Method for removing thick glue edge on wafer

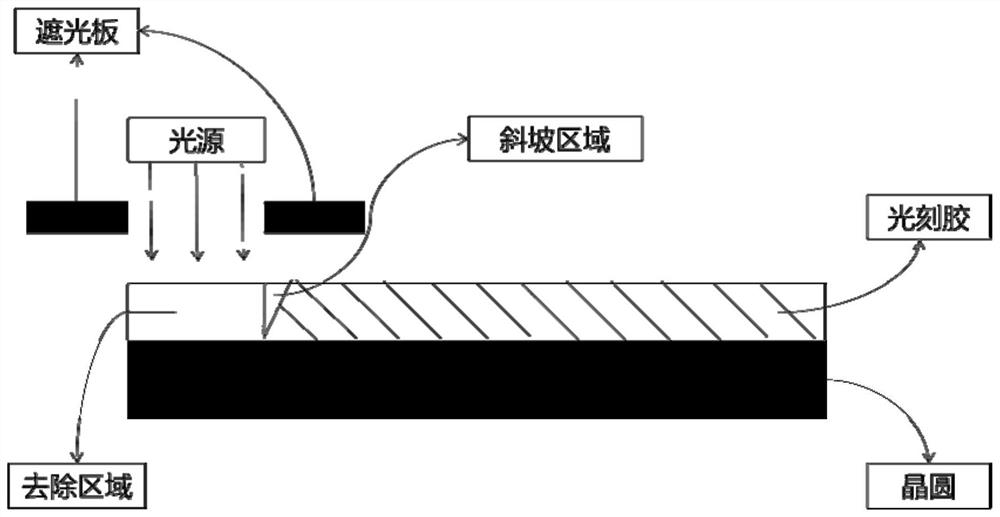

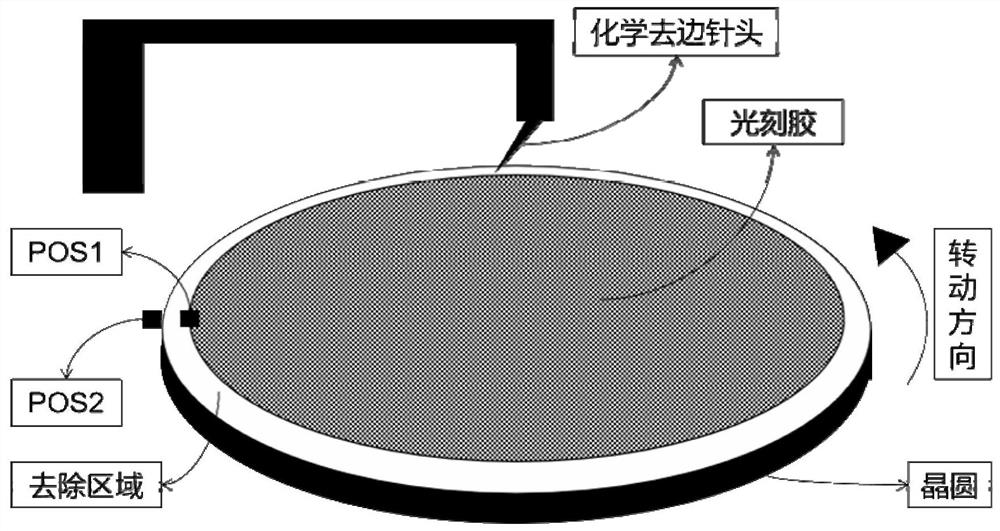

A wafer and edge technology, applied in the field of removing thick glue edges on wafers, can solve problems such as difficult control of slope, high consumption of chemicals, uneven edges, etc., to achieve clean edges, narrow slope width, and contour neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

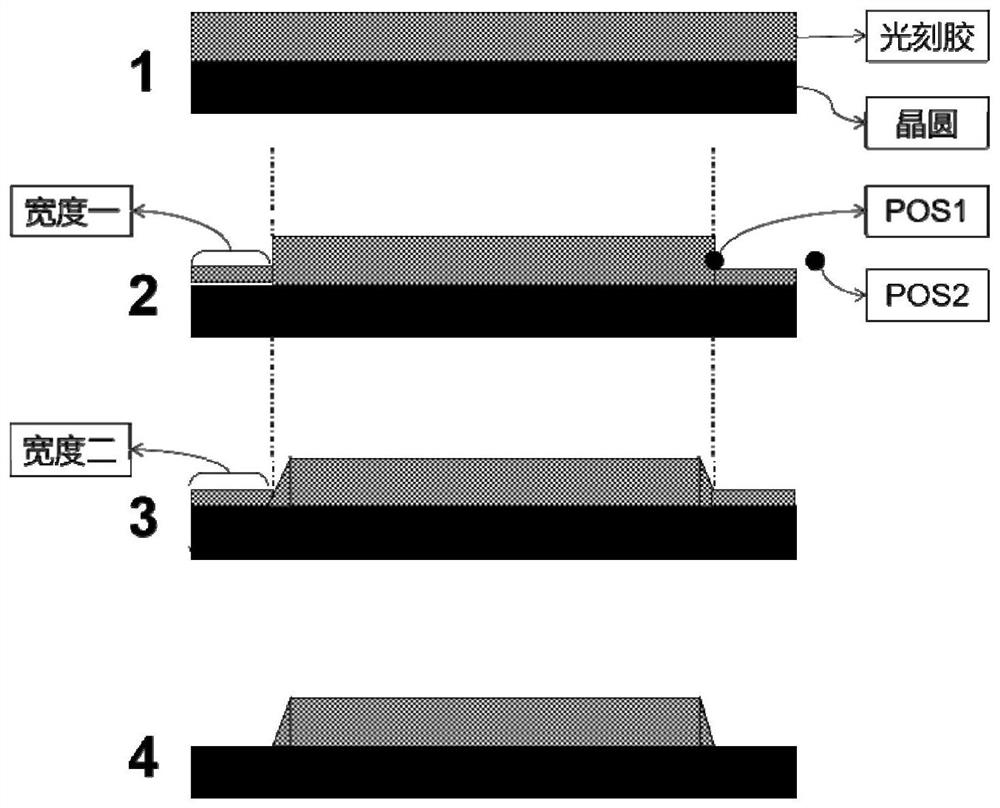

[0044] A certain photoresist PI (same as Comparative Example 1) was used, the coating thickness was 7.7 μm, the edge removal target was W1=W2=1±0.1 mm, the chemical removal solution was OK73, and the wafer was a silicon wafer with a diameter of 300 mm. Such as image 3 As shown, combining chemical removal with edge exposure, adjusting various parameters and trying a variety of time combinations, the best removal effect of this method is obtained. The chemical edge removal takes 11s, the edge exposure takes 42s, the total time is 148.5s, the required amount of chemical solution is 3.6ml, the edge removal effect is better, reaching the spec, and the slope width is about 0.02mm.

[0045] From the recorded data, it can be found that for this embodiment, the method of the present invention has the best effect. Considering the time length, the amount of chemicals used, and the removal effect comprehensively, the method achieves the purpose of the invention.

Embodiment 2

[0051] A certain positive photoresist (same as Comparative Example 3) was used, the coating thickness was 15 μm, the edge removal target was W1=W2=1.3±0.15 mm, the chemical removal solution was OK73, and the wafer was a silicon wafer with a diameter of 300 mm. Such as image 3 As shown, combining chemical removal with edge exposure, adjusting various parameters and trying a variety of time combinations, the best removal effect of this method is obtained. It takes 8s to remove the edge, 15s to expose the edge, and the total time is 101s. The amount of chemical solution required is 2.6ml. The edge removal effect is better, reaching the spec, and the slope width is about 0.02mm.

[0052] From the recorded data, it can be found that for this embodiment, the method of the present invention has the best effect. Considering the time length, the amount of chemicals used, and the removal effect comprehensively, the method achieves the purpose of the invention.

[0053] Through the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com