Patents

Literature

408results about How to "Sufficient precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacture method of electroconductive aluminum alloy section

The invention discloses a manufacture method of an electroconductive aluminum alloy section. The manufacture method comprises the following steps: cast ingot component control, fusion casting, extruding, quenching and aging heat treatment; in the step of quenching, the water entry temperature of the section is 520-530 DEG C, the cooling rate is 180-350 DEG C / min; and in the step of aging heat treatment, the heat-insulation temperature of the section is 160-180 DEG C and the heat-insulation time is 10-16 hours. The aluminum alloy section manufactured by the manufacture method disclosed by the invention has tensile strength of more than 245 MPa, electrical conductivity of more than 55%IACS (International Annealed Copper Standard), and hardness of more than 80HB.

Owner:SNTO TECH GRP

Steel plate and method thereof used for producing water heater linear enamel by flexible thin slab rolling line

ActiveCN102181805AStable recoveryExcellent anti-scale explosion performanceRoll mill control devicesMetal rolling arrangementsThin slabManganese

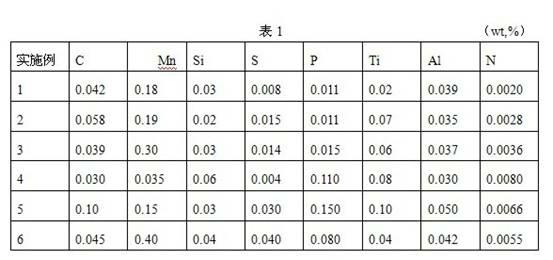

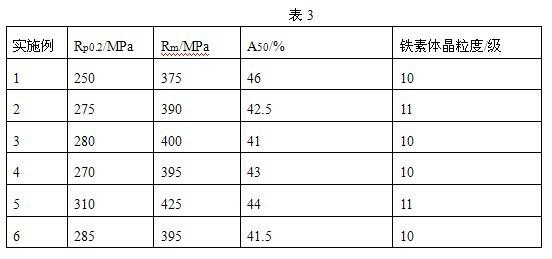

The invention relates to a steel plate and a process method thereof used for producing water heater linear enamel by a flexible thin slab rolling line (FTSR), belonging to the production field of enamel steel plates. The steel plate comprises the following chemical components in percentage by weight: 0.03-0.10wt% of carbon, 0.15-0.40wt% of manganese, less than or equal to 0.06wt% of silicon, 0.004-0.040wt% of sulphur, less than or equal to 0.15wt% of phosphorus, 0.03-0.05wt% of aluminum, 0.002-0.008wt% of nitrogen, 0.02-0.10wt% of titanium and the balance of ferrum and inevitable impurities. The tissue of the water heater linear enamel contains fine grain ferrite and a small quantity of pearlite tissues, and the granularity level of the water heater linear enamel is more than or equal to 10 levels. According to reasonable ingredient design and the FTSR process, steel for manufacturing water-storage water heater linear enamel for home appliances is produced; the steel plate has good enamel adhesion and scaling resistance, and also has the characteristics of few added alloy elements, few production working procedures, low production cost and the like; and a hot rolling scouring plate is used for replacing a cold rolling annealing plate.

Owner:HEBEI IRON AND STEEL

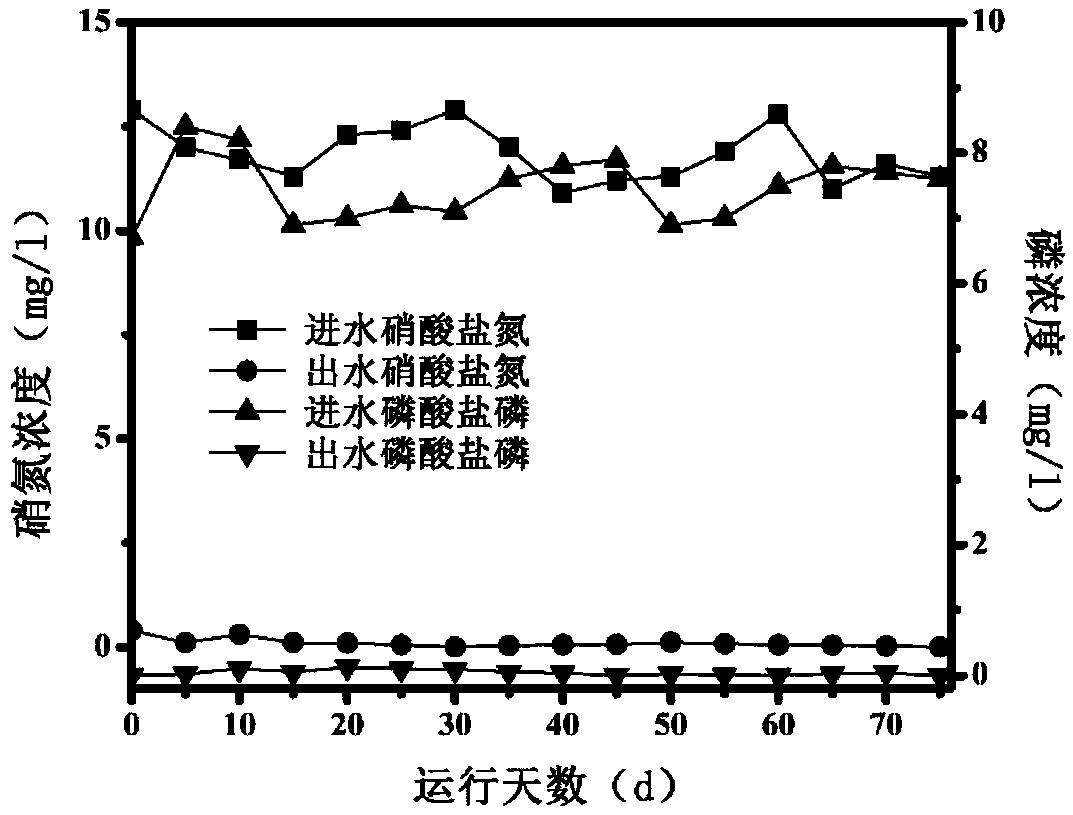

Coupling filler autotrophic denitrification biofilter and application

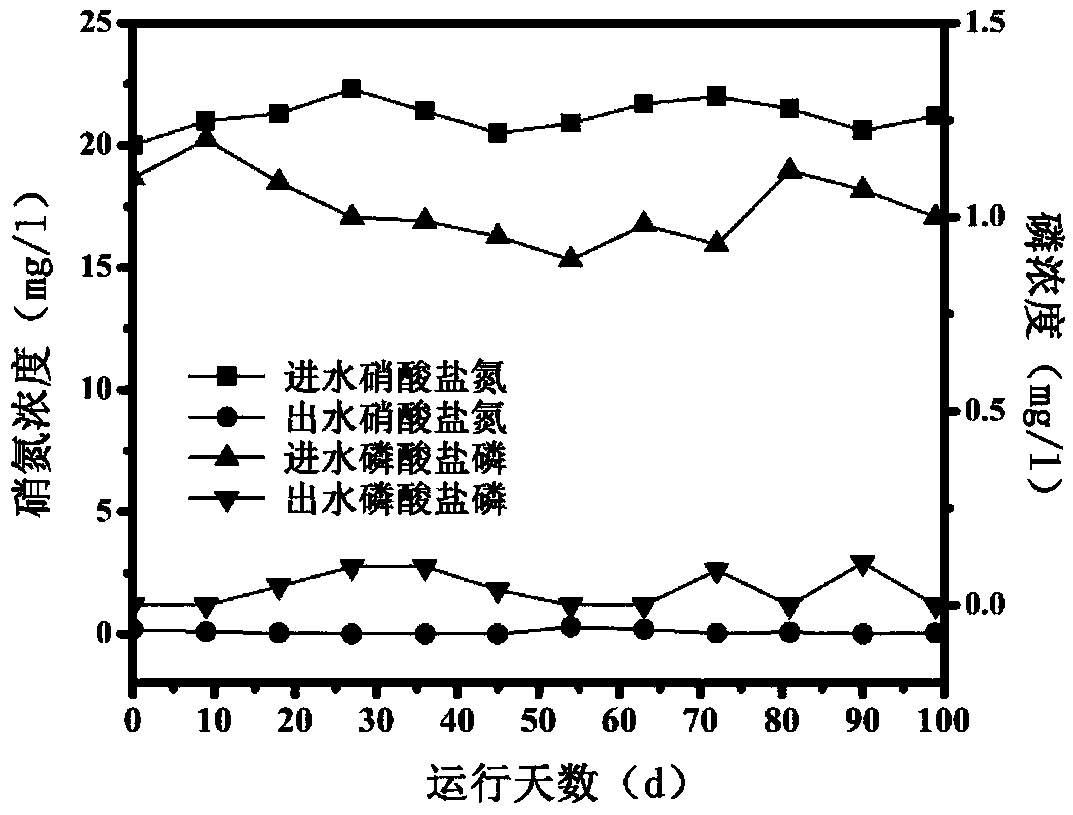

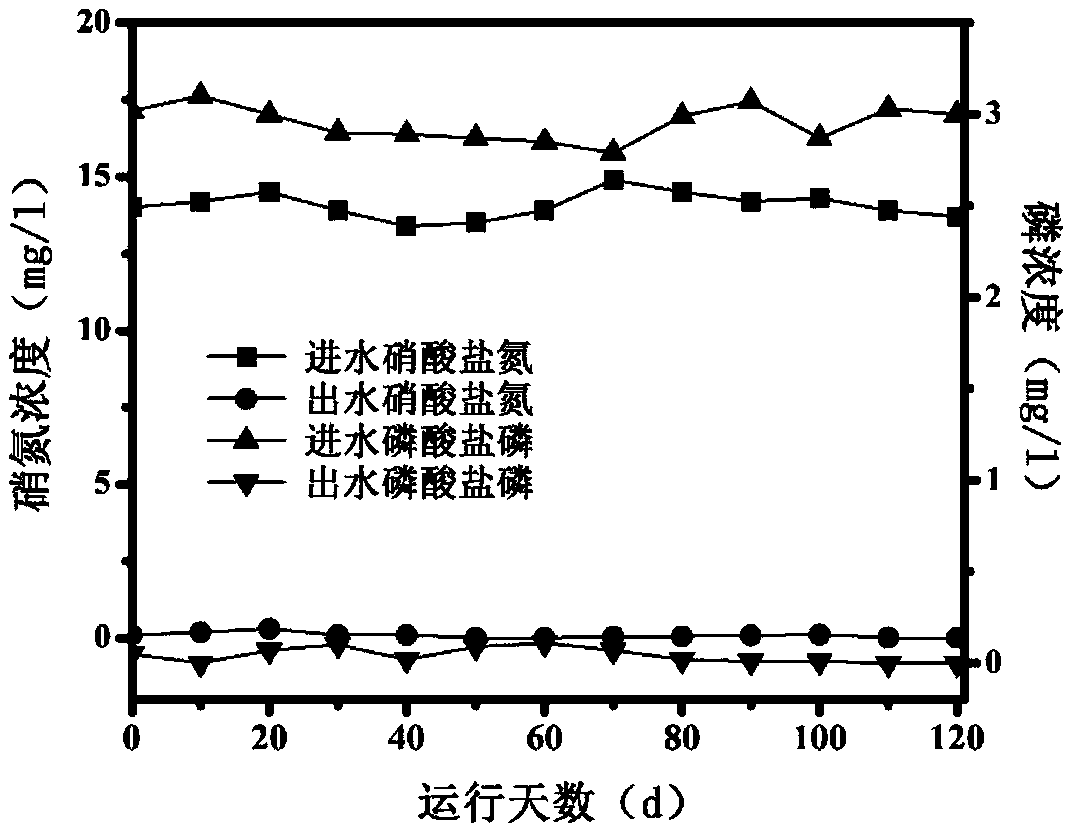

ActiveCN109052641ADifficult to dissolveIncrease speedWater treatment compoundsTreatment with anaerobic digestion processesBiofilmSewage

The invention discloses a coupling filler autotrophic denitrification biofilter and application and belongs to the technical field of sewage treatment. Pyrrhotite, sulfur and a carbon source are utilized to be mixed and coupled according to certain proportion; then the materials are put into a reactor, and the autotrophic denitrification biofilter can be formed after inoculating biofilm formation;sewage flows through the biofilter, and nitrogen and phosphorus in the water are removed. The biofilter disclosed by the invention has the advantages of simpleness, easiness, practicability and shortbiofilm formation time; when the biofilter is utilized to treat nitrogen and phosphorus containing sewage, hydraulic retention time is only 0.5 to 3 h, and yielding water can meet a requirement; furthermore, the biofilter has the advantages of excellent nitrogen and phosphorus removal effect, low cost and suitability for engineering application.

Owner:NANJING UNIV

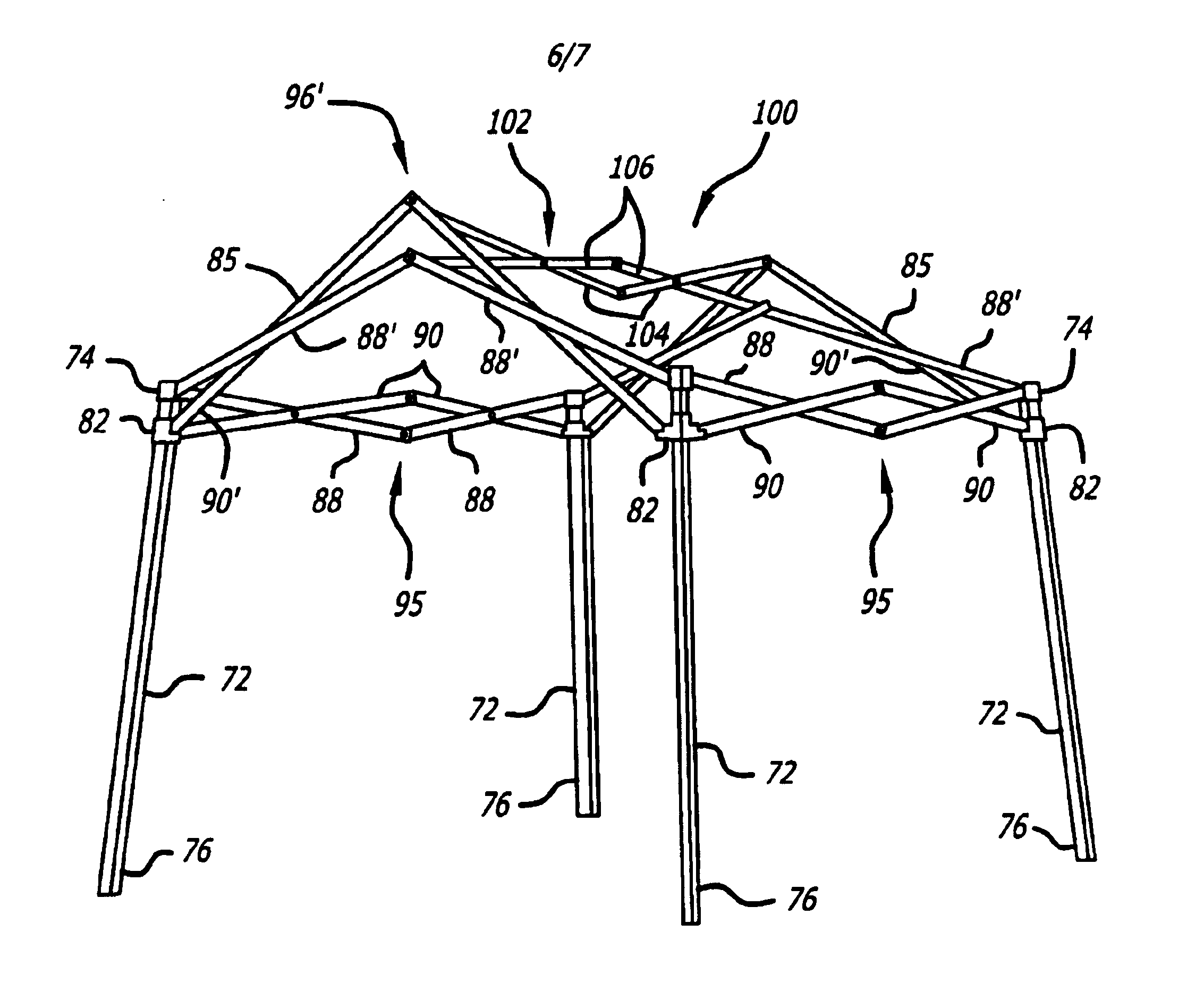

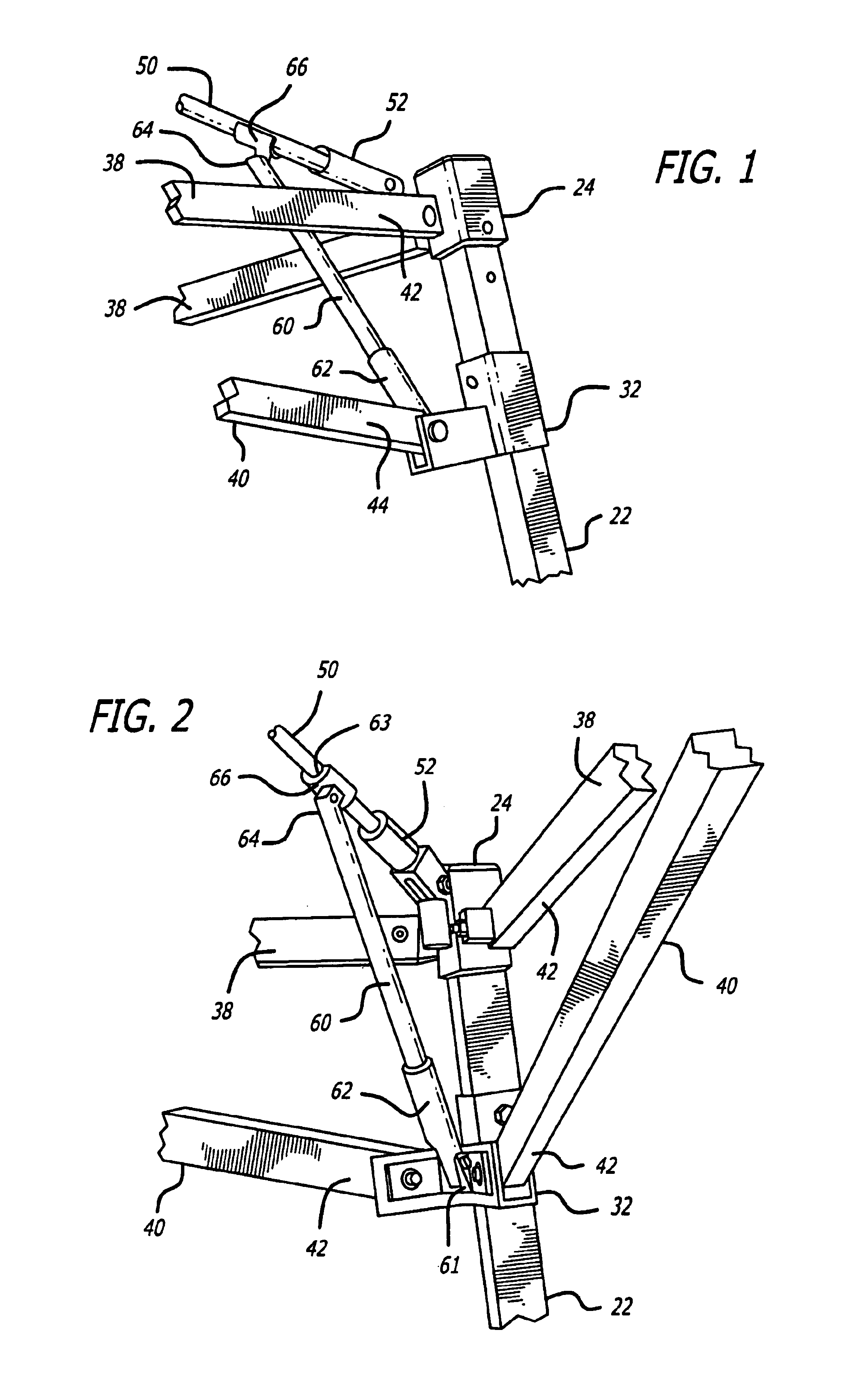

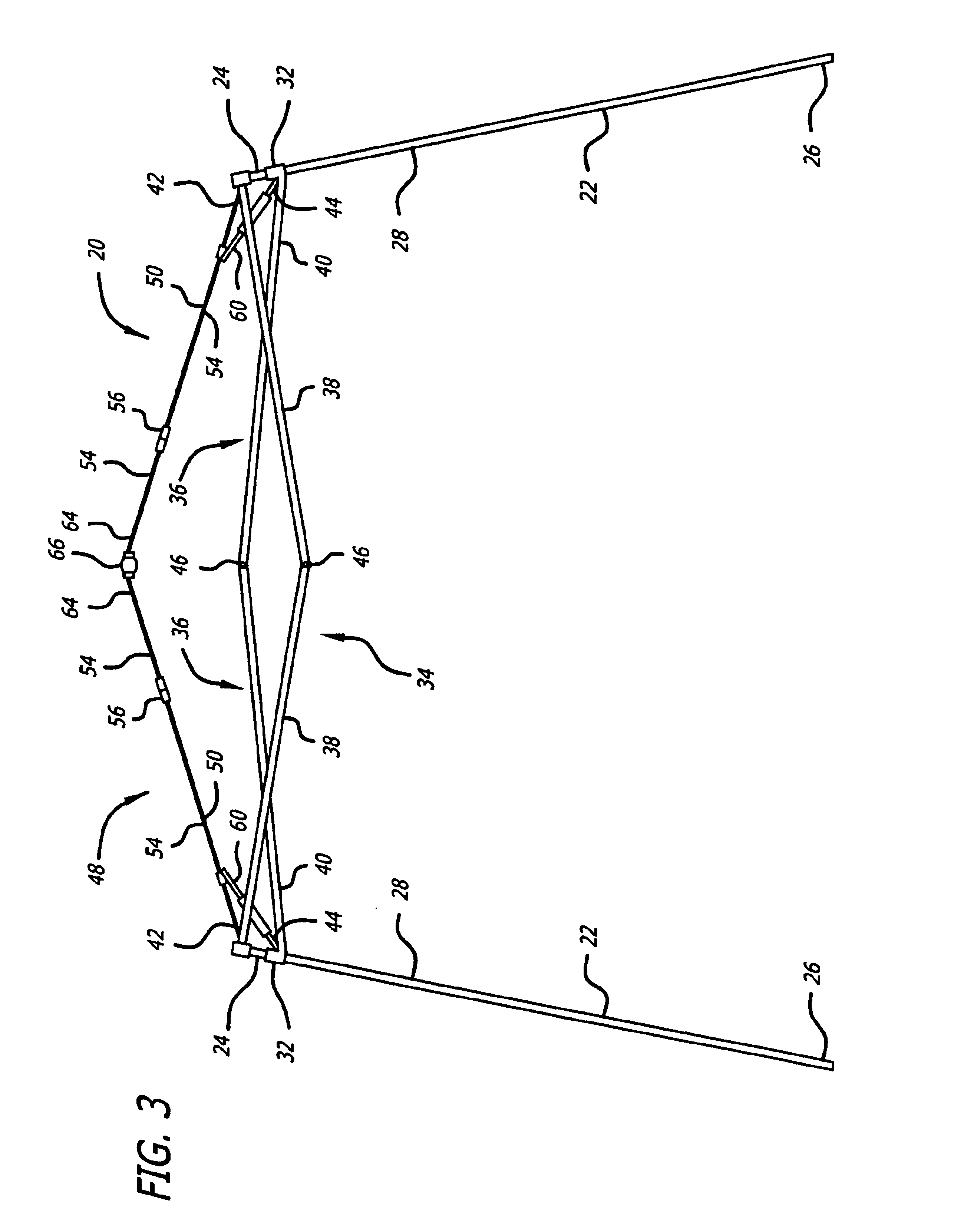

Erectable canopy with reinforced roof structure

InactiveUS6926021B2Sufficient headroomSufficient precipitationTents/canopiesTowersEngineeringMechanical engineering

The lightweight erectable canopy shelters include a plurality of legs connected together by an extendible perimeter assembly of link members. In one embodiment, the roof structure is formed by a pole members pivotally mounted to the upper ends of the legs so as to extend across the shelter, and movable between a lowered position and a raised, upwardly arching position. The pole members are pivotally coupled to a central hub, and each of the pole members comprises pole sections hinged to permit downward folding and upward unfolding until they are fully extended. Corner support strut members are pivotally mounted to the legs, to be rotatable upwardly to engage and support the pole members. In an alternate embodiment, opposing sides of the shelter are connected together by a central assembly of link members, and at least one of the sides of the shelter is raised, being formed by a pair of first and second link members dimensioned so as to extend above the upper ends of the legs when the shelter is in an extended configuration.

Owner:INT E Z UP INC

700MPa grade composite strengthening bainite steel and method for preparing same

InactiveCN101285156AEasy to useReduce alloy costMetal rolling arrangementsChemical compositionThin slab

The invention discloses a 700MPa compound strengthening bainitic steel and a method for making the same. The compound strengthening bainitic steel is manufactured by adopting thin slab continuous casting and rolling process, wherein, the main chemical compositions in percentage by weight of the refined molten steel are: 0.03 to 0.07 percent of C , 1.51 to 2.10 percent of Mn, 0.50 to 0.80 percent of Cr, 0.10 to 0.15 percent of Ti, less than or equal to 0.30 percent of Si, less than or equal to 0.020 percent of P, less than or equal to 0.010 percent of S, the balance being Fe and inevitable residual elements. The invention realizes that the yield strength of the prior 345MPa hot-rolled sheet doubles and opens a new way to produce 700MPa high-strength steel by saving expensive alloying elements like Mo, Ni and so on. At the same time, the steel structure mainly comprises fine bainites, which improves the work hardening capacity of the high-strength steel and has a good forming property.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Method for extracting kaempferol

InactiveCN101845467AHigh extraction rateProtect unstable structuresOrganic chemistryFermentationAcetic acidEthyl ester

The invention relates to a method for preparing kaempferol. The method comprises the following technical steps of: crushing raw materials, and extracting alkaline solution; performing enzymolysis after acid adjustment, and extracting enzymolysis liquid by using ethyl acetate; and performing concentration under reduced pressure on the extract liquor, and recrystallizing by using methanol to obtain the product. The method for producing the kaempferol has the advantages of simple process, high utilization ratio of raw materials, and high purity.

Owner:苏州北商智业管理咨询有限公司

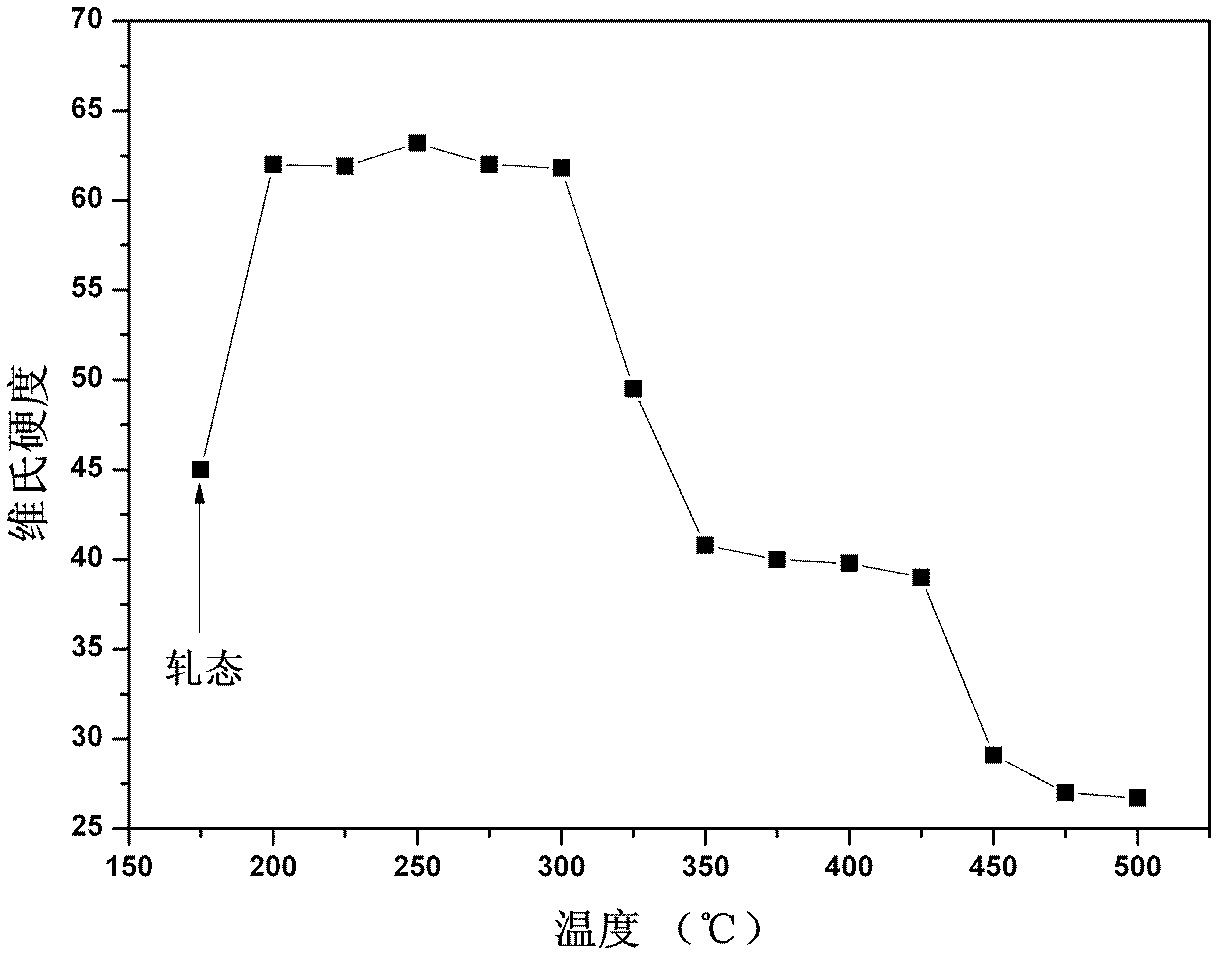

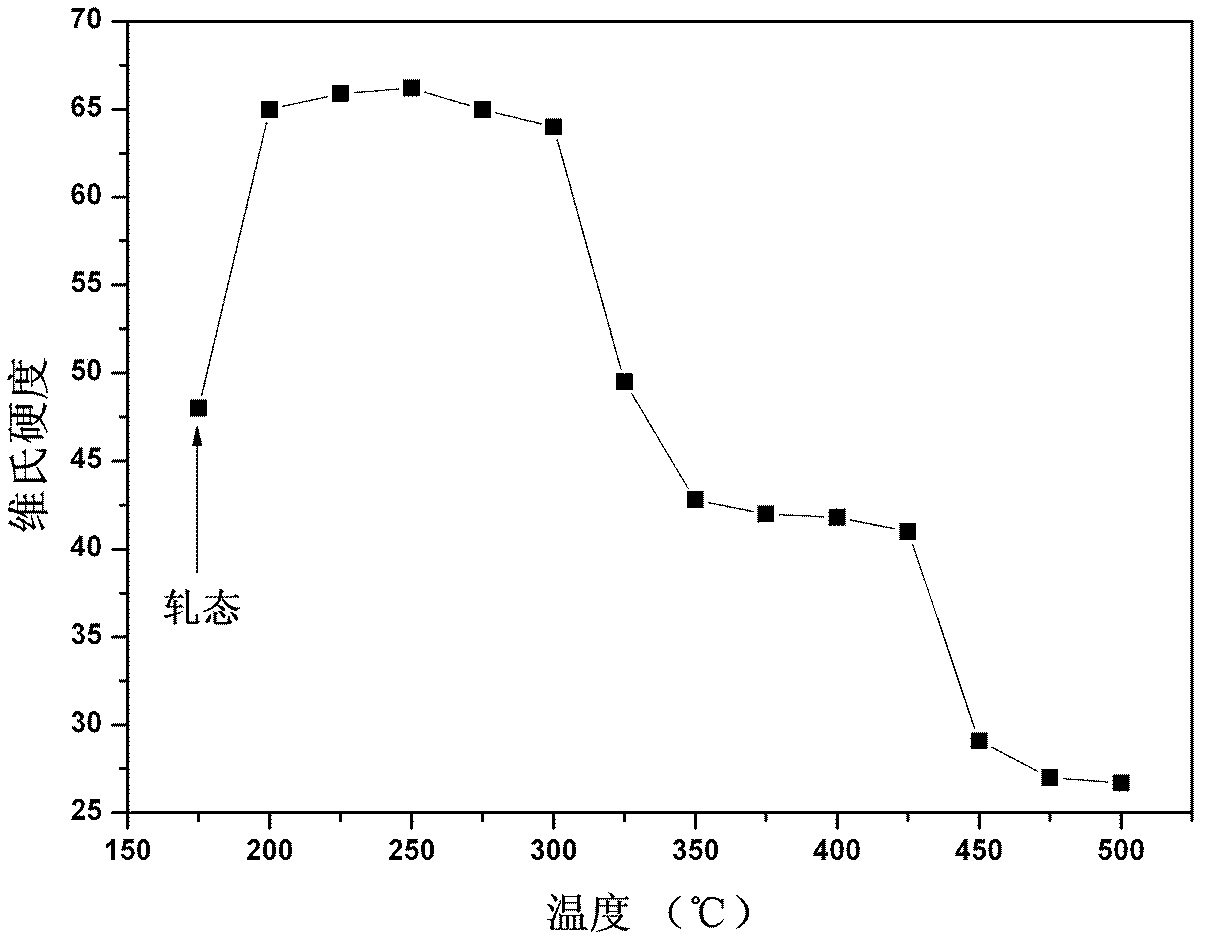

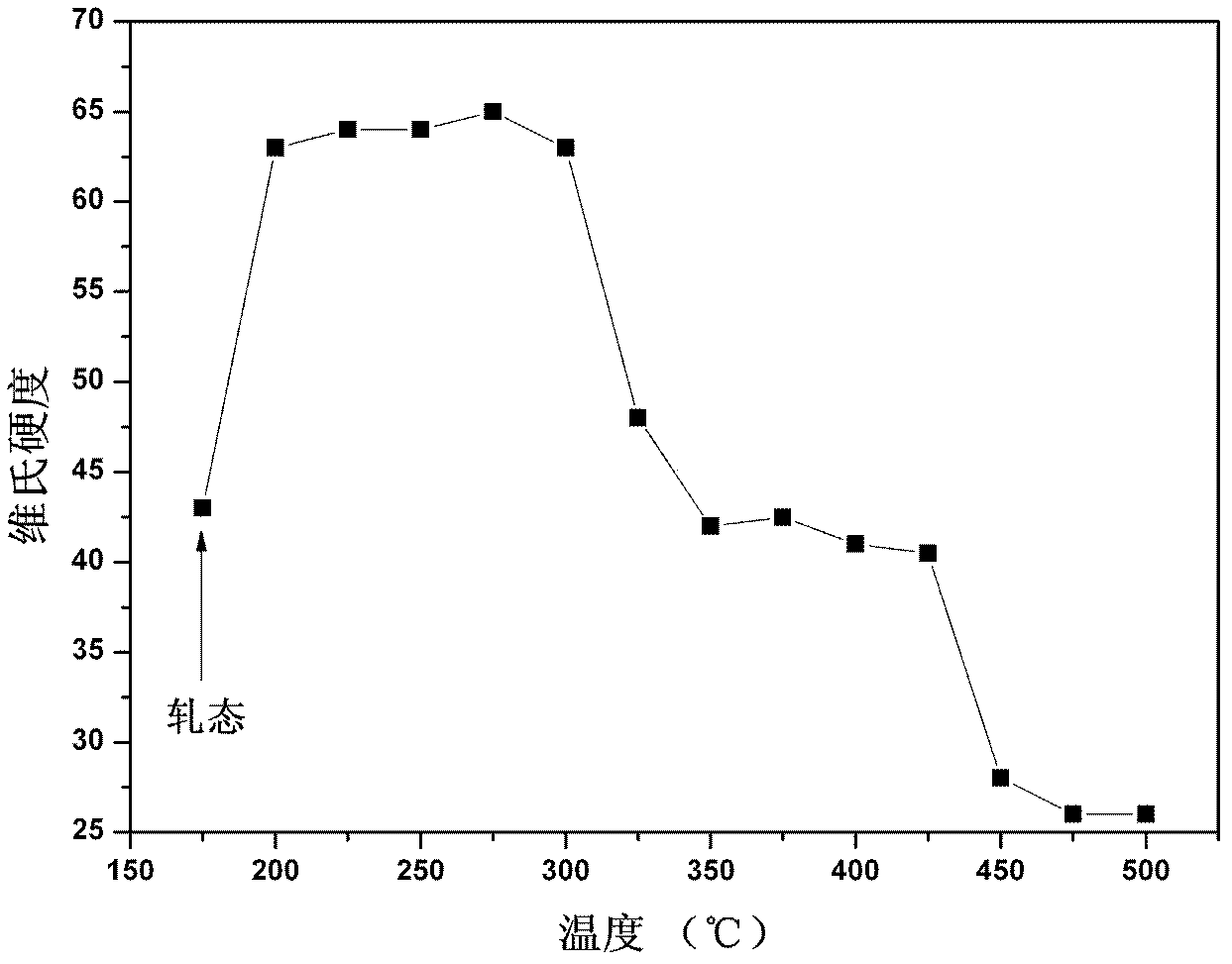

High-strength, high-conductivity and heat-resistant aluminum alloy conductor material and preparation method thereof

InactiveCN102534318AImprove conductivitySufficient precipitationMetal/alloy conductorsHeat resistanceIngot

The invention relates to a high-strength, high-conductivity and heat-resistant aluminum alloy conductor material and a preparation method thereof, and belongs to the technical field of alloy materials. The conductor material comprises the following components in percentage by weight: 0.2 to 0.3 percent of Zr, 0.15 to 0.25 percent of Er, less than 0.3 percent of impurities and the balance of aluminum. The preparation method comprises the following steps of: adding an AlEr intermediate alloy and an AlZr intermediate alloy in the process of smelting the aluminum, smelting at the temperature of 780+ / -10 DEG C, preserving heat for 30 minutes, and casting; and performing homogenization treatment, rolling and heat treatment on an ingot in turn. Er and Zr in the component ratio are compositely microalloyed, a large number of precipitated phases which are distributed in a dispersed mode can be precipitated by the process, a large number of deformation structures can be stored, and the high conductivity (59.6 to 60 percent international annealed copper standard IACS), high strength (Vickers hardness 62.5 to 66.5) and heat resistance (capability of resisting the temperature of 375 DEG C in a short term and resisting the temperature of 225 DEG C in a long term) of the alloy are kept simultaneously.

Owner:BEIJING UNIV OF TECH

Preparation method for gill tissue paraffin section

InactiveCN103940648AImprove the effect of dipping waxFull penetrationPreparing sample for investigationAntigenIn situ hybridisation

The invention discloses a preparation method for a gill tissue paraffin section. The preparation method comprises the following steps: fixing, decalcifying, dehydrating, transparentizing, carrying out paraffin permeation, embedding, slicing, sticking sections, expanding the sections, de-waxing and rehydrating, staining, re-staining, sealing and the like. Compared with an existing paraffin section manufacturing method, an operation process of dehydrating, transparentizing and immersing by wax is improved; the preparation fixing and tissue wax immersing effects of gill tissue paraffin are improved; a slicing problem when the gill tissue paraffin section is prepared is improved; the structure definition of the gill tissue section is greatly improved; a plurality of problems in a gill tissue manufacturing process in the prior art are solved. The preparation method is good for antigen positioning of immunocytochemical staining, so that when experiments including in-situ hybridization, immunohistochemistry, immunofluorescence and the like are carried out on the gill tissue paraffin section, tissue distribution and cell positioning of some genes and proteins can be displayed, and further feasible conditions are provided for carrying out gill research on levels of cells, genes and proteins.

Owner:SHANXI AGRI UNIV

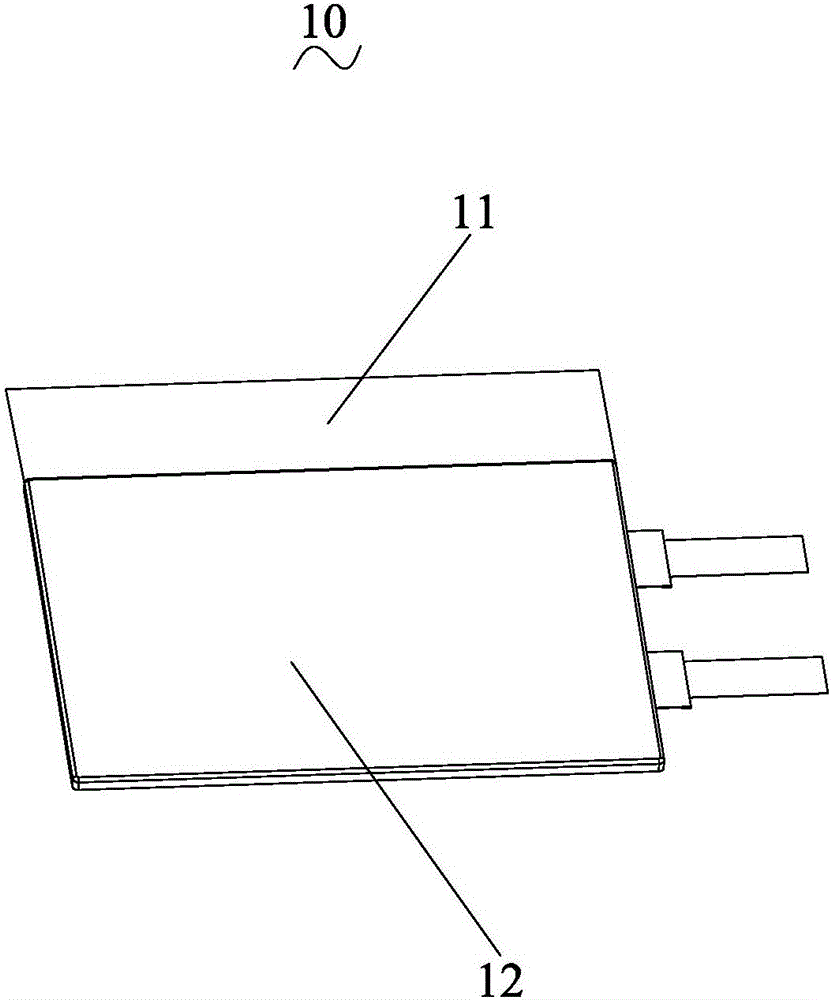

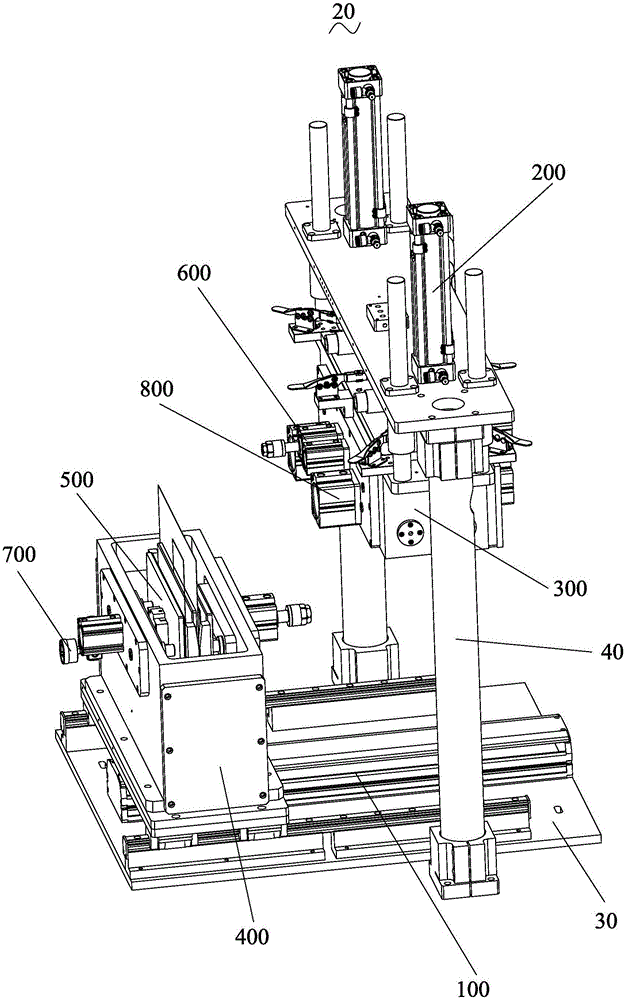

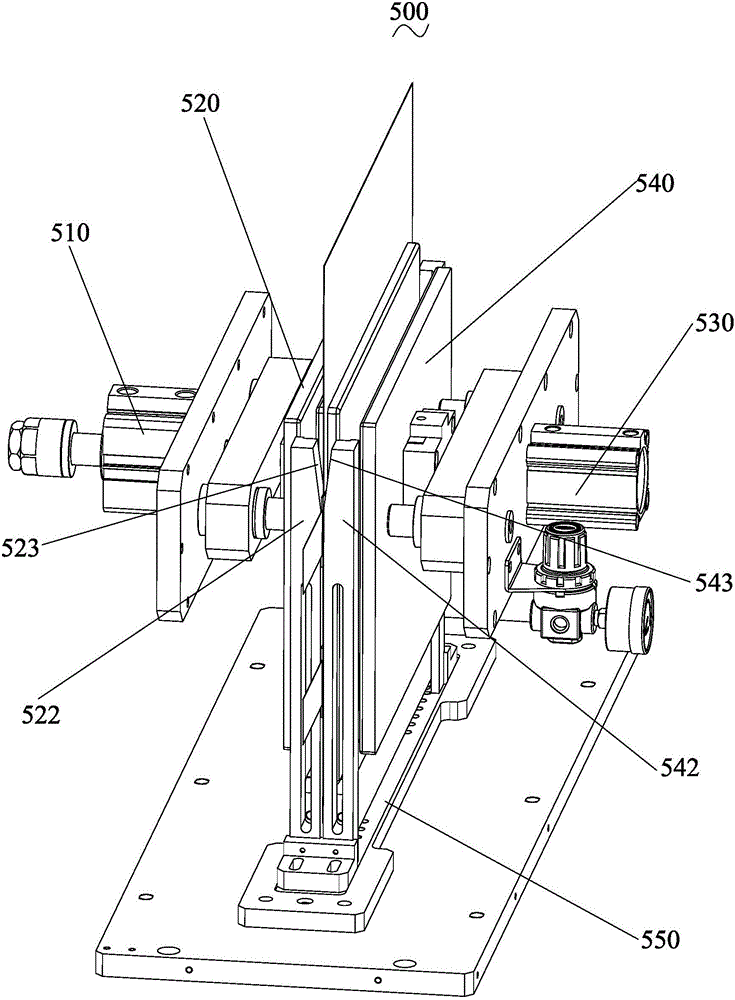

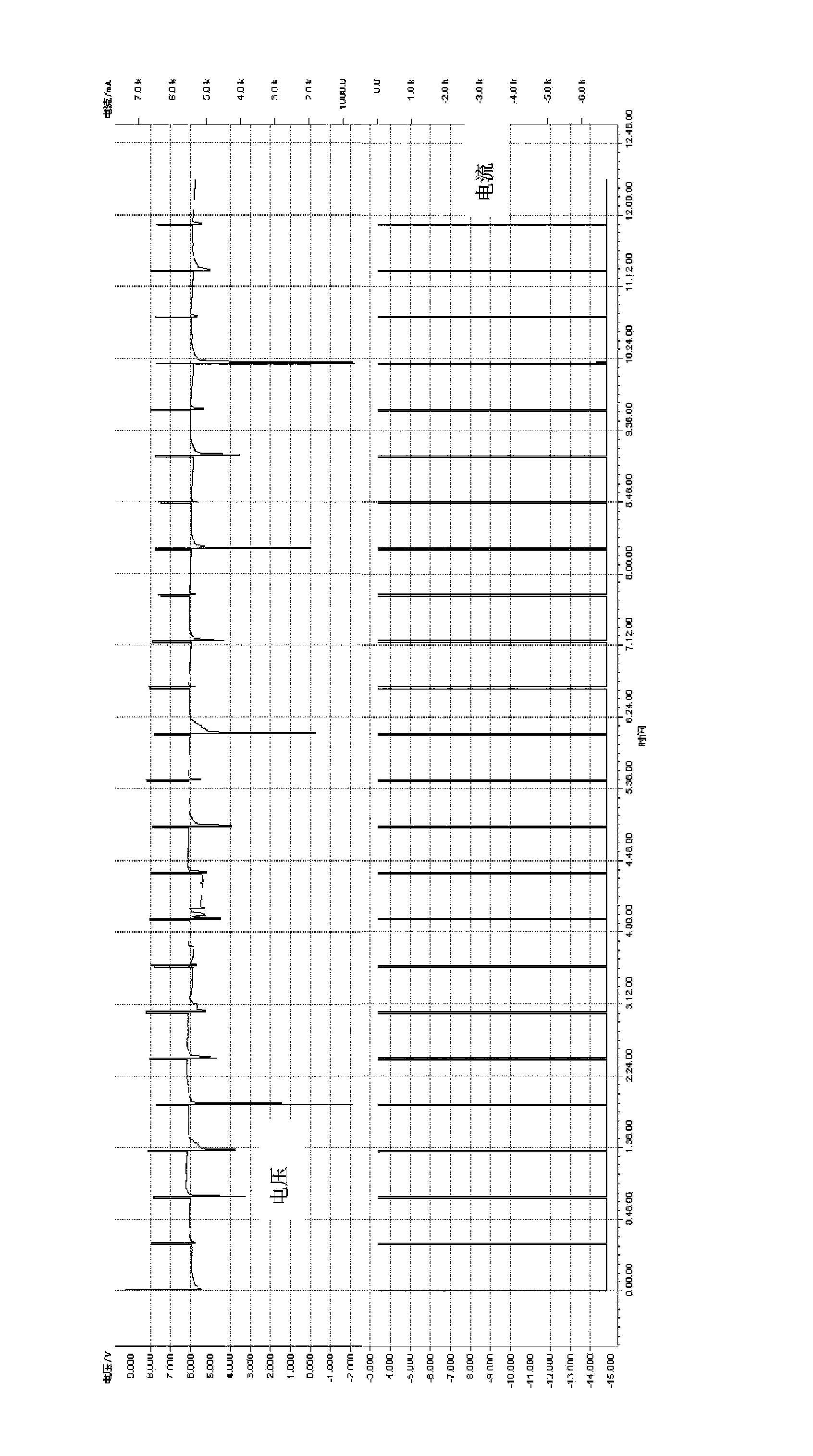

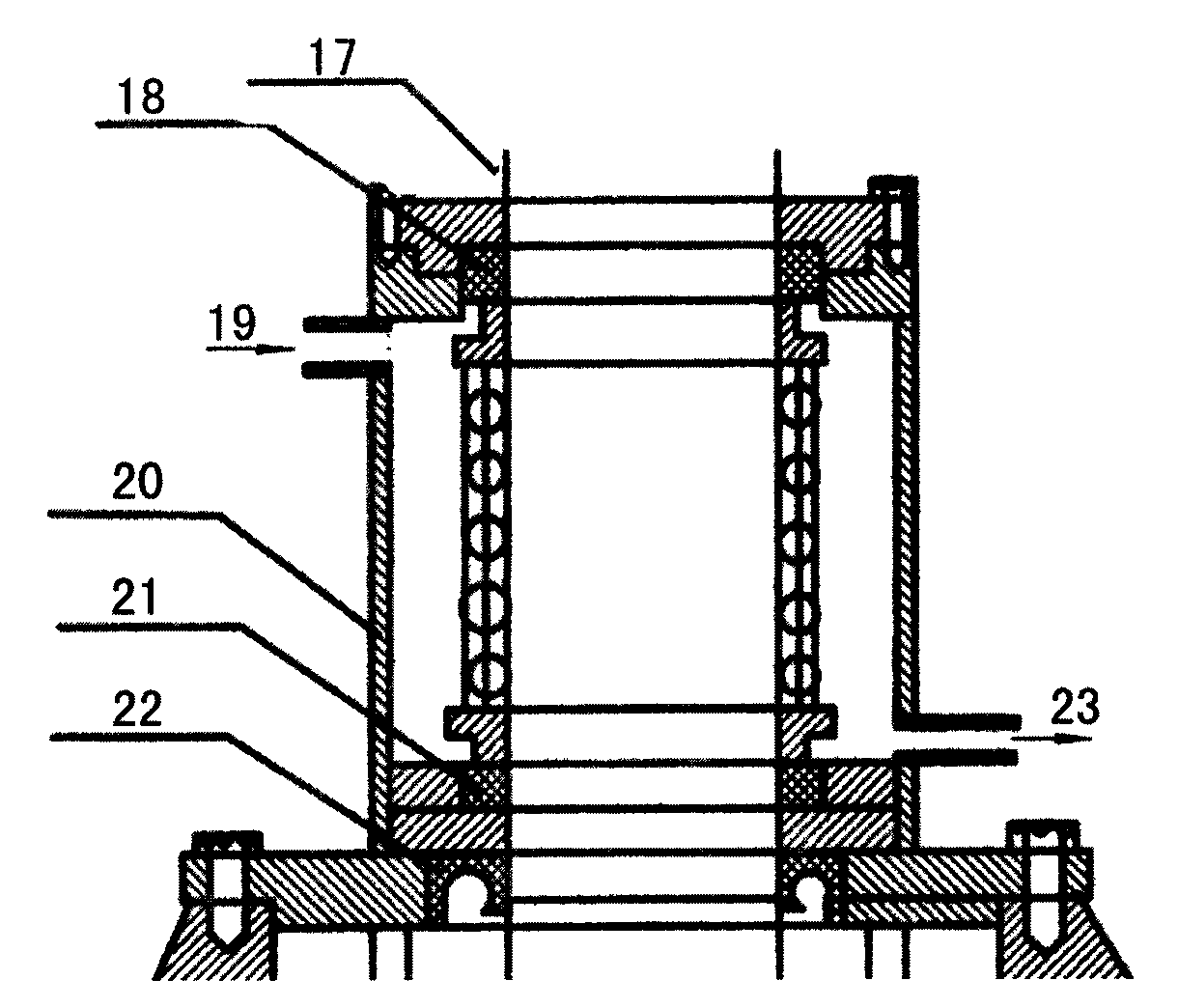

Vertical type air exhaust packaging device for soft package battery

ActiveCN106602122AQuality improvementAvoid spillingPrimary cell manufactureAssembling battery machinesMoving partsPlastic film

The invention discloses a vertical type air exhaust packaging device for a soft package battery. The vertical type air exhaust packaging device comprises a substrate, a support frame arranged on the substrate, a horizontal reciprocating moving part arranged on the substrate, a vertical reciprocating lifting part arranged on the support frame, an upper cavity, a lower cavity, a battery fixed flapping part, a battery puncturing part, a vacuum pumping part and a packaging part. The horizontal reciprocating moving part is used for driving the lower cavity to perform a reciprocating motion along the horizontal direction, the vertical reciprocating lifting part is used for driving the upper cavity to perform reciprocating lifting along the vertical direction, the battery fixed flapping part and the vacuum pumping part are mounted on the lower cavity, and the battery puncturing part and the packaging part are mounted on the upper cavity. According to the vertical type air exhaust packaging device for the soft package battery disclosed by the invention, the large soft package battery in a vertical condition is packaged through air pumping, an electrolyte inside an aluminum plastic film is prevented from being separated out to cause a leakage accident, and meanwhile air inside the aluminum plastic film is pumped more sufficiently, so that the quality of the product is improved.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

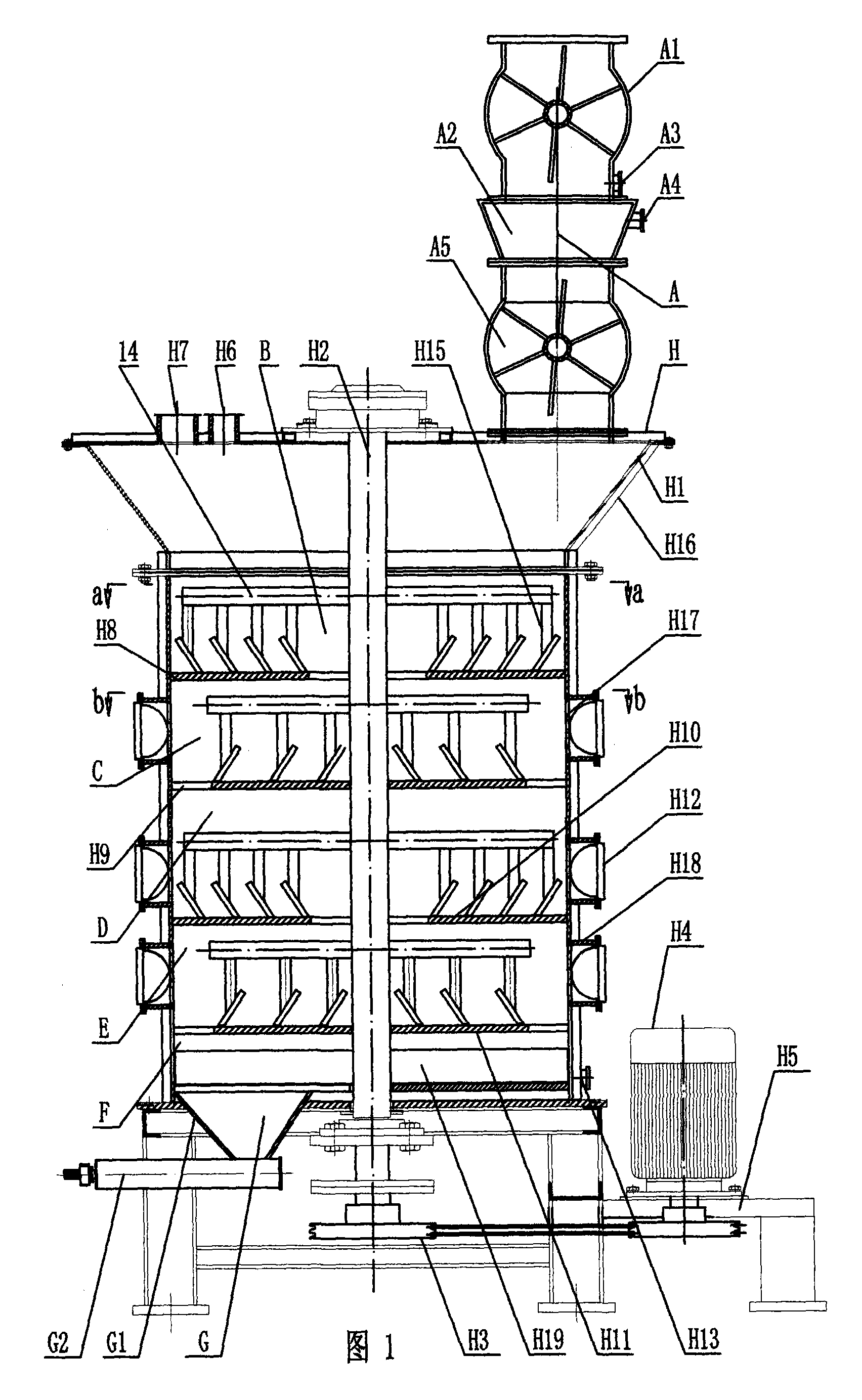

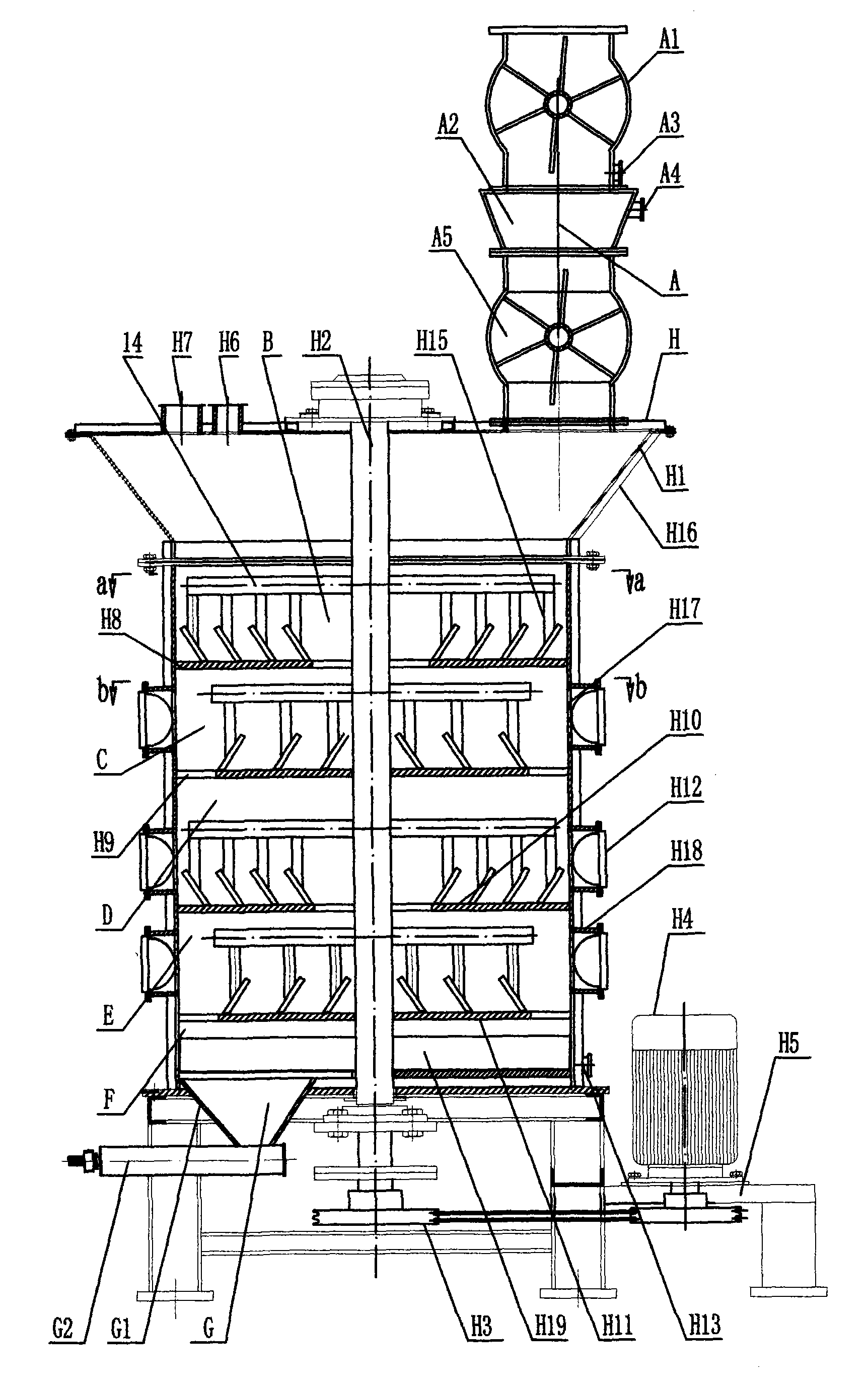

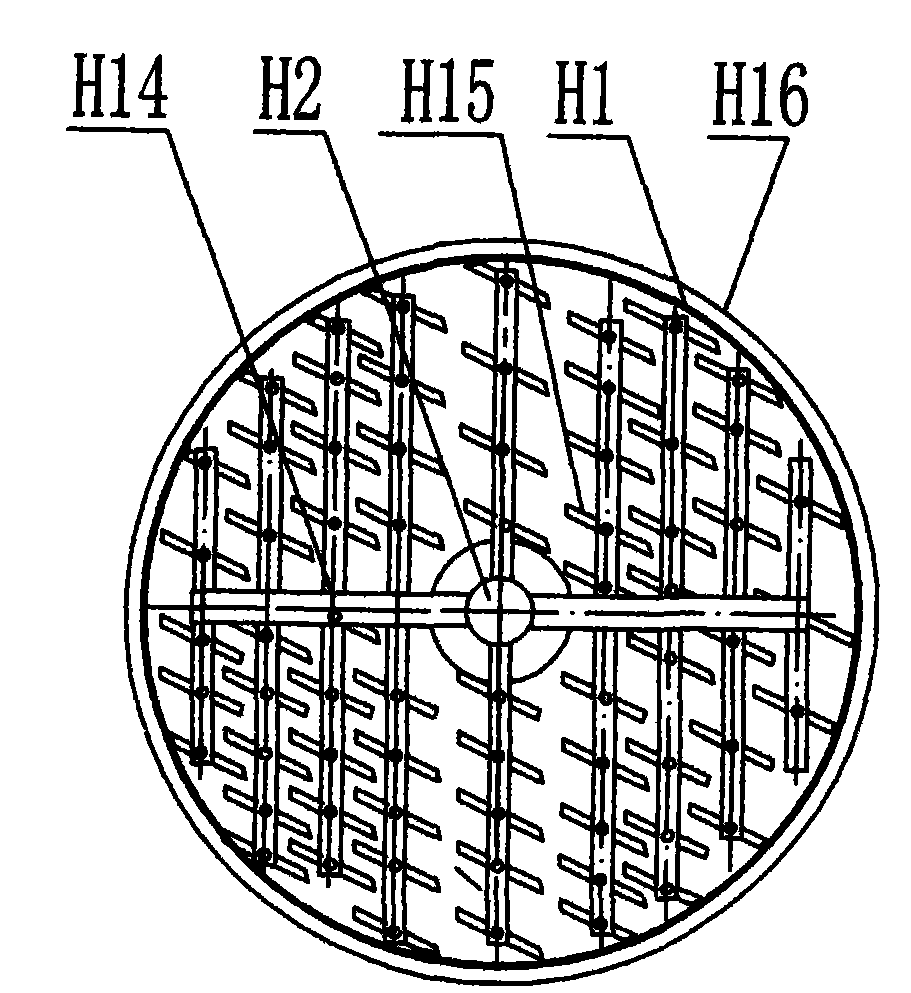

Vertical continuous microwave heating low-temperature cracking furnace for garbage

InactiveCN101811129AImprove continuityNovel and reasonable designSolid waste disposalSpecial form destructive distillationMicrowaveResource utilization

The invention provides a continuous reductive atmospheric microwave heating low-temperature cracking furnace structure for urban domestic garbage, which fulfills the purposes of improving the cracking efficiency, promoting the resource utilization level of garbage cracking reclamation substances, and realizing hazard-free treatment. The low-temperature cracking furnace consists of a feeding and garbage gas displacement mechanism arranged on a main body cylinder in a main body part, a garbage preheating and cracking vapor delivery chamber, a garbage water evaporation and heating chamber, a main garbage cracking chamber, a cracking material carbonization chamber, a carbonized material collecting chamber and a carbonized material collecting mechanism. The low-temperature cracking furnace has the advantages of continuously treating the garbage, consuming low energy, having minimum dust discharge amount, particularly avoiding the risks of generating NOx and dioxin, and basically reaching zero emission of the generated NOx and dioxin.

Owner:深圳市兖能环保科技有限公司

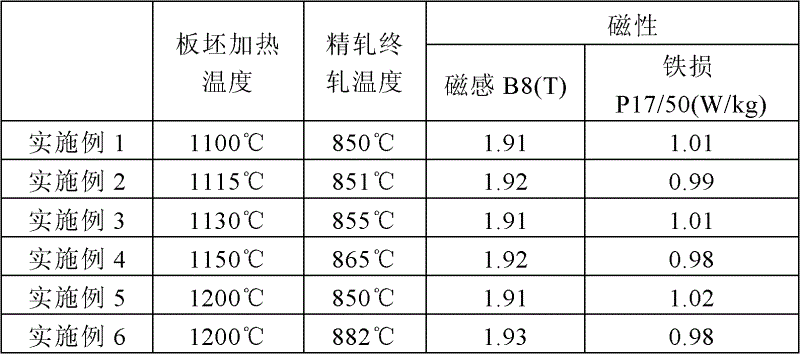

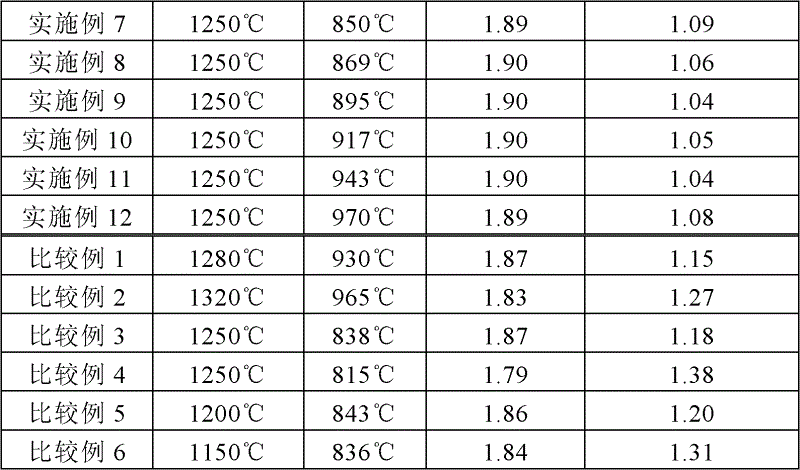

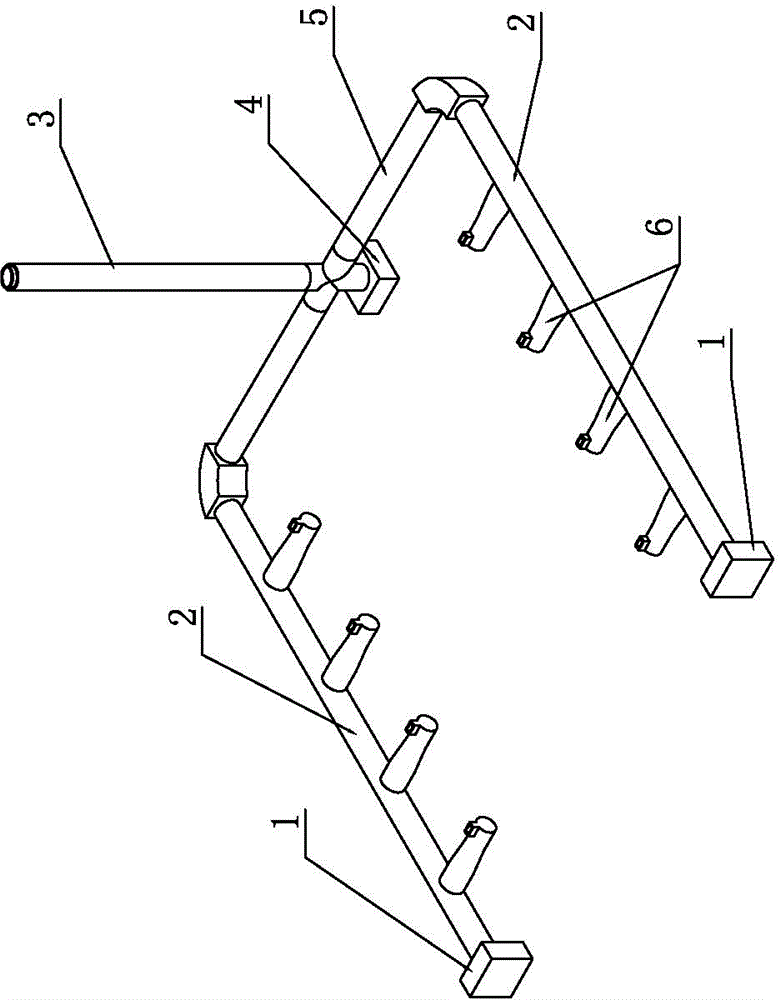

Production method of high magnetic induction oriented silicon steel

The invention discloses a production method of high magnetic induction oriented silicon steel, comprising the following steps: a) carrying out steel-making and continuous casting to produce slabs, wherein the slabs comprise 0.05-0.10 wt% of C, 2.5-4.0 wt% of Si, 0.008-0.028 wt% of S, 0.008-0.040 wt% of Als, 0.004-0.012 wt% of N, 0.08-0.20 wt% of Mn, 0.08-0.30 wt% of Cu, and the balance of Fe; b) preserving heat at no higher than 1250 DEG C and then carrying out hot rolling, wherein the finishing temperature is higher than 850 DEG C; c) carrying out annealing, pickling, once cold rolling or twice cold rolling containing intermediate annealing to get finished product thickness; d) decarburizing annealing, and preserving heat in wet nitrogen-hydrogen protective atmosphere; e) coating an annealing isolation agent and then carrying out high temperature annealing; f) carrying out nitriding treatment; and g) coating an insulating coating, and carrying out stretching, flattening and annealing. According to the invention, the types and distribution of the inhibitor is adjusted, the stable and high inhibition capability is guaranteed, by cooperating with hot rolling and twice recrystallization, the high magnetic induction oriented silicon steel with stable properties is obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

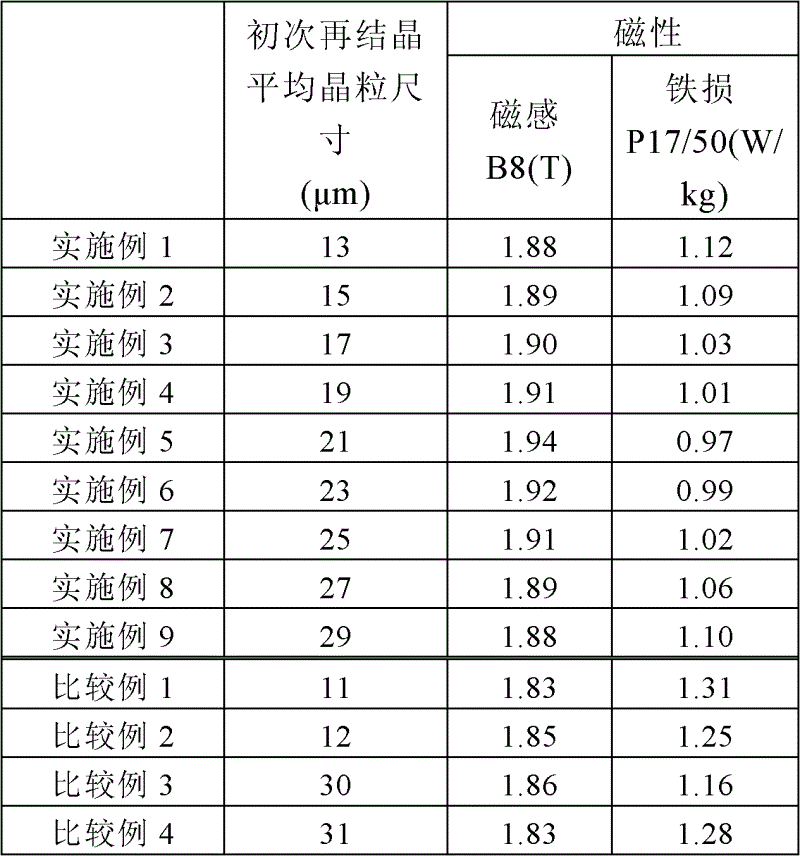

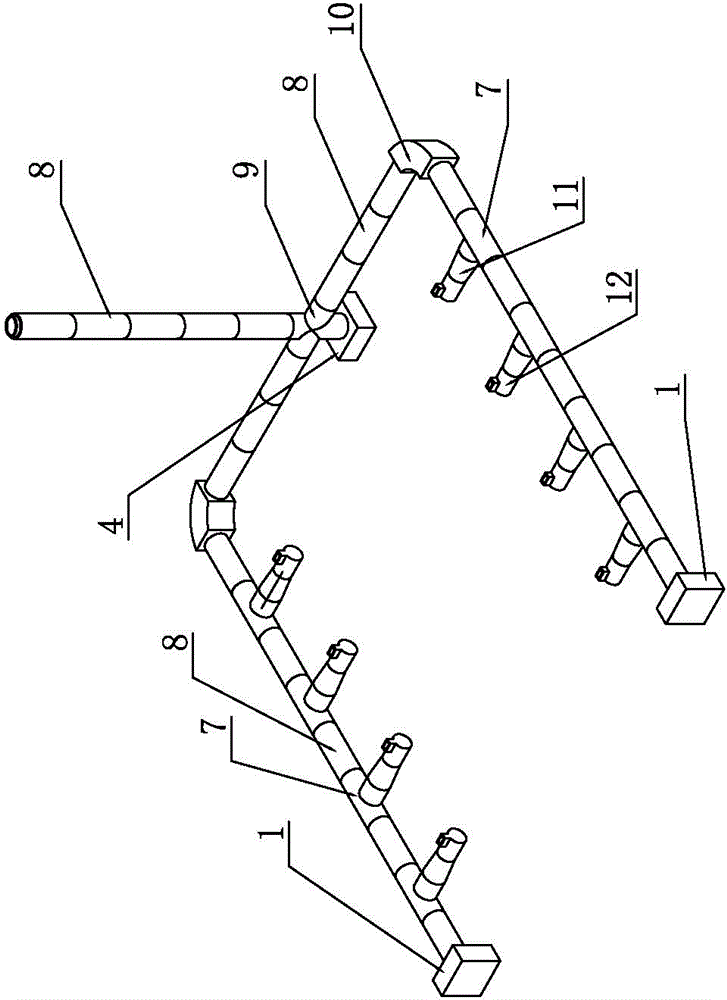

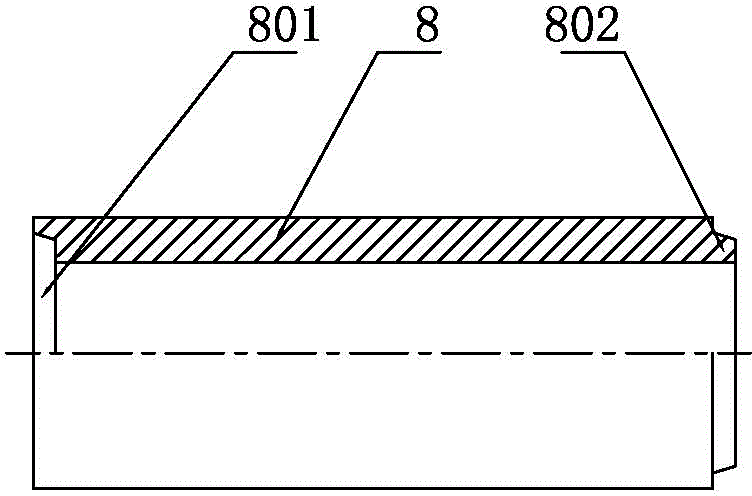

Ceramic casting system

ActiveCN103978158APurified hot metalEasy to manufactureFoundry mouldsFoundry coresMaterials scienceCasting

The invention discloses a ceramic casting system in the technical field of casting. A sprue, a cross gate and an ingate of the ceramic casting system are obtained by connection of several equal-diameter straight pipes, a fourway pipe, elbow pipes, variable-diameter straight pipes, t-branch pipes and flat mouth pipes made of a ceramic material. The sprue and the inlet section of the cross gate are obtained by connection of the equal-diameter straight pipes. The upward opening of the fourway pipe is connected to a lower end of the sprue. Two side openings of the fourway pipe are connected to one end of the inlet section of the cross gate. The elbow pipes are connected between the inlet section and an outlet section of the cross gate. The outlet section of the cross gate is obtained by connection of the equal-diameter straight pipes and the t-branch pipes. The equal-diameter straight pipes are connected to straight-through openings of the t-branch pipes. The ingate is obtained by connection of the variable-diameter straight pipes and the flat mouth pipes. Large-diameter ends of the variable-diameter straight pipes are connected to side openings of the t-branch pipes and each one of small-diameter ends of the variable-diameter straight pipes is connected to an end of the corresponding flat mouth pipe. Sides of the flat mouth pipes are provided with rectangular outlets communicated with a casting cavity. The ceramic casting system solves the problem of sand washing of the existing casting system in large-scale part casting, improves casting quality and is suitable for large-scale part casting.

Owner:KOCEL EQUIP

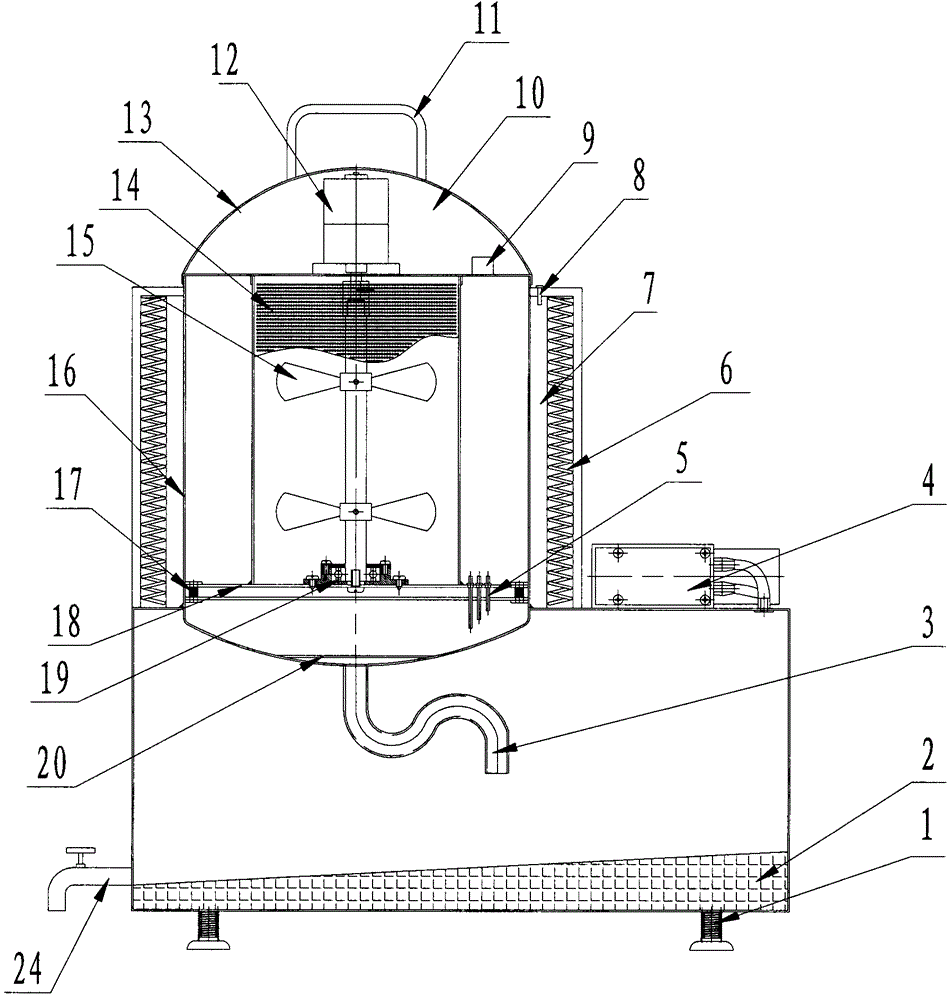

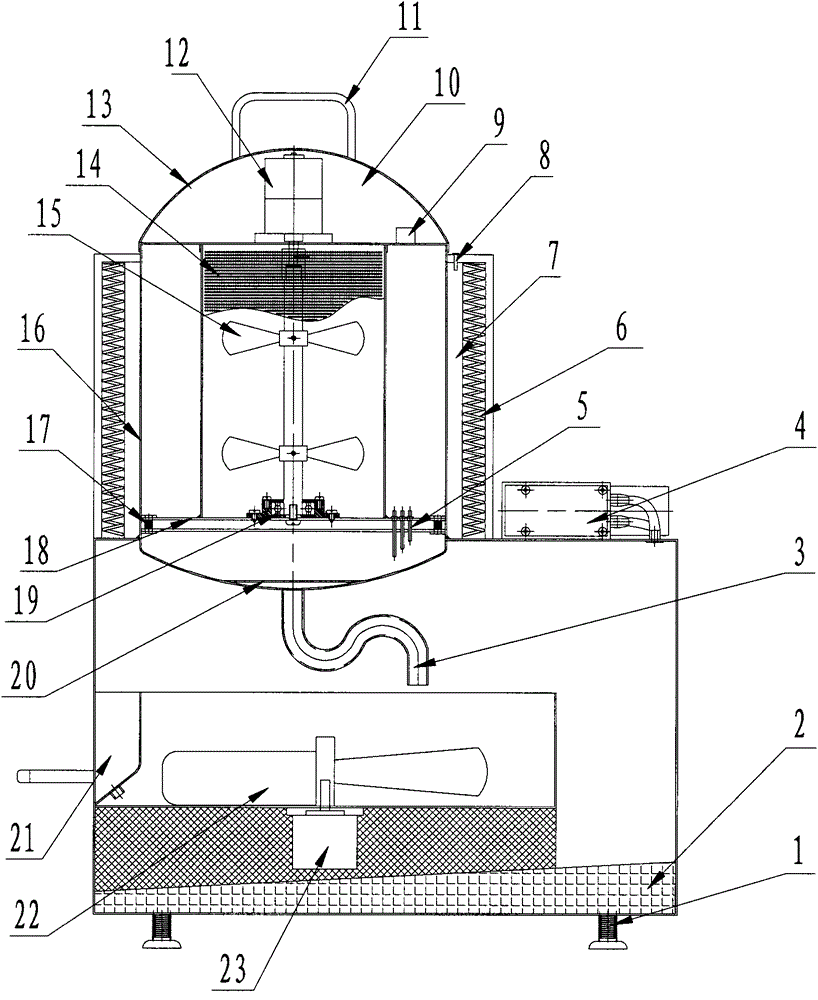

Traditional Chinese medicine preparation boiling and decoction machine

InactiveCN105310882AAchieve the desired effectFully contactedPharmaceutical product form changeMedicinal herbsSlag

The invention discloses a traditional Chinese medicine preparation boiling and decoction machine, which comprises a medicine container, a medicine decorating tube and a vacuum heating cavity, wherein the medicine decorating tube is integrally arranged on the top of the medicine container; the bottom of the medicine decorating tube is communicated with an inner cavity; the medicine decorating tube comprises an outer tube body, an upper cover, a secondary filtering screen, a primary filtering screen and an inner tube; the upper cover is separably and fixedly arranged on the top of the outer tube body; the secondary filtering screen and the primary filtering screen are separately arranged above a bottom plate of the outer tube body from bottom to top; the inner tube is in coaxial arrangement with the outer tube body; the upper side and the lower side of the inner tube are provided with openings; the side wall of the inner tube is provided with sieve holes, wherein the center of the bottom plate is provided with a liquid discharge hole; the bottom of the inner tube is fixedly connected with a hole plate; a stirring shaft is arranged in the center of the inner tube; the bottom of the stirring shaft is rotationally connected with the hole plate; the center part inside the upper cover is fixedly provided with a stirring motor; the stirring motor and the stirring shaft are in separable transmission connection. The automatic medicine decoction machine is divided into the inner tube and an outer tube. Medical materials are charged into the inner tube; water is added for infiltration heating; medicine liquid can be separated to the outer tube to form practical slag medicine separation; a secondary filtering function is realized, so that the medicine liquid is purer.

Owner:李悦

Preparation method of nanometer iron phosphate

ActiveCN102408102AHigh purityIncrease productivityNanotechnologyPhosphorus compoundsNanoparticlePhosphoric acid

The invention discloses a preparation method of nanometer iron phosphate, which belongs to the field of chemistry and chemical engineering. The method comprises the following steps of: previously adding proper amount of ferric iron salt water solution of phosphoric acid as iron source; taking phosphate water solution as phosphorus source; using micro mixer to quickly mix the iron source with the phosphorus source to obtain iron phosphate precursor with better monodispersity in a state of nanometer particle; and using normal pressure hydrothermal method to directly process product slurry to obtain nanometer iron phosphate material with high purity and average particle size of about 100nm. The method has the advantages of simple preparation process, high production efficiency, high product purity, uniform particle size, good monodispersity and easy industrial amplification.

Owner:TSINGHUA UNIV

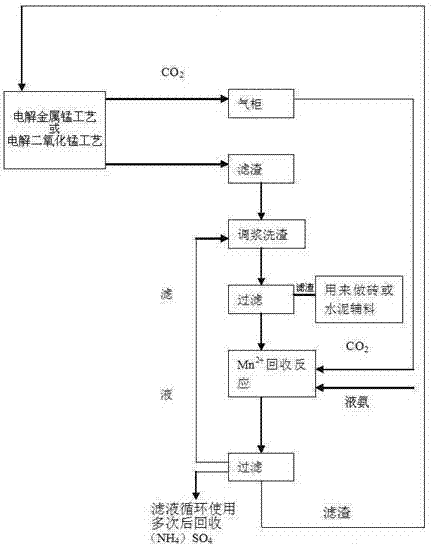

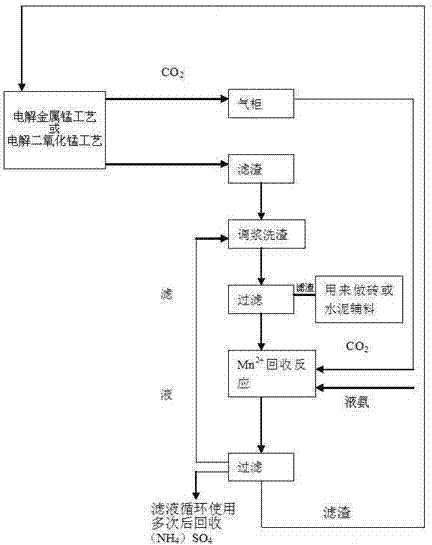

A production process for recovering manganese from waste water containing manganese by using waste gas

The invention discloses a production process for recovering manganese from manganese-containing waste water and slag by using waste gas. Add lotion to the manganese slag produced by the electrolytic manganese or electrolytic manganese dioxide process, and then filter the leaching solution after stirring fully; c. adjust the leaching solution pH to 7-7.8, and pass it into the CO2, while continuously feeding ammonia gas to react and maintain the pH value of the solution. After the reaction, solid-liquid separation is obtained to obtain MnCO3 precipitation and filtrate; d. MnCO3 precipitation is returned to the electrolytic metal manganese or electrolytic manganese dioxide process in the form of slurry, and the filtrate is used as the washing liquid Return to step b for recycling. The invention greatly improves the recovery rate of manganese in the production process of electrolytic manganese metal and electrolytic manganese dioxide, also recovers available ammonium sulfate, improves resource utilization rate, reduces CO2 and manganese emissions, and protects the environment.

Owner:湘潭电化集团有限公司

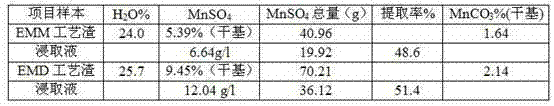

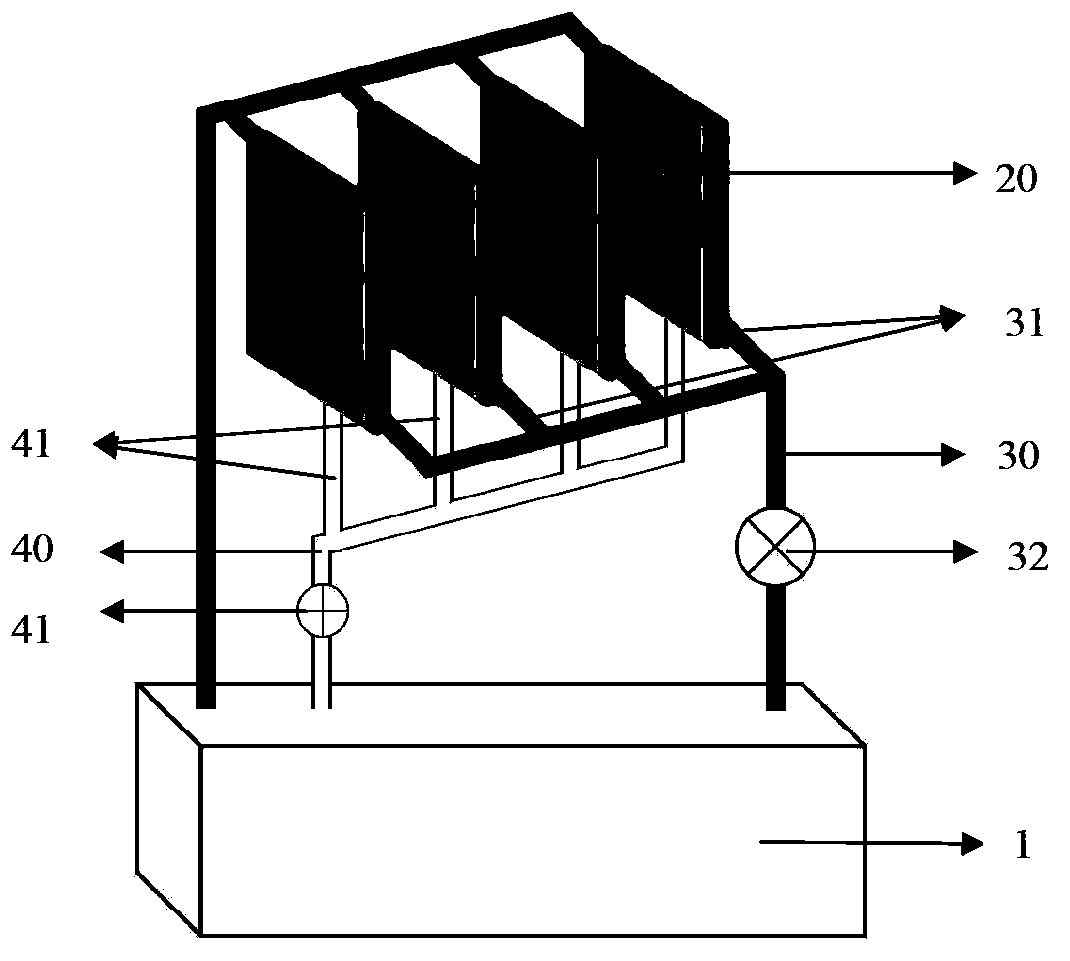

Electrolyte storage box for metal-air cell system

ActiveCN103855446ASufficient precipitationEasy to separateFuel and primary cellsElectrolyte stream managementElectrolysisEngineering

The invention discloses an electrolyte storage box for a metal-air cell system. The electrolyte storage box is connected to an electrolyte chamber of the metal-air cell system. The electrolyte storage box is a hollow container. In the electrolyte storage box, a product isolation baffle plate and a product filter screen are orderly arranged from left to right. The hollow container is divided into a product chamber, an electrolyte / product mixing chamber and an electrolyte chamber mutually independent by the product isolation baffle plate and the product filter screen. The product chamber is connected to an electrolyte cycle opening arranged at the upper part of the electrolyte chamber of the metal-air cell system by a pipe. The electrolyte chamber is connected to an electrolyte feeding inlet at the lower part of the electrolyte chamber of the metal-air cell system by a pipe. The management system of the metal-air cell system has the advantages that 1, products can be fully precipitated and grading-filtered, 2, the products can be momentarily discharged, 3, heat in the cell can be timely discharged with the discharged products, and 4, availability of a cell anode plate can be improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

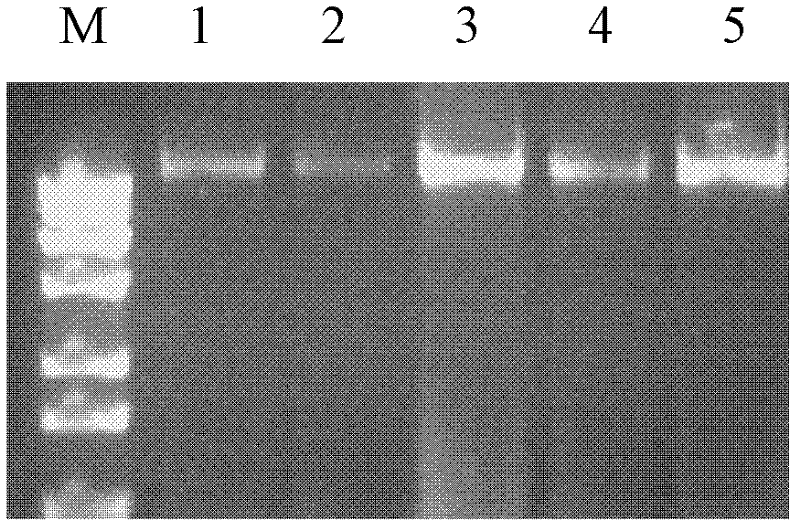

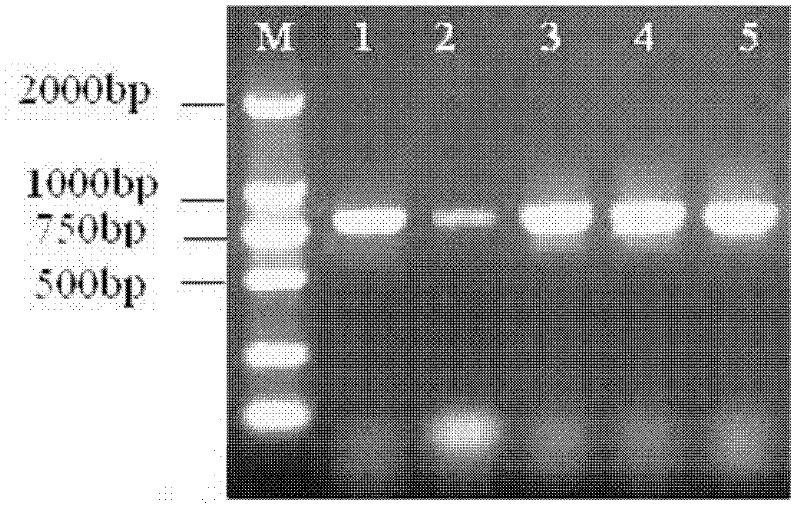

High throughput method for rapidly extracting genomic DNA of fungus

The invention provides a high throughput method for rapidly extracting genomic DNA of a fungus. According to the method, a fungal bacterium block or a mycelium undergoes a simple physical grinding process and is subjected to impurity removal by an improved CTAB solution to obtain the purified DNA. The method of the invention mainly has the following beneficial effects: 1, a complex process that aspecial agent liquid nitrogen must be used to grind in present methods is avoided; 2, the usage of toxic carcinogenic regents of phenol and the like in the present methods is avoided; 3, the usage ofa toxic odorous chemical reagent beta-mercaptoethanol is avoided; and 4, the method of the invention only needs 1h, the extraction time is shortened by 2h, the experiment speed is greatly accelerated, and the high throughput rapid extraction can be realized. The method of the invention is also suitable for the rapid extraction of the genomic DNA of other various fungi.

Owner:CHINA JILIANG UNIV

Method for preparing (+)-(S-)-clopidogrel hydrosulfate high melting point crystal I

ActiveCN101100471AAvoid it happening againSufficient precipitationOrganic chemistryHydrogen SulfateAlcohol

Preparation of (+)-(S)-chlorpyrroline hydrogen sulfate high-smelting point crystal Iis carried out by dissolving chlorpyrroline free alkali into ketone solvent, adding into concentrated sulfuric acid, eluting crystal out, adding into alcohol solvent, agitating while crystallizing, filtering, washing for filter cake by ketone solvent, pumping and vacuum drying to obtain final product. It's simple and efficient, has gentle reactive condition and can be used for industrial production.

Owner:ZHEJIANG JIUZHOU PHARM CO LTD

Austenite grain size refining control method for high-temperature carburized gear steel

The invention discloses an austenite grain size refining control method for high-temperature carburized gear steel. The austenite grain size refining control method comprises the procedures of EAF smelting, LF refining, VD vacuum degassing, continuous casting, casting blank slow cooling, primary heating, cogging rolling, cogging dephosphorization, secondary rolling heating, secondary-fire rollingdephosphorization, finish rolling, slow cooling, straightening, peeling and ultrasonic and magnetic flux leakage combined flaw detection. The aluminum content of the procedures of LF refining and VD vacuum degassing is controlled to 0.010%-0.045%. The gear steel prepared with the austenite grain size refining control method has good austenite grain size control stability and can meet the control requirement of a high-temperature carburizing technology for the austenite grain size, thus a gear obtained after high-temperature carburizing has good processability and usability, and the austenite grain size refining control method is simple and easy to conduct.

Owner:NANJING IRON & STEEL CO LTD

High-strength material for flexible connection of new energy power battery and manufacturing method of high-strength material

The invention belongs to the technical field of aluminum foil calendering manufacturing, and discloses a high-strength material for flexible connection of a new energy power battery and a manufacturing method of the high-strength material. The material comprises the following components of, in percentage by mass, 0.20%-0.30% of Si, 0.40%-0.60% of Fe, 0.08%-0.12% of Cu, 1.05%-1.20% of Mn, smaller than or equal to 0.05% of Zn, smaller than or equal to 0.03% of Ti and the balance Al; and the technological process comprises the steps of smelting, cast rolling, rough rolling, intermediate homogenizing annealing, intermediate rolling trimming, finished product finish rolling, withdrawal and straightening cleaning, slitting, finished product annealing and the like. The product and the method havethe advantages of being high in strength, good in forming plasticity, good in model and surface end surface quality and good in flexible electric conduction effect, and the problem of poor conductivity of a battery pack caused by looseness and breakage of a fastener due to vibration in the running process of an automobile can be solved.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Crystallization purification method of thiourea

ActiveCN102976990AGood moisturizing effectPrevent problems such as darkening of colorOrganic chemistryThioureaPhysical chemistry

The invention belongs to the technical field of fine chemical industry and relates to crystallization purification technology of chemicals, in particular to the crystallization purification technology for of thiourea. According to the crystallization purification method of the thiourea, surfactant is mainly adopted to solubilize impurity of the thiourea solvent system in a selected mode, the crystallization ability of the impurity is reduced, the impurity is left in fluid phase, and the purity degree of the thiourea is increased. The crystallization purification method of the thiourea is simple in operation, easy to control, low in energy consumption and free of special equipment input, obtained products are even in crystallization and good in whiteness, content of crystallization is higher than 99%, and the crystallization purification method of the thiourea suitable for crystallizing the thiourea product in industrial production, satisfying demands of medicine, fine chemical and other industries, and improving purity degree of down-stream products.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

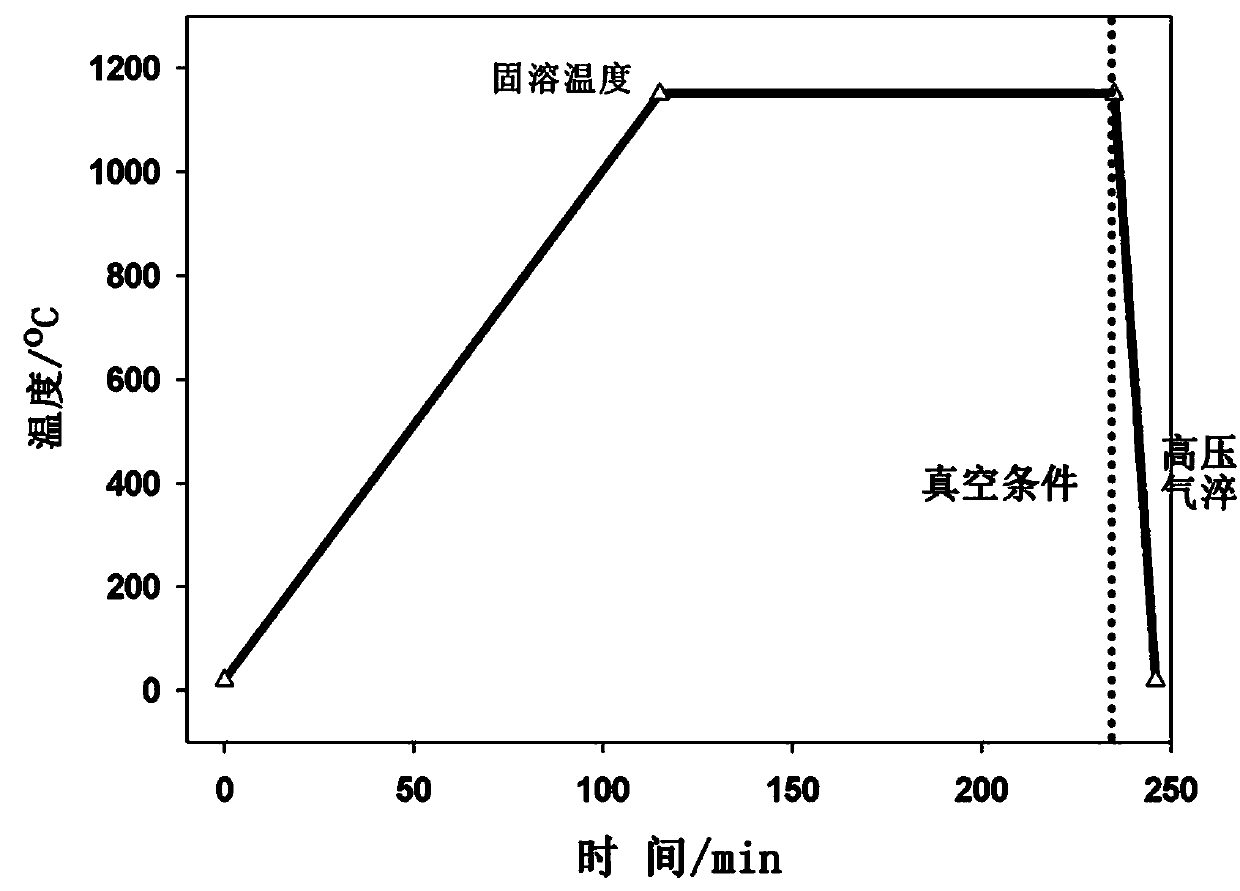

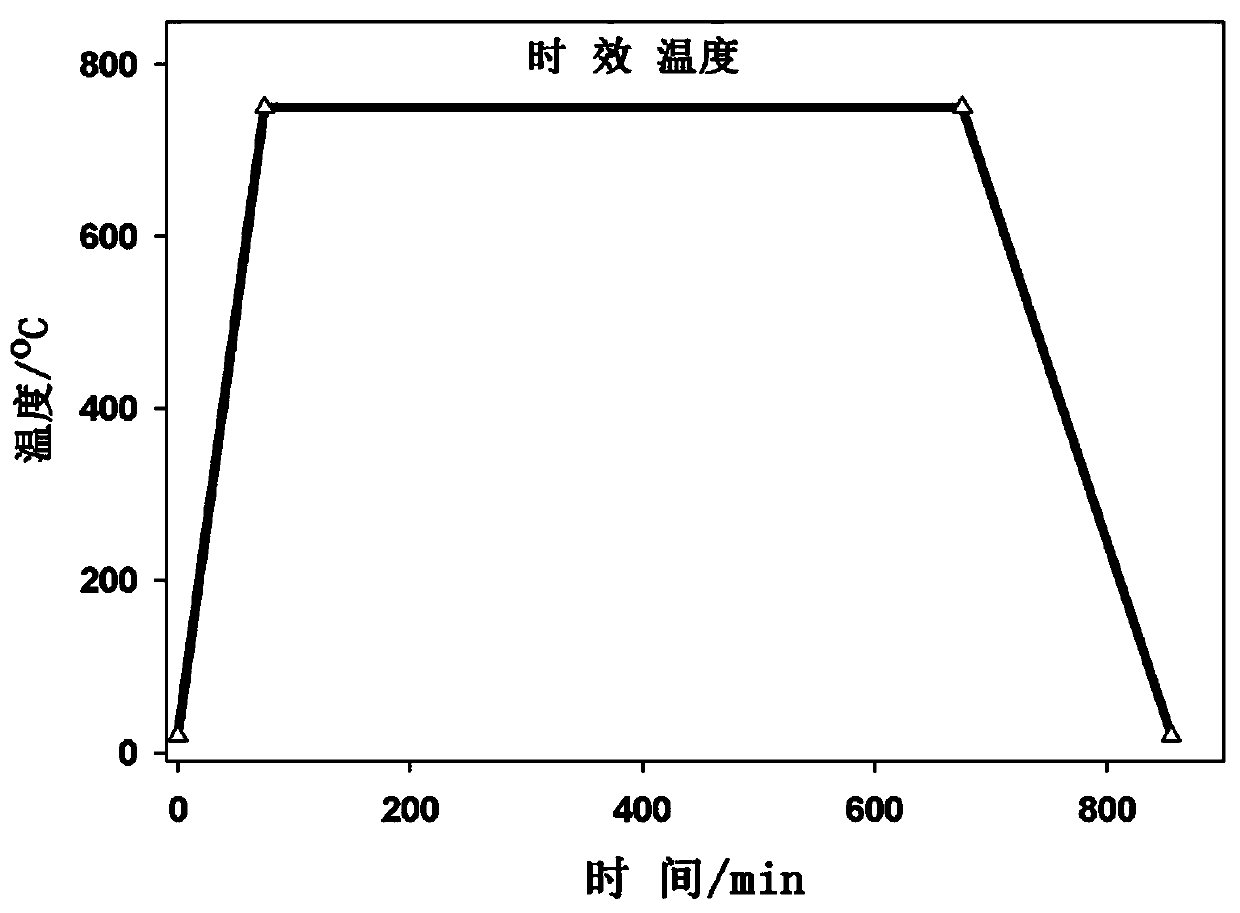

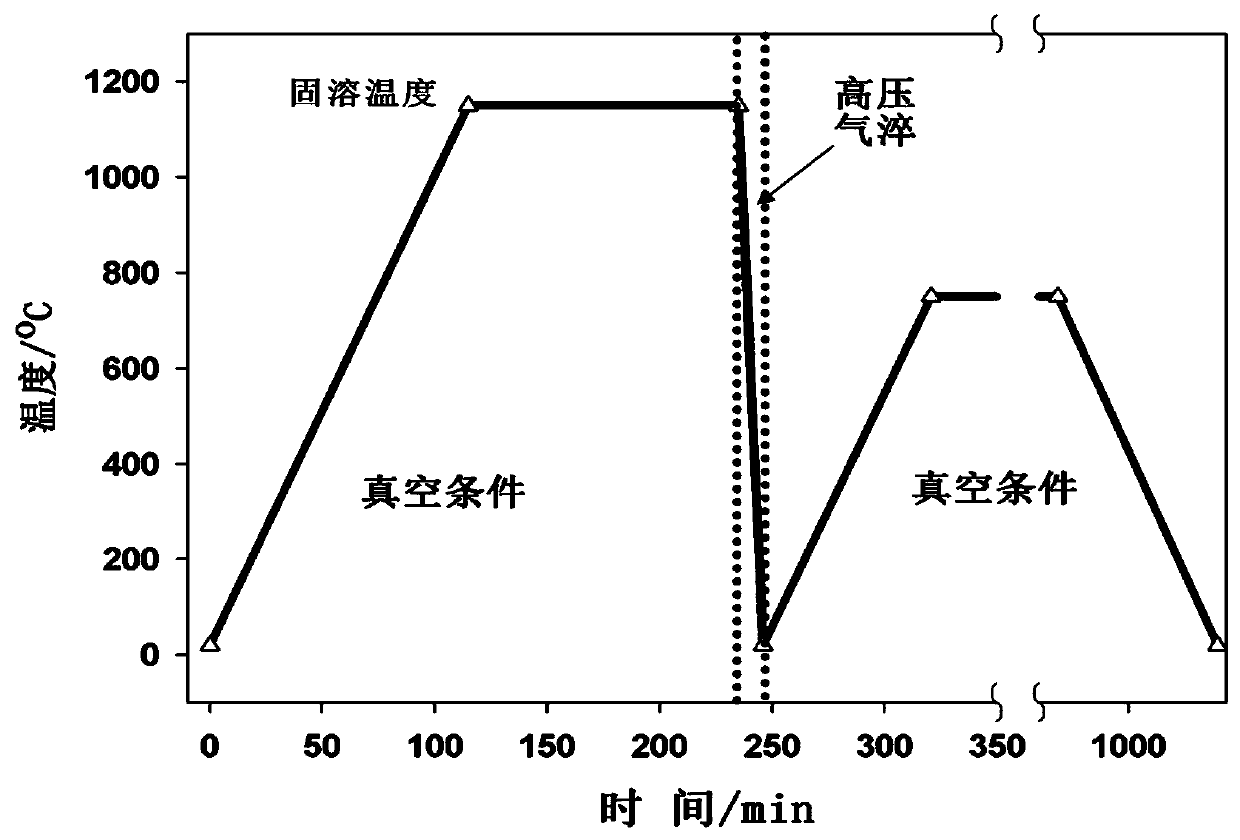

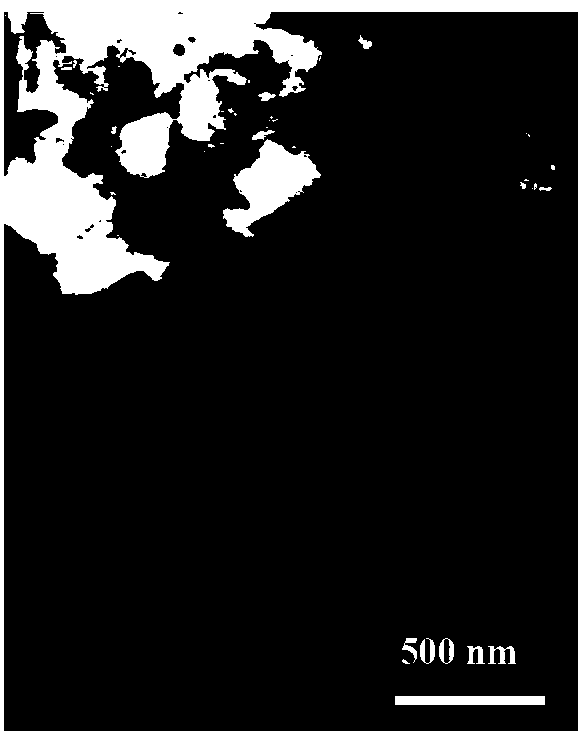

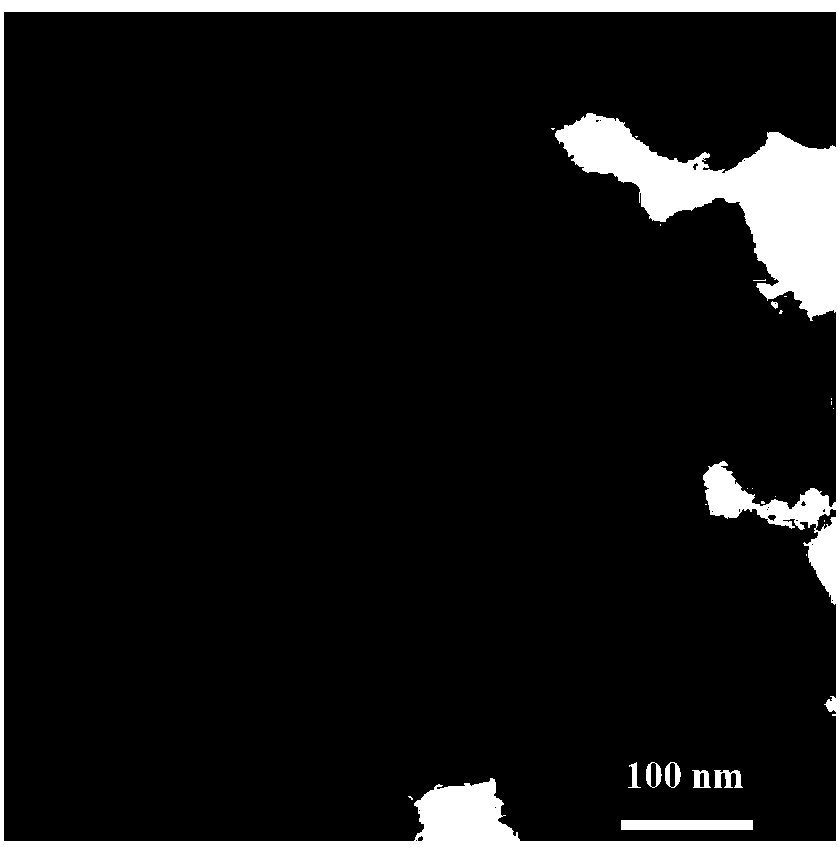

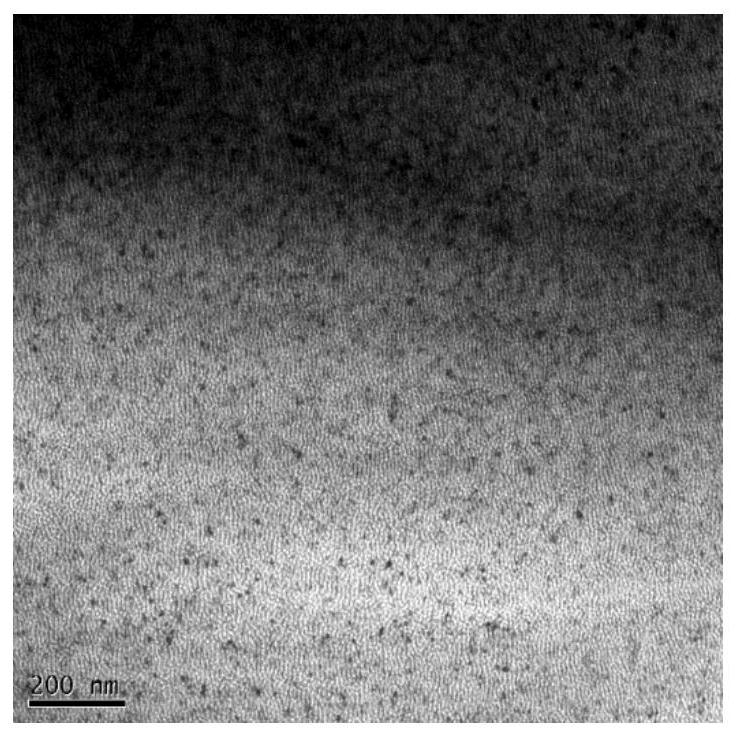

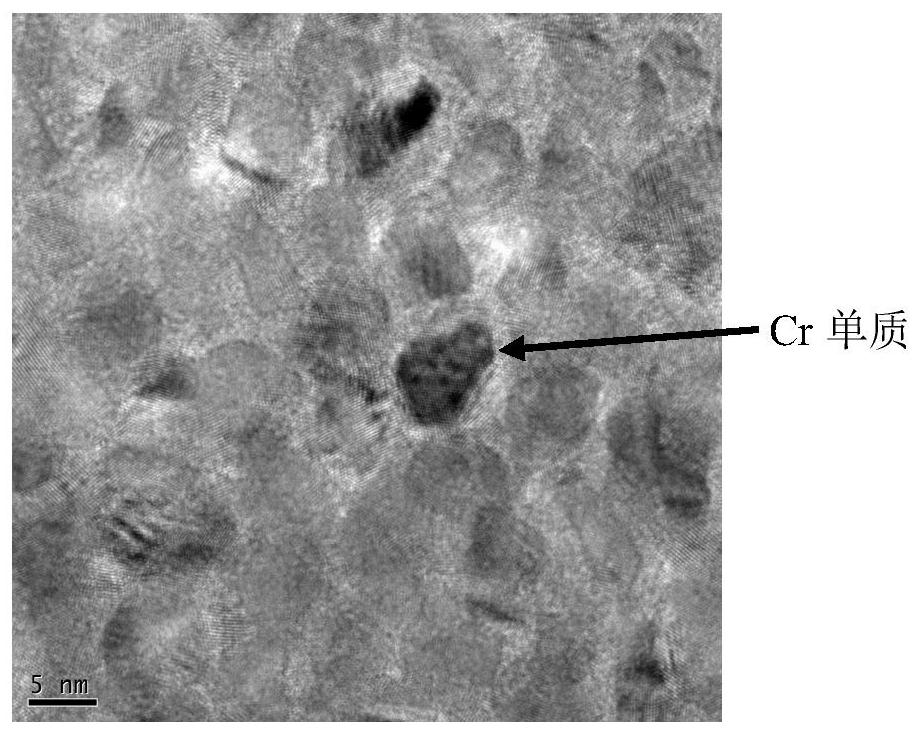

Heat treatment method of WC-Co-Ni3Al hard alloy

The invention discloses a heat treatment method of a WC-Co-Ni3Al hard alloy. The heat treatment method sequentially comprises the following steps: heating the WC-Co-Ni3Al hard alloy to a solid solution temperature of 1000-1300 DEG C under a vacuum condition of lower than 1 Pa at a speed of not less than 10 DEG C / min, and then, preserving the temperature for 10-120 minutes to carry out a solid solution treatment; introducing high pressure N2 or Ar after the temperature maintaining treatment, and cooling the hard alloy to the room temperature at a cooling speed of not less than 100 DEG C / min; heating the hard alloy to 600-900 DEG C under a vacuum condition of lower than 1 Pa at a speed of not less than 10 DEG C / min, preserving the temperature for not less than 10 h to carry out an aging treatment; and then, slowly cooling the hard alloy to the room temperature to obtain the WC-Co-Ni3Al hard alloy with obviously increased gamma'(Ni3Al) phase precipitation amount; compared with an alloy without heat treatment, the precipitation amount of the gamma' phase in the heat treated alloy disclosed by the invention is obviously increased, the strengthening effect is more obvious, the bending strength of the alloy is further improved, obviously, and meanwhile, stress generated in an early stage gas quenching rapid cooling process can be eliminated; moreover, the heat treatment method is simple in process, simple and convenient to operate, efficient and environment-friendly.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

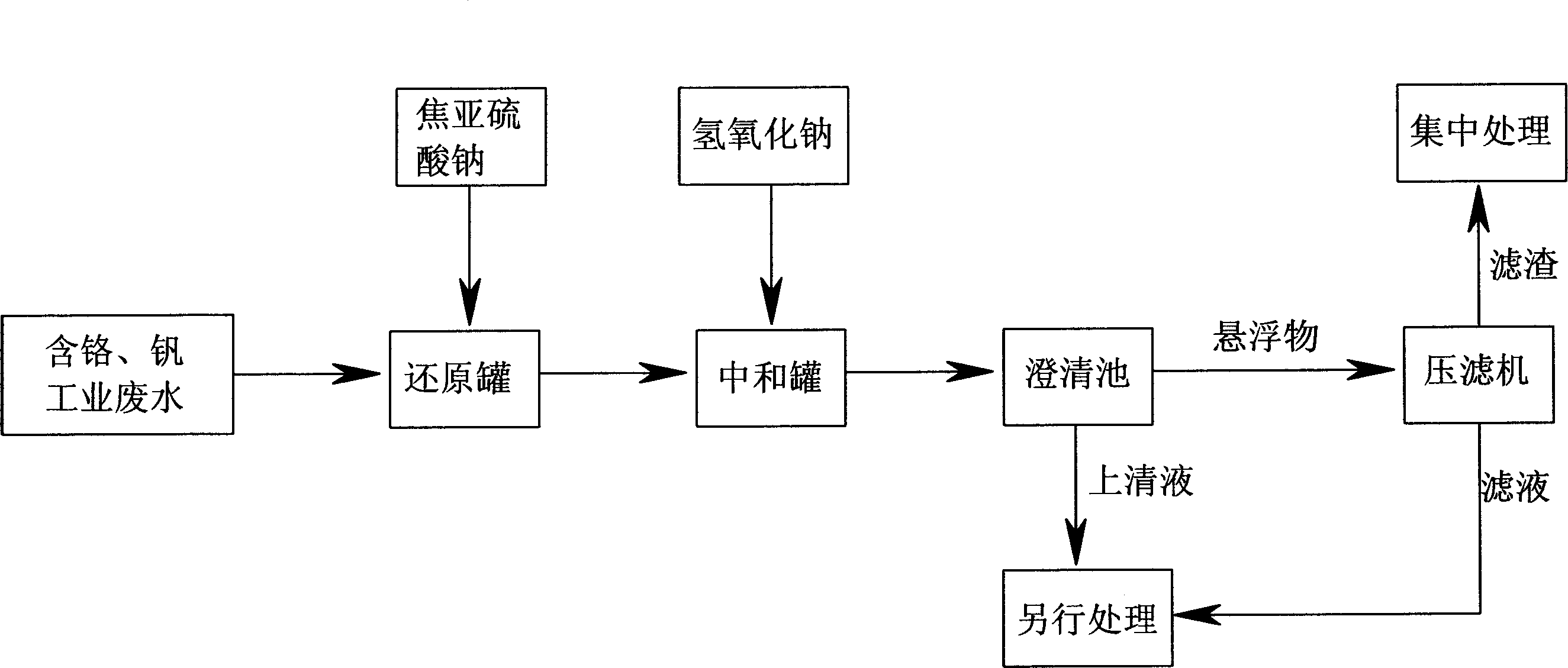

Process for treating industrial waste water containing chromium, vanadium

InactiveCN1724406AReduced chromium contentAvoid pollutionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationIndustrial waste waterSewage

A process for treating the industrial sewage containing Cr and V includes such steps as preparing the solution of sodium pyro-sulfite, proportionally adding it to the sewage in reduction tank, reducing the 6-valence Cr to 3-valence Cr, proportionally adding the solution of sodium hydroxide to the sewage in neutralizing tank for reaction between V2O2 and sodium hydroxide to generate Na2V4O9 * 4H2O, reaction between V4O9 and said 3-valence Cr to generate Cr2(V4O9)3 deposit and changing residual 3-valence Cr to chromium hydroxide deposit, regulating pH=7.5-8.5, clarifying, and press filtering of suspended substance.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Novel reinforcement technique of 6XXX aluminum alloy welding joint

InactiveCN103572180AIncrease densityImprove mechanical propertiesSolution treatmentUltimate tensile strength

The invention discloses a novel reinforcement technique of a 6XXX aluminum alloy welding joint, mainly solves the defects such as high cost, large equipment and noise, complex operation, workpiece damage, additional consumption of materials and energy, additional increment of workpiece weight and residual stress, reduction of workpiece plasticity and air hole mingling in the traditional reinforcement methods of the 6XXX aluminum alloy welding joint, and achieves the reinforcement effect to the 6XXX aluminum alloy welding joint. The technique comprises the specific operation steps of solution treatment, subzero treatment and ageing treatment. The technique has the advantages of simple technique, low cost, ideal reinforcement effect, energy conservation, environmental protection and largely improved strength and plasticity, can effectively solve the problems of air holes and mingling inside the joint, and has excellent industrial application prospect.

Owner:葛鹏

Low activation steel and making method thereof

ActiveCN103409690ASufficient precipitationImprove mechanical propertiesMetallurgyBiological activation

The invention provides low activation steel and a making method thereof. The low activation steel includes 0.08-0.12wt% of C, 0.01-0.04wt% of N, 0.30-0.60wt% of Ta, 0.50-0.70wt% of Mn, 1.40-1.60wt% of W, 9.0-9.5wt% of Cr, 0.15-0.35wt% of V, and the balance Fe. The low activation steel has good mechanical performances and a good anti-irradiation performance.

Owner:TSINGHUA UNIV

Method for preparing renewable magnesium-containing heavy metal adsorbent, and adsorbent prepared therethrough

InactiveCN107486151AReduced operating and development costsImprove adsorption efficiencyOther chemical processesWater contaminantsActive carbonTreatment costs

The invention discloses a method for preparing a renewable magnesium-containing heavy metal adsorbent and an adsorbent prepared therethrough. The method comprises the following steps: preprocessing a catalysis carrier, impregnating the catalysis carrier in s magnesium source solution, standing the impregnated and adsorbed catalysis carrier in ammonia water or a sodium hydroxide solution to precipitate magnesium ions, cleaning the obtained aged magnesium-containing active carbon until the solution is clear, drying the cleaned magnesium-containing active carbon to obtain the high-efficiency magnesium-containing heavy metal adsorbent. An active component Mg(OH)2 and the carrier active carbon are mutually bonded to form the heavy metal adsorbent having specific properties. The magnesium-based material is loaded to the carrier having rich pore structures and a large specific surface area by using the high activity and the high adsorbing capacity, so the disadvantages of high treatment cost and difficult recovery of single adsorbent are overcome, and a proper desorbent (complexing agent) is used to desorb and enrich heavy metals in order to regenerate the supported adsorbent.

Owner:JIANGSU HELPER FUNCTIONAL MATERIALS

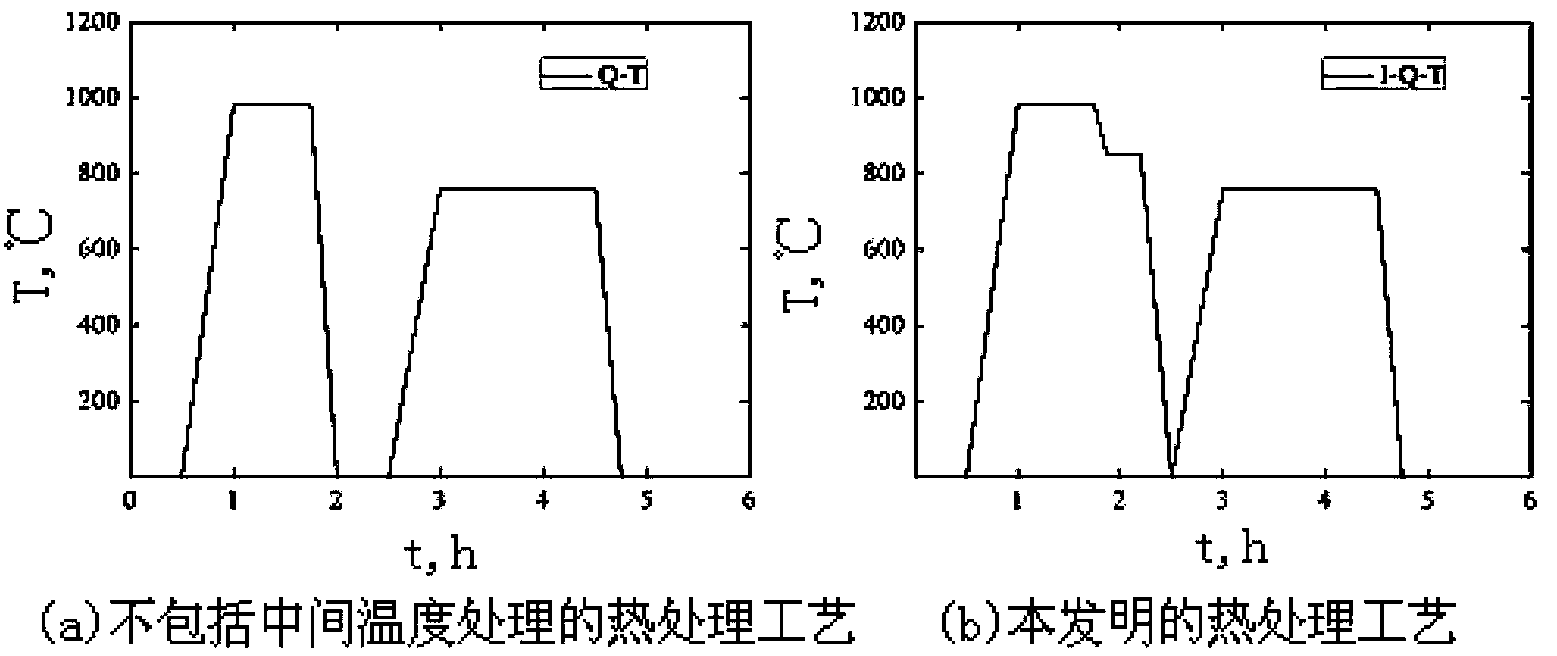

Heat treatment process for improving obdurability of near beta type or metastable beta type titanium alloy

The invention relates to a heat treatment process for improving obdurability of a near beta type or metastable beta type titanium alloy. The process comprises the following steps of: firstly, preserving heat at the temperature of T which is more than or equal to T beta-50 DEG C and less than or equal to T beta-10 DEG C, wherein the heat preservation time T (min) is eta * delta max, the delta max is the maximum section thickness of a forge piece, the unit is mm, the eta is a heating coefficient, and the value of the heating coefficient eta is 0.5 to 1.5min / mm; secondly, discharging the forge piece out of a furnace and cooling the forge piece to room temperature by air or water; thirdly, preserving heat of the cooled forge piece at the temperature of T which is more than or equal to 520 DEGC and less than or equal to 560 DEG C, wherein the heat preservation time T is more than or equal to 20min and less than or equal to 1.5h; fourthly, discharging the forge piece out of the furnace andcooling the forge piece to room temperature by air; fifthly, slowly heating the cooled forge piece to the temperature of T which is more than or equal to 480 DEG C and less than or equal to 540 DEG Calong with the furnace, wherein the heating rate is controlled to be within 5 DEG C / min, and the heat preservation time T is more than or equal to 6h and less than or equal to 12h; and finally, cooling the forge piece along with the furnace or discharging the forge piece out of the furnace and cooling the forge piece to room temperature by air. The process is suitable for heat treatment of the near beta type or metastable beta type titanium alloy with ultrahigh obdurability so as to obtain a tissue with high comprehensive performance and multi-scale precipitated phases, which has the requiredultrahigh strength (Rm is more than or equal to 1,500 MPa), high plasticity (A is more than or equal to 5 percent) and high obdurability (KIC is more than or equal to 45 MPa.m < 1 / 2 >), and meet important bearing structural members with ultrahigh obdurability matching required by airplanes.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

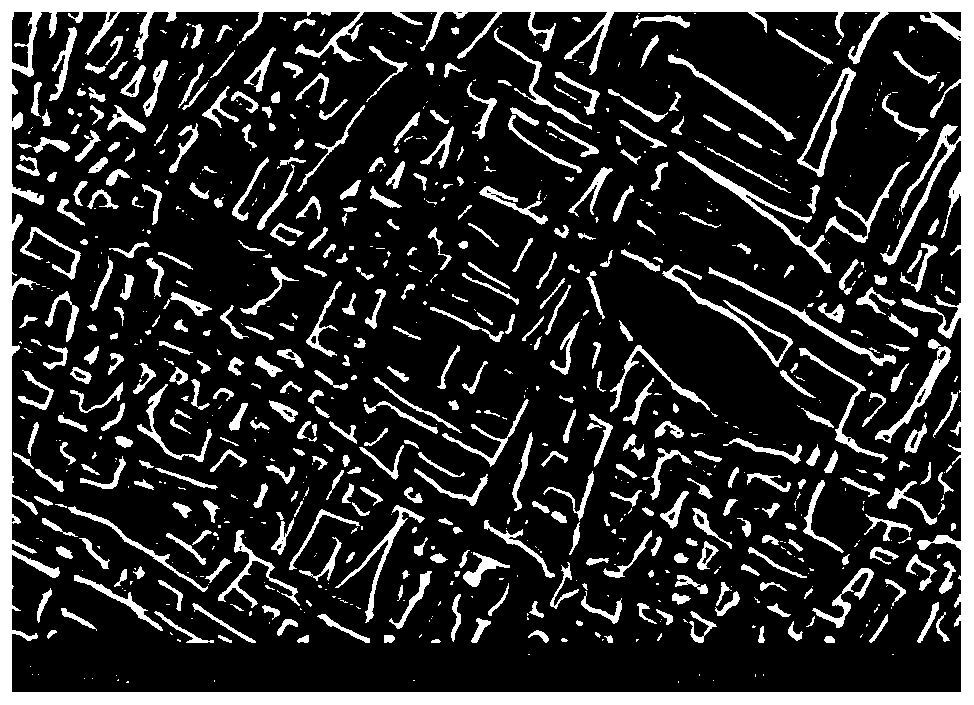

High-strength high-conductivity copper alloy material, preparation method thereof and application thereof

ActiveCN111996411AHigh temperature softening resistanceReduce residual stressSemiconductor/solid-state device detailsSolid-state devicesLead frameUltimate tensile strength

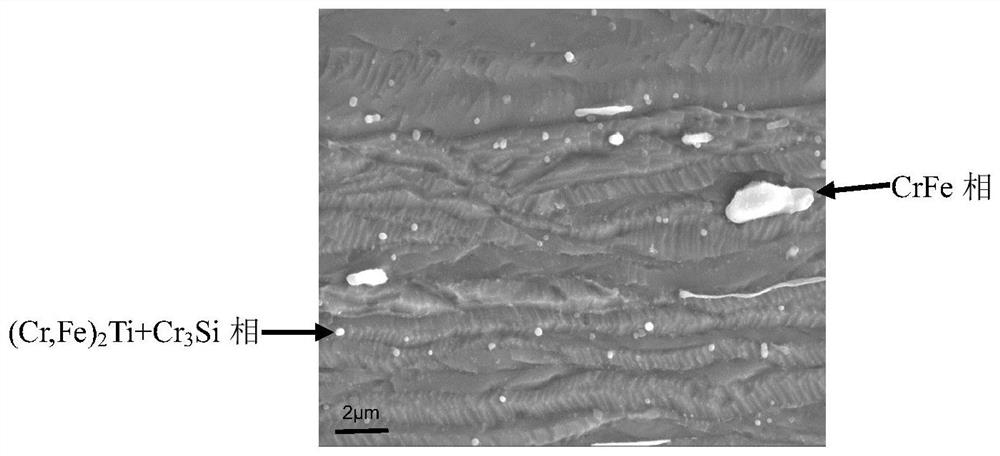

The invention discloses a high-strength high-conductivity copper alloy material. The high-strength high-conductivity copper alloy material comprises, by weight percentage, 0.3wt%-0.8wt% of Cr, 0.05wt%-0.5wt% of Fe, 0.05wt%-0.3wt% of Ti, 0.01wt%-0.1wt% of Si and the balance Cu and inevitable impurities. The high-strength high-conductivity copper alloy is prepared through the alloying design of Cr,Fe, Ti, Si and other elements and a thermo-mechanical treatment technology taking two-stage aging as a main process. By means of the control over the sizes and the densities of a CrFe phase, a (Cr, Fe)2Ti and Cr3Si composite precipitated phase and a Cr elementary substance phase in a microscopic structure of the alloy, the effects of strengthening the alloy and improving the conductivity of the alloy are achieved. The copper alloy material can be applied to large-scale integrated circuit lead frames, folding screens and other products, the yield strength of manufactured strips is 650MPa or above, the electric conductivity is 65%IACS or above, and the good high-temperature softening resistance is achieved.

Owner:NINGBO POWERWAY ALLOY PLATE & STRIP CO LTD +1

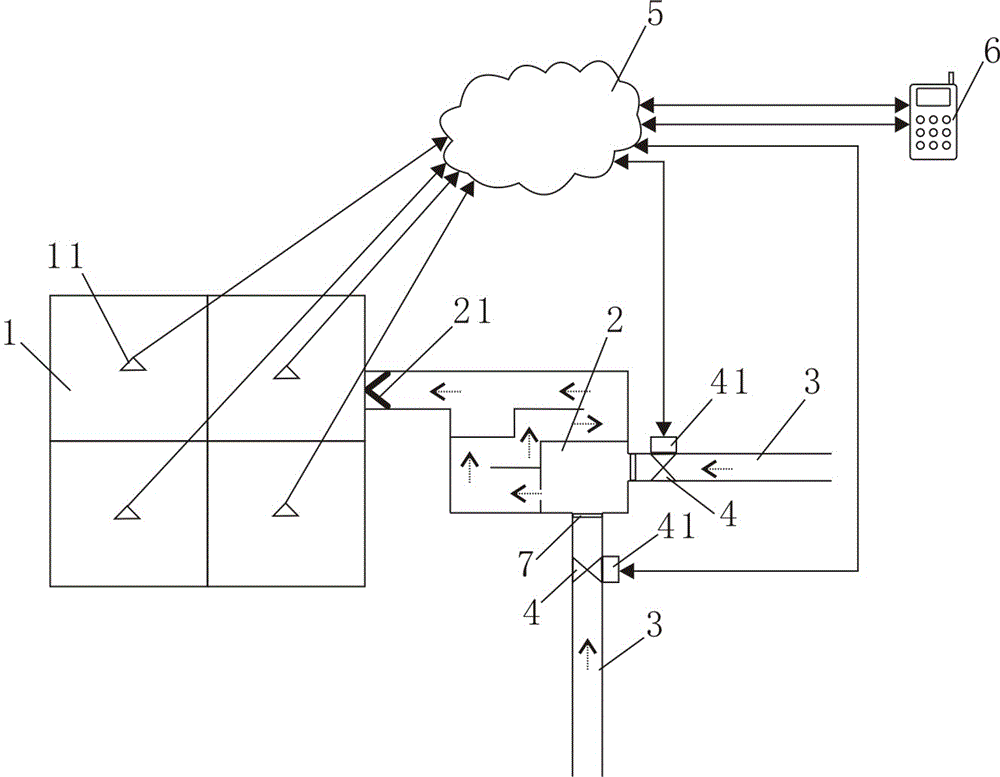

Water resource regulating and controlling system and water resource regulating and controlling method in irrigation area

InactiveCN106718693AWell mixedEfficient removalData processing applicationsWatering devicesWater requirementMaterial resources

The invention discloses a water resource regulating and controlling system and a water resource regulating and controlling method in an irrigation area. The water resource regulating and controlling system comprises a mixing tank, a soil moisture content monitoring unit, a crop water requirement monitoring unit, a wireless transmission unit, a cloud service platform, an automatic monitoring unit and a payment unit. According to the water resource regulating and controlling system disclosed by the invention, a crop water requirement model is established according to regional crop types, growing characteristics, different-stage water requirement and the like, and irrigation water amount required by irrigation is calculated according to soil water content monitored by a soil moisture content probe, so that irrigation efficiency can be increased, the irrigated water amount and irrigation time are closer to actual crop water requirement, water resource is saved, plant growth is facilitated, and a lot of labor force and material resources are saved. Furthermore, a user can utilize a mobile terminal to remotely acquire real-time water content and water requirement of a farmland, farmland irrigation can be realized by means of the mobile terminal, the operation is simple and quick, and the labor force is further saved.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

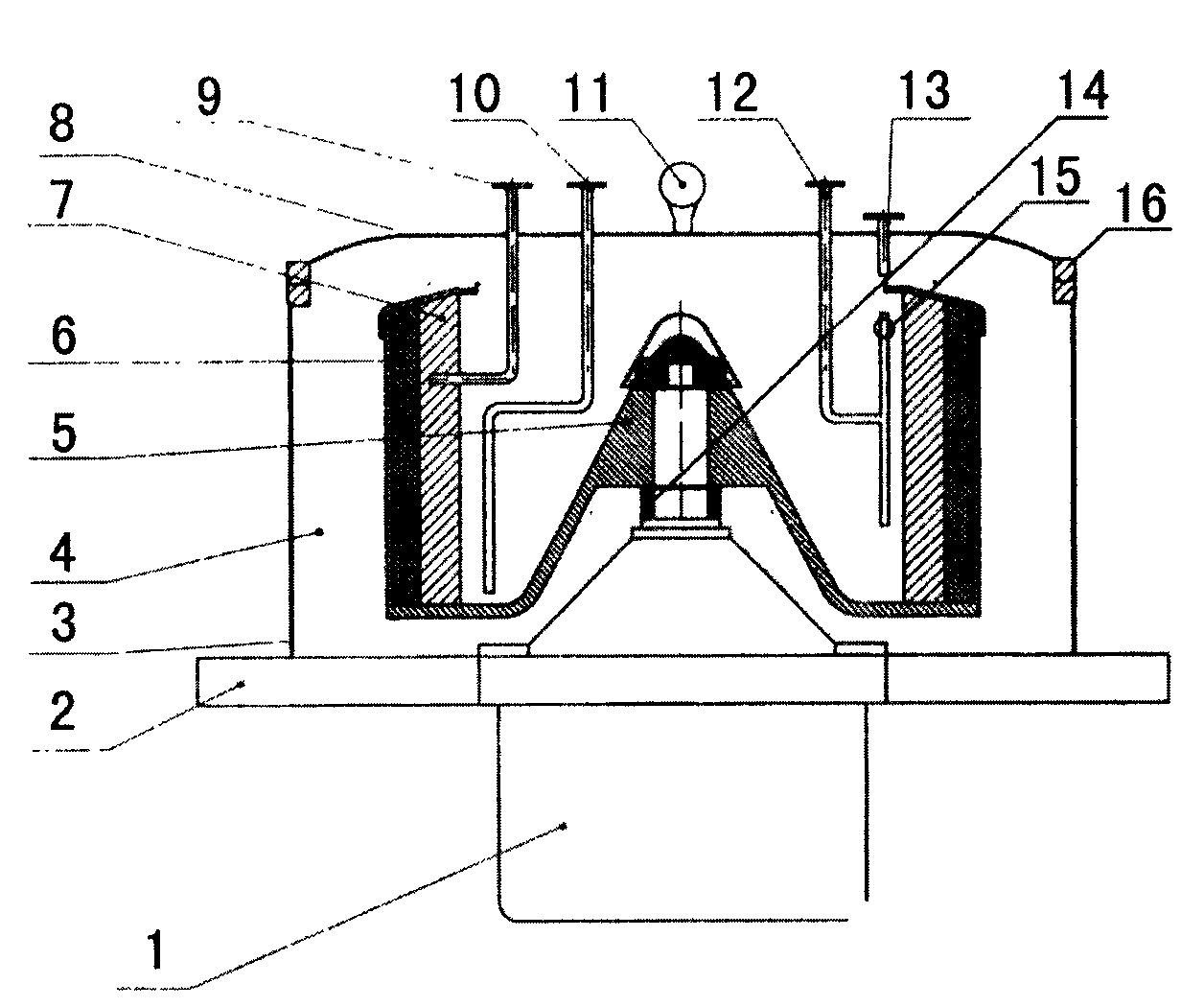

Plate-type settling centrifuge for perfusion

InactiveCN101653749AHigh recovery rateSufficient precipitationRotary centrifugesEngineeringPerfusion

The invention discloses a plate-type settling centrifuge for perfusion, which is used for recycling cultured cells suspended in a bioreactor. A cover of the centrifuge is provided with a material inlet / recycling pipe, a liquid casting pipe, a culture medium conveying pipe and a spraying hole, all of which extend into a rotary drum and are respectively connected with a bioreactor, a supernate storage tank and a culture medium storage tank through a T-shaped valve set. A transmission principal shaft is connected with a rotary drum cavity through four in-series sealing connections comprising framework seal, mechanical sealing, water sealing and mechanical sealing. The rotary drum cavity and the connecting pipes can be sterilized by steam. The cultured material in the bioreactor is sent into the rotary drum through the material inlet / recycling pipe, the centrifugated cells settle on the rotary drum wall, supernate is absorbed out through the liquid casting pipe, the culture medium is sprayed on the settled cells on the rotary drum wall rotating slowly through the culture medium conveying pipe and the spraying hole, and the suspended cells are conveyed back into the bioreactor through the recycling / material inlet pipe.

Owner:BEIJING MABWORKS BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com