Method for preparing lithium chloride silica gel composite turning wheels

A technology of lithium chloride and silica gel, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high viscosity of silicate aqueous solution, good dehumidification performance, poor adhesion of silicic acid, etc., and achieve increased adhesion Effects of adhesion strength, improved moisture absorption capacity, and low regeneration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

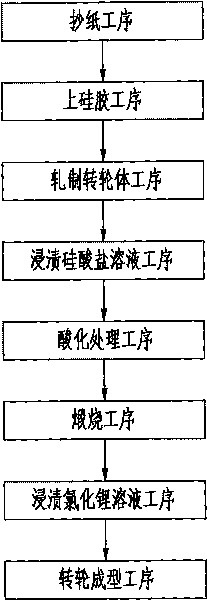

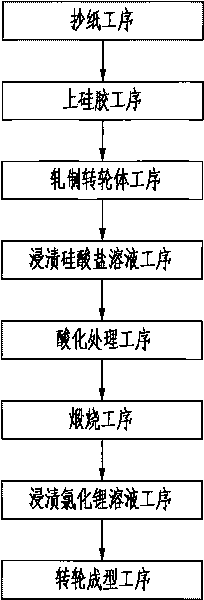

[0023] see figure 1 , the preparation method of the lithium chloride silica gel composite runner in this embodiment consists of the papermaking process, the silica gel upper process, the rolling runner body process, the immersion silicate solution process, the acidification treatment process, the calcination process, and the lithium chloride impregnation process. It consists of a solution process and a runner forming process.

[0024] In the papermaking process of this embodiment, ceramic fibers and organic fibers are used as raw materials to make fibrous base paper, wherein the amount of organic fibers is less, and the papermaking process in the present invention is a prior art. In the silica gel process of this embodiment, use the slurry that contains silicic acid, polyvinyl alcohol, modified polyacrylonitrile, vinyl chloride and water to coat on the surface of the fiber base paper, and the slurry coating amount on the fiber base paper surface is 70g / m 2 , not only can bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com