Seed crystal support for growing silicon carbide crystal with high quality

A silicon carbide and seed crystal technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of reducing the quality and yield of the wafer, and achieve the suppression of backside evaporation, elimination of planar hexagonal defects, and improvement of crystal quality and The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

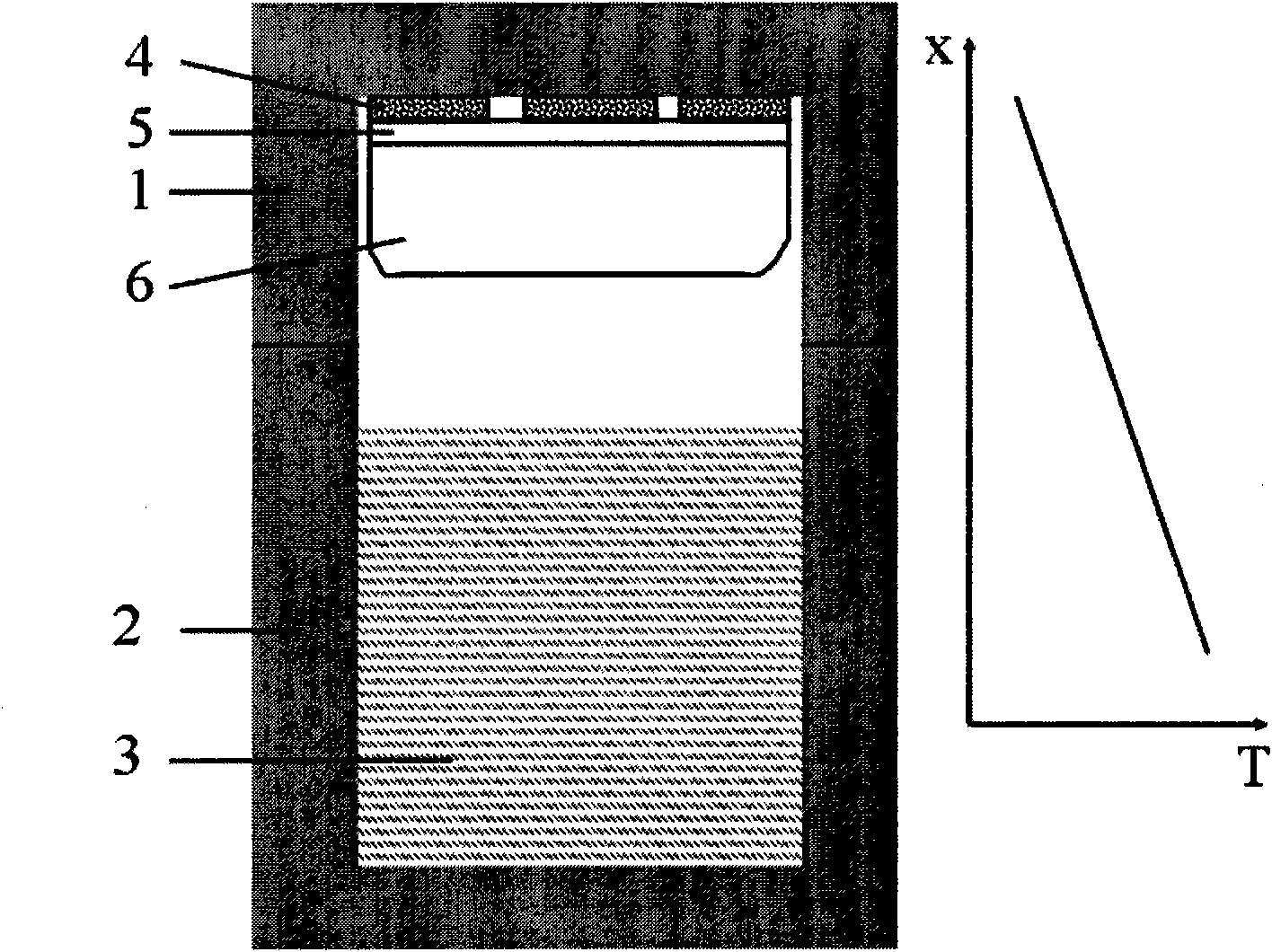

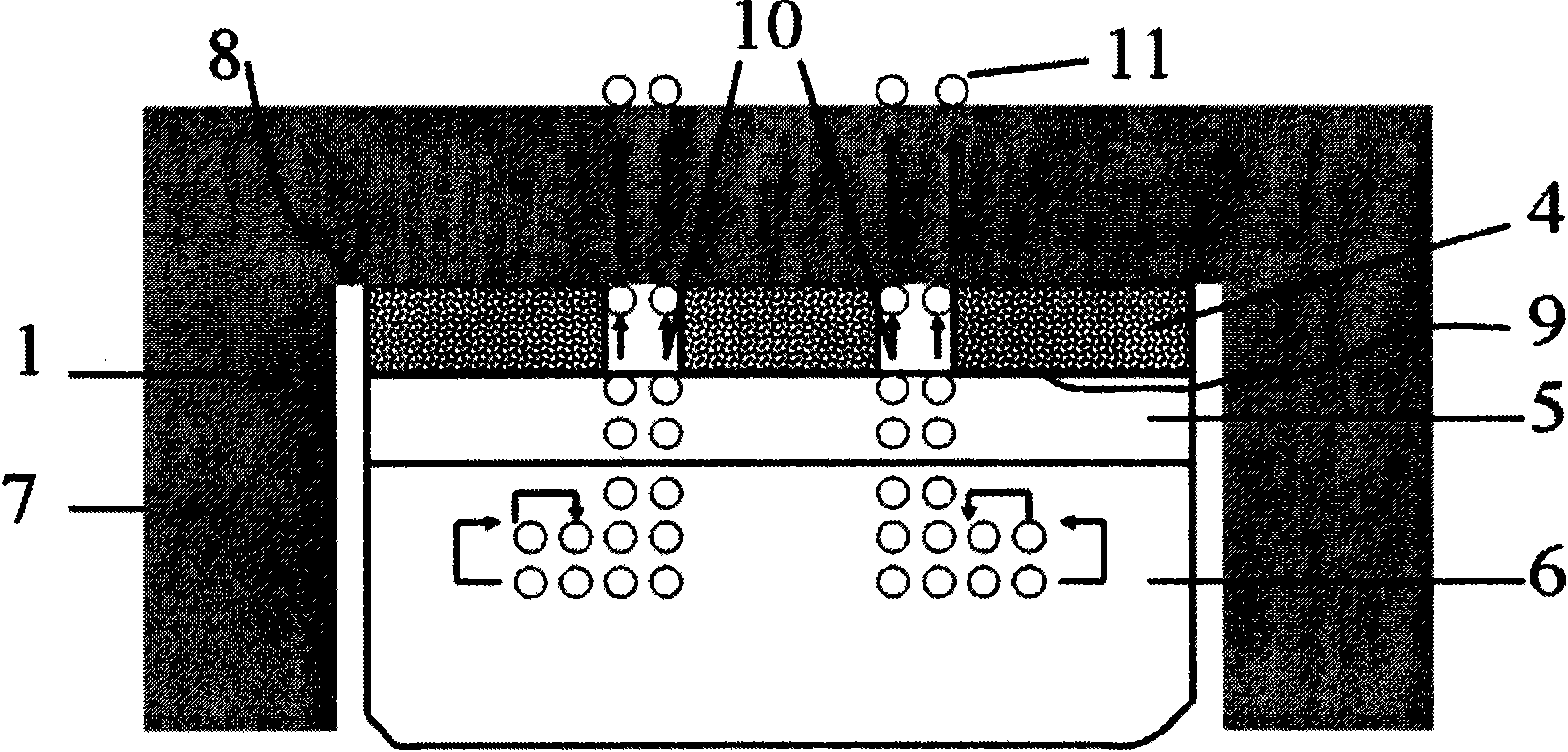

[0023] The seed crystal support structure of the present invention will be described in detail below with reference to the accompanying drawings.

[0024] figure 2 It is a schematic diagram of the seed crystal support structure commonly used to grow SiC crystals at present. The graphite cover 1 is processed from Sangao graphite, and the flatness of its inner surface 8 is better than 10 μm. The seed crystal 5 is adhered to the inner surface 8 of the graphite cap 1 by means of an adhesive 4 . Due to factors such as poor machining accuracy and uneven bonding of the adhesive 4 , some pores 10 inevitably exist between the back surface 9 of the seed crystal and the inner surface 8 of the graphite cap 1 . The difference in thermal conductivity between the pores 10 and the binder 4 after high-temperature carbonization will lead to uneven temperature distribution on the rear surface 9 of the seed crystal. When the crystal grows, there is a certain temperature gradient in the growin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com