Frame sealing glue coating device

A technology of coating device and sealing glue, which is applied to the device for coating liquid on the surface, spraying device, liquid spraying device, etc., can solve the problem of poor uniformity of the thickness of the sealing glue, thick coating of the sealing glue, and long process time. and other problems, to avoid coating overlap, improve coating efficiency, and shorten process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to shorten the process time for coating the frame sealant, increase the coating efficiency, and improve the thickness uniformity of the frame sealant coating, an embodiment of the present invention provides a frame sealant coating device. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

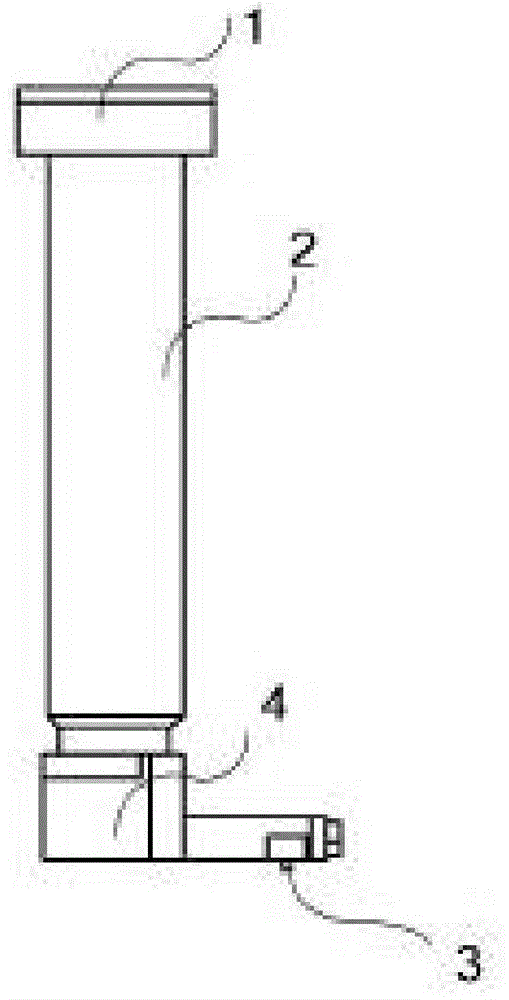

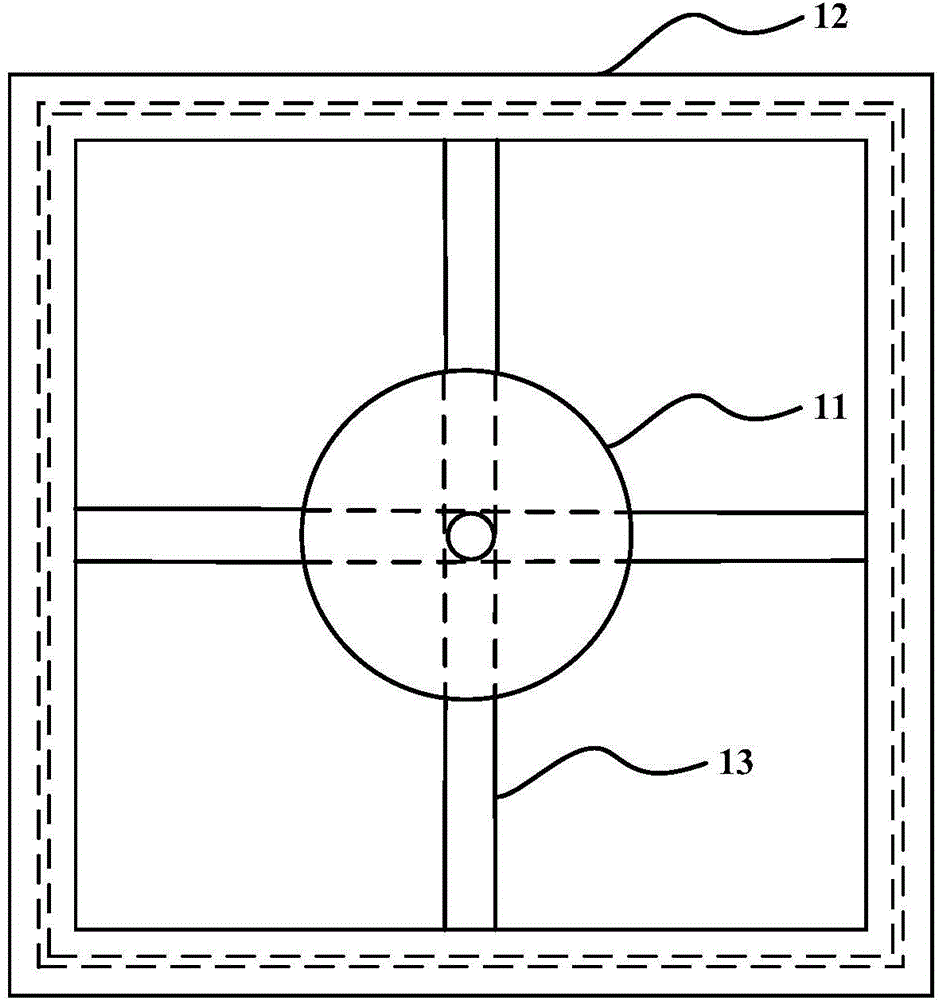

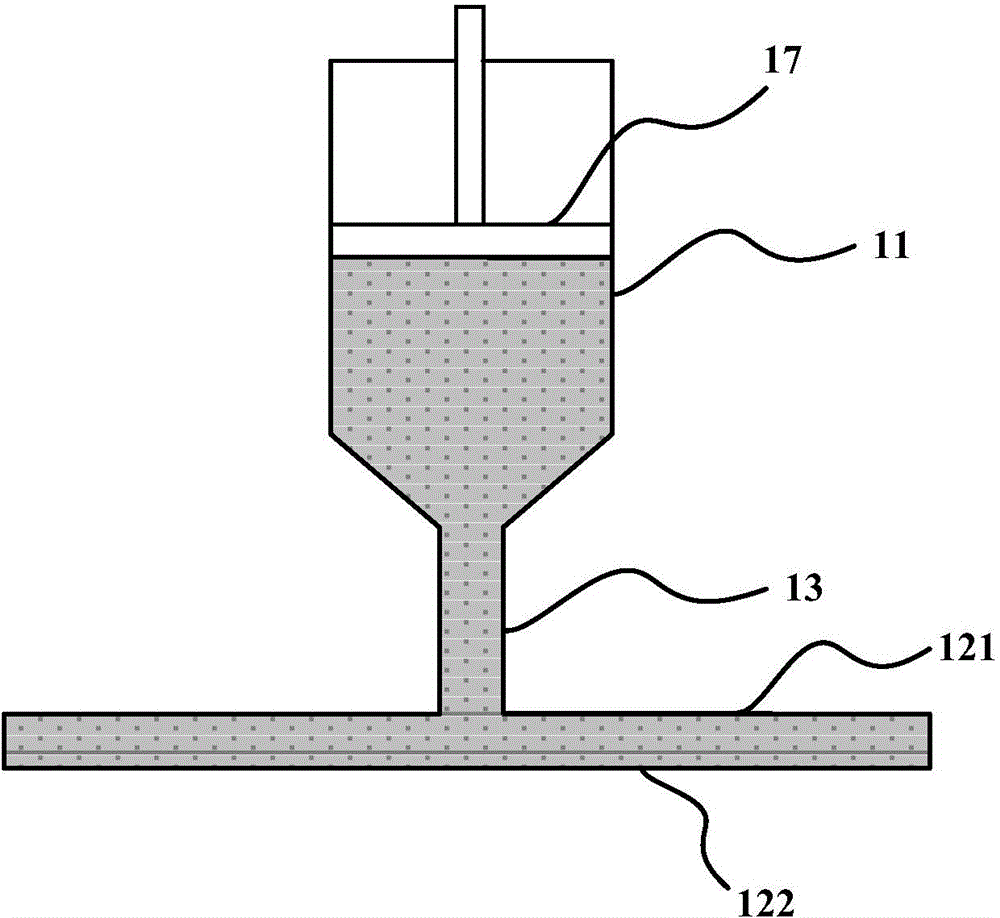

[0035] Such as figure 2 and image 3 As shown, the frame sealant coating device provided by an embodiment of the present invention includes a storage chamber 11, a nozzle 12, a connecting conduit 13 and a power pushing part, wherein:

[0036] The nozzle 12 includes a nozzle cavity 121 and a mouth 122. The mouth 122 is located below the nozzle cavity 121 and matches the shape of the sealant coating area of the substrate; the connecting conduit 13 communicates the storage cavity 11 with the nozzle cavity 121; The sealant in the storage chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com