Duplex stainless steel wire material for arc additives and duplex stainless steel member

A technology of duplex stainless steel and wire materials, which can be used in the direction of additive processing, additive manufacturing, process efficiency improvement, etc., and can solve the problem of high austenite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

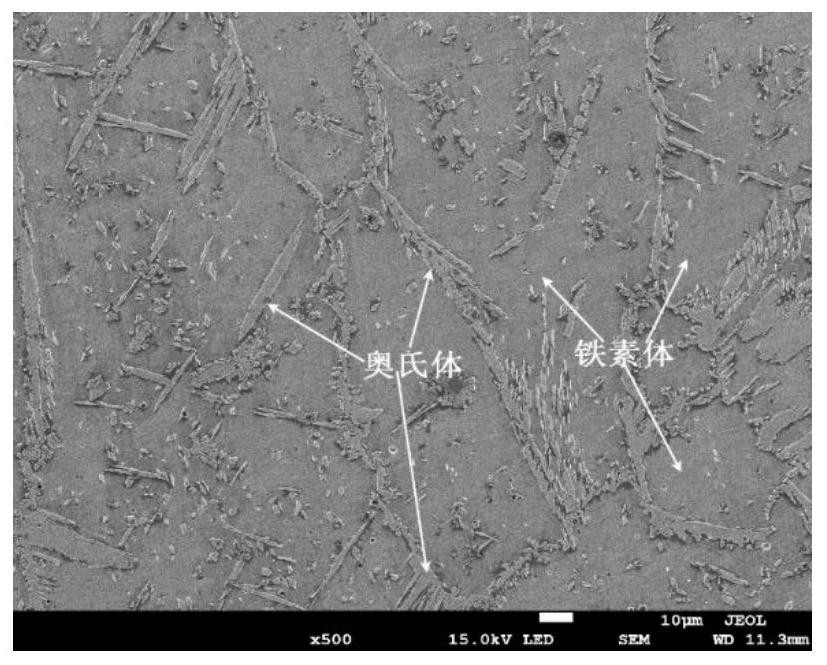

Embodiment 1

[0029] An arc of this embodiment by using duplex stainless steel wire material, a steel core and a metal powder composition, wherein the mass of metal powder core per total mass of wire (i.e. fill rate) of 25%.

[0030] Steel is 304L stainless steel, the cross-sectional dimensions of 0.4 * 10mm, a mass fraction of its chemical composition is: 18.16% chromium, 0.00% molybdenum, 8.16% Ni, 0.21% Si, 1.51% Mn, 0.05% nitrogen, and balance iron.

[0031] Additive arc embodiment of the present embodiment was prepared as follows using duplex stainless steel wire:

[0032] (1) the mass fraction of 90.00% chromium metal powder, nickel metal powder mass fraction of 0.00%, 10.00% iron powder content ratio by weighing the powder mixed for 10 minutes to obtain a mixed metal powder; Example embodiments are used in the metal powder Shanghai Jiuding Co powder material is metal powder, powder particle size of 80 mesh;

[0033] (2) A 304L stainless steel strip after the ultrasonic cleaning equipment...

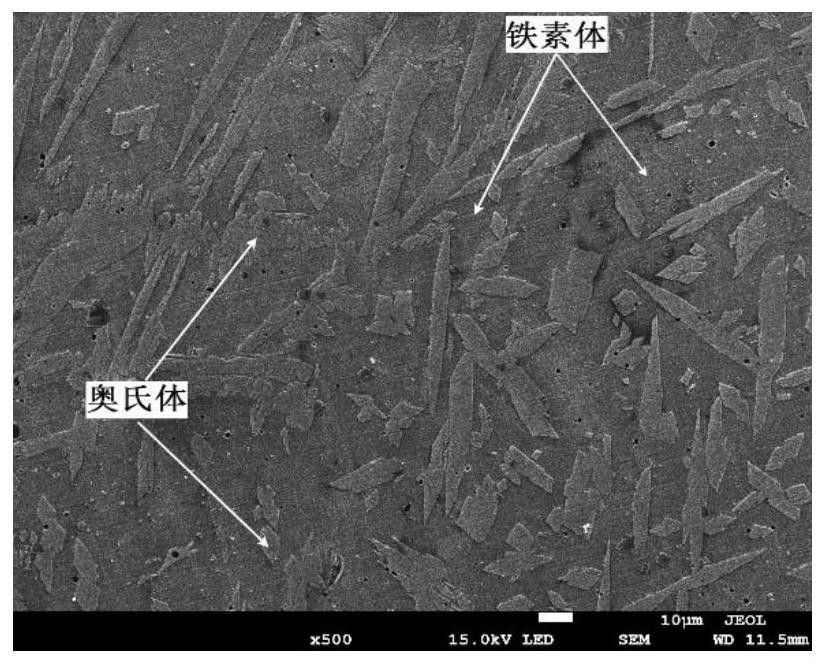

Embodiment 2

[0041] An arc of this embodiment by using duplex stainless steel wire material, a steel core and a metal powder composition, wherein the mass of metal powder core per total mass of wire (i.e. fill rate) of 25%.

[0042] Steel is 304L stainless steel, the cross-sectional dimensions of 0.4 * 10mm, a mass fraction of its chemical composition is: 18.16% chromium, 0.00% molybdenum, 8.16% Ni, 0.21% Si, 1.51% Mn, 0.05% nitrogen, and balance iron.

[0043] Additive arc embodiment of the present embodiment was prepared as follows using duplex stainless steel wire:

[0044] (1) the mass fraction of 55.00% chromium metal powder, nickel metal powder mass fraction of 5.50%, 39.50% iron powder content ratio by weighing the powder mixed for 10 minutes to obtain a mixed metal powder; metal powders embodiment are used Shanghai Jiuding Co powder material is metal powder, powder particle size of 80 mesh;

[0045] (2) A 304L stainless steel strip after the ultrasonic cleaning equipment, with a conventi...

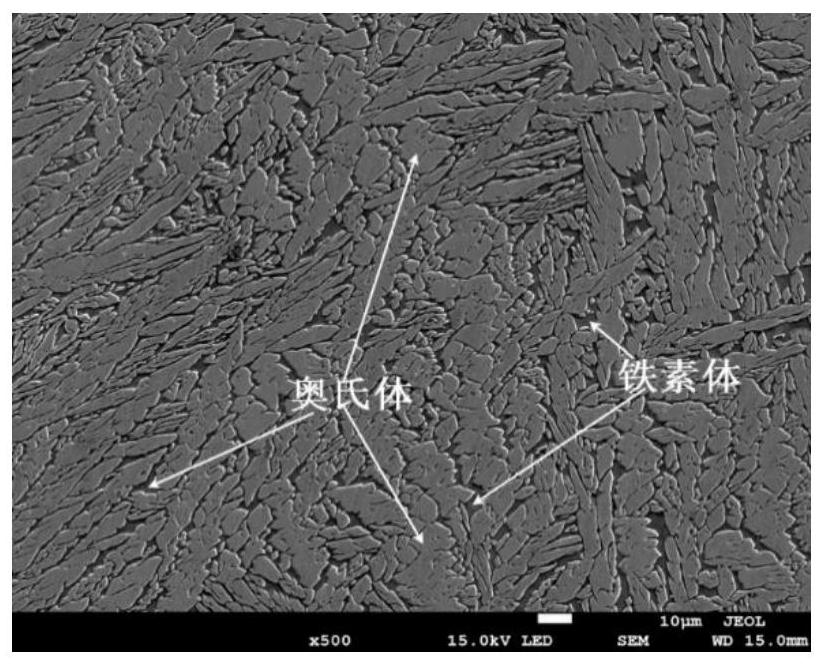

Embodiment 3

[0051] An arc of this embodiment by using duplex stainless steel wire material, a steel core and a metal powder composition, wherein the mass of metal powder core per total mass of wire (i.e. fill rate) of 20%.

[0052] Steel is 304L stainless steel, the cross-sectional dimensions of 0.4 * 10mm, a mass fraction of its chemical composition is: 18.16% chromium, 0.00% molybdenum, 8.16% Ni, 0.21% Si, 1.51% Mn, 0.05% nitrogen, and balance iron.

[0053] Additive arc embodiment of the present embodiment was prepared as follows using duplex stainless steel wire:

[0054] (1) the mass fraction of 90% chromium metal powder, nickel metal powder content of 0%, metal iron content of 10% by the proportion of mixed powder weighed 10 minutes to obtain a mixed metal powder; Example embodiments are used in the metal powder Shanghai Jiuding Co powder material is metal powder, powder particle size of 80 mesh;

[0055] (2) A 304L stainless steel strip after the ultrasonic cleaning equipment, with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com