Process for treating industrial waste water containing chromium, vanadium

A technology for industrial wastewater and trivalent chromium, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of high treatment cost, poor treatment effect, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

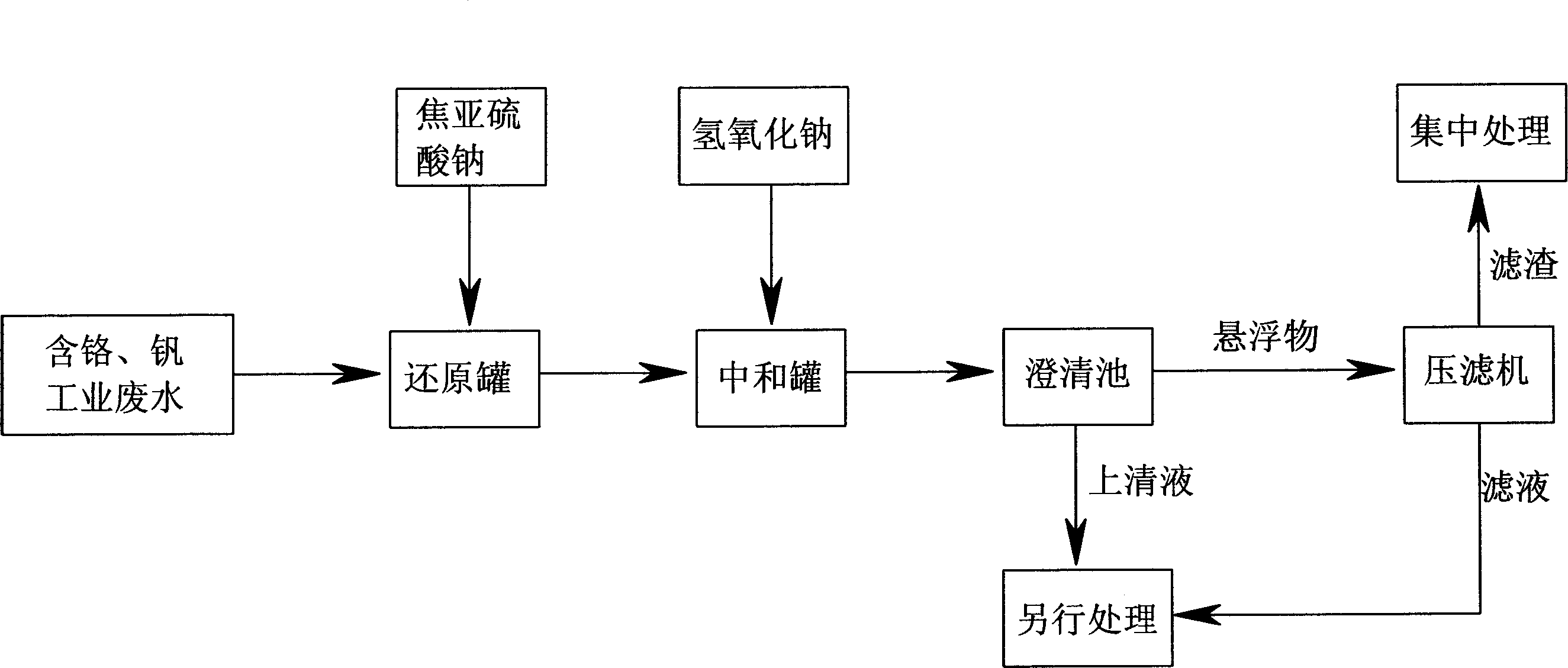

Image

Examples

Embodiment 1

[0011] Embodiment 1: the method for processing containing chromium, vanadium industrial waste water is: (1), preparation sodium pyrosulfite solution is standby, and the concentration of sodium pyrosulfite solution is 38~42%, and its pH value is 4.2; (2), contains chromium, The vanadium industrial waste water is placed in the reduction tank and treated according to Cr 6+ with Na 2 S 2 o 5 The molar ratio is 4:3~3.5, and the above-mentioned sodium metabisulfite solution is metered to reduce the hexavalent chromium in the chromium-containing and vanadium-containing industrial wastewater to trivalent chromium; (3), and then put the wastewater described in (2) into the and tank, and metered sodium hydroxide solution to make the V in chromium and vanadium-containing industrial wastewater 2 o 2 4+ React with sodium hydroxide to form Na 2 V 4 o 9 4H 2 O, where V 4 o 9 2- It reacts with trivalent chromium to form Cr 2 (V 4 o 9 ) 3 Precipitation, the remaining trivalent ...

Embodiment 2

[0012] Embodiment 2: the method for processing containing chromium, vanadium industrial waste water is: (1), preparation sodium pyrosulfite solution is standby, and the concentration of sodium pyrosulfite solution is 40~42%, and its pH value is 4.5; (2), contains chromium, The vanadium industrial waste water is placed in the reduction tank and treated according to Cr 6+ with Na 2 S 2 o 5 Molar ratio is 4: 3.2~3.4 ratio metering adds above-mentioned sodium pyrosulfite solution, the hexavalent chromium in the chromium-containing, vanadium industrial waste water is reduced to trivalent chromium; (3), put the waste water described in (2) into and tank, and metered sodium hydroxide solution to make the V in chromium and vanadium-containing industrial wastewater 2 o 2 4+ React with sodium hydroxide to form Na 2 V 4 o 9 4H 2 O, where V 4 o 9 2- It reacts with trivalent chromium to form Cr 2 (V 4 o 9 ) 3 Precipitation, the rest of the trivalent chromium completely form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com