Preparation method of silicon-based negative electrode material for lithium-ion batteries

A silicon-based negative electrode material and lithium-ion battery technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as low compaction density and decreased volumetric energy density of batteries, achieve low manufacturing costs, and improve electrochemical performance. Improvement in performance and electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

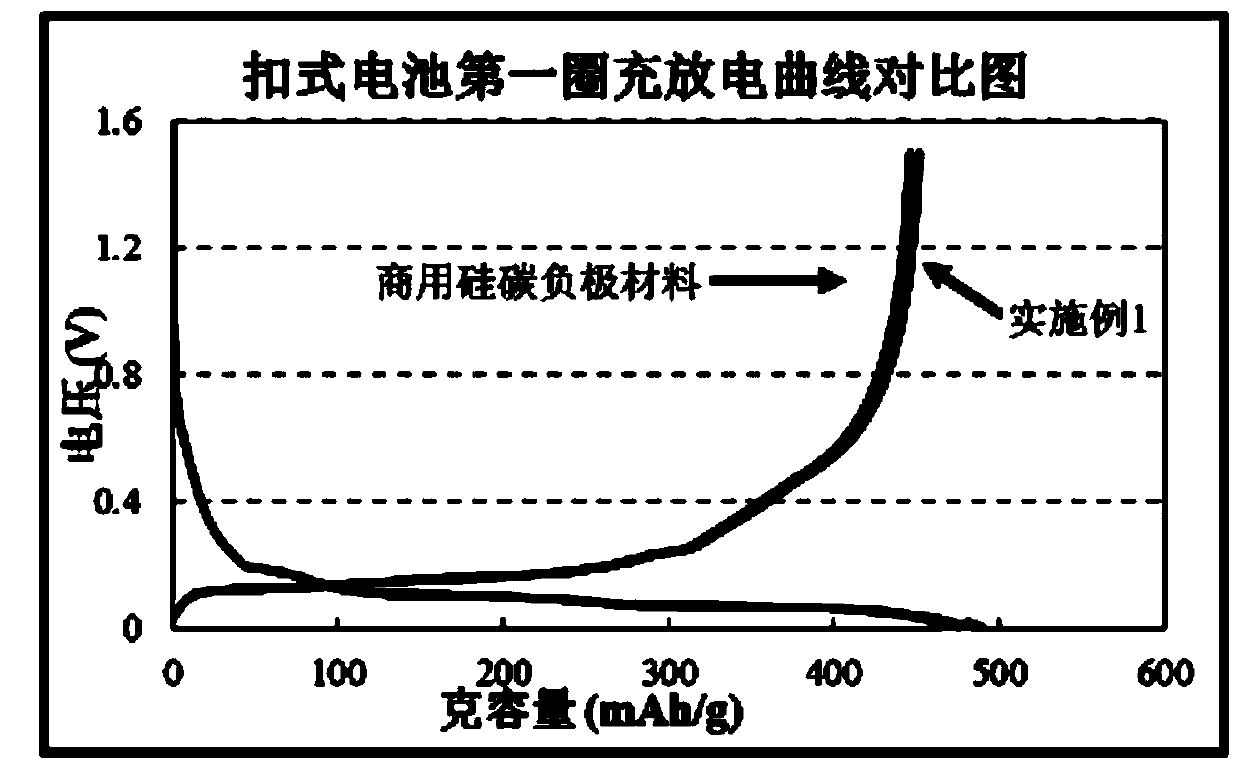

Embodiment 1

[0031] A method for preparing a silicon-based negative electrode material for a lithium-ion battery, specifically comprising the following steps:

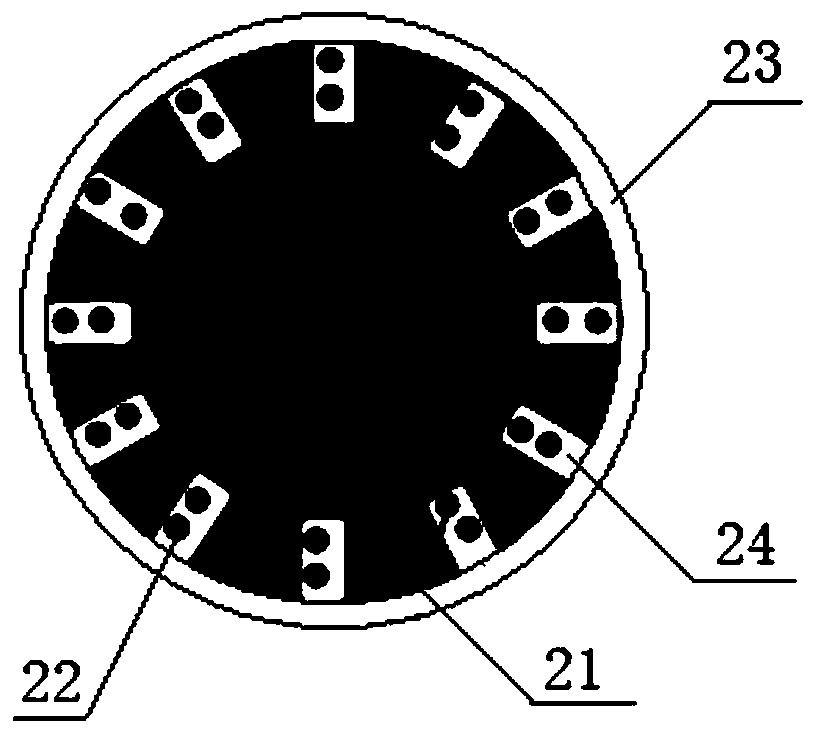

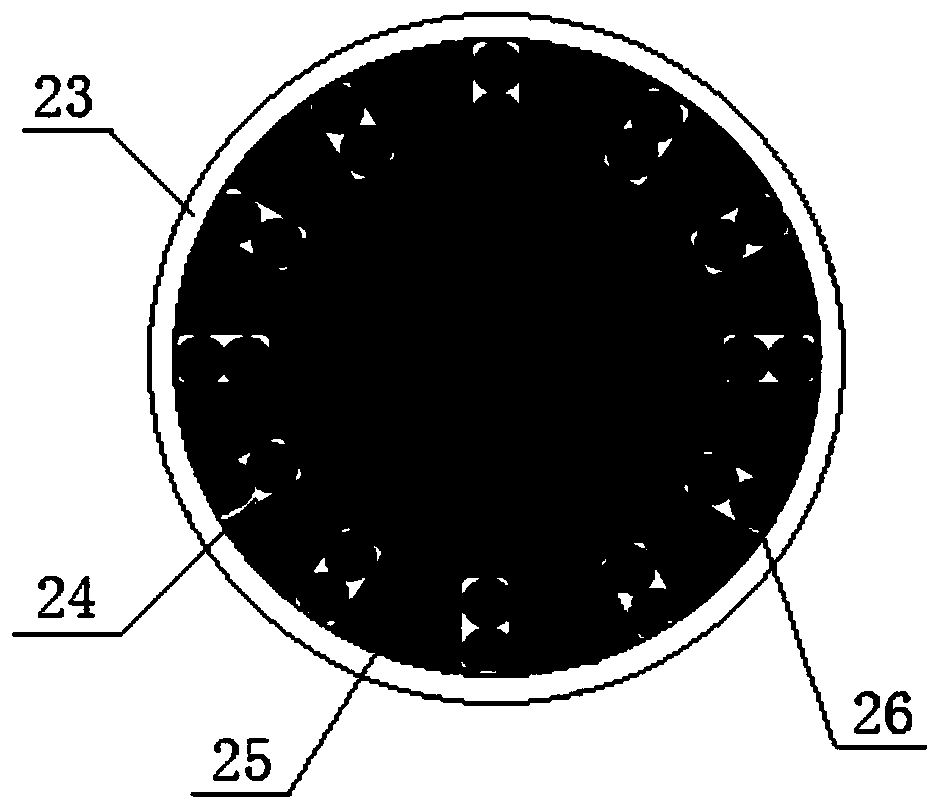

[0032] (1) Add an appropriate amount of pore-forming agent to needle coke (the precursor of artificial graphite), and after high-temperature graphitization (the average particle size D50 of graphite is 15 microns), pores with a depth of about 1 micron are formed on the surface;

[0033] (2) Weigh 9.5 kg of graphite prepared in step (1), and place it in a roller mill jar with 0.5 kg of silicon with an average particle diameter D50 of 81 nanometers, add an appropriate amount of zirconium balls, and mill for 2 hours;

[0034] (3) Weigh 9.5kg of the material obtained in step (2), fully mix it with 1.0kg of low-temperature asphalt, and place it in a rotary tube furnace, inject nitrogen gas at high temperature, and fully decoke at 300-500°C , and then carbonized at 800-1000 ° C, after the reaction is completed, it is cooled to room tempe...

Embodiment 2

[0043] A method for preparing a silicon-based negative electrode material for a lithium-ion battery, specifically comprising the following steps:

[0044] (1) Use hydrogen-containing plasma to anisotropically etch the surface of natural graphite (average particle size D50 is 12 microns), forming multiple regular hexagonal holes on the graphite surface, with an etching depth of about 0.1 microns ;

[0045] (2) Weigh 4.95 g of the graphite prepared in step (1), put it in a planetary ball mill jar with 0.05 g of silicon with an average particle diameter D50 of 36 nanometers, add an appropriate amount of zirconium balls, and mill for 1 hour;

[0046] (3) Weigh the material obtained in step (2) and place it in a rotary tube furnace, raise the temperature to 950°C according to a certain program, keep it warm for 2 hours under an appropriate amount of acetylene / nitrogen (according to a certain ratio), and then pass in nitrogen After cooling down to room temperature, it is a silicon-...

Embodiment 3

[0048] A method for preparing a silicon-based negative electrode material for a lithium-ion battery, specifically comprising the following steps:

[0049] (1) Add an appropriate amount of pore-forming agent to the needle coke, and after high-temperature graphitization (the average particle size D50 of graphite is 17 microns), pores with a depth of about 3 microns will be formed on the surface;

[0050] (2) Weigh 4.75 g of the graphite prepared in step (1), put it in a planetary ball mill jar with 0.25 g of silicon with an average particle diameter D50 of 65 nanometers, add an appropriate amount of zirconium balls, and mill for 1 hour;

[0051] (3) Weigh the material obtained in step (2) and place it in a rotary tube furnace, raise the temperature to 950°C according to a certain program, keep it warm for 2 hours under an appropriate amount of acetylene / nitrogen (according to a certain ratio), and then pass in nitrogen After cooling down to room temperature, it is a silicon-base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com