Pretreatment process suitable for hot aluminum spraying on surface of steel plate and detection method

An inspection method and pretreatment technology, applied in spray guns, manufacturing tools, metal processing equipment, etc., can solve the problems of corrosion at the joint of the coating and residues on the surface, and achieve the effect of improving the bonding strength and strong pinning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

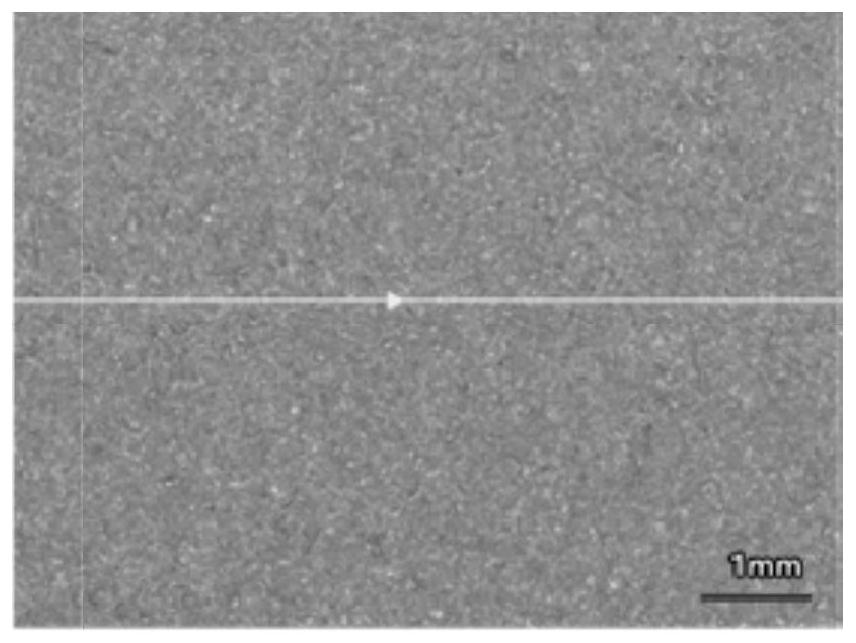

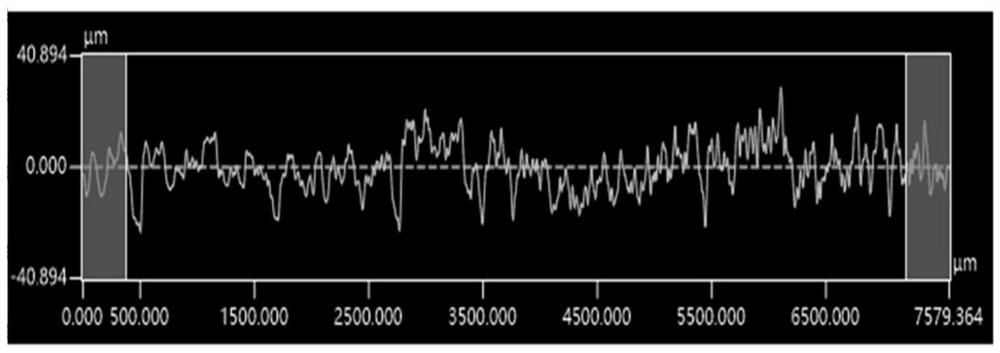

[0025] Pretreatment and inspection of Q235 steel plate before thermal spraying aluminum.

[0026] (1) The pretreatment method of sandblasting is adopted, and the sandblasting medium is angular alumina particles, and the particle size is 1mm;

[0027] (2) The sandblasting equipment is Shenzhen Jiecheng automatic sandblasting equipment: JIC 1212A, equipped with compressed air, and the pressure of the compressed air is maintained at 0.8MPa during the sandblasting and purging process;

[0028] (3) When sandblasting, the spray gun is 20mm away from the surface to be sandblasted, and the horizontal plane of the surface to be sandblasted is 45°, the sandblasting speed is 20cm / min, and the surface color after sandblasting is uniform off-white;

[0029] (4) After sandblasting, use compressed air to blow, the compressed air outlet is 90° to the horizontal plane of the surface after sandblasting, and blow to the surface without dust;

[0030] (5) For impurity detection on the surface of...

Embodiment 2

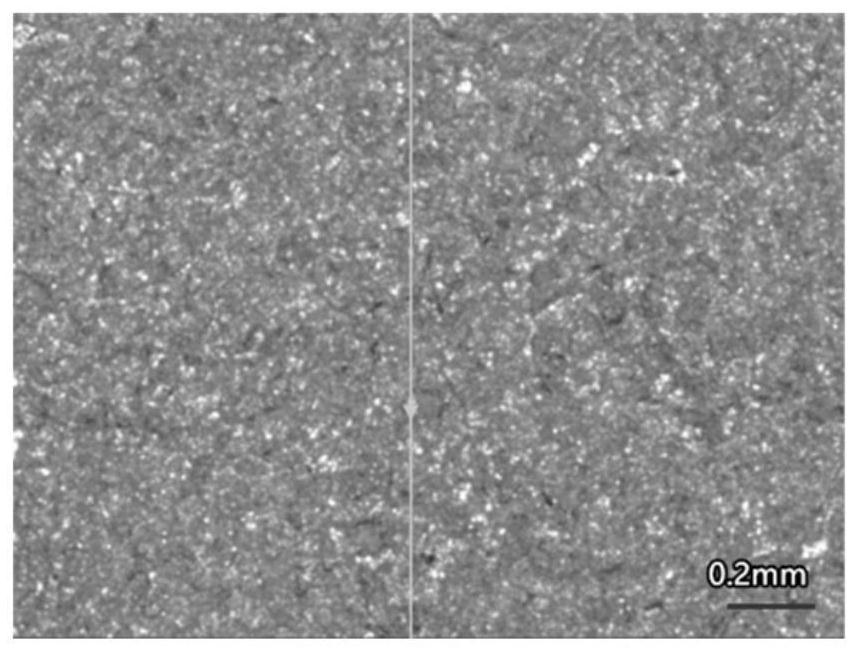

[0037] Pretreatment and inspection of Q345 steel plate before thermal spraying aluminum.

[0038] (1) The pretreatment method of sandblasting is adopted, and the sandblasting medium is angular alumina particles with a particle size of 1.5mm;

[0039] (2) The sandblasting equipment is Shenzhen Jiecheng automatic sandblasting equipment: JIC 1212A, equipped with compressed air, and the pressure of the compressed air is maintained at 1.2MPa during the sandblasting and purging process;

[0040] (3) When sandblasting, the spray gun is 30mm away from the surface to be sandblasted, 60° to the horizontal plane of the surface to be sandblasted, the sandblasting speed is 25cm / min, and the surface color after sanding is uniform off-white:

[0041] (4) After sandblasting, use compressed air to blow, the compressed air outlet is 90° to the horizontal plane of the surface after sandblasting, and blow to the surface without dust;

[0042] (5) For impurity detection on the surface of the pret...

Embodiment 3

[0049] Pretreatment and inspection of Q235 steel plate before thermal spraying aluminum.

[0050] (1) The pretreatment method of sandblasting is adopted, and the sandblasting medium is angular alumina particles with a particle size of 1.2mm;

[0051] (2) The sandblasting equipment is Shenzhen Jiecheng automatic sandblasting equipment: JIC 1212A, equipped with compressed air, and the pressure of the compressed air is maintained at 1MPa during the sandblasting and purging process;

[0052] (3) When sandblasting, the spray gun is 22mm away from the surface to be sandblasted, and the horizontal plane of the surface to be sandblasted is 55°, the sandblasting speed is 22cm / min, and the surface color after sandblasting is uniform off-white;

[0053] (4) After sandblasting, use compressed air to blow, the compressed air outlet is 90° to the horizontal plane of the surface after sandblasting, and blow to the surface without dust;

[0054] (5) For impurity detection on the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com