Efficient sewage denitrification process

A sewage and denitrification technology, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of large limitations, immaturity, retention, etc., and reduce the Effects of energy consumption, less oxygen amount, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

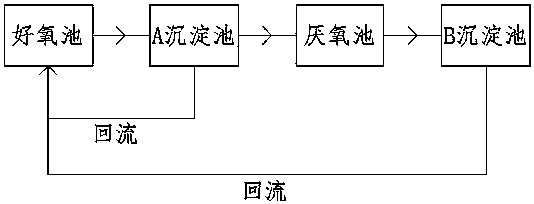

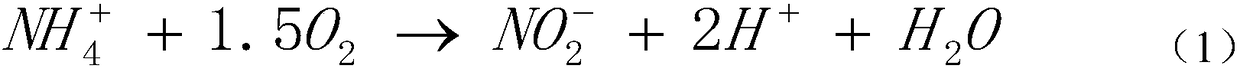

[0030] Such as figure 1 As shown, an efficient sewage denitrification process uses aerobic nitrifying bacteria in the aerobic tank to convert part of the ammonia in the ammonia-containing sewage into nitrite, and introduces the sewage treated in the aerobic tank into the anaerobic tank. Ammonia and nitrite are converted to nitrogen gas in an anaerobic pond using anammox bacteria. This program uses aerobic nitrifying bacteria to convert part of the ammonia into nitrite, and then uses anammox bacteria to convert the remaining ammonia and nitrite into nitrogen. Compared with the traditional treatment method, it can treat the same amount of sewage , the time for nitrification treatment in the aerobic tank is shorter and the amount of oxygen consumed is less, which can reduce the energy consumption of aeration, shorten the process time and reduce the construction and use cost of the aerobic tank. Using anammox bacteria to treat ammonia and nitrite at the same time can improve the ...

Embodiment 2

[0032] On the basis of the foregoing embodiments, in this embodiment, a highly efficient sewage denitrification process specifically includes the following steps:

[0033] Step S1: Cultivate nitrifying bacteria in the aerobic pool, introduce the sewage into the aerobic pool, use the nitrifying bacteria to convert part of the ammonia in the sewage into nitrite through nitrification, and the residence time of the sewage in the aerobic pool is 2~ 6d, so that the molar ratio of ammonia and nitrite in the sewage discharged from the aerobic tank is 1:1. In the present embodiment, described nitrifying bacteria adopts nitrous acid bacteria. The temperature in the aerobic pool is controlled at around 25°C. And the pH value in the aerobic pool is slightly alkaline, and the specific pH value is controlled between 7.5 and 8.0. In this way, the activity of nitrous bacteria can be improved, thereby improving the efficiency of nitrous bacteria for nitrification treatment and shortening the...

Embodiment 3

[0040] On the basis of above-mentioned embodiment, in the present embodiment, in described step S1, described aerobic tank carries out nitrification treatment under the condition of limiting oxygen. Under oxygen-limited conditions, ammonia can be converted into nitrite instead of nitrate. Nitrate may make the treated sewage acidic in the subsequent treatment and further treatment is required to make the environment of the anaerobic tank alkaline. The cost of treatment is increased, and the purification effect of anammox bacteria is reduced, thereby increasing the workload of subsequent treatment and production cost. In this embodiment, the content of other undescribed parts is the same as that of the above embodiment, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com