A production process for recovering manganese from waste water containing manganese by using waste gas

A production process and wastewater technology, applied in the direction of improving process efficiency, can solve problems such as waste, pollution, environmental pollution, etc., and achieve the effects of improving resource utilization, reducing emissions, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

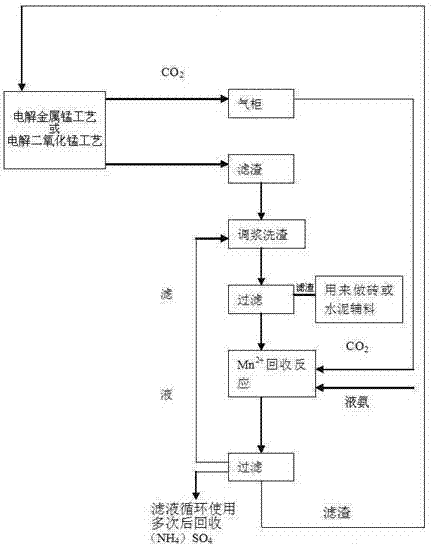

[0032] Such as figure 1 Shown, a kind of production technology that utilizes exhaust gas to reclaim manganese from manganese-containing waste water waste residue comprises the following steps:

[0033] a. Collection of CO produced in the electrolytic manganese metal process 2 in a gas cabinet;

[0034] b. Take the manganese slag produced in the electrolytic metal manganese process, add washing liquid to the manganese slag to adjust the pulp and wash the slag (the washing liquid added for the first time is water), the mass percentage of the manganese slag and the washing liquid is 1:3, (the manganese slag is determined here The mass percentage of slag and lotion is just for the convenience of calculating the extraction rate. In the actual process, the percentage of manganese slag and lotion should be selected and set according to the specific conditions of the production line) and stirred for 10 minutes to obtain the leaching solution;

[0035] c. Feed liquid ammonia to ...

Embodiment 2

[0041] A kind of production technology that utilizes waste gas to reclaim manganese from manganese-containing waste water waste residue, comprises the following steps:

[0042] a. Collection of CO produced in the electrolytic manganese dioxide process 2 in a gas cabinet;

[0043] b. Take the manganese slag produced in the electrolytic manganese dioxide process, add lotion to the manganese slag to adjust the pulp and wash the slag (the first added lotion is water), the mass percentage of the manganese slag and the lotion is 1:3, and stir for 10 minutes. filtered to obtain the leaching solution;

[0044] c. Add NaOH solution to adjust the pH of the leach solution to be 7-7.8, and pass into the CO in the gas cabinet described in step a. 2 , while continuously adding 10% NaOH solution evenly to maintain the pH value of the solution, react for 2 hours, and separate the solid and liquid after the precipitation to obtain MnCO 3 precipitation and filtrate;

[0045] d. The above...

Embodiment 3

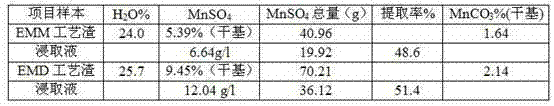

[0050] Take 1Kg of manganese slag from the electrolytic manganese metal process (EMM process), wash the slag with 3Kg of water, stir thoroughly for 10 minutes, then filter, and measure the MnSO in the filtrate 4 content, calculate the extracted MnSO 4 amount.

[0051] Take 1Kg of manganese slag from the electrolytic manganese dioxide process (EMD process), wash the slag with 3Kg of water, stir thoroughly for 10 minutes, then filter, and measure the MnSO in the filtrate 4 content, calculate the extracted MnSO 4 amount.

[0052] The above-mentioned EMM process and the MnSO in the manganese slag filtrate of the EMD process 4 The content is shown in Table 1.

[0053] Table 1

[0054]

[0055] It can be seen from Table 1 that after filtration, the MnSO in waste residue in EMM process and EMD process 4 The extraction rates were 48.6% and 51.4%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com