Ammonia regeneration method and device for activated coke

A technology of active coke regeneration and regeneration device, which is applied in the field of flue gas purification, can solve the problems of high energy consumption and carbon ablation, and achieve the effects of reducing the degree of ablation, inhibiting the oxidation of surface oxygen, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

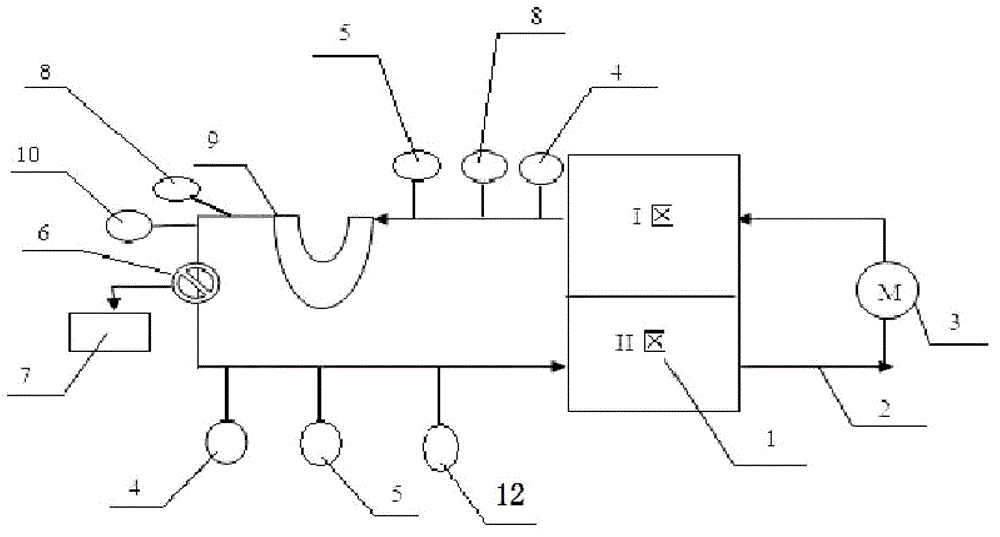

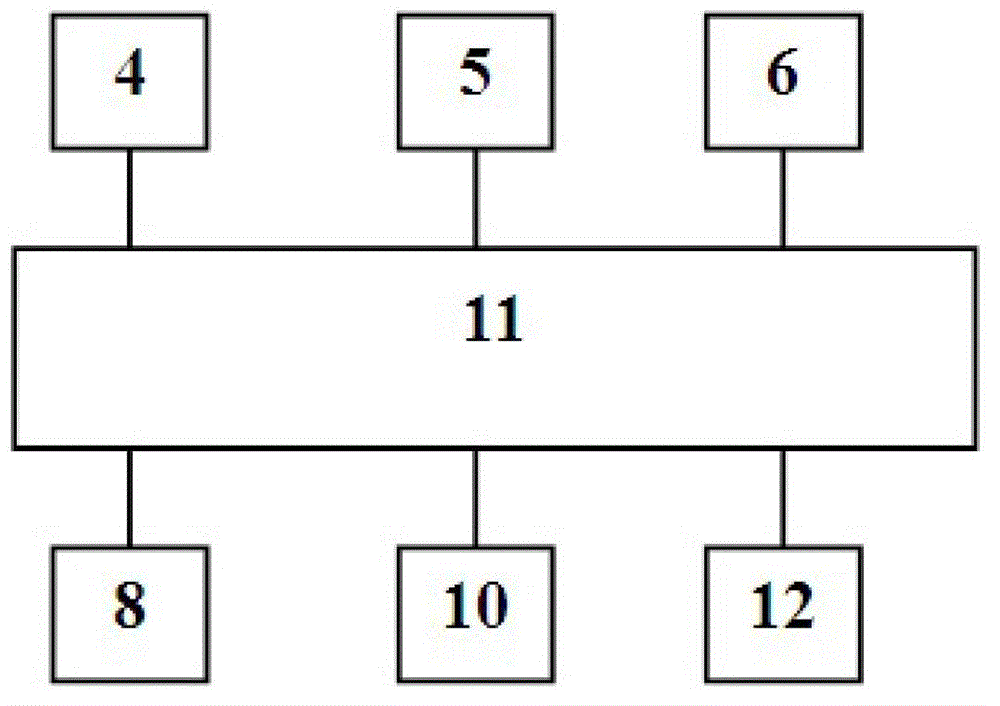

Method used

Image

Examples

Embodiment 1

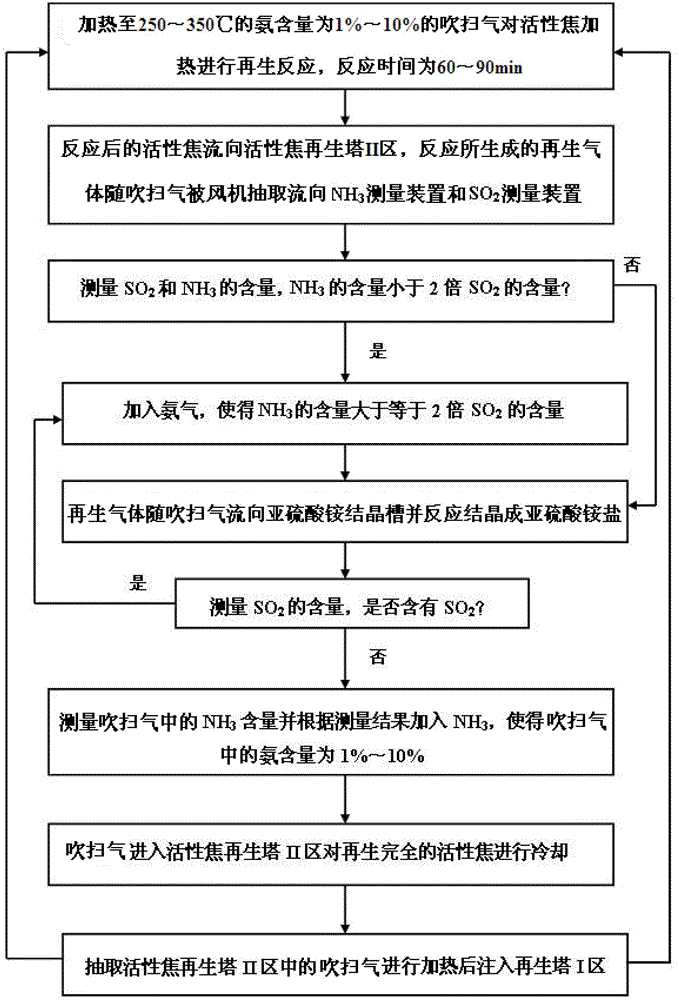

[0033] Embodiment 1 of the present invention: a kind of ammonia regeneration method of active coke, comprises the following steps:

[0034] S1, the purge gas with an ammonia content of 5% heated to 300°C heats the active coke for a regeneration reaction, and the reaction time is 80 minutes;

[0035] S2, the reacted active coke flows to the II area of the active coke regeneration tower, and the regeneration gas generated by the reaction is extracted and flows to the flue along with the purge gas;

[0036] S3, measuring NH in the purge gas 3 content and add NH according to the measurement results 3 , so that the ammonia content in the purge gas is 5%;

[0037] S4, the purge gas enters zone II of the active coke regeneration tower to cool the fully regenerated active coke;

[0038] S5, extracting the purge gas from Zone II of the active coke regeneration tower for heating and then injecting it into Zone I of the active coke regeneration tower, and turning to S1.

[0039] St...

Embodiment 2

[0049] Embodiment 2: a kind of ammonia regeneration method of active coke, comprises the following steps:

[0050] S1, the purge gas with an ammonia content of 10% heated to 350°C heats the active coke for a regeneration reaction, and the reaction time is 90 minutes;

[0051] S2, the reacted active coke flows to the II area of the active coke regeneration tower, and the regeneration gas generated by the reaction is extracted and flows to the flue along with the purge gas;

[0052] S3, measuring NH in the purge gas 3 content and add NH according to the measurement results 3 , so that the ammonia content in the purge gas is 10%;

[0053] S4, the purge gas enters zone II of the active coke regeneration tower to cool the fully regenerated active coke;

[0054] S5, extracting the purge gas from Zone II of the active coke regeneration tower for heating and then injecting it into Zone I of the active coke regeneration tower, and turning to S1.

[0055] Step S2 also includes: au...

Embodiment 3

[0058] Embodiment 3: a kind of ammonia regeneration method of active coke, comprises the following steps:

[0059] S1, the purge gas with an ammonia content of 5% heated to 300°C heats the active coke for a regeneration reaction, and the reaction time is 80 minutes;

[0060] S2, the reacted active coke flows to the II area of the active coke regeneration tower, and the regeneration gas generated by the reaction is extracted and flows to the flue along with the purge gas;

[0061] S3, measuring NH in the purge gas 3 content and add NH according to the measurement results 3 , so that the ammonia content in the purge gas is 5%;

[0062] S4, the purge gas enters zone II of the active coke regeneration tower to cool the fully regenerated active coke;

[0063] S5, extracting the purge gas from Zone II of the active coke regeneration tower for heating and then injecting it into Zone I of the active coke regeneration tower, and turning to S1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com