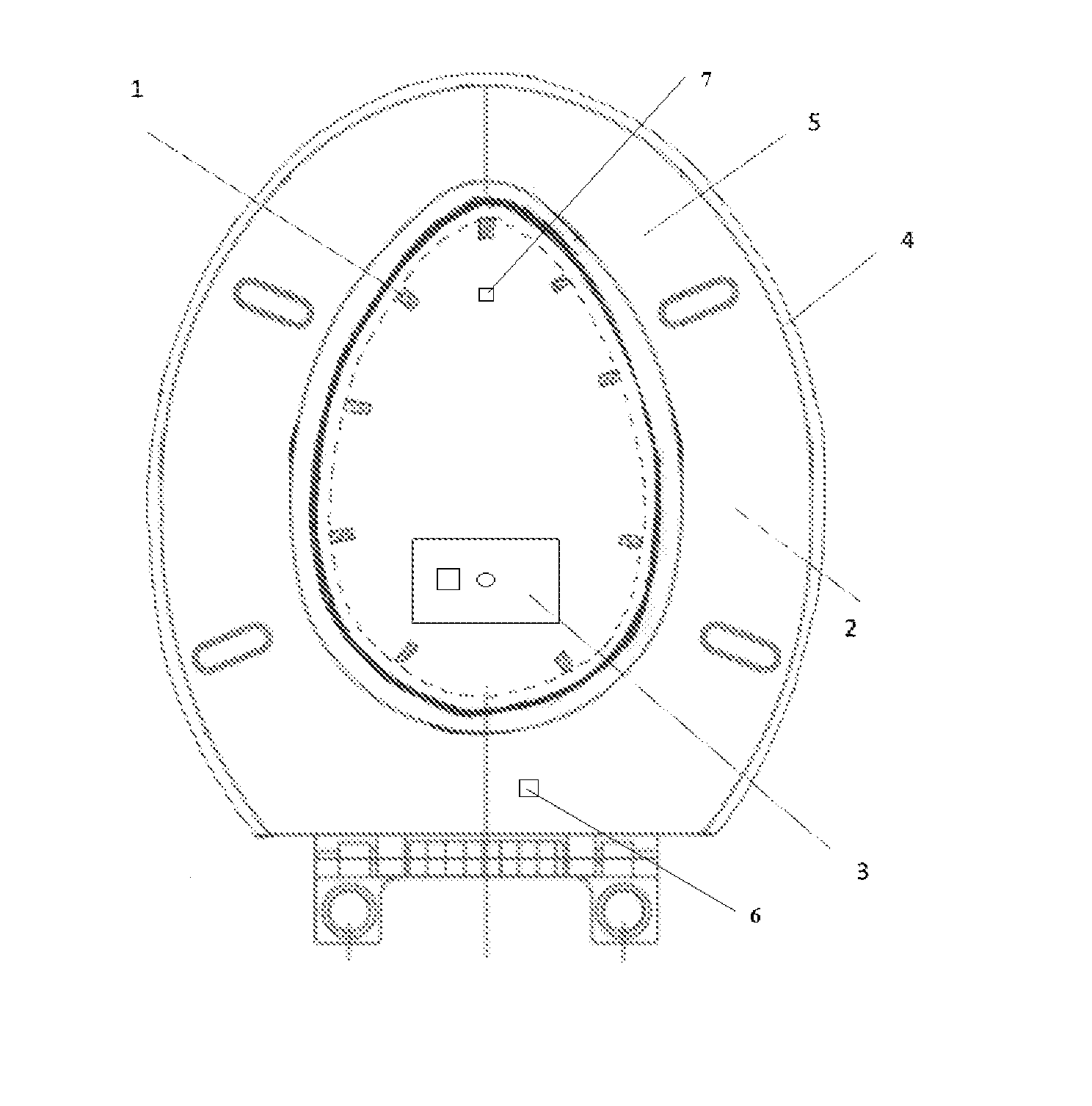

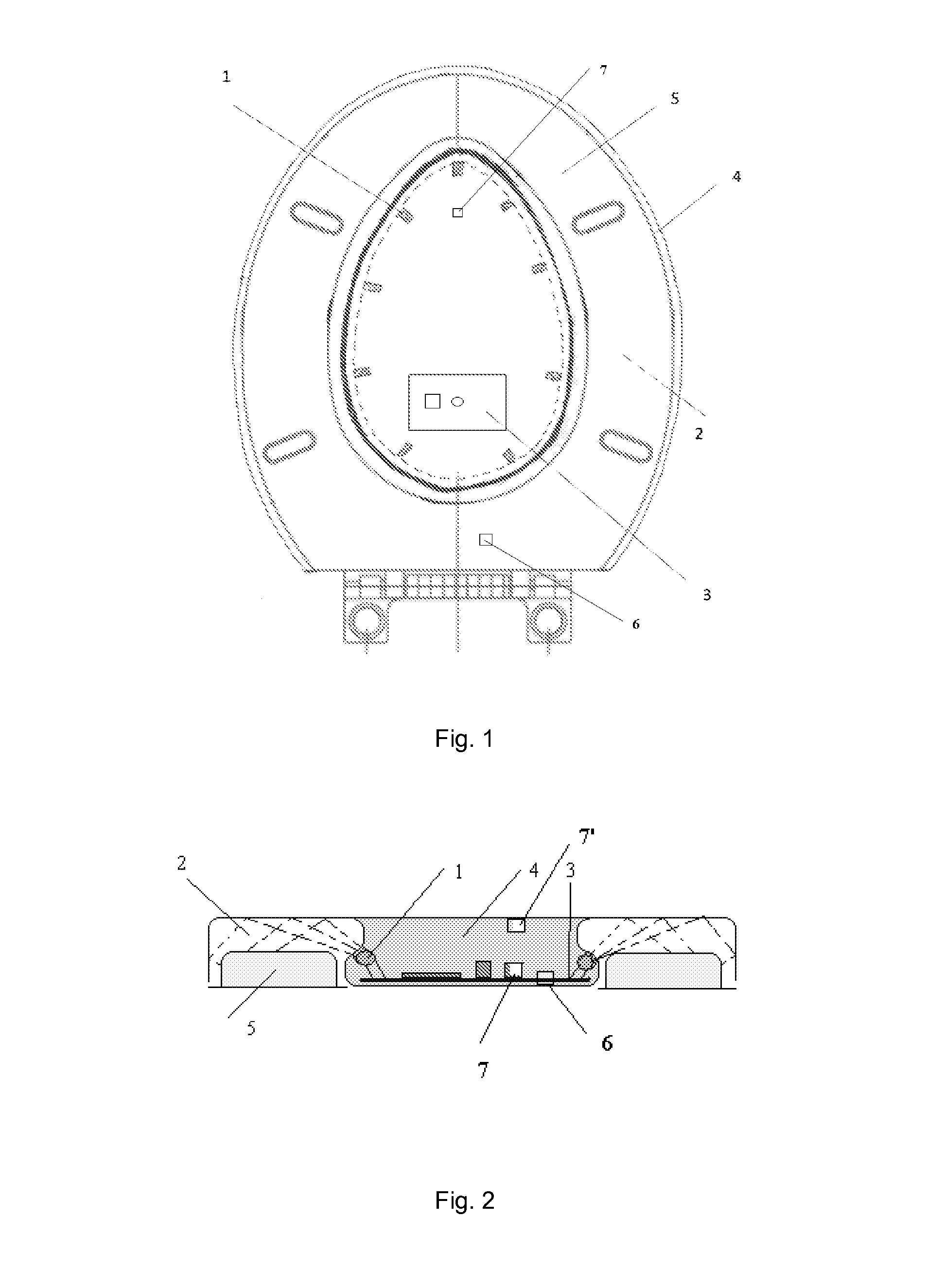

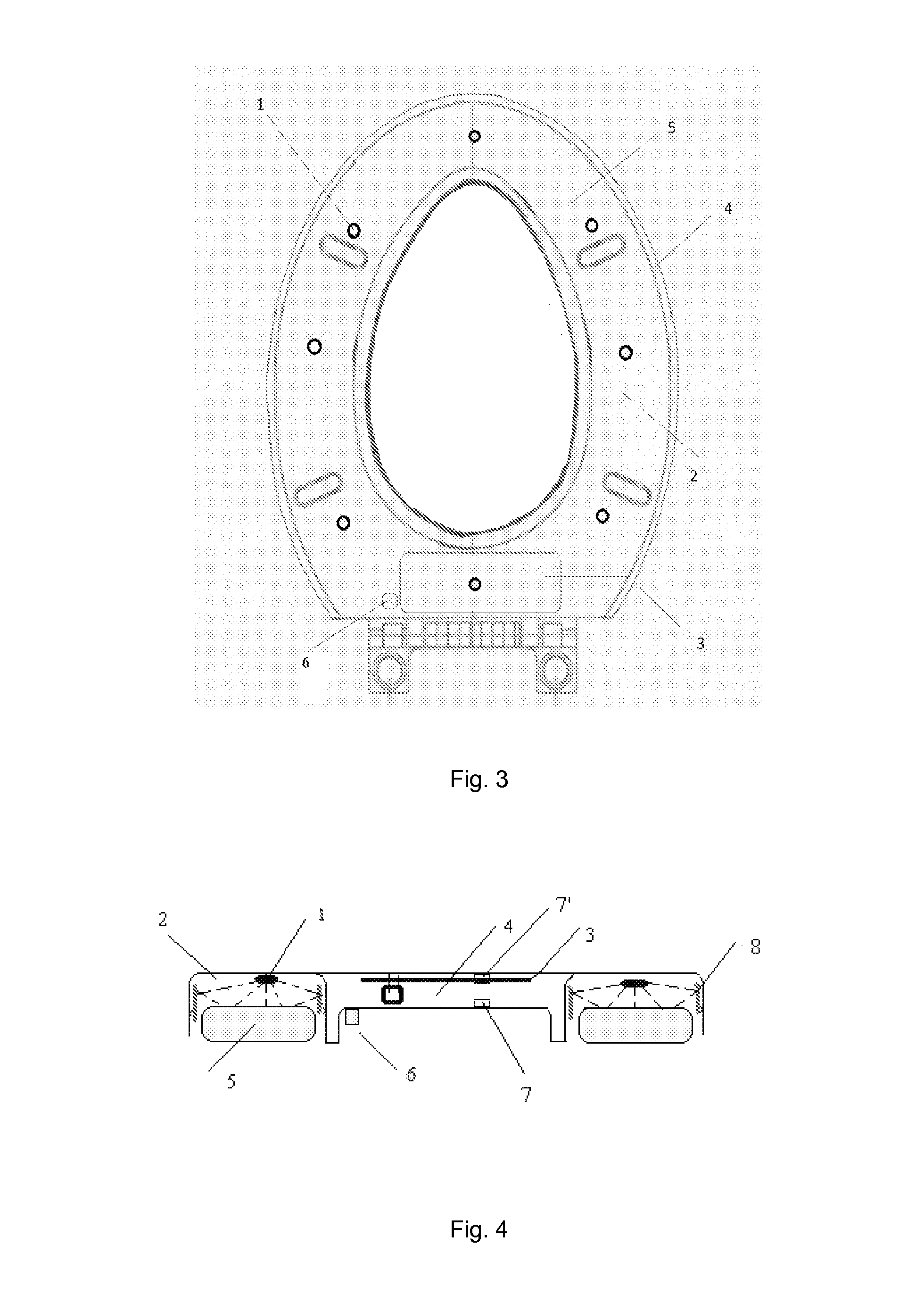

The sanitization mechanism of the toilet seat

InactiveUS20140115764A1Reducing toilet seat paperReducing restroom chemical consumptionWater closetsBathroom coversPublic placeEngineering

The sanitization mechanism of the toilet seat is using control circuit(s) to ensure an enclosed compartment between toilet seat and toilet cover then activating UV LEDs to sanitize the toilet seat. In addition to safe operation, fast response and effective sanitization, it can reduce toilet seat paper or restroom chemicals consumption, especially in high traffic public locations.

Owner:CHENG YING CHANG +2

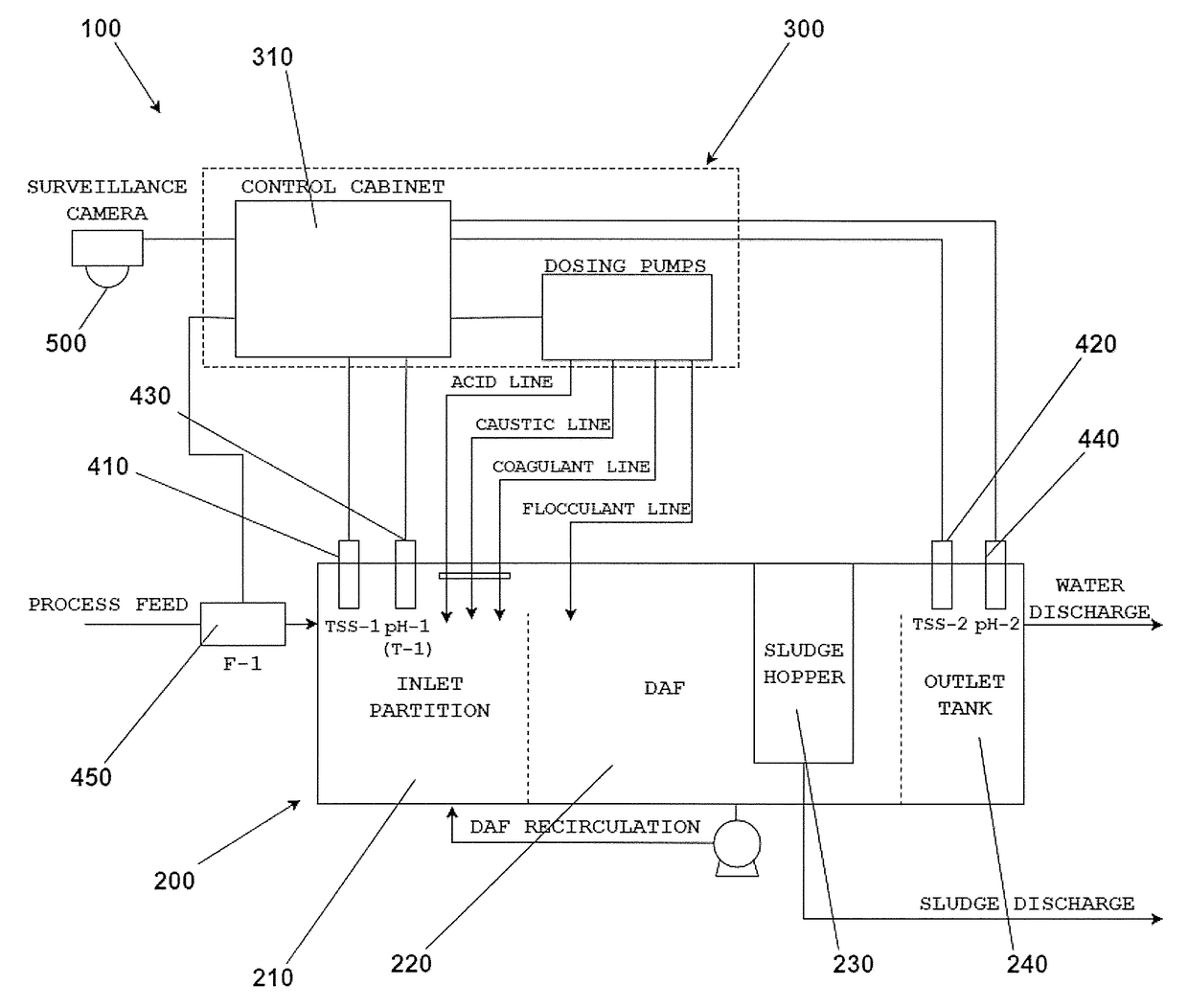

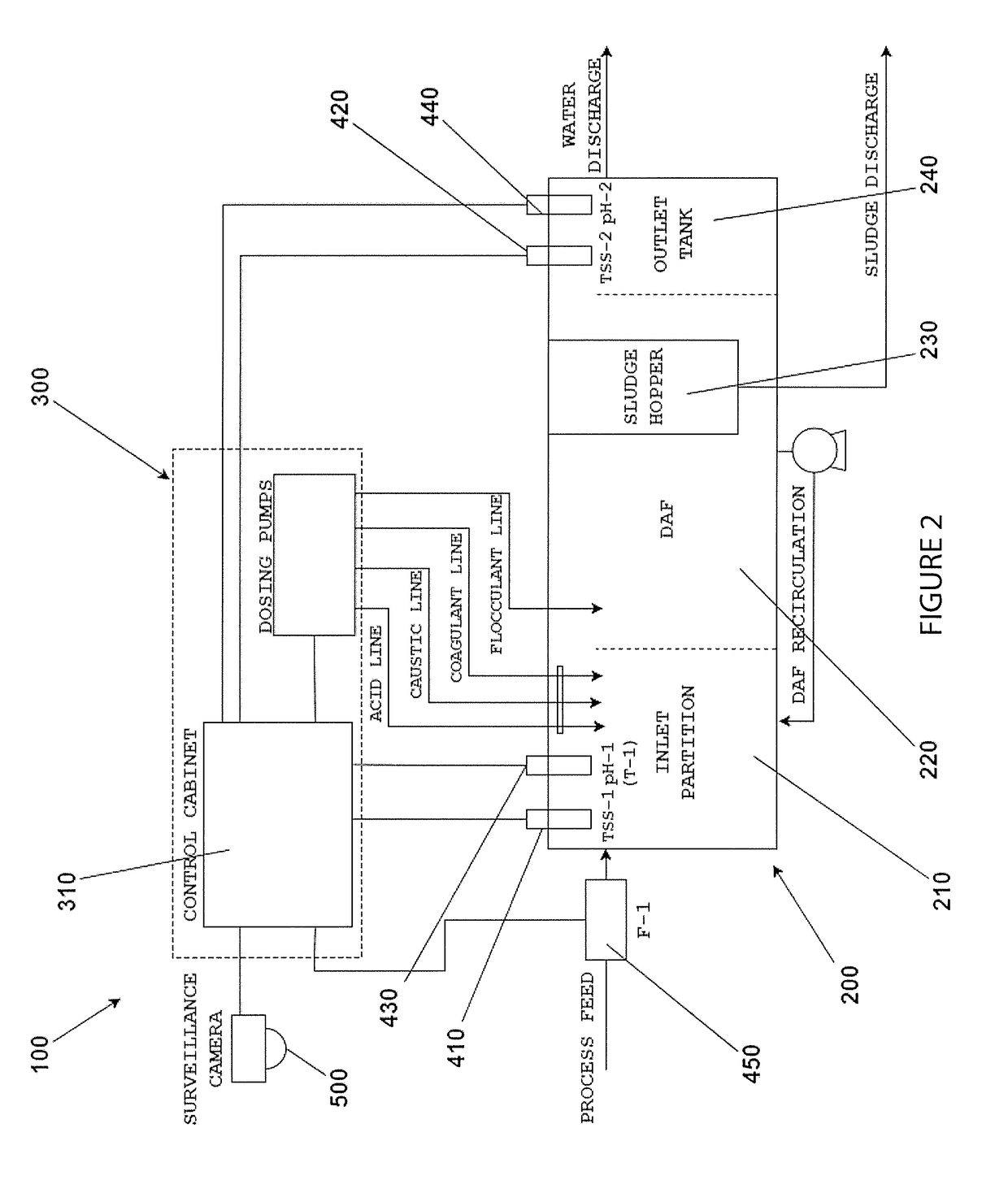

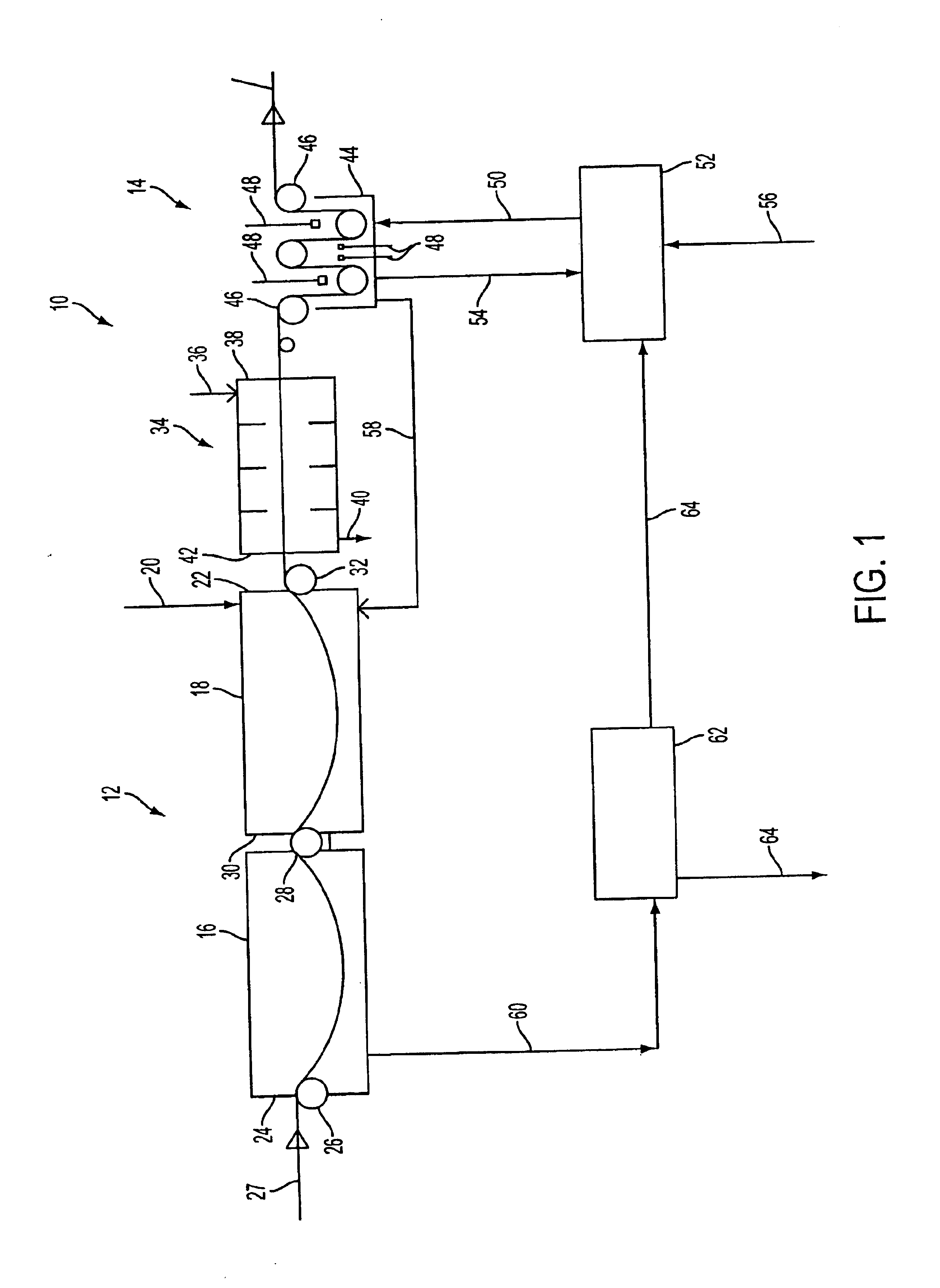

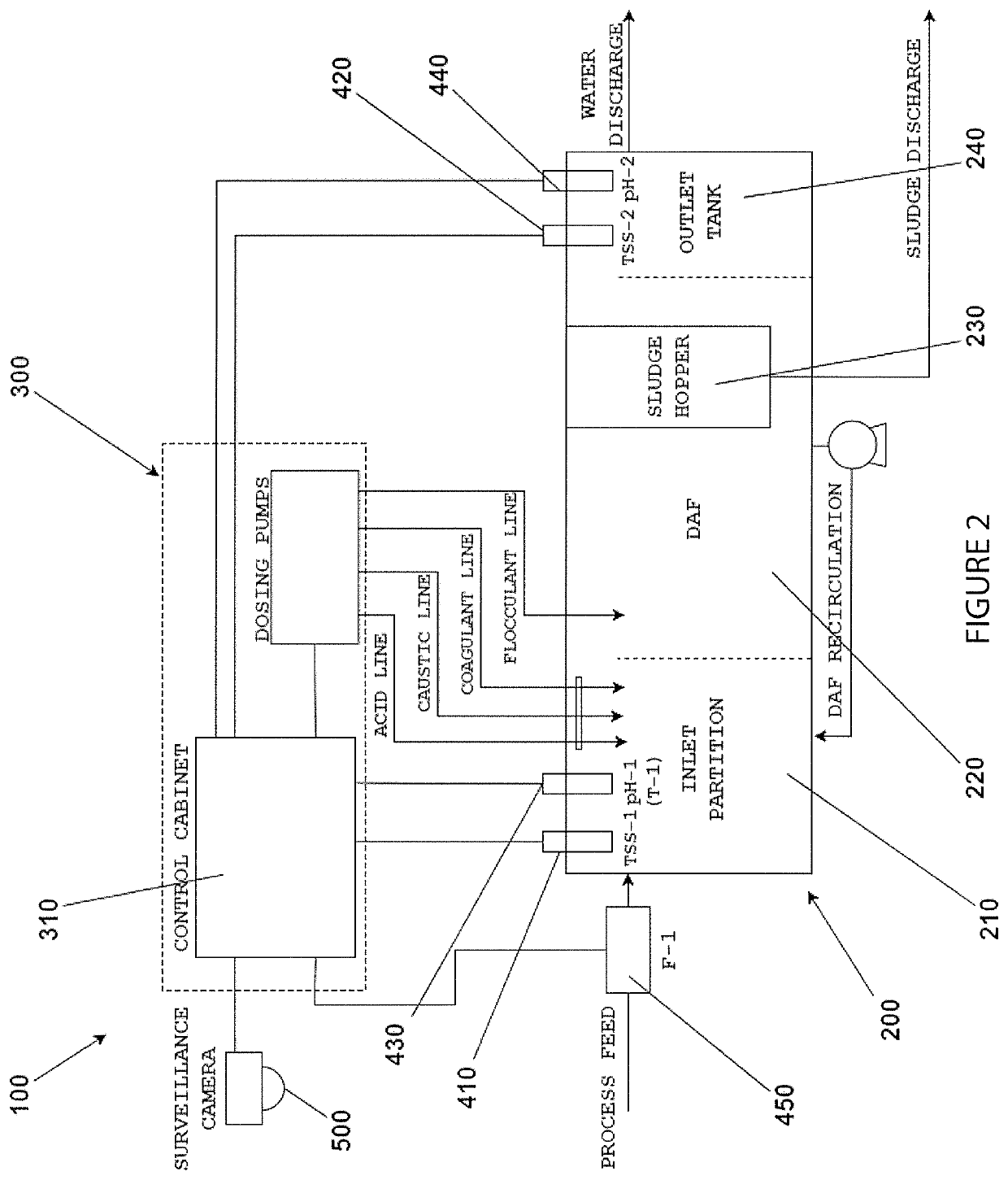

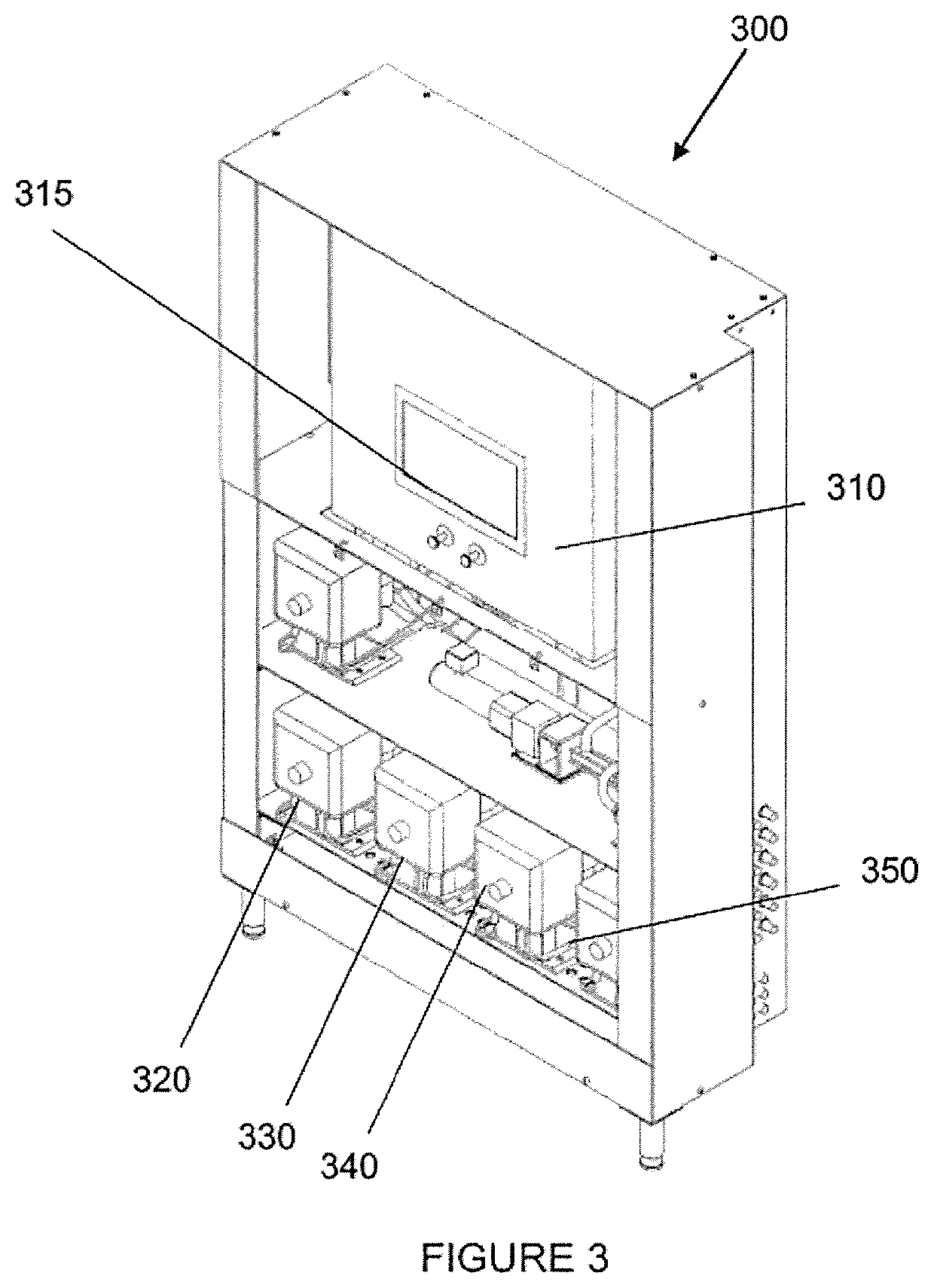

Water treatment system and method

ActiveUS20170297929A1Discharge costReduce and even eliminate non-complianceWater treatment parameter controlNature of treatment waterWater treatment systemNatural-gas processing

Disclosed herein is a water treatment system for connection to a water treatment plant (e.g. a dissolved air flotation device). The plant may have an inlet for the receipt of feed water (e.g. waste water) and an outlet for the discharge of treated water. The treatment system may comprise a first sensor disposed such that it is in fluidity communication with the feed water, and a second sensor disposed such that it is in fluidity communication with the treated water. The first and second sensors may be configured to sense parameters of the feed and treated water. The system may further comprise a first applicator (e.g. a pump) that is configured to discharge a treatment source (e.g. a chemical source) to the plant to treat the feed water. The disclosed system may be used to treat waste water (e.g. the treatment of effluent from oil refineries, petrochemical and chemical plants, natural gas processing plants, paper mills and general water treatment). The system has analogous applications in other processing methods that also use DAF, or very similar, systems, such as the processing of mineral ores and other such solid extraction processing methods.

Owner:WATERWERX TECH PTY LTD

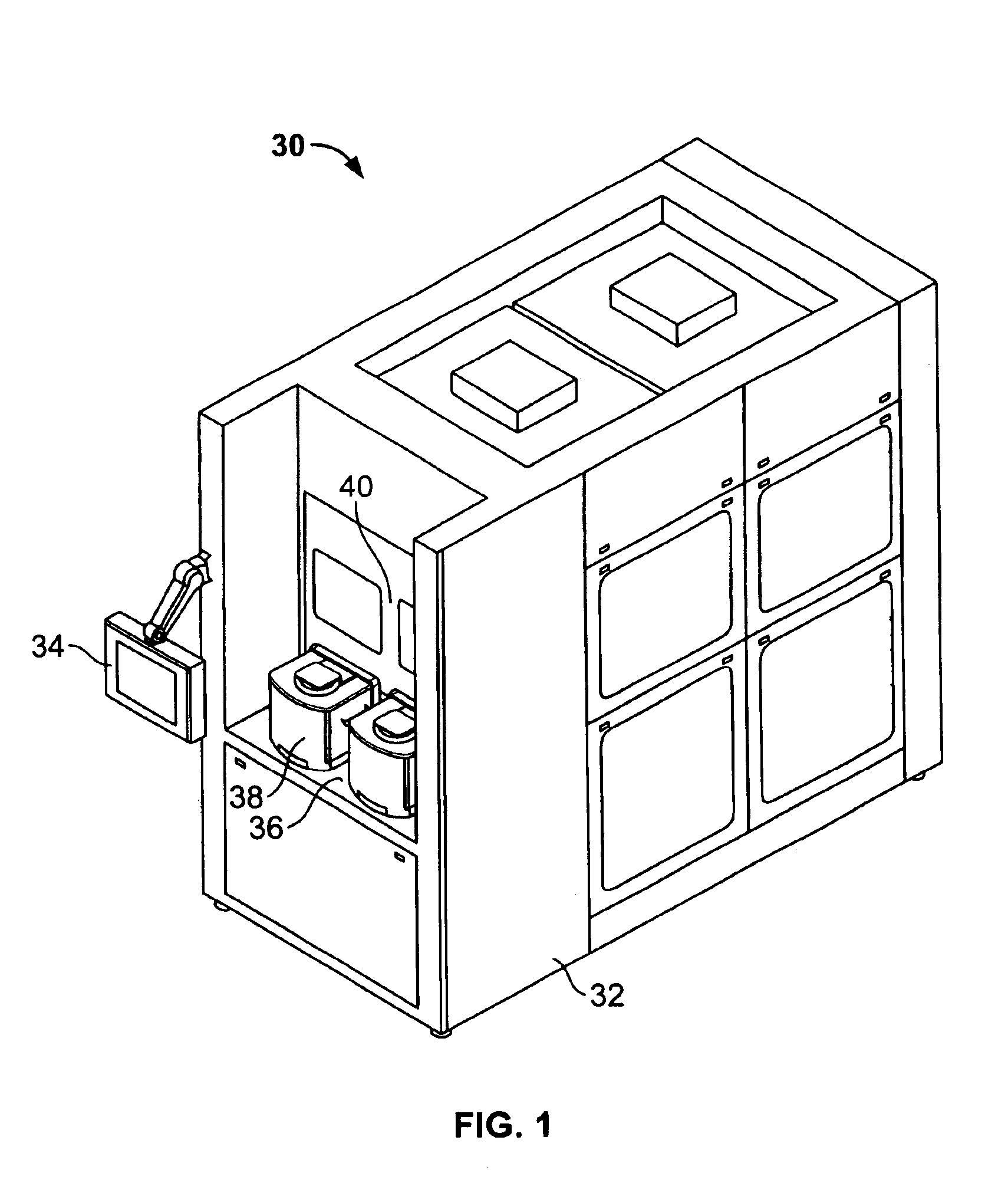

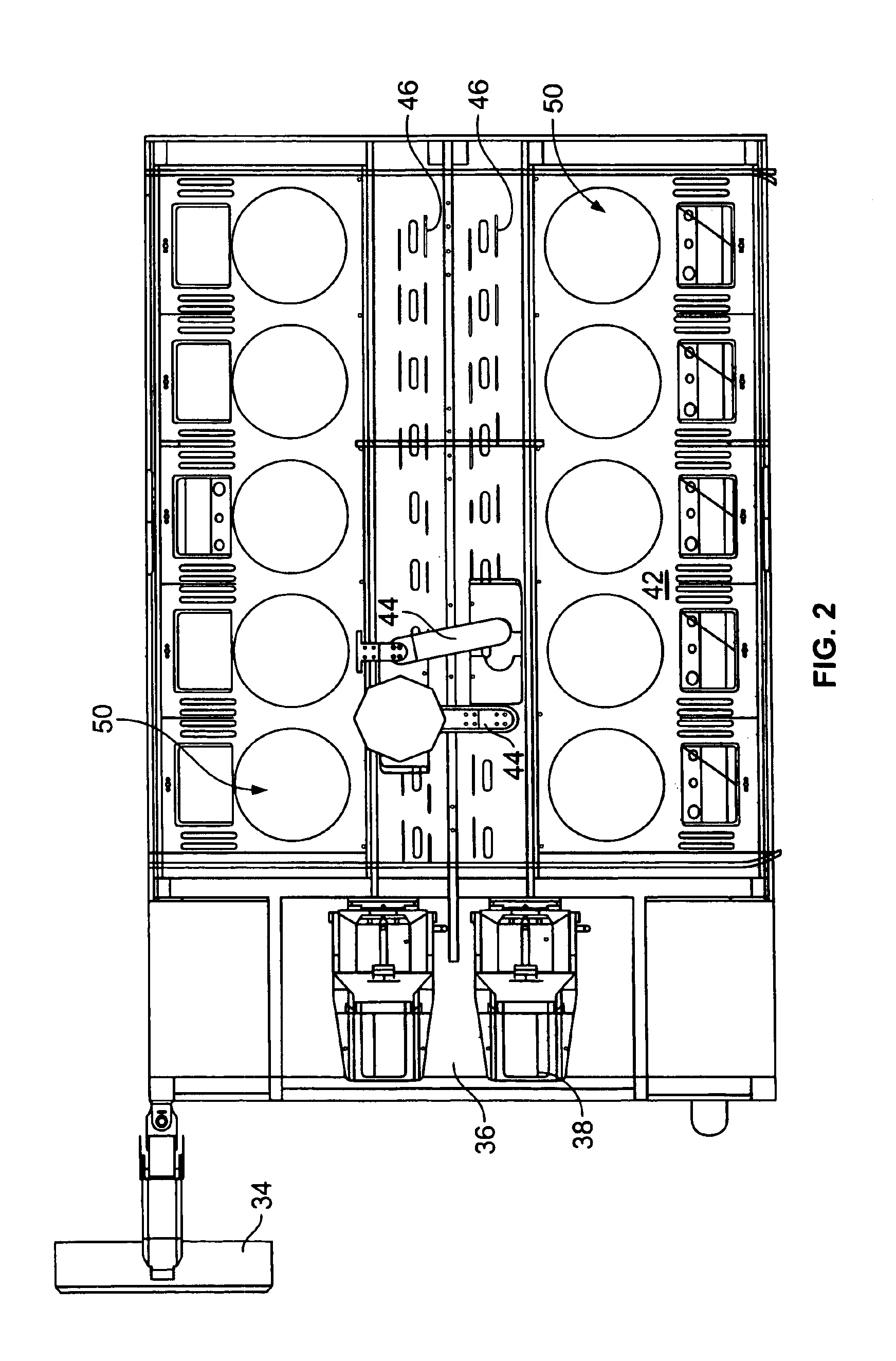

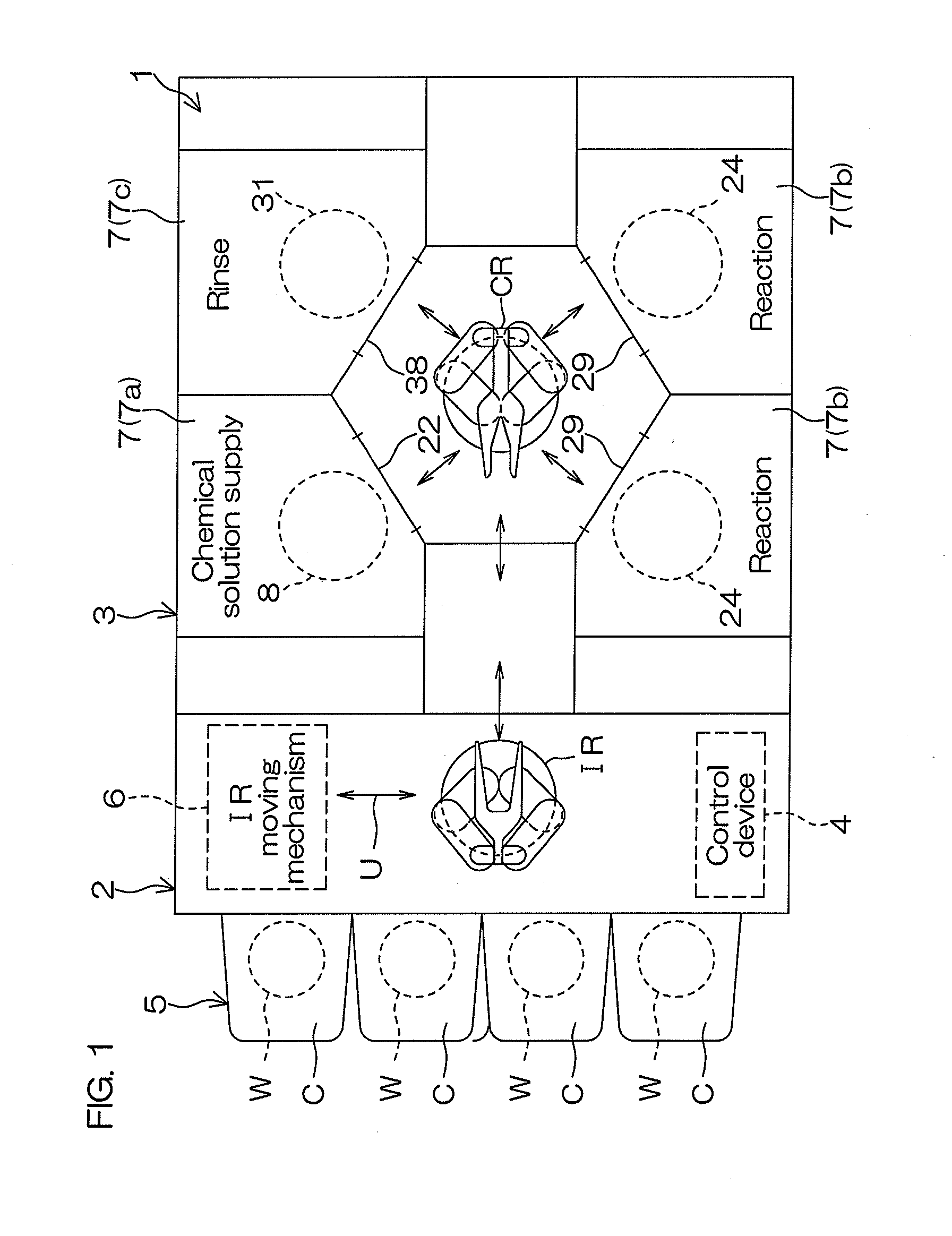

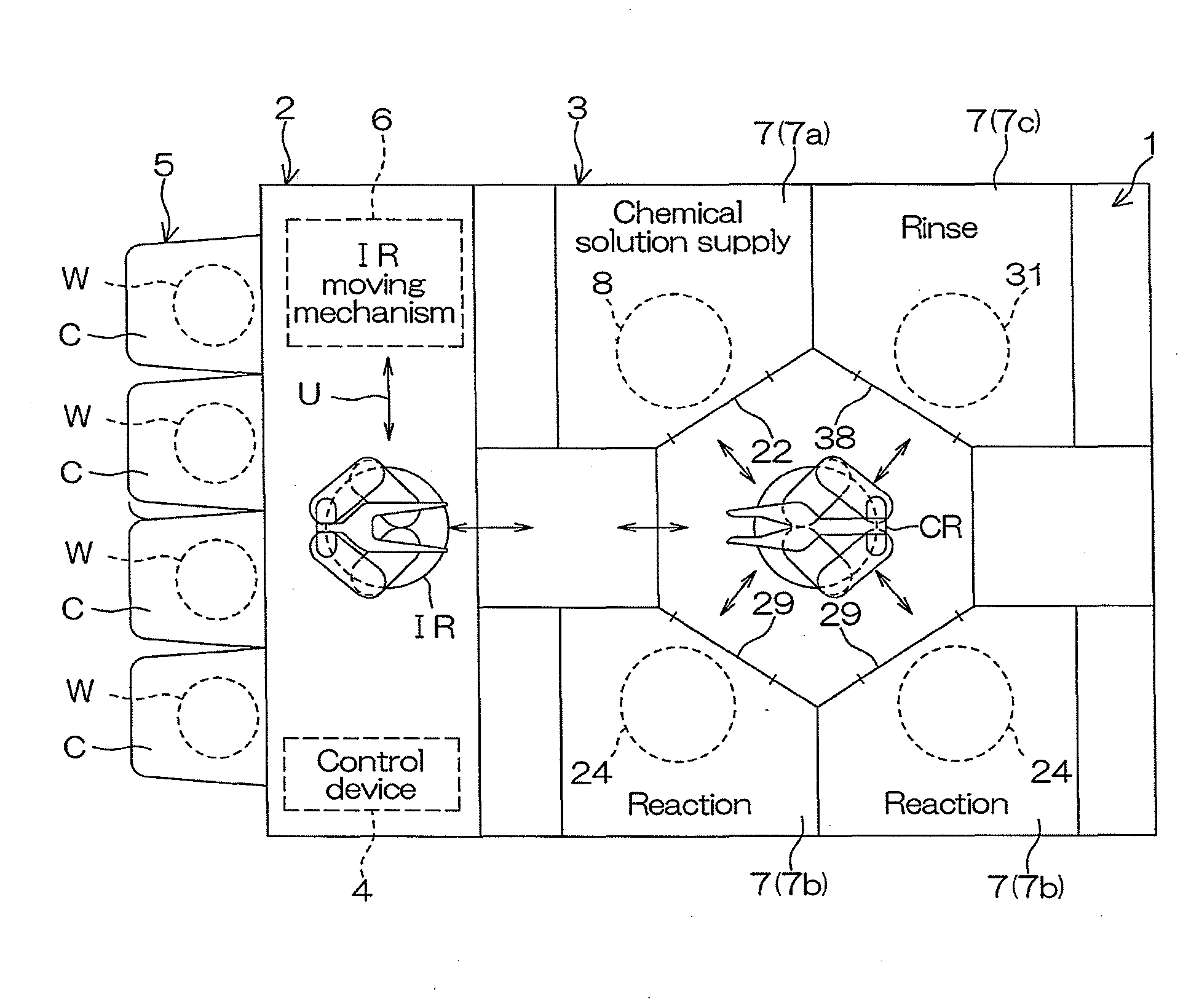

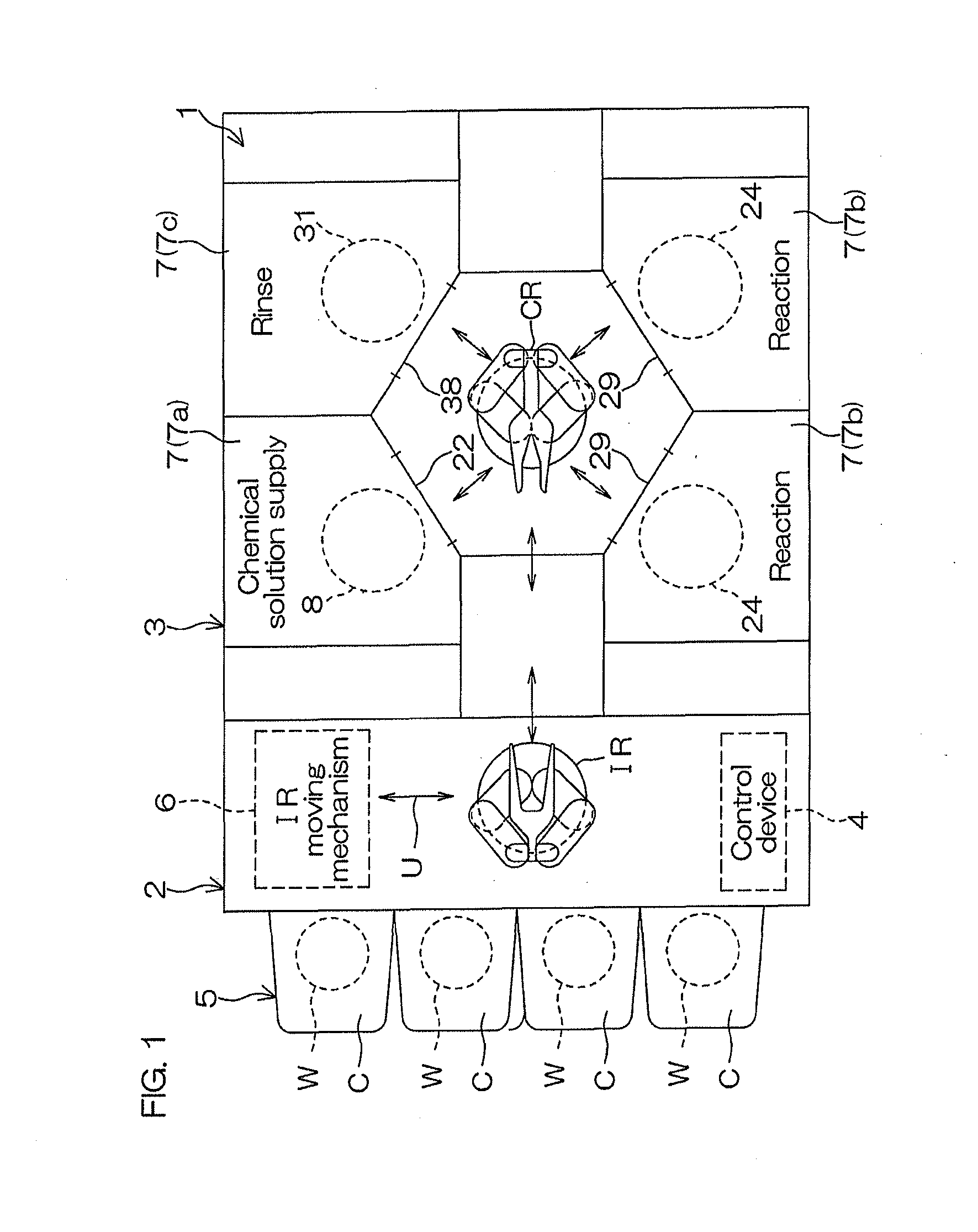

Single workpiece processing system

InactiveUS6900132B2Reduces downtimeLower costElectrolysis componentsSemiconductor/solid-state device manufacturingProcess engineeringSemiconductor

Owner:APPLIED MATERIALS INC

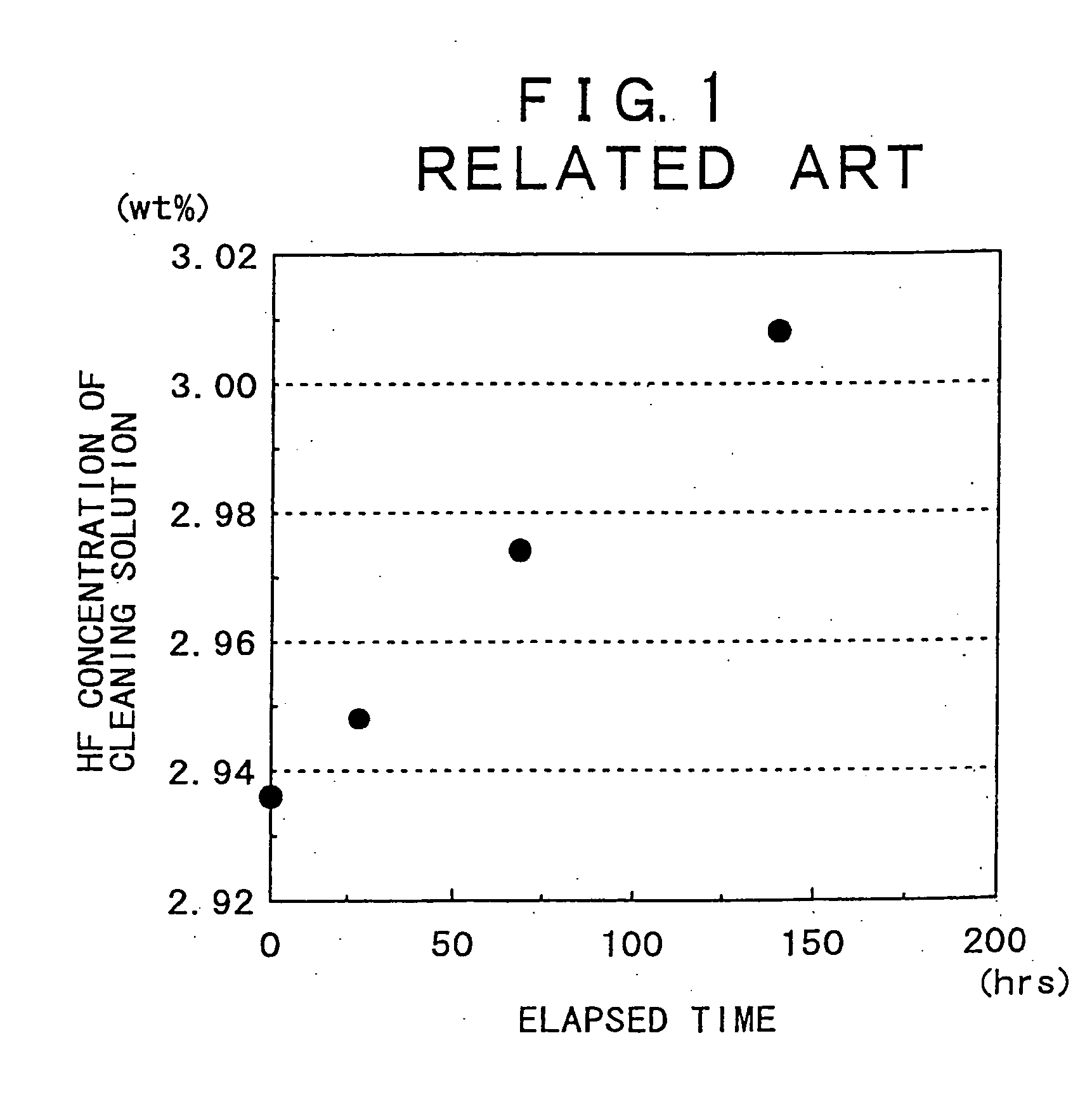

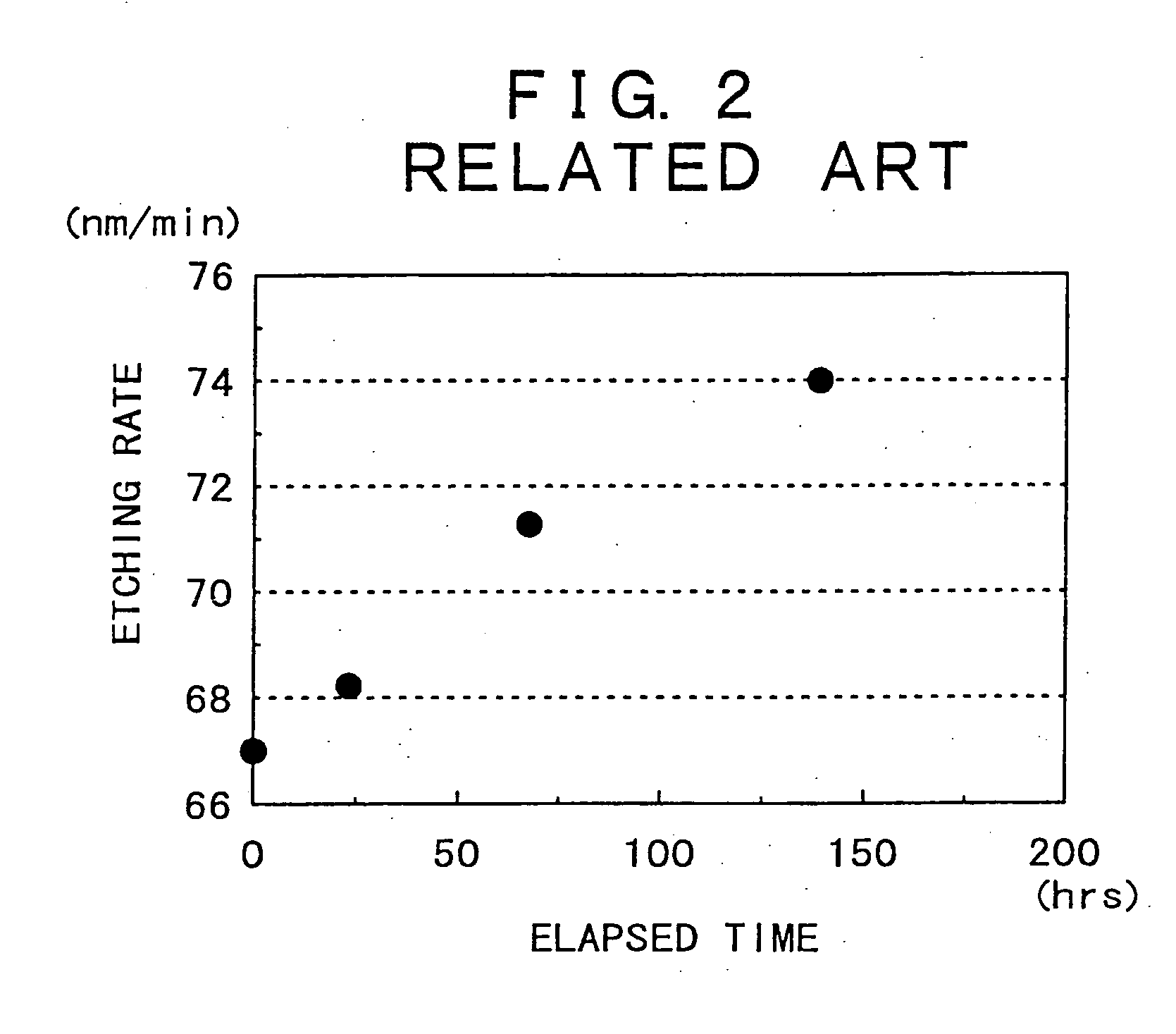

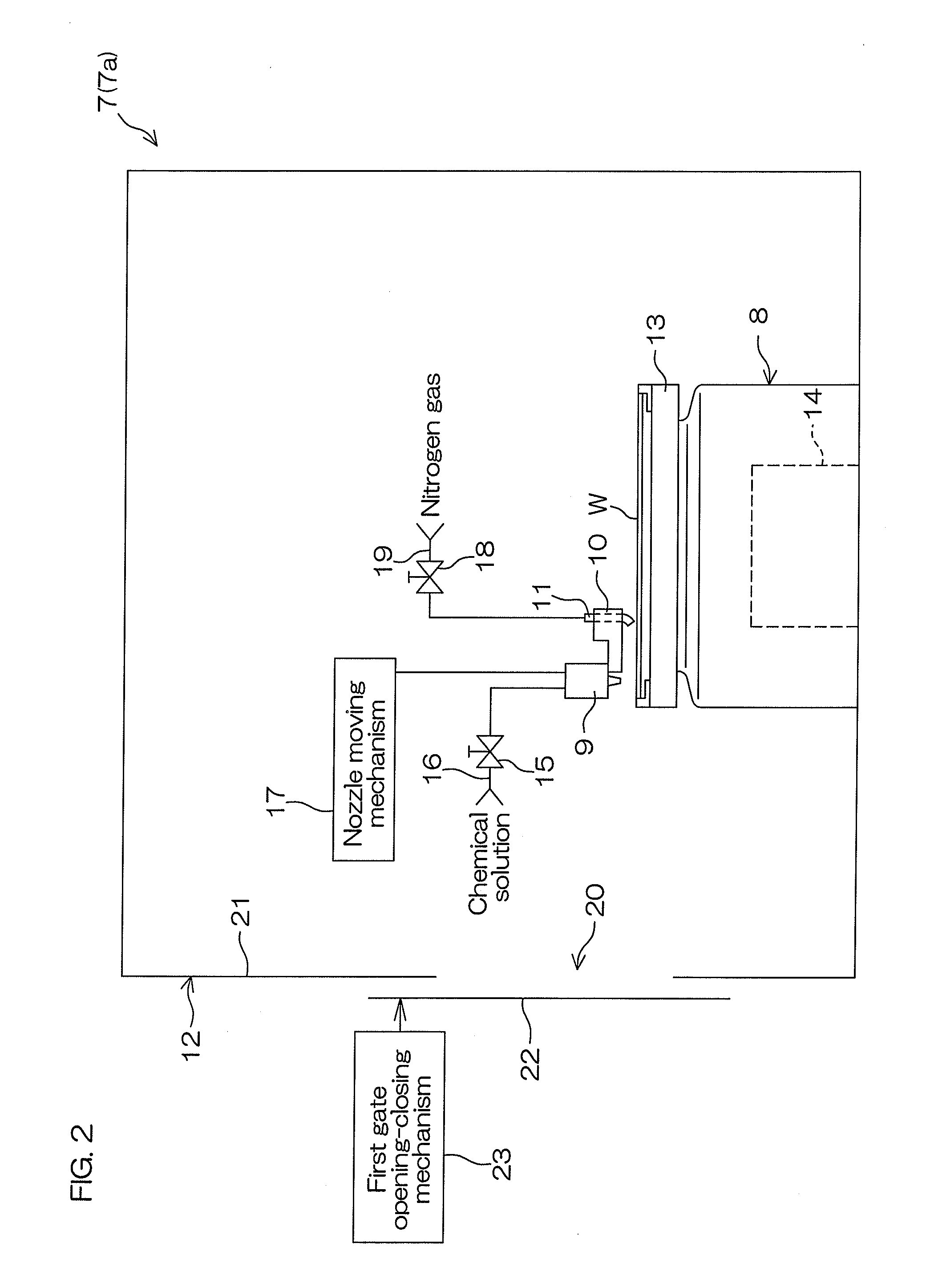

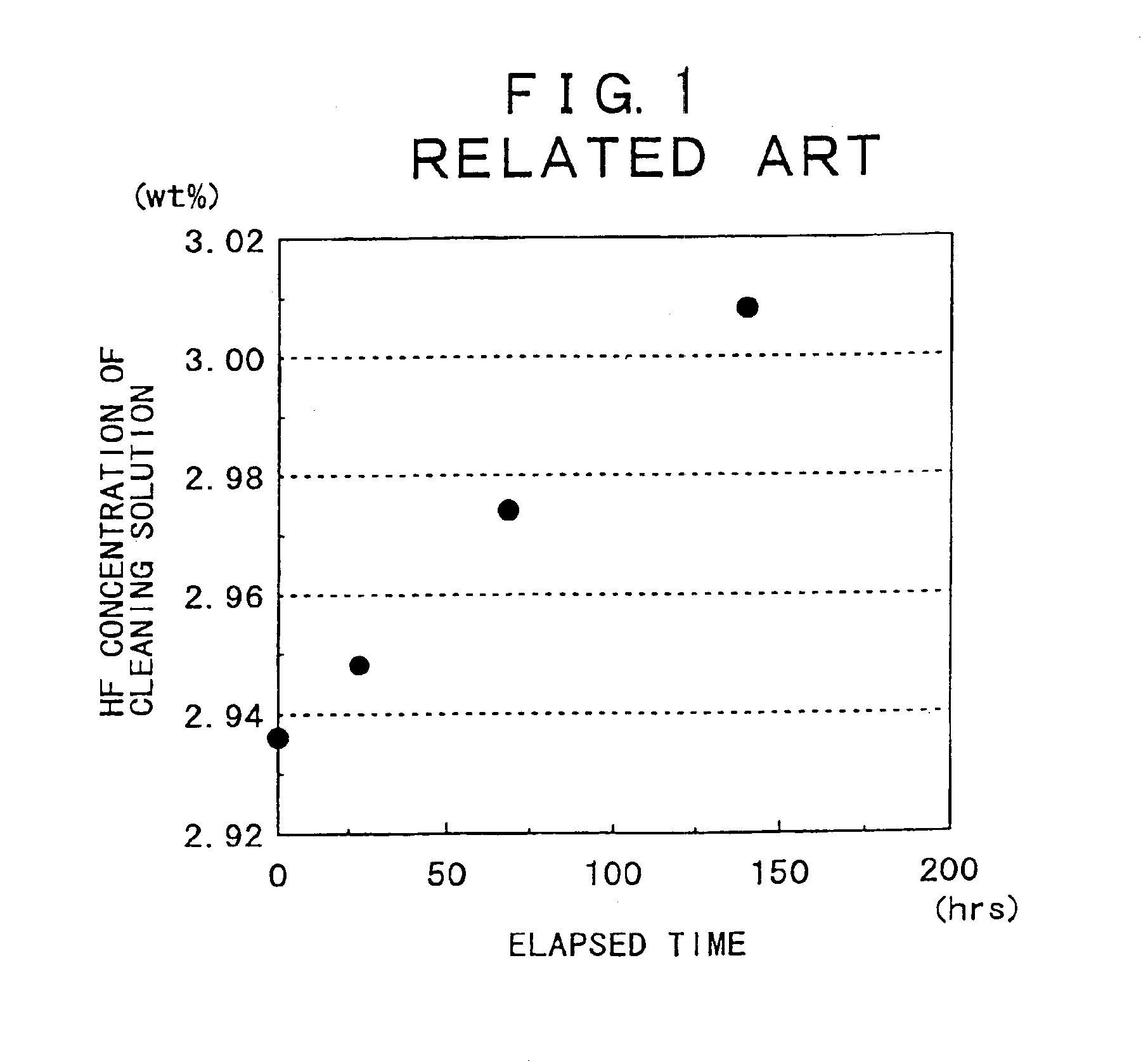

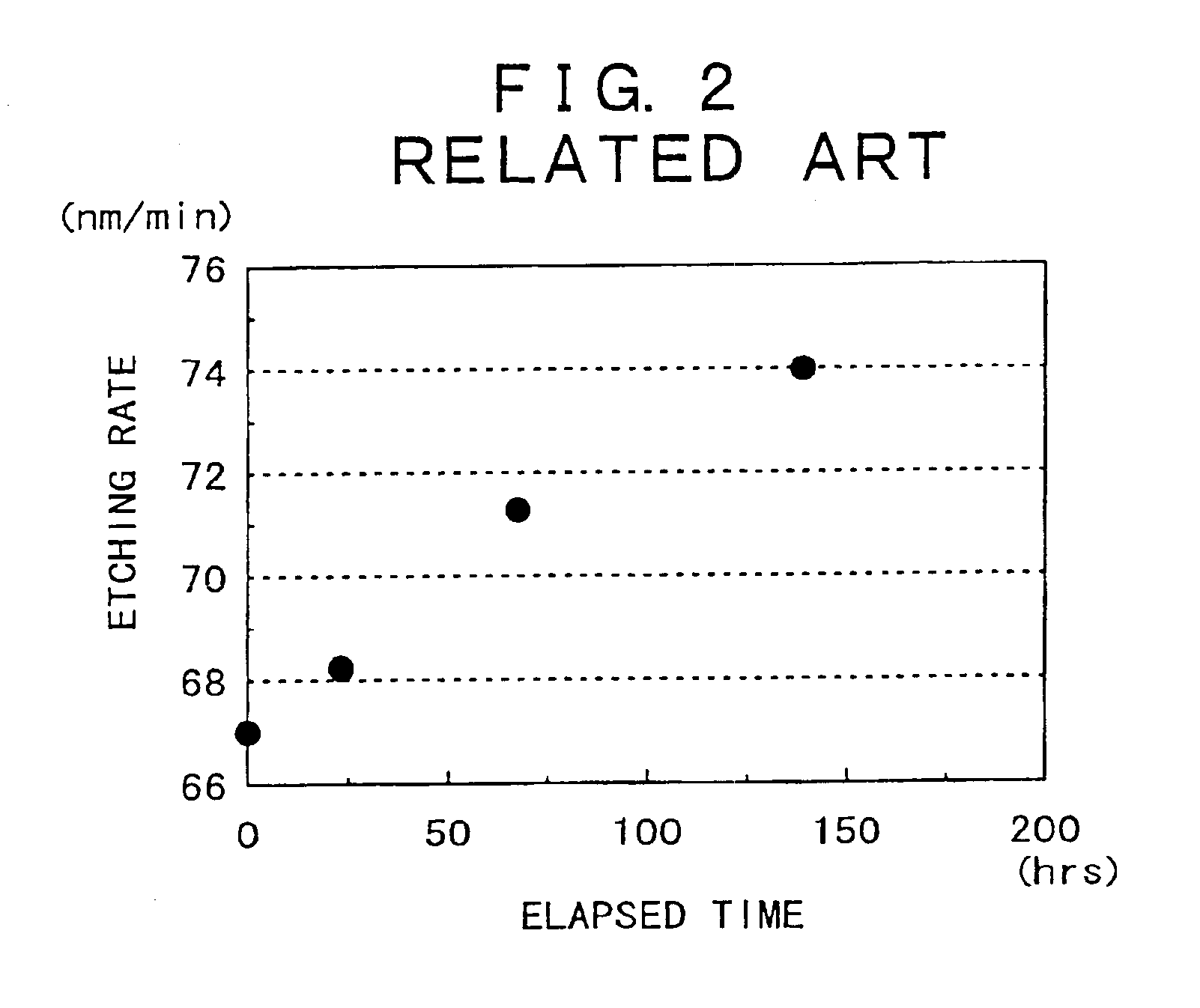

Method and apparatus for wet-cleaning substrate

InactiveUS20050000545A1Reduce replacementAmount of solution is decreasedSemiconductor/solid-state device testing/measurementLighting and heating apparatusAqueous solutionActive component

In the art of wet-cleaning a substrate by etching with a cleaning solution prepared by dissolving hydrofluoric acid as an active component in water, using the process of measuring the concentration of a predetermined component regularly and then replenishing the cleaning solution with a component for correcting the concentration at need on the basis of the result of measurement on the concentration in case of cleaning the substrate with an aqueous solution of ammonium fluoride as the cleaning solution while controlling air in a cleaning draft at an exhaust rate within a predetermined range.

Owner:SONY CORP

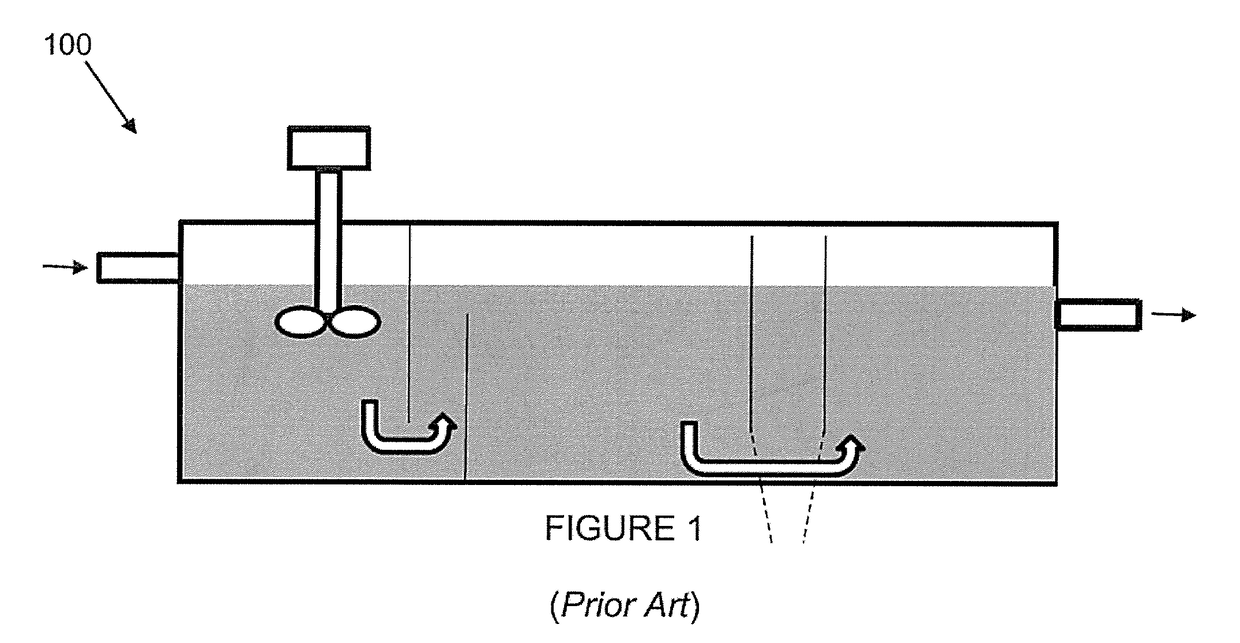

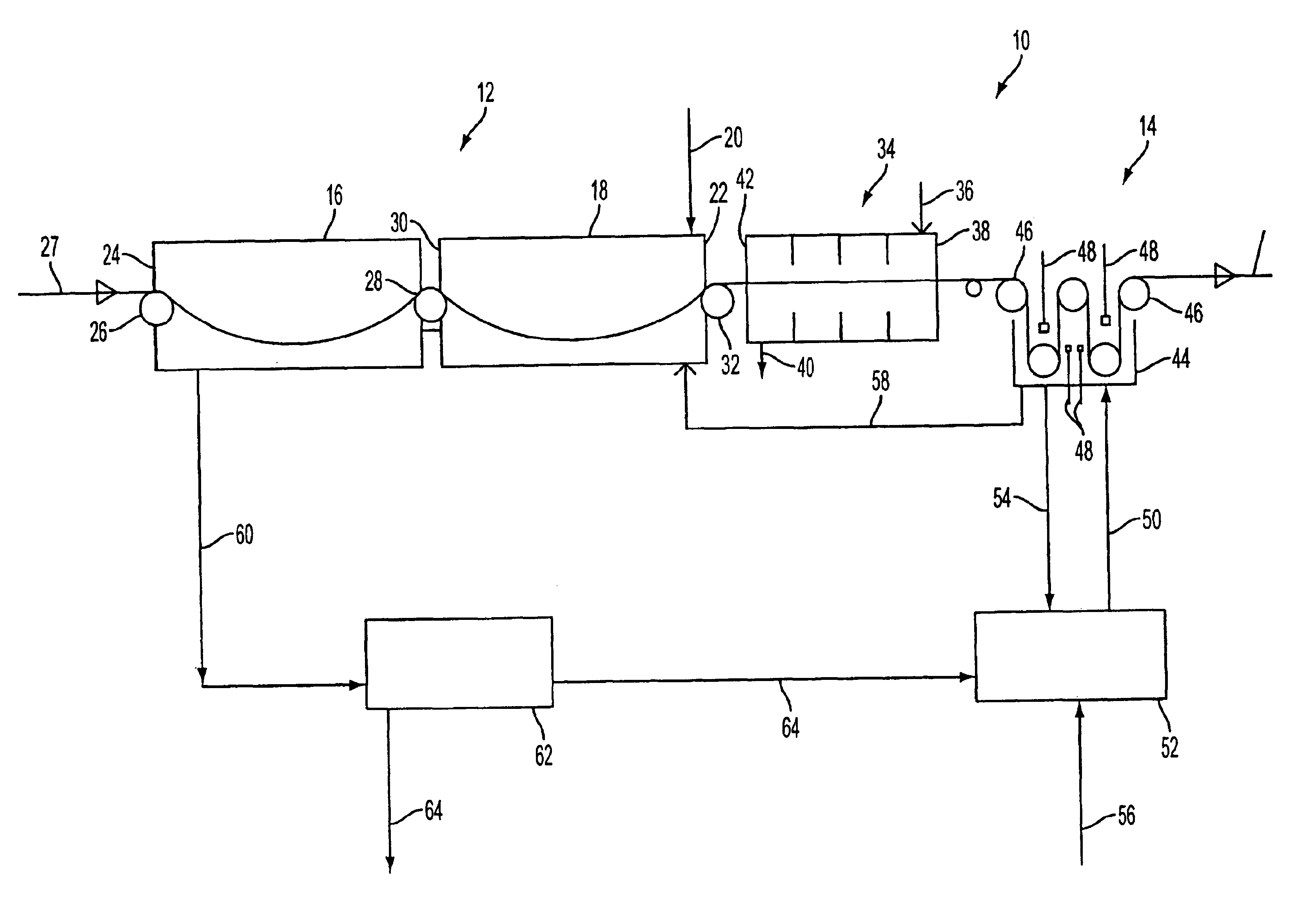

System for continuous optimization of wastewater treatment

ActiveUS20090230033A1Minimize chemical consumptionIncrease wastewater treatmentWater treatment parameter controlOther chemical processesWater treatment systemWaste product

A system for controlling the injection of wastewater treatment chemicals into a wastewater treatment stream includes a holding tank for collecting and holding wastewater being treated, a camera positioned for making images of the wastewater in the holding tank, means for automatically making the images of the wastewater in the holding tank at scheduled intervals, means for analyzing the images in order to determine the necessity for injecting wastewater treatment chemicals into the wastewater stream, comprising measuring the size, distribution and number of pixels of differing colors and appearances, such that pixels of differing colors and appearances represent differing moieties in the wastewater stream including unreacted waste products and unreacted wastewater treatment chemicals, and means for injecting wastewater treatment chemicals into the wastewater stream responsive to the analysis of the images indicating the necessity of such injection.

Owner:BOWERS JR GREGORY SCOTT

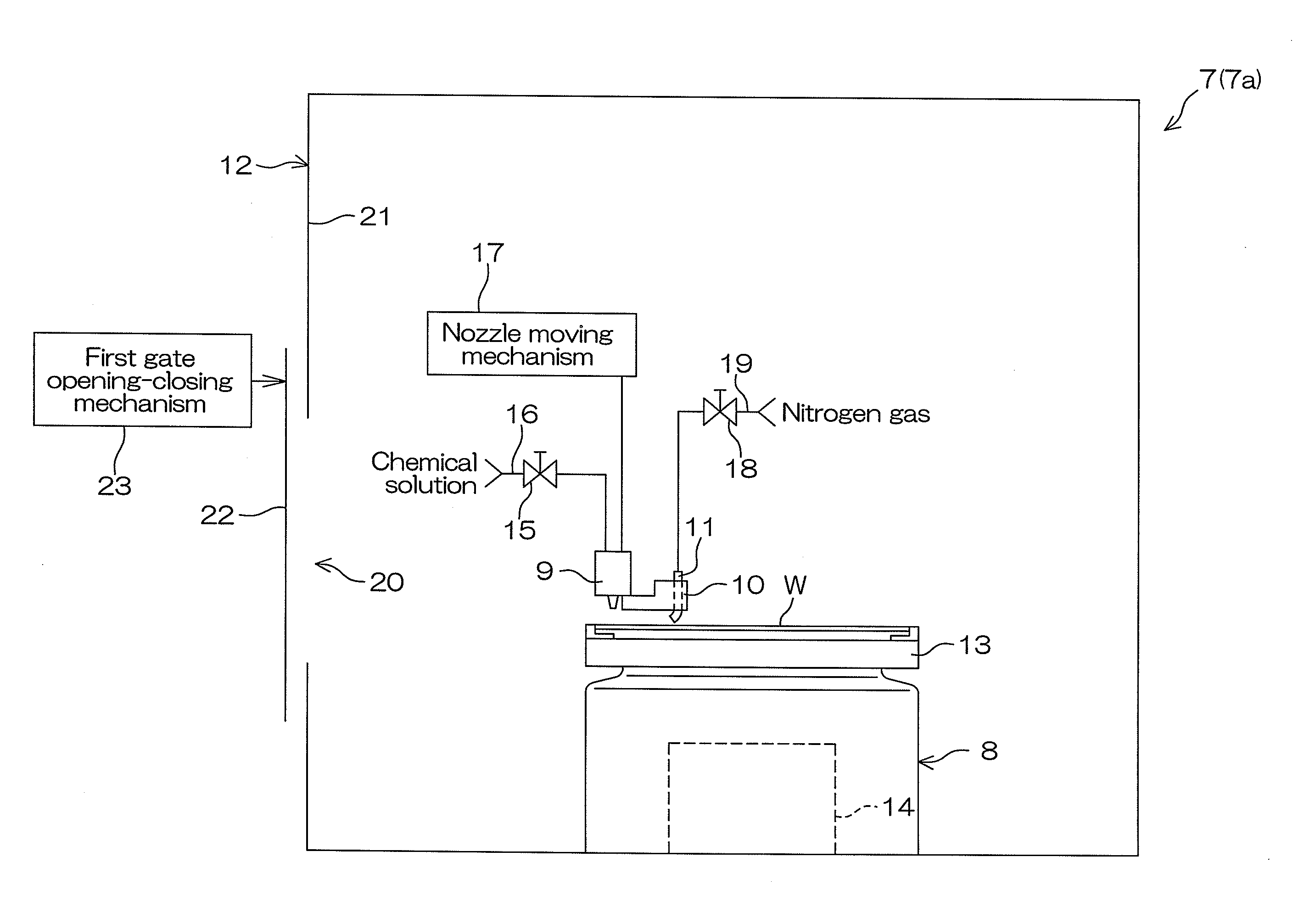

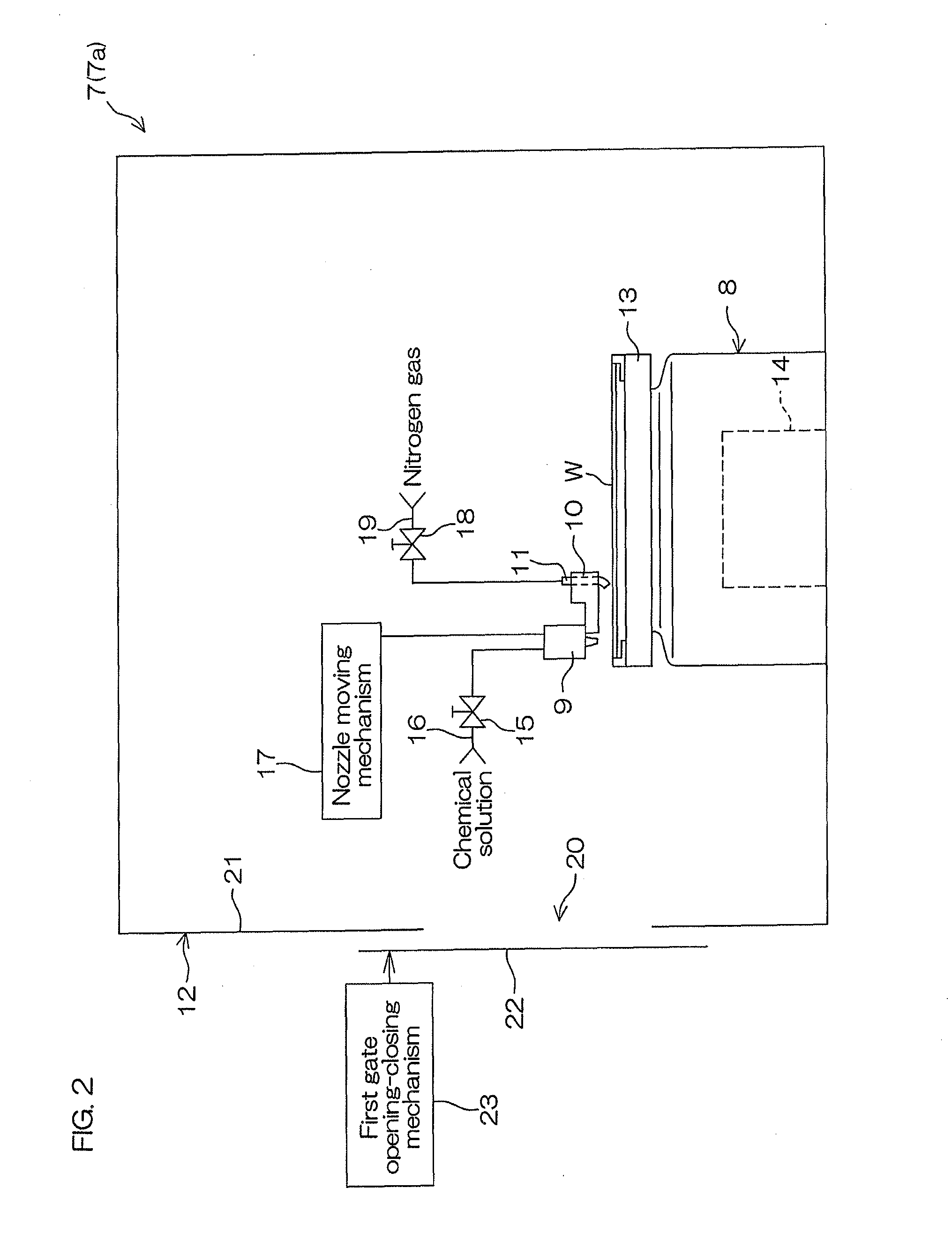

Substrate processing apparatus and substrate processing method

ActiveUS20120223054A1High viscosityFlowability of solution is loweredLiquid surface applicatorsDecorative surface effectsChemical solutionChemistry

A substrate processing apparatus includes a first processing chamber and a second processing chamber, a first substrate holding unit that holds a substrate in the first processing chamber, a chemical solution supply unit that supplies a chemical solution containing an etching component and a thickening agent to the substrate held by the first substrate holding unit, a substrate transfer unit that transfers the substrate from the first processing chamber to the second processing chamber in a state in which the chemical solution is held on the substrate, and a second substrate holding unit that holds a plurality of substrates on each of which the chemical solution is held in the second processing chamber.

Owner:MITSUBISHI GAS CHEM CO INC +1

Oxo process

InactiveUS20050215828A1Effective meanImprove throughputOrganic compound preparationPreparation by carbon monoxide reactionHigh concentrationOrganic acid

The Oxo Process that recycles its cobalt primarily as cobalt salt is improved by concentration of the cobalt salt solution from the demetalling section and the addition of a separation step for organic acid and water. This allows for a higher reuse of acid in the process and thus a lower amount of acid in the waste water. Injecting a higher concentration of cobalt salt solution to the reaction section also reduces the requirement for cobalt source.

Owner:EXXONMOBIL CHEM PAT INC

Oxo process

InactiveUS7081554B2Improve throughputReduce chemical consumptionOrganic compound preparationPreparation by carbon monoxide reactionHigh concentrationOrganic acid

The Oxo Process that recycles its cobalt primarily as cobalt salt is improved by concentration of the cobalt salt solution from the demetalling section and the addition of a separation step for organic acid and water. This allows for a higher reuse of acid in the process and thus a lower amount of acid in the waste water. Injecting a higher concentration of cobalt salt solution to the reaction section also reduces the requirement for cobalt source.

Owner:EXXONMOBIL CHEM PAT INC

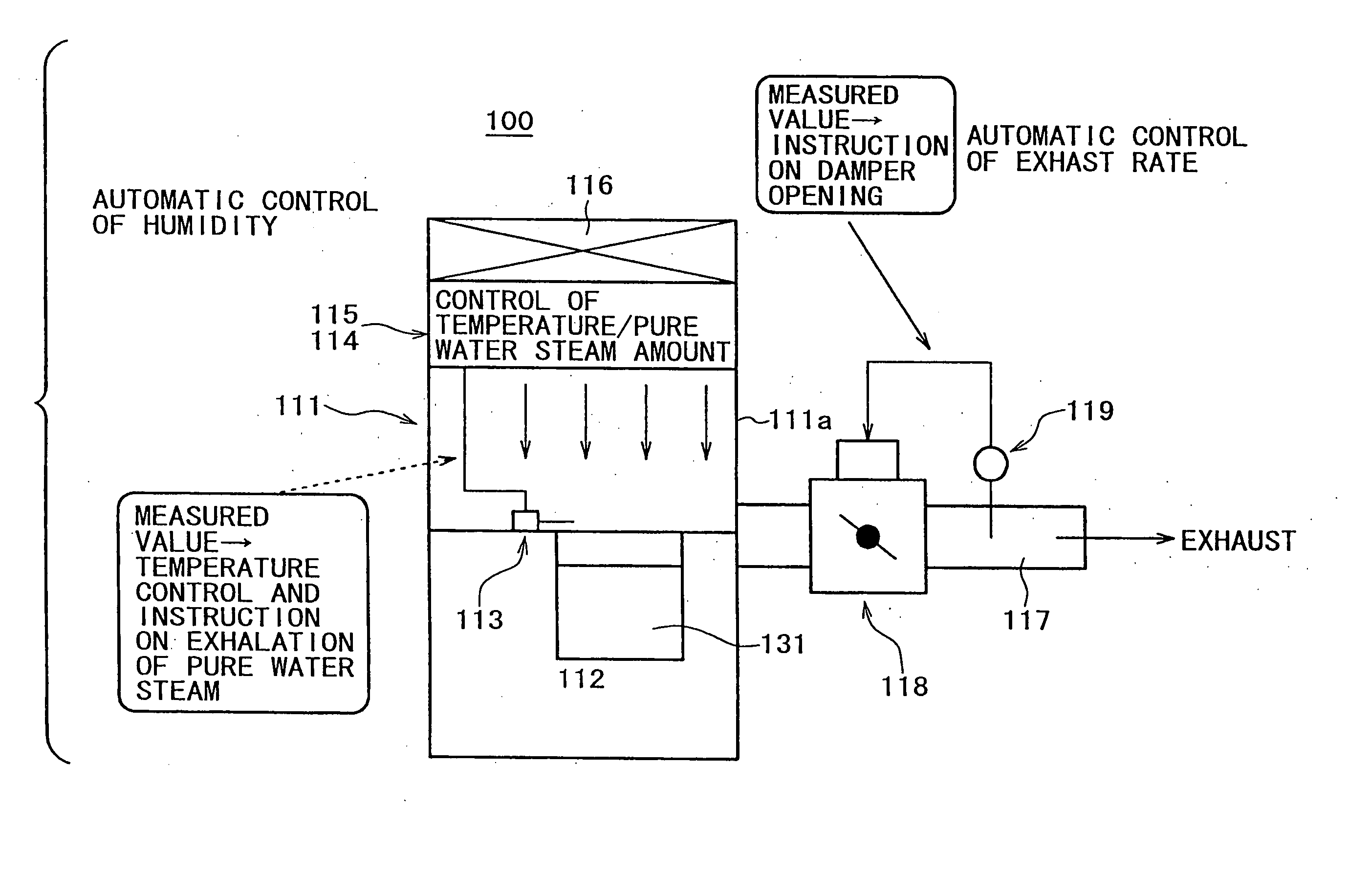

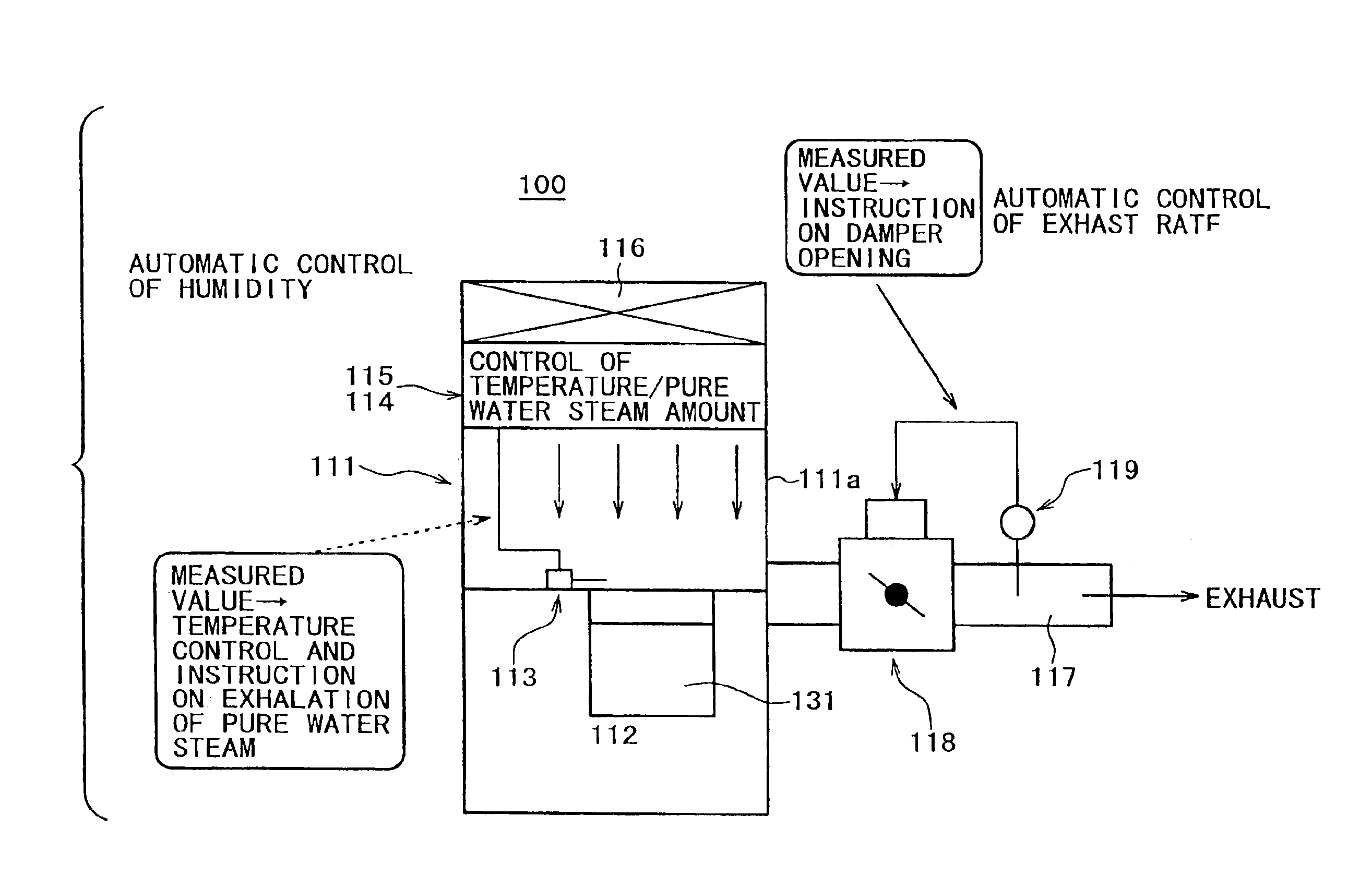

Method and apparatus for wet-cleaning substrate

InactiveUS6938626B2Reduce environmental burdenReduce chemical consumptionSemiconductor/solid-state device testing/measurementLighting and heating apparatusWet cleaningHygrometer

An apparatus for wet cleaning a substrate includes a clean air supplier for supplying the clean air into a cleaning draft, a humidifier for supplying steam or mist like water drops into the cleaning draft, a hygrometer, connected to the humidifier and positioned at the level of the cleaning solution, an exhaust piping and an exhaust rate control means.

Owner:SONY CORP

Method of processing chemical pulp

ActiveUS20130105097A1Improve washingReduce chemical consumptionPulp properties modificationWashing/displacing pulp-treating liquorsVegetable fibersChemical pulp

A method is presented, by which dewatering in paper product production, optical properties, bulk and surface smoothness of the paper product can be increased. The method involves at least one step physical treatment of the vegetable fiber raw material.

Owner:UNIV DE CONCEPCION50

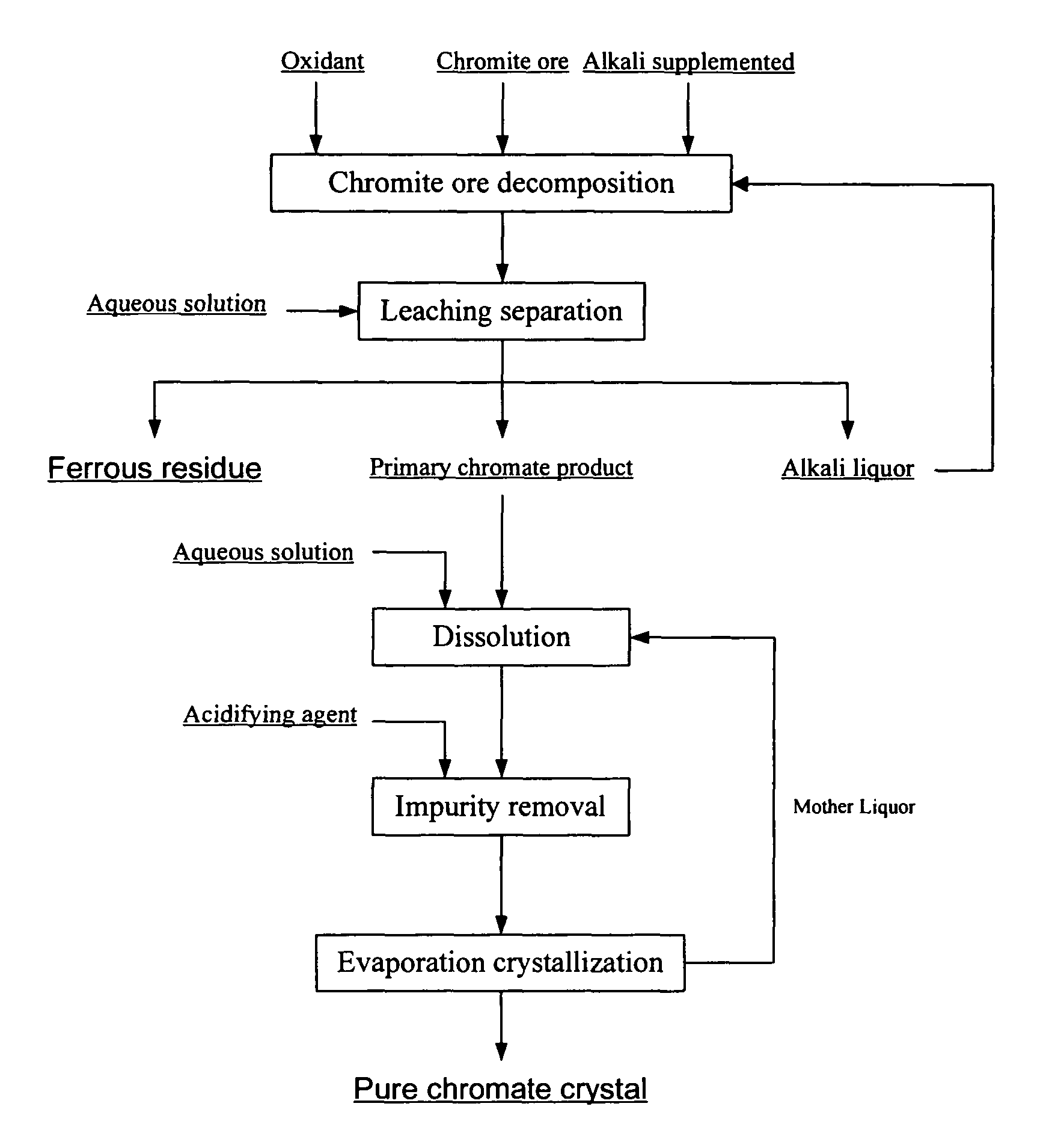

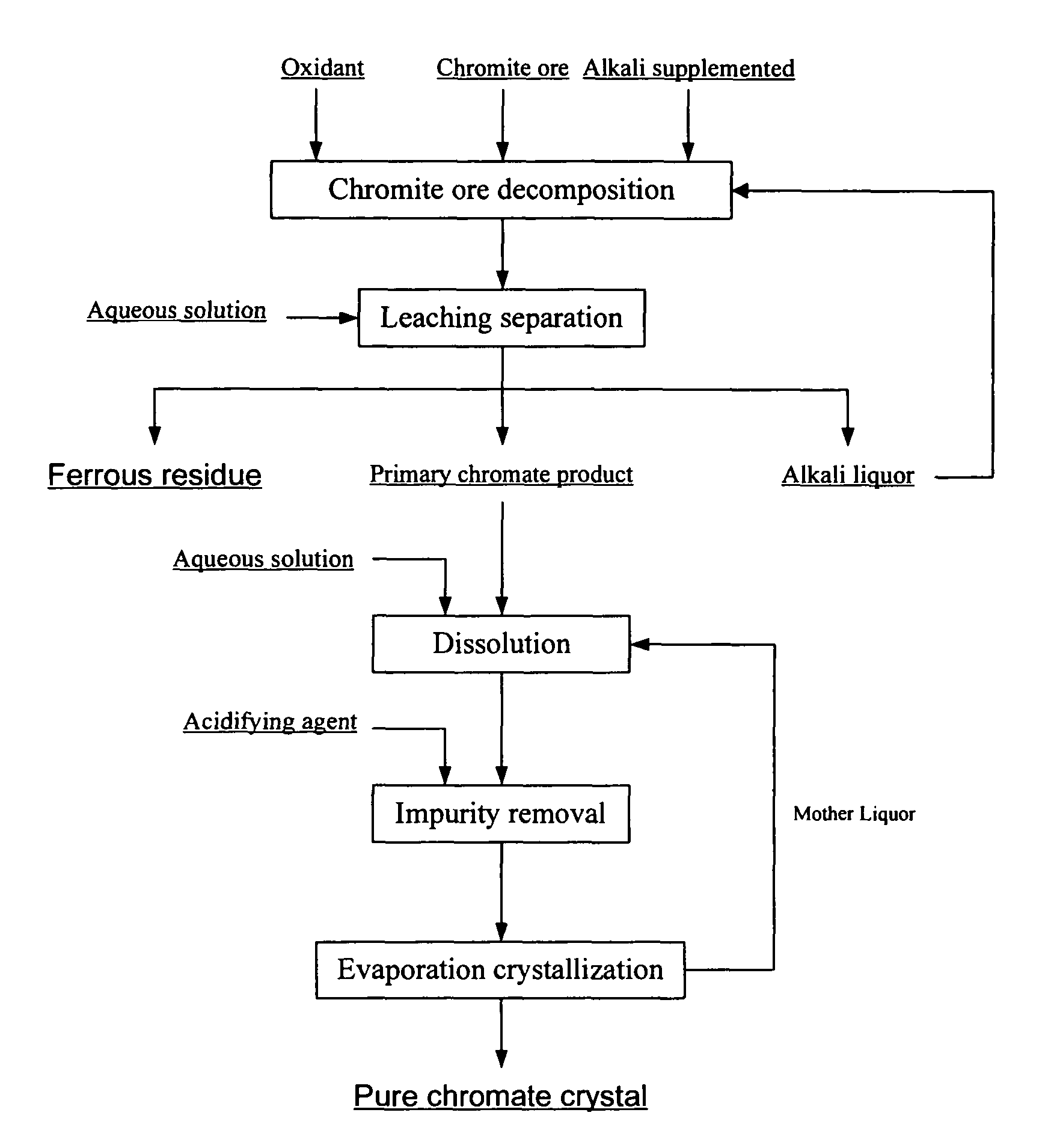

Method for production of alkali metal chromates

InactiveUS7968066B2Effective resourcesRaise the reaction temperatureMolybdeum compoundsChromates/bichromatesChromium CompoundsReaction temperature

This invention relates to a method for producing chromates, especially for producing alkali metal chromates. The method comprises following steps: the obtaining of a mixture of alkali metal hydroxide, alkali metal chromate, and ferrous residue after the reaction of chromite ore with an oxidant in the reactor in the presence of molten salt or in aqueous solution of alkali metal hydroxide, the obtaining of a leaching slurry by leaching the reaction products with aqueous solution of alkali metal hydroxide, the separating of the primary chromate product from the leaching slurry, the obtaining of pure chromate crystal by purifying the primary chromate product. Both the primary chromate product and the pure chromate crystal can be used as the raw materials to manufacture other chromium compounds. Compared with the currently-used roasting method, the method has the advantages of decreasing the reaction temperature by about 700° C., of improving the chromium recovery rate up to nearly 100%, of minimizing the amount of the ferrous residue by not adding calcium-containing auxiliaries, and of completely eliminating the disposal problem of the chromium-containing residue and the environmental pollution due to the addition of calcium-containing auxiliaries, by using ferrous residue as the raw materials for other industries after extraction of magnesium.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

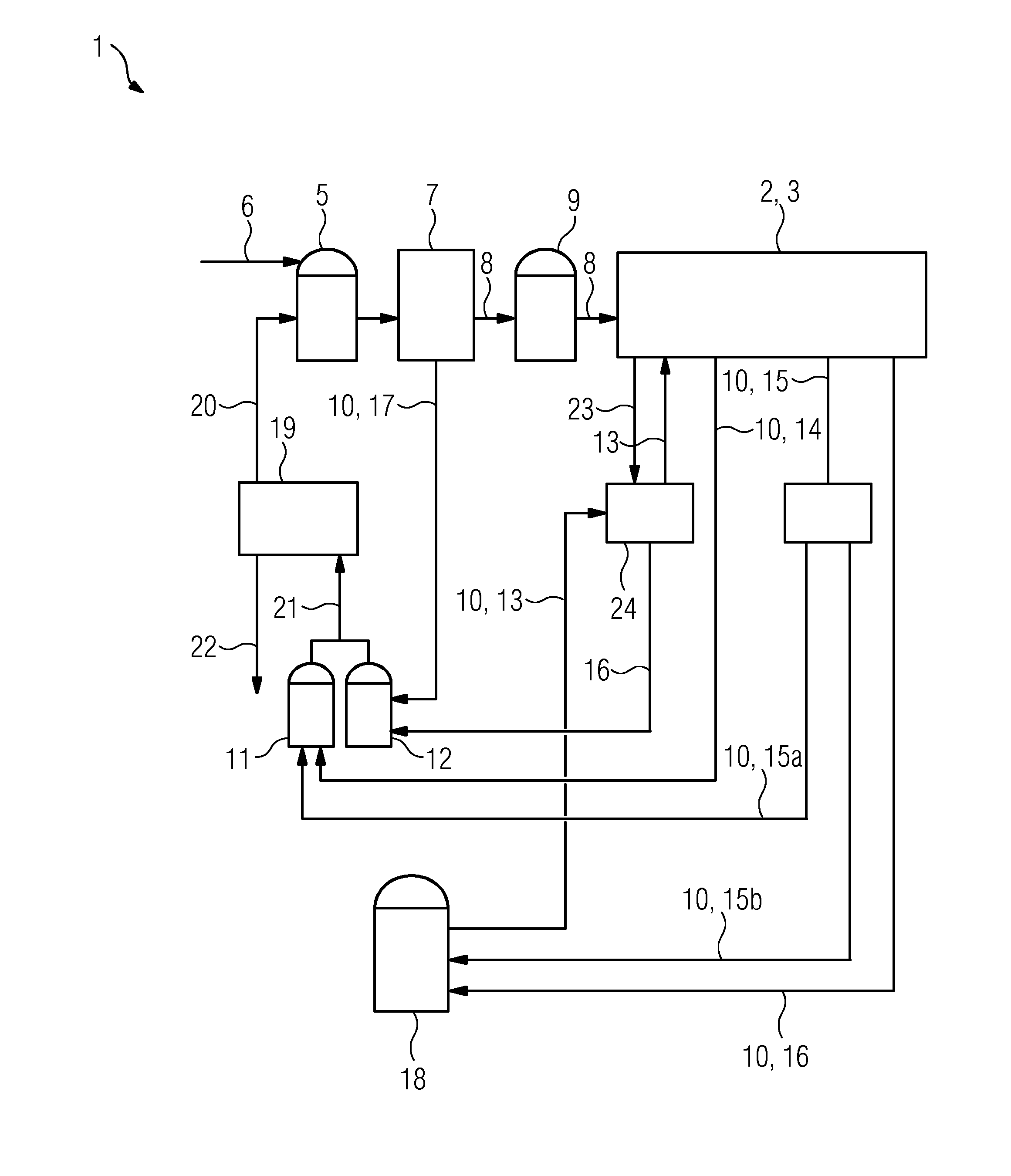

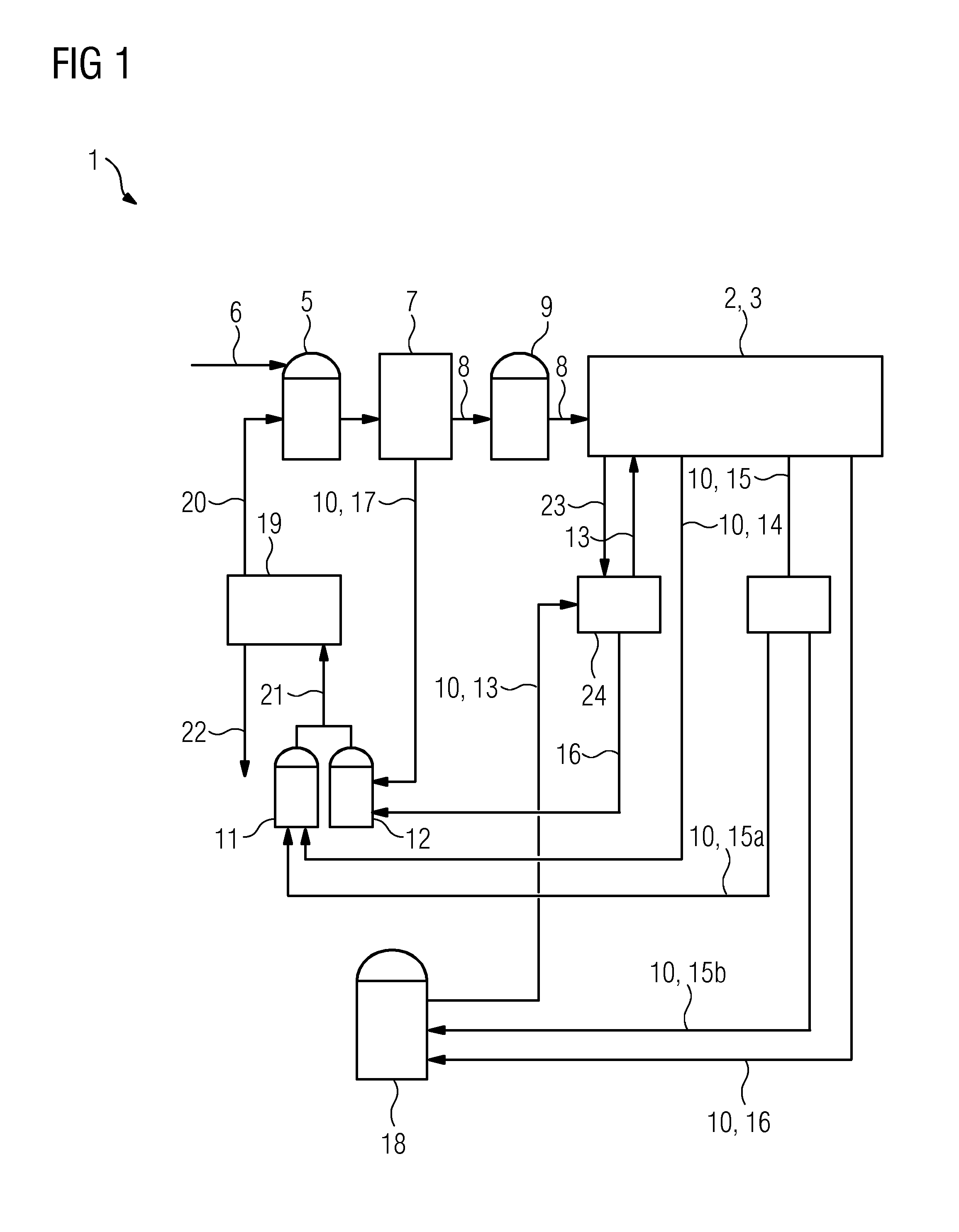

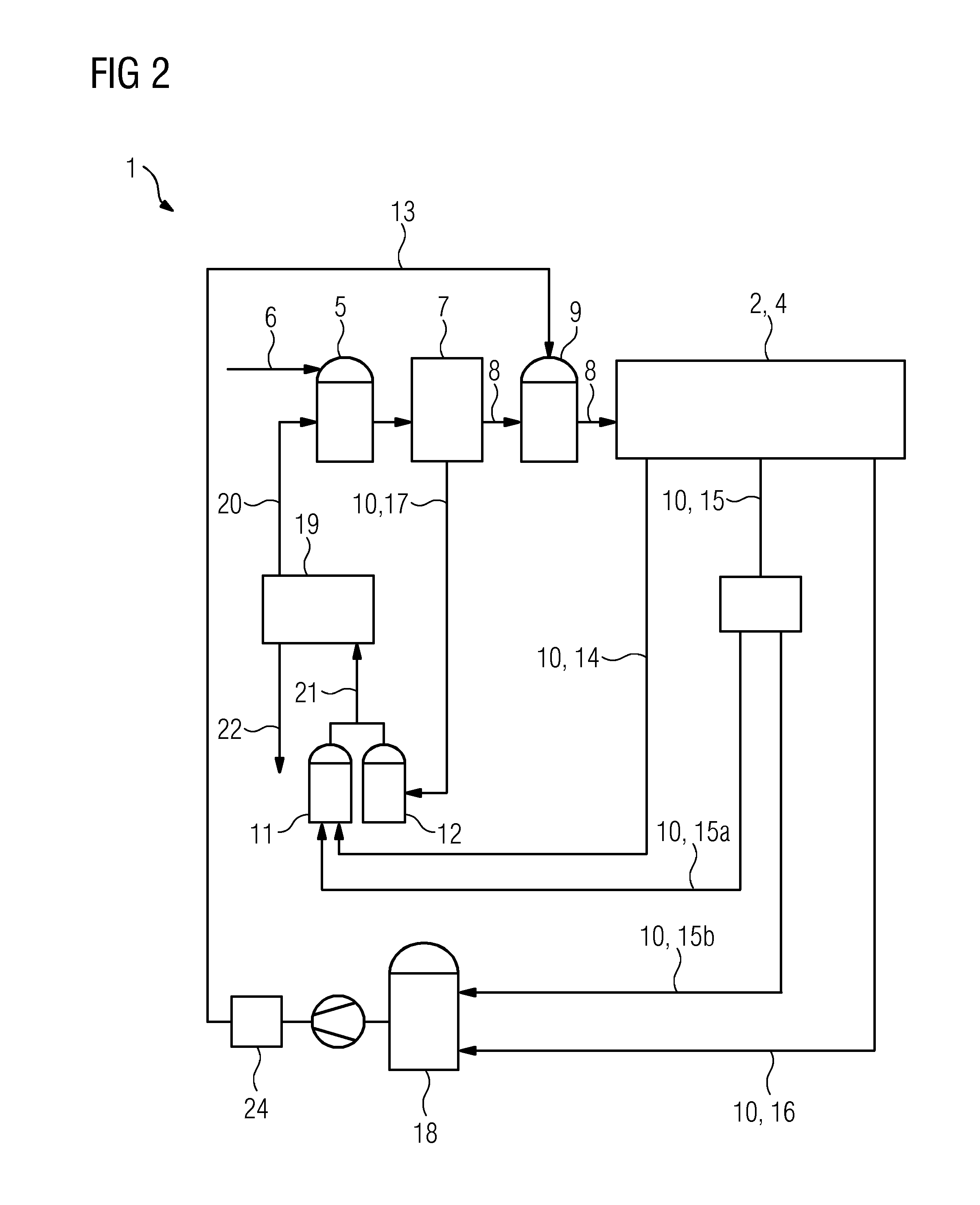

Method for recovering process wastewater from a steam power plant

ActiveUS20150251144A1Reduced service lifeIncrease loadWater treatment parameter controlMixing methodsPower stationSteam power

A method for operating a steam power plant having a water-steam circuit, according to which method the process wastewater produced is collected from the water-steam circuit, in a separated manner according to the degree of contamination thereof, in a number of partial wastewater quantities is provided. At least a first partial wastewater quantity having a first degree of contamination and at least a second partial wastewater quantity having a second degree of contamination are formed in the process. The second degree of contamination is higher than the first degree of contamination. The first partial wastewater quantity and the second partial wastewater quantity are mixed together in such a manner that a combined process wastewater is produced, which is fed to a wastewater treatment plant.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

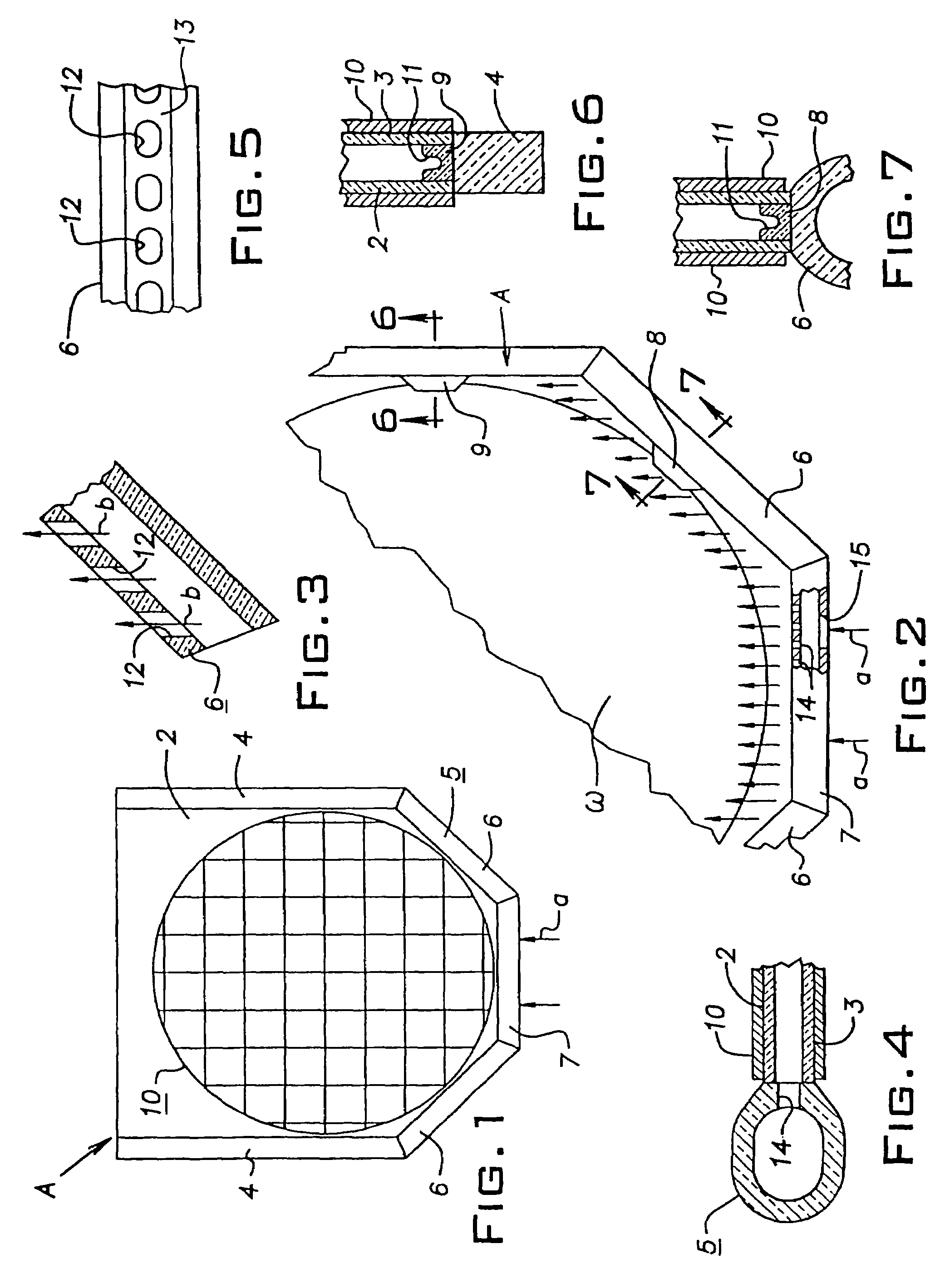

Wafer cleaning system

InactiveUS7674695B1Improving particle removal efficiencyIncrease etch rateSemiconductor/solid-state device manufacturingElectrostatic cleaningLine widthTransducer

An electromegasonic wafer cleaning system is disclosed that is extremely important, if not essential, in the fabrication of advanced microelectronic devices having a line width or feature size of from 0.05 to 0.10 micron. A unique synergistic combination is provided wherein piezoelectric transducer means are operated at a tolerable power level, such as from 1 to 2 watts per square centimeter, to minimize the risk of harm to the extremely delicate microcircuits and wherein the face of each wafer is negatively charged to a temperate voltage, such as from 5 to 20 volts, sufficient to cause effective removal of colloidal or sub 0.4-micron contaminant particles.This unique wafer cleaning system supersedes and replaces the standard megasonic-assisted RCA-type wet wafer cleaning systems which have never been able to eliminate or provide efficient purging of harmful sub 0.1-micron particles.

Owner:LOXLEY TED A

Apparatus for electrically coating a hot-rolled steel substrate

A process and apparatus are provided for producing an electrolytically coated, hot-rolled steel strip without any intervening strips. The apparatus includes a chemical pickling section being combined in one line with an electrolytic coating section containing electrolytic cells so that the pickled steel strip is fed directly to the electrolytic coating section without any intermediate steps. The spent electrolyte solution from the electrocoating section to the pickling section to pickle the steel. The spent pickling acid can also be used to generate the electrolyte solution that is fed to the electrocoating section.

Owner:ANDRITZ PATENTVERW GES

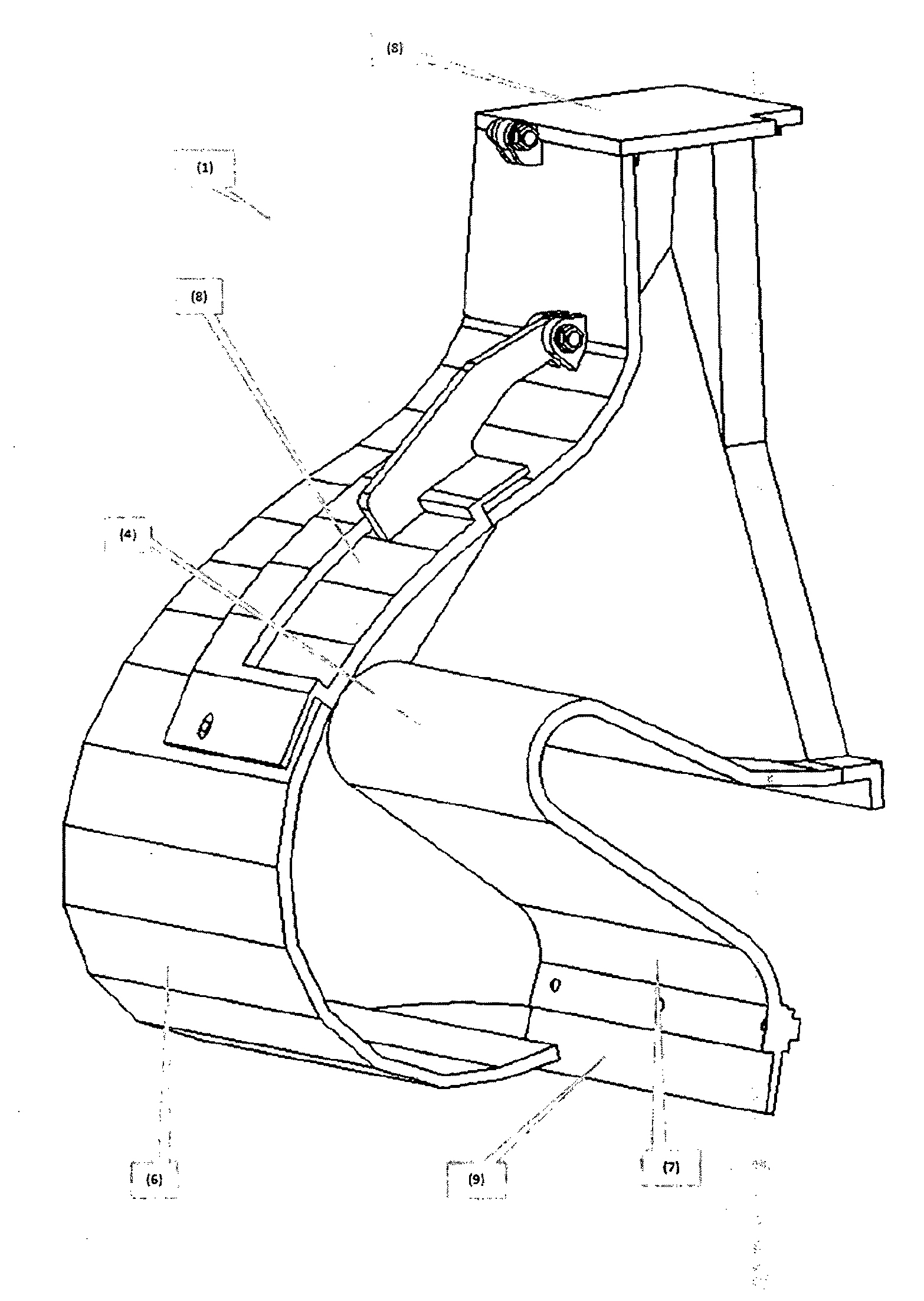

Feeder channel for mud shaker

InactiveUS20130139914A1Increase receiving capacityEnhance particle separationPipe supportsServomotor componentsParticle flowFiltration

A feeder channel for use in a filter separator machine is used for separation of undesired particles from a well fluid used in petroleum industry which has a purpose of guiding fluid and particle flow to the area of the filter that provides the best utilization of available filtration area and includes: a feeder channel is arranged so that the upstream well fluid is guided via a guiding- and turning plate, which is installed in series in opposite repeated direction in which the outlet of each guiding- and the turning plate facing the center of the vertical line. The fluid will for this reason be independent on how the feeder channel is installed in the direction and angle, and will provide a homogeneous flow profile as it guided through the mouth guide plate and internal guide fin against the distribution plate. The fluid is then distributed to the filter's inner part and utilizes the entire filter surface area and the filter separator machines movement and function.

Owner:OPTIPRO

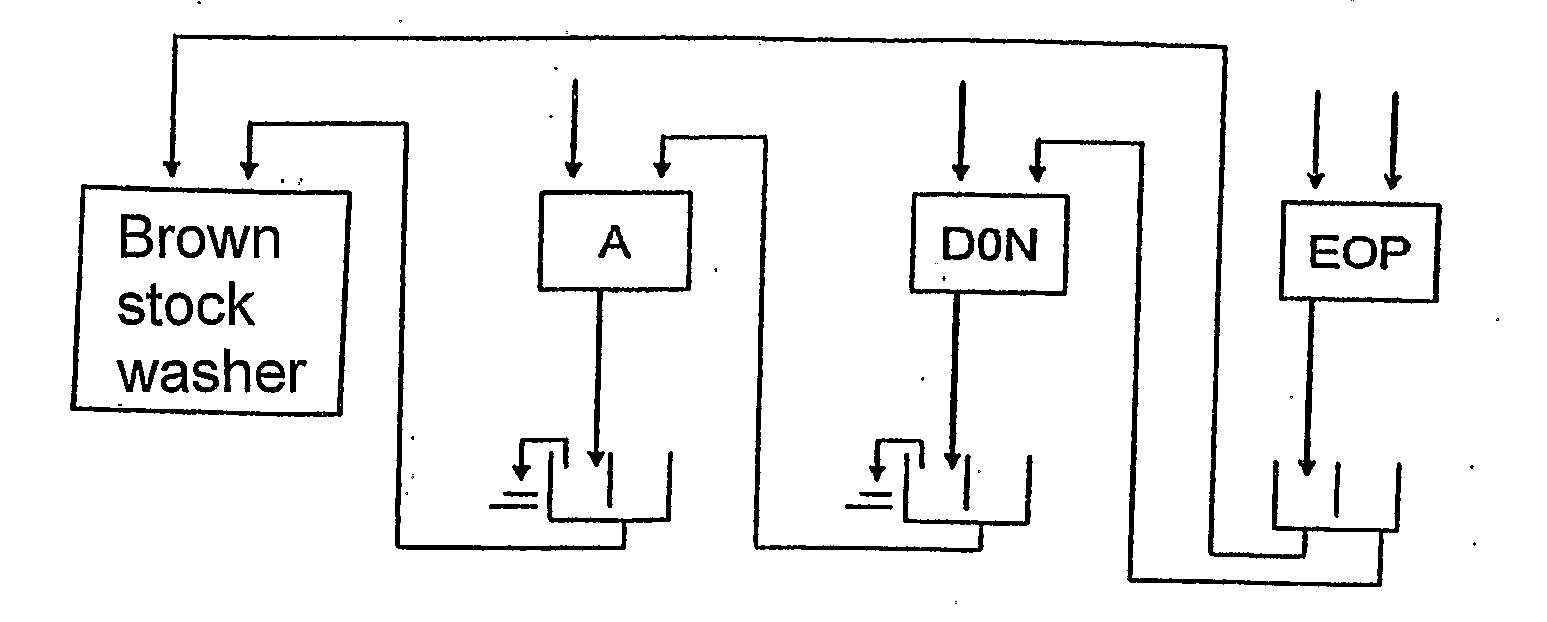

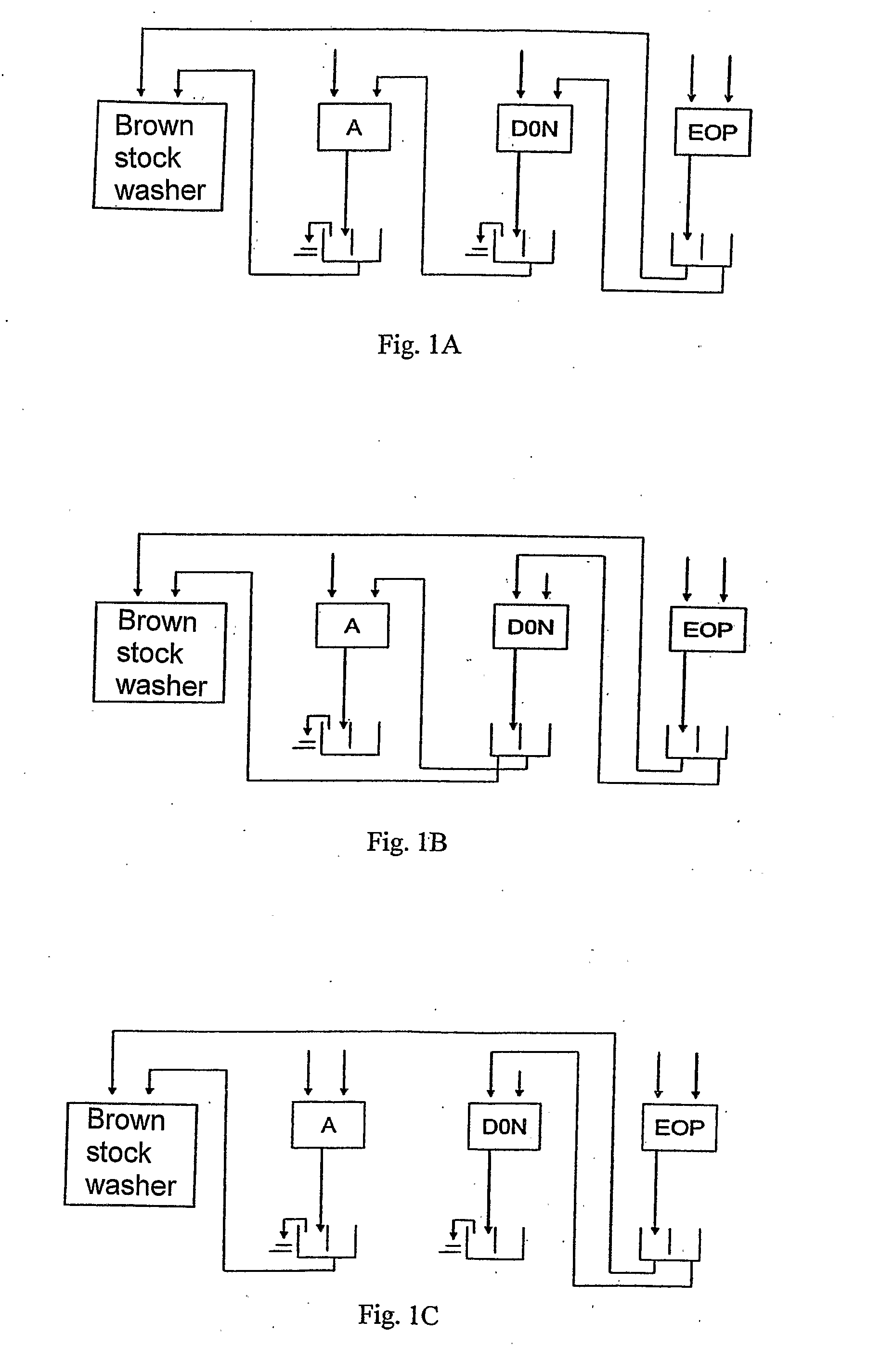

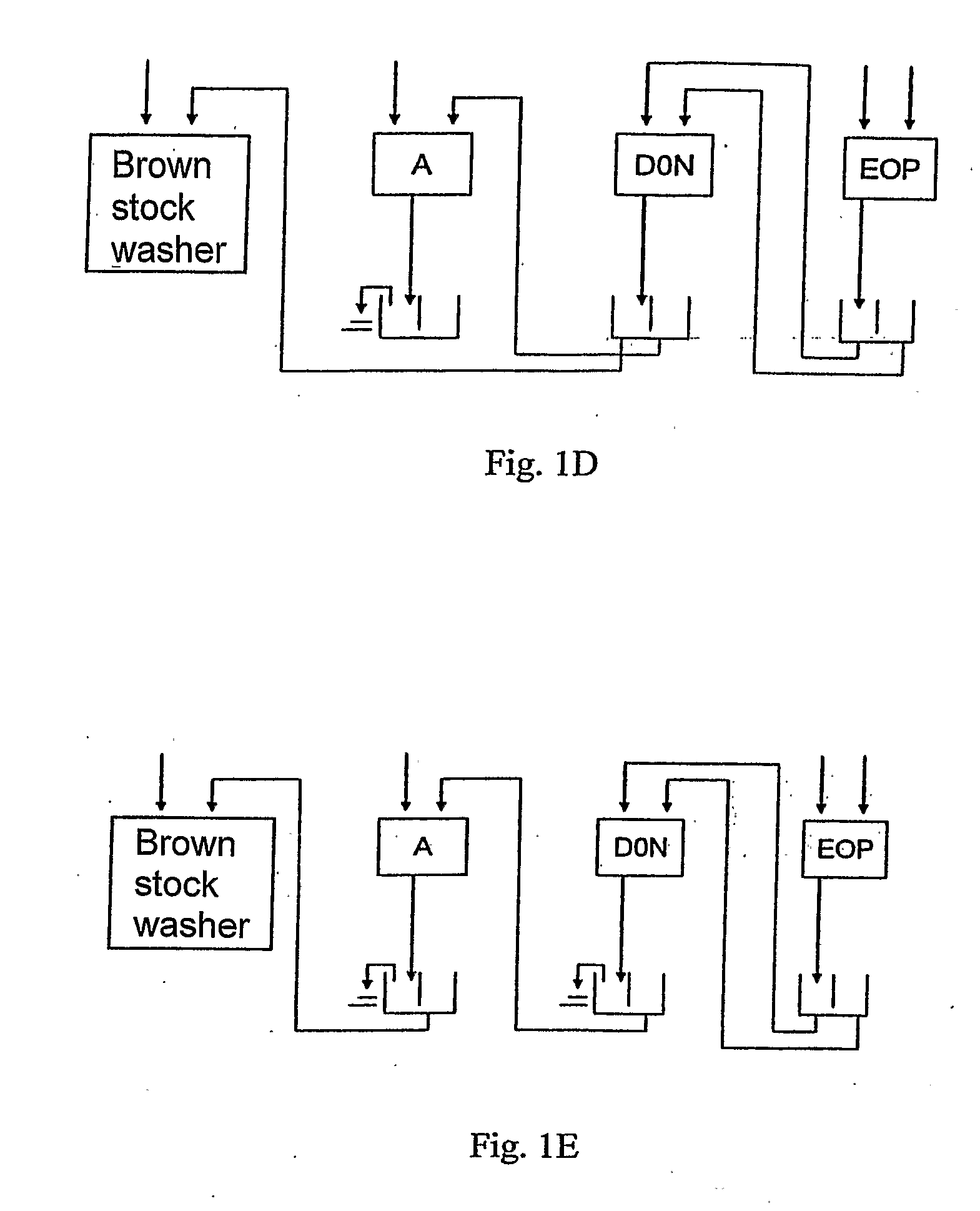

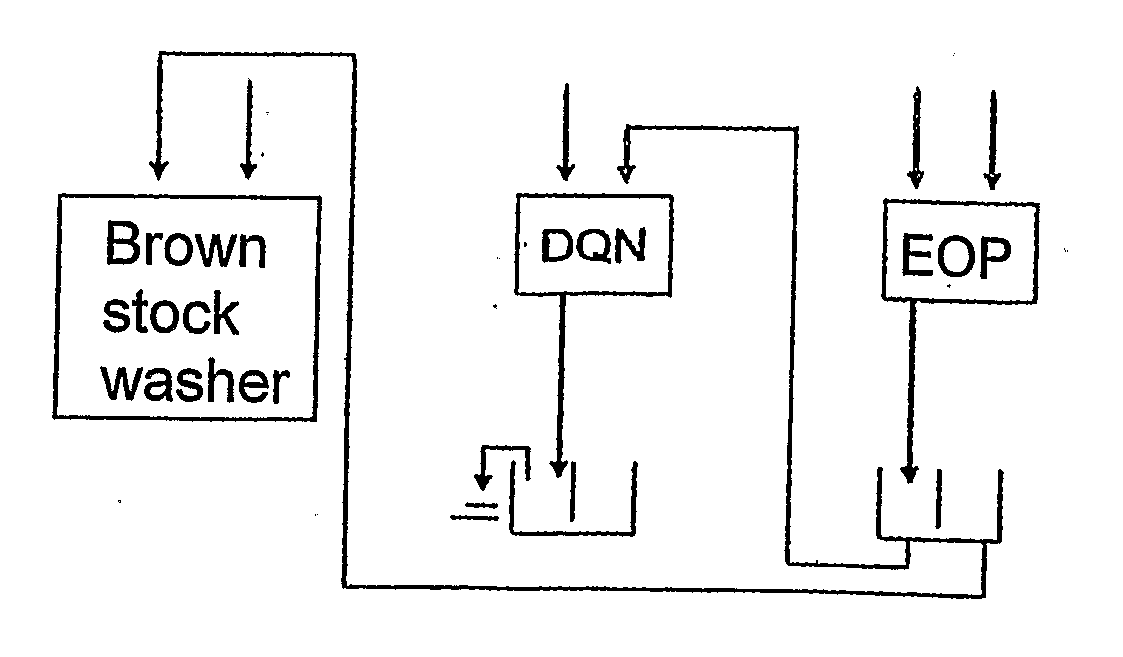

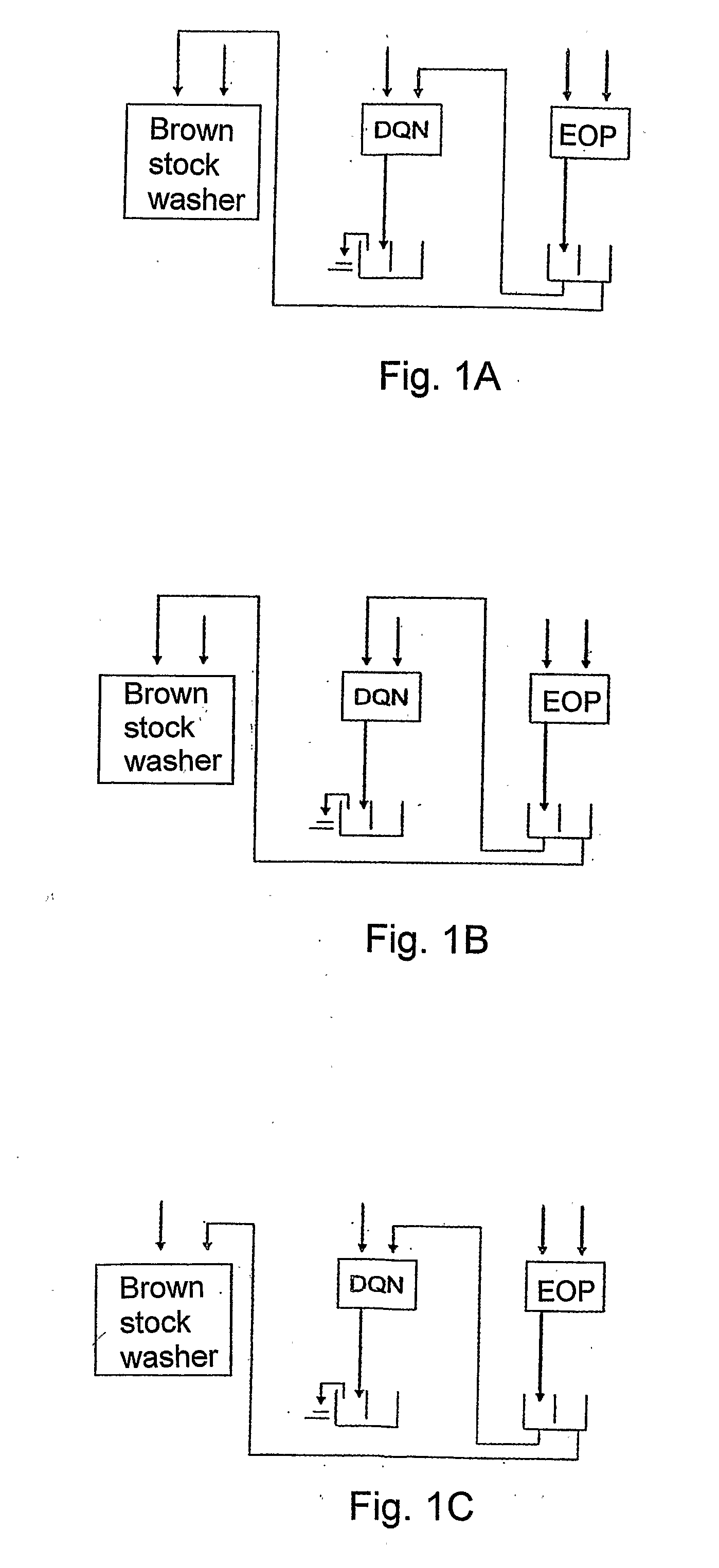

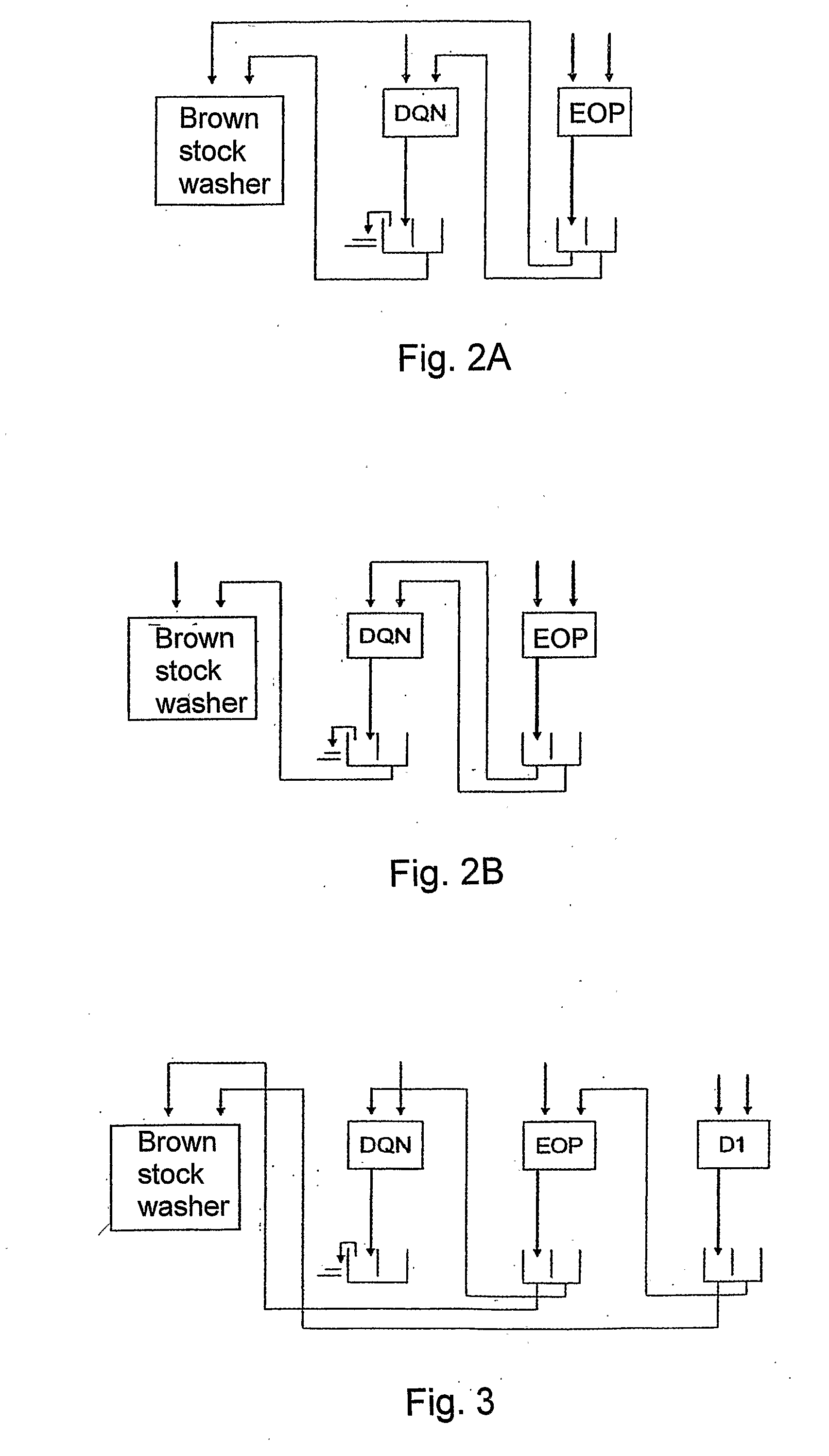

Bleaching process of chemical pulp

InactiveUS20090242152A1Reduce effluentFacilitate controlWashing/displacing pulp-treating liquorsPulp bleachingChemistryChemical pulp

A process for the bleaching of chemical pulp, wherein the initial bleaching of the pulp includes a first chlorine dioxide treatment (D0) and a following alkaline treatment with oxygen and hydrogen peroxide (EOP), which stages are separated from each other with a washing stage, and a treatment of the pulp to reduce the content of transition metals of the pulp prior to the peroxide treatment. The process is characterized in that alkali is added to the pulp after addition of chlorine dioxide in the D0 stage to adjust the pH of the pulp to neutral or basic (N stage) prior to the washing stage following the chlorine dioxide stage, whereby the initial bleaching includes the sequence D0N EOP.

Owner:LANNEN TUTKIMUS WESTERN RES

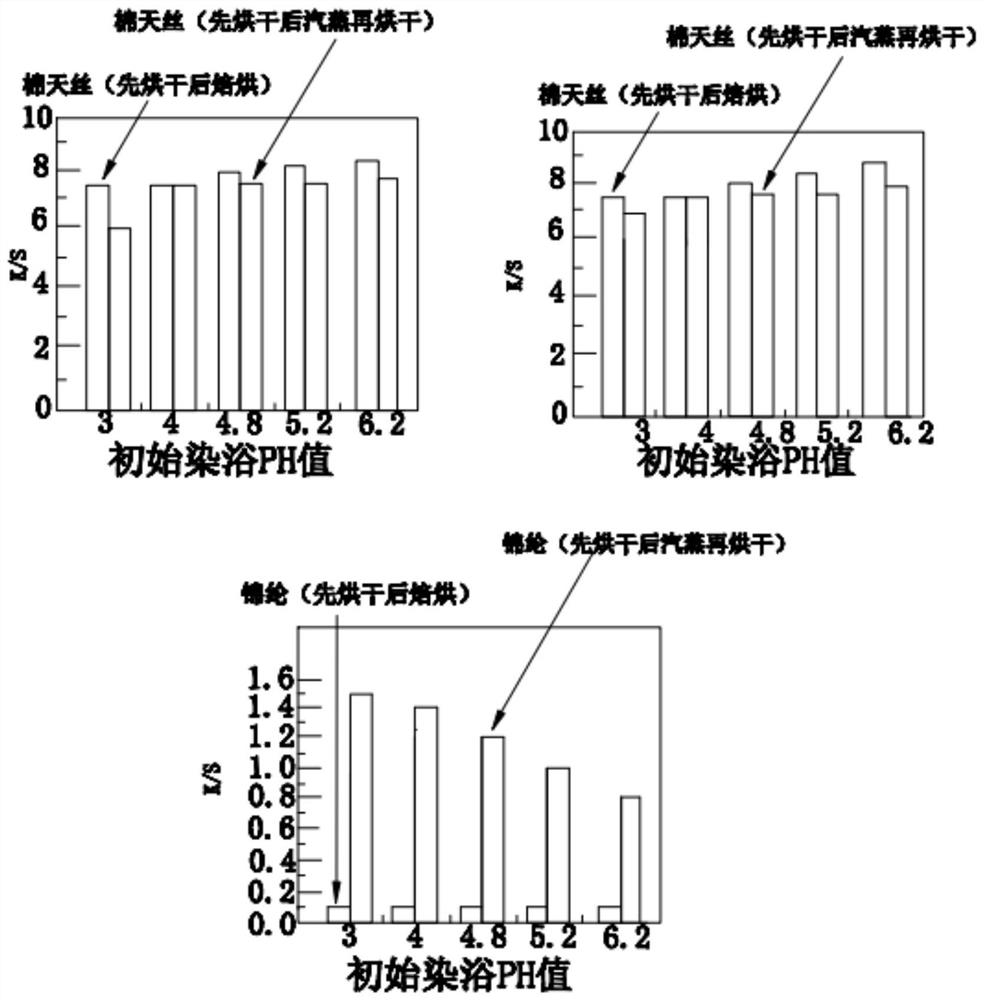

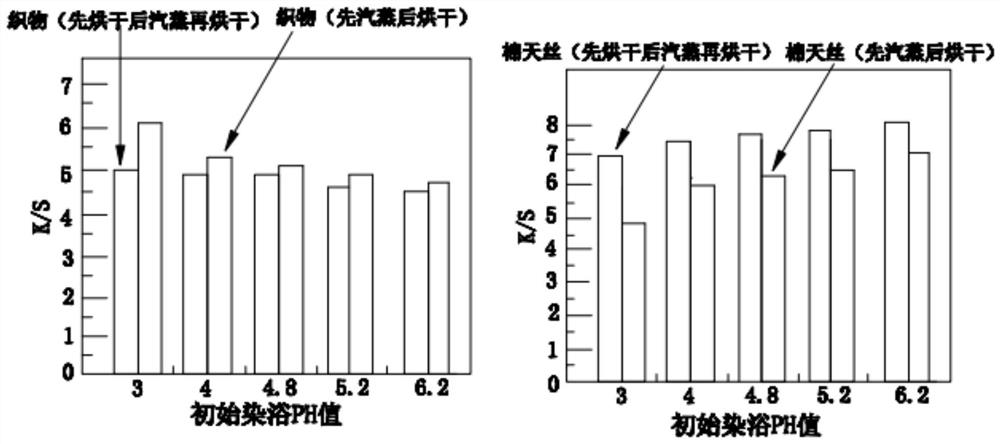

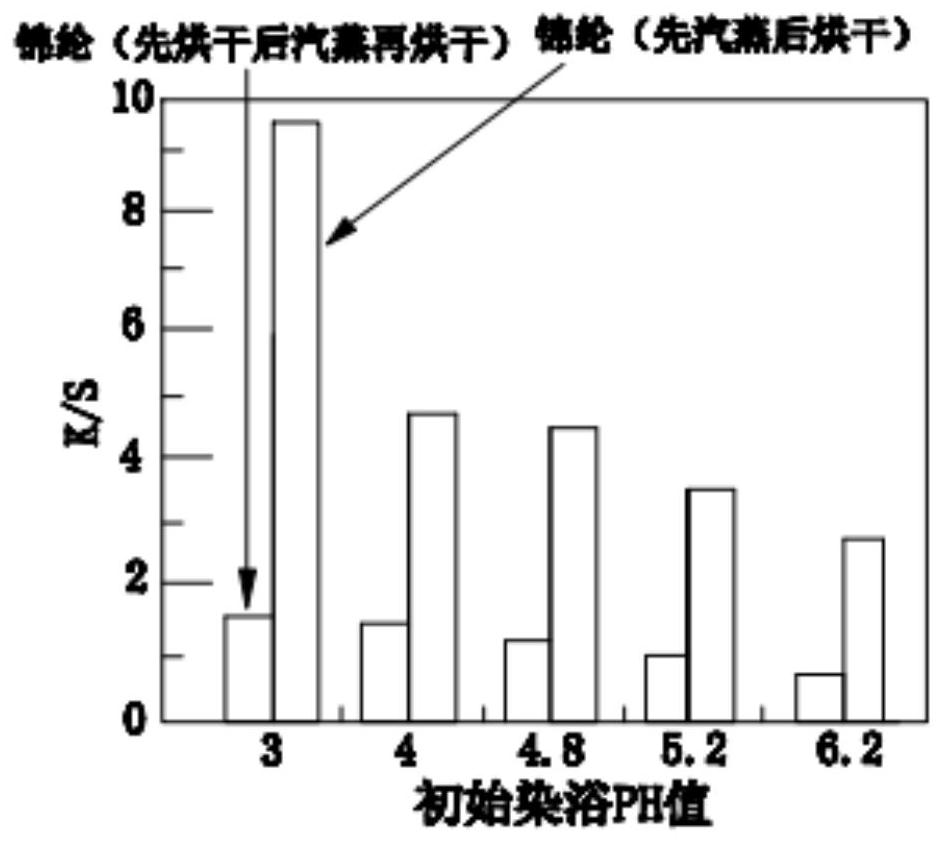

Reactive dye wet short steaming clean pad dyeing process for cotton/chinlon/lyocell fabric

PendingCN114855475ALow water and energy consumptionGood dyeabilitySucessive textile treatmentsTextile/flexible product manufactureColour fastnessPulp and paper industry

The invention relates to the technical field of textile dyeing and finishing, in particular to a cotton / chinlon / lyocell fabric reactive dye wet short steaming clean pad dyeing process which comprises the following steps: (1) preparing dye liquor by adopting M-type reactive dye, and adjusting the pH value of the dye liquor to be acidic; (2) padding and padding in dye liquor: performing two-time padding and two-time padding, wherein the liquor detention rate is 71-93%; (3) steaming; (4) padding in alkaline color fixing liquid: dipping twice and rolling twice, wherein the liquor detention rate is 20-28%; (5) steaming; (6) washing with cold water; (7) washing with hot water; (8) soaping; (9) washing with hot water; (10) washing with cold water; the dyeing process of the cotton / chinlon / lyocell three-component fabric can be shortened, migration and time consumption are reduced, cost and chemical consumption are reduced, energy consumption is reduced, pollution is reduced, energy consumption and carbon emission are reduced, and the fabric is good in dye permeability and leveling property and high in color yield and color fastness.

Owner:QINGDAO UNIV

System for continuous optimization of wastewater treatment

ActiveUS8293097B2Minimize consumptionReduce chemical consumptionWater treatment parameter controlOther chemical processesInjection portSewage

A system for controlling the injection of wastewater treatment chemicals into a wastewater treatment stream includes a holding tank for collecting and holding wastewater being treated, a camera positioned for making images of the wastewater in the holding tank, a computer for automatically making the images of the wastewater in the holding tank at scheduled intervals. The computer analyzes the images in order to determine the necessity for injecting wastewater treatment chemicals into the wastewater stream by measuring the size, distribution and number of pixels of differing colors and appearances, such that pixels of differing colors and appearances represent differing metal moieties in the wastewater stream. A pump and injection port injects wastewater treatment chemicals into the wastewater stream responsive to the analysis of the images indicating the necessity of such injection.

Owner:BOWERS JR GREGORY SCOTT

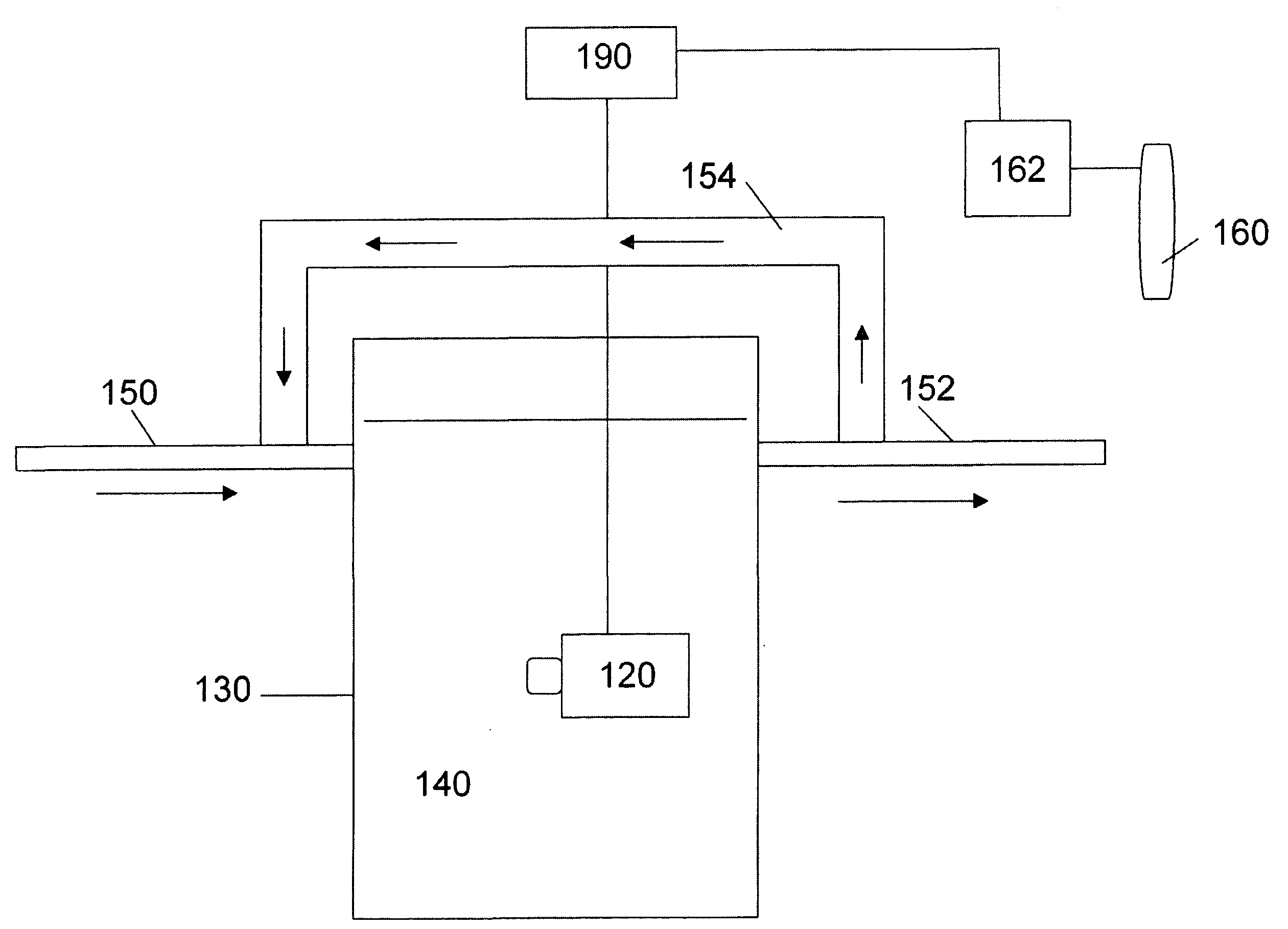

Method and apparatus for cavitation threshold characterization and control

ActiveUS7443079B2Reduce surface damageReduce chemical consumptionAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidCavitationAcoustic energy

An apparatus and method for characterizing cavitation that occurs in a fluid exposed to acoustic energy. The apparatus comprises a vessel for holding the fluid; an acoustic energy generating means for generating acoustic energy, the acoustic energy generating means being positioned to transmit the acoustic energy into the fluid while the fluid is held in the vessel; and a cavitation detection means for detecting cavitation in the fluid held in the vessel. In a preferred embodiment, the cavitation detection means comprises a light detection means, such as a photomultiplier tube, that detects sonoluminescent emission from the fluid. The method comprises the steps of exposing a volume of process fluid to acoustic energy at a specified power level; measuring the photon output from the fluid over a period of time; and when the photon output deviates from a desired level, initiating a remedial step to bring the photon output back to approximately the desired level.

Owner:PROD SYST

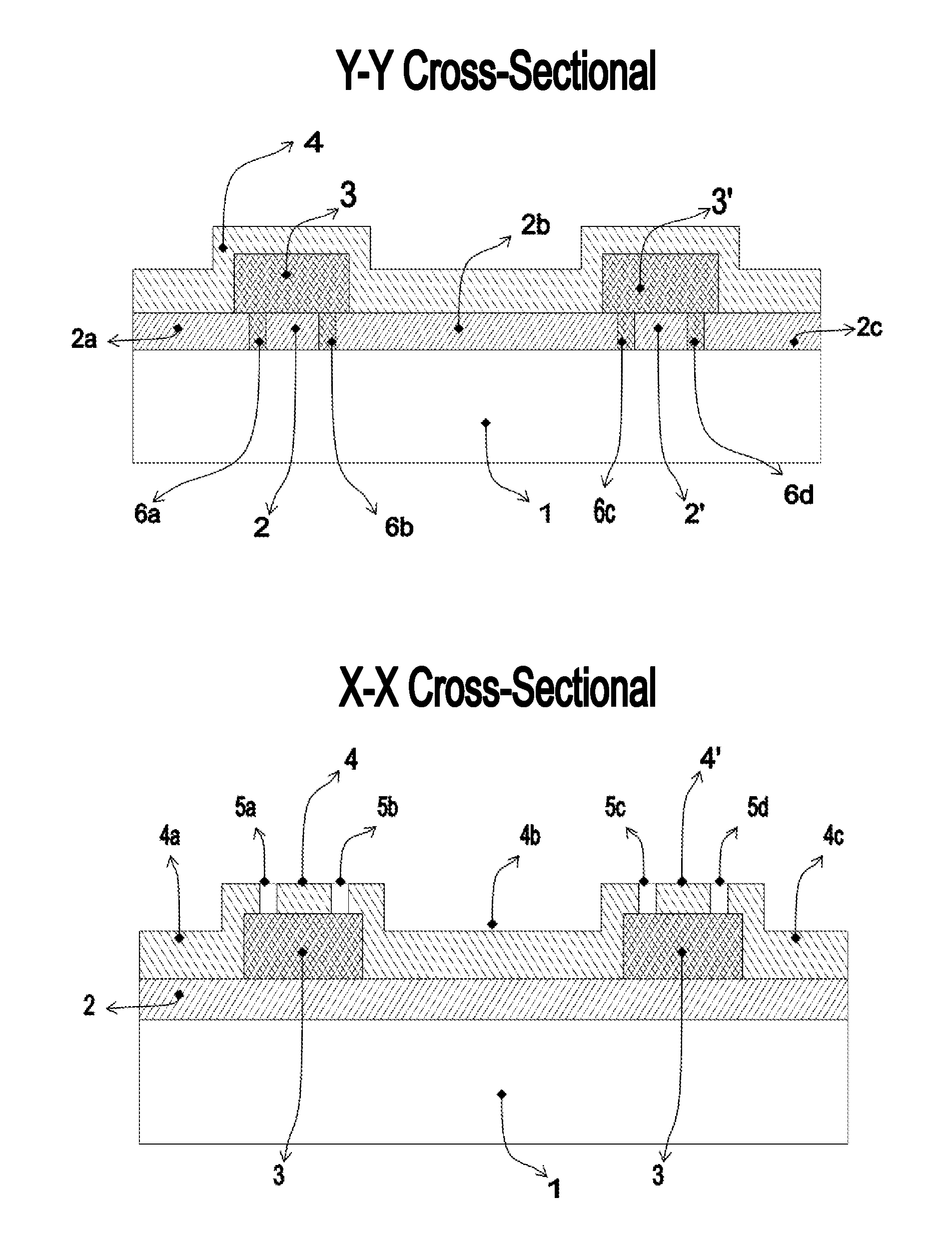

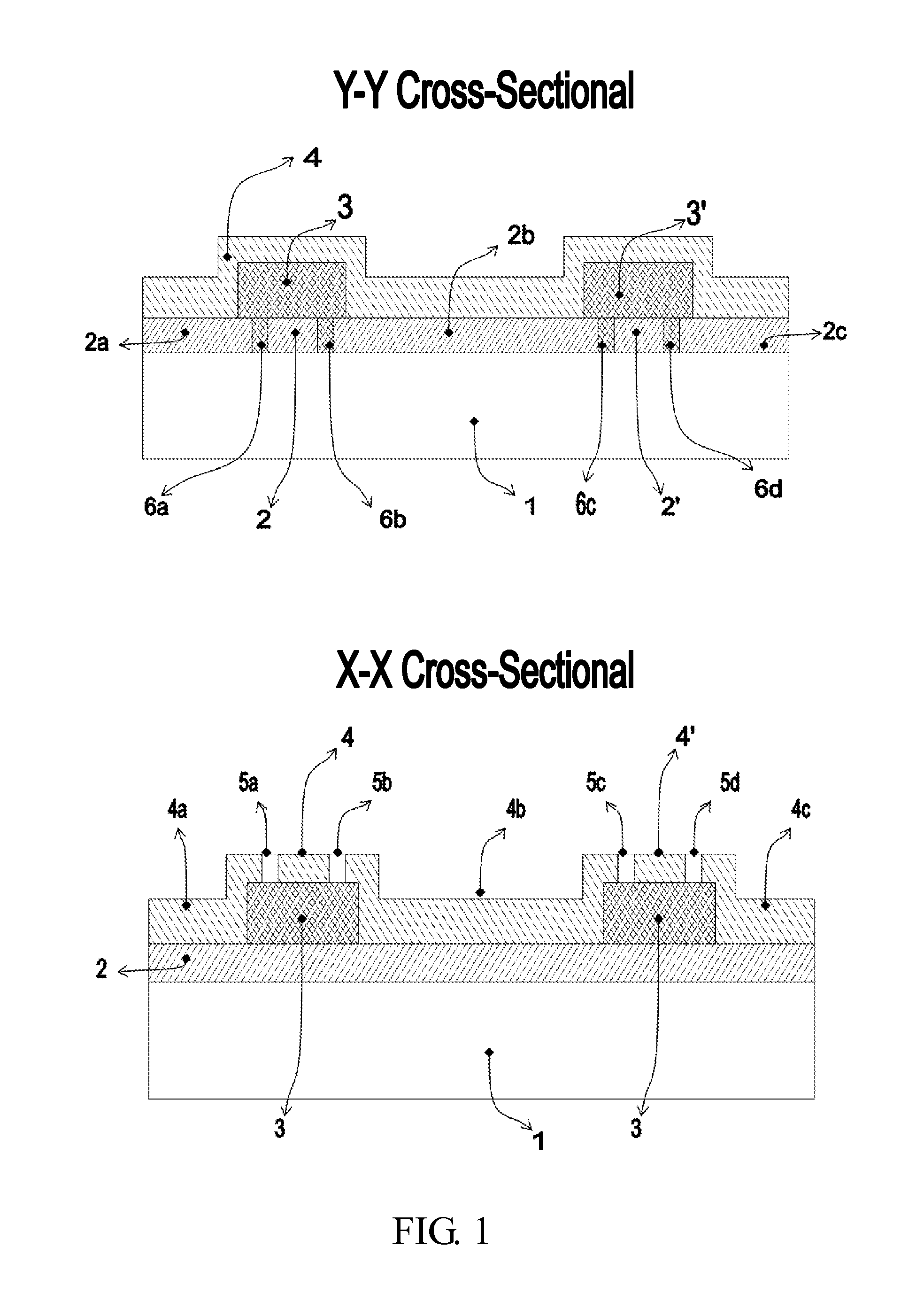

Structure and the associated manufacturing process for a single-sided multi-layer mutual capacitance touch panel

InactiveUS20150253902A1Solve the thickerThinnerInput/output processes for data processingManufacturing technologyMaterial consumption

A structure for a mutual capacitance touch panel consists of two conducting layers formed on the same side of a non-conducting substrate, insulating gaps within the structure, and insulating blocks formed between the two conducting layers for electrical isolation. This structure relies on the insulating gaps to form a touch function circuit in the first direction, a first auxiliary touch function region on the first conducting layer, a second touch function circuit in the second direction, and a second auxiliary touch function region on the second conducting layer. The insulating blocks are arranged at intersecting points of the first and second conducting touch function circuits that electrically isolate the first and the second conducting circuits. This structure is achieved by using a simple manufacturing process with a high yield but low material consumption thereby allowing a novel touch function structure to be implemented.

Owner:CN INNOVATIONS

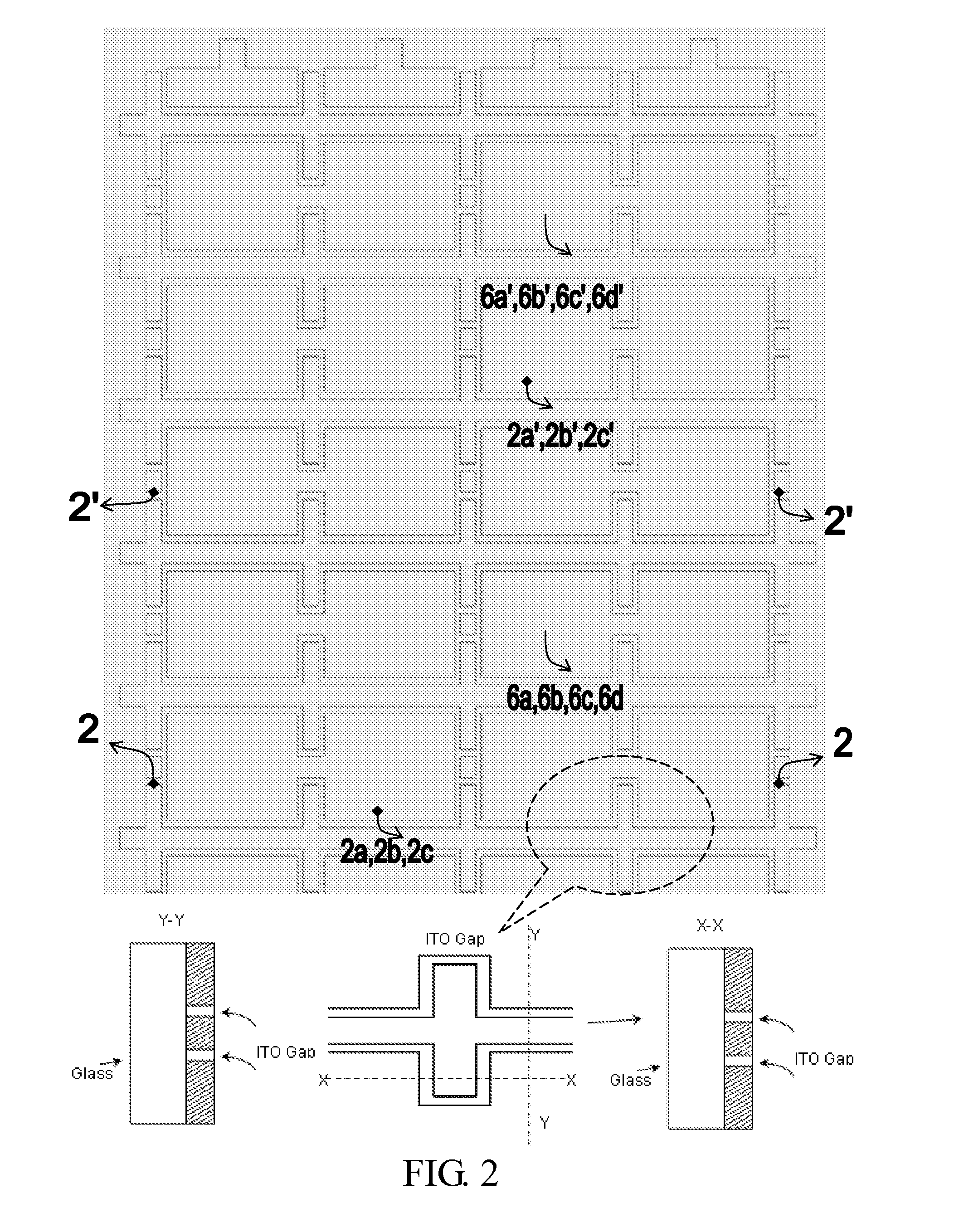

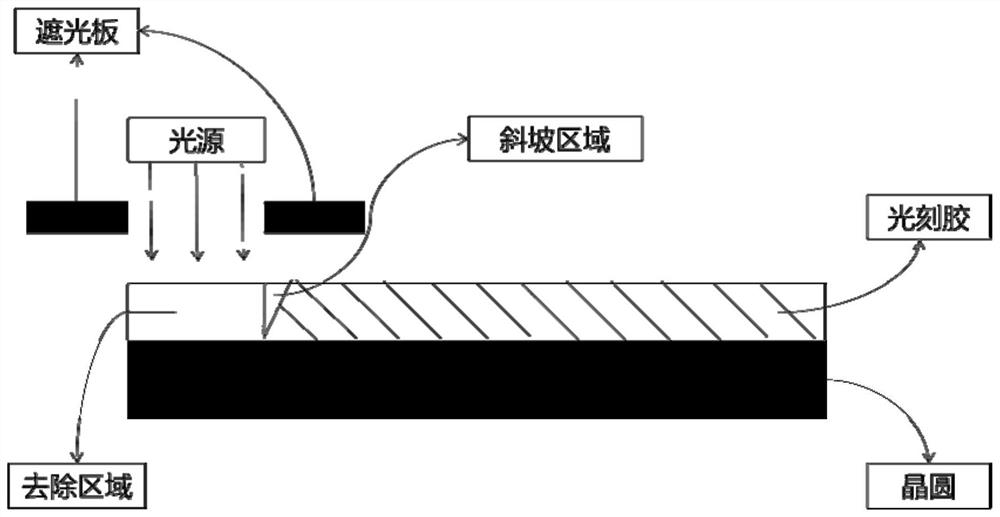

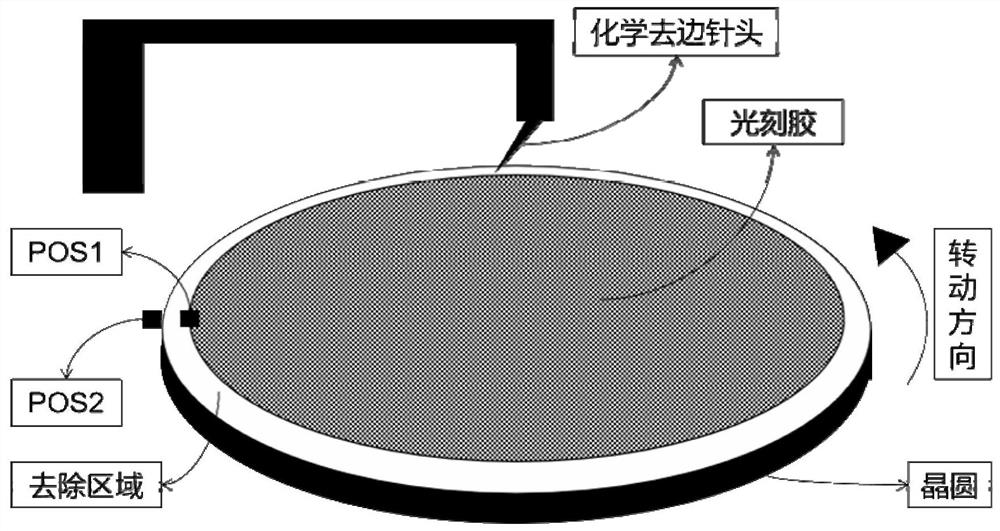

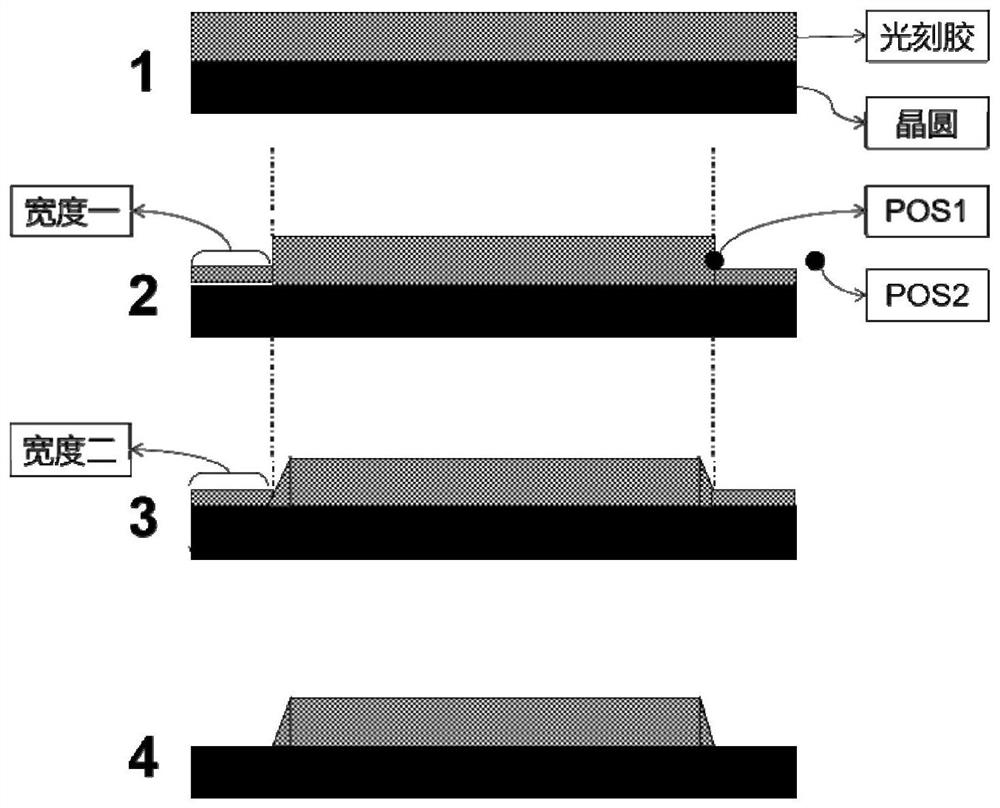

Method for removing thick glue edge on wafer

PendingCN112748638AShorten process timeReduce chemical consumptionPhotomechanical coating apparatusPhotosensitive material processingPhotoresistSemiconductor

The invention discloses a method for removing a thick glue edge on a wafer, belonging to the technical field of semiconductor photoetching. According to the method, the thick glue (7-20 microns) edge on the wafer is removed. The method comprises the following steps that firstly, the thickness of a glue film in an edge area of the wafer is reduced in a chemical mode; and then thorough removal is carried out in an edge exposure mode. Compared with the prior art, the method of the invention has the advantages that time for removing photoresist on the thick glue edge is shortened; and by adjusting various technological parameters, on the premise of ensuring edge removal effect, productivity is improved, the consumption of chemical edge removal liquid and the edge exposure time are reduced, and the effects of reducing cost and increasing yield are achieved.

Owner:SHENYANG KINGSEMI CO LTD

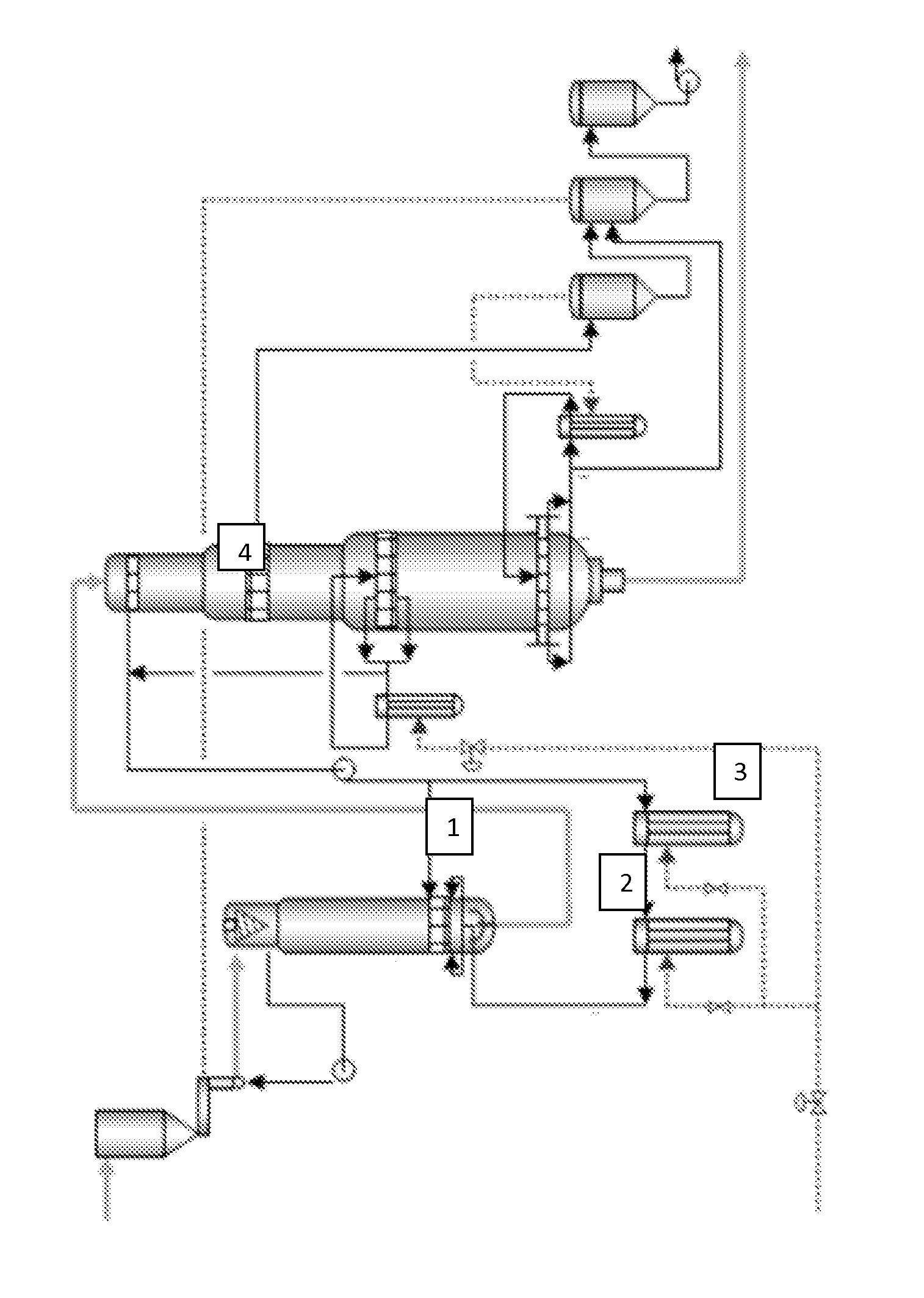

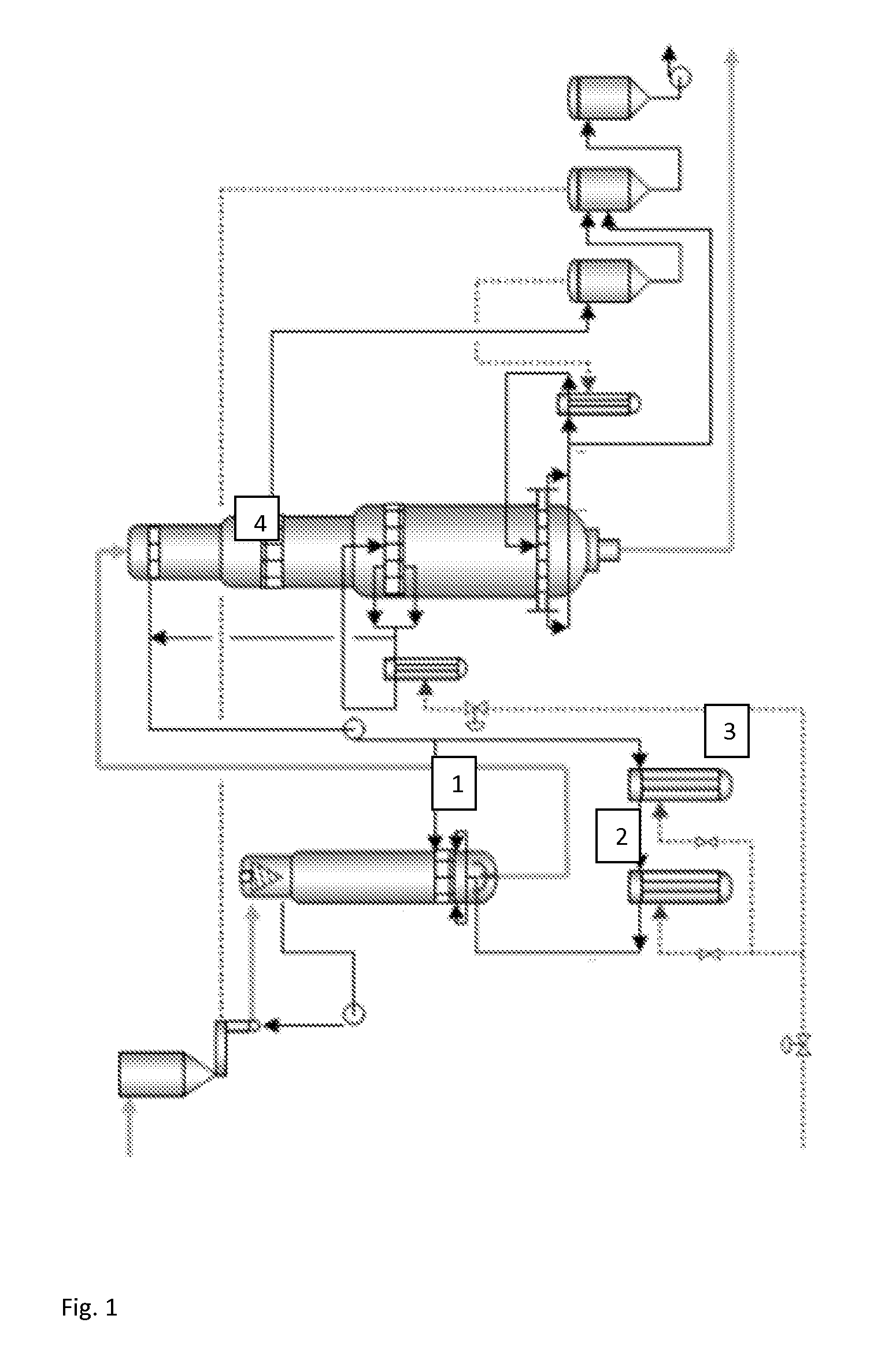

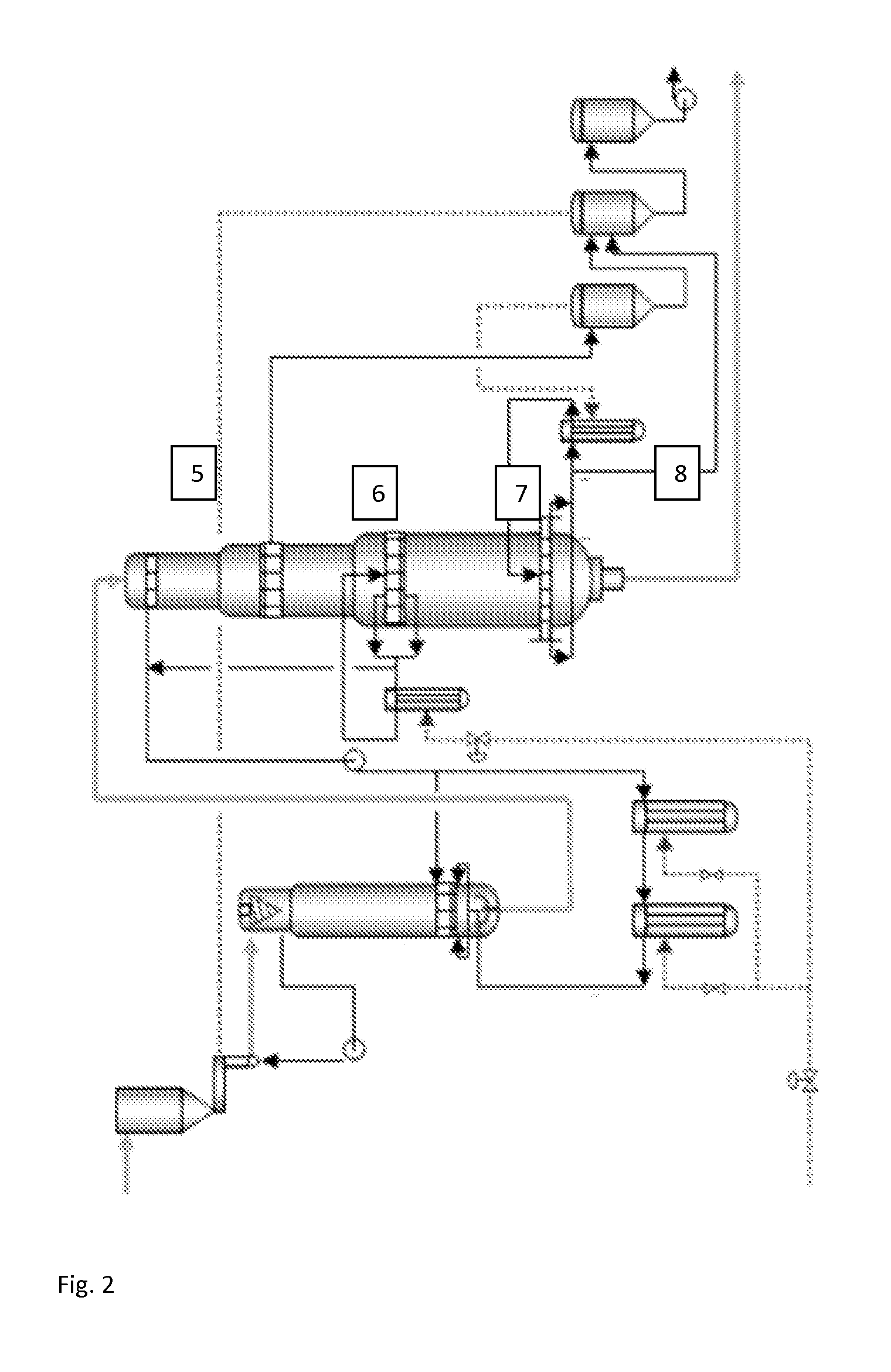

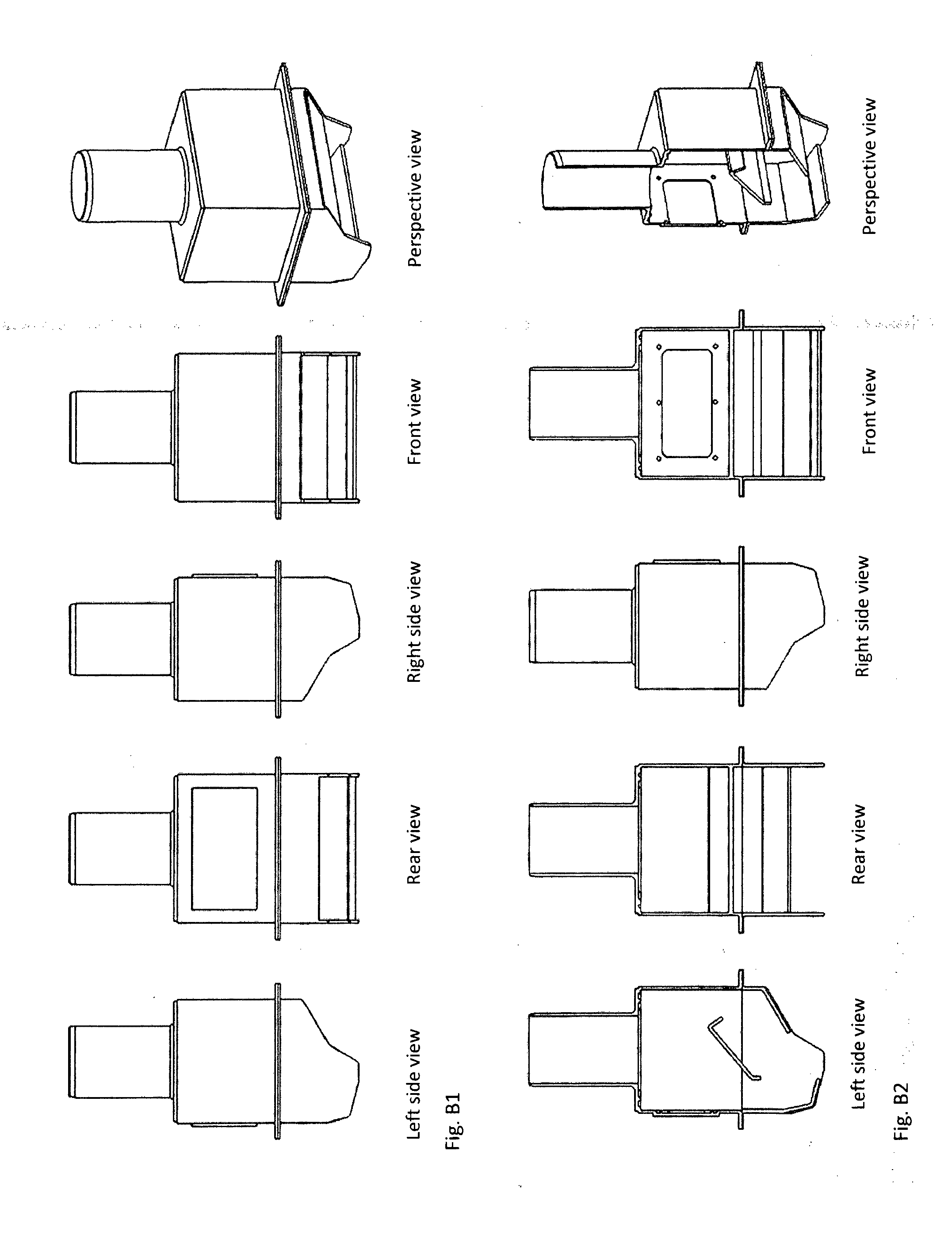

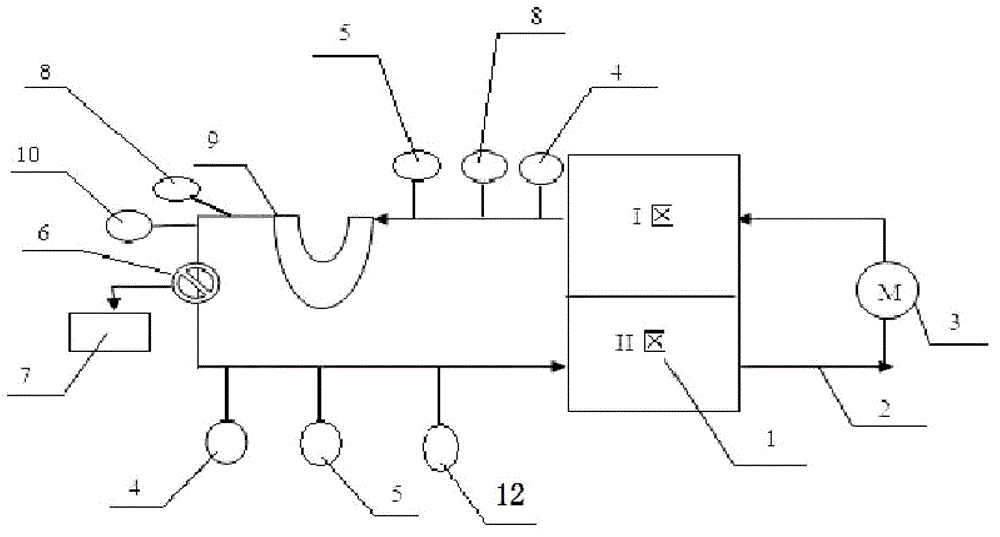

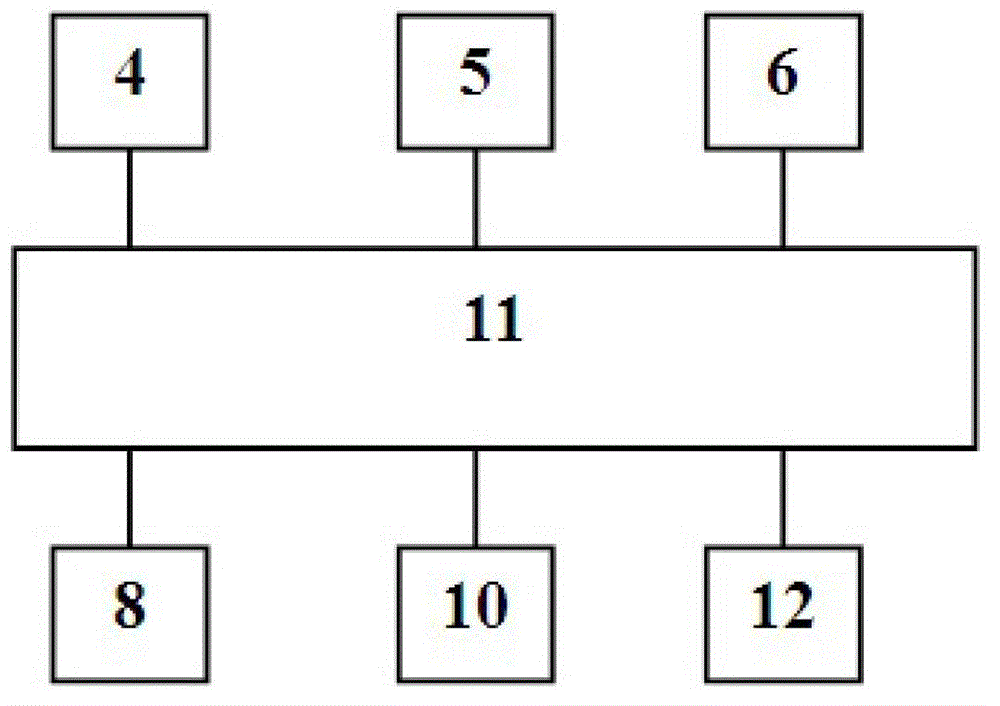

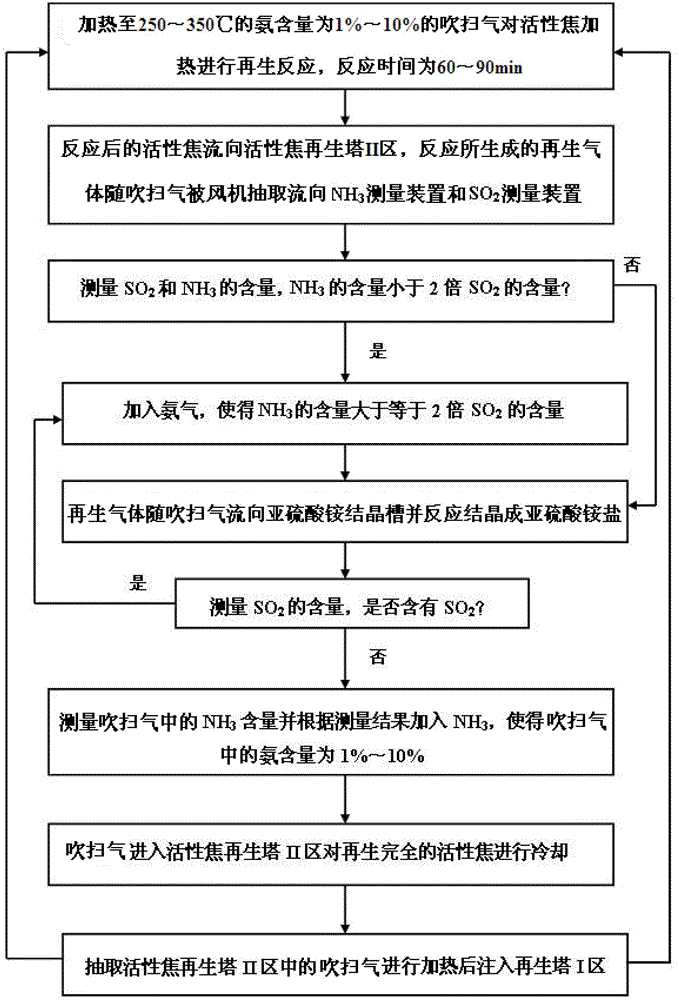

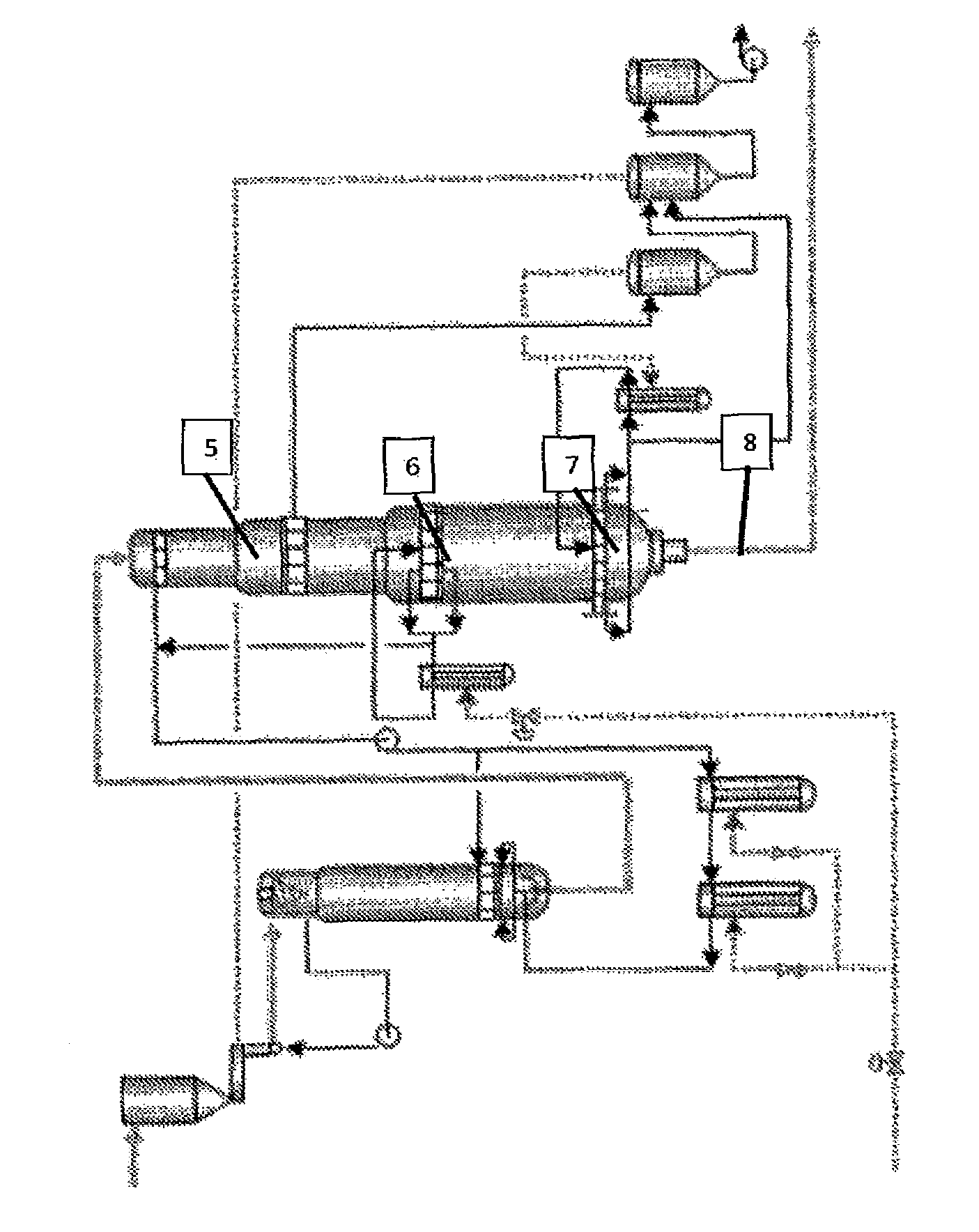

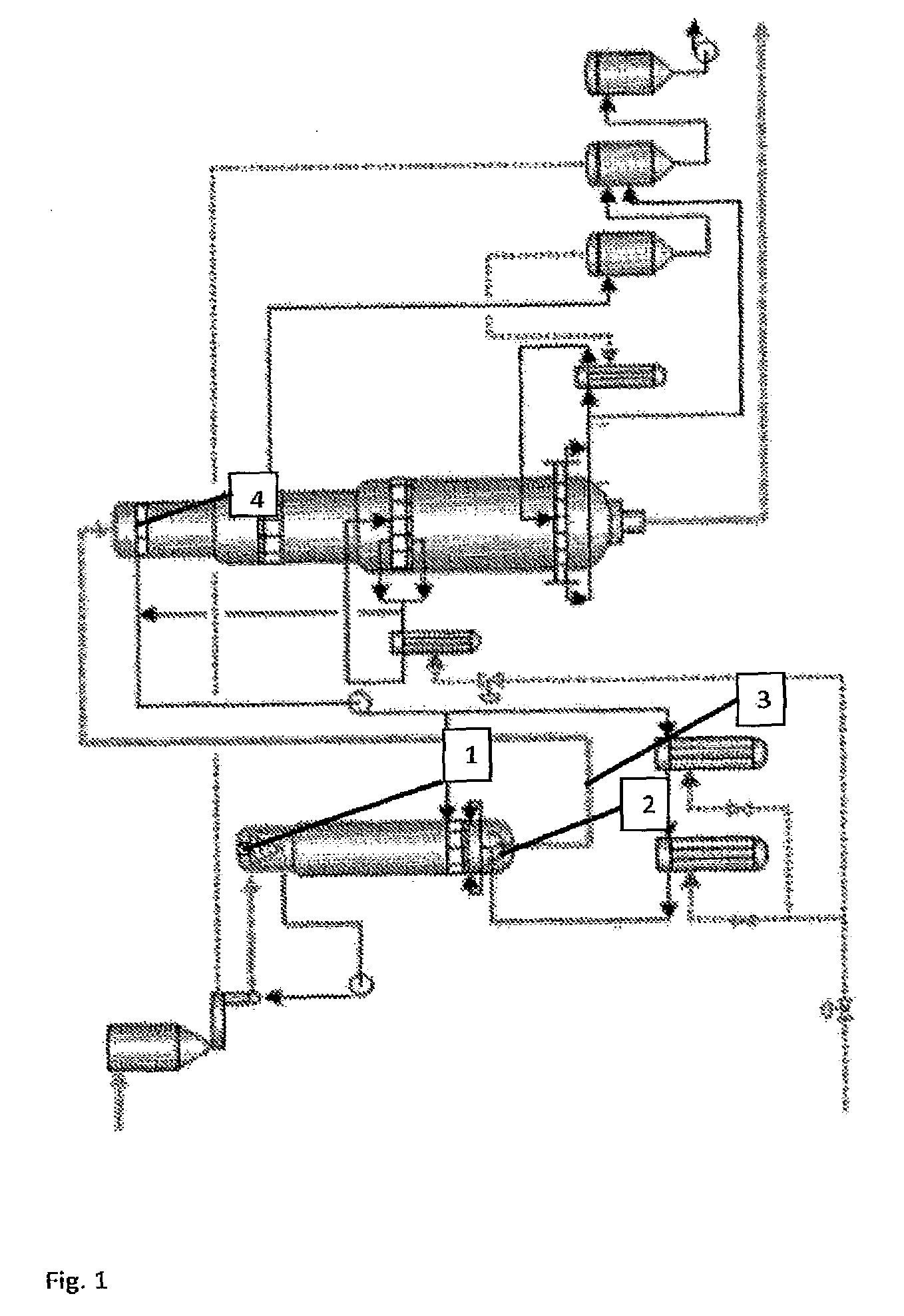

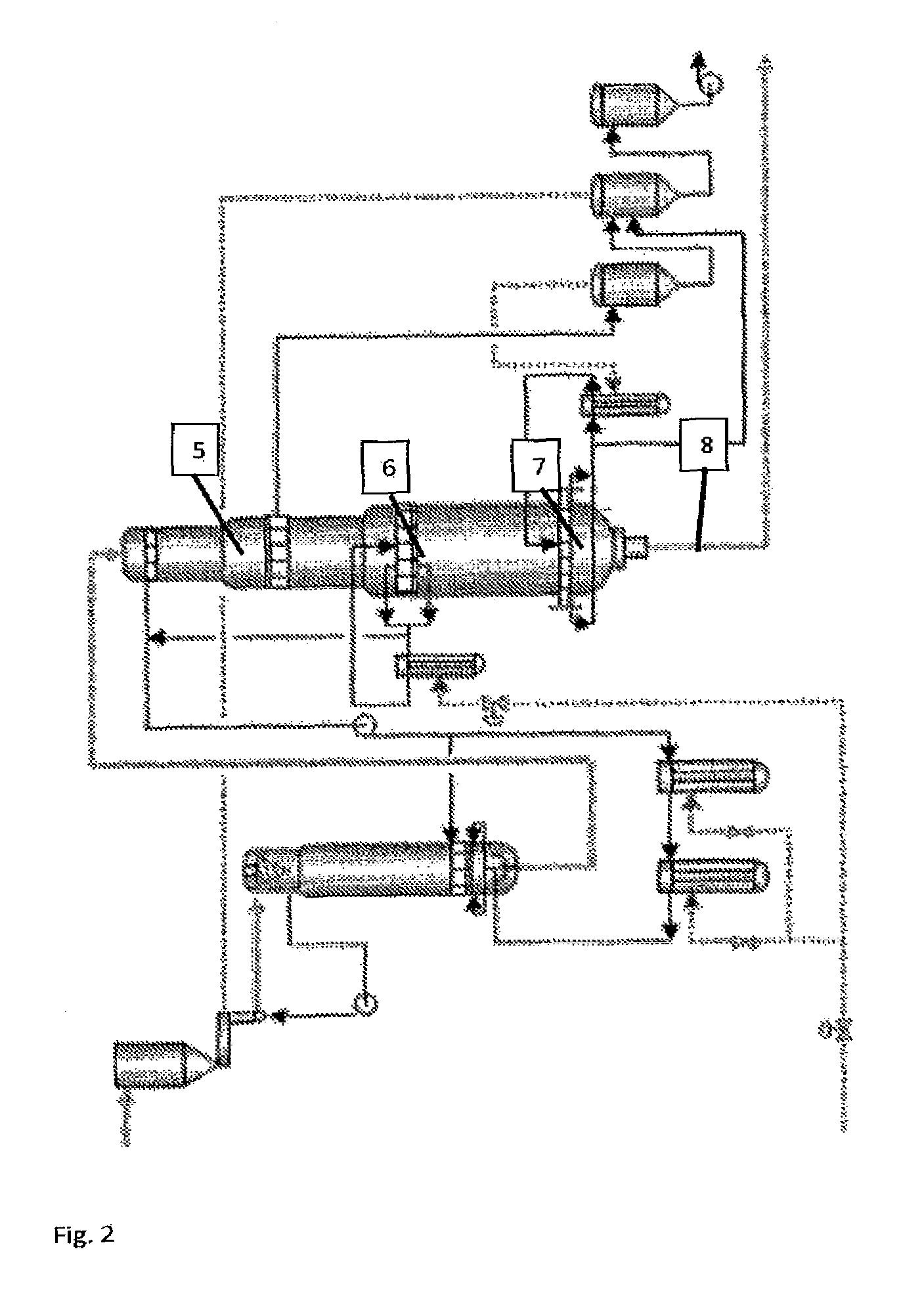

Ammonia regeneration method and device for activated coke

ActiveCN102716667BLow regeneration temperatureLow reaction temperatureDispersed particle separationNH3 measurementEngineering

The invention discloses an ammonia regeneration method and an ammonia regeneration device for activated coke. The device comprises an activated coke regeneration tower 1, a flue 2, an electric heater 3, an NH3 measurement device 4, an NH3 spraying device 5, a computer control end 11 and a fan 12, wherein a baffle plate is arranged in the activated coke regeneration tower 1 and divides the activated coke regeneration tower 1 into a regeneration heating reaction region I and a regeneration cooling region II; the electric heater 3 and the NH3 measurement device 4 are respectively arranged on the flue 2 between the region I and the region II of the activated coke regeneration tower 1; the NH3 spraying device 5 is arranged on the flue 2 between the NH3 measurement device 4 and the region II; the fan 12 is arranged on the flue 2 between the NH3 spraying device 5 and the region II; and the NH3 measurement device 4, the NH3 spraying device 5 and the fan 12 are respectively connected with the computer control end 11. 1 to 10 percent of ammonia is added into the sweep gas, so that the energy consumption is reduced, and the utilization efficiency of the activated coke is improved.

Owner:CHINA HUADIAN ENG +1

Bleaching process of chemical pulp

InactiveUS20090277596A1Reduce consumptionIncrease profitWashing/displacing pulp-treating liquorsPulp bleachingChlorine dioxideChelation

A process for the bleaching of chemical pulp, comprising a first chlorine dioxide treatment (D) of the initial bleaching and chelation (Q) to be carried out in connection therewith, forming together a DQ treatment. The process is characterized in that the chelation is carried out at the pH of from 2 to 7, and it is followed by an alkalizing stage (N) of the pulp, without intermediate washing for raising the pH of the pulp to above 7 and at most to 12 prior to a following stage which is a washing step.

Owner:LANNEN TUTKIMUS WESTERN RES

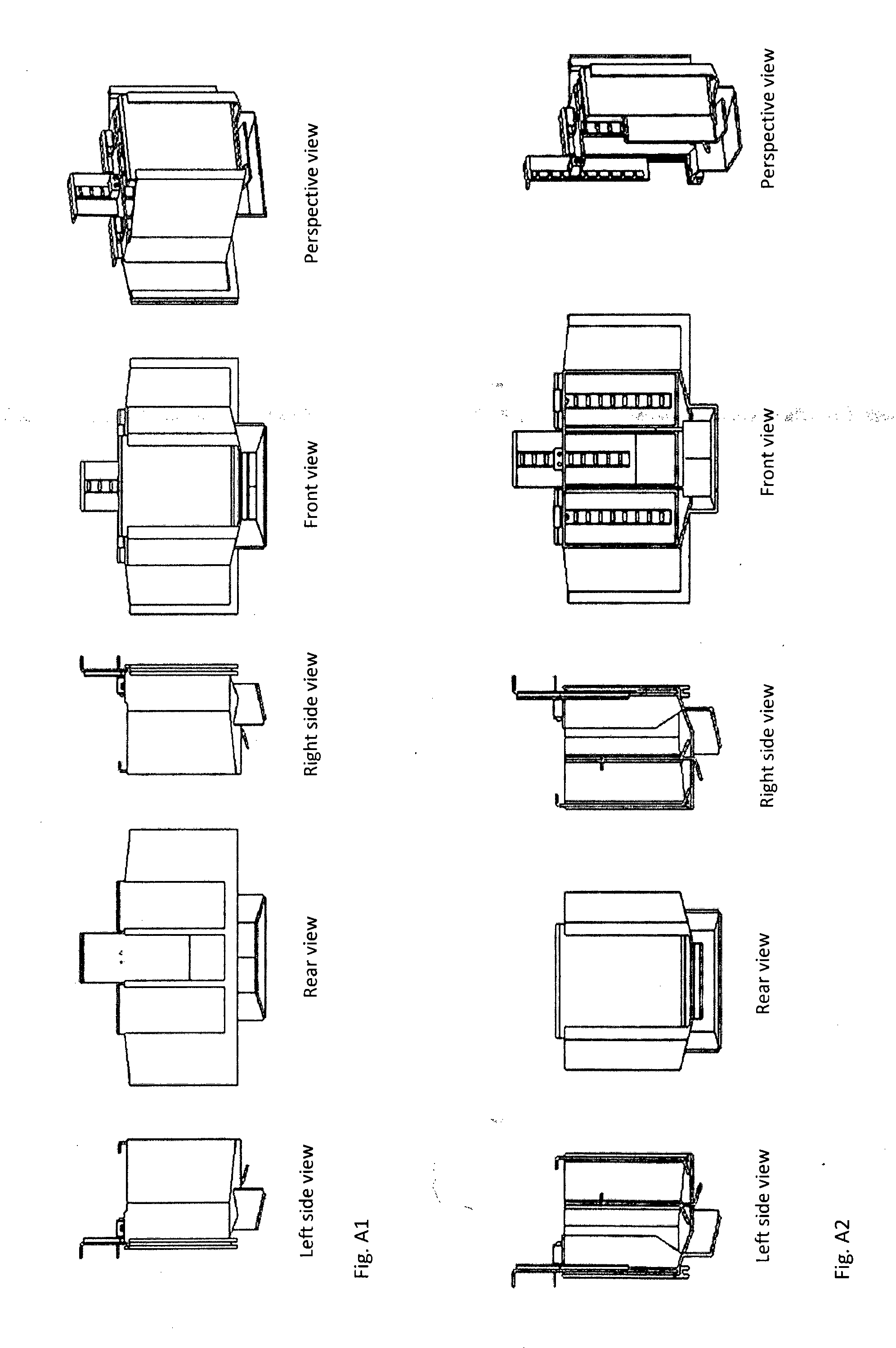

Production device and production method for coated duplex board with grey back

InactiveCN105728256AAdjust warpingAdjustable water volumeLiquid surface applicatorsCoatingsProcess engineeringIndustrial engineering

The invention relates to a production device and production method for a coated duplex board with a grey back. The production device comprises first coating equipment, second coating equipment and atomizing spray equipment 8, which are sequentially arranged along the paper walking direction, wherein the first coating equipment and the second coating equipment are used for first coating and second coating on the surface layer of the paper respectively; and the atomizing spray equipment 8 is used for atomizing spray on the back surface of the paper. The production device for the coated duplex board with the grey back only needs two coating procedures; the atomizing spray equipment is additionally arranged to the back surface to adjust paper warpage; the atomizing spray water quantity can be adjusted; the paper coating quantity is greatly reduced; and the chemical consumption is reduced. The coating procedures are added to the surface layer and the back surface of the paper respectively, so that paper machine equipment is greatly reduced; and factory occupation and fixed equipment investment are greatly reduced.

Owner:NINE DRAGONS PAPER TAICANG LTD

Method of processing chemical pulp

ActiveUS9139955B2Same yieldReduce consumptionPulp properties modificationWashing/displacing pulp-treating liquorsOptical propertyPulp and paper industry

A method is presented, by which dewatering in paper product production, optical properties, bulk and surface smoothness of the paper product can be increased. The method involves at least one step physical treatment of the vegetable fiber raw material.

Owner:UNIV DE CONCEPCION50

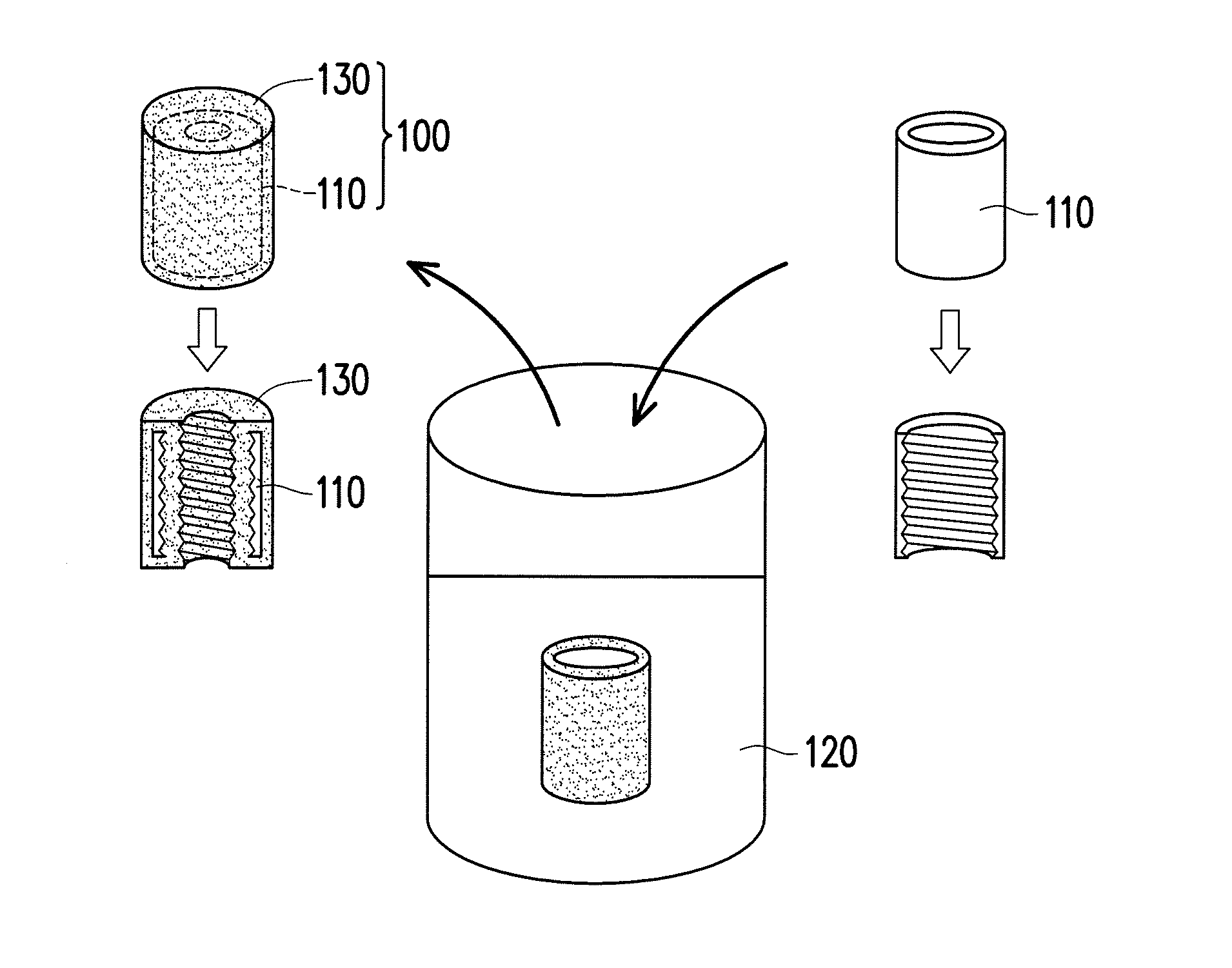

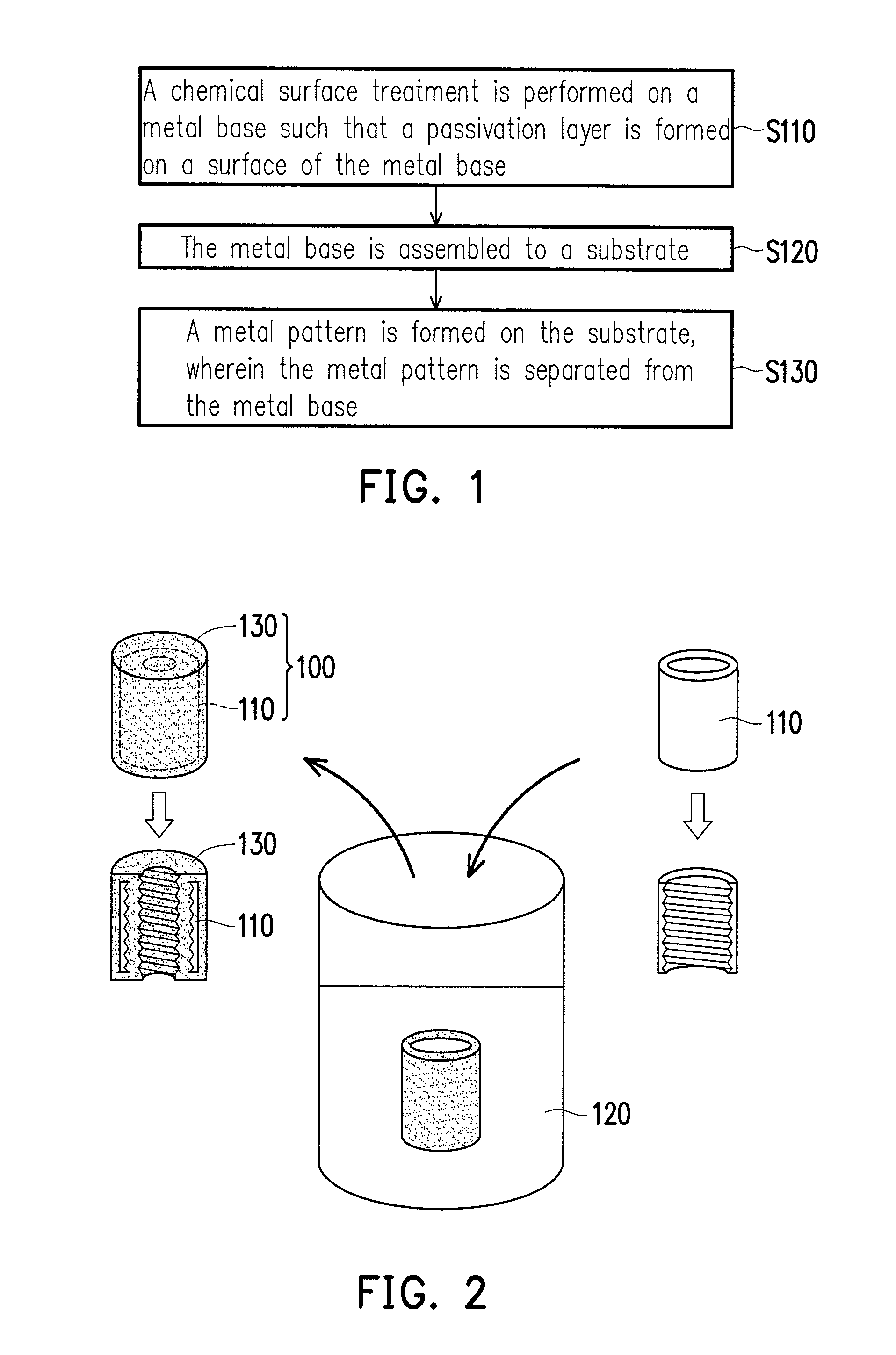

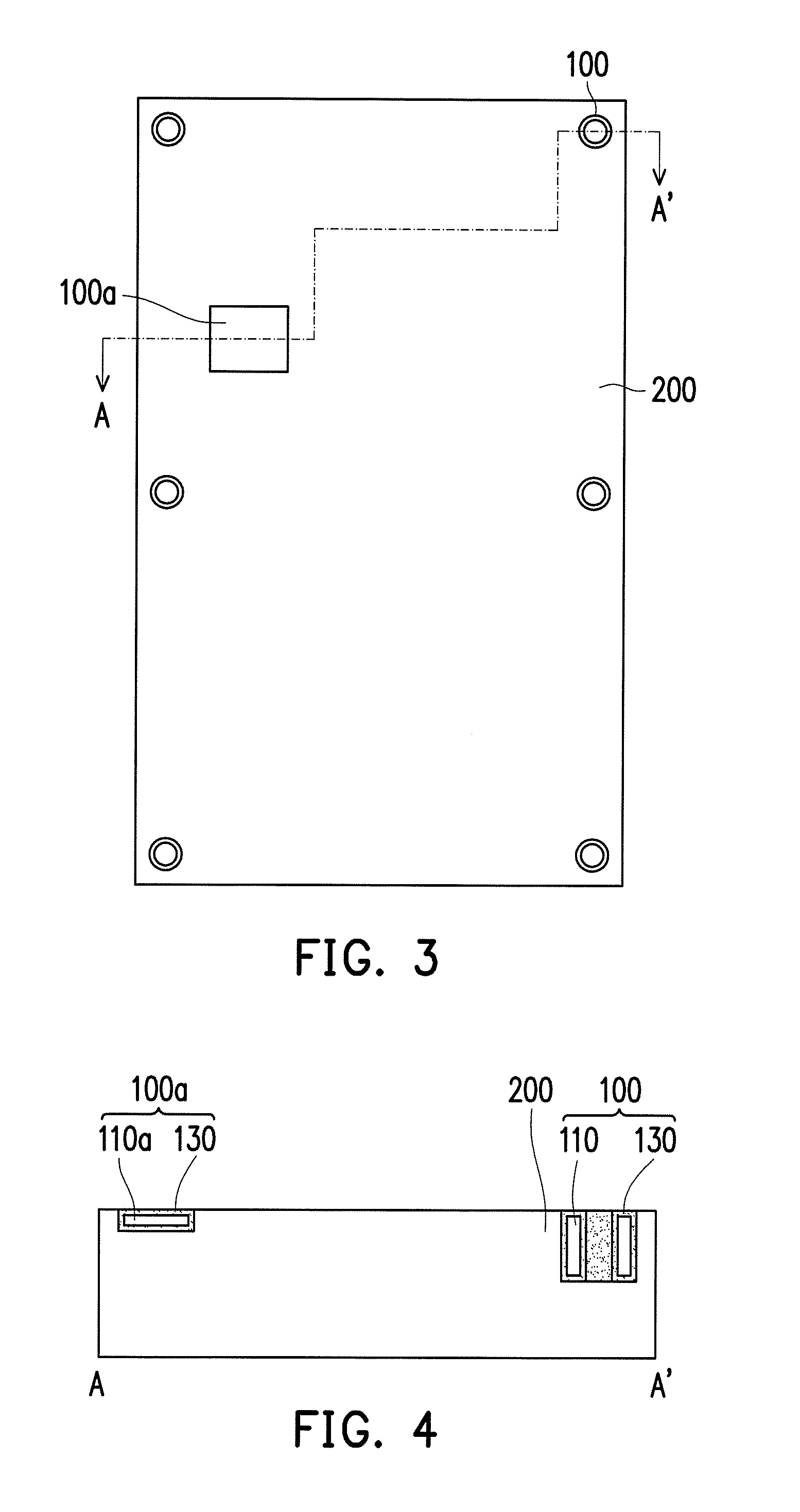

Manufacturing method of substrate structure, substrate structure and metal component

ActiveUS20160014907A1Simple methodReduce consumptionLiquid/solution decomposition chemical coatingConductive pattern formationMetal

A manufacturing method of a substrate structure including the following steps is provided. A chemical surface treatment is performed on a metal base such that a passivation layer is formed on a surface of the metal base. The metal base is assembled to a substrate. A metal pattern is formed on the substrate, wherein the metal pattern is separated from the metal base. A substrate structure and a metal component are also provided.

Owner:WISTRON NEWEB

Water treatment system and method

ActiveUS10640404B2Reduce and even eliminate non-complianceLow costWater treatment parameter controlNature of treatment waterWater treatment systemNatural-gas processing

Disclosed herein is a water treatment system for connection to a water treatment plant (e.g. a dissolved air flotation device). The plant may have an inlet for the receipt of feed water (e.g. waste water) and an outlet for the discharge of treated water. The treatment system may comprise a first sensor disposed such that it is in fluidity communication with the feed water, and a second sensor disposed such that it is in fluidity communication with the treated water. The first and second sensors may be configured to sense parameters of the feed and treated water. The system may further comprise a first applicator (e.g. a pump) that is configured to discharge a treatment source (e.g. a chemical source) to the plant to treat the feed water. The disclosed system may be used to treat waste water (e.g. the treatment of effluent from oil refineries, petrochemical and chemical plants, natural gas processing plants, paper mills and general water treatment). The system has analogous applications in other processing methods that also use DAF, or very similar, systems, such as the processing of mineral ores and other such solid extraction processing methods.

Owner:WATERWERX TECH PTY LTD

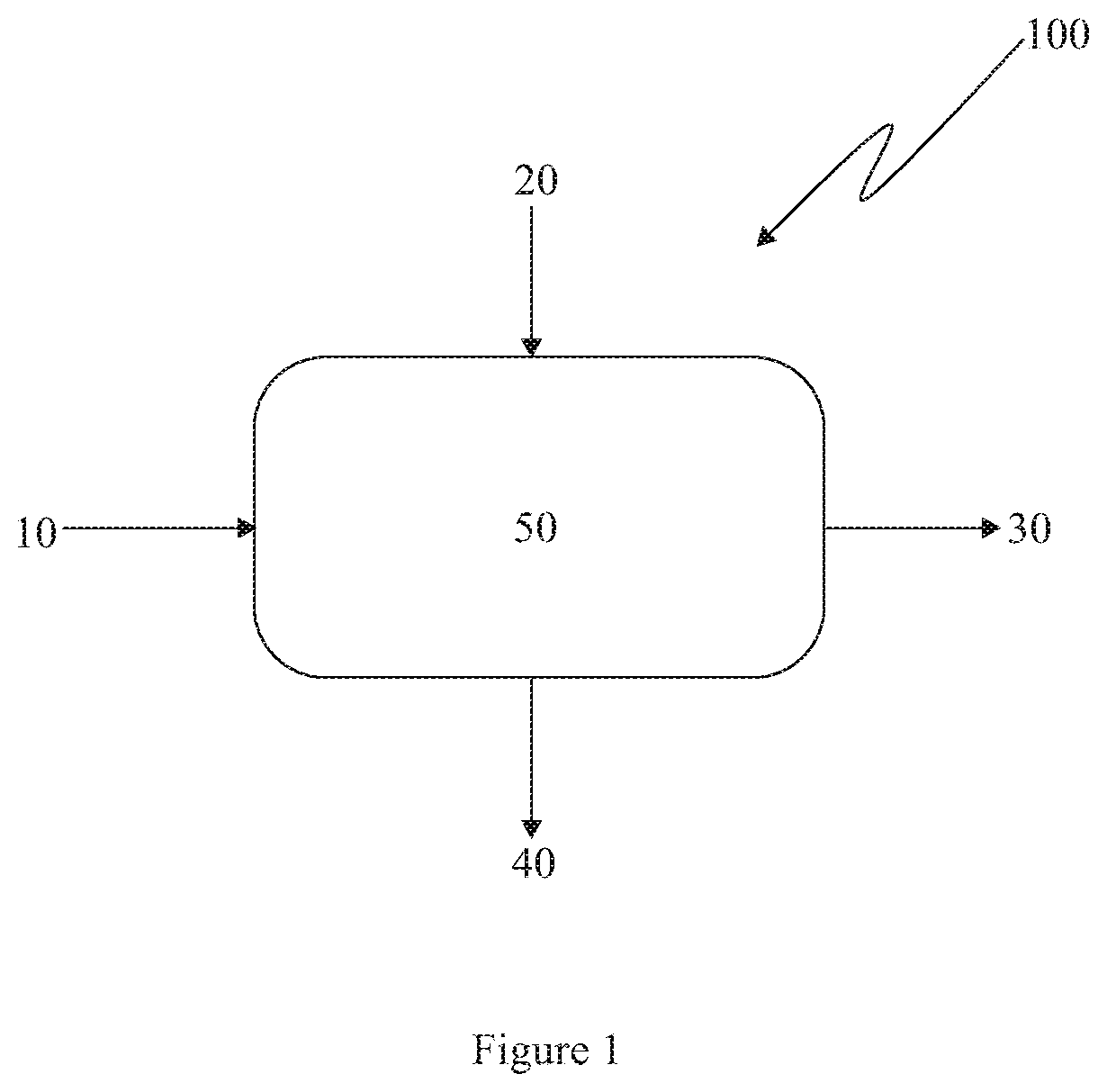

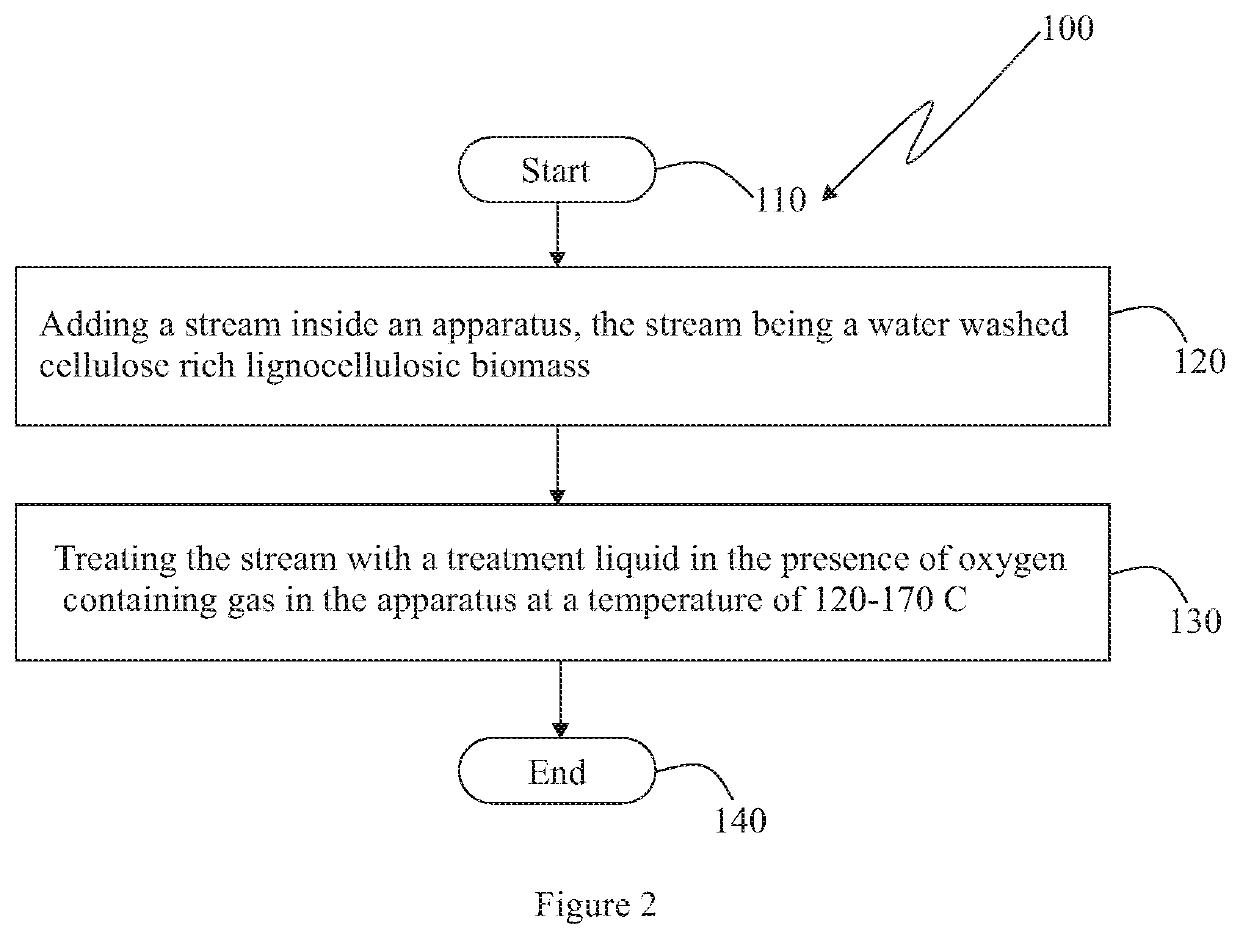

A method for non-catalytic delignification of biomass inside an apparatus

PendingUS20220136171A1Ensure qualityReduce chemical consumptionCellulosic pulp after-treatmentPretreatment with water/steamPtru catalystOrganosolv

The present invention provides a method for non-catalytic delignification of biomass, without externally added catalyst, with a mixed solvent of oxygenated organic solvent and water in the presence of an oxidant, at moderate temperature and pressure. Further, the separation of delignified cellulose from liquid mixture is carried out at around equivalent process conditions. Low modified kappa number delignified cellulose is obtained after separation of a liquid mixture containing a mixed solvent, hemicelluloses, lignin and traces of miscellaneous compounds. Furthermore, the method has lower chemical consumption in the downstream process, ease of operation and robustness.

Owner:LIGNOPURA AGROTECH PVT LTD

Substrate processing apparatus

InactiveUS20140283992A1High viscosityFlowability of solution is loweredSemiconductor/solid-state device manufacturingChemical solutionAnalytical chemistry

A substrate processing apparatus includes a first processing chamber and a second processing chamber, a first substrate holding unit that holds a substrate in the first processing chamber, a chemical solution supply unit that supplies a chemical solution containing an etching component and a thickening agent to the substrate held by the first substrate holding unit, a substrate transfer unit that transfers the substrate from the first processing chamber to the second processing chamber in a state in which the chemical solution is held on the substrate, and a second substrate holding unit that holds a plurality of substrates on each of which the chemical solution is held in the second processing chamber.

Owner:DAINIPPON SCREEN MTG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com