Patents

Literature

344 results about "Graphite substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphite substrates. Graphite substrates are manufactured from graphite grade ET. Graphite substrates are used in the cement industry, for laboratory research.

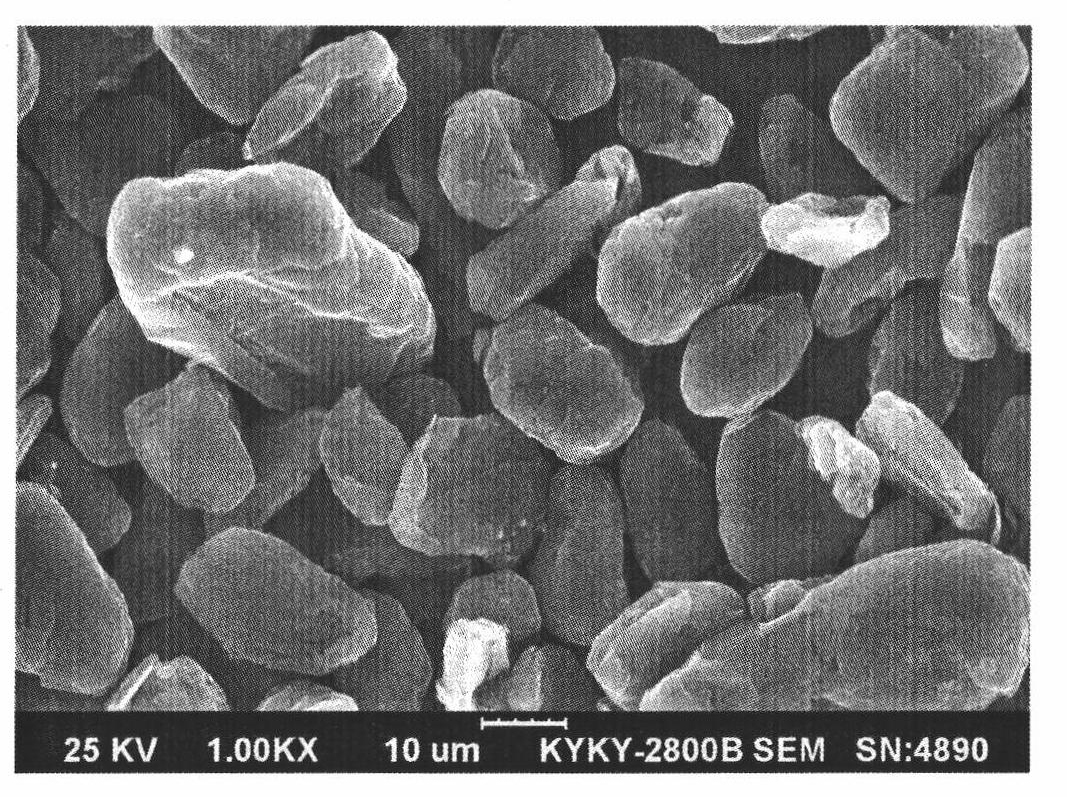

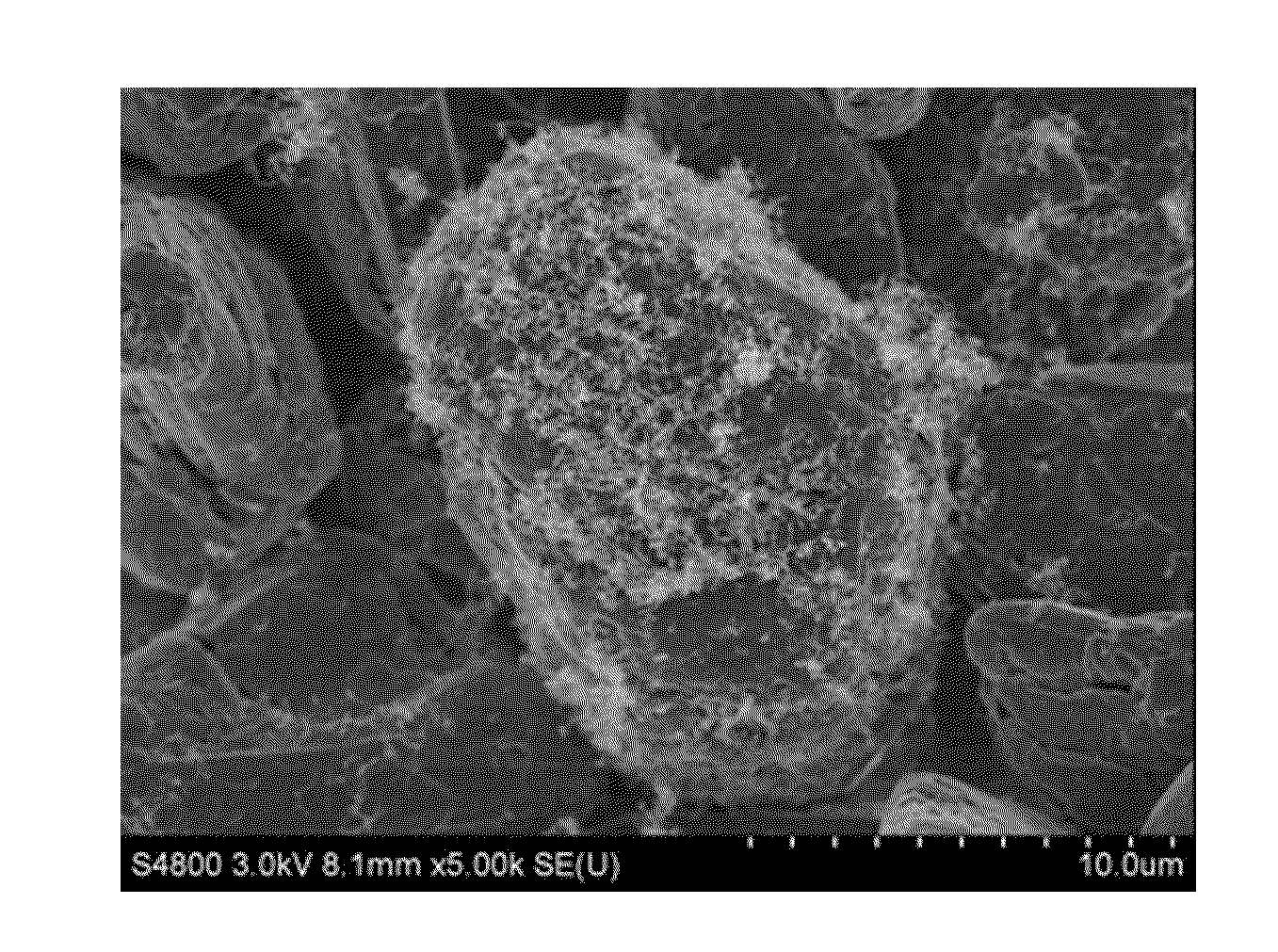

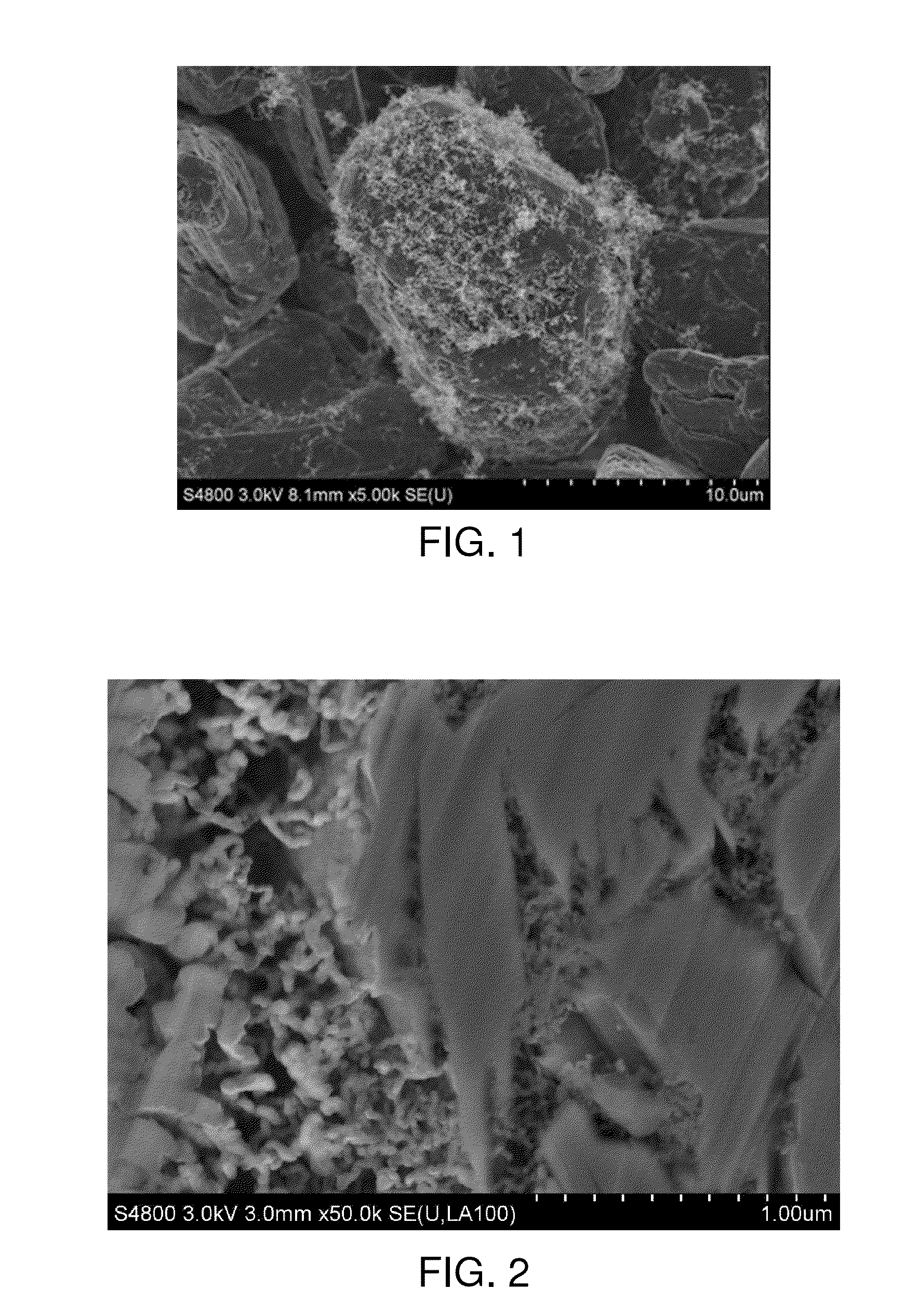

Silicon-carbon composite negative electrode material for lithium ion battery and preparation method thereof

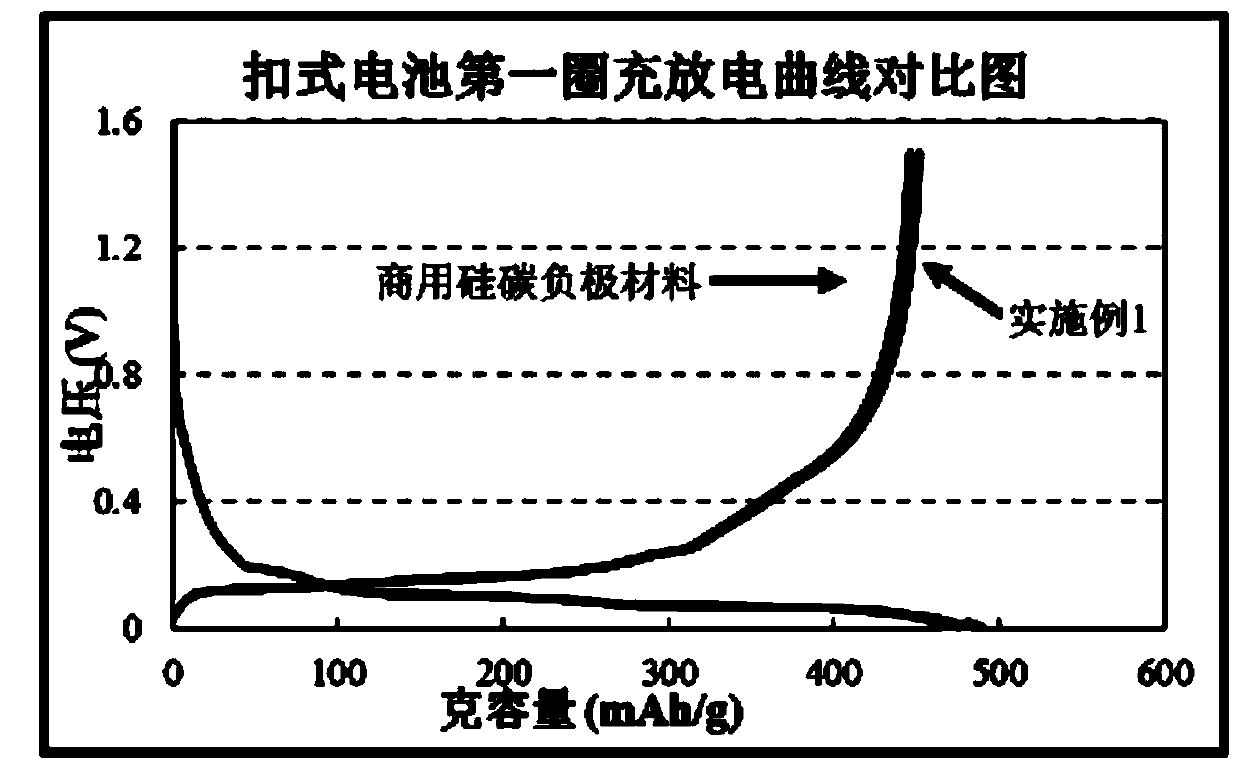

ActiveCN103474667AImprove cycle performanceHigh charge and discharge capacityMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

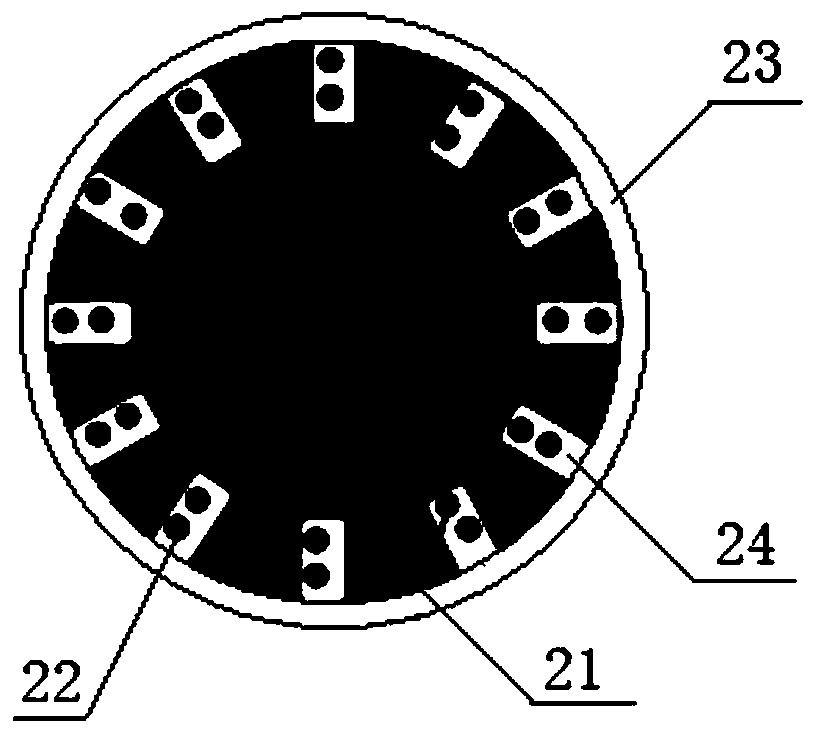

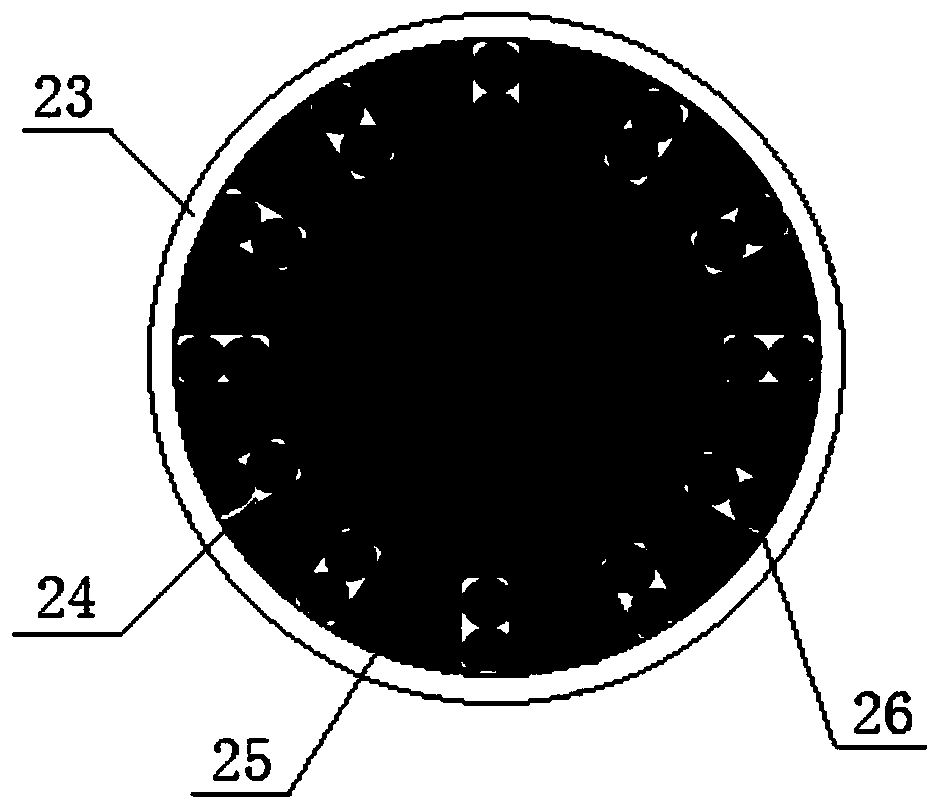

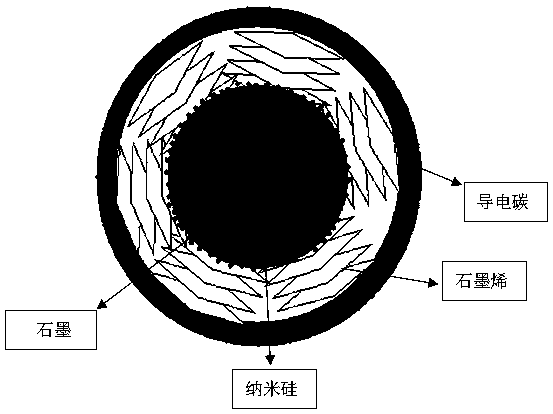

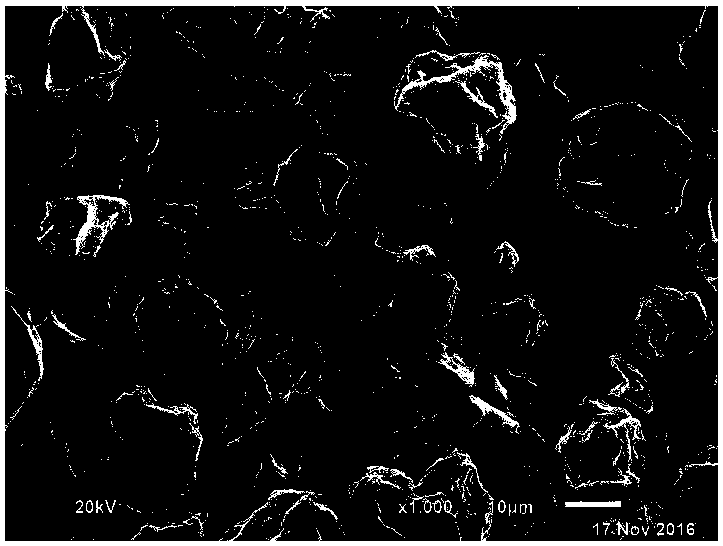

The invention relates to a silicon-carbon composite negative electrode material and a preparation method thereof. The silicon-carbon composite negative electrode material successively comprises nano silicon / graphite particles, a first carbon coating layer and an organic cracking carbon layer from inside to outside. The nano silicon / graphite particles are globular or globular-like composite particles formed by employing graphite as an inner core of a volume expansion buffer substrate and coating a nano silicon particle layer; the first carbon coating layer comprises carbon nanotubes and / or amorphous carbon, the carbon nanotubes and / or amorphous carbon are interspersed in a gap network formed by gaps of the nano silicon particles and / or are coated outside the nano silicon particle layer, so that the nano silicon is tightly wrapped between the carbon nanotubes and / or between the carbon nanotubes and the graphite substrate, and besides, the material ion conductivity is effectively enhanced; the organic cracking carbon layer is an outermost coating layer of the silicon-carbon composite negative electrode material. The silicon-carbon composite negative electrode material has excellent cycle performance, excellent multiplying power charging and discharging performance and lower volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

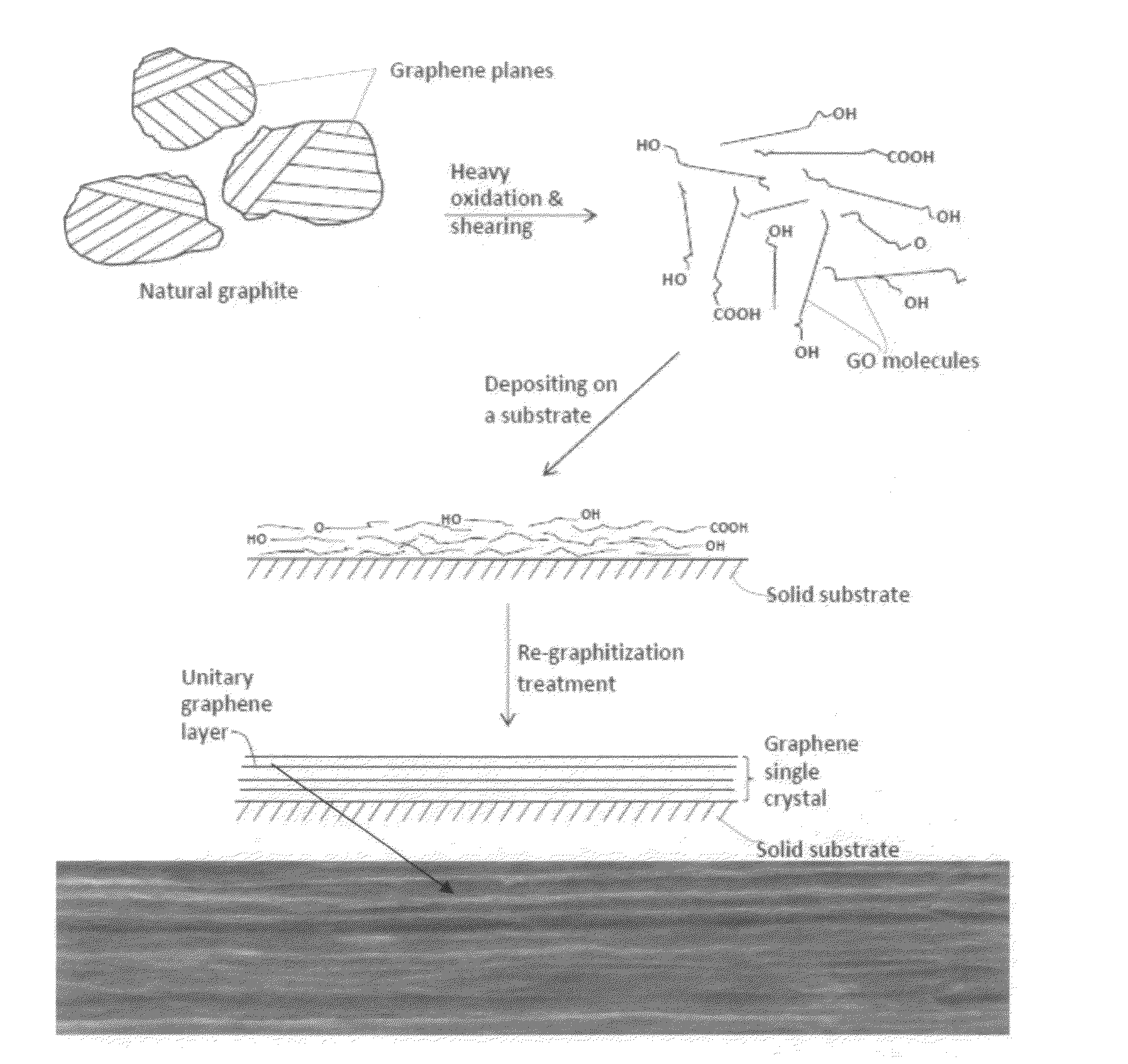

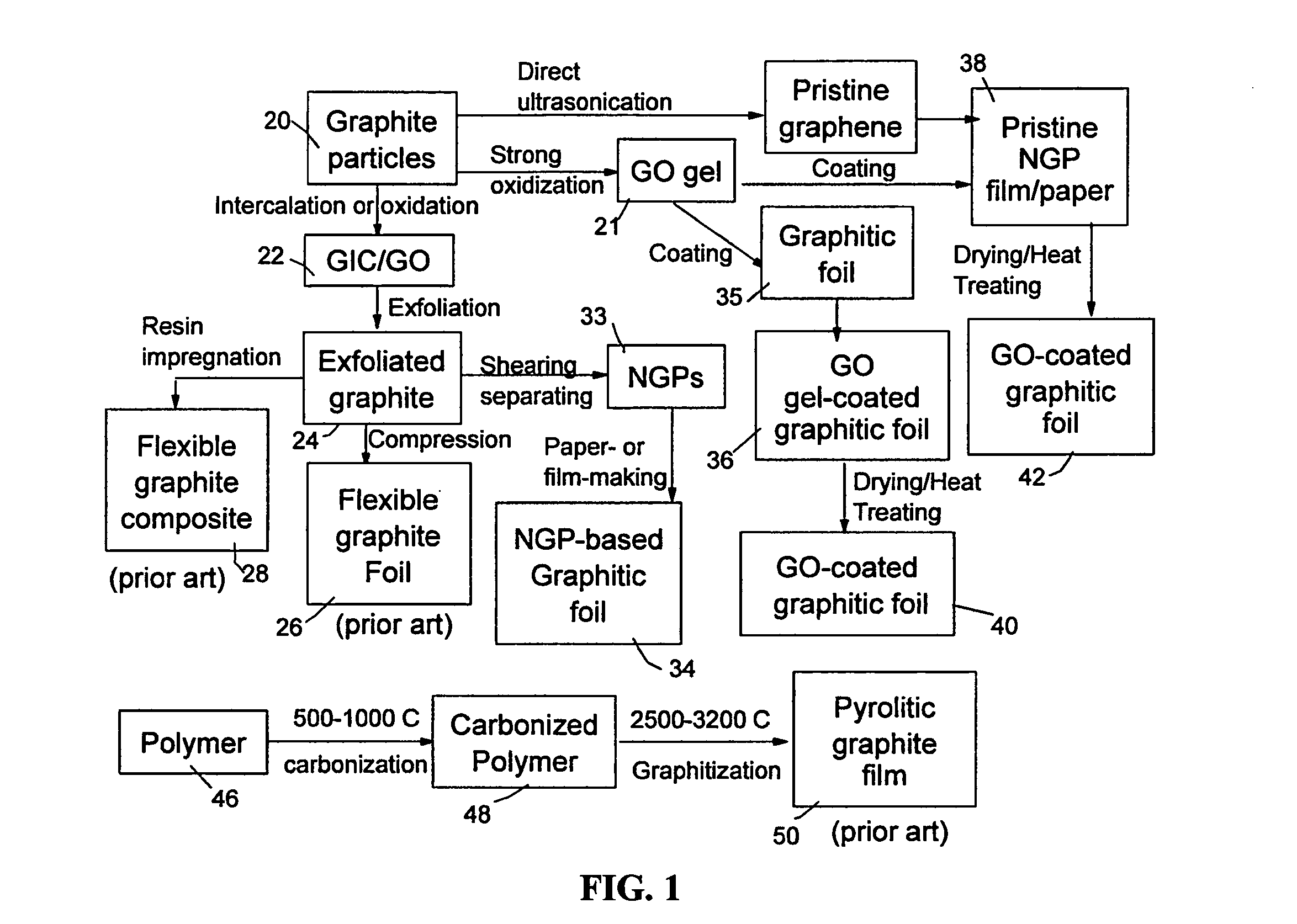

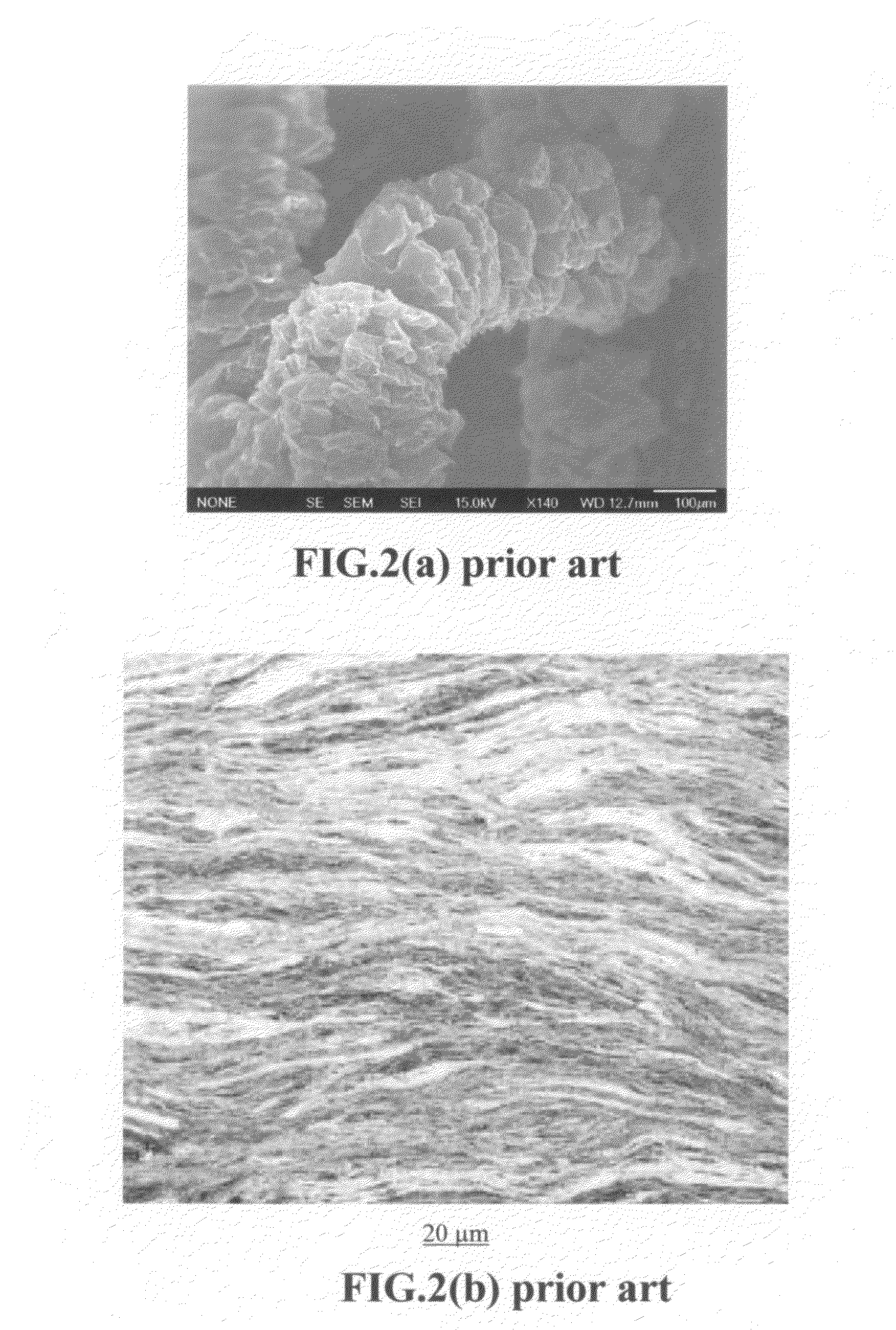

Graphene oxide-coated graphitic foil and processes for producing same

ActiveUS20140127488A1Reduce eliminateImprove surface smoothnessMaterial nanotechnologyGraphiteCarbon compositesFiber

A graphene oxide-coated graphitic foil, composed of a graphitic substrate or core layer having two opposed primary surfaces and at least a graphene oxide coating layer deposited on at least one of the two primary surfaces, wherein the graphitic substrate layer has a thickness preferably from 0.34 nm to 1 mm, and the graphene oxide coating layer has a thickness preferably from 0.5 nm to 1 mm and an oxygen content of 0.01%-40% by weight based on the total graphene oxide weight. The graphitic substrate layer may be preferably selected from flexible graphite foil, graphene film, graphene paper, graphite particle paper, carbon-carbon composite film, carbon nano-fiber paper, or carbon nano-tube paper. This graphene oxide-coated laminate exhibits a combination of exceptional thermal conductivity, electrical conductivity, mechanical strength, surface smoothness, surface hardness, and scratch resistance unmatched by any thin-film material of comparable thickness range.

Owner:GLOBAL GRAPHENE GRP INC

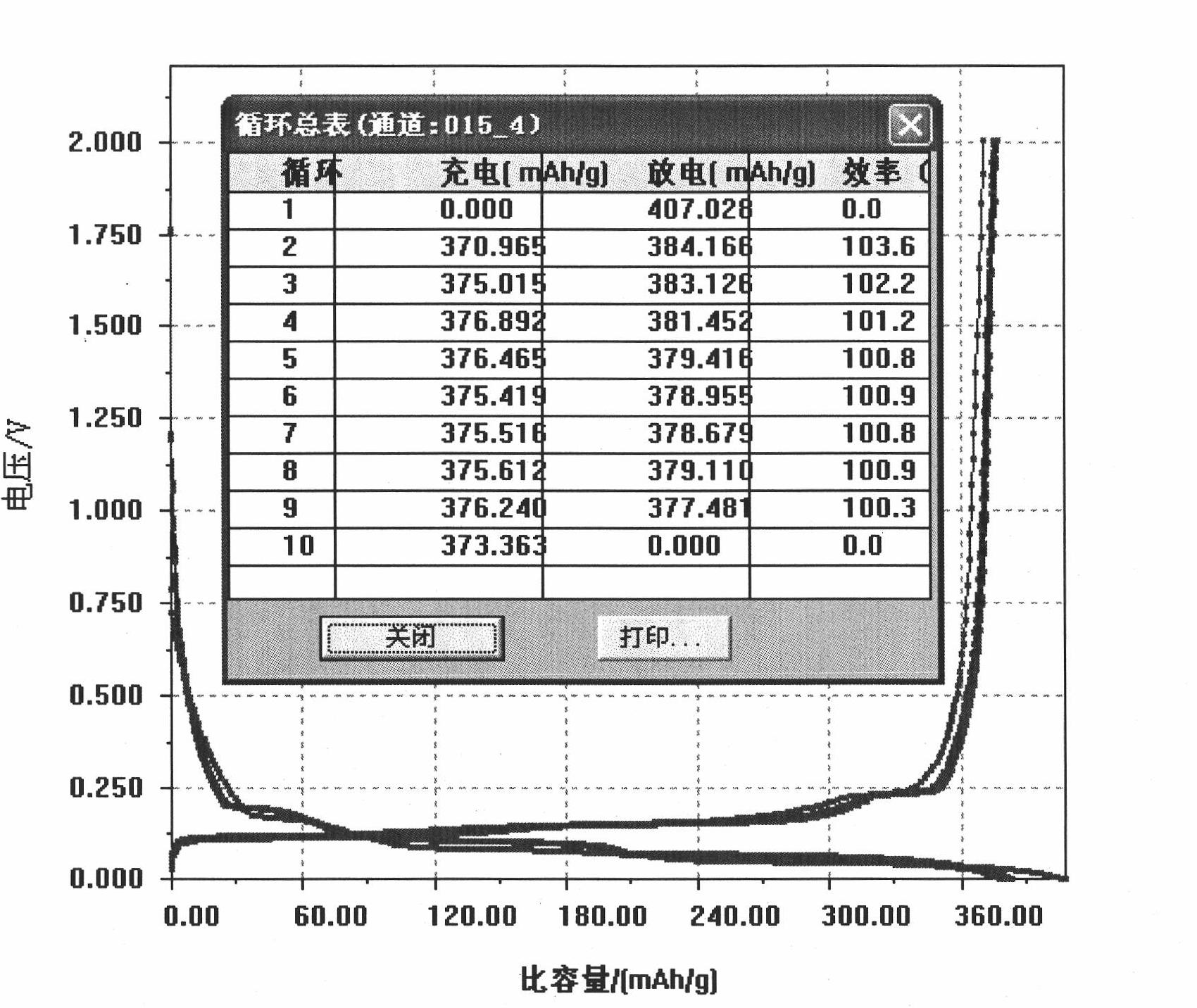

Lithium ion battery cathode composite material and preparation method thereof

ActiveCN101916846AExtend your lifeCyclic stabilityCell electrodesGraphite substrateLithium electrode

The invention discloses a lithium ion battery cathode composite material and a preparation method thereof. The invention aims to lower the cost of the cathode material of the lithium ion battery and enhance the conductivity thereof. Graphite is used as the substrate of the material, and an organic polymer and / or high molecular conducting polymer are / is coated outside the substrate. The preparation method comprises the following steps: purifying or graphitizing natural crystalline flake graphite, microcrystal graphite, crystallized veined graphite or needle coke and petroleum coke to obtain the graphite substrate, mixing the graphite substrate and the organic high molecular polymer and / or high molecular conducting polymer liquid phase, spray-drying, and carrying out oven-drying to obtain the lithium ion battery cathode composite material. Compared with the prior art, the invention has the advantages of simplified technique, firmer and more compact coating layer, and stable circulation of the lithium ion battery; the powder resistivity is below 7*10<-6> omega m; and when the material is used for manufacturing the pole piece of the battery, the use amounts of adhesive and conducting agent are reduced in the pole piece manufacturing process, thereby lowering the battery cost.

Owner:BTR NEW MATERIAL GRP CO LTD

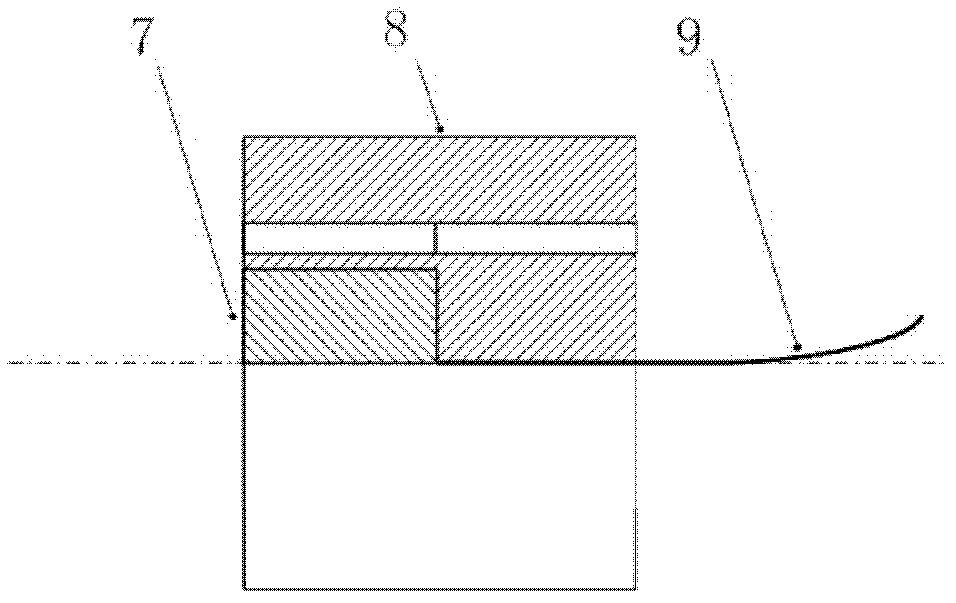

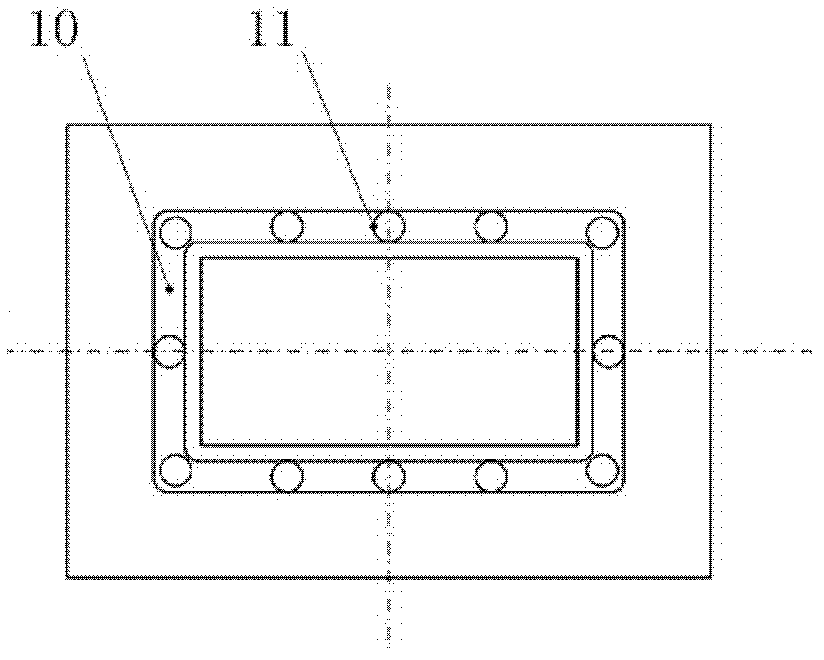

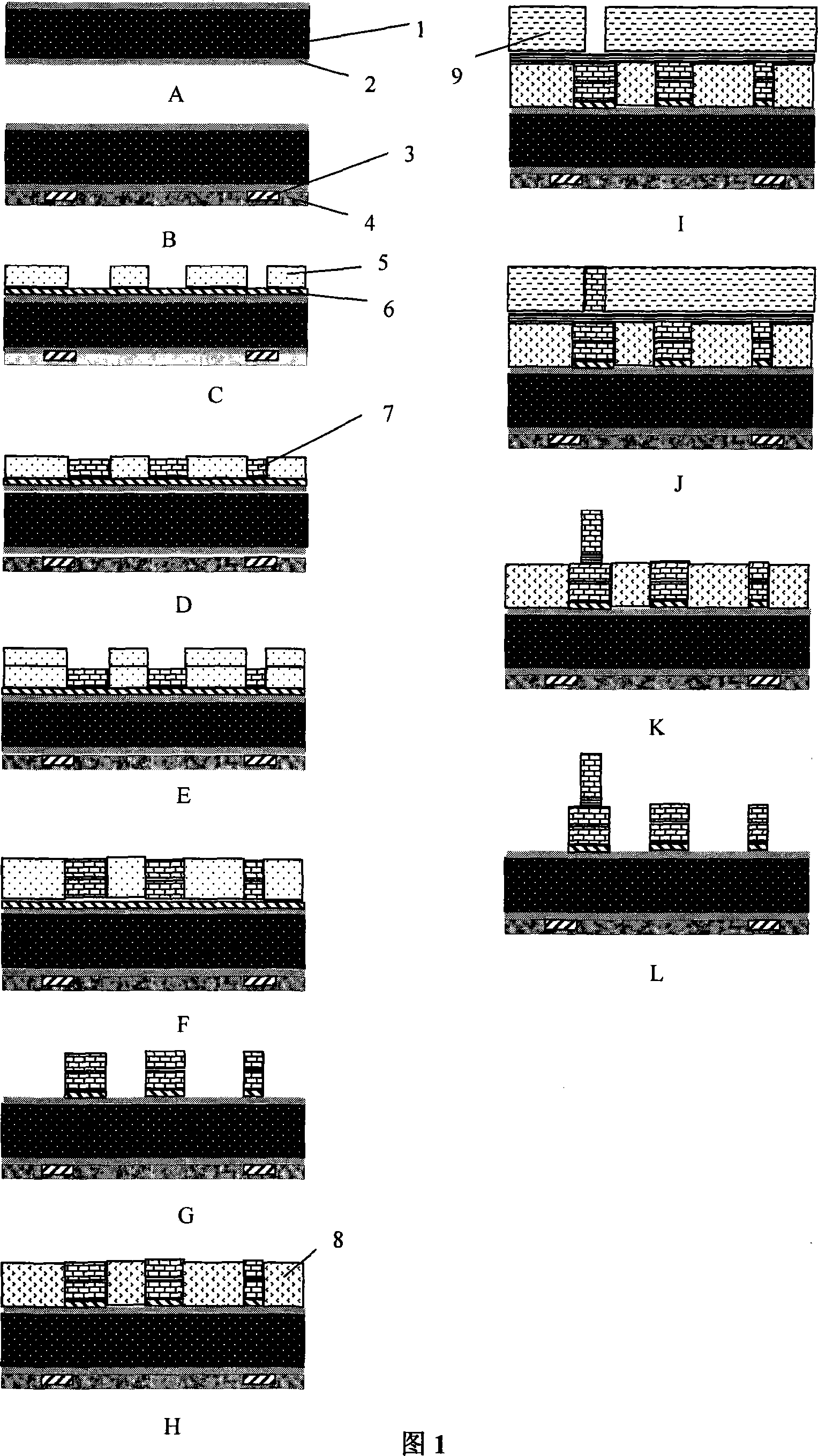

Seed crystal support for growing silicon carbide crystal with high quality

ActiveCN101580964AEliminate defects caused by porosityEliminate flat hex defectsPolycrystalline material growthFrom condensed vaporsPorosityGas phase

The invention provides a seed crystal support for growing a silicon carbide crystal with high quality by a physical vapor phase transport method. The seed crystal support comprises a graphite substrate and a compact film layer arranged on the surface of the graphite substrate. The compact film layer is stable and compact at high temperature and eliminates the defects of the graphite substrate caused by porosity. The compactness of the film layer inhibits steam generated by the back evaporation of the crystal from escaping from a hole of the graphite substrate, eliminates the planar hexagonal defect caused by back evaporation in the process of crystal growth and greatly improves the quality and the yield of the silicon carbide crystal.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD

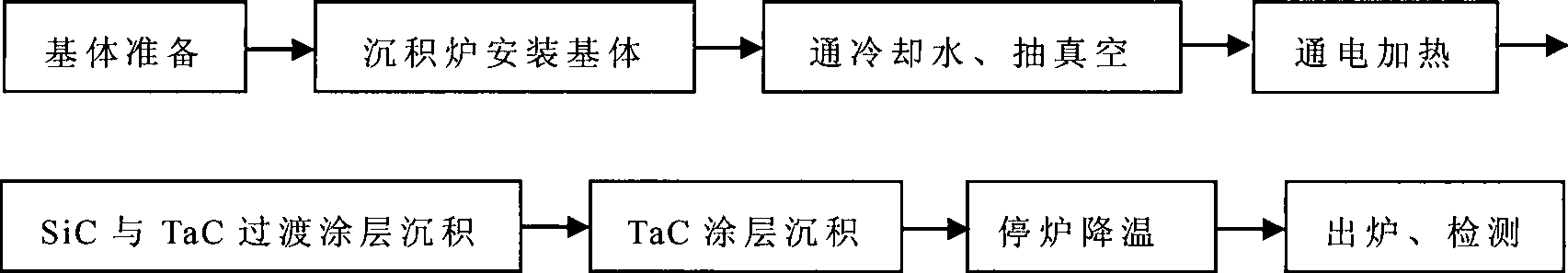

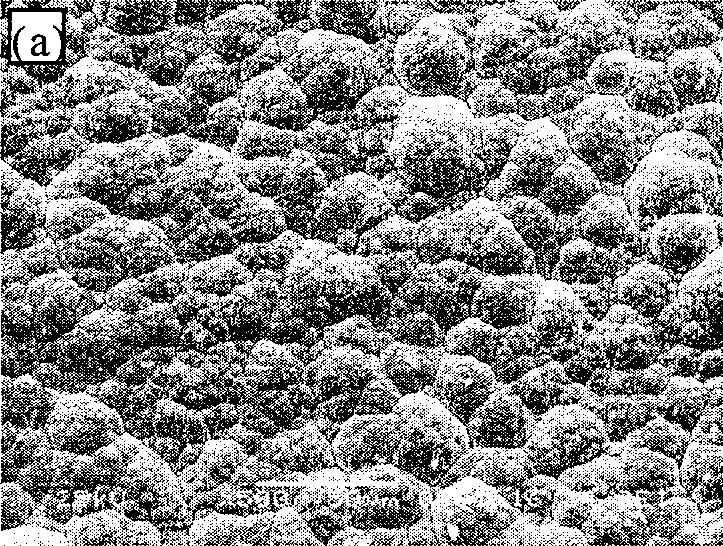

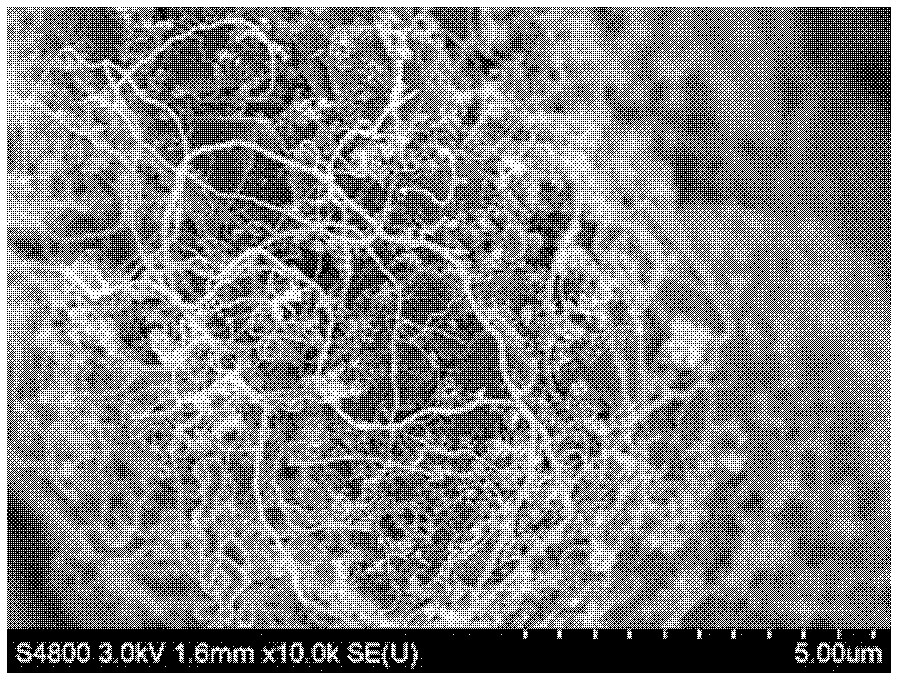

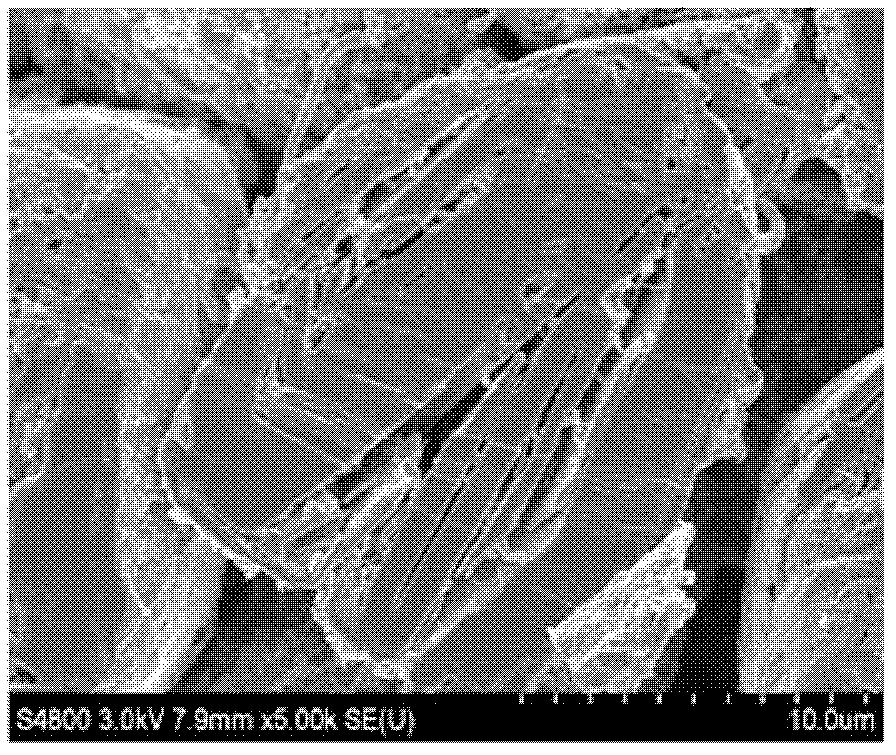

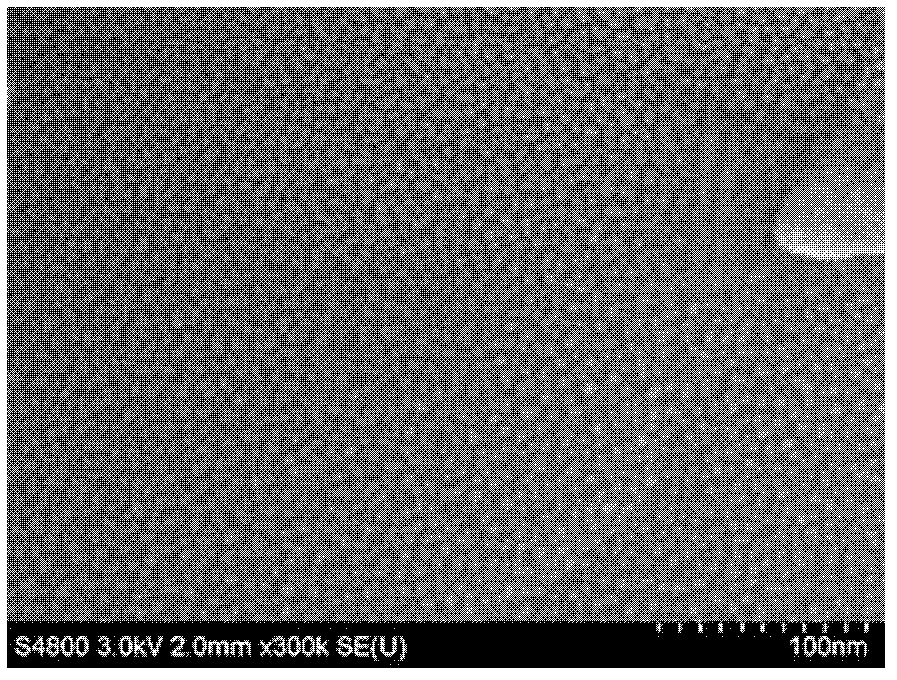

Graphite matrix flawless TaC coating and manufacturing method thereof

InactiveCN101445392AImprove corrosion resistanceImprove diffusion resistanceGraphite substrateThermal stability

The invention discloses a graphite matrix flawless TaC coating and a manufacturing method thereof. A tie coat is deposited on a graphite matrix. A TaC main coating is deposited on the outer layer of the tie coat. The tie coat is composed of a SiC-TaC codeposition coating or compounded by two transition layers of the SiC-TaC codeposition coating and a SiC-TaC laminated coating. When the tie coat is compounded by two transition layers of the SiC-TaC codeposition coating and the SiC-TaC laminated coating, the SiC-TaC codeposition coating serves as a first transition layer, and the SiC-TaC laminated coating serves as a second transition layer; and then the deposition of the tie coat is ended; or the SiC-TaC codeposition coating and the SiC-TaC laminated coating are alternatively deposited many times. Good TaC coating which has small heat stress, no macroscopic cracking, corrosion-resistance, and good thermal stability is deposited out of the surface of the graphite material. The method is suitable for preparing graphite substrate, graphite crucible, graphite windpipe, graphite guide shell coating in the crystal and semiconductor production, protecting and cleaning coating such as antisepsis, anti-pollution, anti-infiltration, anti-oxidation of graphite parts in other various hot environments.

Owner:CENT SOUTH UNIV

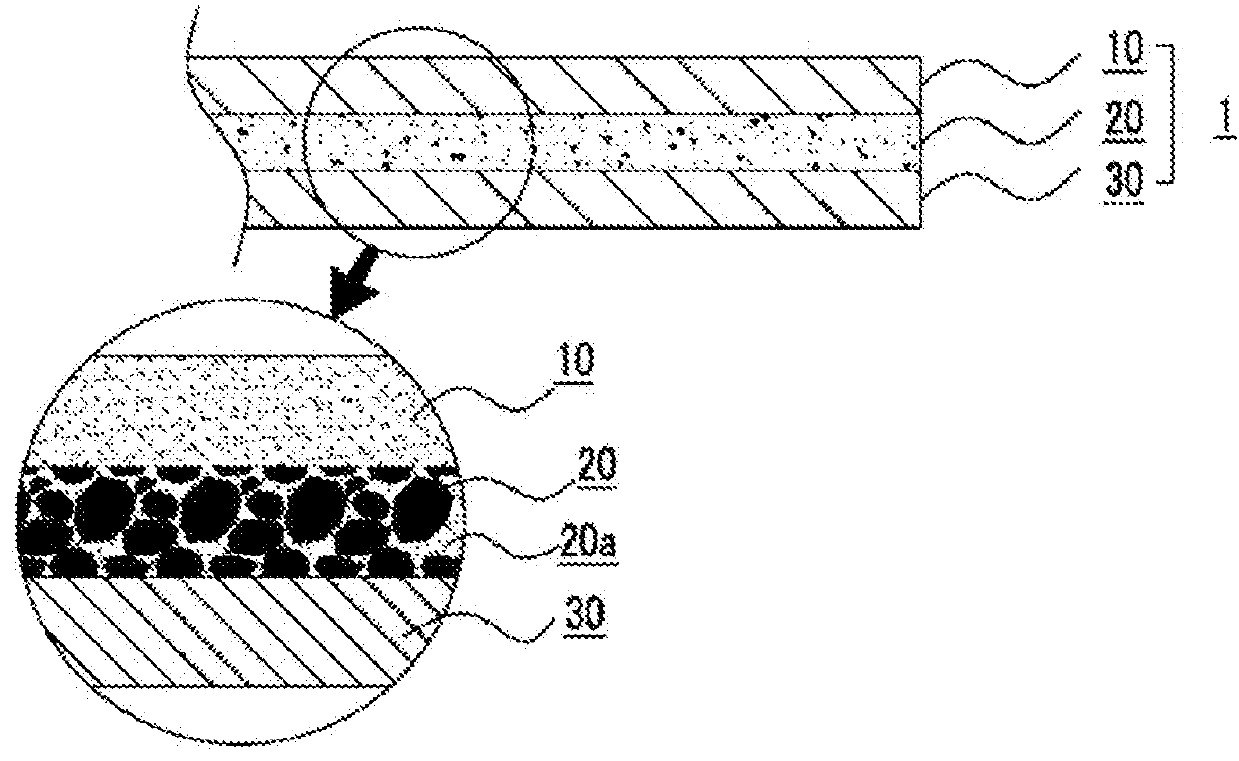

Lithium-ion battery negative electrode material and preparation method thereof, lithium-ion battery

ActiveCN102299308ASolve the "island" effectHigh reversible capacityCell electrodesSecondary cellsCarbon nanotubeGraphite substrate

The invention discloses a lithium ion battery cathode material, and a preparation method and a lithium ion battery thereof. The technical problem to be solved is to increase the discharge capacity, the multiplying power, the liquid absorption and the circulation performance of the lithium ion battery. The cathode material disclosed by the invention is a composite material which is composed of a graphite substrate, a mesh carbon nano-tube and / or nano-carbon fibre growing in situ of the graphite substrate, and / or the mesh carbon nano-tube and / or the nano-carbon fibre mixed in the graphite substrate, and a nano columnar structure. The preparation method disclosed by the invention comprises the following steps of: adding a catalyst into the graphite substrate material; putting in a furnace chamber; and introducing carbon source gas at 300-1300 DEG C. Compared with the prior art, the cathode material disclosed by the invention has the advantages of simplicity in process, precision for control and easiness for reproduction; the specific surface area of the cathode material is increased; the conductivity is increased; the discharge capacity is increased by 10-30 mAh / g; the ratio of 10C / 1C is more than or equal to 94%; the battery is manufactured from the material in the invention; the use amount of a conductive agent can be reduced; and the cost of the lithium ion battery can be reduced.

Owner:BTR NEW MATERIAL GRP CO LTD

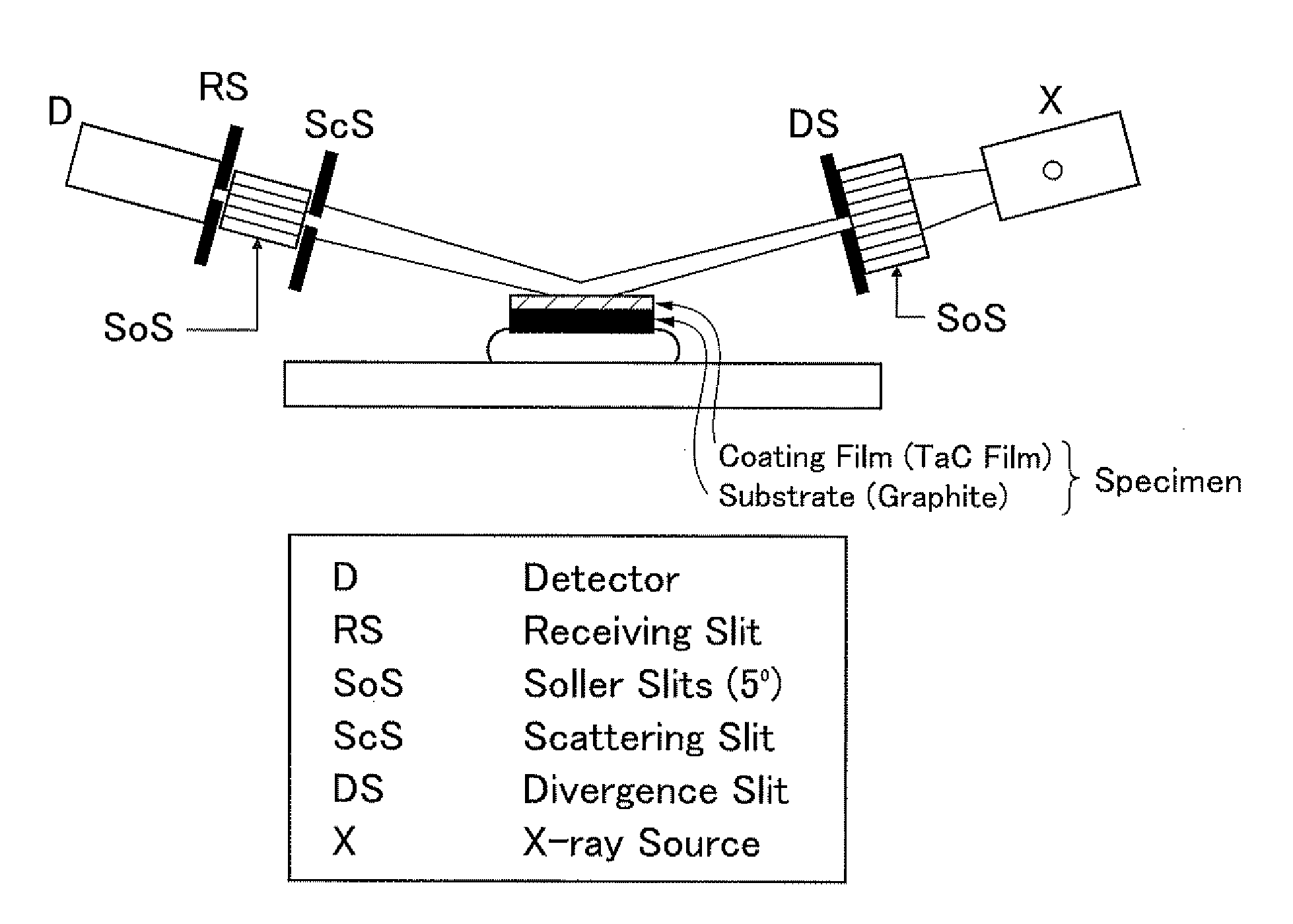

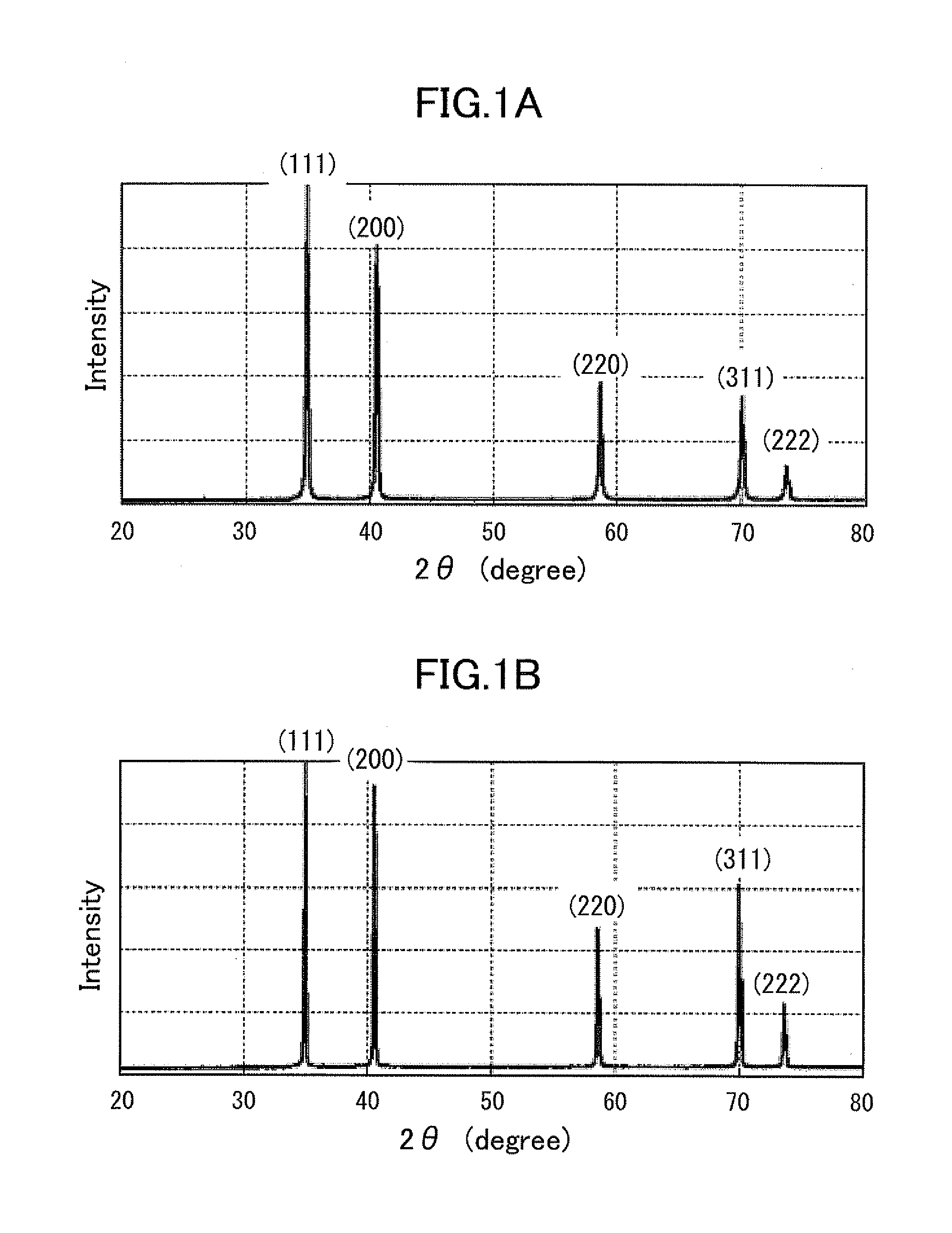

High heat-resistant member, method for producing the same, graphite crucible and method for producing single crystal ingot

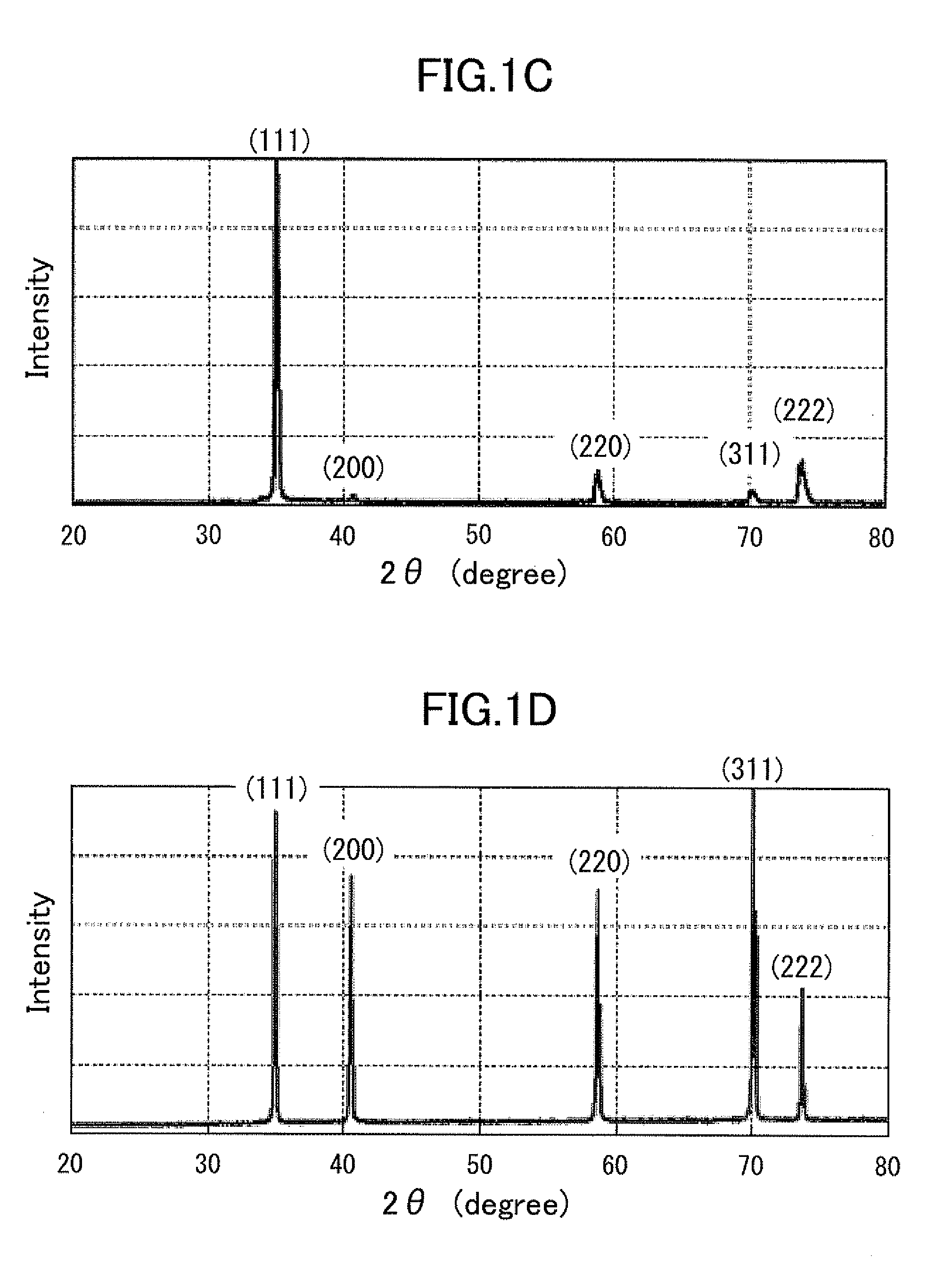

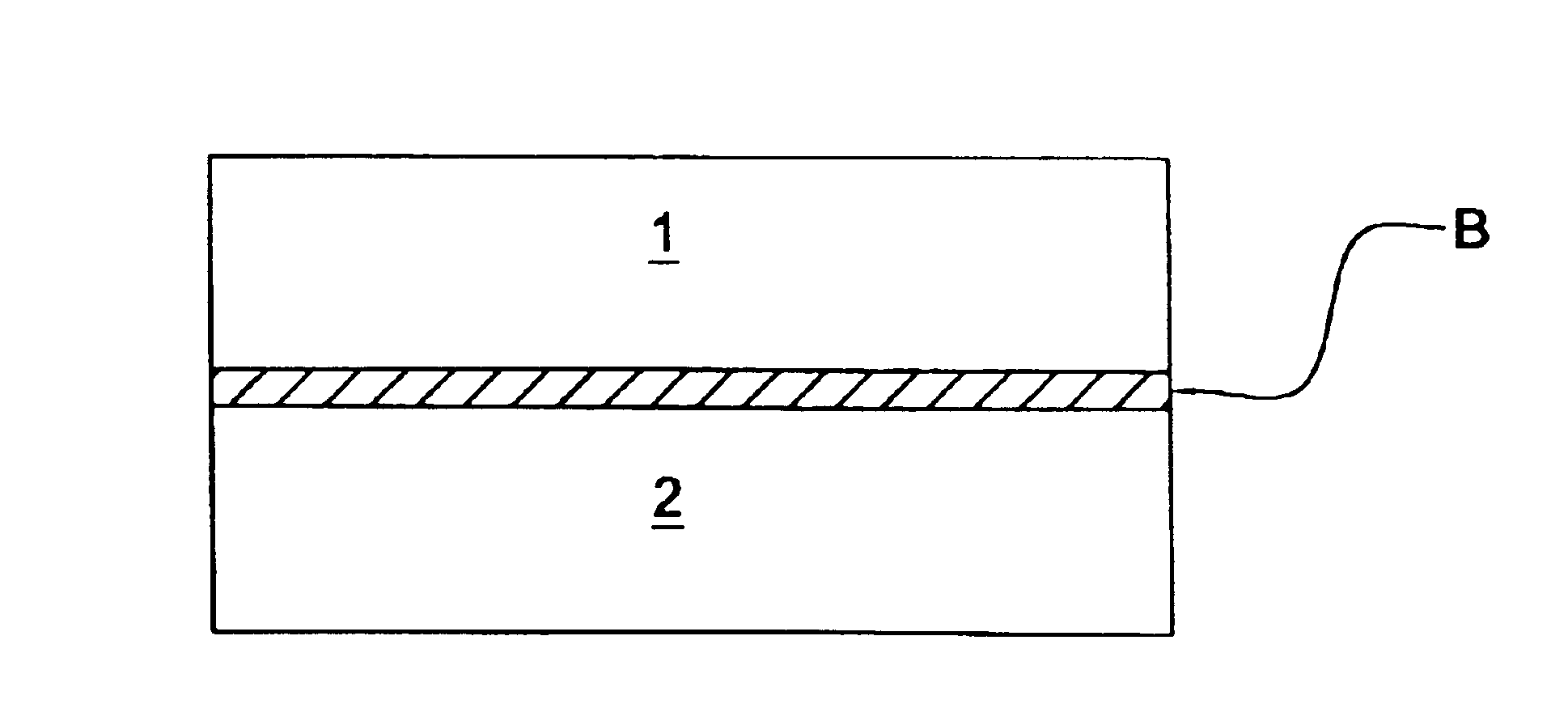

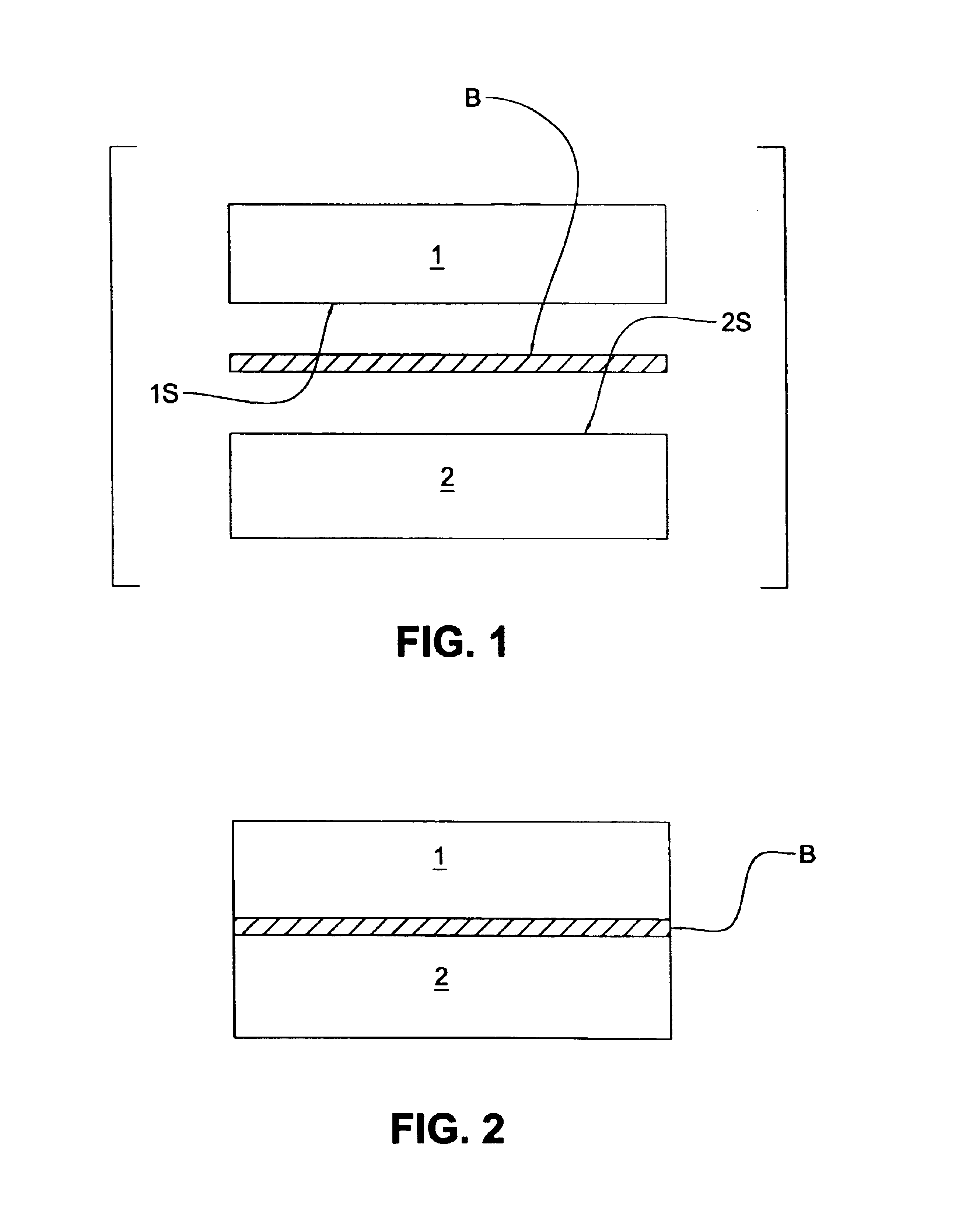

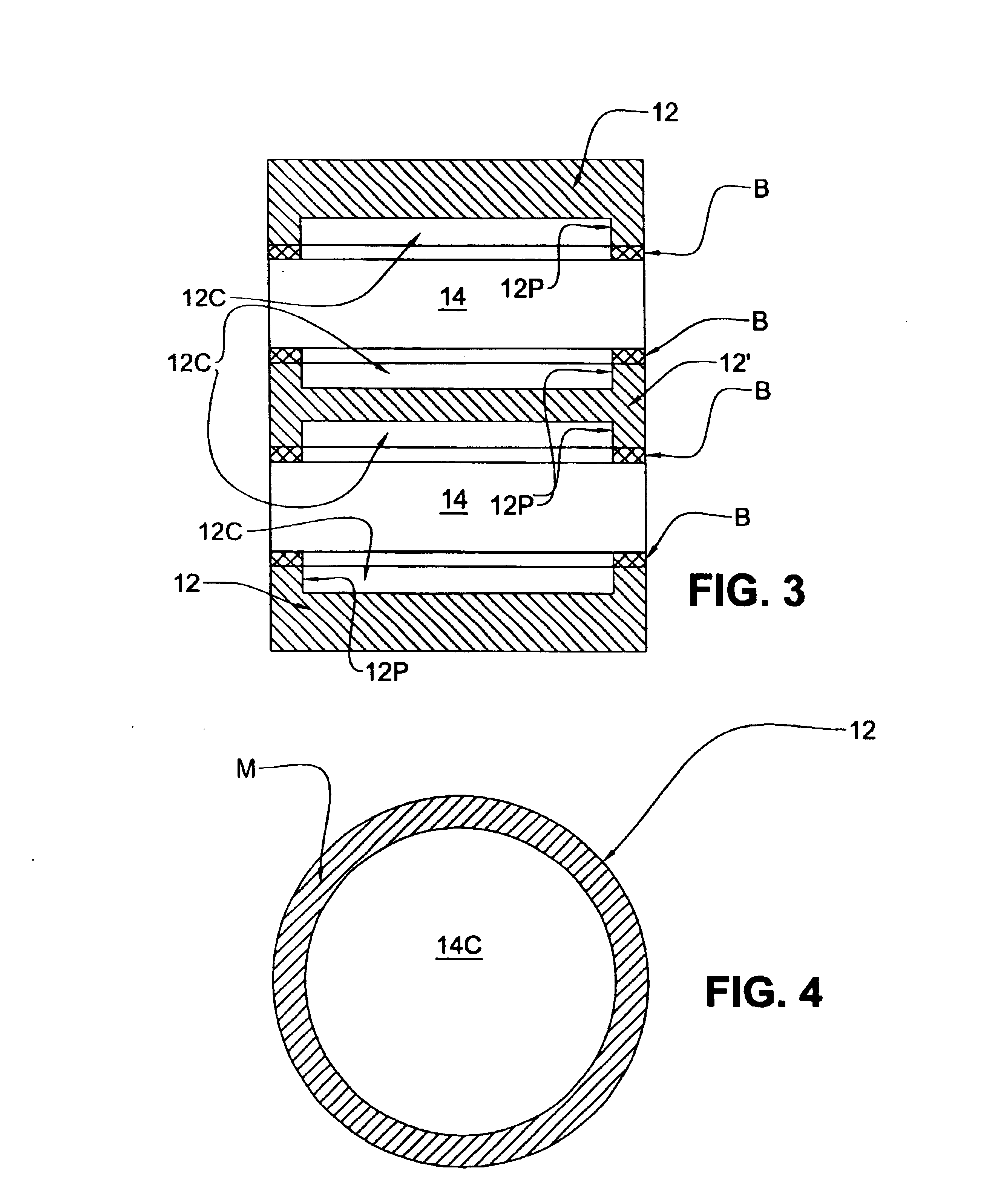

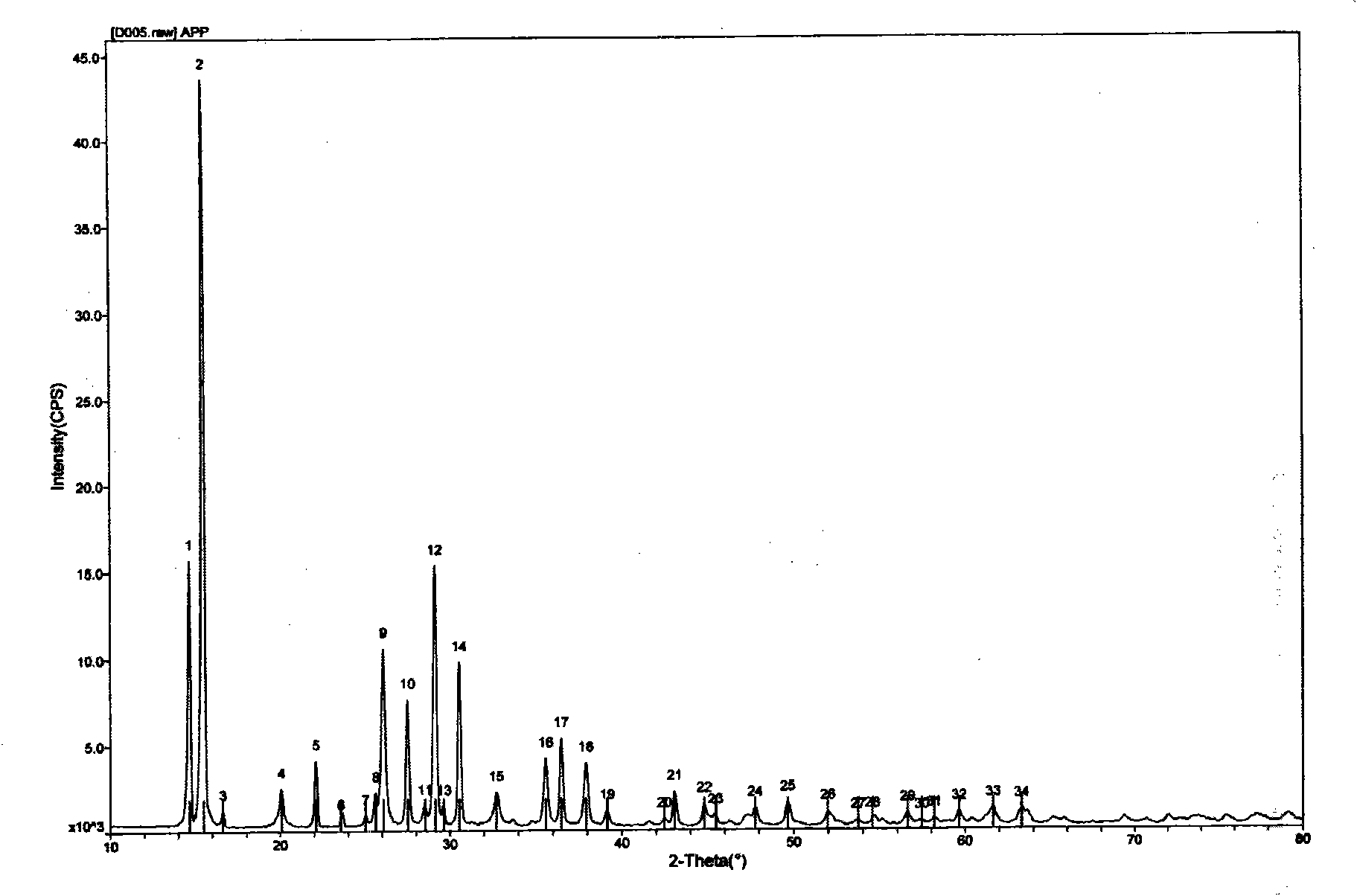

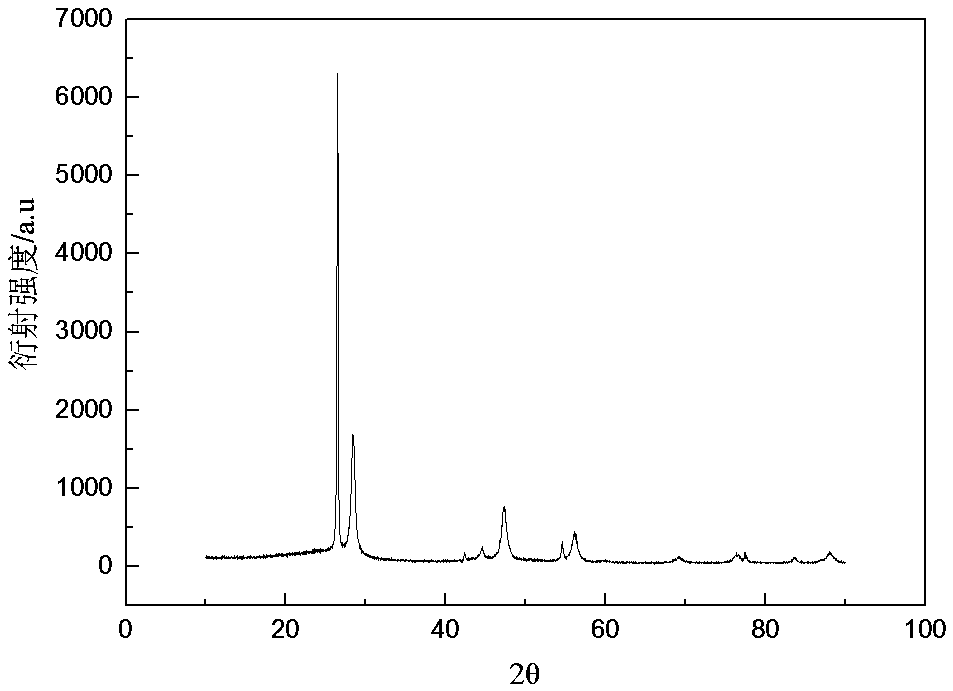

ActiveUS20130061800A1Improve heat resistanceIncreased durabilityAfter-treatment apparatusPolycrystalline material growthCarbide coatingX-ray

A high heat-resistant member includes a graphite substrate including isotropic graphite and a carbide coating film including a carbide, such as tantalum carbide, and covering a surface of the graphite substrate, the carbide coating film having a randomly oriented isotropic grain structure in which crystallites having a size indexed by a full width at half maximum of a diffraction peak of an X-ray diffraction spectrum of not more than 0.2° from (111) planes are accumulated at substantially random. The orientation of the carbide coating film is determined by whether degree of orientation (F) in any Miller plane calculated based on an XRD spectrum using the Lotgering method is within a range from −0.2 to 0.2.

Owner:TOYOTA CENT RES & DEV LAB INC

Method of joining ceramic or graphite to metal with an alloy having high nickel or cobalt content, alloys for joining the same, and products formed therewith

A brazed product has a metal substrate, a ceramic or graphite substrate, and a brazing alloy containing one of a high nickel content and cobalt content joining the ceramic or graphite substrate to the metal substrate. A method of joining these materials include providing a metal layer coating of titanium or nickel on the surface of the ceramic or graphite substrate to be joined or using a high nickel content or high cobalt content and containing titanium. The brazing alloy contains a high nickel content 70-95% by weight, or a high cobalt content between 45-55% by weight. This brazing alloy can contain titanium in the range between 0.5-5% by weight.

Owner:THOMAS SANDIN CONSULTING

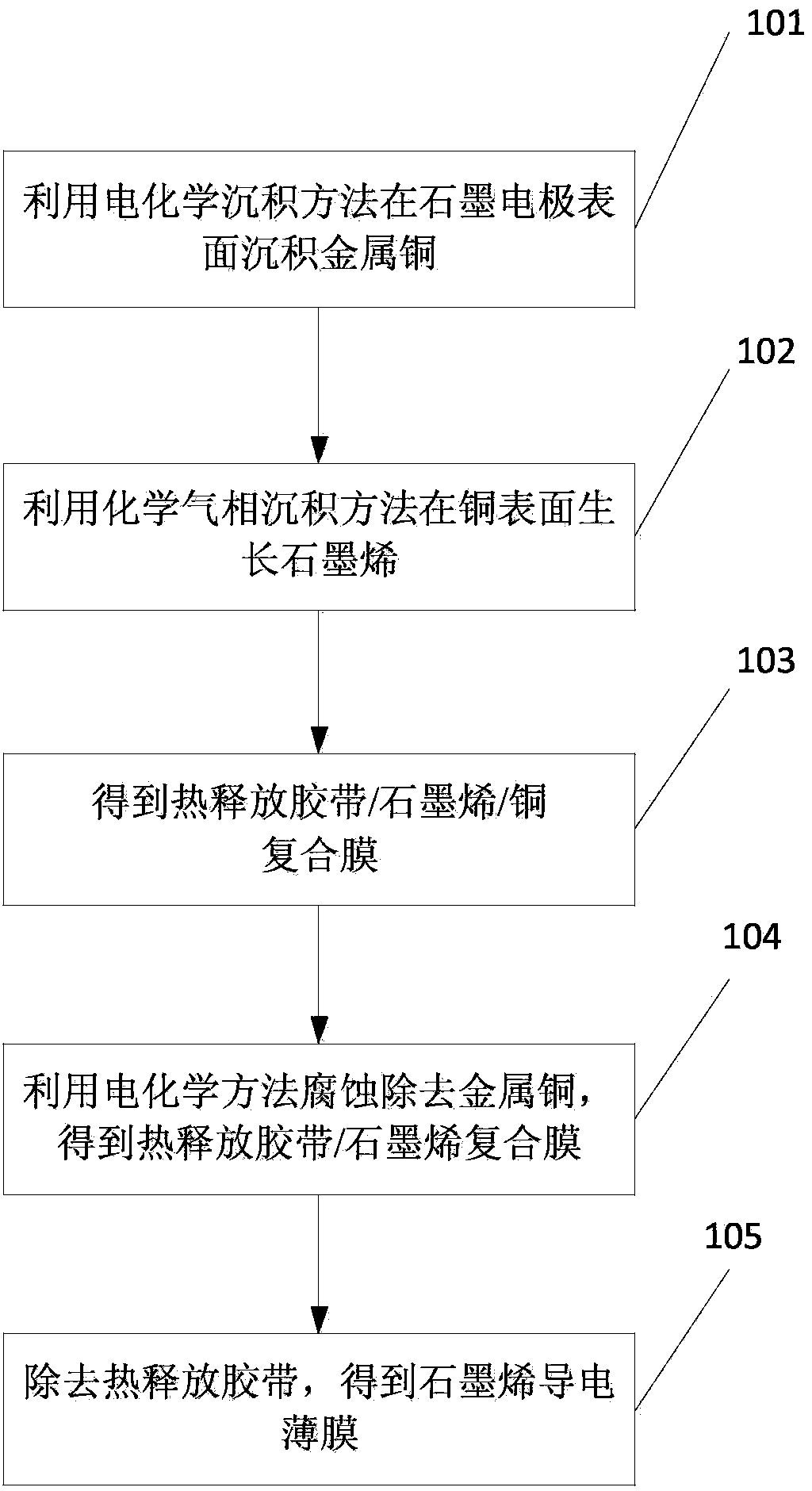

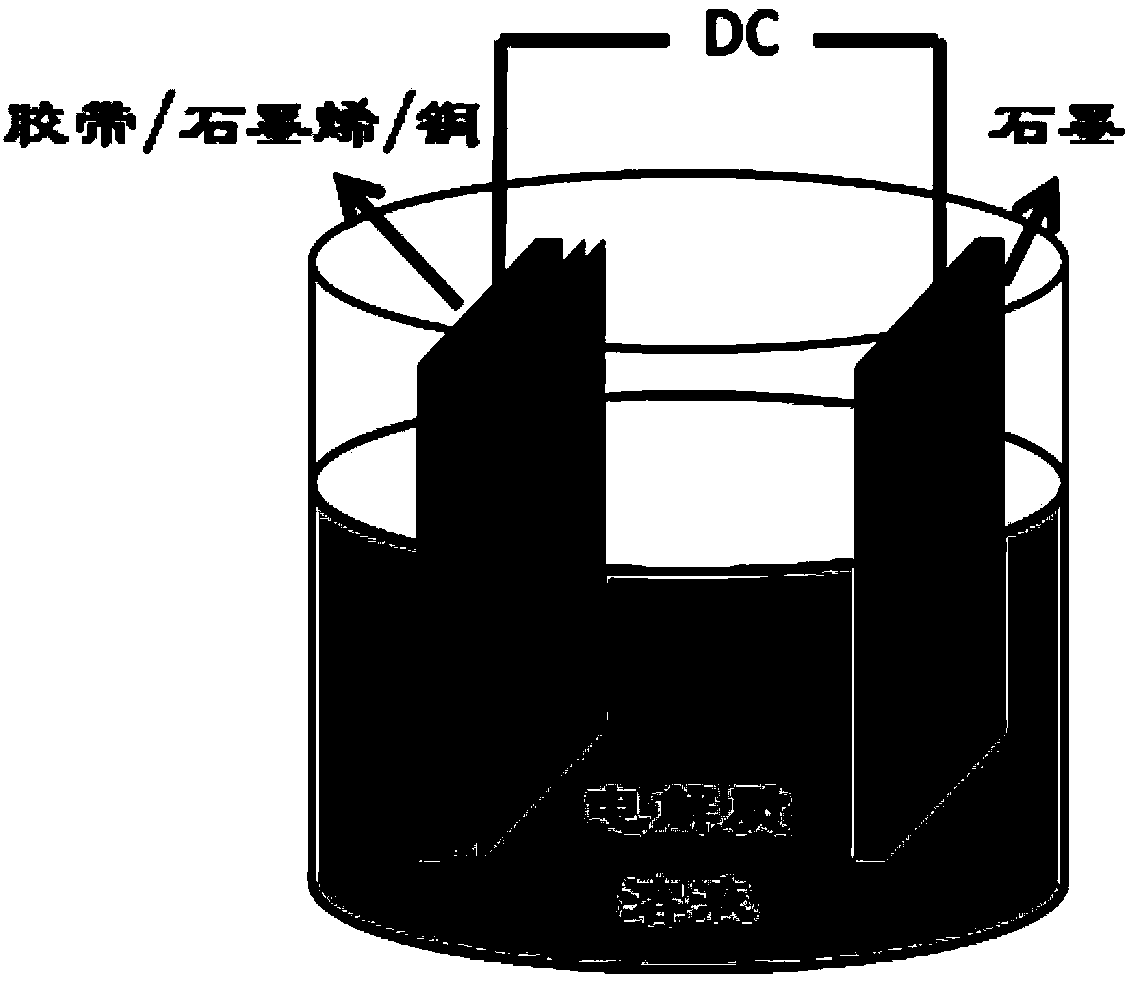

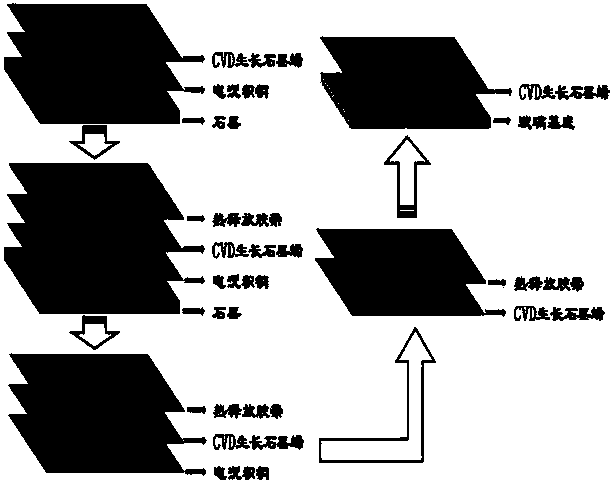

Preparation method of graphene conductive film

ActiveCN103387230AReduce breakageShort manufacturing timeGrapheneSemiconductor materialsComposite film

The invention discloses a preparation method of a graphene conductive film, belonging to the technical field of semiconductor material preparation. The method comprises the following steps of: depositing metal copper on the surface of a graphite electrode by an electrochemical method; growing graphene on the copper surface by a chemical vapour deposition method; pasting a heat release adhesive tape on the graphene surface, and stripping a copper film from the surface of a graphite substrate to obtain an adhesive tape / graphene / copper composite film; by taking the composite film as an anode and the graphite as a cathode, corroding by an electrochemical method to remove copper at the outermost layer of the composite film to obtain an adhesive tape / graphene composite film; and transferring the graphene on the composite film to a transparent substrate to finally obtain a graphene conductive film. The preparation method of the graphene conductive film, disclosed by the invention, not only can effectively reduce the damage of graphene, but also shortens the preparation time and reduces the cost by synchronously finishing the preparation of the copper film and the corrosion of copper, and can be applied to the preparation of a large-area graphene conductive film.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

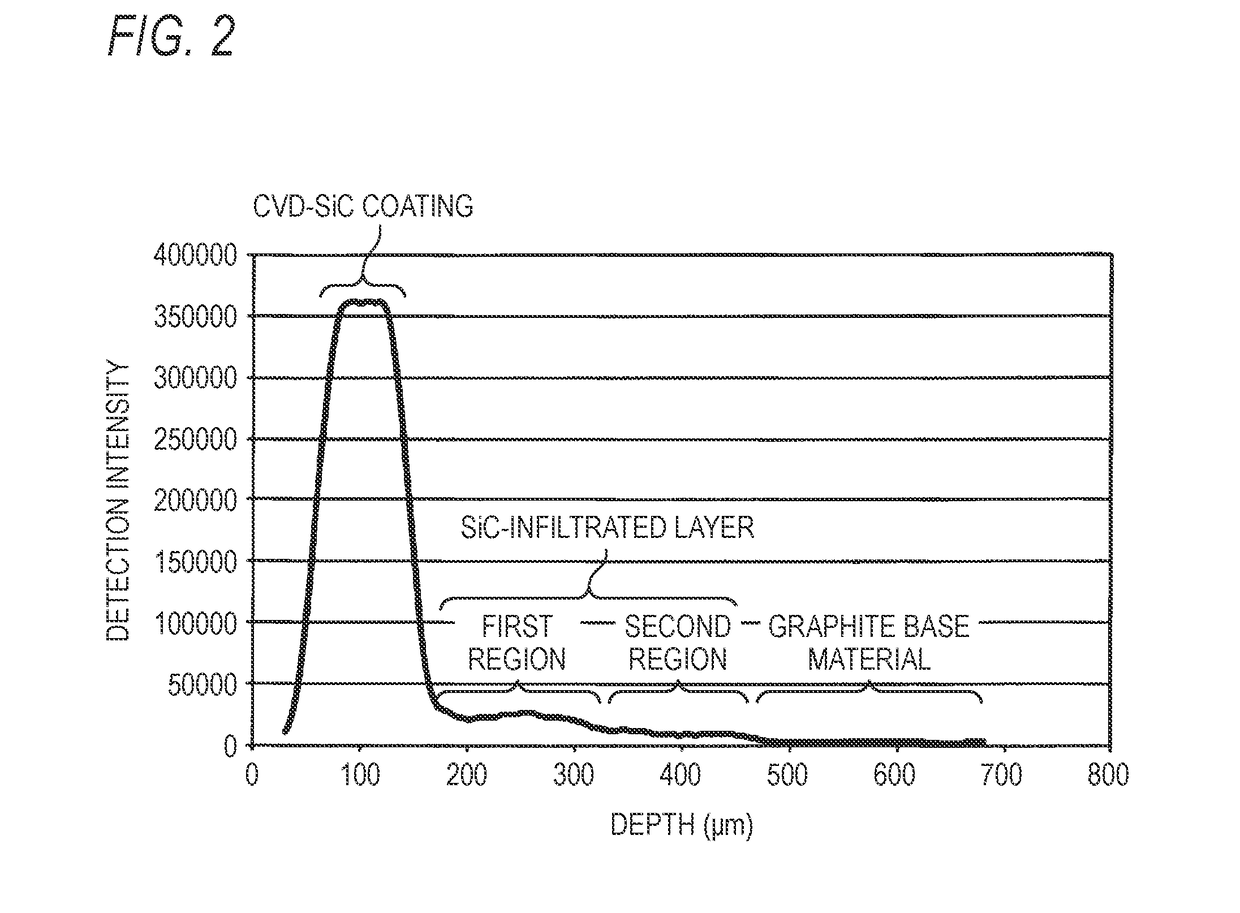

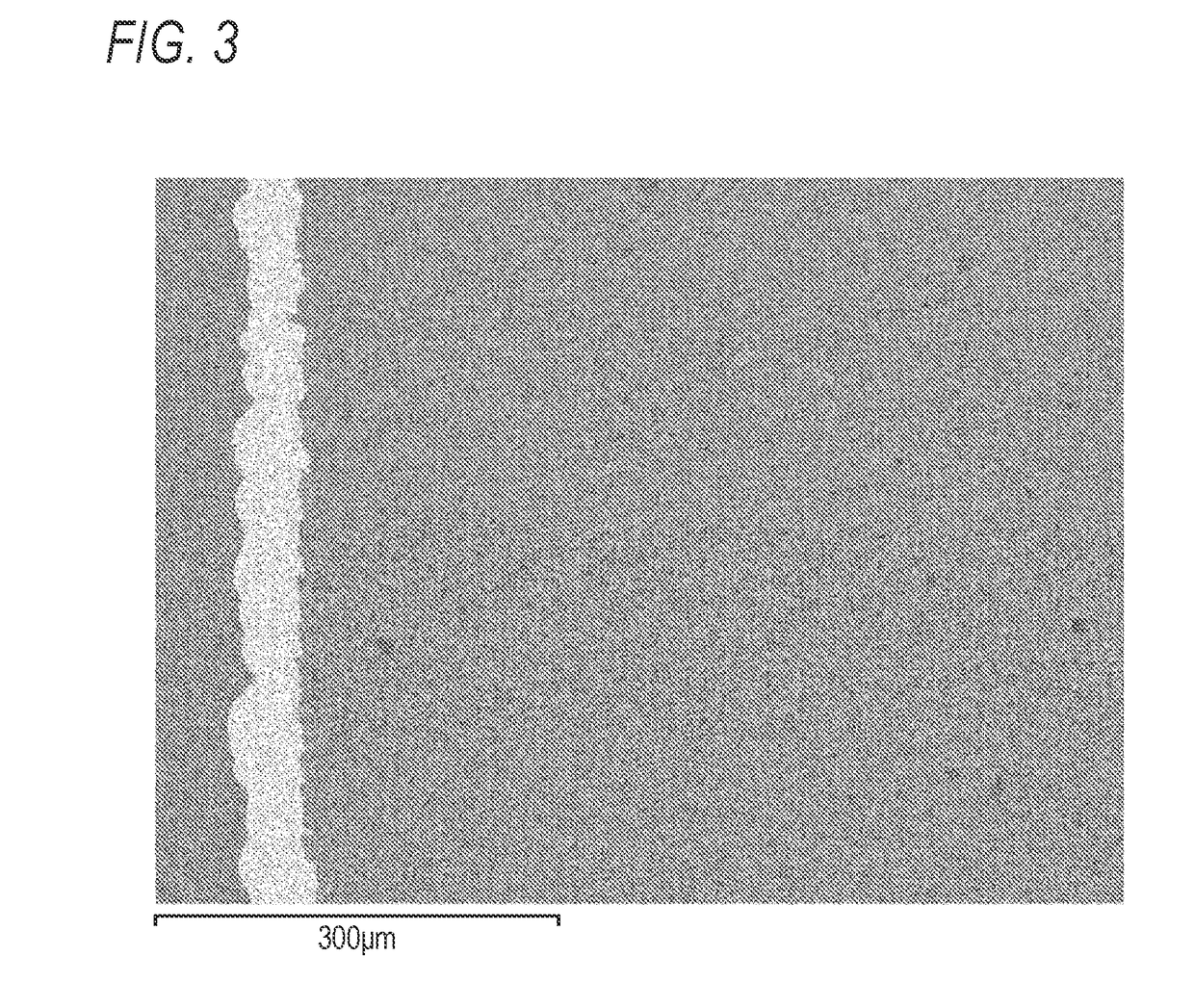

SiC-COATED CARBON COMPOSITE MATERIAL

ActiveUS20180002236A1Well formedHigh strengthGraphiteChemical vapor deposition coatingPorosityCarbon composites

Provided is a SiC-coated carbon composite material including a graphite base material and a CVD-SiC coating covering the graphite base material. A porosity of a core part of the graphite base material is 12 to 20%, and a SiC-infiltrated layer extending from the CVD-SiC coating is included in a periphery of the core part of the graphite base material. The SiC-infiltrated layer is constituted of a plurality of regions arranged such that Si content becomes smaller stepwise in an order from a first surface on the CVD-SiC coating side toward a second surface on the graphite base material side.

Owner:IBIDEN CO LTD

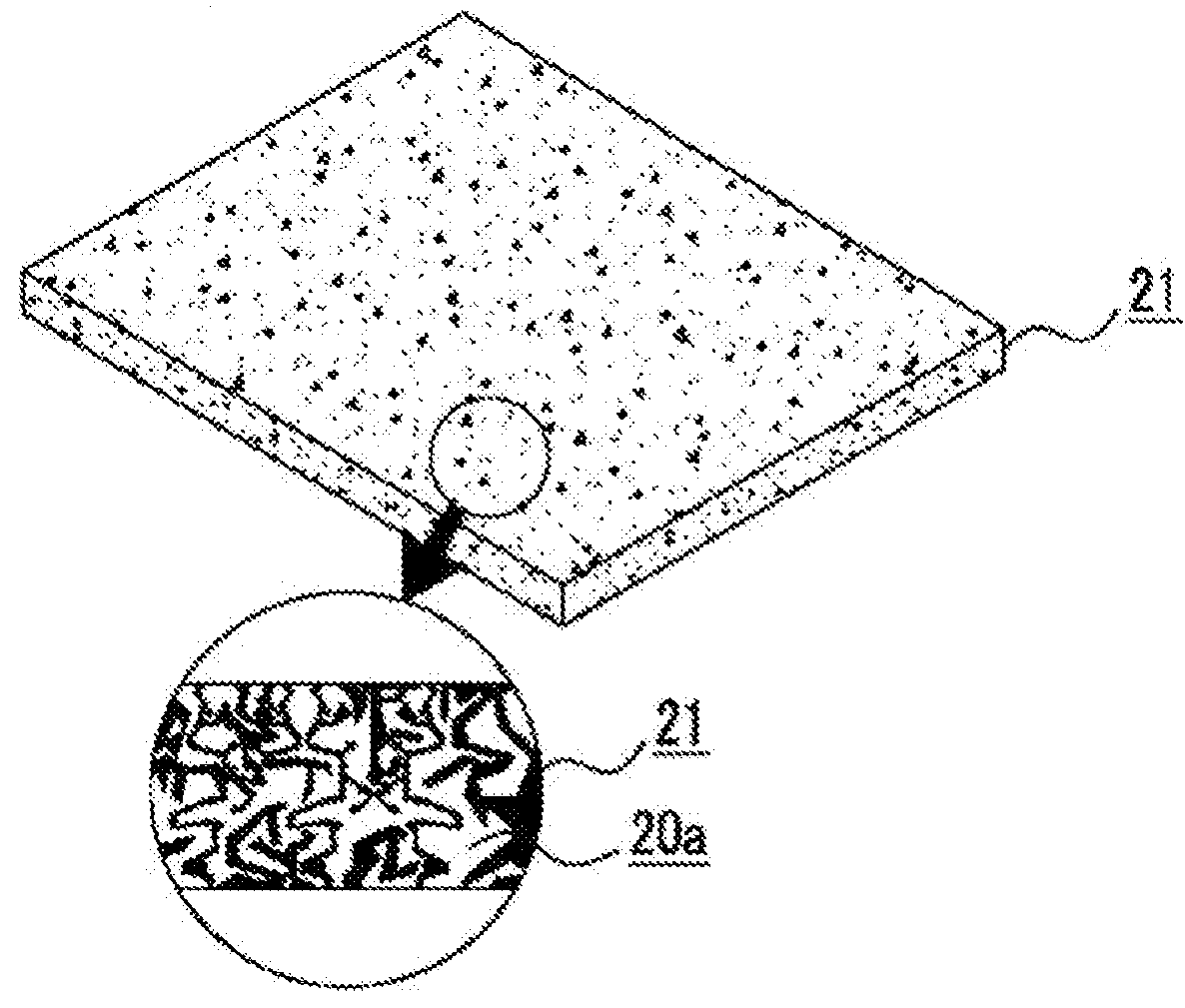

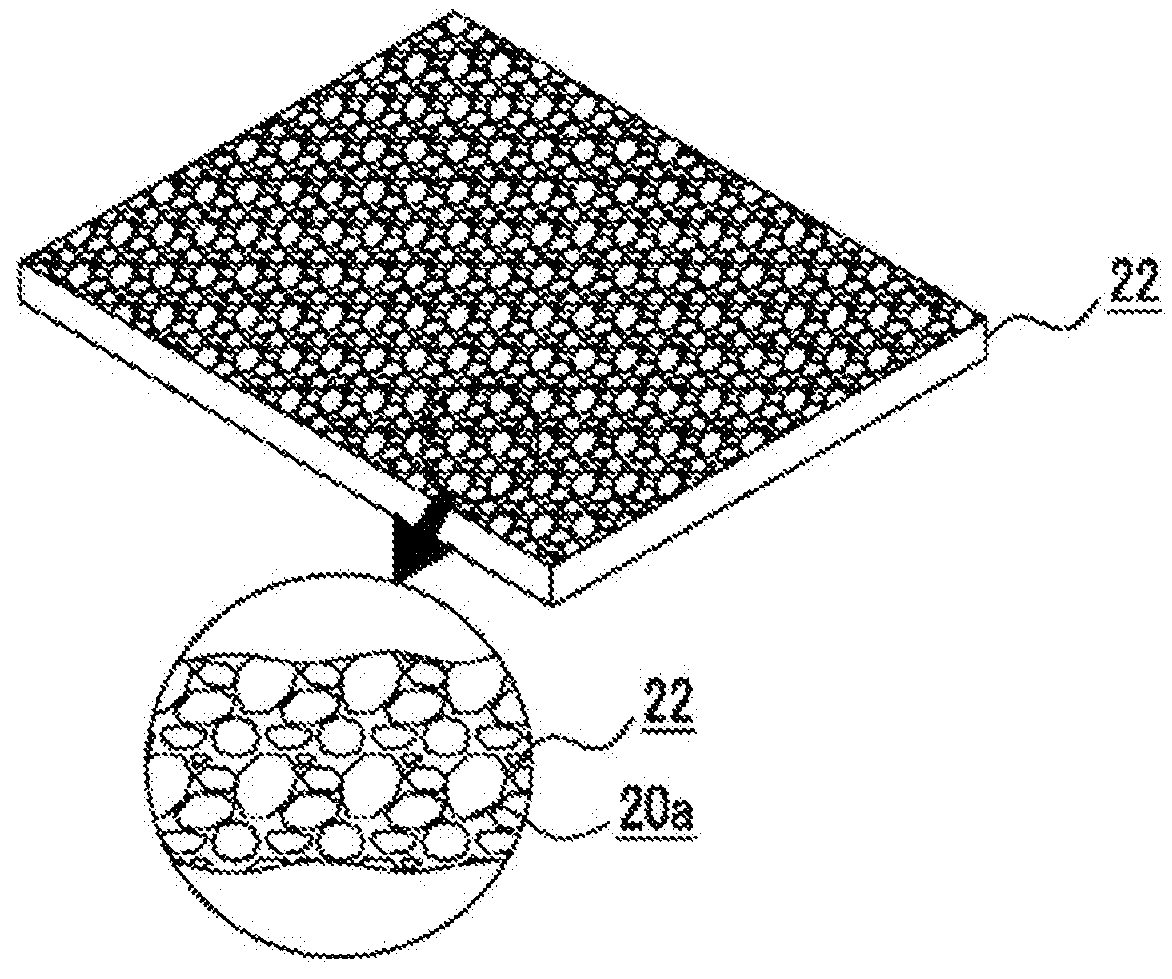

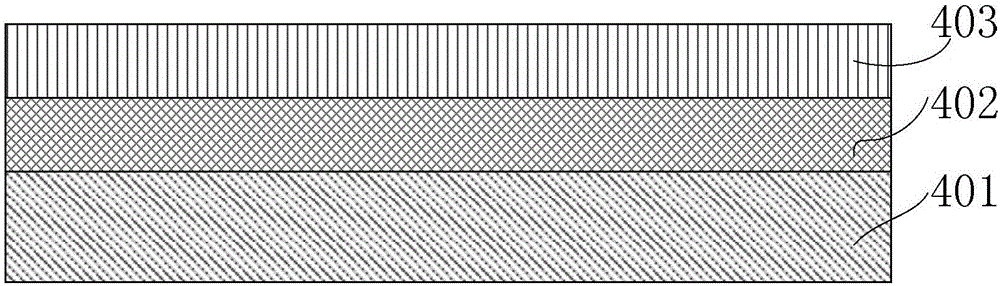

Lithium ion battery graphite negative electrode material and preparation method thereof

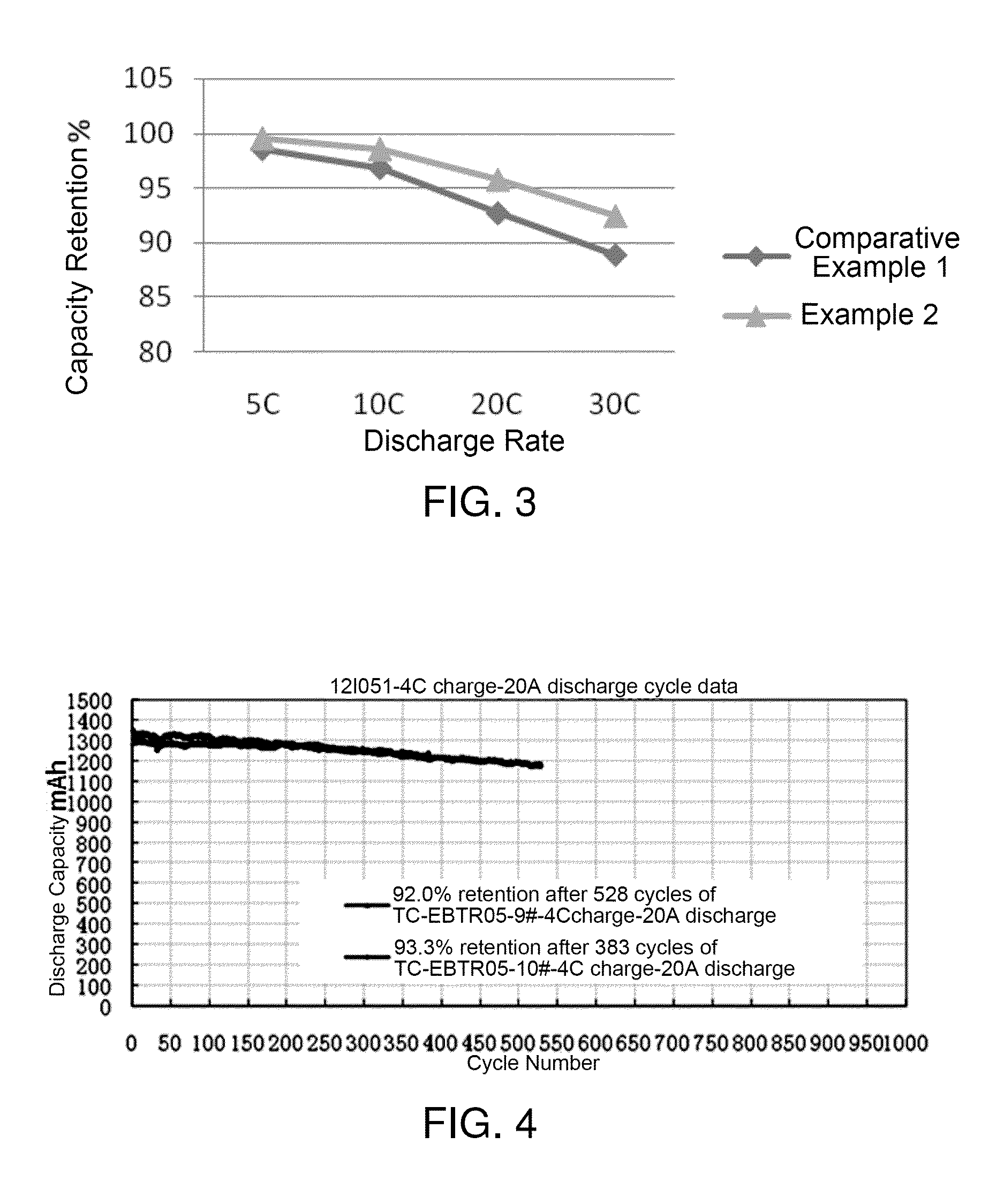

ActiveUS20140302394A1Improve rate performanceImprove cycle stabilityCarbon nanotubesCarbon preparation/purificationDischarge efficiencyCarbon nanofiber

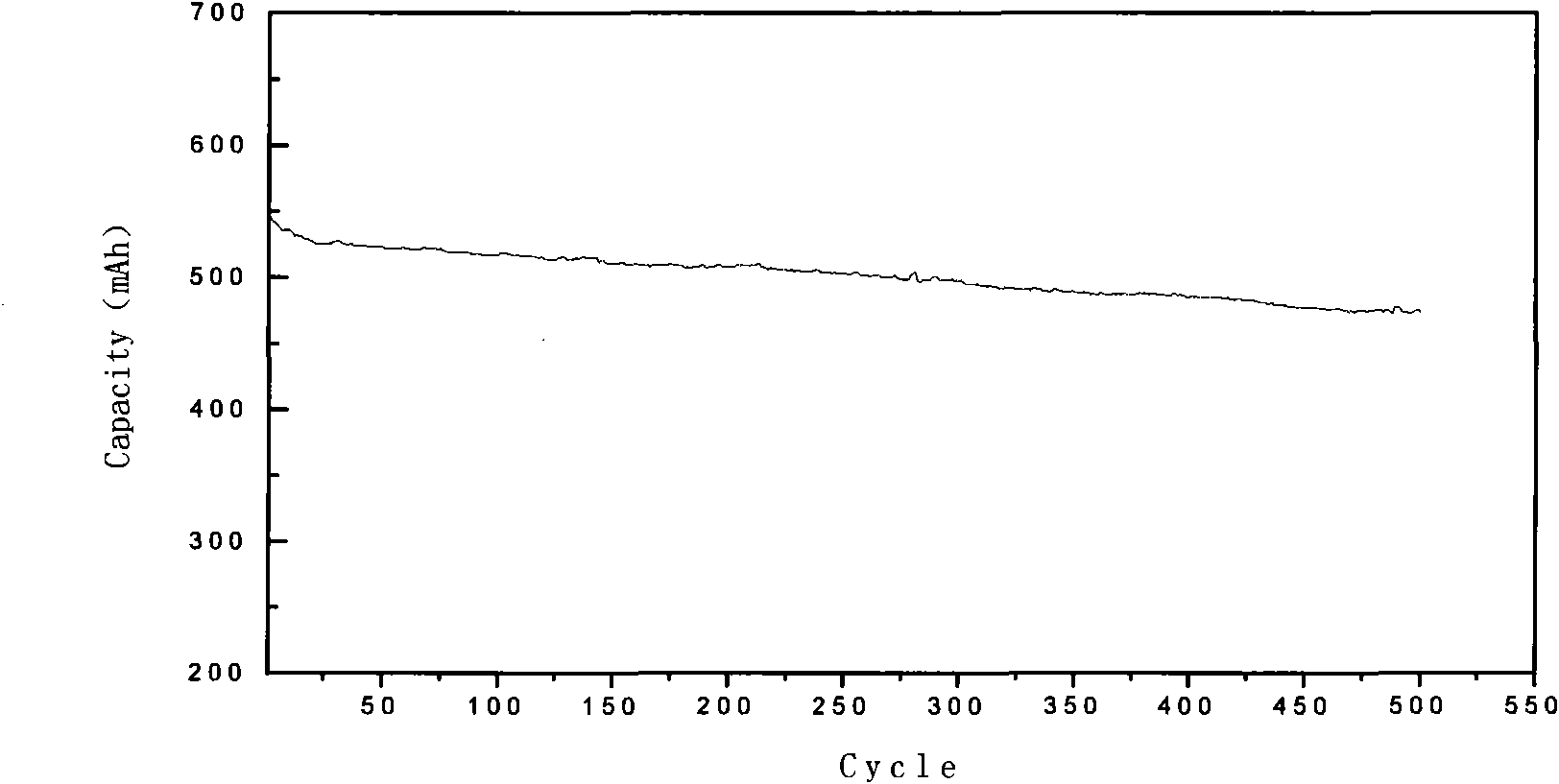

A lithium ion battery graphite negative electrode material and preparation method thereof. The lithium ion battery graphite negative electrode material is a composite material including graphite substrates, surface coating layers coated on the graphite substrates and carbon nanotubes and / or carbon nanofibers grown in situ on the surface of the surface coating layers. The preparation method thereof includes, in solid phase or liquid phase circumstance, the coated carbon material precursor forms the surface coating layer of amorphous carbon by carbonization, and then carbon nanotubes and / or carbon nanofibers having high conductive performance are formed on the surface of the surface coating layers by vapor deposition. This coating mode of the combination of solid phase with gas phase or of liquid phase and gas phase makes the amorphous carbon formed on the surface of the graphite substrates more uniform and dense. The lithium ion battery graphite negative electrode material has properties of high charging-discharging efficiency at first time and excellent cycle stability at either high or low temperatures. The charging-discharging efficiency at first time is up to more than 95%, and the capacity retention after 528 cycles is more than 92%.

Owner:BTR NEW MATERIAL GRP CO LTD

Fused sheet for electromagnetic wave absorption-extinction and shielding, and for electronic equipment high heat dissipation, and method of manufacturing the same

ActiveUS20180162098A1Improve cooling effectImprove efficiencyMagnetic/electric field screeningSemiconductor/solid-state device detailsShell moldingExtinction

The present invention discloses a fused sheet for electromagnetic wave absorption / extinction and shielding, and for electronic equipment high heat dissipation. The fused sheet for electromagnetic wave absorption / extinction and shielding, and for electronic equipment high heat dissipation of the present invention includes a premolded graphite sheet prepared by molding a graphite substrate into a sheet form having a density in a range of 0.1-1.5 g / cm3 and an incomplete state of crystal structure; and a porous metal sheet having a plurality of pores connected to upper and lower surfaces of the porous metal sheet, wherein the premolded graphite sheet is stacked on one surface of the porous metal sheet, and press molded to be integrally attached and combined, so as to have a density of 1.6 g / cm3-6.0 g / cm3

Owner:JOO HAK SIK

Carbon nano tube composite graphite film for heat dissipation

InactiveCN104810336AImprove cooling effectImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesCarbon nanotubeGraphite substrate

The invention discloses a carbon nano tube composite graphite film for heat dissipation. The carbon nano tube composite graphite film comprises a graphite heat-conduction layer and a carbon nano tube heat-dissipation layer which are compounded with each other, wherein the graphite heat-conduction layer is provided with a first surface and a second surface which are opposite to each other; the first surface and / or the second surface is at least coated with a layer of carbon nano tube heat-dissipation layer. Compared with the prior art, the carbon nano tube composite graphite film has the advantages that the heat dissipation capability of the graphite heat-conduction layer in a vertical direction is enhanced because the surface of the graphite heat-conduction layer is directly coated with the carbon nano tube heat-dissipation layer; meanwhile, the graphite heat-conduction layer has better excellent mechanical performance and flexibility due to the coating of an organic coating, and the using performance of the graphite heat-conduction layer is remarkably improved; a simple and convenient using and coating manner can be applicable to efficient coating of graphite substrates of different morphologies, and thus the carbon nano tube composite graphite film has important commercial value in large-scale application.

Owner:SUZHOU CREATIVE CARBON NANOTECH

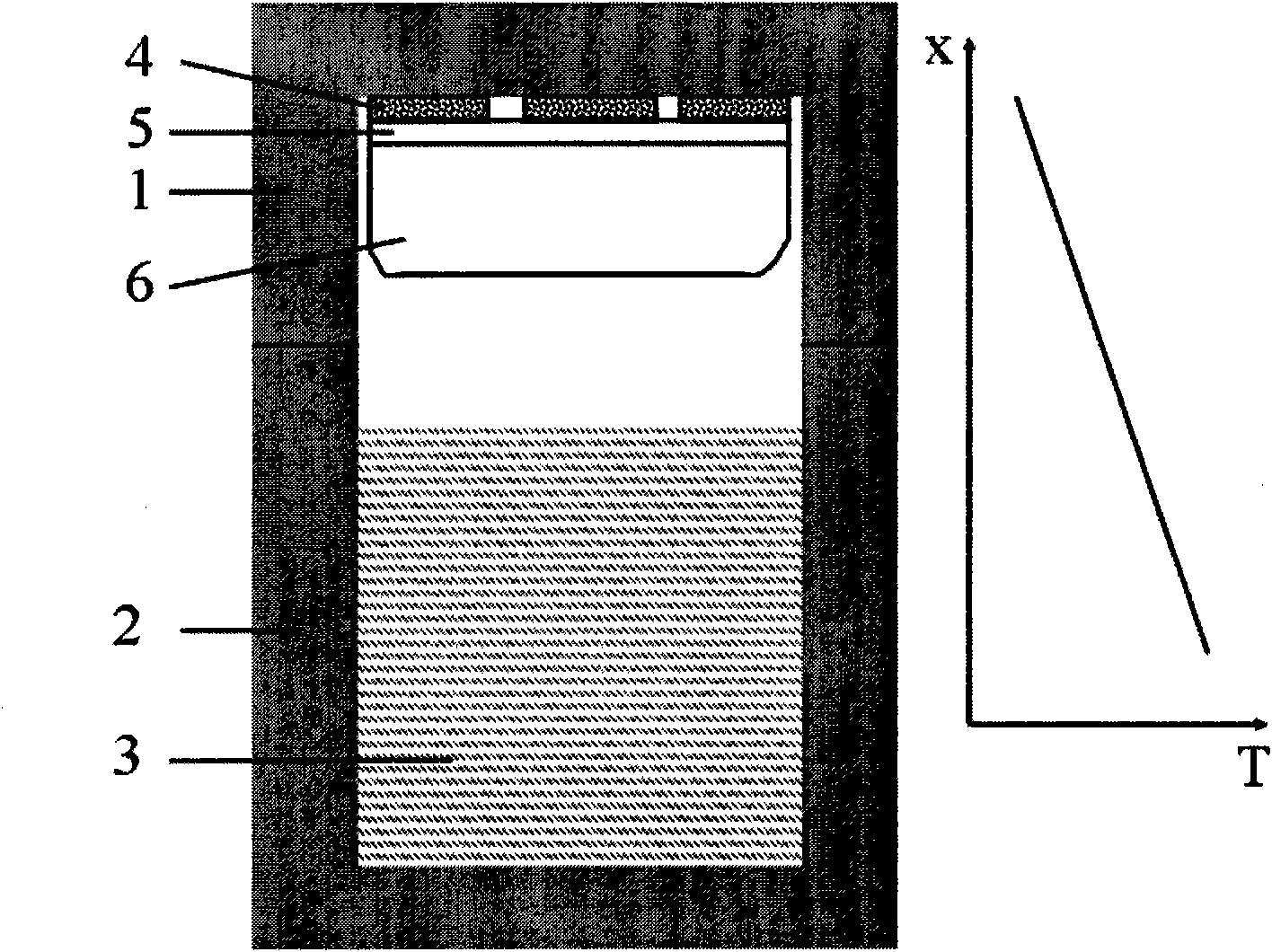

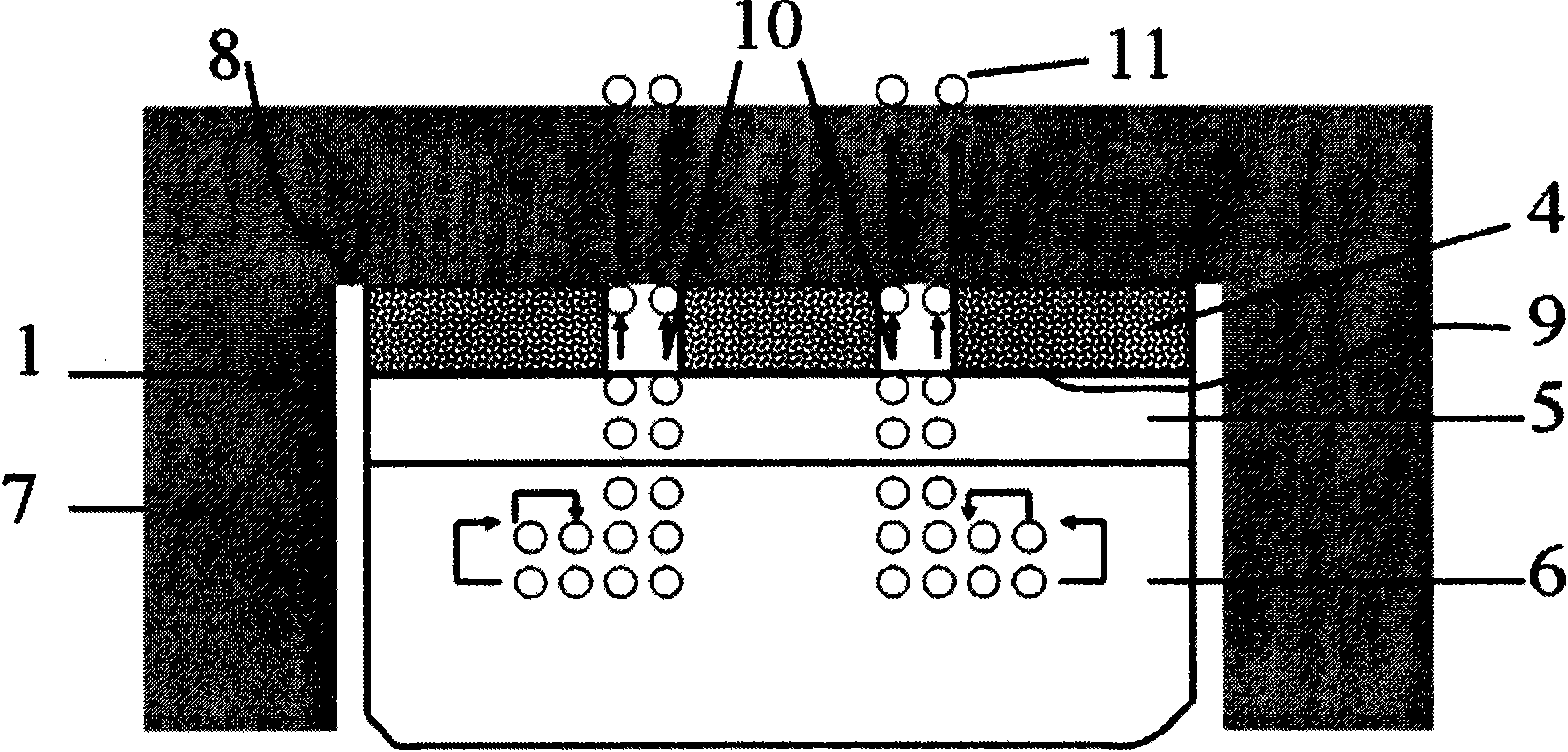

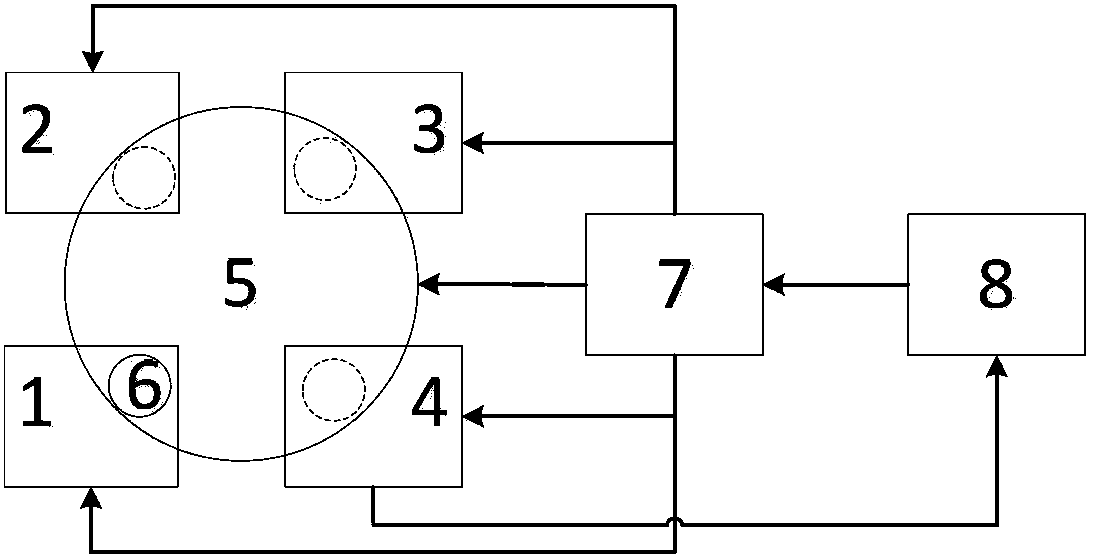

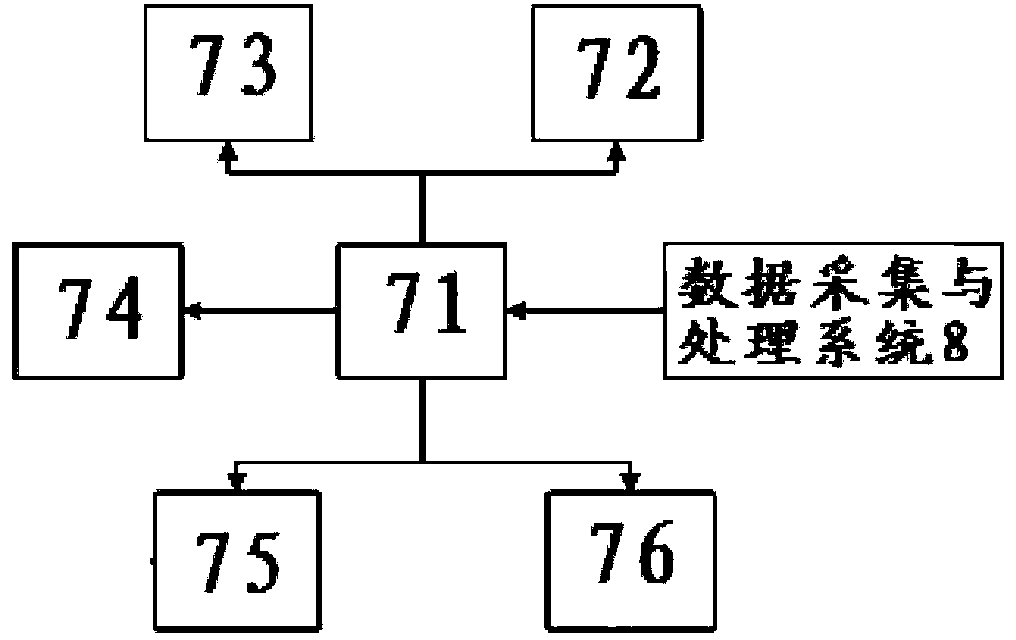

Laser-induced breakdown spectrometry continuous detection device and method for heavy metal of water body

ActiveCN103411930ARealize continuous online automatic detectionSimple and fast operationAnalysis by material excitationAutomatic controlEngineering

The invention discloses a laser-induced breakdown spectrometry continuous detection device and method for heavy metal of a water body, and is based on the laser-induced breakdown spectrometry technology, graphite substrates are taken as water sample carriers, and continuous, on-line and automatic detection of content of heavy metal of the water body can be realized effectively in a laboratory through automatic loading and unloading of graphite substrates on an automatic control rotating platform, automatic sample introduction and accurate titration of a water sample, drying of the sample, and spectral measurement and analysis. The method is simple and convenient to operate, all that is needed is to add graphite substrates periodically, the detection speed is high, the sensitivity is high, the whole working process is carried out in a full-automatic manner, no chemical reagent is used, no secondary pollution is caused, the operation and maintenance costs are low, and the purpose of continuous, on-line and automatic detection of multiple elements of heavy metal of the water body can be achieved at the same time. The device and the method fill the blank in the technical field of continuous, on-line and automatic detection of heavy metal of a water body in the country, can satisfy the use requirements for continuous and on-line measurement of water body environment in the country, and have a very broad application prospect.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Graphite electrode with diameter of 348 mm and manufacture method thereof

ActiveCN104129782ASolve the problems of easy cracking and low yieldOvercome the shortcomings of low bulk density and low flexural strengthGraphite electrodeGraphite substrate

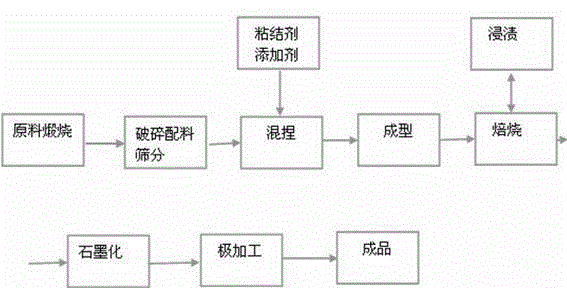

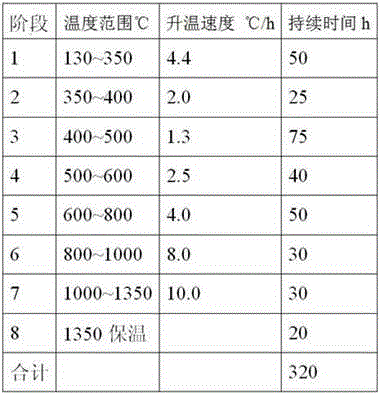

The invention discloses a graphite electrode with diameter of 348mm. The electrode mainly uses high quality hybrid petroleum coke as a raw material to prepare dry materials in different sizes; the dry materials are subjected to calcining, burdening, preparation of electrode green products, baking, graphitization and electrode preparation to obtain the finished products. The invention adopts the hybrid petroleum coke with middle and small particle sizes, wherein petroleum coke with small particle size less than 0.5 mm accounts for18-25%, so as to overcome the insufficiencies of low volume density and small flexural strength of the existing electrode, and prepare the electrode suitable for the need of graphite crucible and impermeable graphite material. A baking curve maintains at 400 to 800 DEG C for 165 h, and the key volatile period slows down to prevent product crack because that volatiles can be discharged in time under excessive heating; the method successfully solves the problems of easy cracking in roasting and graphitization heat treatment processes and low rate of finished product of multielectrode made of small granularity powder; and the first baking qualified rate of products and qualified rate of graphitization reach 98.5% and 99.2% respectively.

Owner:焦作市中州炭素有限责任公司

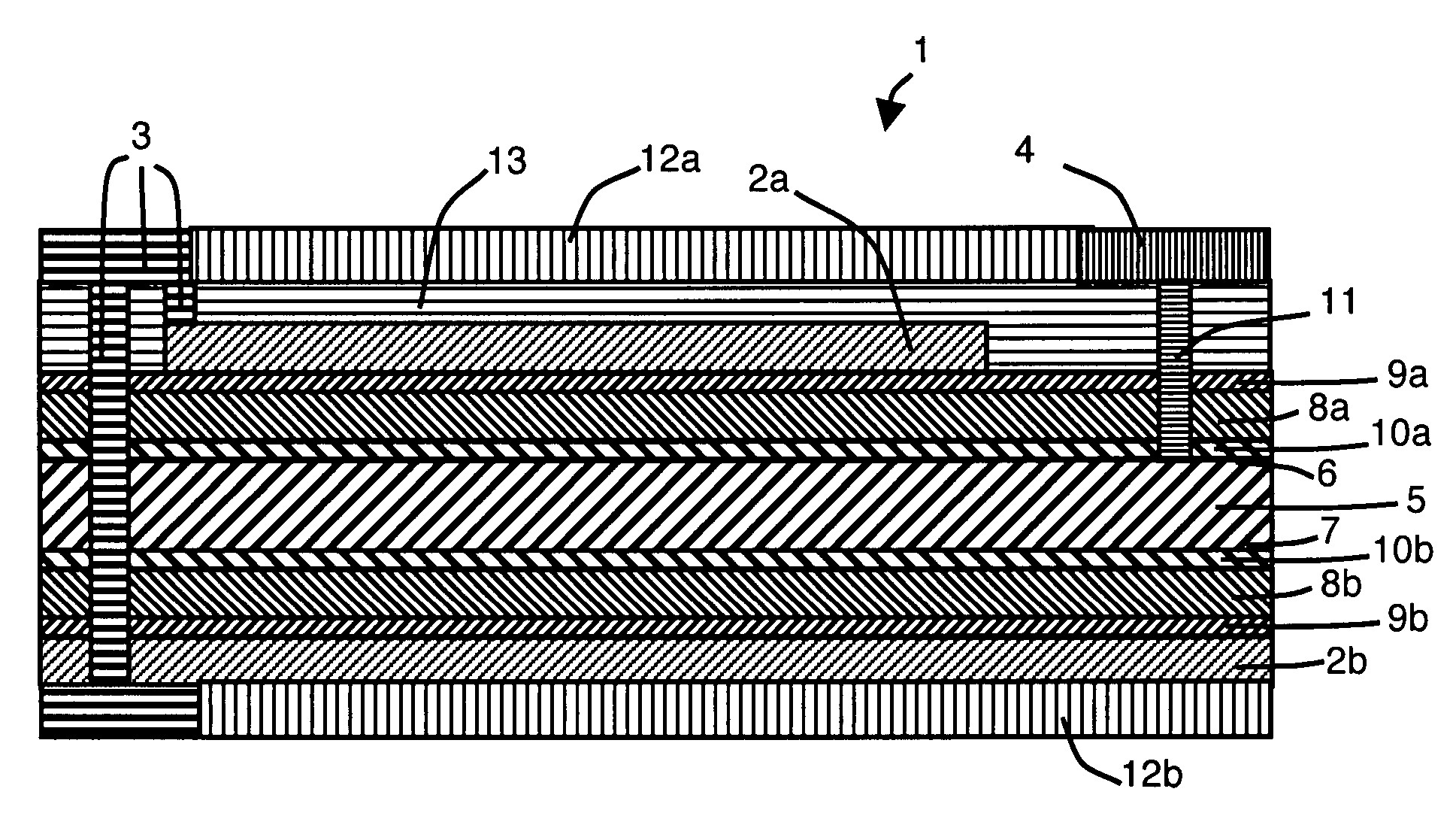

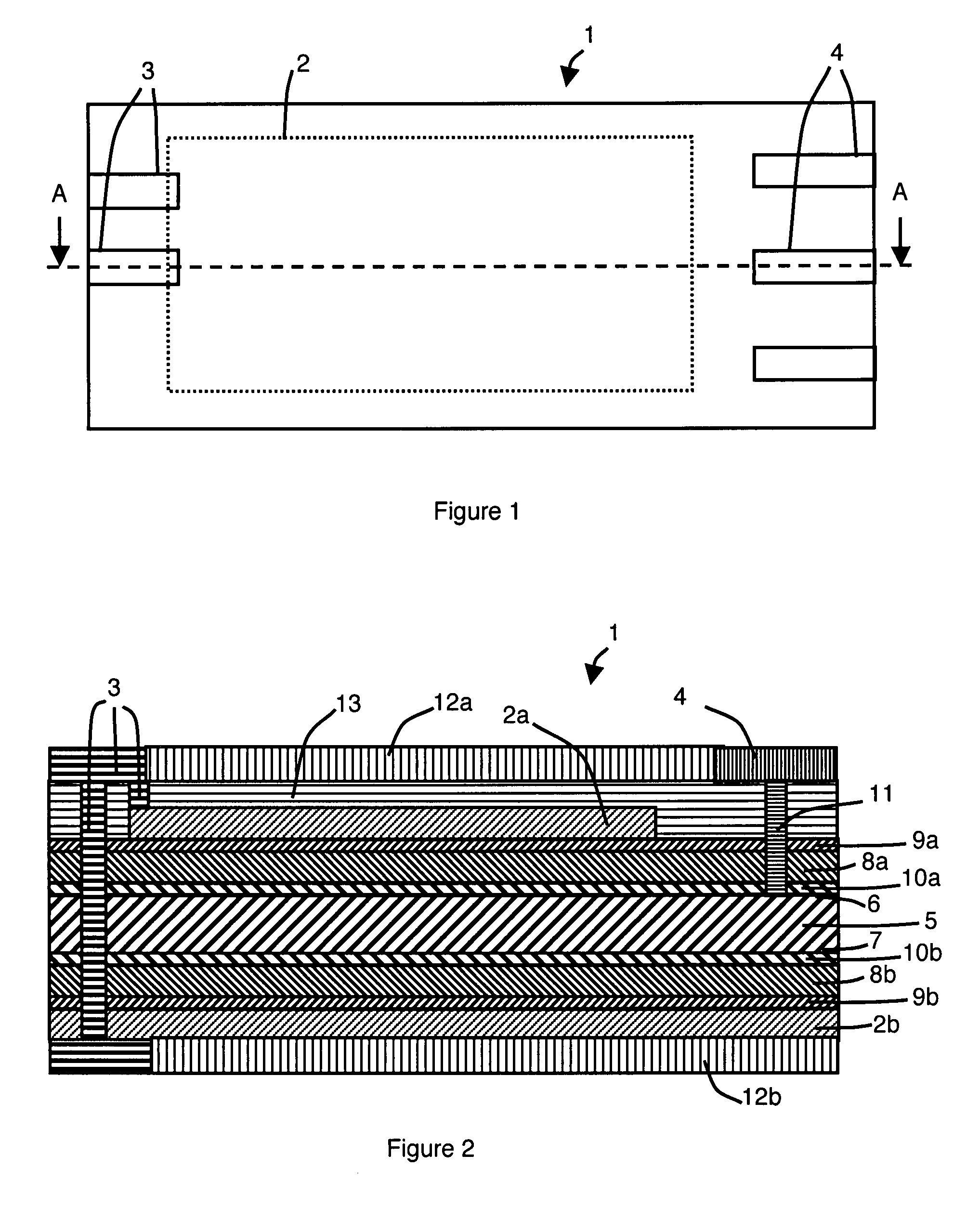

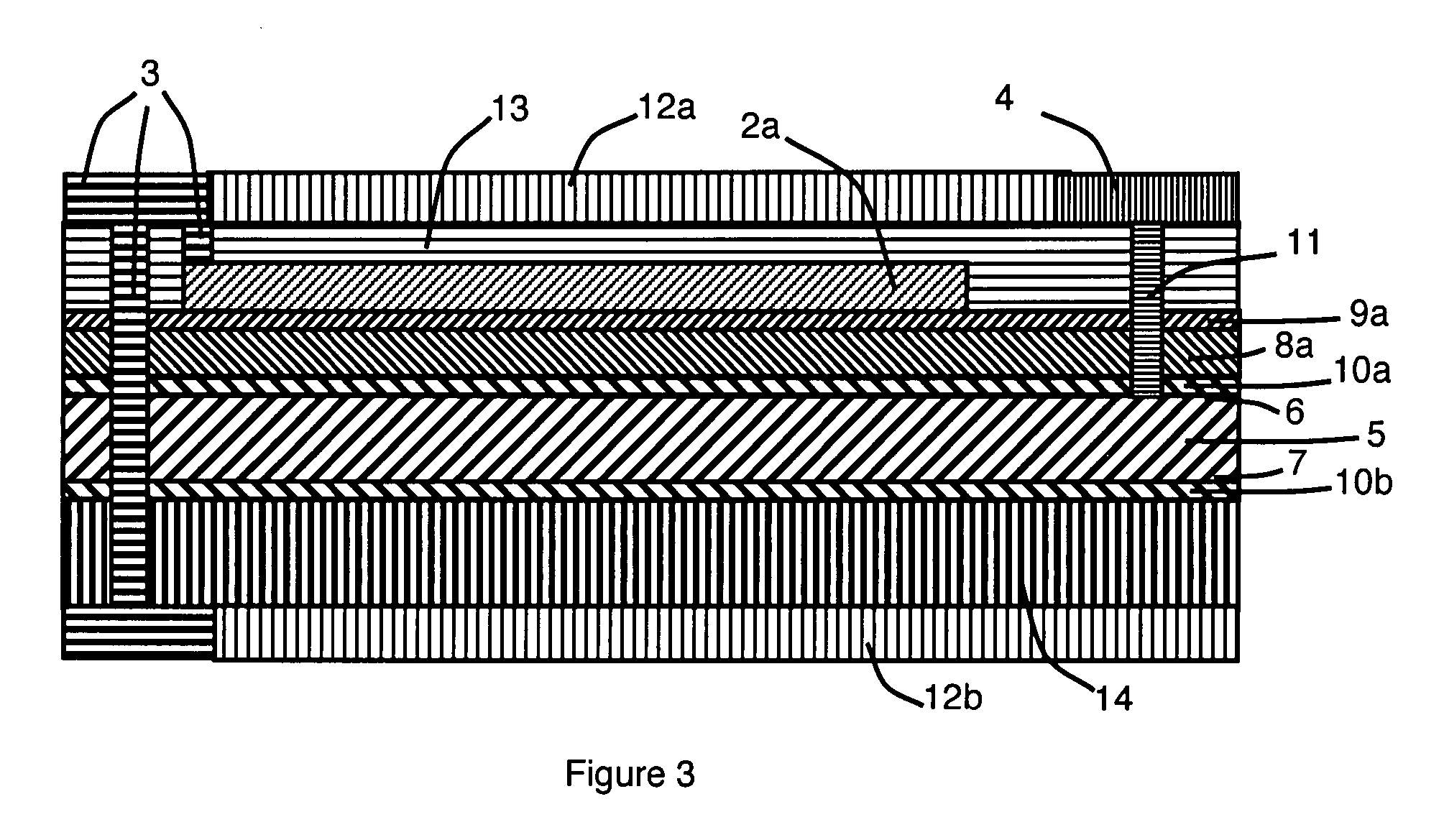

Solar cell and method for fabricating the same

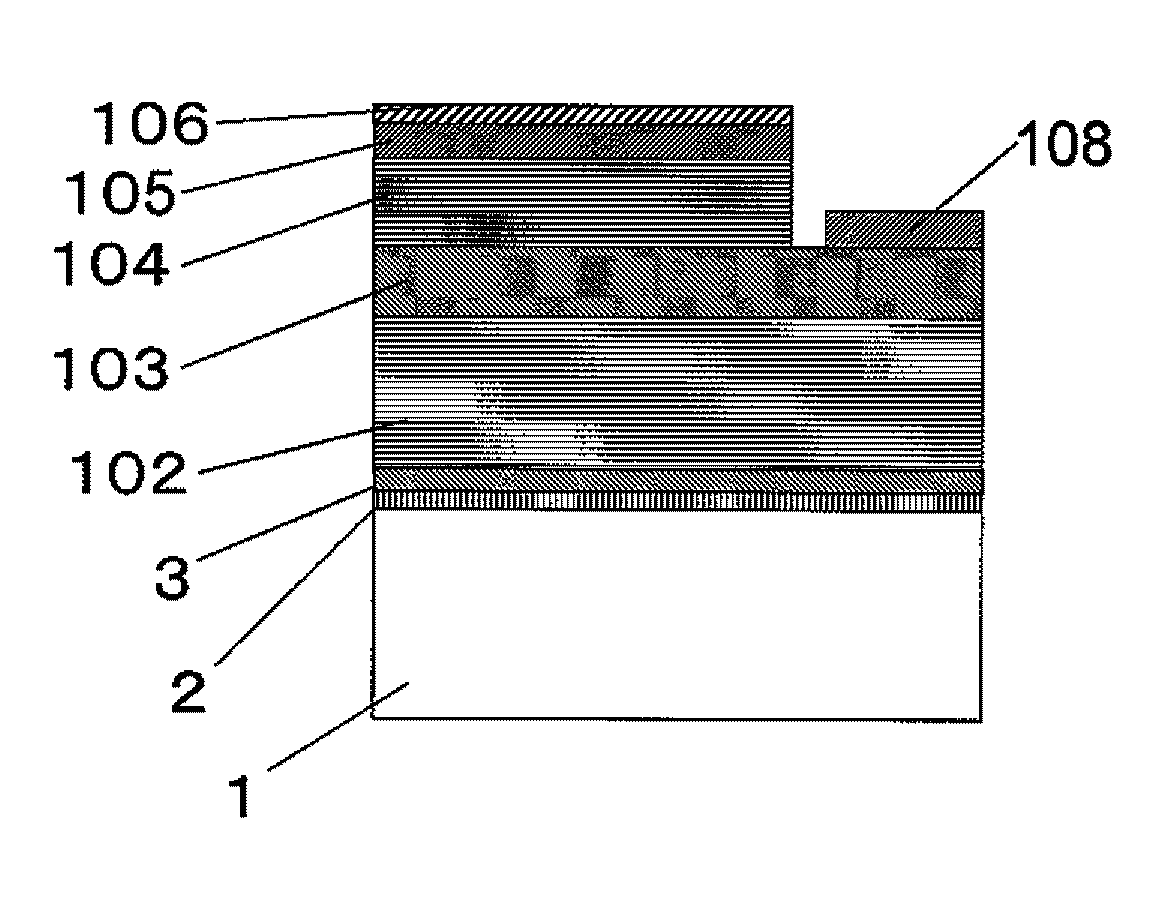

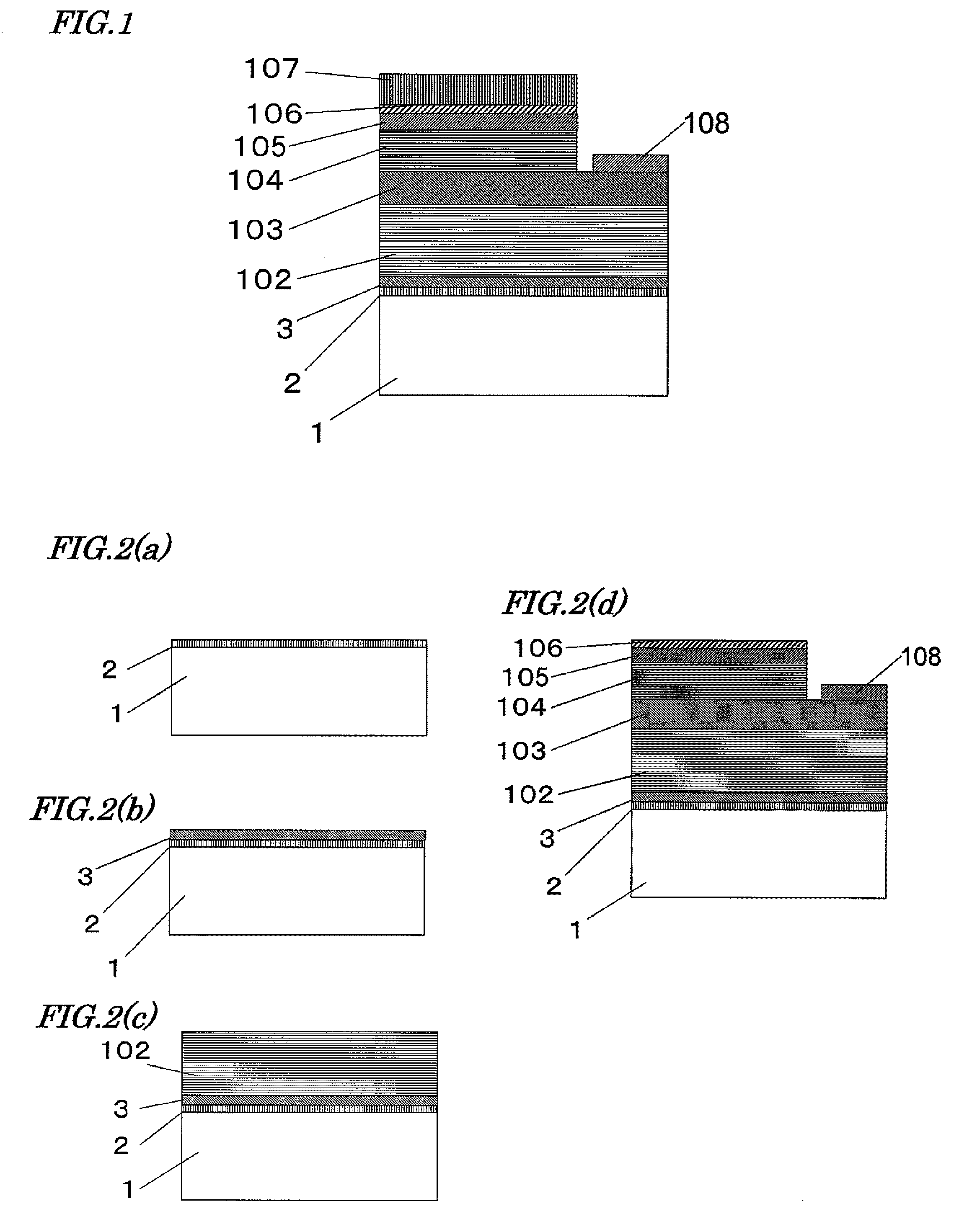

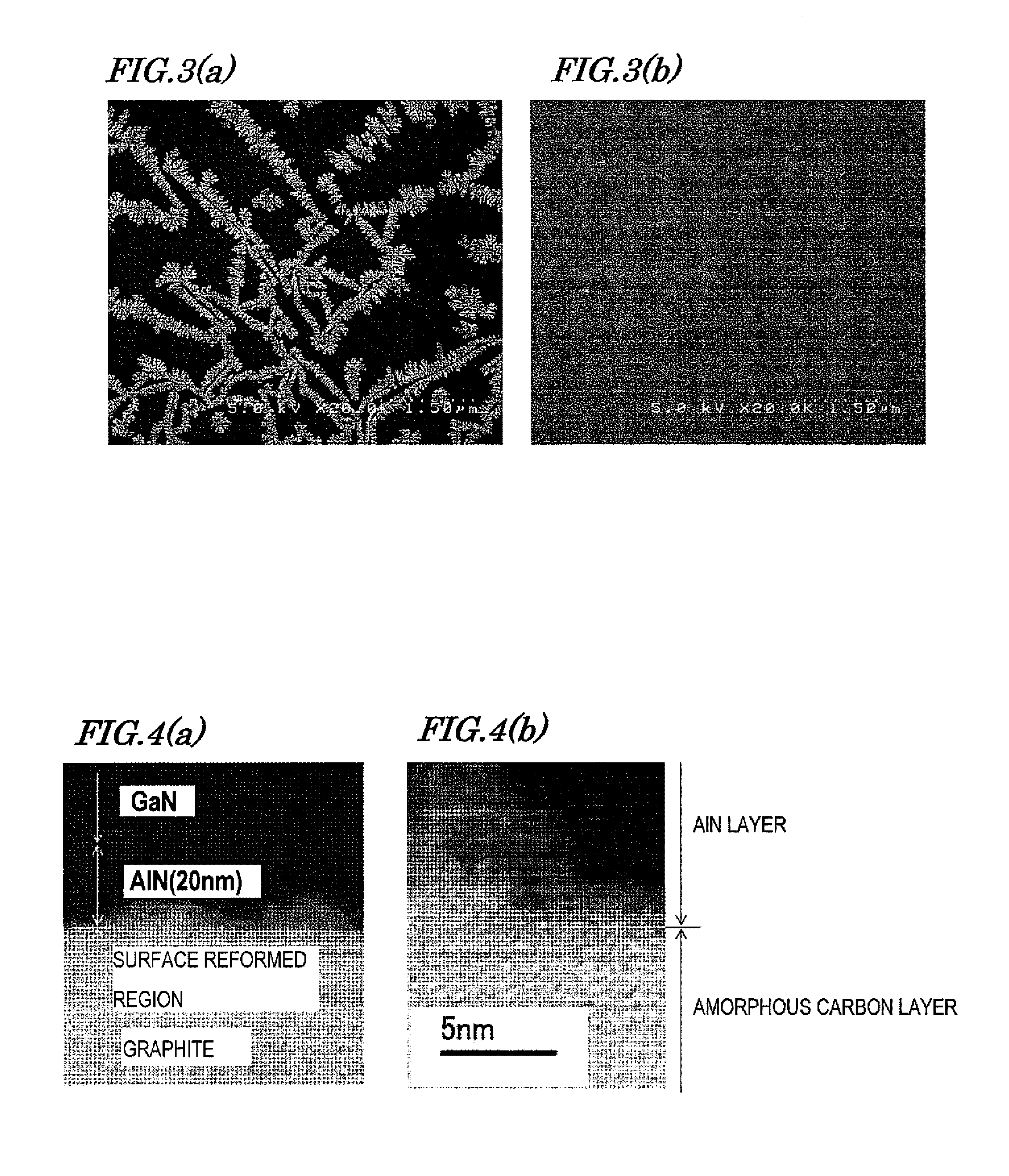

InactiveUS20110203651A1Maintain good propertiesLow costPolycrystalline material growthFinal product manufactureGraphite substrateSolar cell

A solar cell includes a graphite substrate, an amorphous carbon layer having a thickness of not less than 20 nm and not more than 60 nm formed on the graphite substrate, an AlN layer formed on the amorphous carbon layer, a n-type nitride semiconductor layer formed on the AlN layer; a light-absorption layer including a nitride semiconductor layer formed on the n-type nitride semiconductor layer; a p-type nitride semiconductor layer formed on the light-absorption layer; a p-side electrode electrically connected to the p-type nitride semiconductor layer; and an n-side electrode electrically connected to the n-type nitride semiconductor layer. The amorphous carbon layer is obtained by oxidizing the surface of the graphite substrate.

Owner:PANASONIC CORP

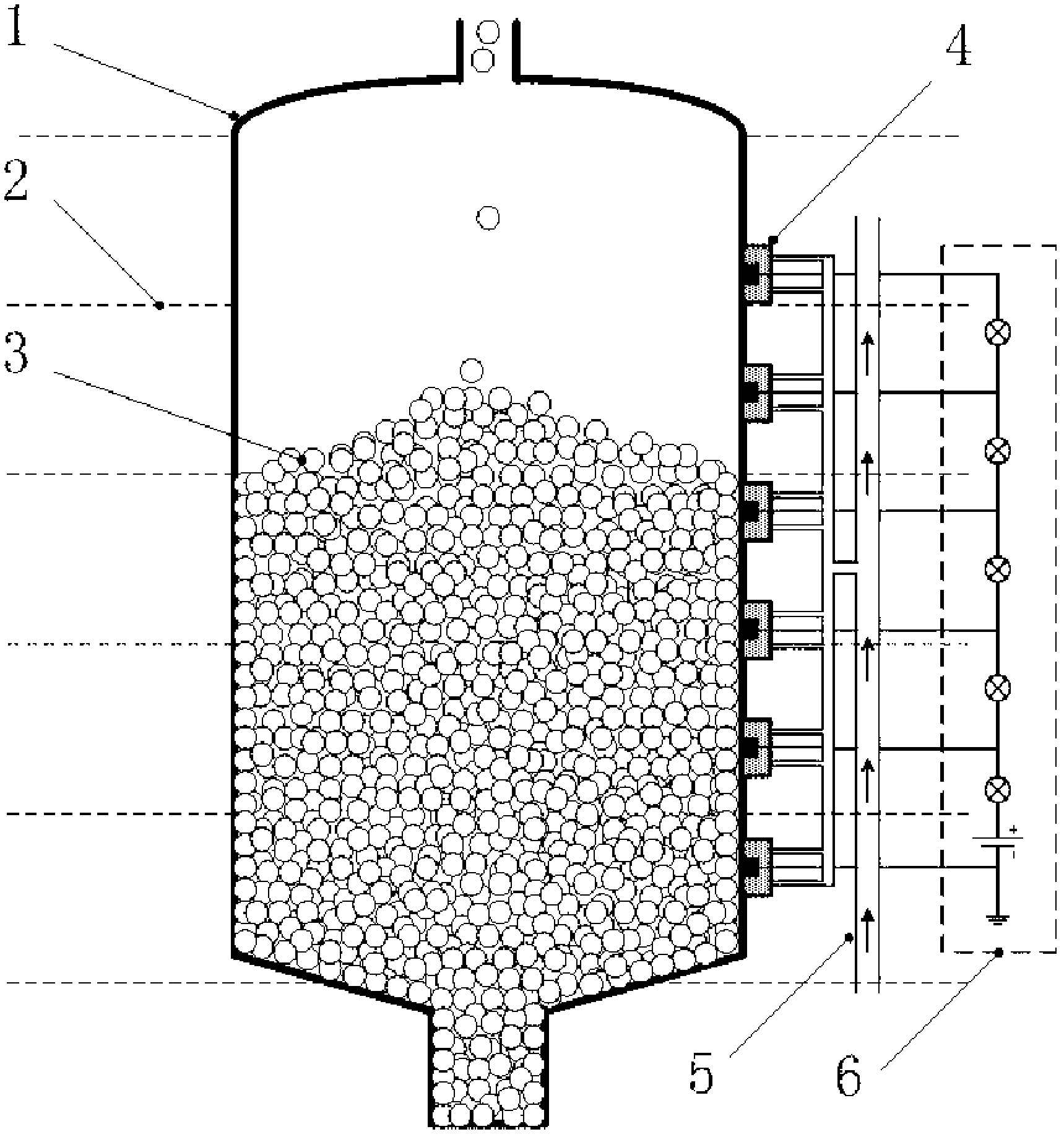

Reactor core fuel sphere position measurement device of pebble-bed-type high-temperature gas cooled reactor

ActiveCN103137226ASimple structureAvoid accumulationNuclear energy generationNuclear monitoringMeasurement deviceImage resolution

The invention discloses a reactor core fuel sphere position measurement device of a pebble-bed-type high-temperature gas cooled reactor. A reactor core is a cylindrical cavity with a cone-shaped bottom, the cylindrical cavity is formed by graphite blocks in a stacking mode, the graphite blocks form side reflection layers, and fuel is a spherical body with a graphite substrate. The measurement device comprises a plurality of sphere position probes arranged on the side reflection layers at intervals, each sphere position probe is connected with an electrode lead, and the electrode leads are connected with a secondary indication instrument to display fuel sphere position information detected by the sphere position probes. The measurement device is simple in structure, stable, reliable, and capable of providing precise sphere position information in the gas cooled reactor; currently a high-temperature gas cooled experiment reactor cannot achieve the functions; electrode contact-type measurement adapts to various measurement ranges and meets requirements of the resolution ratio, the sphere position information can be directly displayed through the indication instrument, measurement circuits are obviously simplified, and stability is improved; and annular air nozzles and gas guide channels in the sphere position probes can achieve helium washing, avoid accumulation of graphite dust, and guarantee long-term operation of a measurement system.

Owner:TSINGHUA UNIV

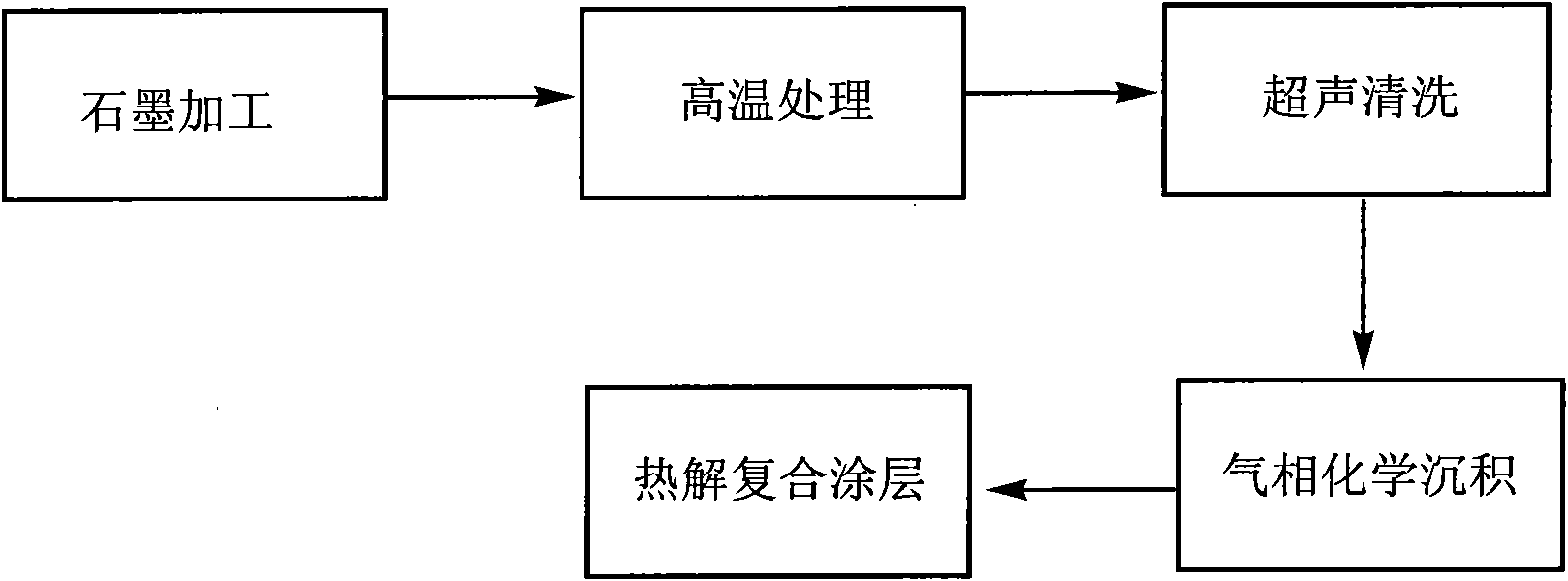

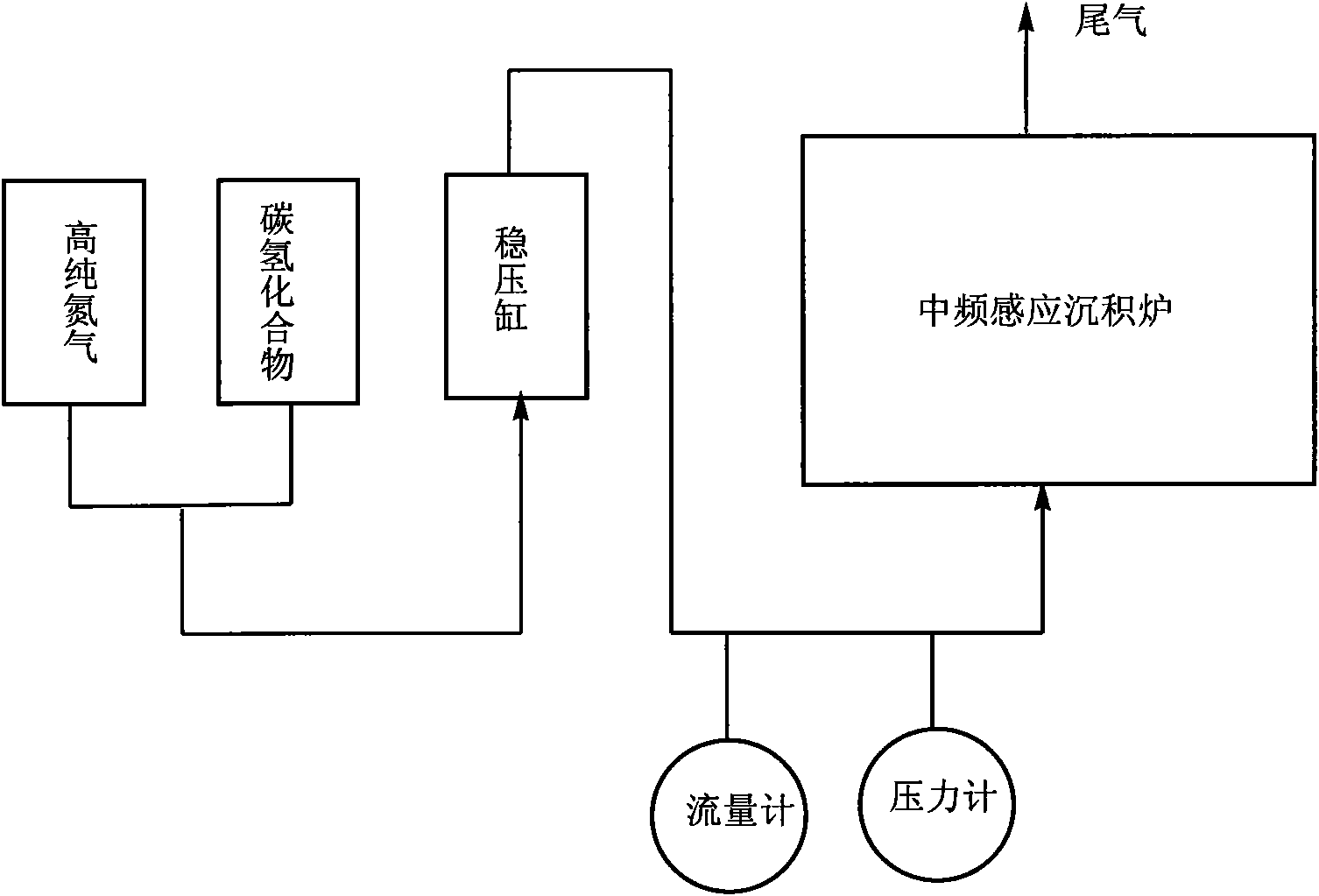

Pyrolytic graphite composite coating and applications thereof

InactiveCN101660137AChemical/physical/physico-chemical processesChemical vapor deposition coatingGraphite substratePhosphate

The invention relates to a pyrolytic graphite composite coating and applications thereof. The preparation method of the pyrolytic graphite composite coating comprises the following steps: the surfaceof the graphite is processed in a pyrolytic graphite coating mode to obtain the pyrolytic graphite composite coating; in the preparation process, pyrolysis, dehydrogenation and polymerization are carried out on the surface of the high-temperature graphite substrate by utilizing a chemical vapor deposition technique and using high-purity hydrocarbon gas or vapor, and the produced huge aromatic hydrocarbon molecules impact the surface of the high-temperature substrate so as to deposit carbon; and the pyrolytic graphite coating treatment is carried out in a medium-frequency induction deposition furnace. The invention has the advantages that erosion does not occur in the existence of phosphoric acid or ammonium phosphate salts at the high temperature of 300-320 DEG C, and no graphite powder slides into the reactor; and the pyrolytic graphite composite coating can be used for preparing crystal form II ammonium polyphosphate by using phosphoric acid or ammonium phosphate salts as the initialmaterial through the high-temperature polyreaction, and can also be used for other synthesizing high-temperature phosphoric acid and(or) high-temperature ammonium phosphate salts by using the reaction medium.

Owner:EAST CHINA UNIV OF SCI & TECH

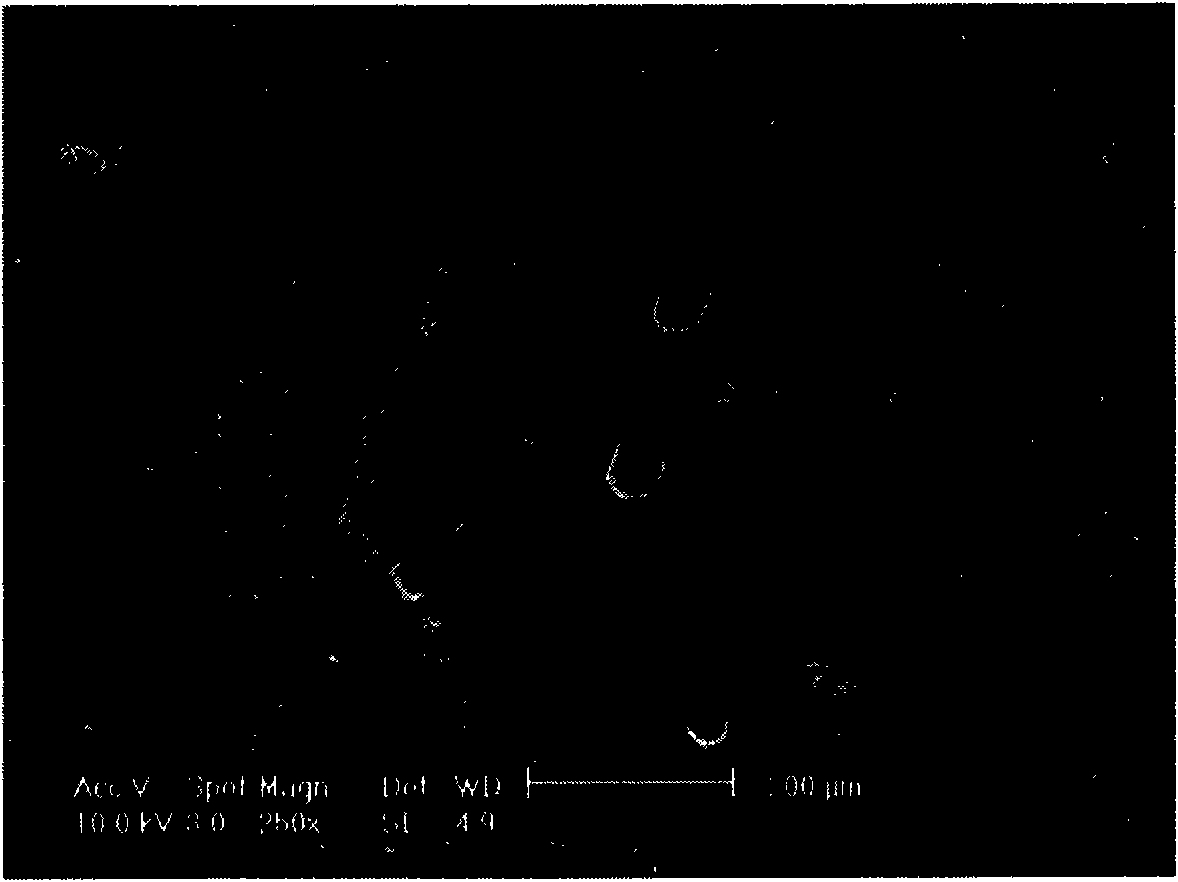

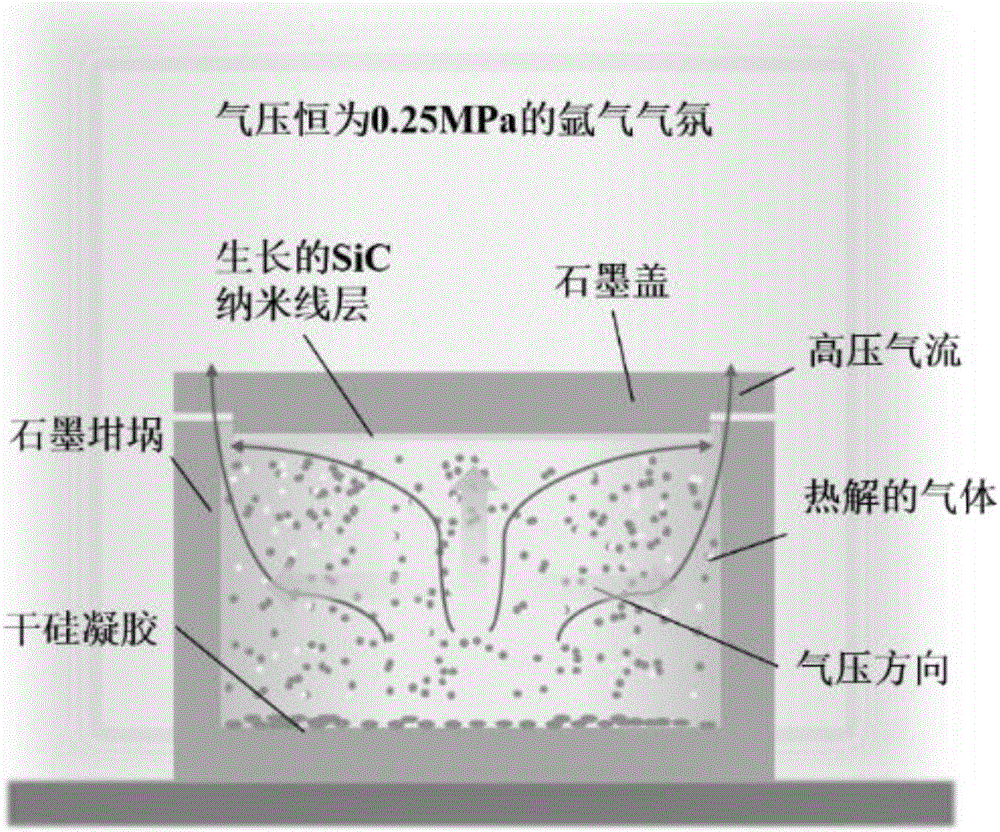

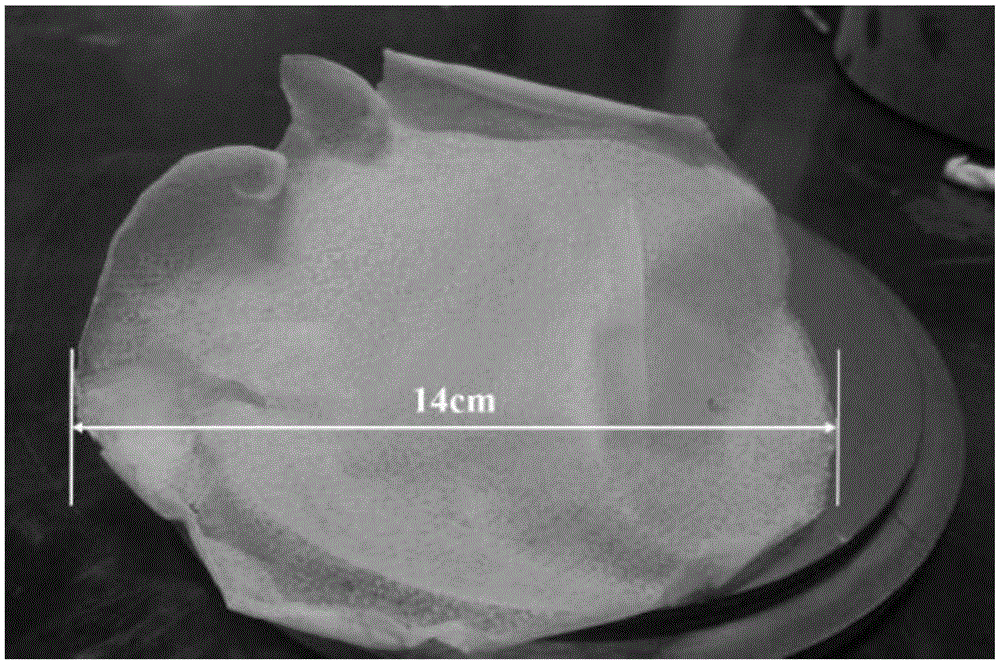

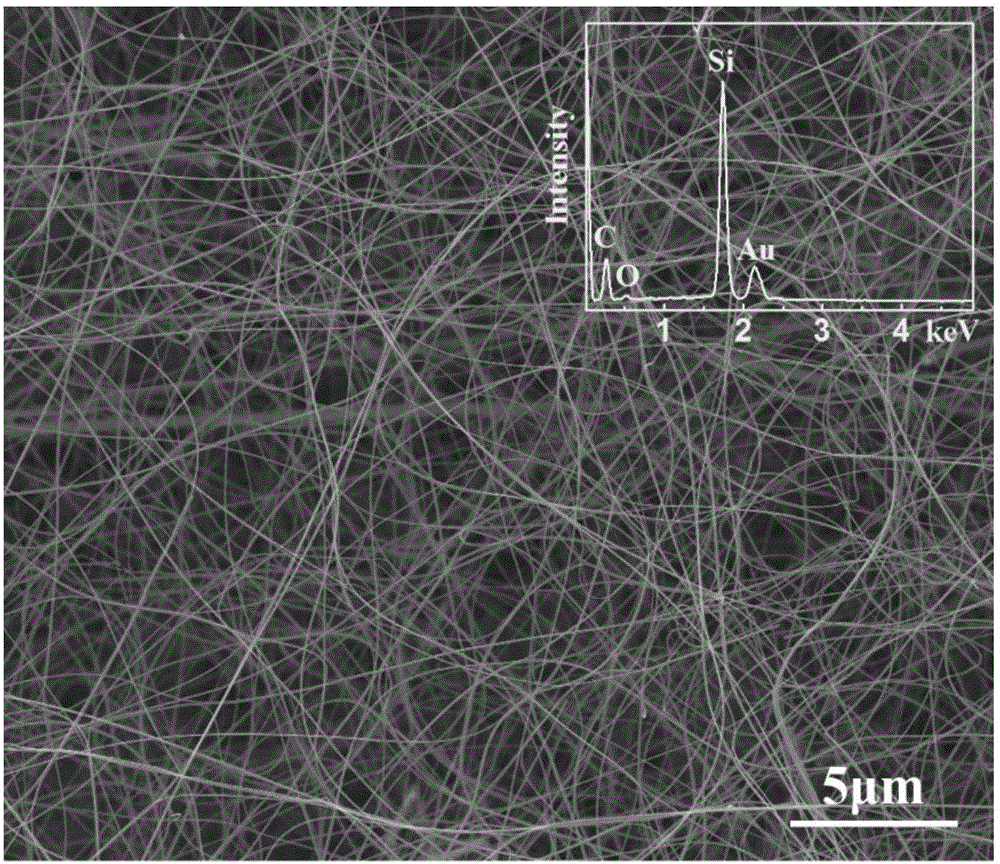

Self-supporting silicon carbide nanowire paper and preparing method thereof

The invention discloses self-supporting silicon carbide nanowire paper and a preparing method thereof, and belongs to the field of nanomateiral preparing and self-assembly technology thereof. The preparing method includes the following steps that methyl trimethoxy silane and dimethyl dimethoxysilane are used as raw materials, nitric acid is used as a crosslinking catalyst, a cohydrolysis method is adopted to prepare silica gel, and then the silica gel is dried to prepare xerogel; the xerogel is put into a graphite crucible with a graphite cover, the graphite crucible is put in an air pressure sintering furnace, air of the air pressure furnace is pumped until the air pressure is 0.1 Pa or below, the air pressure furnace is filled with high-purity argon, the air pressure furnace is heated to 1320-1500 DEG C at the speed of 2-10 DEG C / min, and the temperature is kept for 1 h; the product is cooled to the room temperature along with the furnace, a greyish-green nanowire layer can grow on a graphite substrate and is striped from the graphite substrate to prepare the self-supporting silicon carbide nanowire paper. Self-assembly of nanowires can be achieved in the process of nanowire growth, the thickness of the nanowire paper prepared through the method is adjustable, and the area of the nanowire paper prepared each time is large.

Owner:XI AN JIAOTONG UNIV

Graphite-silicon carbide composite and making method

InactiveUS20080241475A1Improve antioxidant capacityMinimized variation in qualityLayered productsProjectorsGraphite substrateSilicon carbide

A graphite-silicon carbide composite comprises a graphite substrate and a silicon carbide layer formed thereon and comprising silicon carbide particles in fused and contact bonded state. The composite has excellent oxidation resistance and finds a wide range of application as heat resistant material. The method of forming a silicon carbide layer on graphite surface is simple and consistent.

Owner:SHIN ETSU CHEM IND CO LTD

Sic-coated carbon composite material

InactiveCN107207373AFull strengthImprove permeabilityGraphiteChemical vapor deposition coatingCarbon compositesPorosity

Provided is an SiC-coated carbon composite material comprising a graphite substrate and a CVD-SiC coating that coats the graphite substrate. The porosity of the central core of the graphite substrate is 12-20%, and surrounding the central core of the graphite substrate is an SiC permeable layer extending from the CVD-SiC coating. The SiC permeable layer is composed of a plurality of regions disposed such that there is a stepped decrease in Si content in order from a first surface on the side of the CVD-SiC coating toward a second surface on the side of the graphite substrate.

Owner:IBIDEN CO LTD

Graphite surface titanium metallization method and product manufactured with the same

InactiveCN104694897ASolve the technical difficulties of low bonding strengthGood for diffusion reactionVacuum evaporation coatingSputtering coatingMetallic materialsGraphite substrate

The invention discloses a graphite surface titanium metallization method and a product manufactured with the same to solve the problem that when graphite is connected with Cu or Cu alloy, it is difficult to wet graphite with liquid metal, the difference between graphite and Cu or Cu alloy is large in terms of expansion factor and elasticity modulus, and connection is hard. According to the method, a titanium film is deposited on the surface of a graphite substrate with the magnetron sputtering method, and then hot isostatic pressing is conducted on the deposited titanium film, so that a titanium thin film is formed on the surface of the graphite substrate. The problem that coating-substrate combination strength of a surface titanium metallization layer is low during diffusion bonding of the non-metal material graphite can be effectively solved, and the metal titanium thin film high in coating-substrate combination strength can be prepared on the graphite substrate. According to the titanium thin film, the concentration of titanium becomes larger gradually from the graphite substrate to the outside in a gradient mode, and the strength of combination between a titanium coating and the substrate is high. The method can meet the requirement for research of fusion reactor plasma facing materials and has great significance for development of fusion reactor elements.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Cadmium-Te solar battery with ultra-thin graphite slice as underlay

The invention relates to a CdTe solar cell which has a substrate of ultra-thin flake graphite,belonging to the field of new energy material and device. The invention uses flexible ultra-thin flake graphite as the substrate material, and sputters a layer of copper on the flake graphite, then carries heat treatment. The copper diffuses into graphite forming copper-doped flake graphite. The invention deposits a layer of tellurium on the copper-doped fake graphite, then deposits the CdTe and carries annealing treatment. In the process of deposition and annealing treatment of CdTe, heavily doped CuxTe layer is formed between flake graphite and CdTe, thus realizing ohmic contact between flexible ultra-thin graphite substrate and CdTe. And the invention deposits CdS, transparent conductive film and grid pattern aluminum electrode in turn to obtain flexible CdTe film solar cell. The invention solves the contradiction which is between high processing temperature required by preparing high efficient flexible CdTe and low tolerance temperature of conventional flexible substrate.

Owner:SICHUAN UNIV

Preparation method of silicon-based negative electrode material for lithium-ion batteries

InactiveCN110098380AImprove electrochemical performanceImprove lithium intercalation reactionCell electrodesMicron scaleCarbon coating

The invention discloses a preparation method of a silicon-based negative electrode material for lithium-ion batteries, which comprises the steps of firstly, etching the surface of a carbon material byadopting a physical or chemical method, and forming multiple nano-scale to micron-scale holes on the surface of the carbon material; then mixing and ball-milling the carbon material with holes with acertain proportion of nano-silicon, and embedding the nano-silicon into the holes of the carbon material; and finally, carrying out carbon coating on the mixed and ball-milled material to obtain thesilicon-based negative electrode material for the lithium-ion batteries. The volume expansion of silicon can be greatly buffered by graphite, and good electrical contact is kept between silicon and graphite, so that the silicon-based negative electrode material prepared according to the invention greatly improves the electrochemical performance; and meanwhile, the hole prepared on the surface of graphite can greatly improve the lithium intercalation reaction of lithium ions on the graphite substrate, so that the material greatly improves the rate and low temperature performance of the lithium-ion batteries.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Nanometer silicon composite negative electrode material used for lithium ion battery

InactiveCN108598391AAlleviate the effect of volume expansion and contractionImprove performanceCell electrodesSecondary cellsCarbon coatingSilicon alloy

The invention relates to a nanometer silicon composite negative electrode material used for a lithium ion battery. The composite negative electrode material adopts an ''egg'' model structure, whereinthe egg yolk comprises a graphite substrate and a nanometer silicon material uniformly dispersed in the interior and on the surface of the graphite substrate; the egg white is graphene uniformly dispersed on the surfaces of the graphite substrate and the nanometer silicon; and the egg shell is a conductive carbon coating layer. By combination of nanometer compounding, surface medication and surface coating technologies, the silicon alloy negative electrode material with the ''egg'' model structure is prepared, and the negative electrode material has high specific capacity, high initial charging-discharging efficiency and excellent cycle stability; and the preparation process is simple, environment friendly and free of pollution.

Owner:HUNAN SHINZOOM TECH

Rectangular Semi-Conducting Support for Microelectronics and Method for Making Same

ActiveUS20080001274A1Semiconductor/solid-state device detailsSolid-state devicesGraphite substrateSemiconductor

The semi-conducting support comprises a graphite substrate having a front surface and a rear surface and at least a first stack arranged on the front surface of the substrate. The first stack successively comprises a single-crystal diamond layer, an electrically insulating oxide layer and a semi-conducting layer. The support can comprise a second stack arranged on the rear surface of the substrate and comprising the same succession of layers as the first stack or comprising a polymer material layer. A thermal connection passing through the first and / or second stacks and connecting the graphite substrate to an external surface of the support enables heat to be removed. The method can comprise production of the semi-conducting layer by molecular bonding of rectangular silicon strips onto the oxide layer.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

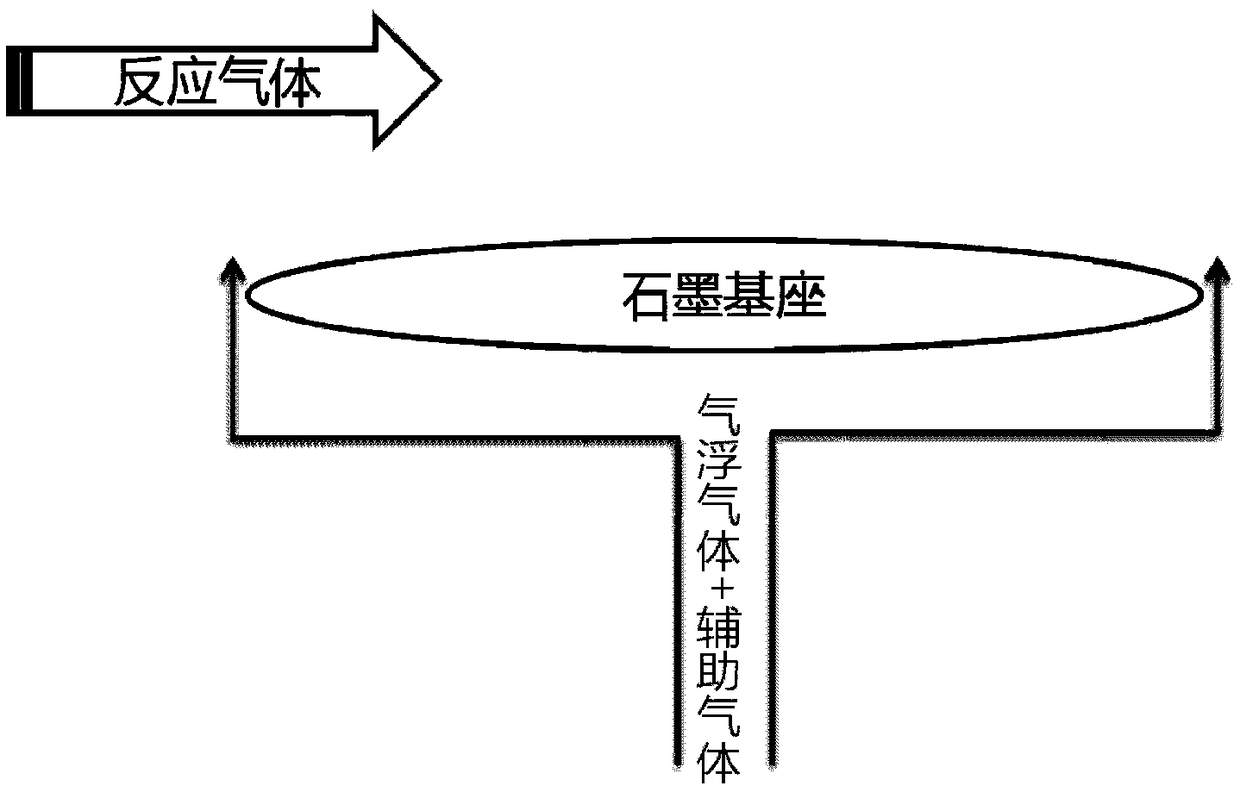

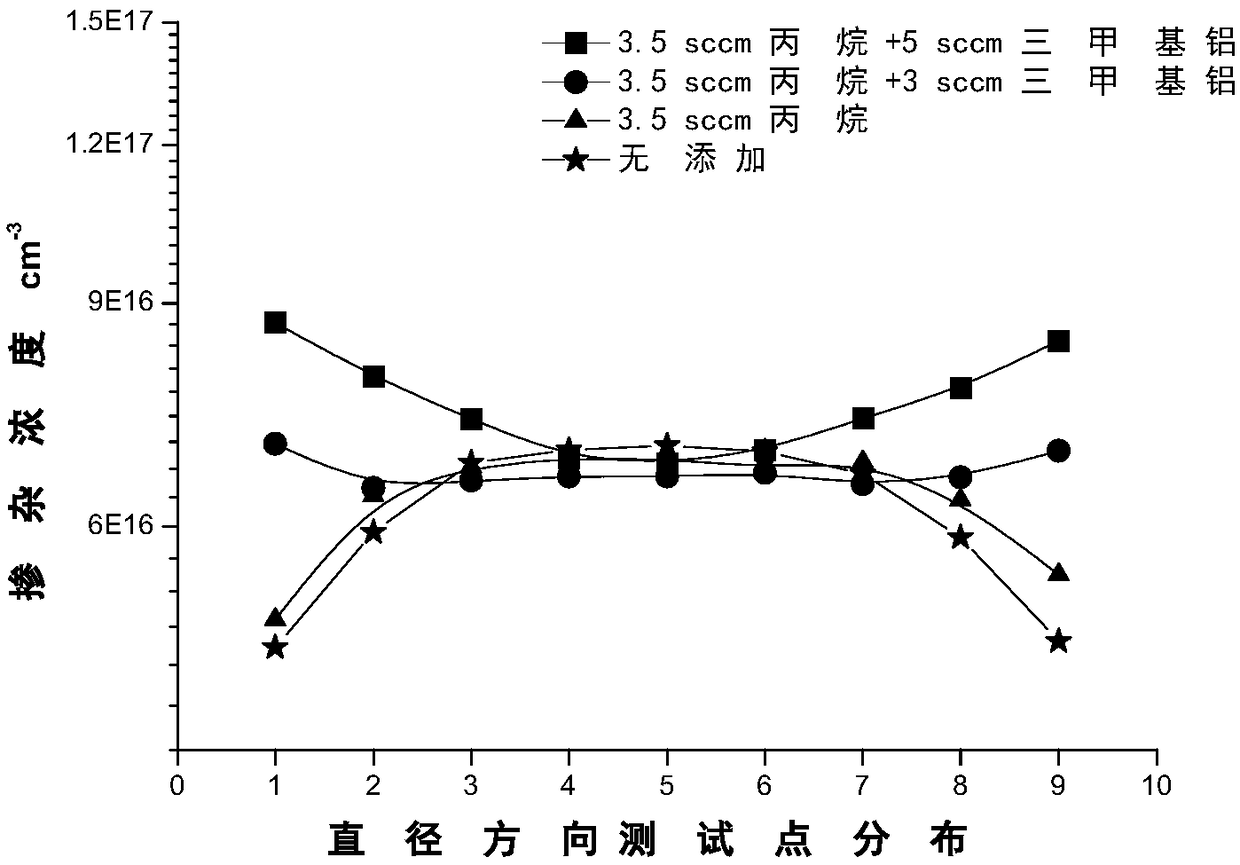

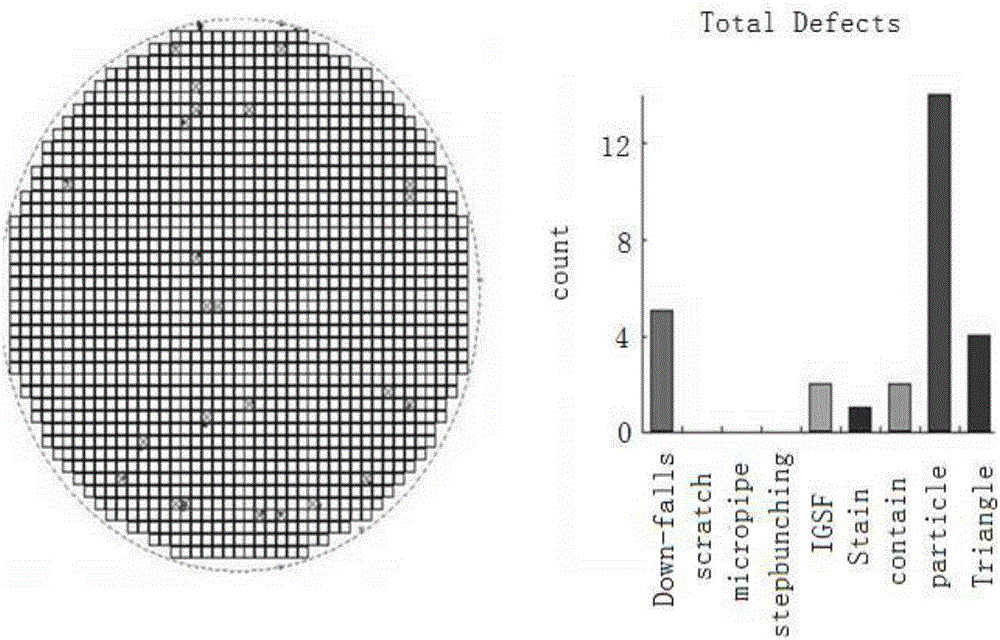

Method for improving uniformity of p-type doping concentration in silicon carbide epitaxial wafer

ActiveCN108796616ADoping Concentration Uniformity OptimizationExcellent background concentrationDiffusion/dopingGraphite substrateChemical vapor deposition

The invention discloses a method for improving the uniformity of p-type doping concentration in a silicon carbide epitaxial wafer. Based on a chemical vapor deposition growth technique, a small amountof silicon source, carbon source, hydrogen chloride, trimethylaluminum and the like are added into a substrate air-floating gas, and then a small amount of process gas is pushed to an edge of a graphite substrate by taking the air-floating gas as a carrier gas, so that the p-type doping efficiency of the edge of the substrate is finely adjusted. By adopting the method, the deviation of the dopingconcentration of an edge point and a center point caused by nonlinear depletion of the epitaxial wafer is effectively reduced, and the uniformity of the intra-wafer doping concentration of the epitaxial wafer is effectively optimized without changing key process parameters. The process is compatible with conventional SiC epitaxial processes, and has a relatively high promotion value.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

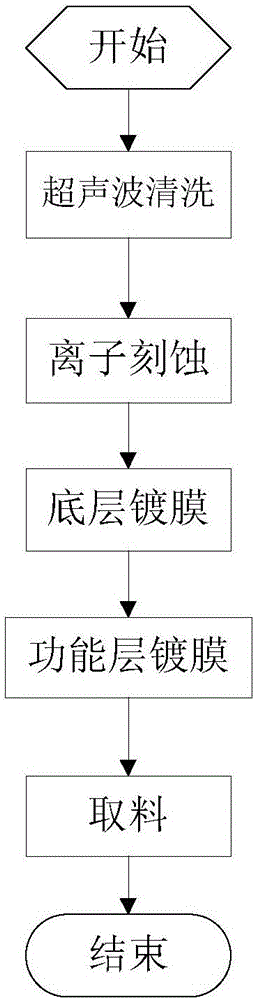

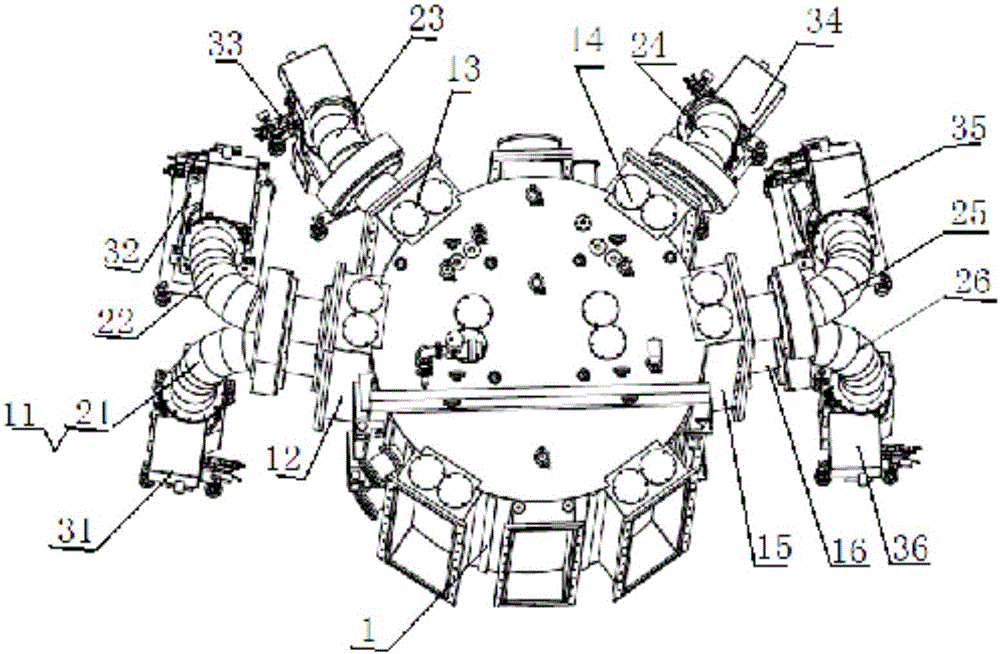

Method for coating high temperature-resistant diamond on graphite substrate

The invention discloses a method for coating high temperature-resistant diamond on a graphite substrate. The method comprises the following steps: an ultrasonic cleaning step, namely, performing ultrasonic cleaning on a surface of the graphite substrate; an ion etching step, namely, placing the graphite substrate into a coating cavity, vacuumizing the coating cavity to 6.0 *10<3> Pa, and performing the ion etching on the surface of the graphite substrate; a bottom layer coating step: vacuumizing the coating cavity to 2.66 *10<3> Pa, and performing bottom layer coating on the graphite substrate, wherein the bottom layer which is obtained by the bottom layer coating is one of a SiC layer, an AlTi layer, an AlTiN layer, a Si layer or a SiN layer; a functional layer coating step, namely, performing functional layer coating on the bottom layer, wherein the obtained functional layer is a hydrogen-containing or hydrogen-free diamond-like layer or a metal-doped diamond-like layer; a material taking step, namely, relieving the vacuum of the coating cavity, and taking out a sample. The method has the technical effects that a protecting effect on the graphite substrate can be achieved in an oxygen-free environment at 600 to 900 DEG C after the graphite substrate is coated with a diamond-like film.

Owner:NANOFILM VACUUM COATING SHANGHAI

Method for realizing microstructure on pyrolytic graphite chip

InactiveCN101200281AHigh positioning accuracyImprove bindingDecorative surface effectsChemical vapor deposition coatingSputteringGraphite substrate

The invention discloses a micro-structural realization method on pyrolytic graphite substrate, belonging to a micro electromechanical technical field, the method adopts pyrolytic graphite as the substrate, and then performs the leveling, cleaning, insulating and re-cleaning of the substrate; the back of the pyrolytic graphite substrate is arranged with lithography alignment marks, multi-layer structure or high aspect ratio structure is formed by overlay; the front of the pyrolytic graphite substrate is sprayed with metallic film as seed layer, positive photoresist, lithography and develop are performed, and then electroplating mold is made so as to form an electroplating structural layer, after performing the positive photoresist, lithography and developing twice, positive photoresist is removed, ultrasonic cleaning is performed, and alumina is sprayed, and then the substrate is ground and is cleaned; the alumina is sprayed with the metallic film as the seed layer, and the seed layer is spread with SU8 negative photoresist, after performing the lithography, developing and electroplating, the SU8 negative photoresist is removed and the alumina is removed, so that the high aspect ratio structure is made on the pyrolytic graphite substrate. The invention has novel substrate materials and special processing performance.

Owner:SHANGHAI JIAO TONG UNIV

Method for reducing scratches on surface of epitaxial wafer

ActiveCN106783540AReduce processing timeReduce epitaxy defectsSemiconductor/solid-state device manufacturingLow speedHydrogen etching

The invention discloses a method for reducing scratches on the surface of an epitaxial wafer. The method comprises the following steps of (1) putting a silicon carbide substrate on a graphite substrate in a reaction chamber of a silicon carbide epitaxial system; (2) replacing a gas in the reaction chamber with argon for multiple times, and then introducing hydrogen into the reaction chamber, gradually increasing the flow of the hydrogen to 20-40L / min, setting the pressure of the reaction chamber to be 700-1,000mbar and gradually heating the reaction chamber to 1400-1500 DEG C; and (3) after reacting a set temperature, keeping all parameters invariable and carrying out in-situ hydrogen etching treatment on the silicon carbide substrate for 10-60 minutes. According to the method disclosed by the invention, the substrate is treated by adopting low-speed hydrogen etching which tends to be isotropic under the conditions of a relatively low temperature, high pressure of the reaction chamber and low-flow hydrogen, so that the scratches on the surface of the substrate can be effectively reduced and weakened, other epitaxial defects derived from the scratches in an epitaxial layer are reduced, the method is compatible with an existing epitaxy process and core process parameters do not need to be modified.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com