Patents

Literature

34results about How to "Strong pinning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

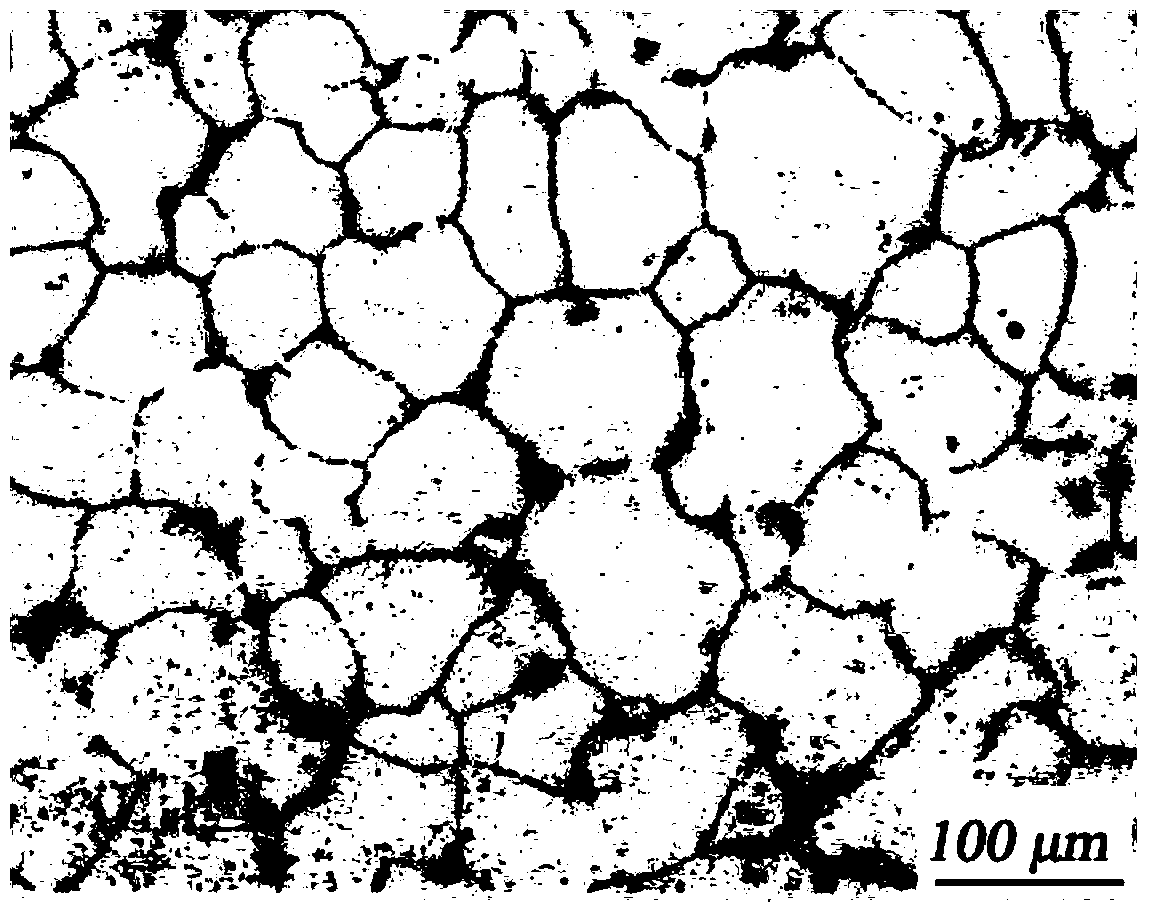

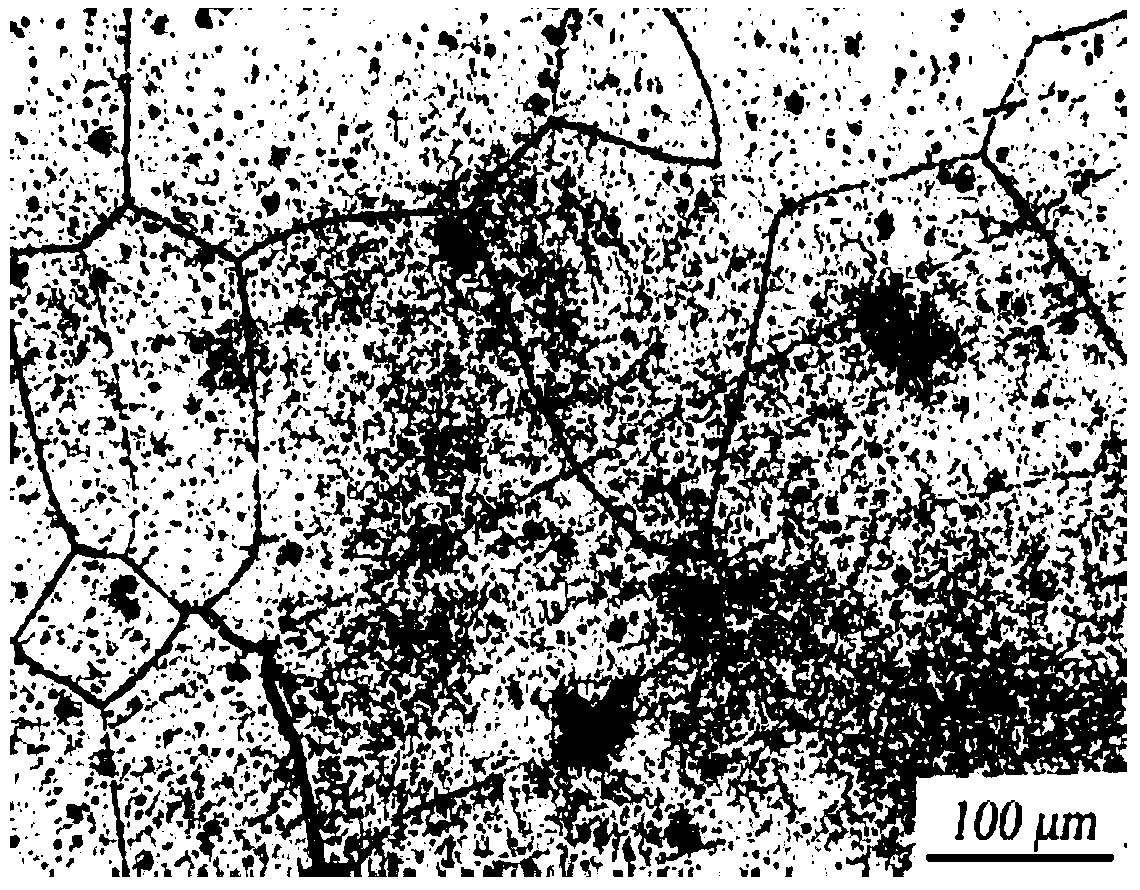

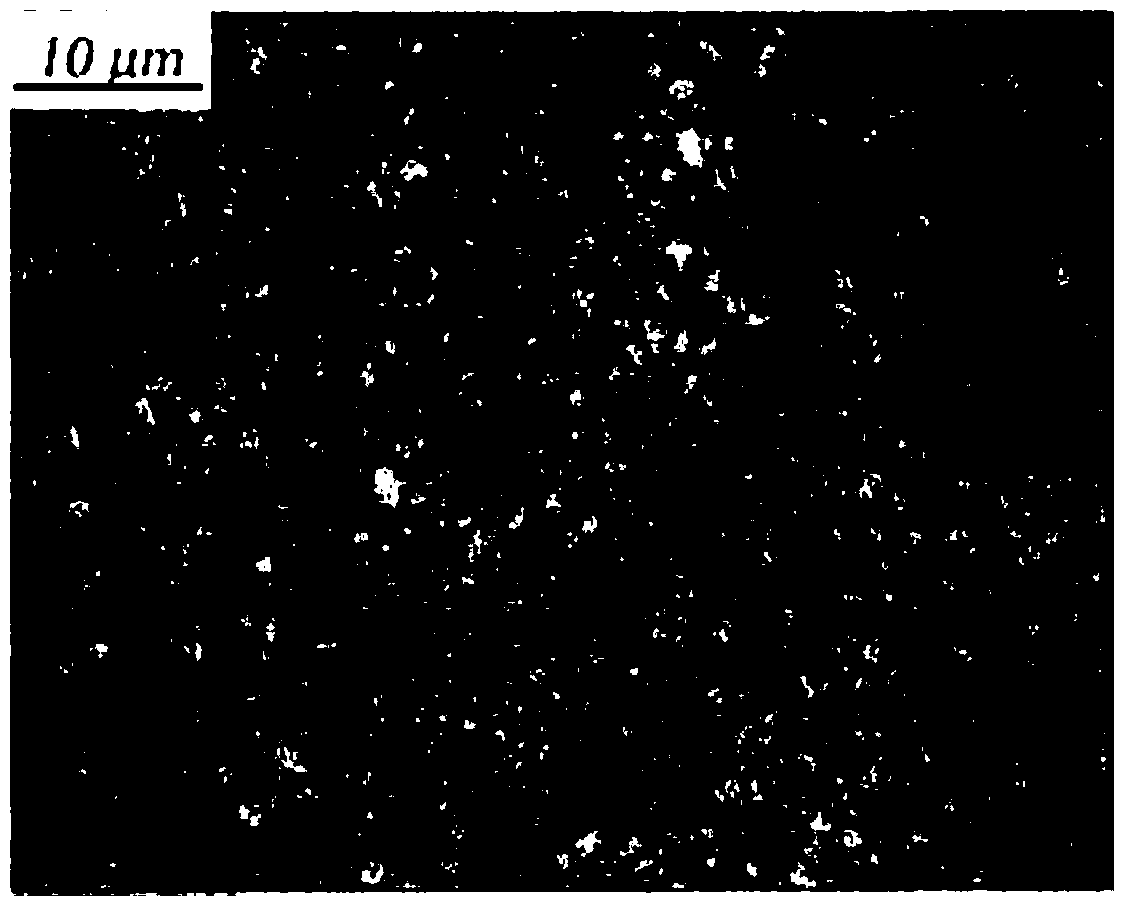

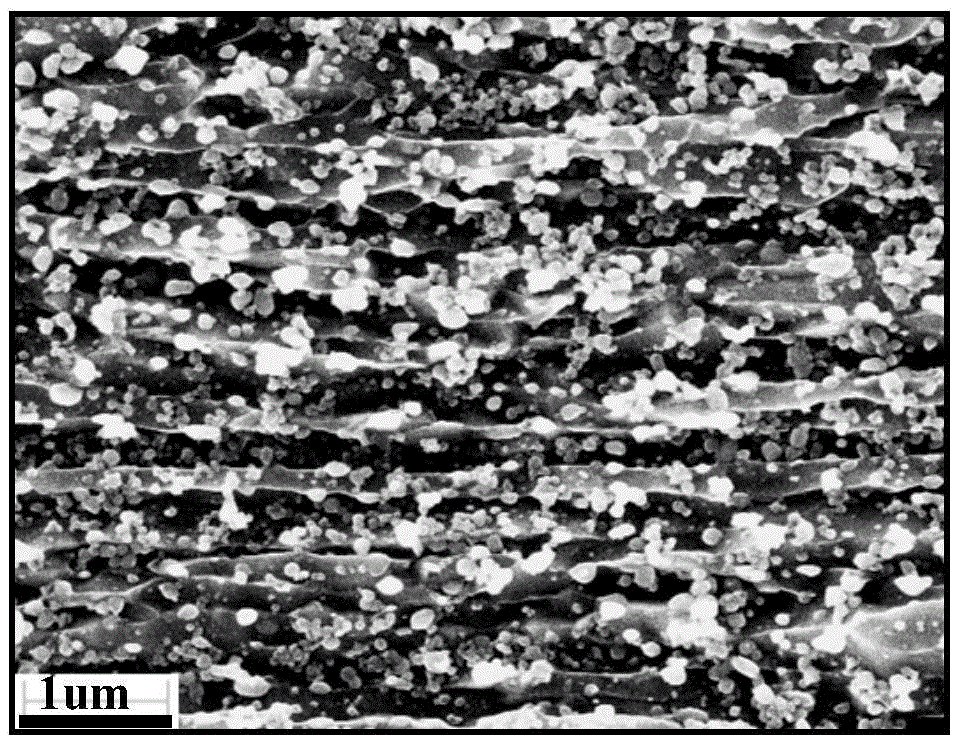

Superfine crystal nickel-based high-temperature alloy and method for preparing same

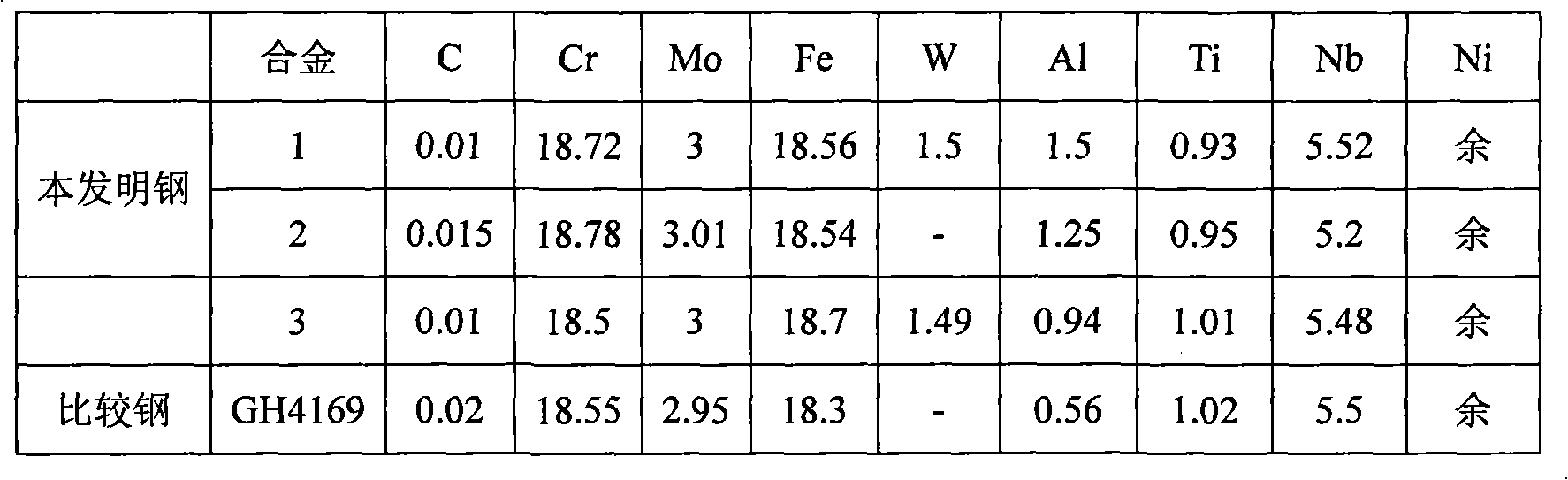

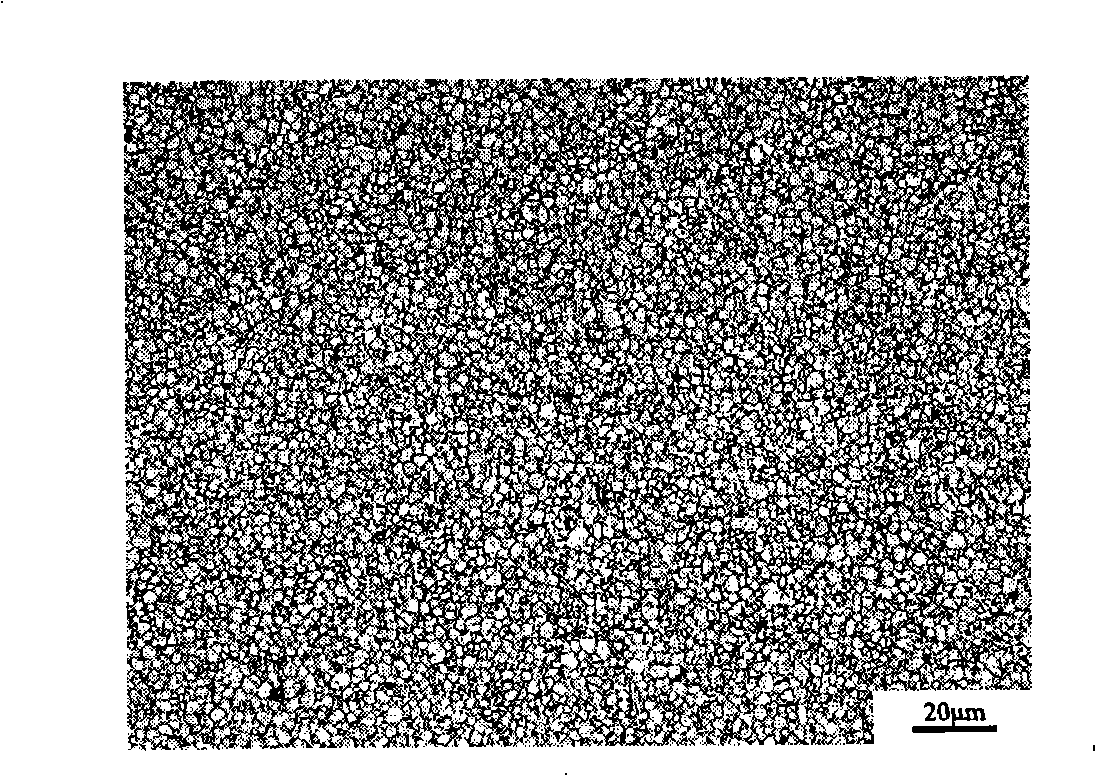

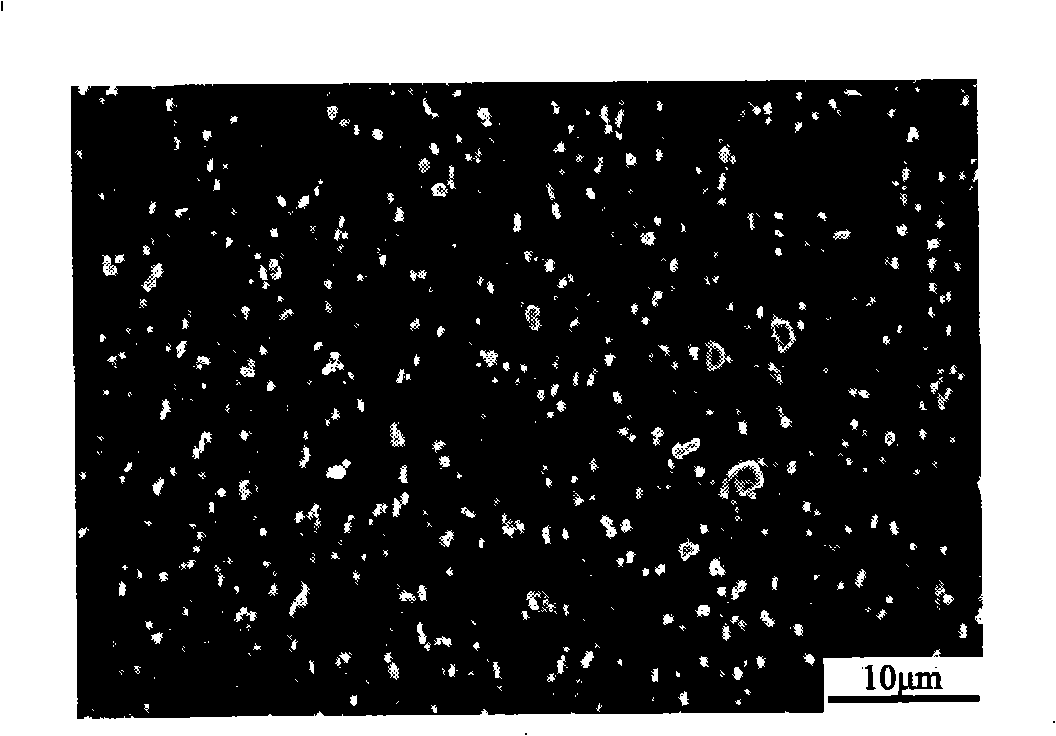

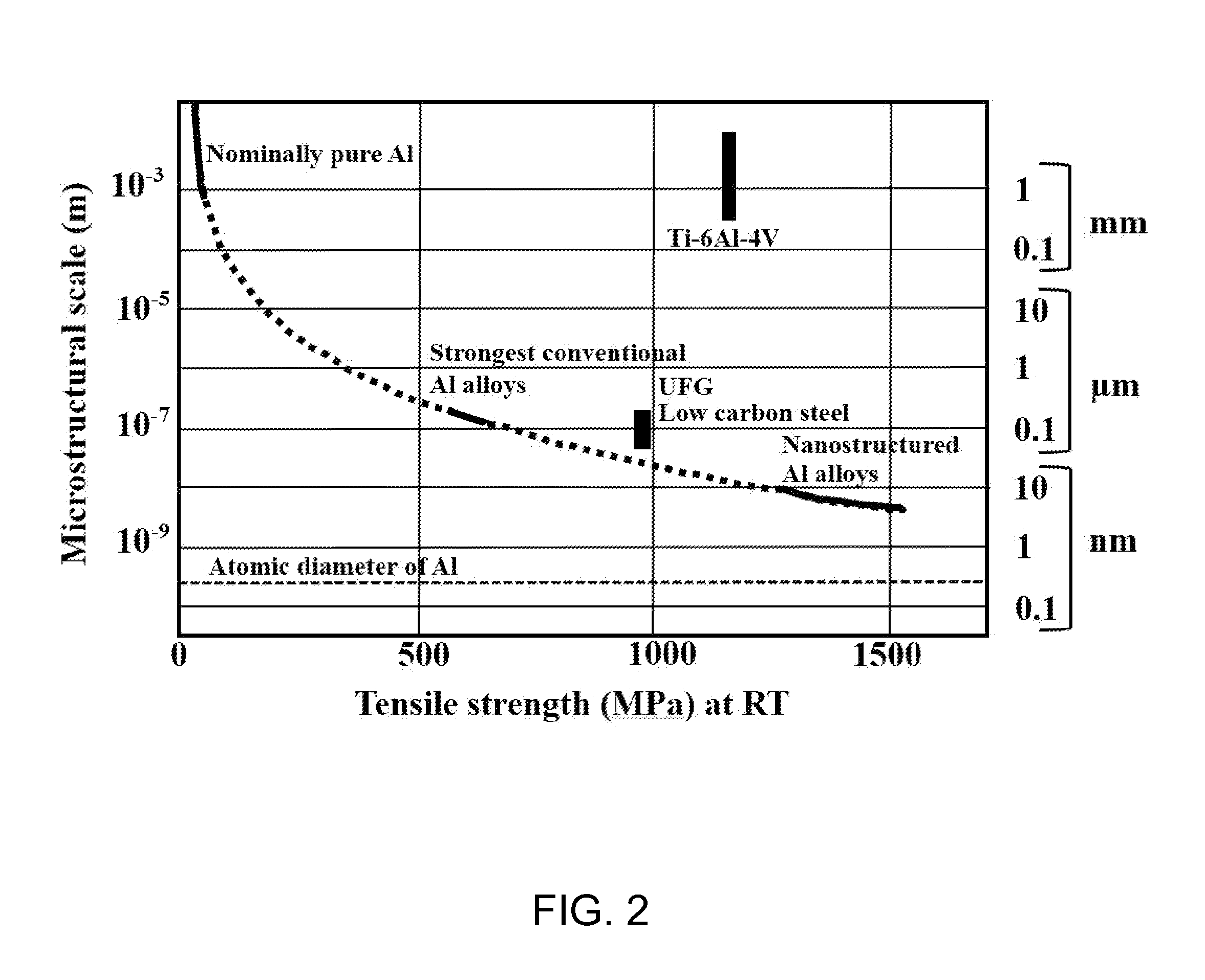

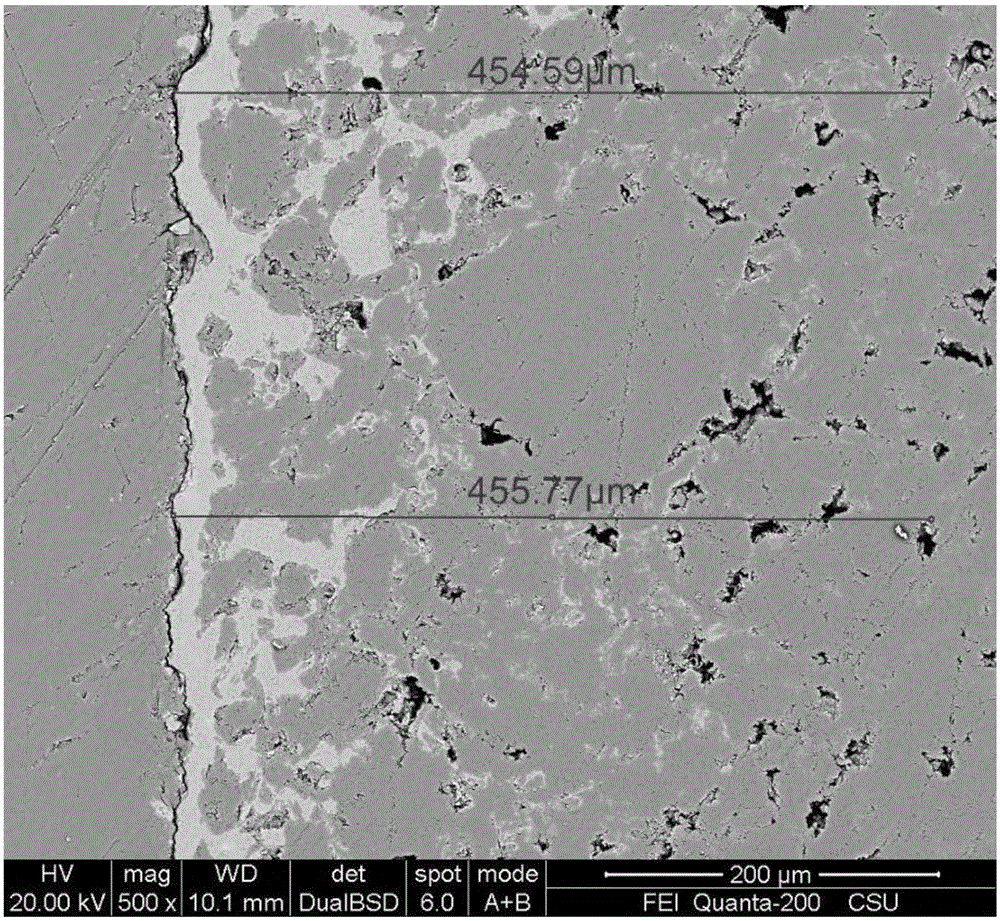

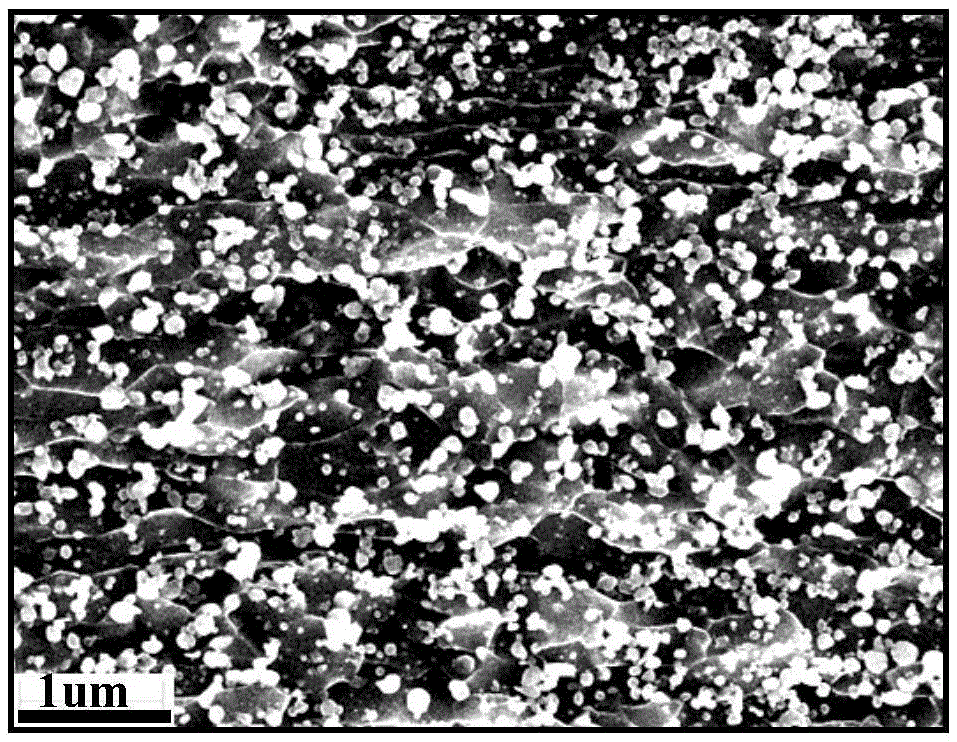

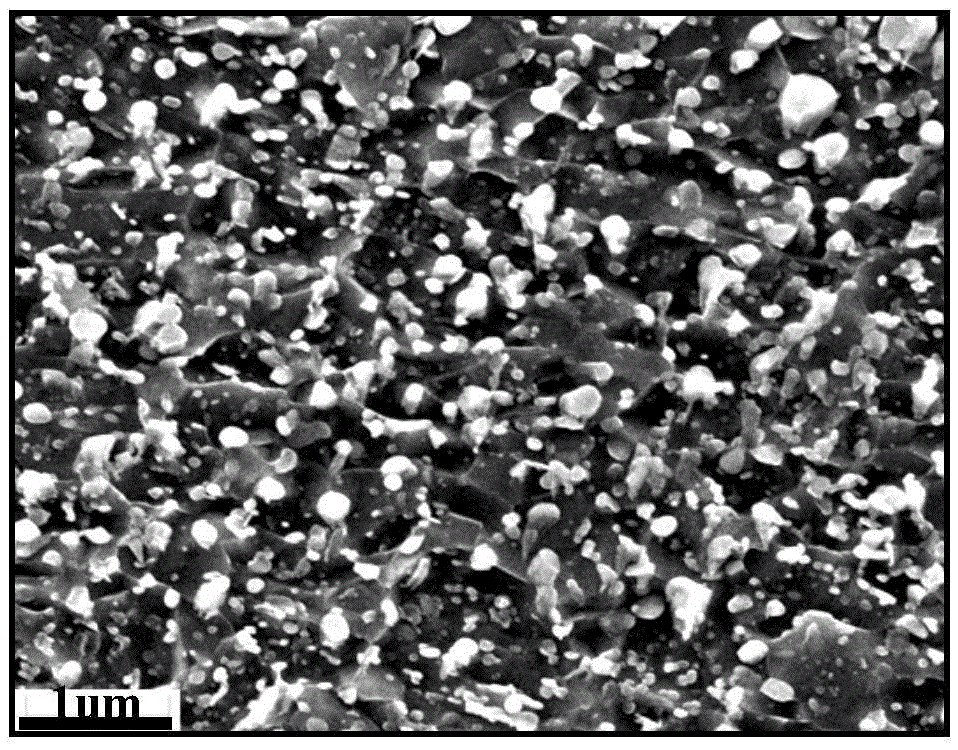

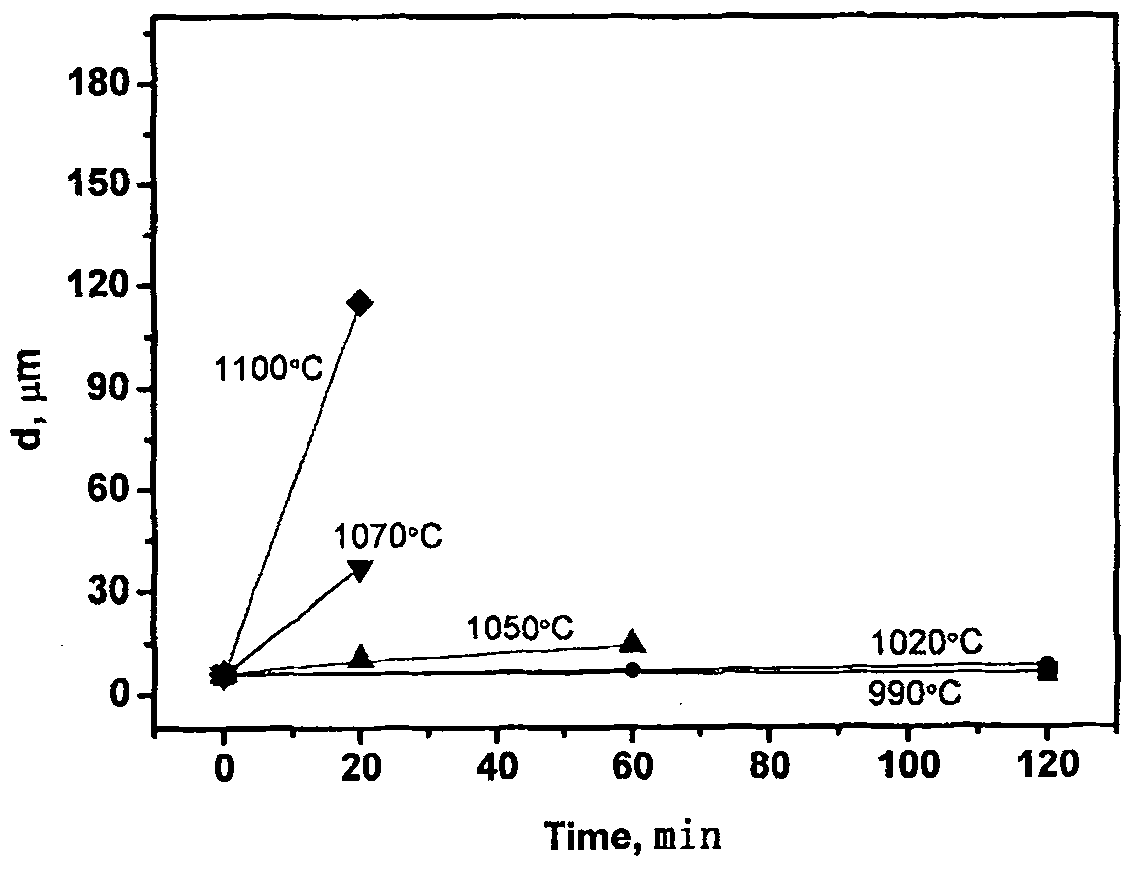

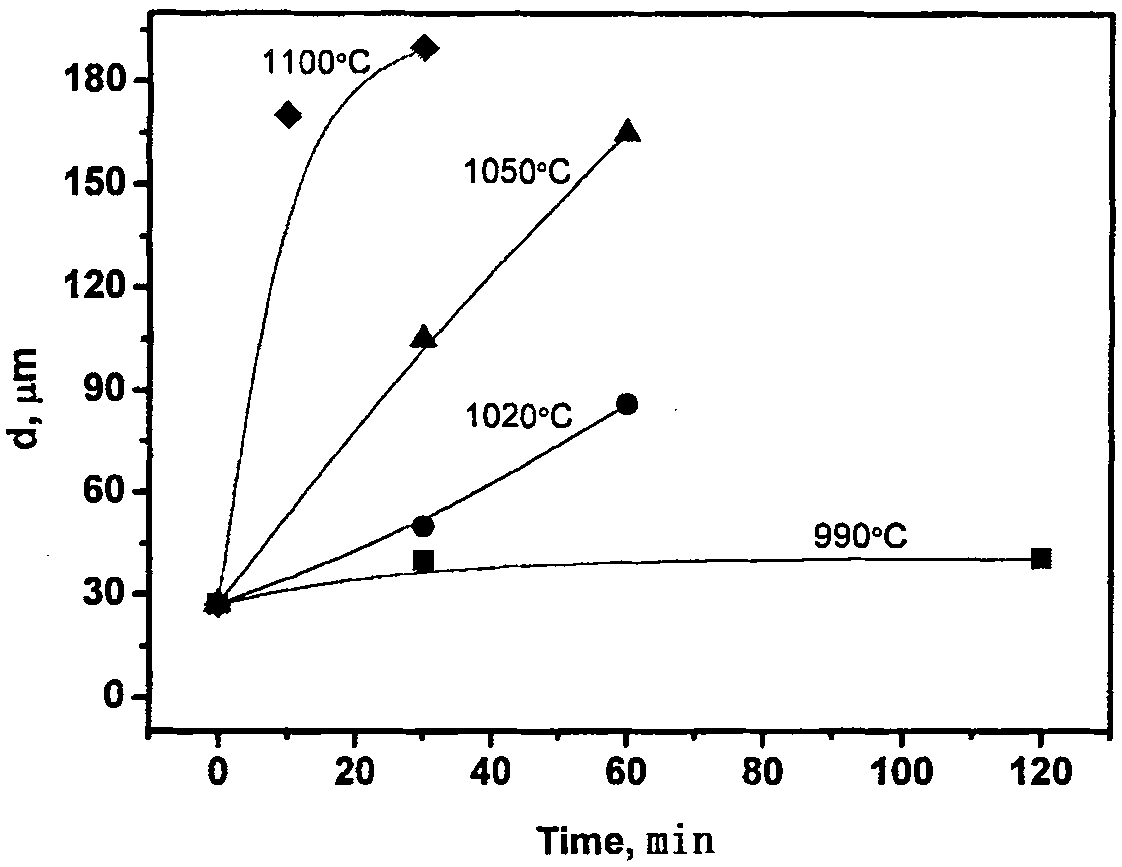

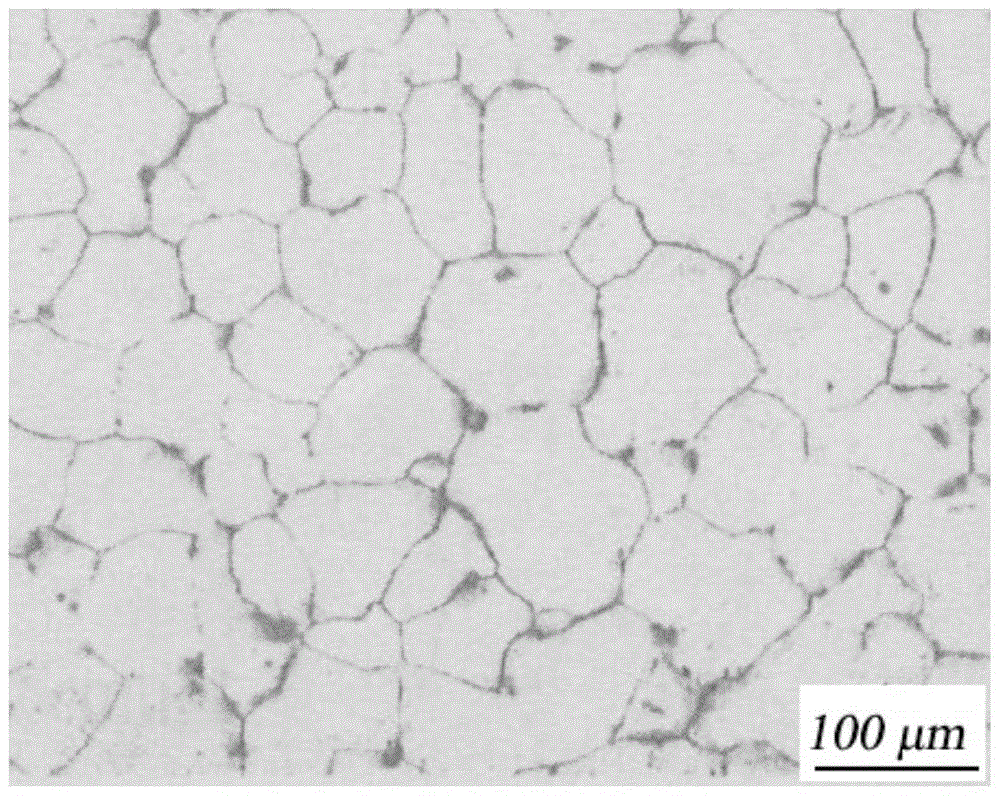

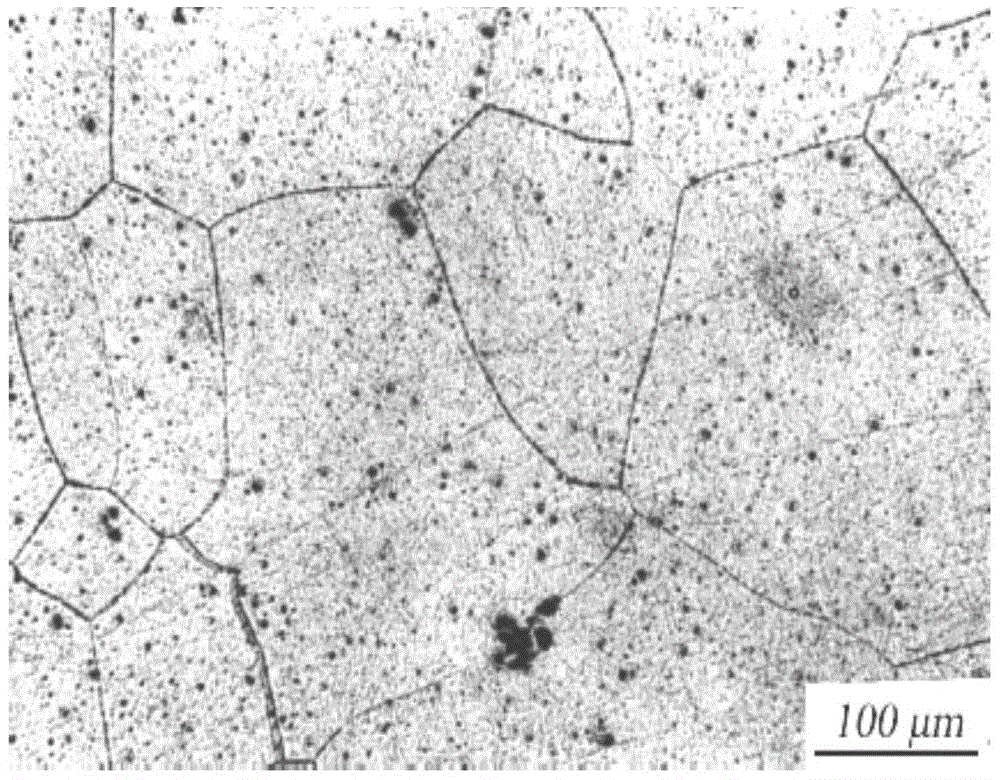

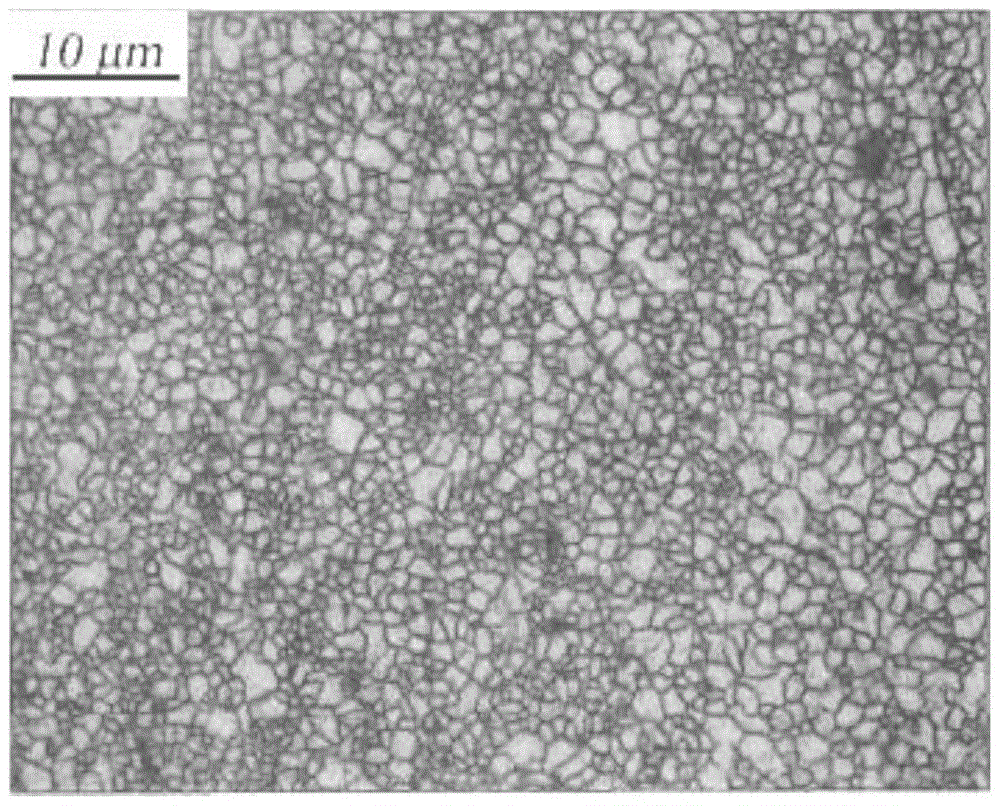

The invention provides an ultra-fine crystalline nickel base high-temperature alloy and a method for preparing the same, belonging to the high-temperature alloy steel field. The ultra-fine crystalline nickel base high-temperature alloy is particularly applicable to a high-temperature structural component which has high requirement to high-temperature strength and fatigue property, requires superplastic forming and has a complicated structure. The chemical compositions by weight percent of the ultra-fine crystalline nickel base high-temperature alloy are: 17 to 19 percent of Fe, 17 to 20 percent of Cr, 2.8 to 3.3 percent of Mo, 0 to 1.5 percent of W, 0.8 to 1.5 percent of Al, 0.3 to 1.3 percent of Ti, 4.7 to 5.7 percent of Nb, less than or equal to 0.015 percent of C, and the balance being Ni. The preparation method reasonably controls the parameter of a deformation process to allow the deformation temperature to be positioned in a grain boundary precipitated phase region and an austenite phase region which have higher solution temperatures, and uses powerful pinning action of a precipitated phase to the grain boundary to produce the ultra-fine crystalline alloy with a grade of grain fineness of between ASTM12 and ASTM13 grade. Compared with the prior art, the ultra-fine crystalline nickel base high-temperature alloy has simple alloy compositions, greatly reduces the resistance to deformation during forming, has small loss to forging and rolling equipment, and prevents crystal grains from growing when the ultra-fine crystalline nickel base high-temperature alloy is heated for a long time at a high temperature.

Owner:UNIV OF SCI & TECH BEIJING

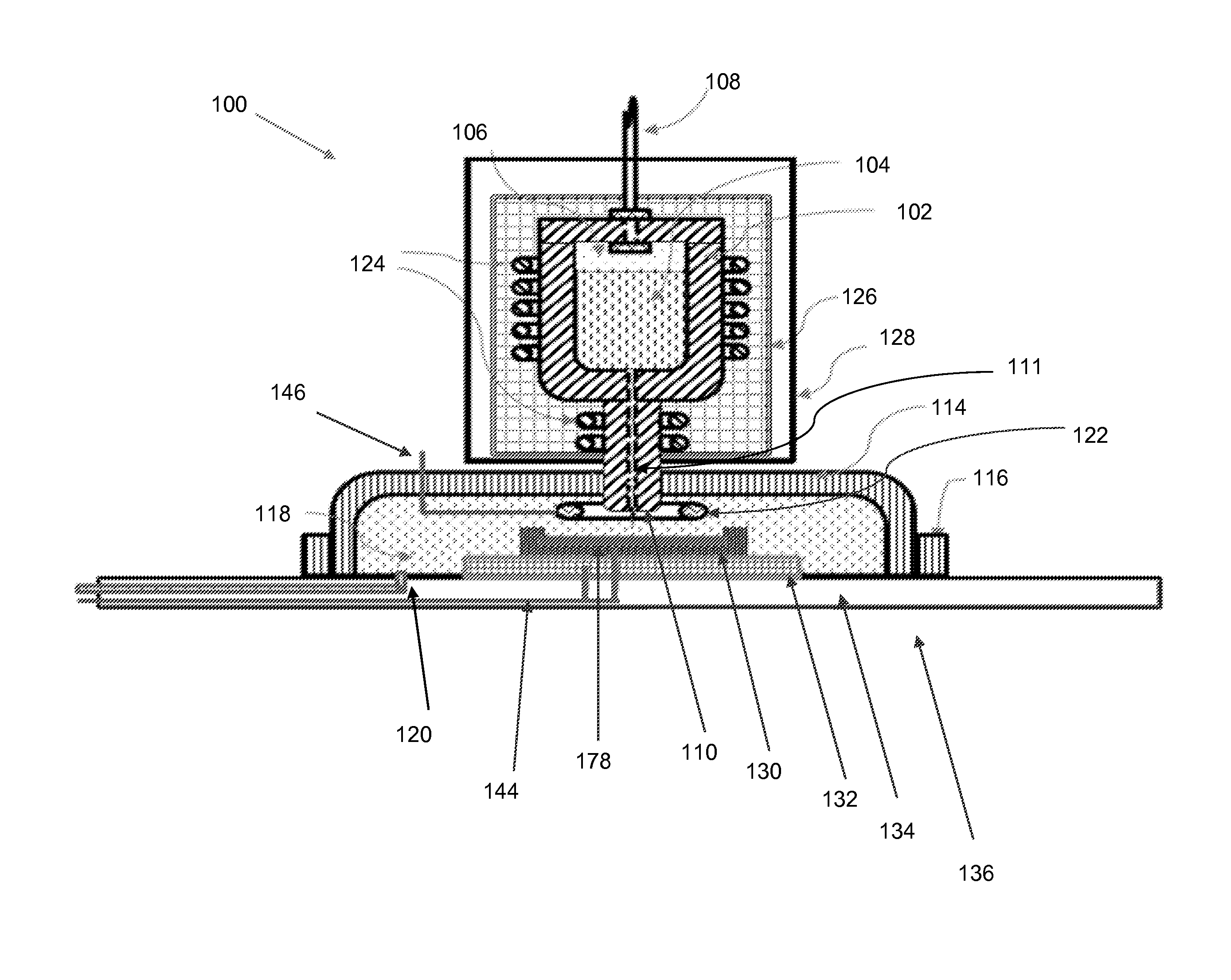

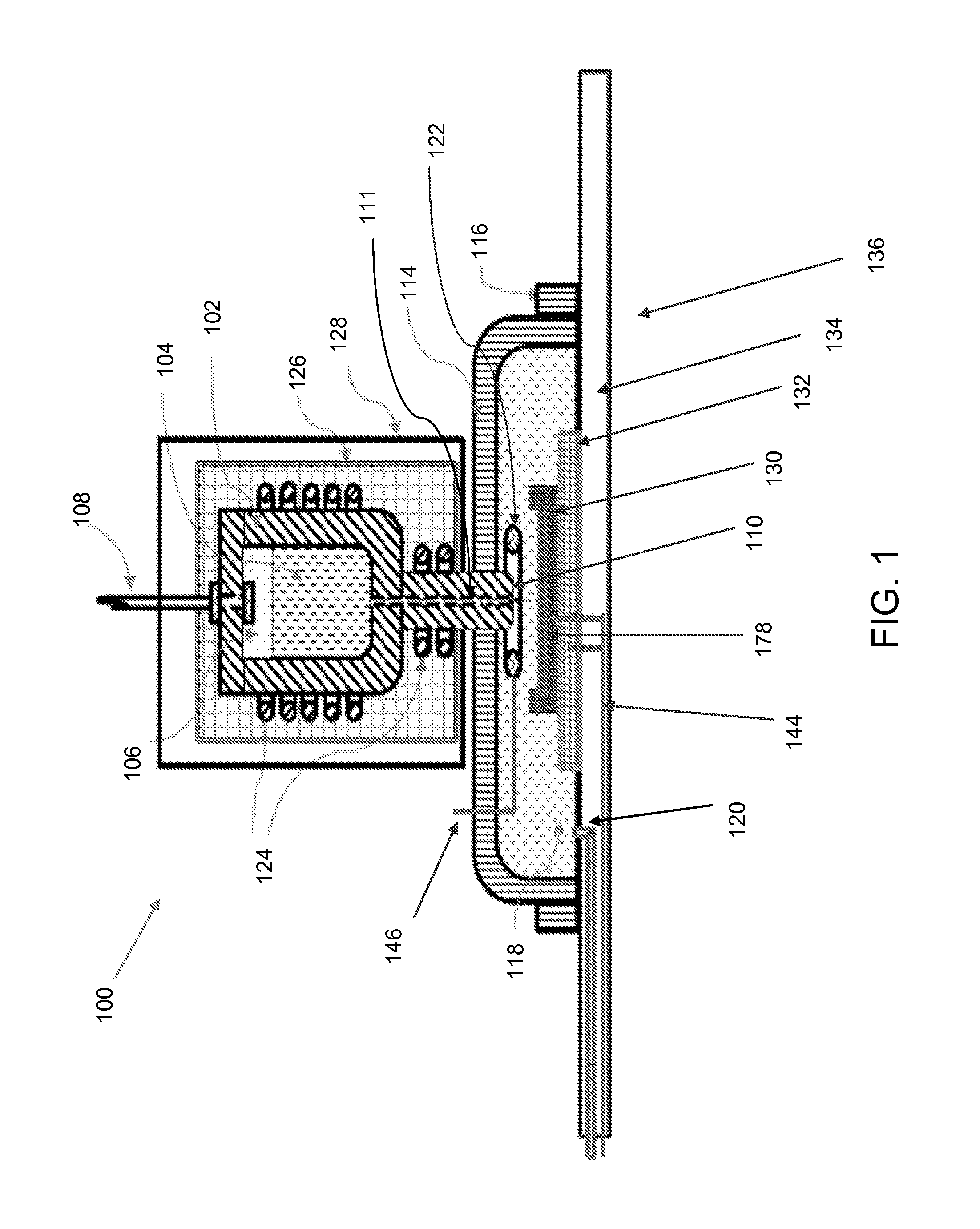

Electrospray pinning of nanograined depositions

ActiveUS20150251213A1Inhibition of recrystallizationEnhanced nucleationLiquid surface applicatorsAdditive manufacturing apparatusGrain growthElectric field

A method and apparatus for fabrication of objects retaining nano-scale characteristics. A composition is provided comprising grain growth inhibitor particles in solution with a binding agent in a molten phase. An electric field and a magnetic field are generated with a combined extraction electrode. The composition is electrosprayed from a nozzle with the electric field to form a stream of droplets. The electric field drives the droplets toward a moving stage holding an object comprising successive deposition layers. The magnetic field limits dispersion of the stream of droplets. The stage is moved laterally as the stream of droplets impacts the object to form a current deposition layer of the object. The stage is moved vertically as necessary to maintain a target stand-off distance between the nozzle and a previous deposition layer of the object, based on profile data of the previous deposition layer.

Owner:Q21 CORPORATION +1

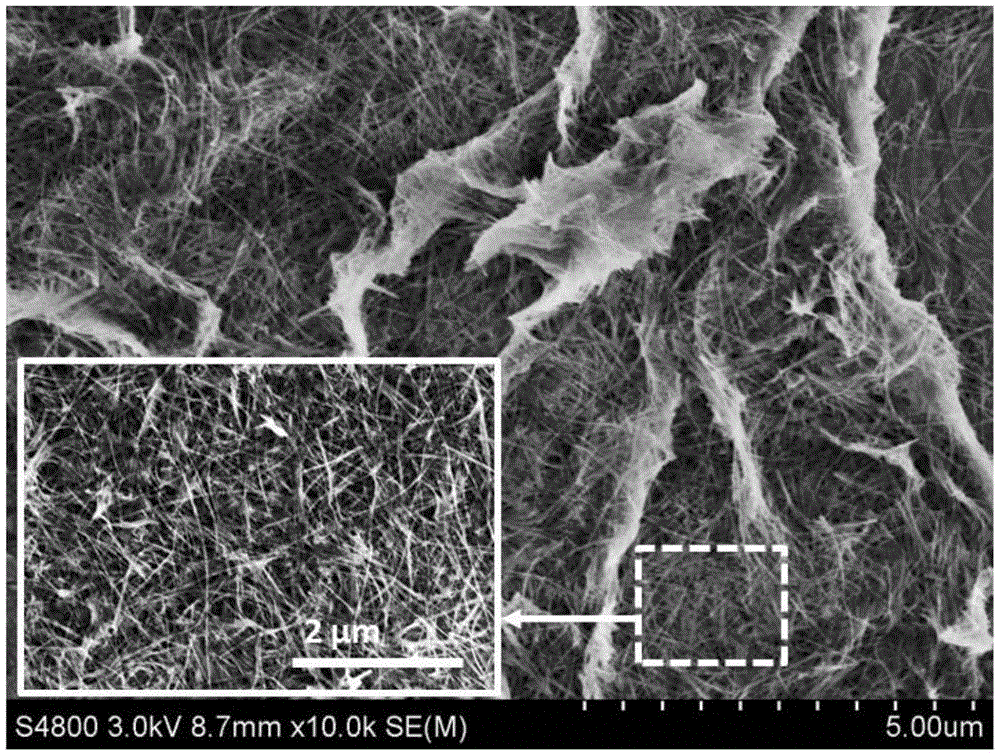

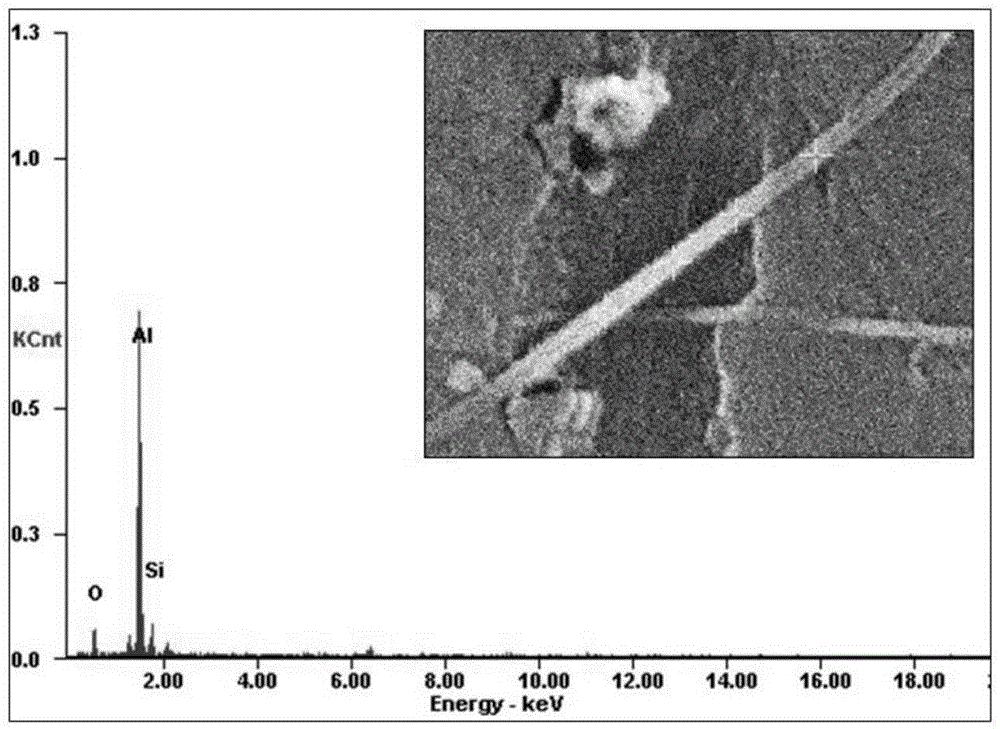

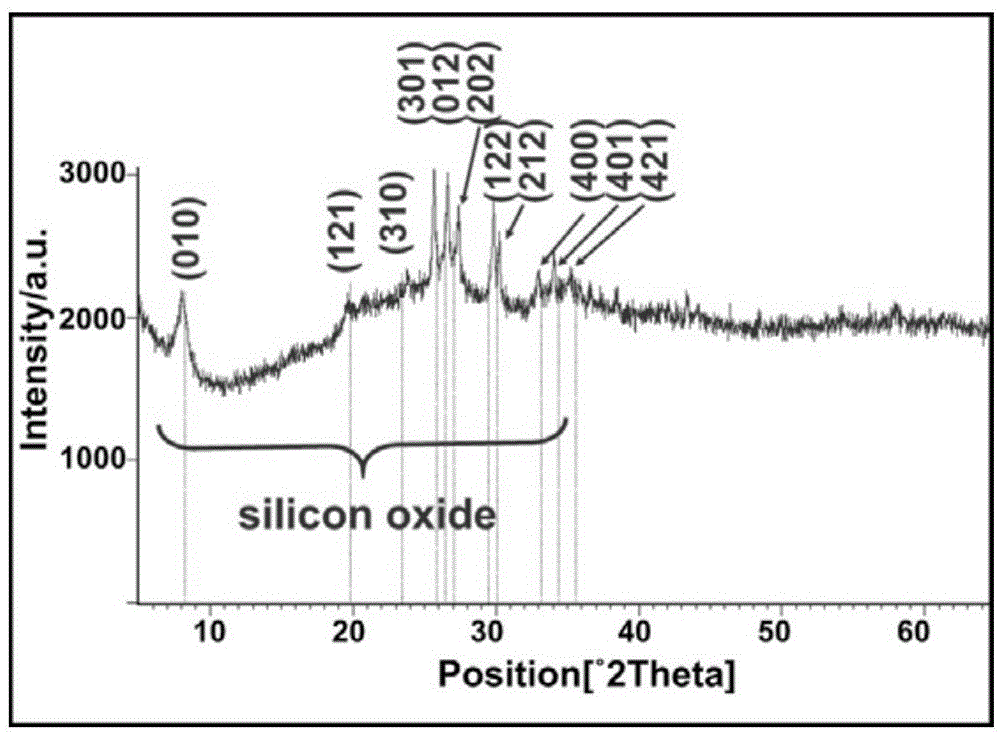

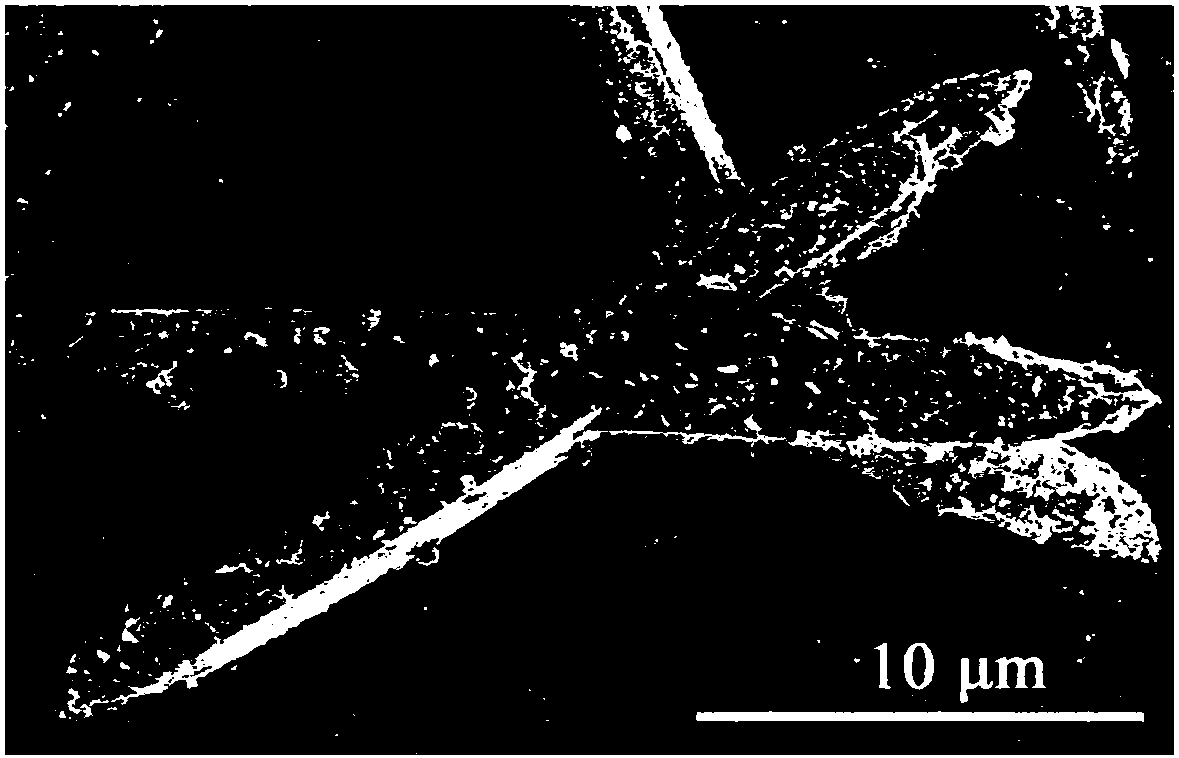

Method for preparing silicon oxide nanofiber

InactiveCN105600793AThe preparation method is convenient and efficientLow costMaterial nanotechnologySilicaPolytetrafluoroethyleneHydrothermal synthesis

The invention discloses a method for preparing silicon oxide nanofiber. The method comprises the following steps of mixing silica sol with a nitrate solution, performing ultrasonic dispersion on the solution, adding ethylenediamine after the dissolution of the nitrate solution, and stirring uniformly to obtain a mixed solution; putting the mixed solution into a stainless steel reaction kettle with a polytetrafluoroethylene liner, standing the reaction kettle in a high-temperature baking oven after the closing of the reaction kettle, and performing a hydrothermal reaction; taking out the reaction kettle and cooling the reaction kettle to room temperature after the completion of the reaction, collecting precipitates in the reaction kettle, and washing the precipitates to obtain a silicon oxide nanofiber crude product; adding the silicon oxide nanofiber crude product into a hydrochloric acid solution, stirring in a thermostatic water bath, removing impurity components from the silicon oxide nanofiber crude product, and performing centrifugal separation to obtain a silicon oxide nanofiber finished product. The method disclosed by the invention has the advantages that not only can the high energy consumption in a nanofiber preparation process through a traditional chemical vapor deposition and thermal evaporation technology be avoided, but also the production is easily expanded by utilization of a hydrothermal synthesis technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

Magnesium lithium alloy, preparation method thereof and preparation method for magnesium lithium alloy plate

The invention discloses magnesium lithium alloy, a preparation method thereof and a preparation method for magnesium lithium alloy plate. The magnesium lithium alloy is composed of 10-15% of Li, 3-6% of Al, 0.3-2.0% of Sr, 0.05-1.0% of Sc, 0.05-0.5% of Zr, less than or equal to 0.005% of impurity element Fe, less than or equal to 0.002% of Ni, less than or equal to 0.02% of Cu and rest of Mg by weight. By means of the Sr and Sc, the heat resistance of the magnesium lithium alloy is improved, the problem of the beta-phase magnesium lithium alloy that the mechanical property of the alloy is lowered obviously due to over-aging is overcame effectively, and moreover, the dendritic crystal growth is hindered because Al3Sc is enriched on a solid-liquid interface, and accordingly the cast structure of the alloy is thinned; after the alloy is solidified, most of the Al3Sc phase is distributed at the crystal boundary, so that the crystal boundary can be pinned greatly, and the yield strength and the tensile strength of the alloy are obviously improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Graphite material with SiC doped layer and preparation method of graphite material

The invention discloses a graphite material with a SiC doped layer and a preparation method of the graphite material. The preparation method of the graphite material with the SiC doped layer comprises the following step: by taking mixed powder of silicon-containing powder and boron nitride as a silicon source, performing liquid-phase siliconing sintering on a graphite material, thereby obtaining the graphite material with the SiC doped layer. The graphite material with the SiC doped layer prepared by using the method comprises a graphite substrate and the SiC doped layer on the surface of the graphite substrate, the SiC doped layer is well combined with the graphite substrate without thermal mismatch, the graphite material is good in oxidation and corrosion resistance and relatively low in cost, and a small amount of silicon is adhered to the surface of the graphite material.

Owner:NAT UNIV OF DEFENSE TECH

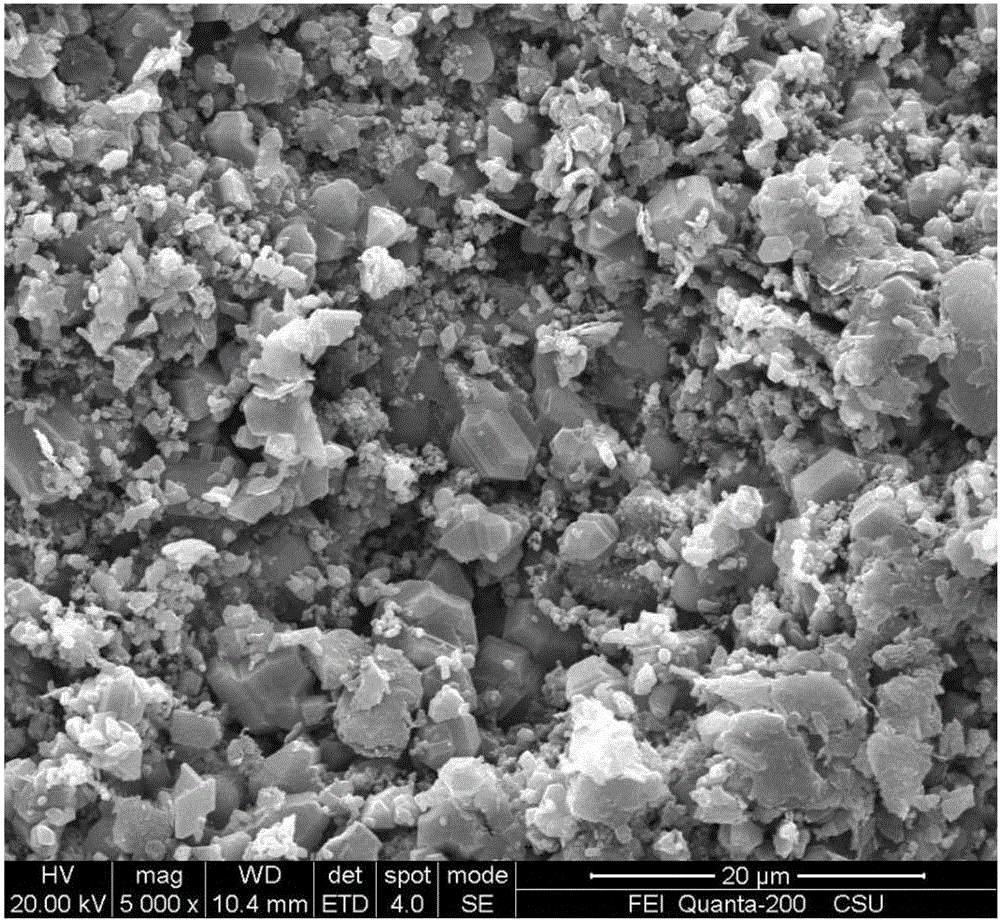

Preparation method of calcium carbonate whisker with continuously controllable morphology

ActiveCN107916452AIncrease growth pointStrong "pinning" effectPolycrystalline material growthFrom normal temperature solutionsFilling materialsWhiskers

The invention discloses a preparation method of a calcium carbonate whisker with continuously controllable morphology. The preparation method comprises the following steps of firstly, adding calcium oxide into deionized water, and digesting at certain temperature; then, adding a crystal form control agent, uniformly stirring, and enabling a double-pipe air ventilating device to lead carbon dioxidegas at certain flow rate to perform carbonation reaction; finally, sucking and filtering the obtained suspension liquid, washing, and drying, so as to obtain a sample. The preparation method has thecharacteristics that the prepared multi-arm whisker is the calcium carbonate whisker with novel morphology, and the number of whisker branches can be controlled through reaction conditions; the whisker is used as a filling material of the composite material, the chemical property and mechanical property are improved, and the like.

Owner:ZHEJIANG UNIV

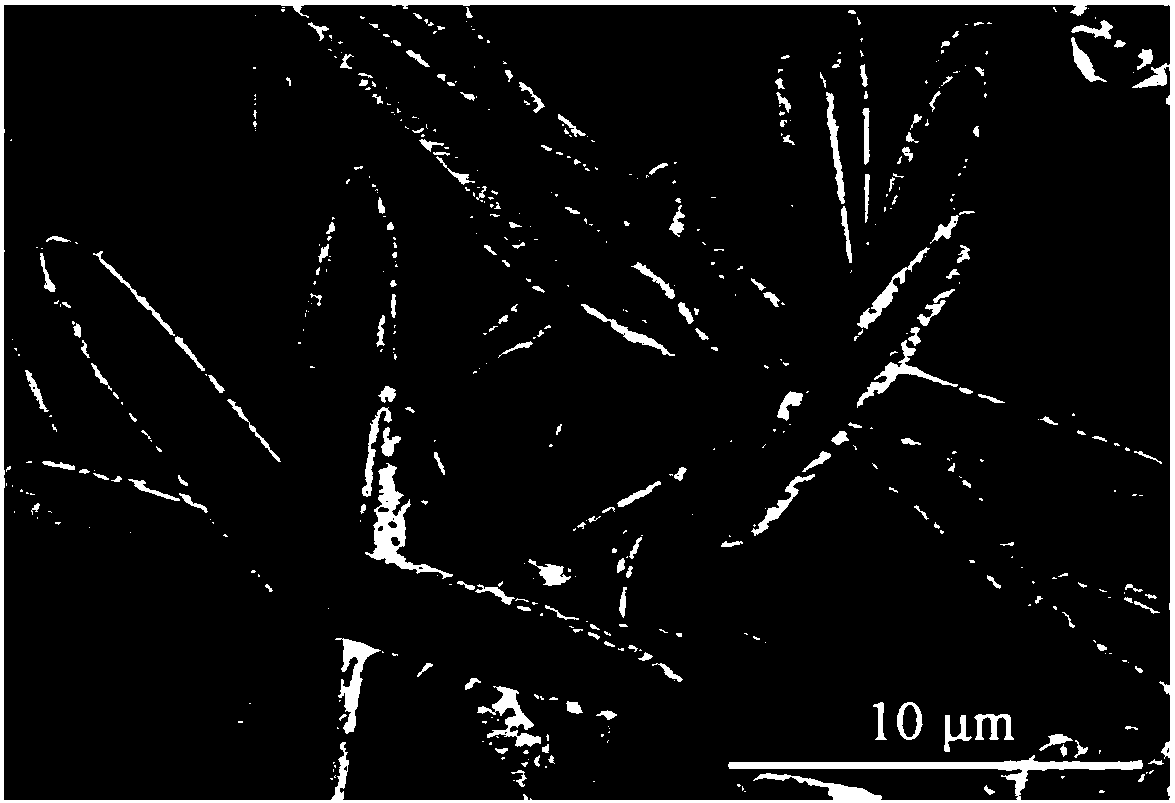

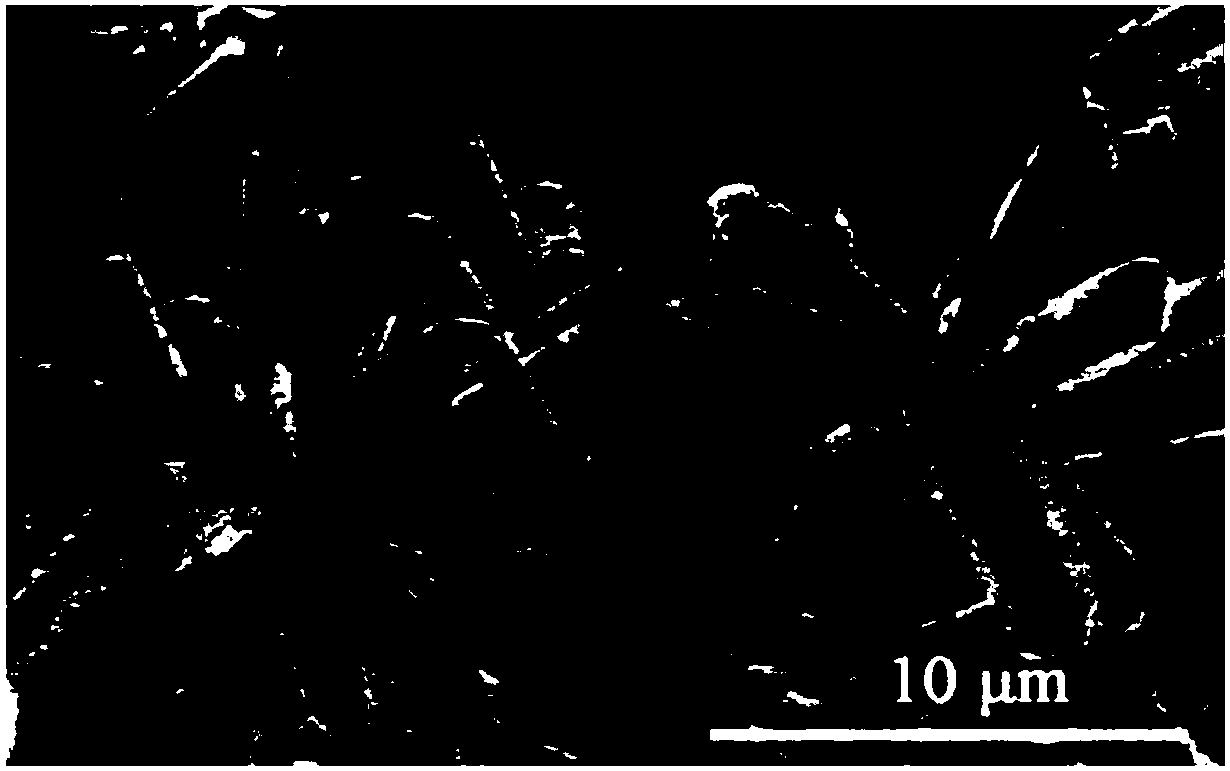

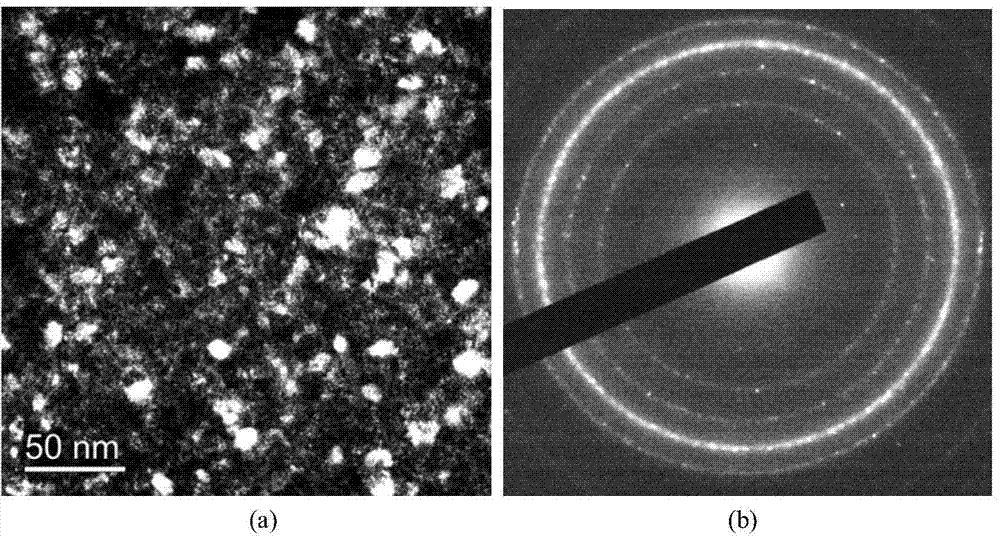

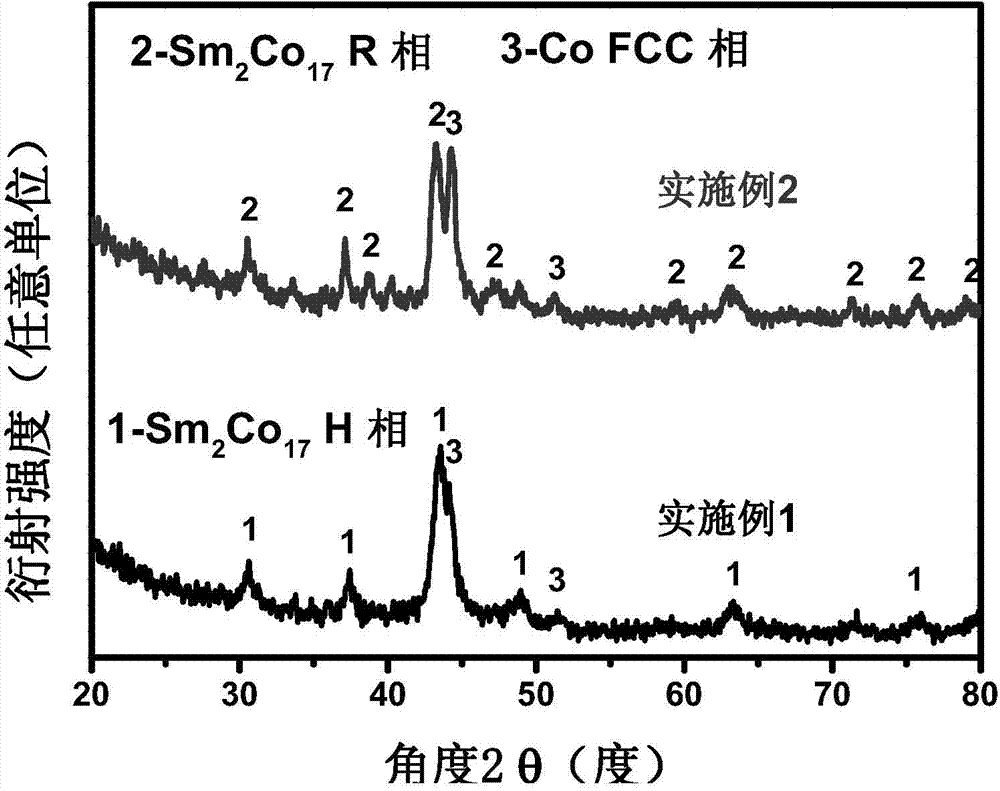

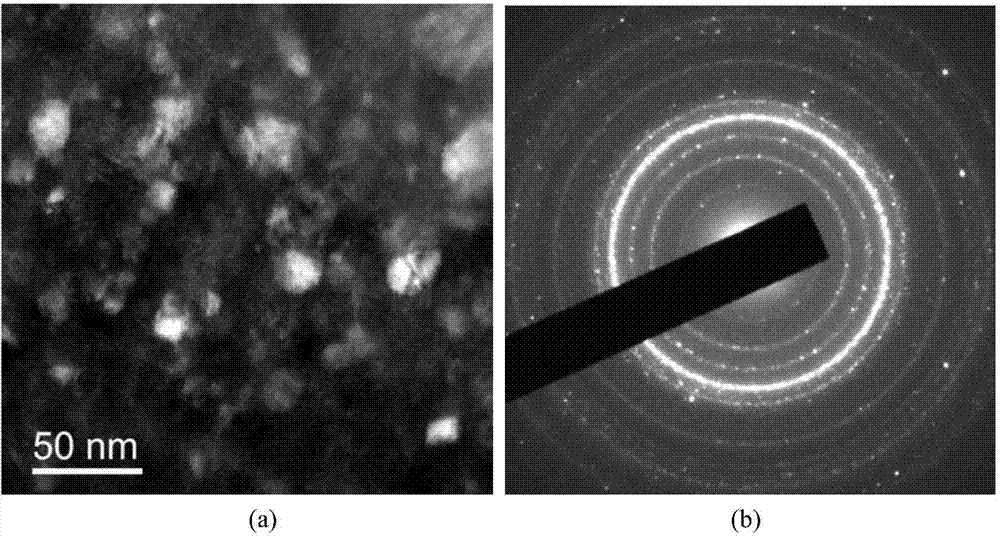

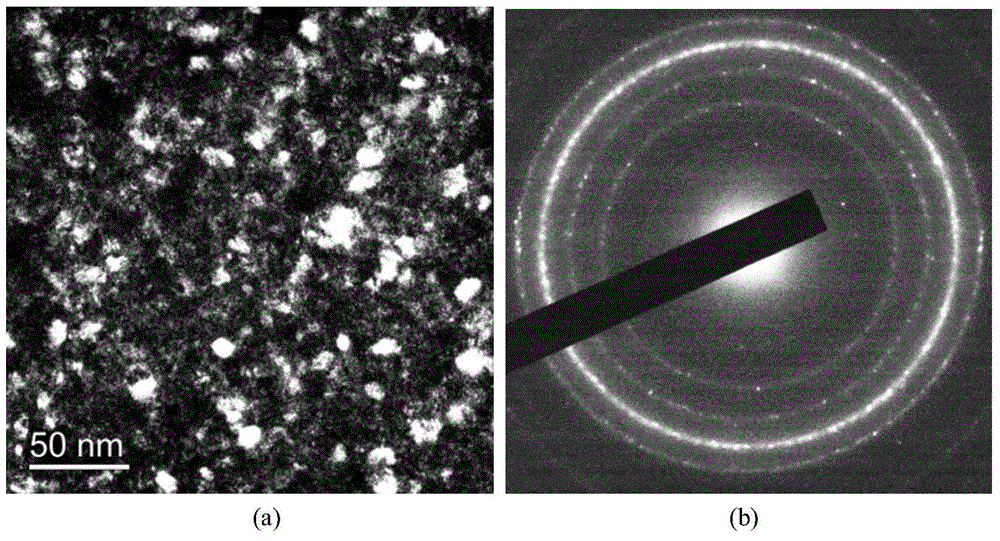

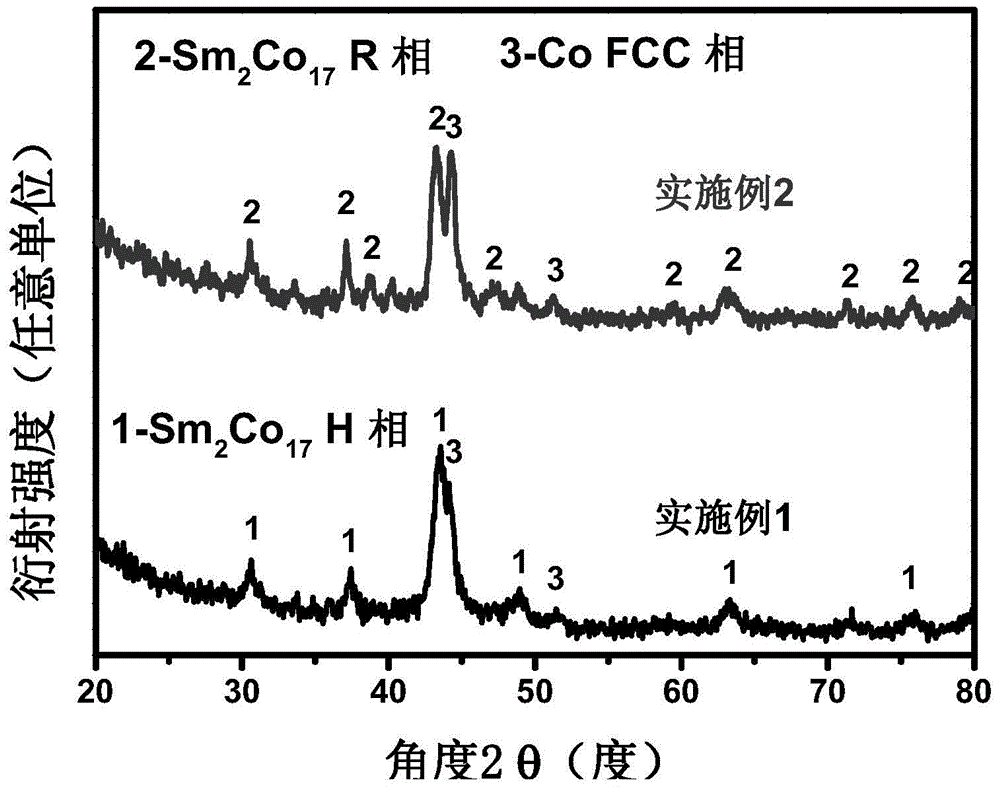

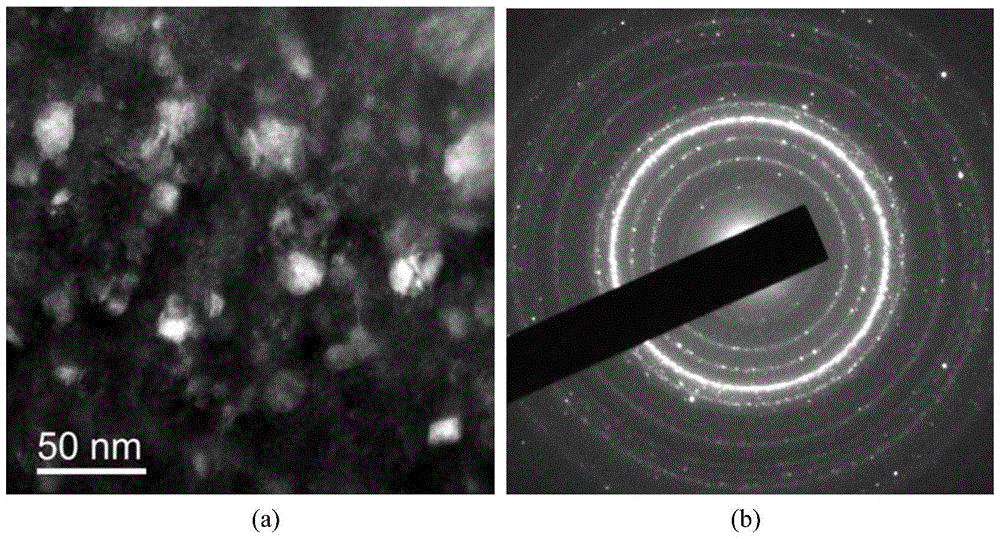

A preparing method of a nanocrystal Sm<2>Co<17>/Co double-phase composite permanent magnetic alloy

The invention provides a preparing method of a nanocrystal Sm<2>Co<17> / Co double-phase composite permanent magnetic alloy, and belongs to the technical field of double-phase composite permanent magnetic alloys. The method includes smelting a pure Sm block, a Co block and an elementary substance of an added element under the protection of argon to obtain a multi-component parent phase alloy; allowing phases and component distribution of the parent phase alloy to be uniform by a plurality of times of remelting and homogenizing annealing; preparing the parent phase alloy into amorphous powder by utilization of high-energy ball milling under the protection of an inert gas; preparing the amorphous powder into an initial nanocrystal alloy block which is a metastable phase alloy by spark plasma sintering; and preparing the nanocrystal Sm<2>Co<17> / Co double-phase composite permanent magnetic alloy by a thermal treatment process. The method has advantages of uniform crystal grain size distribution, controllable crystal grain size, controllable phase composition, controllable phase stability, and the like.

Owner:BEIJING UNIV OF TECH

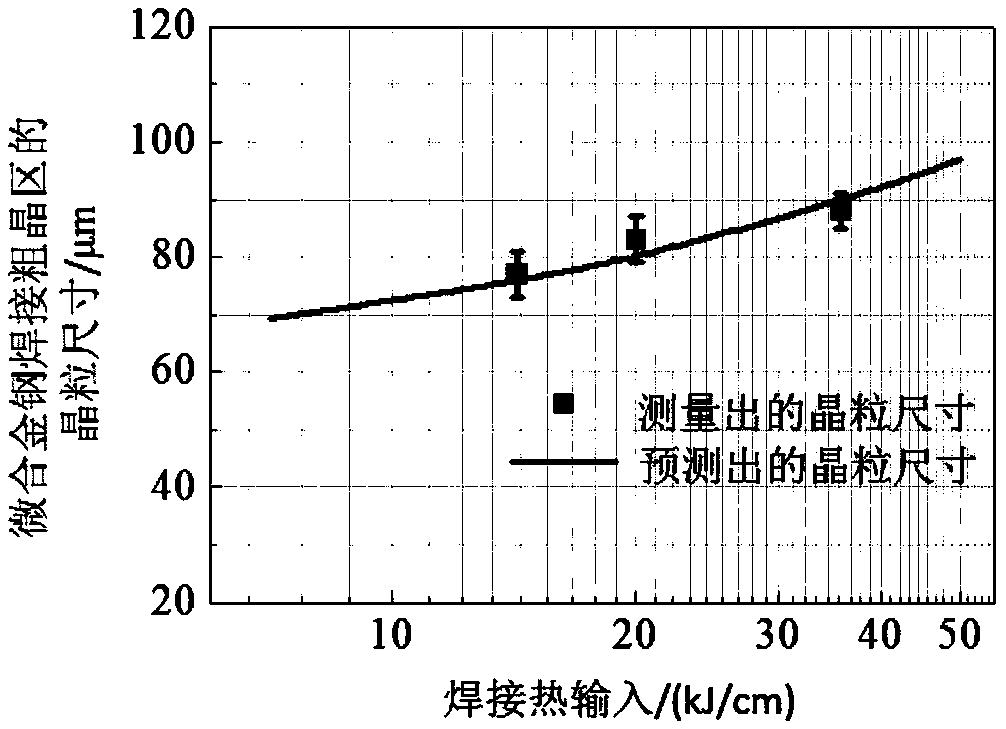

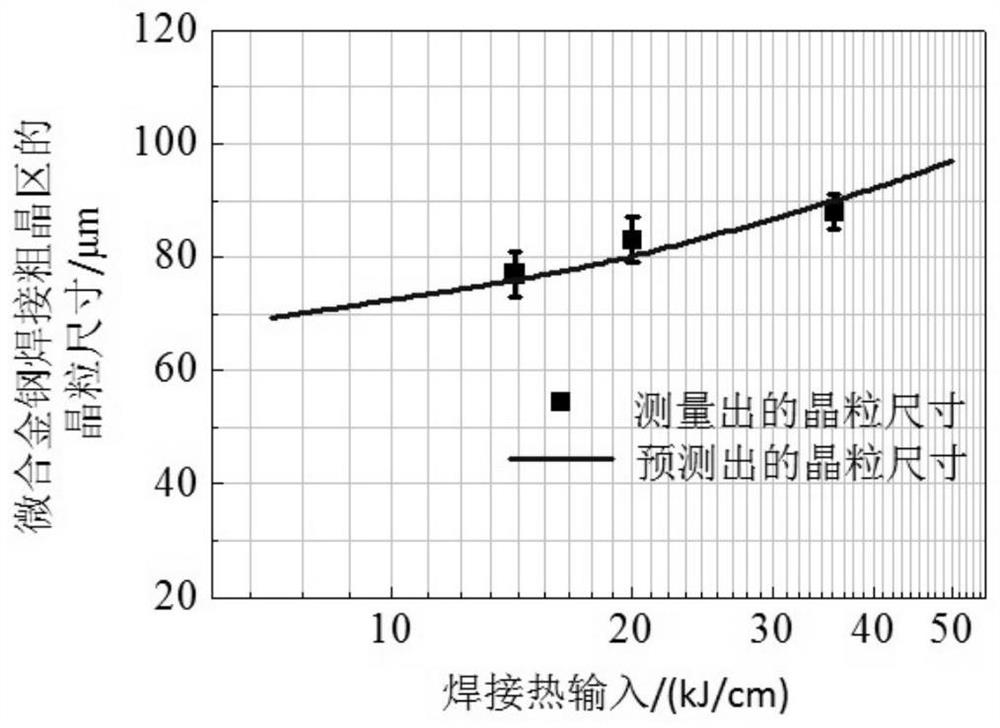

Method for predicting grain size of micro-alloy steel welding coarse grained region

ActiveCN109147873AImprove thermal stabilityReduced thermal stabilityChemical property predictionAustenite grainFinite difference method

The invention relates to a method for predicting the grain size of a micro-alloy steel welding coarse grained region and belongs to the field of physical measurement. The method comprises the steps that firstly, through heat simulation, information of the original austenite grain size of the micro-alloy steel welding coarse grained region under three or more different kinds of heat input is obtained; secondly, the grain growth dynamics formula which is shown in the description is set, wherein M0 and PZ are unknown constants, other parameters are known parameters, corresponding reasonable values are obtained by looking up literature, then the values of the original austenite grain size of the coarse grained region under three different kinds of heat input and the grain growth dynamics formula are fitted (through numerical integration and a finite difference method), and the values of M0 and PZ are obtained through an optimal fitting result; finally, through the grain growth dynamics formula and the fitted values of M0 and PZ, the grain size of the micro-alloy steel welding coarse grained region under different kinds of welding heat input is calculated, and the grain size of the micro-alloy steel welding coarse grained region is predicted. According to the method, the fitting and calculation process is simplified, and importance basis is provided for controlling the grain size ofthe micro-alloy steel welding coarse grained region.

Owner:JIANGXI UNIV OF SCI & TECH

Electric heating wire formulation and electric heating wire preparation process

InactiveCN107641735AImprove creep resistanceEasy to useHeating element materialsAlloyVolumetric Mass Density

The invention discloses an electric heating wire formulation and an electric heating wire preparation process. The electric heating wire formulation comprises, by mass, 30-50% of Cr, 30-50% of Ni, 1-5% of W, 1-3% of Mo, 5-10% of Ai, 1-3% of Si, 0.3-3% of Y2O3 composite oxide and the balance Fe. Corresponding raw material powder is subjected to mechanical alloying, drying, pressing, sintering, forging, hot rolling, bright annealing and surface preoxidation film treatment, nano oxides high in distribution density and small in size exist in a matrix and have a remarkable pinning effect on dislocation motion of alloy under a high-temperature condition, creep resistance of an electric heating wire at a high temperature is improved, the service life of the electric heating wire is longer than that of an existing electric heating wire by ten times or more, the utilization temperature reaches 1400 DEG C, and usability of the electric heating wire is greatly improved.

Owner:南通聚星铸锻有限公司

Casting infiltration method for enhancing hardness and abrasive resistance of surface layer of low-carbon alloy cast steel

The invention belongs to the technical field of material processing, in particular to a casting infiltration method for enhancing hardness and abrasive resistance of a surface layer of low-carbon alloy cast steel. The method comprises the steps of uniformly mixing iron powder and aluminum powder, adding tungsten concentrate powder, mixing with polyvinyl alcohol after uniformly mixing the iron powder, the aluminum powder and the tungsten concentrate powder, adding water to prepare pasty paint, coating an internal wall of a mold with the paint for 3-5 times, then drying, injecting smelted molten low-carbon alloy cast steel into the mold for casting, and when casting is finished, taking a casting out of the mold after the casting is solidified and cooled completely. According to the method, a series of chemical reactions occur during casting of the molten steel, a hard particle phase is generated, surface alloy of a low-carbon alloy cast steel workpiece exerts very good solution strengthening and pinning effects; hard particles and dislocation in a matrix have interaction to avoid dislocation movement, so that the yield strength and microhardness of the matrix are improved, the strengthening effect is significant, the thickness of an infiltration layer is great, and the binding property with the matrix is good.

Owner:LIAONING TECHNICAL UNIVERSITY

Manufacturing method of highly-conductive and heat-resisting electrode cross beam component

The invention provides a casting method of a highly-conductive and heat-resisting electrode cross beam component. The method comprises the following steps of: 1. selecting alloy materials; 2. manufacturing a metal mold according with sizes of the component; 3. founding and forming casting alloy materials; 4. and performing thermal process to cast formed pieces; wherein the composition ingredients of the adopted alloy materials include elements of Al, Mg, Si, Zr, Ce and B; the mass percent content of each composition ingredient contains 0.5-1.0% of Mg, 0.4-0.8% of Si, 0.6-0.8% of Zr, 0.05-0.1% of Ce, and 0.03-0.06% of B; the allowance is Al and inevitable impurities; the mass percent ratio of the impurity elements contained in the alloy materials is that: Fe is less than or equal to 0.2%, Cu is less than or equal to 0.05%, Mn is less than or equal to 0.02%, Cr is less than or equal to 0.02%, Zn is less than or equal to 0.05% and Ti is less than or equal to 0.05%. With the casting method, the aluminum alloy electrode cross beam component with good thermal resistance, mechanical property and high electrical conductivity performance can be cast, the electric conductivity can be up to 45% IACS (International Annealed Copper Standard), the temperature can be up to 250 DEG C in long-term application, and the casting method can be used for manufacturing the electrode cross beam components needed by the industrial field of electrolytic zinc.

Owner:沈阳铸研科技有限公司

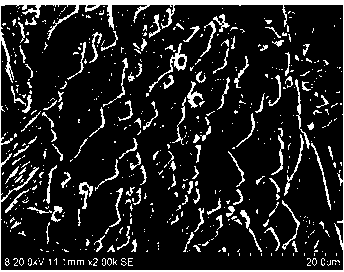

Ferritic steel plate with nanaoscale spherical cementite enhancing function and preparation method of ferritic steel plate

InactiveCN105624567AStrong yield strengthHigh tensile strengthSolid solutionUltimate tensile strength

The invention relates to a ferritic steel plate with a nanaoscale spherical cementite enhancing function and a preparation method of the ferritic steel plate. The steel plate is prepared from, by mass percent, 0.95%-1.05% of Cr, 0.95%-1.00% of Mo, 0.68%-0.75% of Mn, 0.57%-0.62% of Ni, 0.37%-0.52% of Al, 0.39%-0.45% of C and the balance Fe and inevitable impurities. The microstructure of the ferritic steel plate is equiaxed ferritic grains, nanaoscale spherical cementite is dispersed and distributed in the ferritic grain boundary region, the diameter of the grains ranges from 0.4 micrometer to 3 micrometers, and the size of the nanaoscale spherical cementite ranges from 70 nm to 150 nm; and the thickness of the ferritic steel plate ranges from 1.4 mm to 2.0 mm. The preparation method comprises the steps that 1, smelting is carried out under gas shield; 2, hot rolling is carried out after solid solution treatment; 3, warm rolling is carried out after heat treatment; and 4, annealing is carried out to obtain the finished steel plate. According to the steel plate, the yield strength and tensile strength of the steel plate are improved, and the good machining performance and plastic deformation capacity are achieved. The preparation method is simple, and industrial production can be achieved.

Owner:NORTHEASTERN UNIV +1

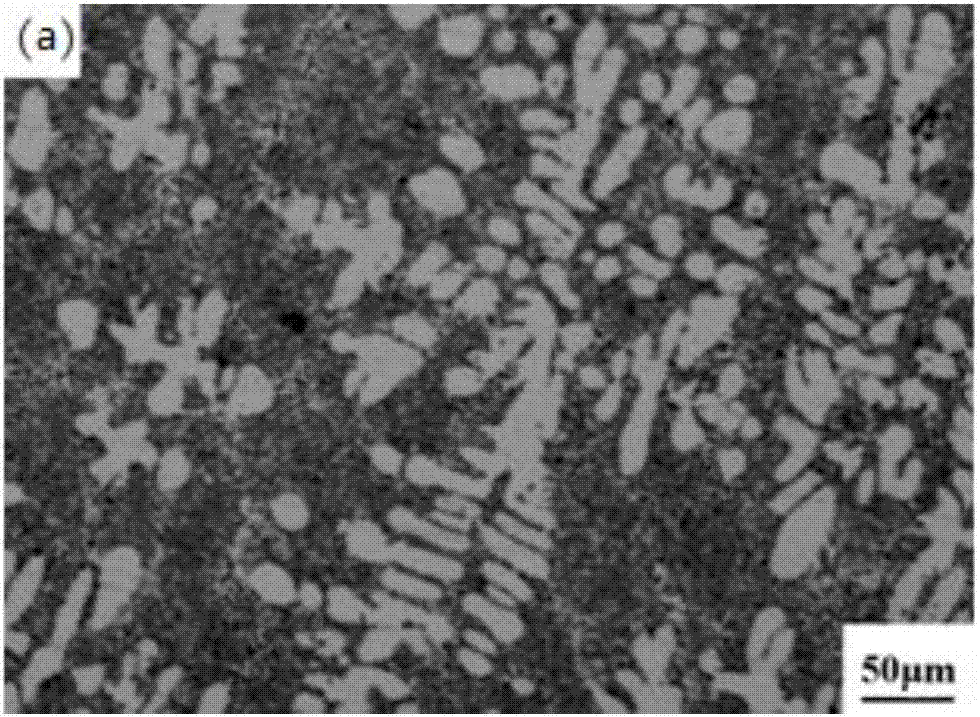

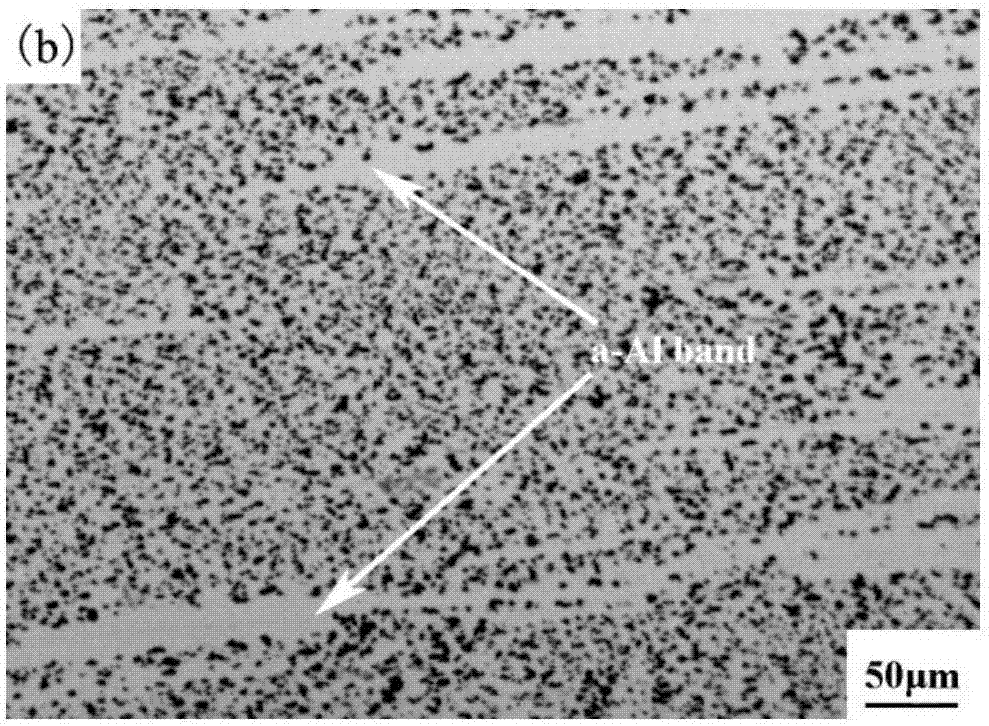

Titanium microalloying high-silicon-content aluminum alloy and preparing method thereof

The invention discloses a titanium microalloying high-silicon-content aluminum alloy and a preparing method thereof. The aluminum alloy comprises, by mass percent, 11.0%-14.0% of Si, 0.2%-0.7% of Mg, smaller than or equal to 0.15% of Fe, 0.015%-0.04% of Sr, 0.01%-0.03% of B, 0.05%-0.25% of Ti and the balance aluminum. The preparing method includes the steps that an aluminum-silicon intermediate alloy, a magnesium element, a silicon element and a titanium element are heated and melted, hexachloroethane is added for refining when melt is heated to 720 DEG C to 740 DEG C, Al-Sr and Al-B intermediate alloys are added for metamorphism treatment and grain refining treatment after standing is conducted, heat preservation is conducted for 30 min, vacuum standing is conducted for 30 min to 60 min, the mixture is heated to 710 DEG C to 730 DEG C and poured into a die, and a cast ingot is obtained; annealing is conducted for 3 h to 6 h under the temperature ranging from 520 DEG C to 540 DEG C; and hot extrusion or hot rolling deformation is conducted under the temperature ranging from 400 DEG C to 500 DEG C.

Owner:SOUTHEAST UNIV

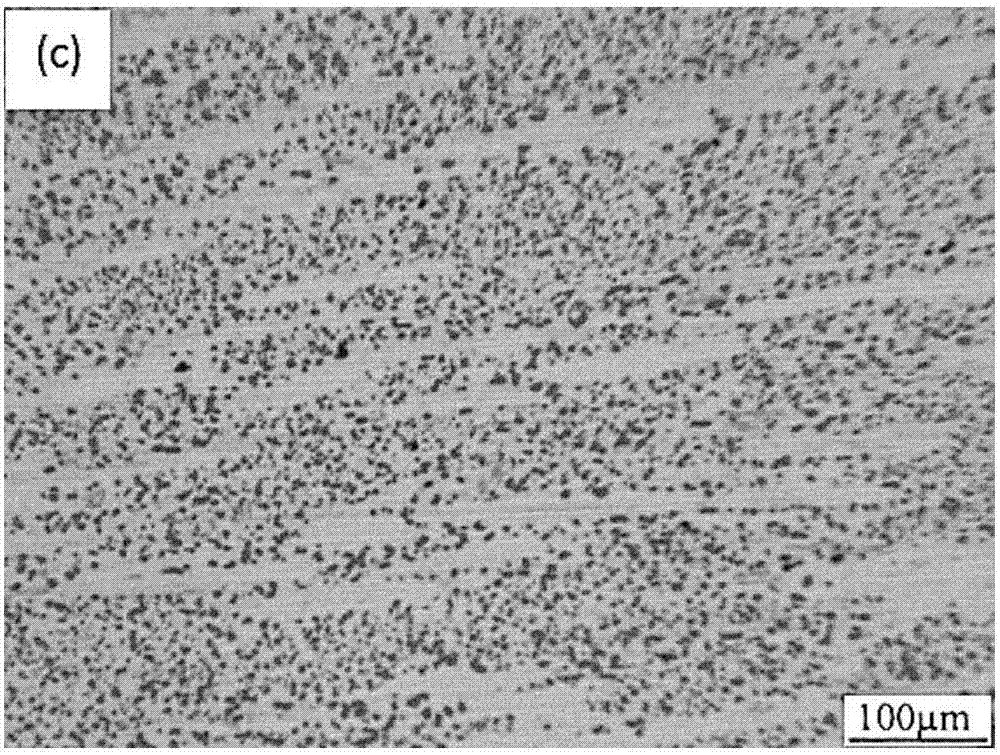

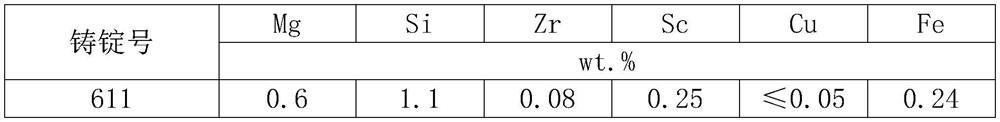

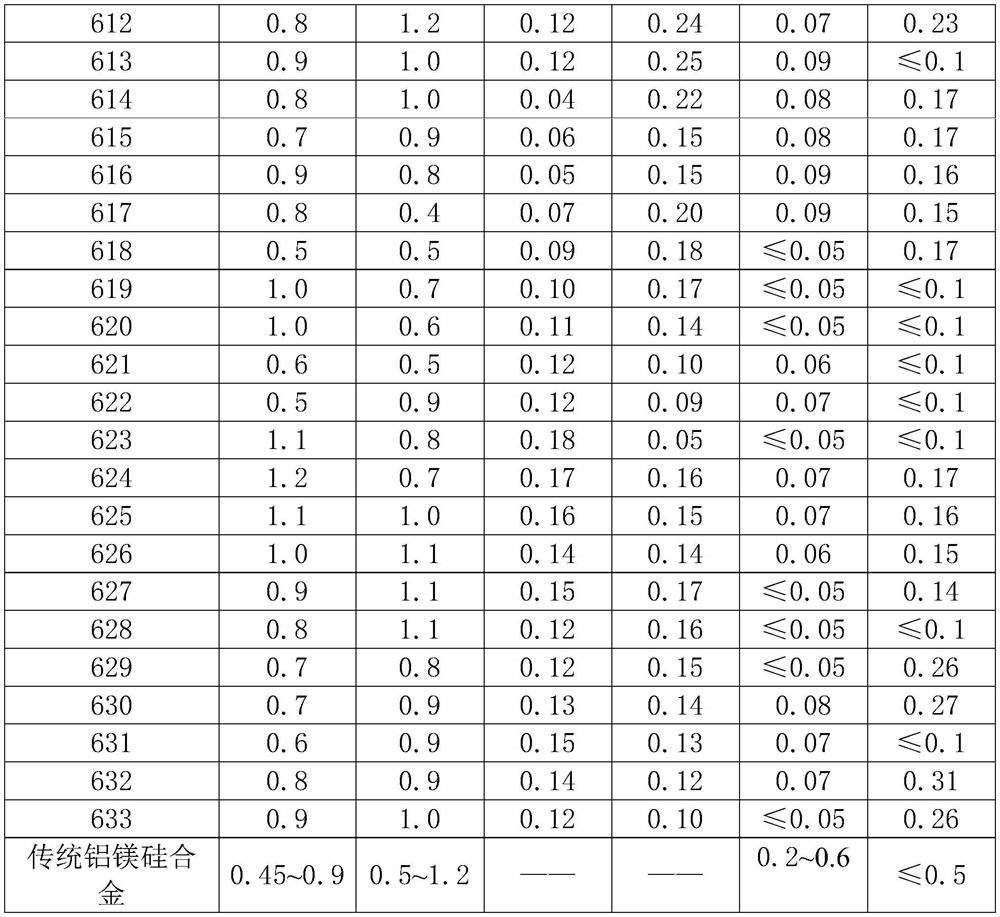

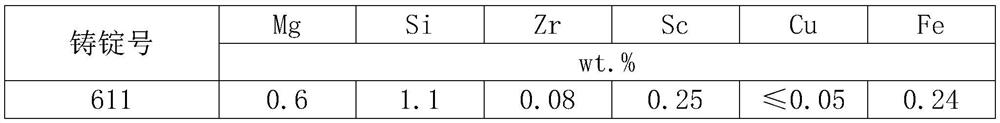

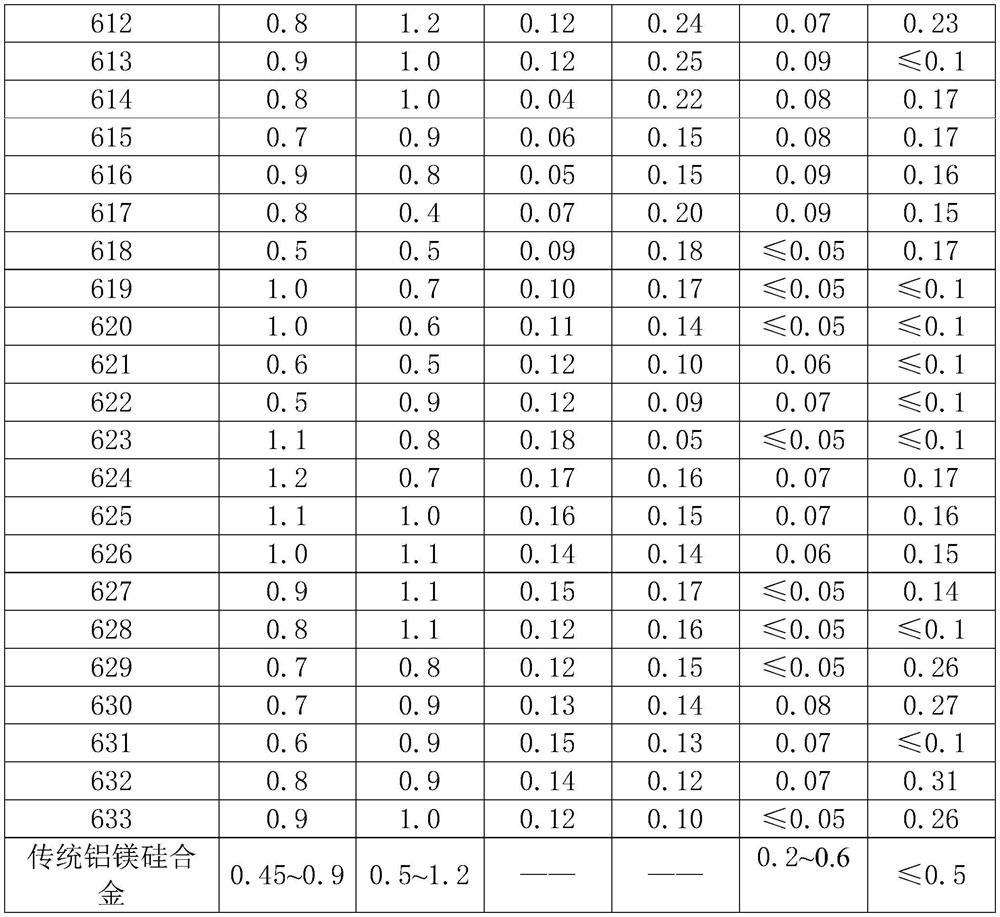

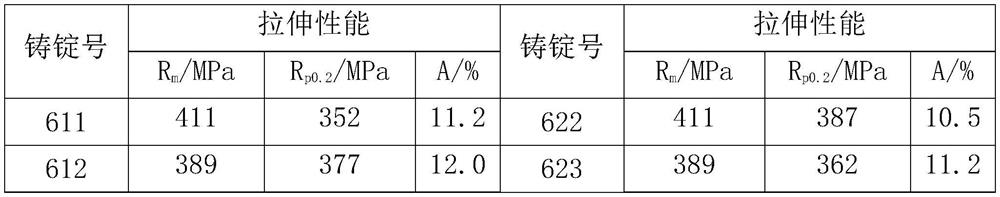

Aluminum-magnesium-silicon-scandium-zirconium alloy and preparation method thereof

The invention relates to an aluminum-magnesium-silicon-scandium-zirconium alloy and a preparation method thereof, the aluminum-magnesium-silicon-scandium-zirconium alloy adopts an element Zr, an element Sc and a Zr / Sc composite microalloying scheme, so that a mixed crystal structure containing a certain component subcrystal texture is obtained, and the strength and plasticity comprehensive performance of the material is improved. In the microalloying scheme, 0.02%-0.25% of the element Sc is selected; 0.04%-0.18% of the element Zr is selected, and Zr+Sc is greater than 0.08% and less than or equal to 0.40% when the two are combined. The purpose is to obtain a mixed crystal structure containing a certain sub-grain texture and improve the comprehensive performance of the material. The novel aluminum-magnesium-silicon-scandium-zirconium alloy product produced by the method of the invention has excellent corrosion resistance and weldability. Compared with a traditional aluminum-magnesium-silicon alloy, the aluminum-magnesium-silicon alloy has high strength and welding softening resistance, the tensile strength and the yield strength are improved by 20%-36% and 30%-51% respectively, and the ductility is higher than 10%; the strength of a welded joint is 51%-54%, and the coefficient of the joint is increased to 0.9 level from 0.8 level. The material product can be used for structural members in the fields of aerospace, nuclear industry, transportation, ships, weapons and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Aluminum alloy section baggage holder for automobile

PendingCN111041388AImproves corrosion and fatigue resistanceStrong pinning effectSupplementary fittingsSpecial surfacesSilicon nitrideLanthanum

The invention relates to an aluminum alloy section baggage holder for an automobile. The aluminum alloy section baggage holder for the automobile comprises a base material and a base material coveringlayer. The base material comprises the following elements in percentage by mass: 1% to 2% of chromium; 1% to 3% of copper; 2% to 3% of manganese; 0.05% 0.15% of zirconium; 0.03% to 0.09% of neodymium; 0.04% to 0.08% of vanadium; 0.5% to 1.0% of germanium; 0.5% to 0.9% of silicon boride fibers; 0.4% to 0.9% of silicon nitride fibers; 0.3% to 0.7% of silicon carbide fibers; 0.1% to 0.3% of nickel;0.05% to 0.08% of titanium; 1.2% to 2.5% of iron; 0.03% to 0.05% of palladium; 0.01% to 0.03% of lanthanum; 0.1% to 0.5% of cobalt; 1.5% to 3.5% of carbon fibers; 0.02% to 0.05% of graphite whiskers;and the balance of aluminum. The ultrahigh strength of the luggage holder is ensured; and the mechanical property of the luggage holder is improved.

Owner:ANHUI LANT ALUMINUM

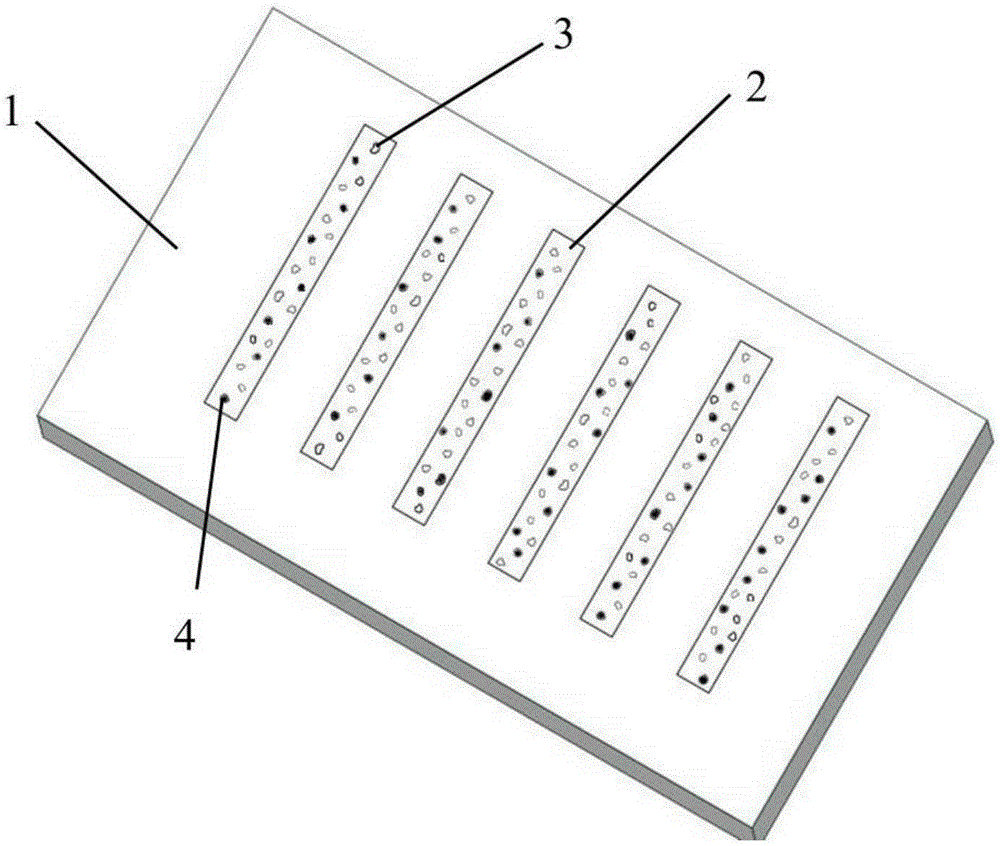

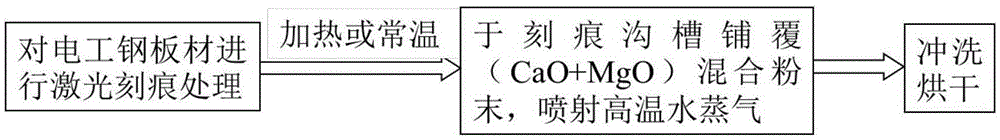

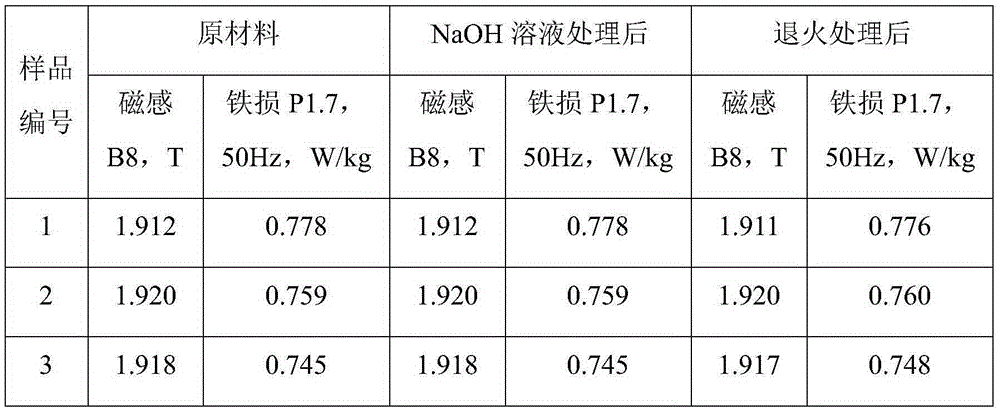

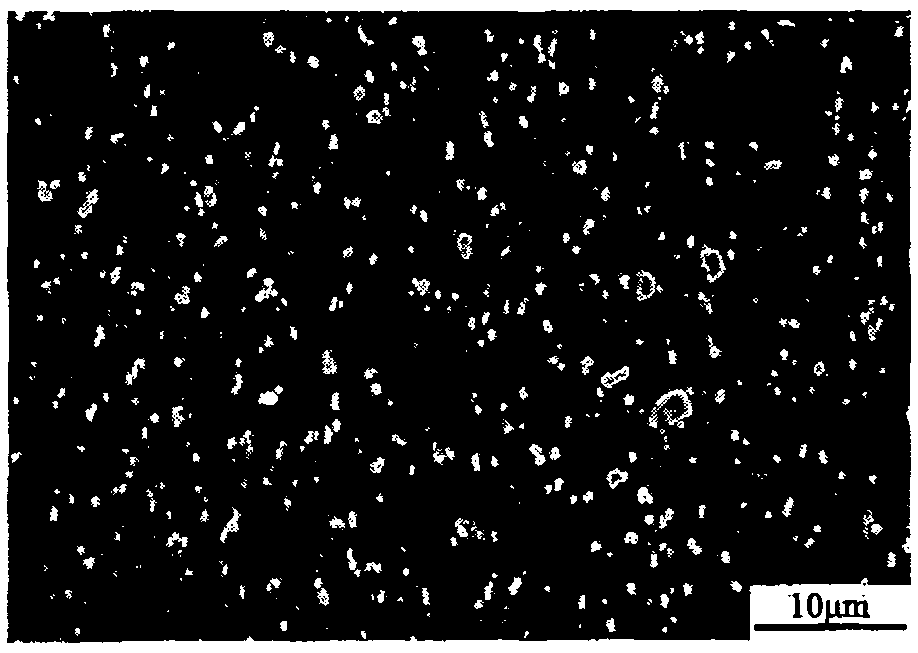

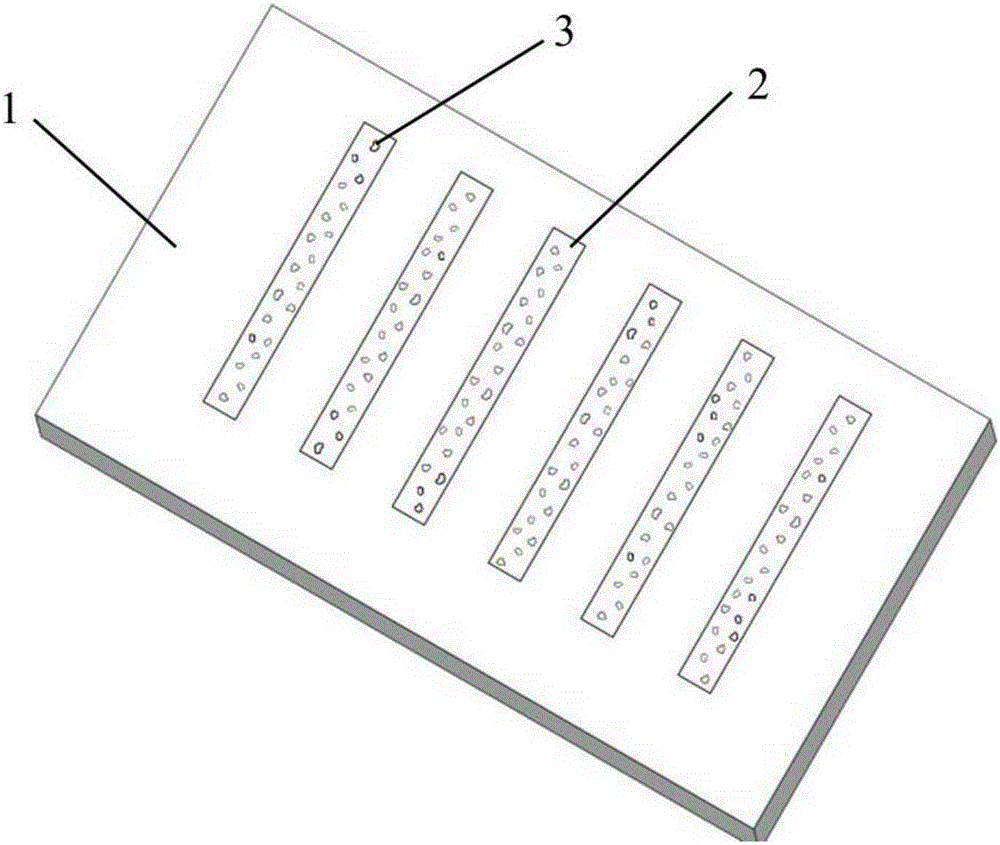

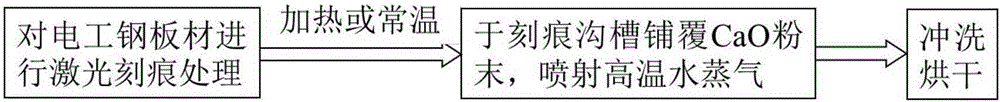

Electrical steel plate material and preparation method thereof

ActiveCN105244135AGuaranteed flatnessIntegrity guaranteedTransformers/inductances detailsInductances/transformers/magnets manufactureCalcium silicateElectrical steel

The invention provides an electrical steel plate material and a preparation method thereof. The electrical steel plate material comprises a platelike electrical steel substrate, nick grooves in the surface of the substrate, and calcium silicate hydrate phase and magnesium silicate hydrate phase distributed on the surface of the nick grooves; the substrate is 0.1-2 mm in thickness; and the diameter of the calcium silicate hydrate phase and magnesium silicate hydrate phase is 1-100 nm. The preparation method comprises the following steps: 1), laser nicking processing; 2), (CaO+MgO) powder processing nick grooves: reacting the CaO, MgO with SiO2 on the surface of the nick grooves to generate the calcium silicate hydrate phase and magnesium silicate hydrate phase; and 3), washing the electrical steel plate material obtained in the step 2) and drying. The electrical steel plate material has excellent heat-resisting effect, namely, the iron loss reduction effect generated by the laser nicking is not eliminated, the original magnetic property of the electrical steel plate material can be maintained, and the insulating coatings on the silicon steel surface are not damaged when the electrical steel plate material is subjected to thermal insulation at the temperature of 800 DEG for 2 hours and annealing treatment; in addition, the preparation method is simple in operation, low in cost and suitable for large-scale industrial production.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

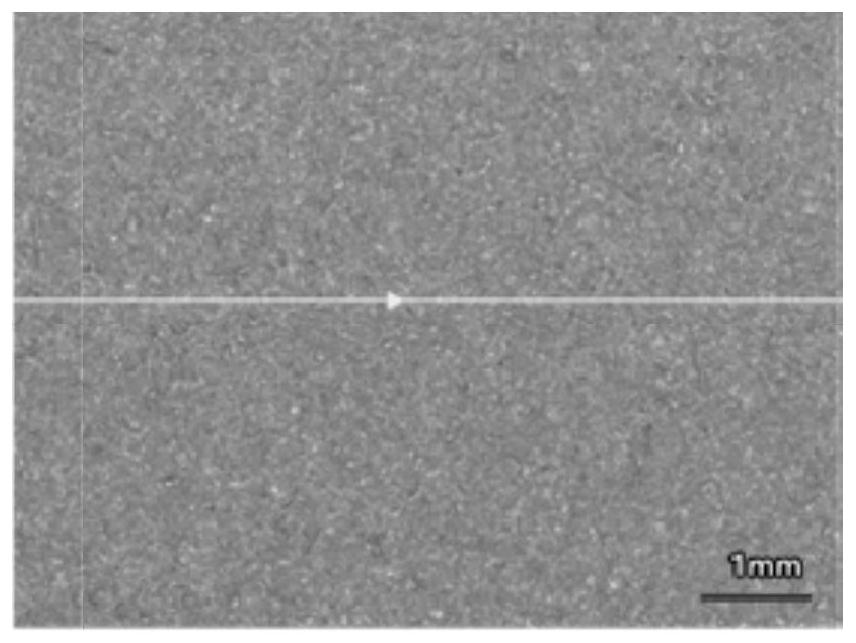

Superfine crystal nickel-based high-temperature alloy and method for preparing same

The invention provides an ultra-fine crystalline nickel base high-temperature alloy and a method for preparing the same, belonging to the high-temperature alloy steel field. The ultra-fine crystalline nickel base high-temperature alloy is particularly applicable to a high-temperature structural component which has high requirement to high-temperature strength and fatigue property, requires superplastic forming and has a complicated structure. The chemical compositions by weight percent of the ultra-fine crystalline nickel base high-temperature alloy are: 17 to 19 percent of Fe, 17 to 20 percent of Cr, 2.8 to 3.3 percent of Mo, 0 to 1.5 percent of W, 0.8 to 1.5 percent of Al, 0.3 to 1.3 percent of Ti, 4.7 to 5.7 percent of Nb, less than or equal to 0.015 percent of C, and the balance beingNi. The preparation method reasonably controls the parameter of a deformation process to allow the deformation temperature to be positioned in a grain boundary precipitated phase region and an austenite phase region which have higher solution temperatures, and uses powerful pinning action of a precipitated phase to the grain boundary to produce the ultra-fine crystalline alloy with a grade of grain fineness of between ASTM12 and ASTM13 grade. Compared with the prior art, the ultra-fine crystalline nickel base high-temperature alloy has simple alloy compositions, greatly reduces the resistanceto deformation during forming, has small loss to forging and rolling equipment, and prevents crystal grains from growing when the ultra-fine crystalline nickel base high-temperature alloy is heated for a long time at a high temperature.

Owner:UNIV OF SCI & TECH BEIJING

A kind of magnesium-lithium alloy and its preparation method and the preparation method of magnesium-lithium alloy plate

The invention discloses a magnesium-lithium alloy, a preparation method thereof, and a preparation method of a magnesium-lithium alloy plate, wherein the magnesium-lithium alloy is composed of the following components by weight percentage: 10% to 15% of Li; 3% to 6% of Al ; 0.3% to 2.0% of Sr; 0.05% to 1.0% of Sc; 0.05 to 0.5% of Zr; limiting impurity elements Fe≦0.005%, Ni≦0.002%, Cu≦0.02%; the rest is Mg. The magnesium-lithium alloy provided by the present invention not only improves the heat resistance of the alloy through the addition of elements Sr and Sc, but also effectively overcomes the significant reduction in the mechanical properties of the alloy due to overaging of the β-phase magnesium-lithium alloy, and the Al 3 The enrichment of Sc at the solid-liquid interface can hinder the growth of dendrites, thereby refining the as-cast structure of the alloy, because the Al 3 The Sc phase is mostly distributed in the grain boundary, which has a strong pinning effect on the grain boundary, and can significantly improve the yield strength and tensile strength of the alloy.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Graphite material with sic doped layer and preparation method thereof

The invention discloses a graphite material with a SiC doped layer and a preparation method of the graphite material. The preparation method of the graphite material with the SiC doped layer comprises the following step: by taking mixed powder of silicon-containing powder and boron nitride as a silicon source, performing liquid-phase siliconing sintering on a graphite material, thereby obtaining the graphite material with the SiC doped layer. The graphite material with the SiC doped layer prepared by using the method comprises a graphite substrate and the SiC doped layer on the surface of the graphite substrate, the SiC doped layer is well combined with the graphite substrate without thermal mismatch, the graphite material is good in oxidation and corrosion resistance and relatively low in cost, and a small amount of silicon is adhered to the surface of the graphite material.

Owner:NAT UNIV OF DEFENSE TECH

A nanocrystalline sm 2 co 17 Preparation method of /co two-phase composite permanent magnet alloy

The invention provides a preparing method of a nanocrystal Sm<2>Co<17> / Co double-phase composite permanent magnetic alloy, and belongs to the technical field of double-phase composite permanent magnetic alloys. The method includes smelting a pure Sm block, a Co block and an elementary substance of an added element under the protection of argon to obtain a multi-component parent phase alloy; allowing phases and component distribution of the parent phase alloy to be uniform by a plurality of times of remelting and homogenizing annealing; preparing the parent phase alloy into amorphous powder by utilization of high-energy ball milling under the protection of an inert gas; preparing the amorphous powder into an initial nanocrystal alloy block which is a metastable phase alloy by spark plasma sintering; and preparing the nanocrystal Sm<2>Co<17> / Co double-phase composite permanent magnetic alloy by a thermal treatment process. The method has advantages of uniform crystal grain size distribution, controllable crystal grain size, controllable phase composition, controllable phase stability, and the like.

Owner:BEIJING UNIV OF TECH

A kind of aluminum magnesium silicon scandium zirconium alloy and preparation method thereof

The present invention relates to an aluminum magnesium silicon scandium zirconium series alloy and a preparation method thereof. The aluminum magnesium silicon scandium zirconium alloy adopts the element Zr, Sc, Zr / Sc composite microalloying scheme to obtain a subgrain texture containing a certain component The mixed crystal structure improves the overall strength and plasticity properties of the material. In this microalloying scheme, the element Sc is selected from 0.02% to 0.25%, the element Zr is selected from 0.04% to 0.18%, and when the two are combined, 0.08%≤Zr+Sc≤0.40% is selected, the purpose of which is to obtain a subgrain containing a certain component The mixed crystal structure of the texture improves the comprehensive strength and plastic properties of the material. The new aluminum-magnesium-silicon-scandium-zirconium alloy products produced by the method of the present invention have excellent corrosion resistance and weldability, compared with traditional aluminum-magnesium-silicon alloys. Higher strength and resistance to welding softening, tensile strength and yield strength increased by 20% to 36% and 30% to 51% respectively, and elongation is higher than 10%; welded joint strength is 51% to 54%, and the joint coefficient is from The 0.8 level was raised to the 0.9 level. The material product can be used for structural parts in the fields of aerospace, nuclear industry, transportation, ships, weapons and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

A Method for Predicting the Grain Size of Welding Coarse Grain Zone of Microalloyed Steel

ActiveCN109147873BImprove thermal stabilityReduced thermal stabilityChemical property predictionAustenite grainMetallurgy

The invention relates to a method for predicting the grain size of the welded coarse-grained zone of micro-alloy steel, which belongs to the field of physical measurement. Firstly, the information of the prior austenite grain size in the microalloyed steel welded coarse-grained zone under three or more different heat inputs is obtained through thermal simulation; secondly, M in the grain growth kinetic formula is set 0 and P Z is an unknown constant, other parameters are known parameters and the corresponding reasonable values are obtained by consulting the literature, and then the values of the prior austenite grain size in the coarse-grained region under three different heat inputs are compared with the grain growth kinetics formula Fitting (by numerical integration and using the finite difference method), the best fit results in M 0 and P Z The numerical value; Finally, through this grain growth kinetics formula and the fitted M 0 and P Z The grain size of the microalloyed steel welded coarse-grained zone is calculated under different welding heat input, and the grain size of the microalloyed steel welded coarse-grained zone is predicted. The invention simplifies the fitting and calculation process, and provides an important basis for controlling the grain size of the microalloy steel welded coarse grain area.

Owner:JIANGXI UNIV OF SCI & TECH

Flux-cored wire for low alloy structure steel and preparing method of flux-cored wire

InactiveCN107186379AImprove performanceEasy to remove slagWelding/cutting media/materialsSoldering mediaCarbonateTitanium boride

The invention discloses a flux-cored wire for low alloy structure steel and a preparing method of the flux-cored wire. The flux-cored wire is composed of a flux core and stainless steel outer skin wrapping the outer side of the flux core; and raw materials of the flux core comprise chromium powder, silica powder, manganese powder, titanium powder, titanium boride powder, silicon nitride powder, magnesium aluminum alloy powder, titanium dioxide powder, iron oxide powder, indium oxide powder, cerium oxide powder, praseodymium oxide powder, carbonate, ferro-molybdenum powder, ferro vanadium powder, ferrozirconium powder and reduced iron powder. According to the flux-cored wire for the low alloy structure steel and the preparing method of the flux-cored wire, the flux-cored wire has the performances that splashing is small, molding is good, deslagging is easy, deposited metal texture is compact, air holes and cracks are avoided, bonding with parent metal is good, and performance is stable; deposited metal has the good hardness, low temperature toughness, abrasion resistance, corrosion resistance, creep resistance and the like, and the good economical benefits are achieved.

Owner:天长市通联焊业有限公司

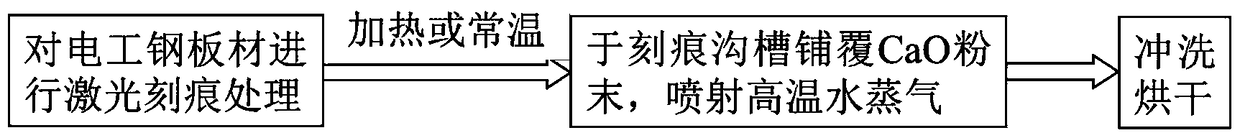

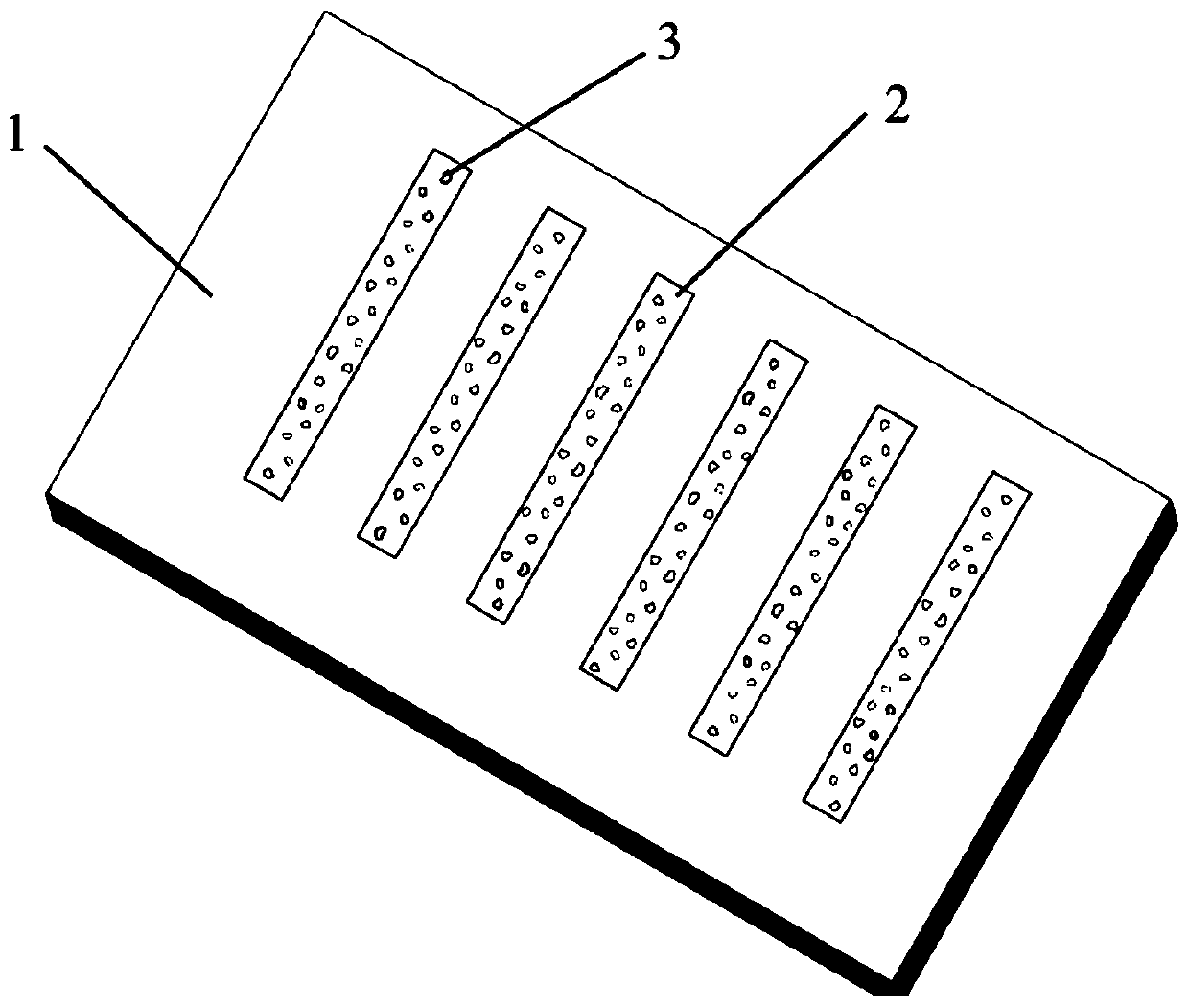

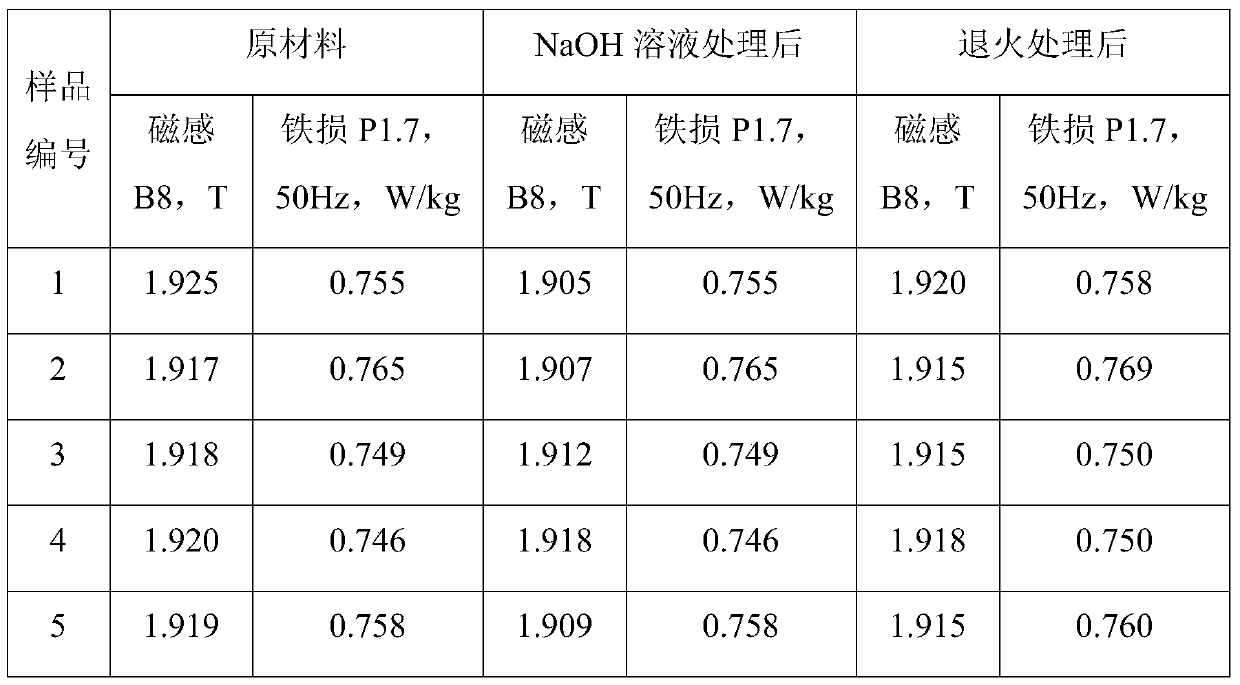

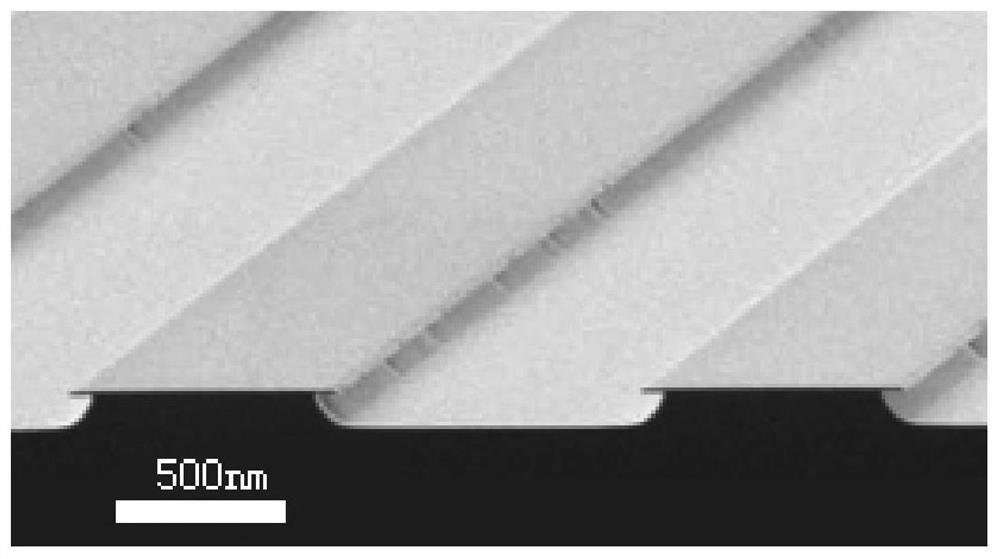

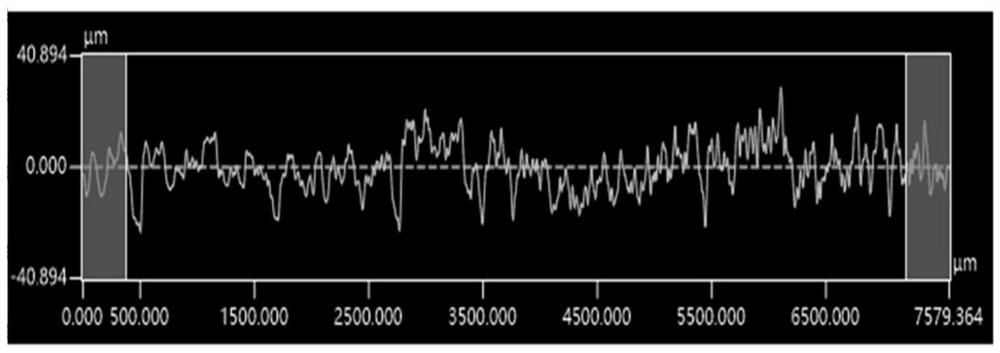

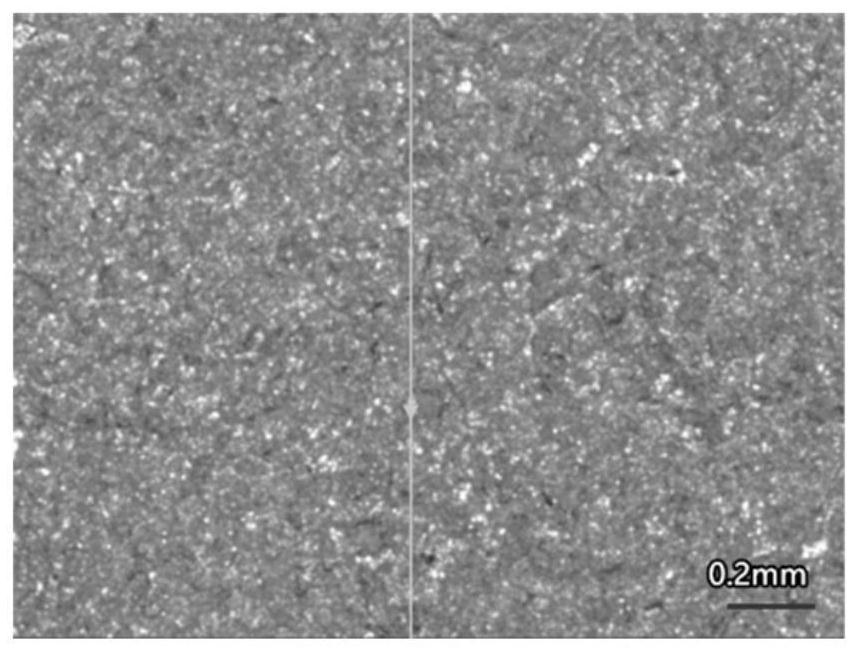

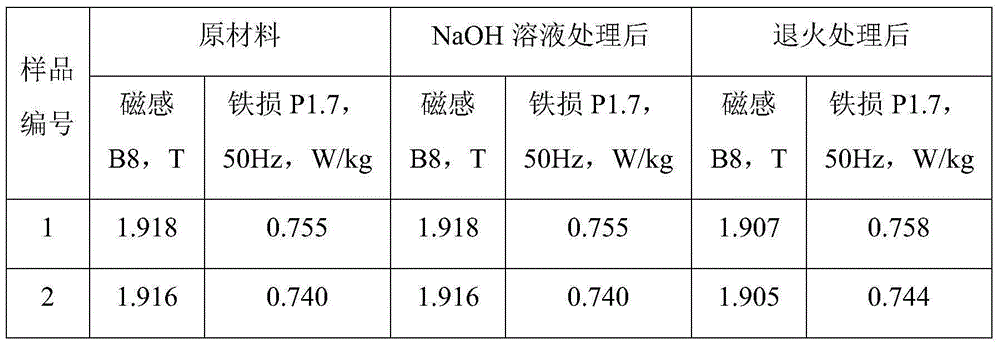

A kind of electrical steel plate and preparation method thereof

ActiveCN105225784BImprove heat resistanceStrong pinning effectInorganic material magnetismLaser beam welding apparatusLaser etchingElectrical steel

The invention provides an electrical steel plate and a preparation method thereof. The electrical steel plate comprises a plate-shaped electrical steel substrate, etching grooves on the surface of the substrate and CaSiO3 phases distributed on the surface of the etching grooves, wherein the thickness of the substrate is 0.1 to 2 millimeters, and the diameter of the CaSiO3 phases is 1 to 100 nanometers. The preparation method comprises the following steps of: 1) carrying out laser etching treatment; 2) processing the etching grooves with CaO powder, wherein CaO and SiO2 on the surfaces of the etching grooves react to generate the CaSiO3 phases on the surfaces of the etching grooves; and 3) washing and drying the electrical steel plate. The CaSiO3 phases have strong pinning effects relative to tensile stress or dislocation of regions around the grooves, a processed laser etching product has excellent thermal resistance, the iron loss reduction effect generated by laser etching cannot be disappeared after the product is subjected to thermal insulation and annealing treatment at 800 DEG C for 2 hours, and the original magnetic performance is basically maintained. The method is simple in operation, and production and application at a large scale are promoted.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

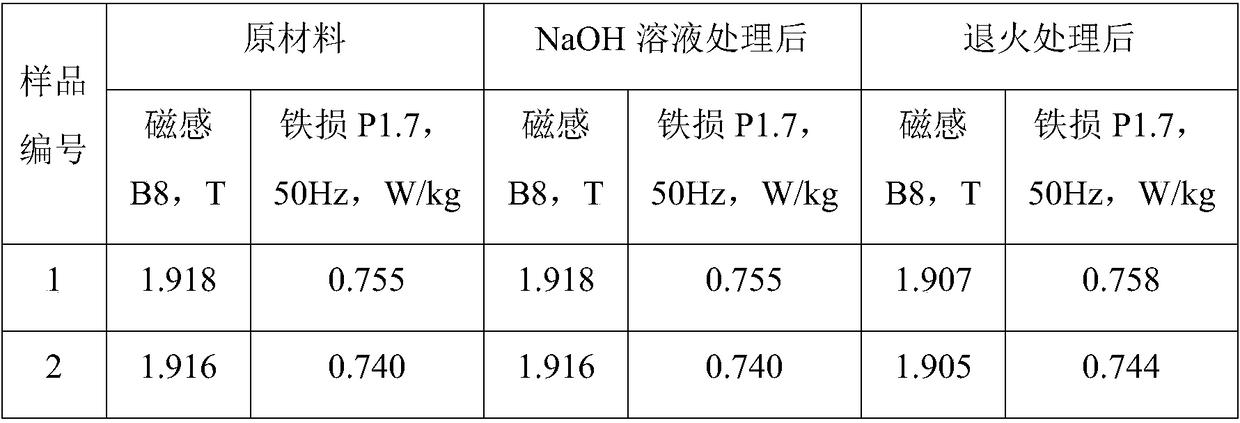

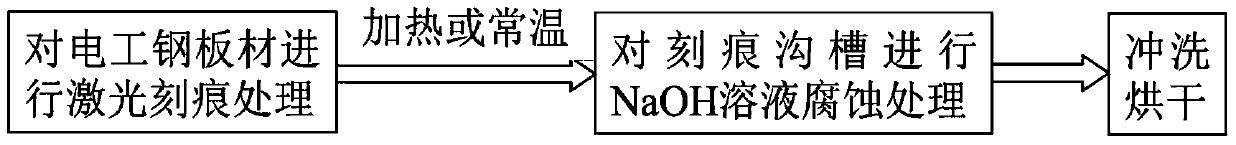

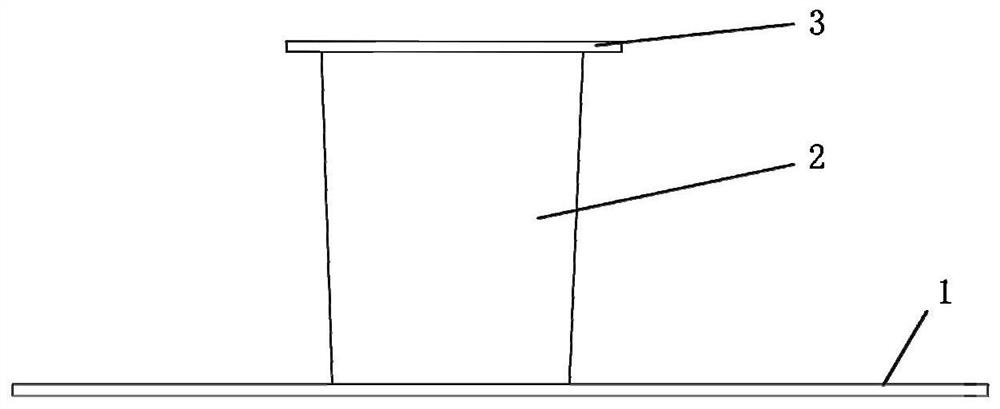

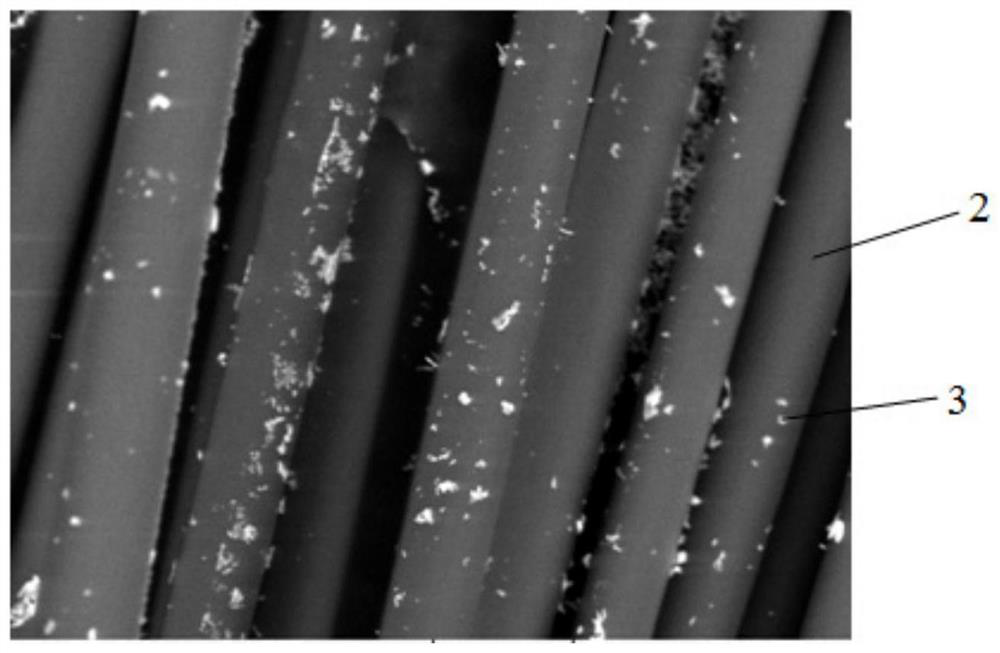

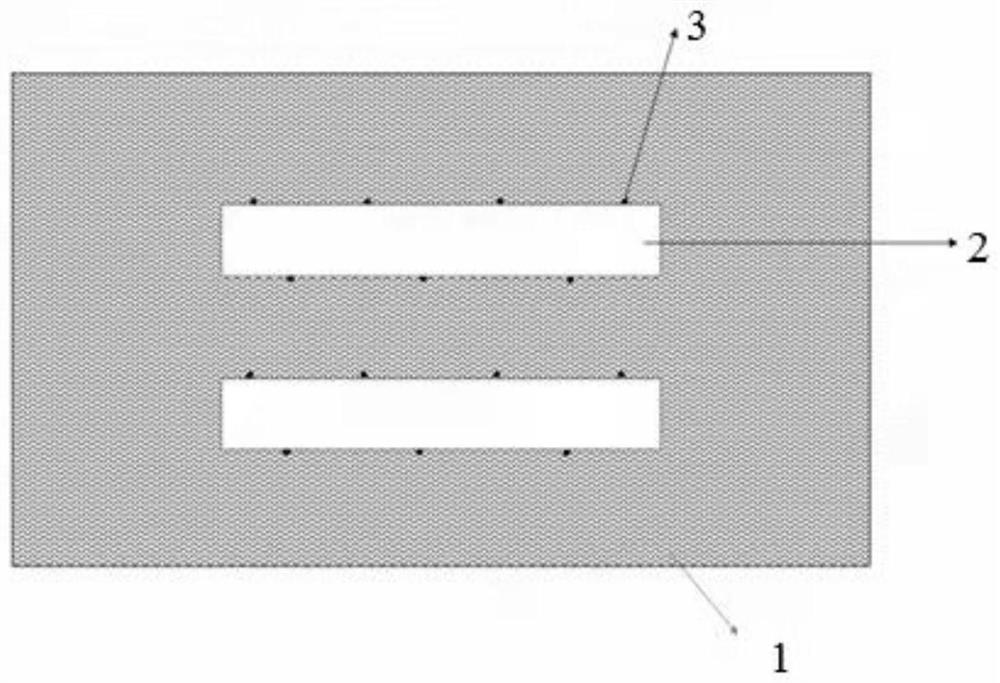

A kind of electrical steel sheet and preparation method thereof

ActiveCN105185503BPrevent rotationStrong pinning effectTransformers/inductances detailsInductances/transformers/magnets manufactureElectrical steelSilicon

The invention provides an electrical steel plate and a preparation method thereof. The electrical steel plate comprises a plate-shaped electrical steel matrix, scoring grooves on the surface of the matrix, pits distributed on the surface of the scoring grooves, and solid solution Na2SiO3 or Na2SiO3 9H2O on the surface of the substrate, the thickness of the substrate is 0.1-2mm, and the diameter of the pit is 1-100nm; the preparation method includes 1) laser scoring treatment; 2) NaOH solution treatment Scored groove; 3) washing and drying treatment. The electrical steel plate prepared by the present invention has excellent heat-resistant effect. After annealing at 800°C for 2 hours, the iron loss reduction effect caused by laser scoring will not disappear, and the original magnetic properties will be maintained, and the insulating coating on the surface of the silicon steel will not disappear. The layer is not damaged, the preparation method of the invention is simple to operate and low in cost, and is suitable for large-scale industrial production.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

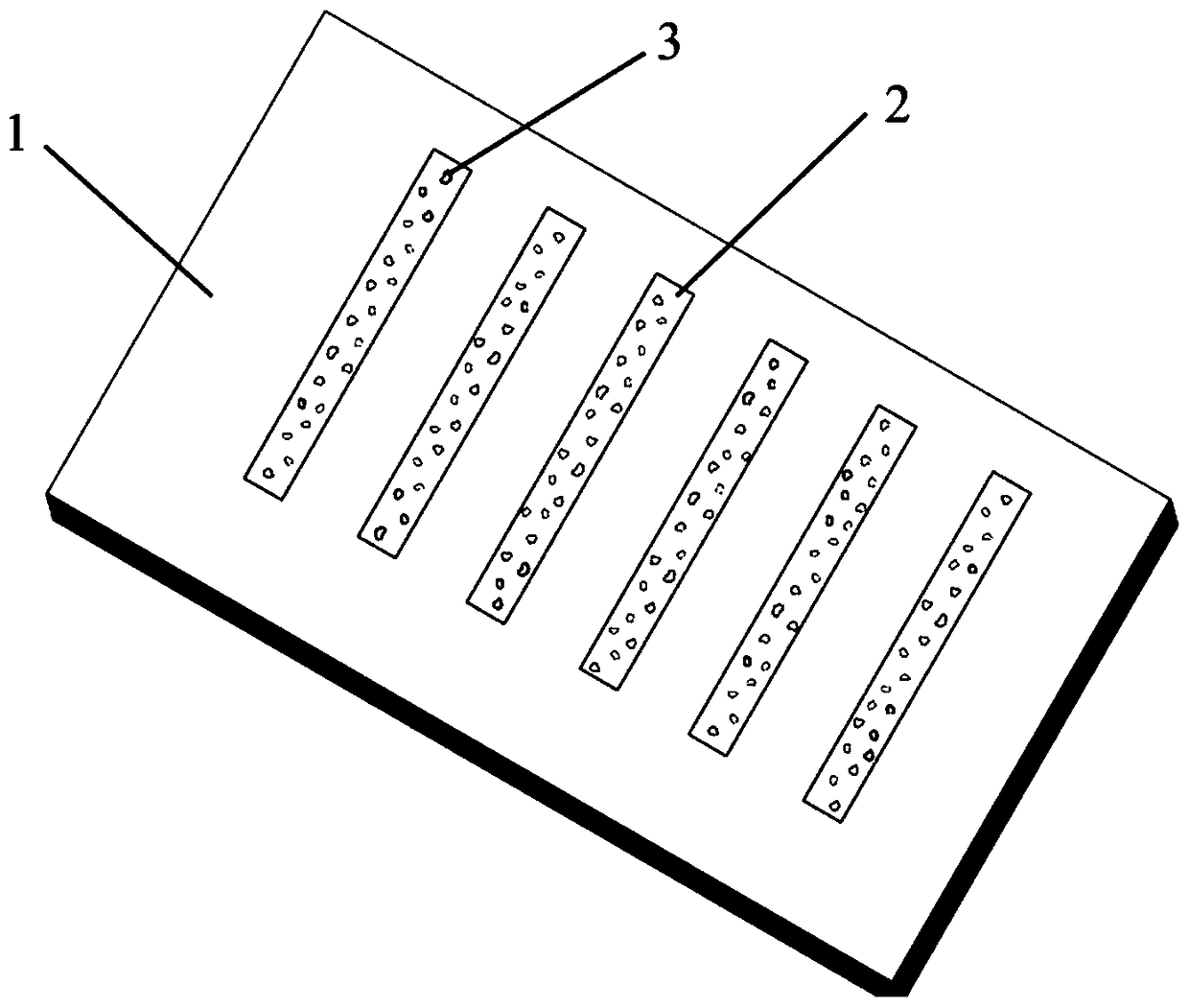

A kind of film for controlling droplet shape and its preparation method and application

ActiveCN111606299BStrong pinning effectInhibited DiffusionDecorative surface effectsSolid-state devicesEtchingTitanium metal

The invention discloses a thin film for controlling the shape of liquid droplets, a preparation method and application thereof. The preparation method of the thin film for controlling the droplet shape includes: providing a substrate; depositing a titanium metal layer on the substrate; writing a pattern on the titanium metal layer by laser direct writing technology to obtain a patterned Titanium metal layer: performing wet etching on the patterned titanium metal layer to obtain a film with a suspension cut structure. The thin film used for controlling the droplet shape prepared by the invention is formed with a hanging cut structure with sharp edges, which has a strong pinning effect on the liquid, thereby improving the robustness of the droplet shape.

Owner:SHENZHEN TECH UNIV

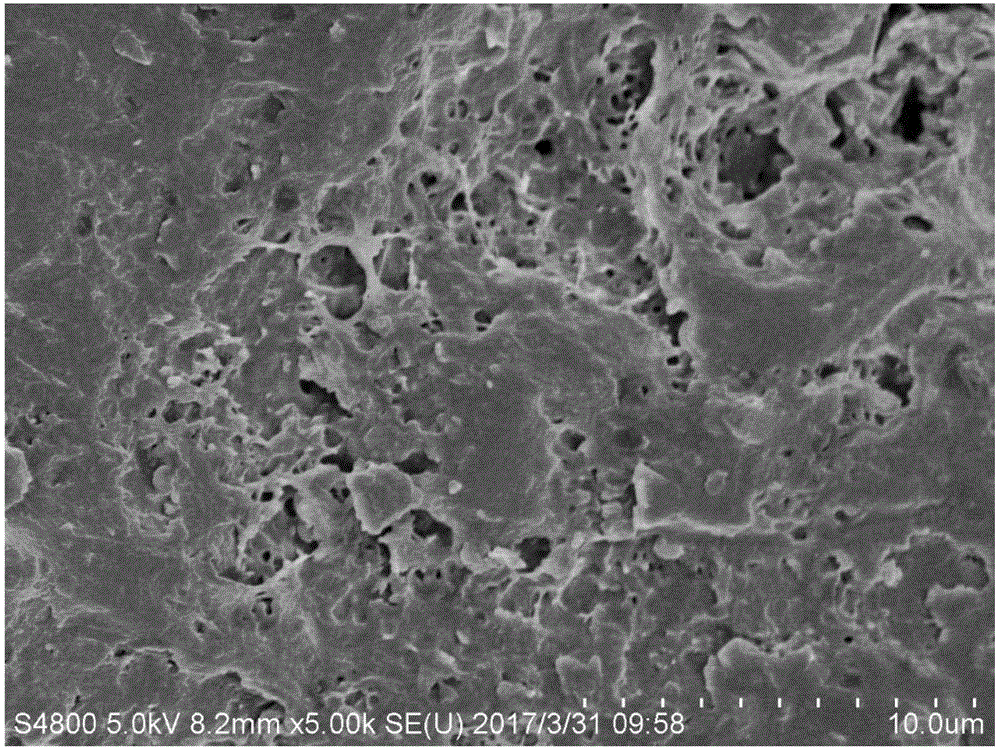

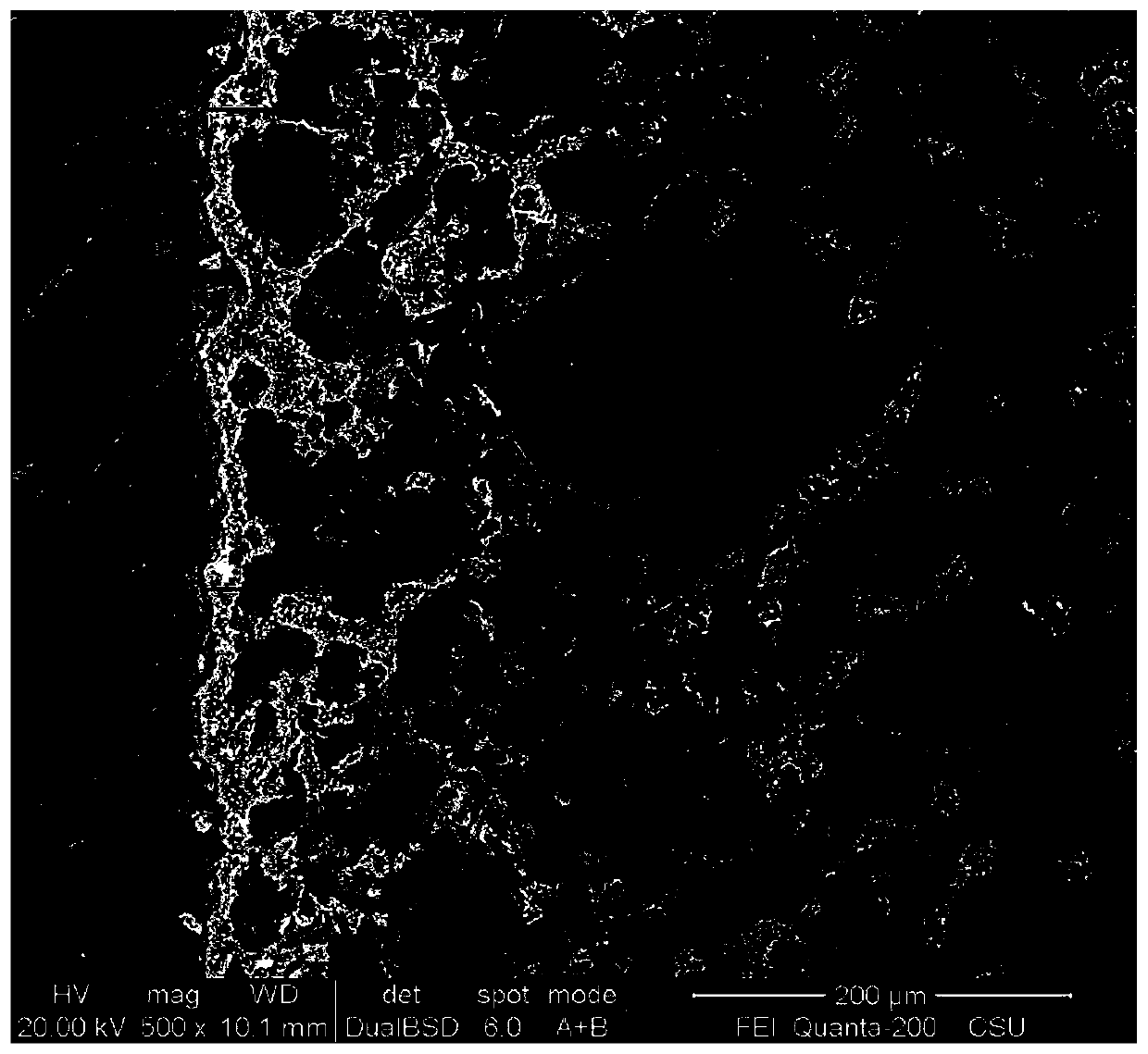

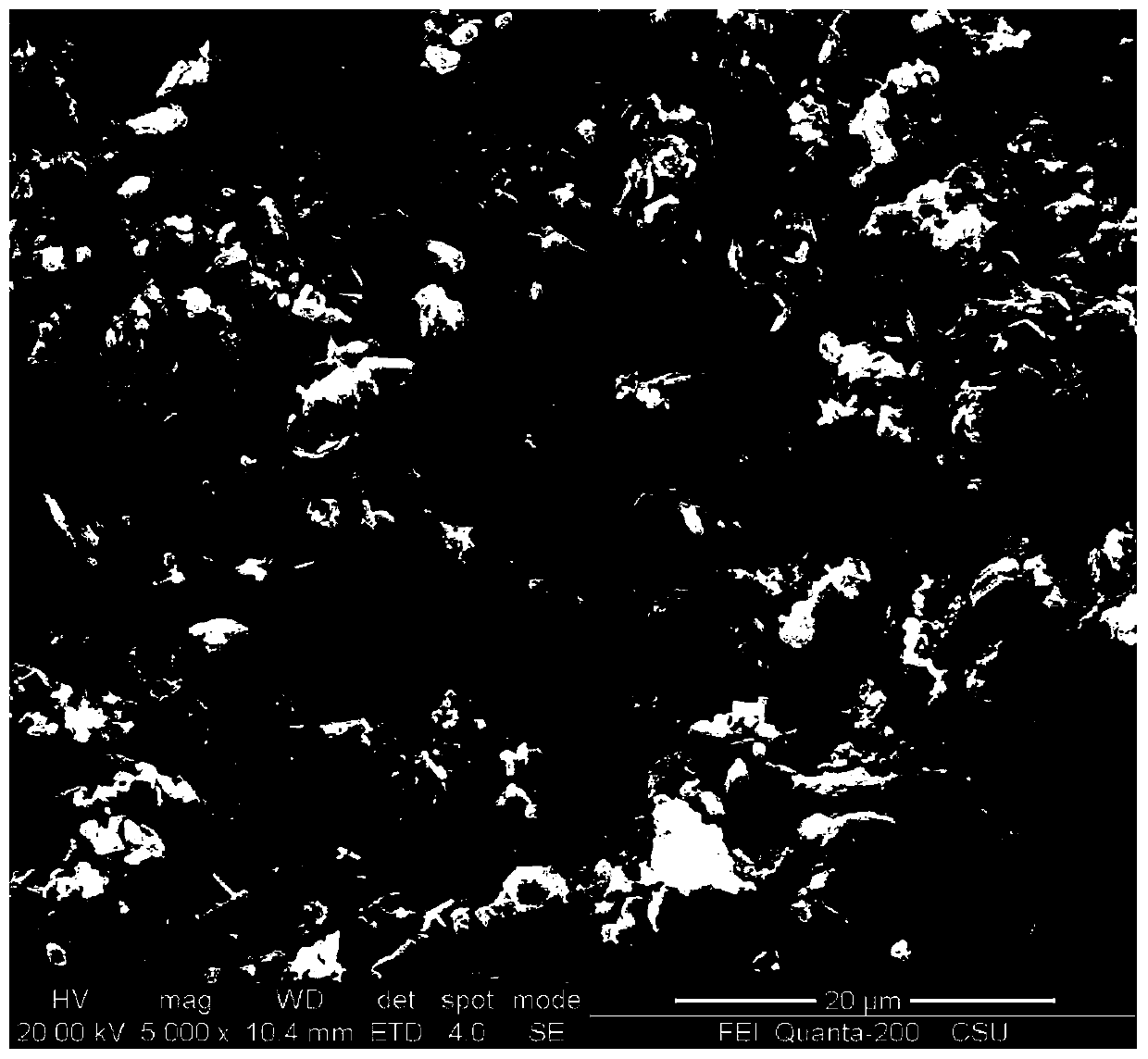

Pretreatment process suitable for hot aluminum spraying on surface of steel plate and detection method

PendingCN113601400AHigh bonding strengthGood compatibilityBlast gunsAbrasive feedersSand blastingUltimate tensile strength

The invention discloses a pretreatment process suitable for hot aluminum spraying on the surface of a steel plate. The pretreatment process comprises the following steps that a sand blasting pretreatment mode is adopted, during sand blasting, a spray gun is 20-30 mm away from the surface to be subjected to sand blasting, an angle of 45-60 degrees is formed between the spray gun and the horizontal plane of the surface to be subjected to sand blasting, and the sand blasting speed is 20-25 cm / min until the surface to be subjected to sand blasting is uniformly grey white; and after sand blasting is finished, the horizontal plane of the sand-blasted surface is blown at 90 degrees until no dust exists on the surface. The invention further discloses a detection method of the pretreated steel plate. By means of the pretreatment and detection method, the standard roughness requirement that Ra is larger than 6 micrometers is met, and the bonding strength of the coating is effectively improved to 23 + / -5 Mpa.

Owner:NANJING IRON & STEEL CO LTD

Electrical steel plate and preparation method thereof

ActiveCN105225784AGuaranteed flatnessIntegrity guaranteedInorganic material magnetismLaser beam welding apparatusLaser etchingElectrical steel

The invention provides an electrical steel plate and a preparation method thereof. The electrical steel plate comprises a plate-shaped electrical steel substrate, etching grooves on the surface of the substrate and CaSiO3 phases distributed on the surface of the etching grooves, wherein the thickness of the substrate is 0.1 to 2 millimeters, and the diameter of the CaSiO3 phases is 1 to 100 nanometers. The preparation method comprises the following steps of: 1) carrying out laser etching treatment; 2) processing the etching grooves with CaO powder, wherein CaO and SiO2 on the surfaces of the etching grooves react to generate the CaSiO3 phases on the surfaces of the etching grooves; and 3) washing and drying the electrical steel plate. The CaSiO3 phases have strong pinning effects relative to tensile stress or dislocation of regions around the grooves, a processed laser etching product has excellent thermal resistance, the iron loss reduction effect generated by laser etching cannot be disappeared after the product is subjected to thermal insulation and annealing treatment at 800 DEG C for 2 hours, and the original magnetic performance is basically maintained. The method is simple in operation, and production and application at a large scale are promoted.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Laser protection coating and preparation method thereof

ActiveCN111996531AImprove bindingImprove laser protectionMolten spray coatingElectrolytic coatingsNano al2o3Nickel alloy

The invention belongs to the technical field of protection coatings, and particularly discloses a laser protection coating and a preparation method thereof. The laser protection coating comprises a zinc dipping layer, a Ni / n-Al 2O3 electroplating layer and a Ni / nAl 2O3 spraying layer which are sequentially stacked from inside to outside. The Ni / n-Al 2O3 electroplating layer comprises nickel and nano aluminum oxide (n-Al 2O 3). The Ni / n-Al 2O3 spraying layer comprises nano aluminum oxide (n-Al 2O3) powder and nickel powder and / or nickel alloy powder. The binding force of the coating and a basebody is high, the internal stress is low, and the problems of cracking, stripping and the like are not likely to happen; and the excellent laser protection capability is achieved, irradiation of 1kW / cm < 2 > laser for 10s and irradiation of 600w / cm < 2 > laser for 100s can be resisted, only the surface of the coating is slightly burnt, only local melting happens under irradiation of 2-5 time aboveenergy laser, and the situations of combustion, breakdown, cracking, stripping and the like are avoided.

Owner:CISDI RES & DEV CO LTD

Carbon fiber reinforced resin-based composite material interface microcell structure regulation and control method

The invention discloses a carbon fiber reinforced resin matrix composite interface microcell structure regulation and control method which comprises the following steps: pretreating carbon fibers, removing surface slurry and impurities, then cleaning and drying to obtain carbon fibers with clean surfaces, loading a pure metal target material into a multi-arc ion plating arc head as a cathode, and carrying out high-temperature ion plating on the pure metal target material to obtain the carbon fiber reinforced resin matrix composite interface microcell structure. The pretreated carbon fibers are arranged on a rotating stand in a vacuum chamber, the vacuum chamber is vacuumized and heated, then argon is introduced, rich metal deposition is carried out on the surfaces of the carbon fibers, after deposition is completed, a sample is taken out, the sample is wrapped with graphite paper and then put into a graphite mold, then the graphite mold is put into an atmosphere protection furnace or a vacuum sintering furnace, and the carbon fibers are obtained. The preparation method comprises the following steps: heating a furnace to 900-1100 DEG C, carrying out an in-situ reaction, carrying out furnace cooling to obtain modified carbon fibers, and treating the modified carbon fibers and a resin solution through a vacuum-assisted resin injection molding process, a compression molding process or a resin transfer molding process to prepare the carbon fiber reinforced resin-based composite material.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com