Lithium ion battery cathode composite material and preparation method thereof

A lithium-ion battery and composite material technology, which is applied in the field of composite lithium-ion battery negative electrode materials and its preparation, can solve problems such as low compaction density, reduced electrical conductivity, and increased cost of negative electrode materials, and achieve a firm and dense coating layer , The effect of reducing the manufacturing cost and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of lithium ion battery negative electrode composite material of the present invention comprises the following steps:

[0022] 1. Graphitization treatment or graphite purification treatment, the carbon content is 85-99.8%, the average particle size is D 50 Spherical, massive and / or flaky natural flake graphite, microcrystalline graphite, crystalline vein graphite or needle coke, petroleum coke raw materials with a spherical shape of 3.0-50 μm and a long-short axis ratio of 1.0-4.5, after purification Or graphitization treatment to obtain a graphite matrix with a carbon content of more than 99.9%. Graphite with a carbon content of 99.9% can also be treated without graphitization or graphite purification.

[0023] Graphitization treatment is to use natural flake graphite, microcrystalline graphite, crystalline vein graphite or needle coke or petroleum coke raw materials with a carbon content of 85-99.8% at a temperature of 1-20°C / min. The heating r...

Embodiment 1

[0044] Example 1, mixing irregular natural flake graphite with a carbon content of 95.2% and 0.5wt% organic high molecular polymer PVA in a liquid phase, and drying the mixture in an instant in the gas phase; The magnetic machine is demagnetized, packed and put into storage.

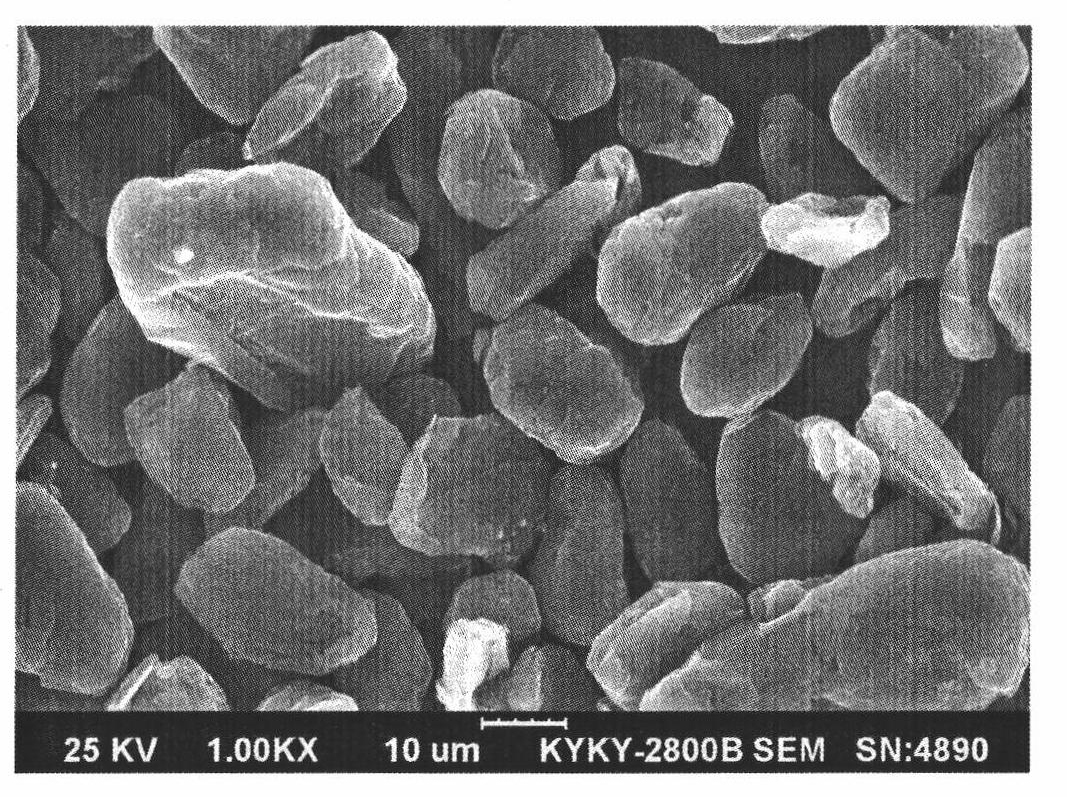

[0045] Such as figure 1 As shown, after coating with high molecular polymer, the coating layer is uniform, and there is no adhesion between particles.

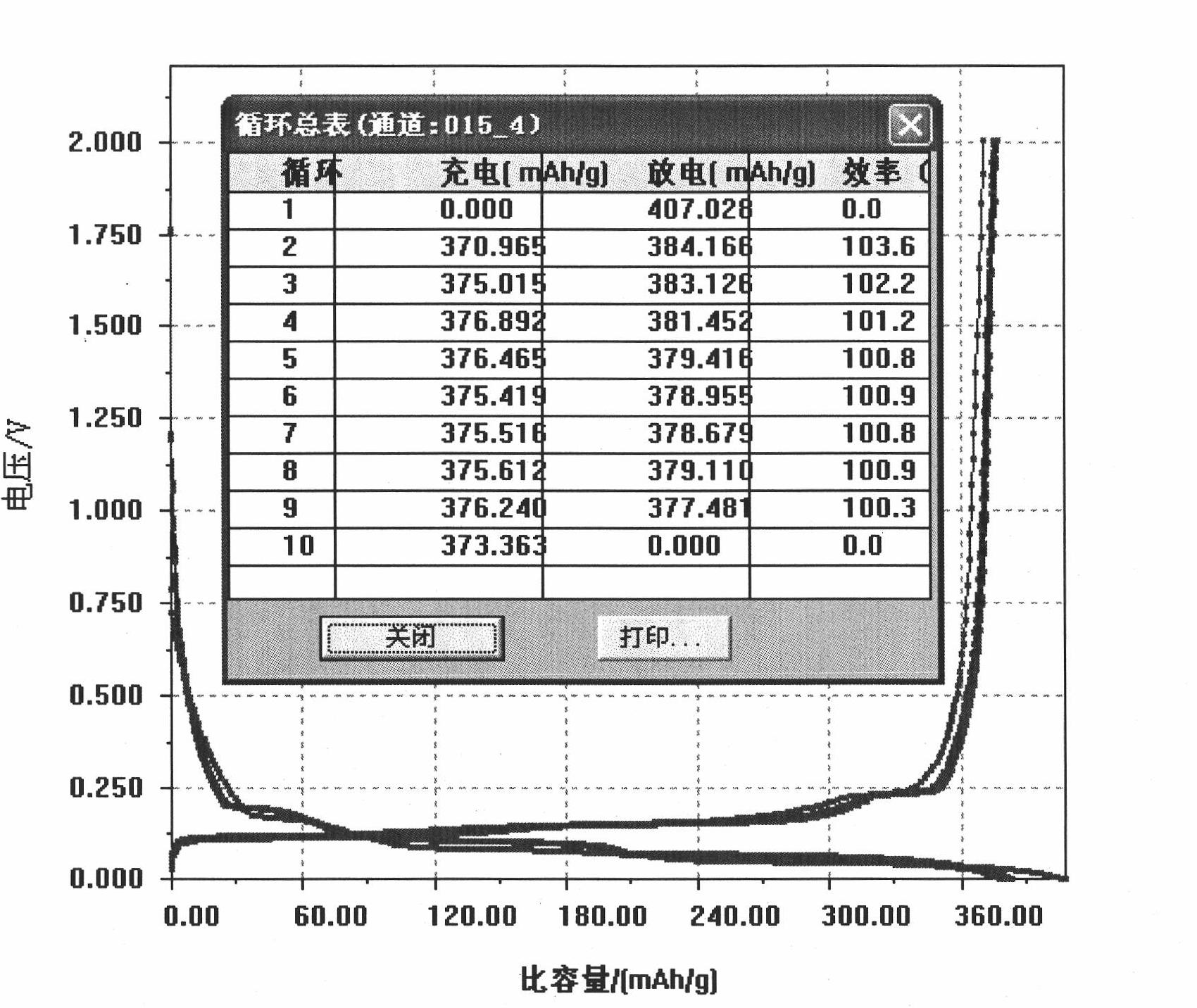

[0046] Such as figure 2 It can be seen that, while the amount of binder is reduced, the gram capacity of the coated material is still 370.9mAh / g.

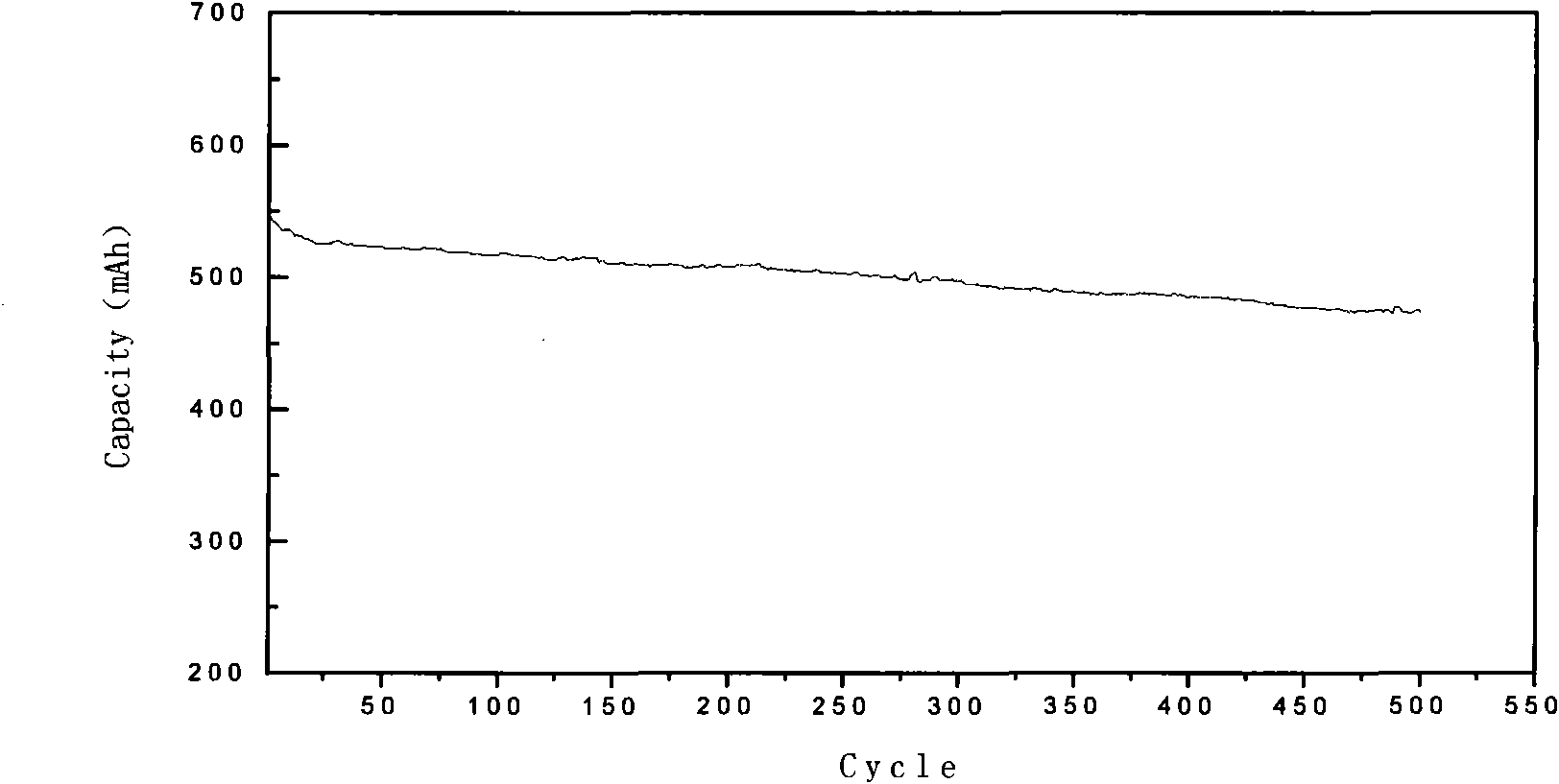

[0047] Such as image 3 As shown, the compaction of the pole piece is 1.75g / cm 3 Under the compacted density, the capacity retention rate of the battery for 500 cycles is 86.8%.

Embodiment 2

[0048] Example 2, mixing irregular graphite with a carbon content of 99.9% and 5wt% organic high molecular polymer PEG liquid phase, and drying the mixture in the gas phase instantly; performing a heat treatment at 900°C, and demagnetizing the resultant through a demagnetizer, Packaging and storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com