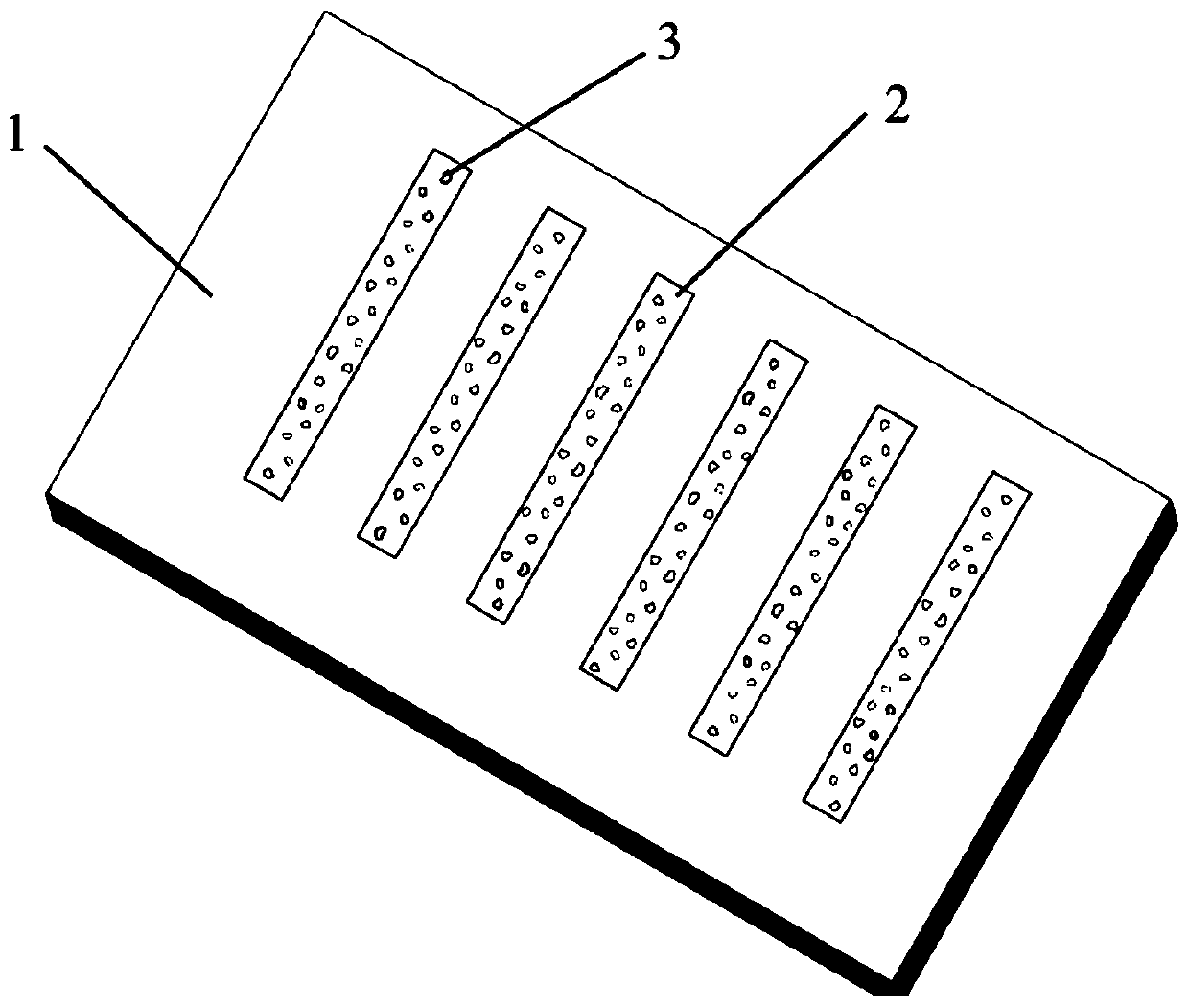

A kind of electrical steel sheet and preparation method thereof

A technology of electrical steel and steel plates, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., and can solve the problem that the scored electrical steel products cannot be applied to wound core transformer annealing treatment, stress relief annealing treatment, and have no heat resistance To achieve the effect of reducing the size of the production site and the requirements for protective facilities, preventing movement or rotation, and retaining magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

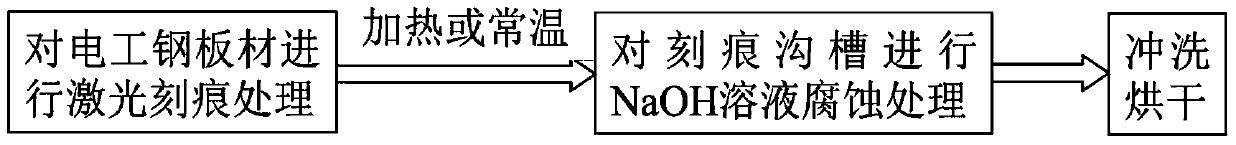

Method used

Image

Examples

Embodiment 1

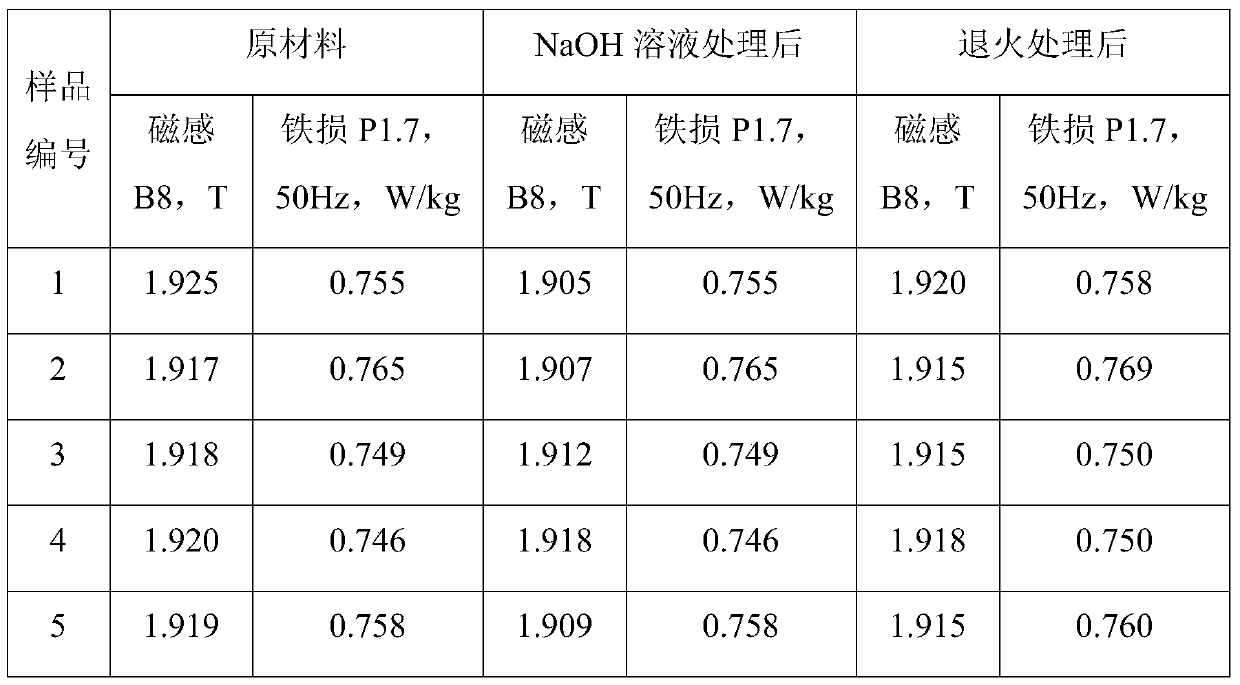

[0044] The raw materials are electrical steel plates processed by laser scoring, and their specifications are 0.18mm thick. Heat the plate to 80°C, keep it warm for 3 minutes, spray NaOH solution with a solution concentration of 5% on its surface, keep it for 6 minutes, and form NaOH on the inner surface of the groove. 2 SiO 3 9H 2 O product, the pit diameter is about 20nm, and the pit area accounts for 30% of the total inner surface area of the groove. The surface is washed with clean water for 2 minutes, and dried at room temperature.

[0045] First, the magnetic properties of the prepared electrical steel samples were tested, and then the samples were annealed at 800°C for 2 hours, and the magnetic properties were tested again. The test results are shown in Table 5. It can be seen from Table 5 that the properties of raw materials remain unchanged after NaOH treatment, and after annealing at 800 °C for 2 hours, the magnetic properties are basically consistent with the in...

Embodiment 2

[0049] The raw materials are electrical steel sheets processed by laser scoring, and their specifications are 0.27mm thick. At room temperature, it is completely immersed in a NaOH solution with a solution concentration of 10%, kept for 2 minutes and then taken out, forming Na on the inner surface of the groove. 2 SiO 3 The product has a pit diameter of about 30nm, and the pit area accounts for 40% of the total surface area of the groove. The surface is washed with clean water for 2 minutes, and dried at room temperature.

[0050] First, the magnetic properties of the prepared electrical steel samples were tested, and then the samples were annealed at 800°C for 2 hours, and then the magnetic properties were tested again. The test results are shown in Table 6. It can be seen from Table 6 that the properties of the raw materials remain unchanged after being treated with NaOH, and after annealing at 800 °C for 2 hours, the magnetic properties are basically consistent with the ...

Embodiment 3

[0054] The raw materials are electrical steel plates processed by laser scoring, and their specifications are 0.30mm thick. At room temperature, it is completely immersed in a NaOH solution with a solution concentration of 15%, kept for 5 minutes and then taken out, forming Na on the inner surface of the groove. 2 SiO 3 The product has a pit diameter of about 60nm, and the pit area accounts for 50% of the total surface area of the groove. The surface is washed with clean water for 2 minutes, and dried at room temperature.

[0055] First, the magnetic properties of the prepared electrical steel samples were tested, and then the samples were annealed at 800 ° C for 2 hours, and then the magnetic properties were tested again. The test results are shown in Table 7. It can be seen from Table 7 that the properties of the raw materials remain unchanged after being treated with NaOH, and after annealing at 800 °C for 2 hours, the magnetic properties are basically consistent with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com