Preparation method of composite dehumidification adsorbent paper sheet prepared from MOF material and lithium chloride

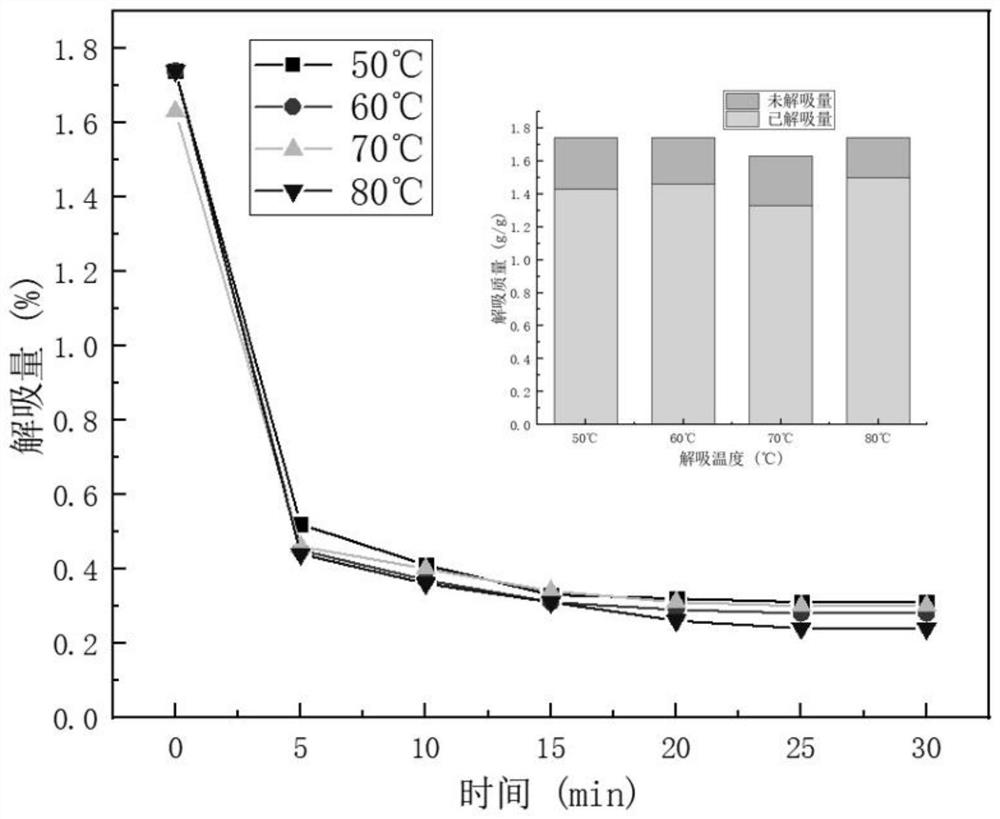

A lithium chloride and adsorbent technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of poor hygroscopic performance and high regeneration temperature, and achieve the effect of short regeneration time and low regeneration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

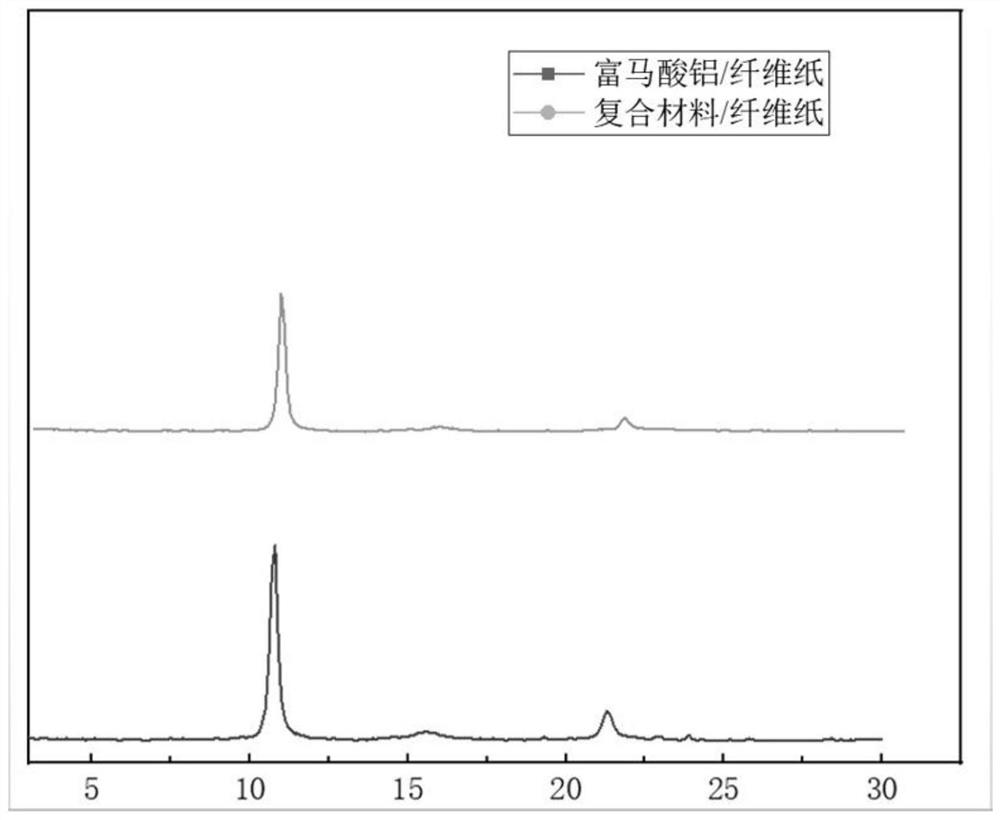

[0044](1) Turn on the constant temperature water bath and keep it stable at 70°C. Weigh 698.8g of aluminum sulfate octadecahydrate and dissolve it in 2.4L of water, stir it in a constant temperature water bath for 30min until it is completely dissolved, and record it as solution A; weigh 244g of fumaric acid and 253.2g of sodium hydroxide and dissolve it in 3.6L of water, stir 15 minutes to complete dissolution, recorded as solution B; drop solution B into solution A, and stir for 3 hours. The above solution was left to stand, centrifuged, and washed with water three times. Dry at 80°C for 10 hours to obtain the crude product, and activate at 100°C for 6 hours to obtain aluminum fumarate powder. Using this ratio can prepare 400g of aluminum fumarate once.

[0045] (2) Cut the glass fiber paper into a square of 10×10mm, weigh a certain amount of aluminum fumarate powder and dissolve it in water, add a certain volume of silica sol solution to it, and stir magnetically for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com