Method for producing sodium hydrogen sulfate and/or hydrate thereof by utilizing side product waste acid residue generated in production of chromic anhydride through sulfuric acid method

A technology of sodium bisulfate and chromic anhydride, which is applied in the field of producing sodium bisulfate and/or its hydrate, and can solve the problems of unfavorable production of high-quality basic chromium sulfate tanning agent, high sodium sulfate content, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

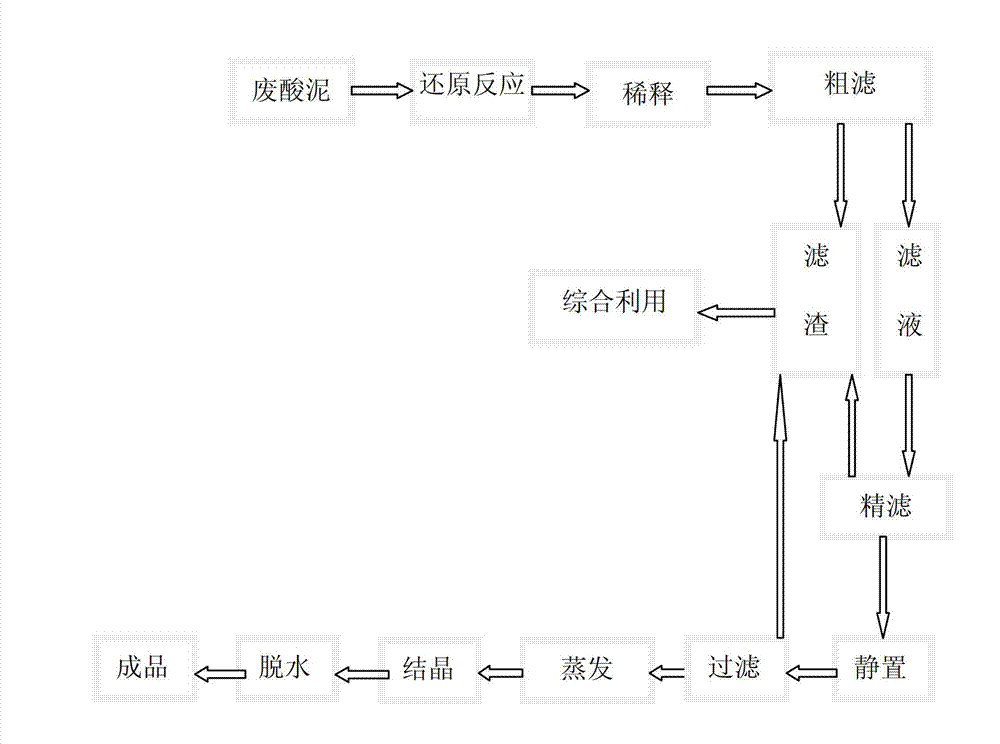

Method used

Image

Examples

Embodiment 1

[0068]Get sulfuric acid method to prepare 500kg of chromium-containing molten waste acid mud of chromic anhydride by-product, add yuanming powder 25kg wherein, record afterwards that hydrogen ion / sulfate ion mol ratio is 1:1 in the mixture gained, and wherein hexavalent chromium is with Na 2 Cr 2 o 7 .2H 2 O content is 1.5wt%. The mixture was warmed to 450 °C and then maintained at this temperature for 120 min. Add condensed water to dilute afterwards, be mixed with the concentration that is 25 DEG B , add sodium sulfate 11.25kg as precipitating agent afterward, stir 80min, precipitation occurs in the feed liquid. The obtained feed liquid was first coarsely filtered twice, and then finely filtered once, and the filtrate obtained by the fine filtration was left to stand for 8hr, and it was found that sedimentation occurred in the filtrate, and the sediment was filtered out. The filtrate obtained by filtering out the sediment is evaporated and concentrated to 55 ° of B é in...

Embodiment 2

[0071] Get sulfuric acid method to prepare 500kg of chromium-containing molten waste acid mud of chromic anhydride by-product, add yuanming powder 25kg wherein, record afterwards that hydrogen ion / sulfate ion mol ratio is 1:1 in the mixture gained, and wherein hexavalent chromium is with Na 2 Cr 2 o 7 .2H 2 O content is 1.5wt%. The mixture was warmed to 190 °C and then maintained at this temperature for 220 min. Add condensed water to dilute afterwards, be mixed with the concentration that is 25 DEG B , add sodium sulfate 11.25kg as precipitating agent afterward, stir 80min, precipitation occurs in the feed liquid. The obtained feed liquid was first coarsely filtered twice, and then finely filtered once, and the filtrate obtained by the fine filtration was left to stand for 8hr, and it was found that sedimentation occurred in the filtrate, and the sediment was filtered out. The filtrate obtained by filtering out the sediment is evaporated and concentrated to 55 ° of B é i...

Embodiment 3

[0074] Get 1000kg of chromium-containing molten waste acid sludge prepared by sulfuric acid method as a by-product of chromic anhydride, add concentrated sulfuric acid 10kg thereto, and record the hydrogen ion / sulfate ion mol ratio in the resulting mixture afterwards as 1:1, and wherein the hexavalent chromium is replaced by Na 2 Cr 2 o 7 .2H 2 O meter content is 3.5wt%, adds the sodium thiosulfate 2.4kg as reducing agent, obtains mixture. The resulting mixture was warmed to 550 °C and then maintained at this temperature for 80 min. Afterwards, add condensed water to dilute to prepare a concentration of 45°Bé, then add 52.5kg of sodium sulfate as a precipitating agent, stir for 90min, and precipitation occurs in the feed liquid. The obtained feed liquid was first coarsely filtered twice, and then finely filtered once, and the filtrate obtained by the fine filtration was left to stand for 8hr, and it was found that sedimentation occurred in the filtrate, and the sediment was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com