Graphite seed crystal support for silicon carbide crystal growth

A crystal growth, silicon carbide technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

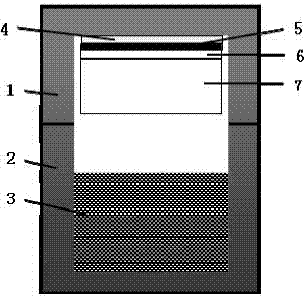

Method used

Image

Examples

Embodiment 1

[0030] First, put the graphite crucible with silicon carbide raw material in the material area and the graphite seed crystal holder without seed crystal on the upper part into the thermal insulation carbon felt, and then put it into the crystal growth furnace chamber, and the vacuum degree is pumped to 1.0×10 -2Below Pa, inflate to the required pressure such as 30 Torr, start to heat up to the target temperature such as 2100°C, grow for a certain period of time such as 10h, cool down to room temperature by program, and start the furnace to obtain polycrystalline silicon carbide with a thickness of about 0.5mm on the graphite seed crystal support. layer, and finally a polycrystalline silicon carbide layer with a flatness of 30 μm and a thickness of 0.2 mm that can be used for SiC crystal growth is obtained by mechanical processing on the graphite seed crystal support. Among them, the thickness of the polycrystalline silicon carbide polycrystalline layer can be adjusted according...

Embodiment 2

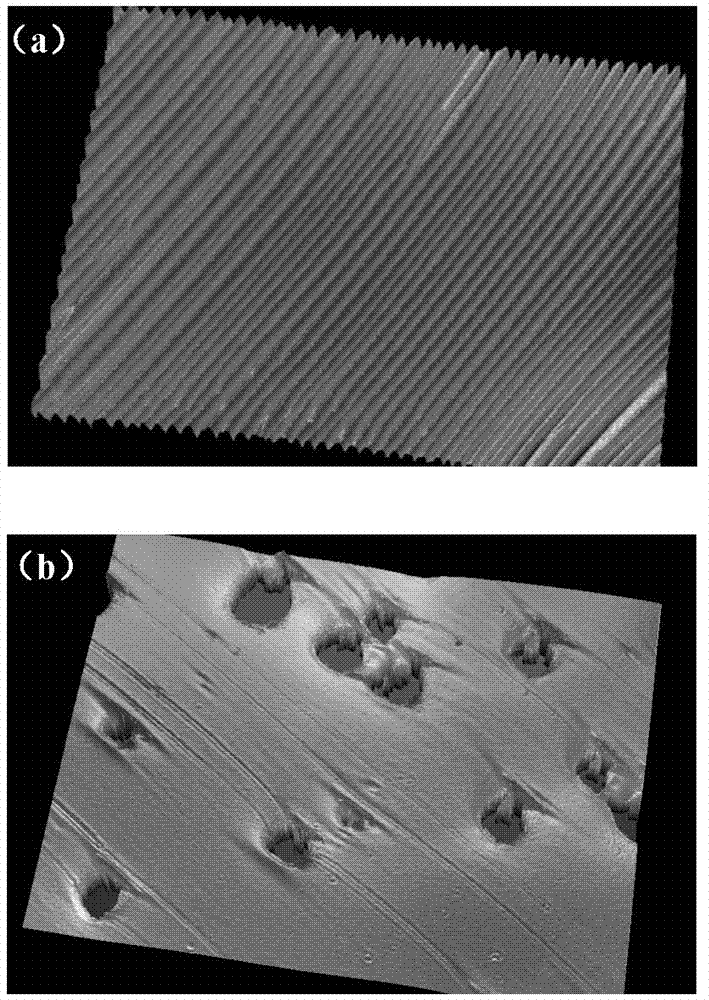

[0032] The graphite seed crystal holder with the polycrystalline silicon carbide layer deposited on the surface obtained in the above examples is used for crystal growth by the PVT method, and the crystal growth surface obtained by observing the obtained crystal growth surface through a white light interference microscope, as shown in figure 2 As shown in (a), it can be clearly seen that there are no defects such as micropipes, black spots and holes on the crystal growth surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com