High-strength high-conductivity copper alloy material, preparation method thereof and application thereof

A copper alloy, high-conductivity technology, used in semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve problems such as reduced conductivity and strength, and achieve low residual stress, strong pinning effect, high resistance The effect of high temperature softening properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

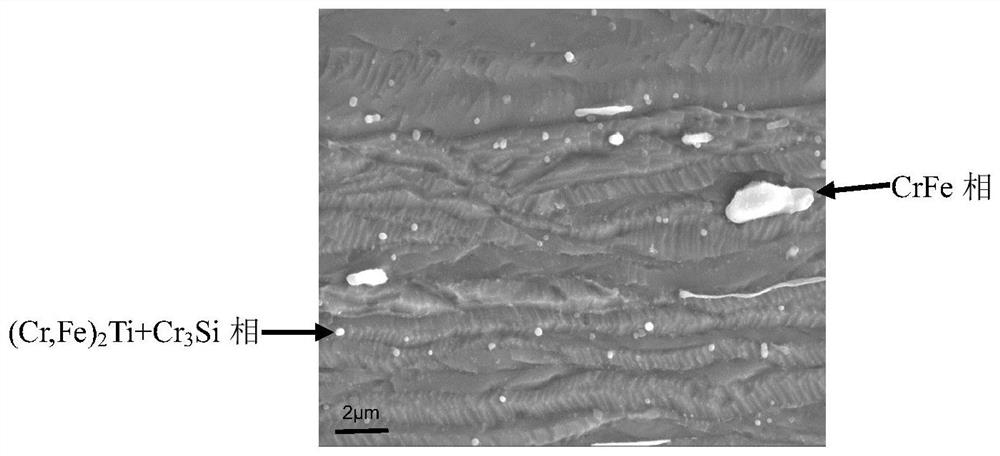

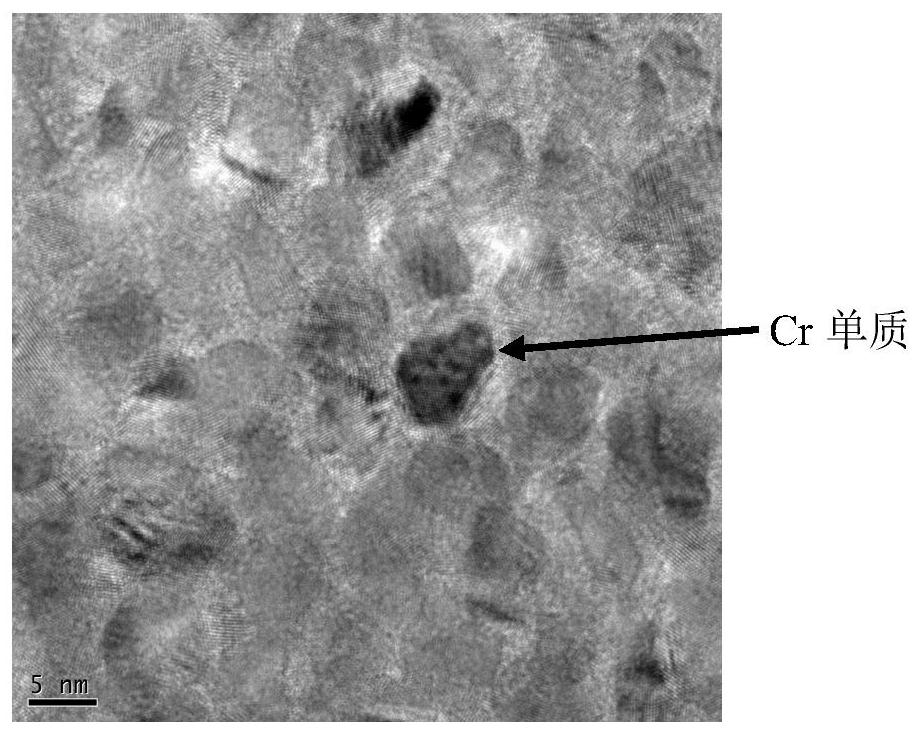

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0043] According to each embodiment of table 1 and table 2 and the copper alloy batching shown in comparative example composition, carry out vacuum melting and casting at 1200~1300 ℃, form ingot and carry out face milling treatment once; Above-mentioned ingot is kept at 850~900 ℃ After 2 to 4 hours, hot rolling is carried out at a rolling rate of not less than 85%; followed by secondary milling, the upper and lower milling faces of the hot rolled plate are 0.5 to 1.0mm; after that, the rolling rate is not lower than 80% Carry out a cold rolling; then, heat the plate after the primary cold rolling at 950-1050°C for 30-200s for solution treatment; Cold rolling, then performing primary aging treatment at 400-550°C, then performing cold finish rolling at a processing rate of 40-80%, and finally performing secondary aging treatment at 200-450°C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com