Patents

Literature

51 results about "Hydrogen etching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

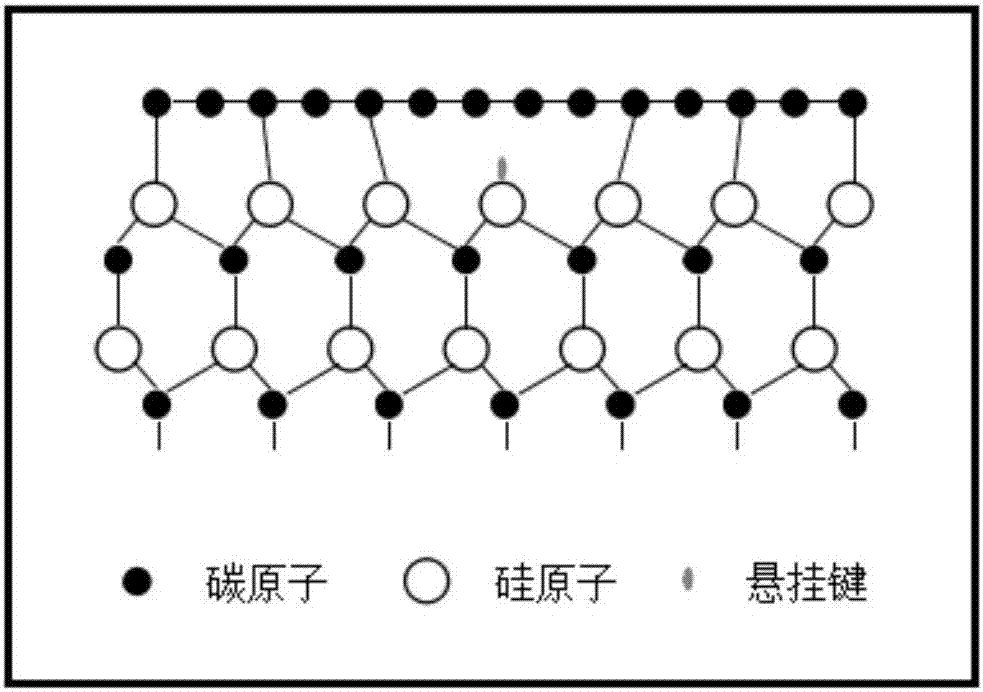

Bipolar Semiconductor Device and Process for Producing the Same

A process for manufacturing a bipolar type semiconductor device in which at least a part of a region where an electron and a hole are recombined during current flowing is formed with a silicon carbide epitaxial layer that has been grown from the surface of a silicon carbide substrate, is characterized by that the surface of the silicon carbide substrate is treated by hydrogen etching and the epitaxial layer is then formed by the epitaxial growth of silicon carbide from the treated surface. A propagation of a basal plane dislocation to the epitaxial layer can be further reduced by treating the surface of the silicon carbide substrate by using chemical mechanical polishing and hydrogen etching in this order.

Owner:THE KANSAI ELECTRIC POWER CO +1

Method for preparing thin layer graphene on surface of metal catalyst

InactiveCN103572247ALarge crystal sizeReduce carbon contentChemical vapor deposition coatingPtru catalystHydrogen etching

The invention discloses a method for preparing thin layer graphene on the surface of a metal catalyst. The method comprises the following steps: 1, putting a metal catalyst matrix in a chemical vapor deposition (CVD) system, and heating and annealing in an H2 and Ar gas mixed atmosphere; 2, carrying out a high temperature carburizing reaction by utilizing different carbon sources; 3, slowly heating samples while etching by introducing a large flow of hydrogen; and 4, completely discharging hydrogen in the CVD system through the Ar gas after the hydrogen etching, and rapidly cooling to room temperature for segregating uniform graphene layers. The number of the graphene layer can be accurately controlled by changing the thickness, the carburizing amount and the hydrogen etching amount of the metal catalyst matrix. The method has the advantages of simple process, easy operation, compatibility with the semiconductor industry, realization of the controllable preparation of graphene, and a graphene material produced through the method has important application prospects in the electronic field, the photoelectric field, the sensing field and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

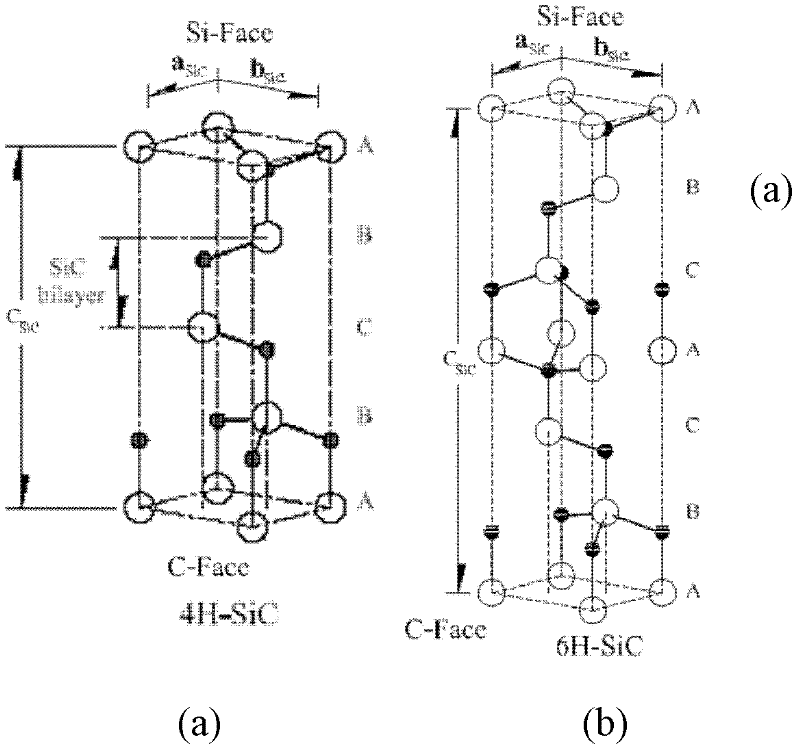

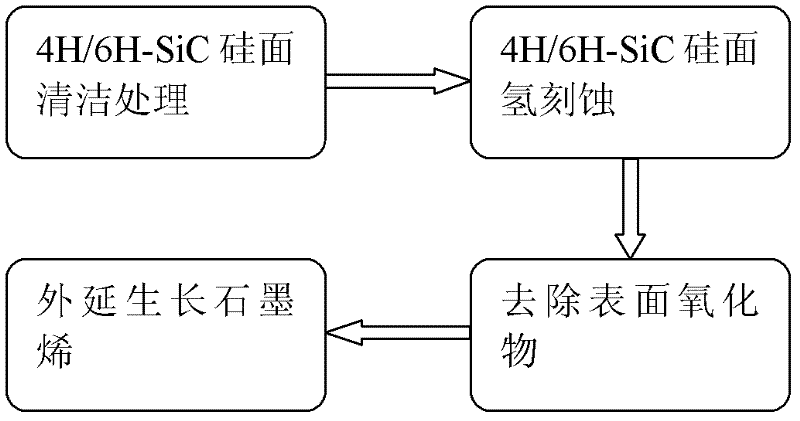

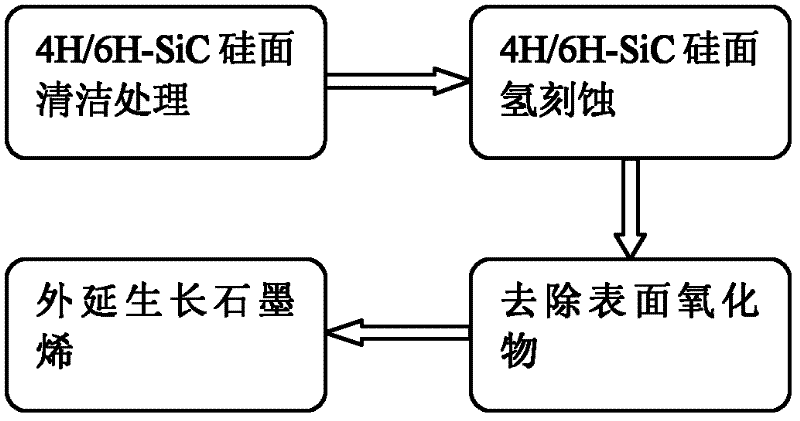

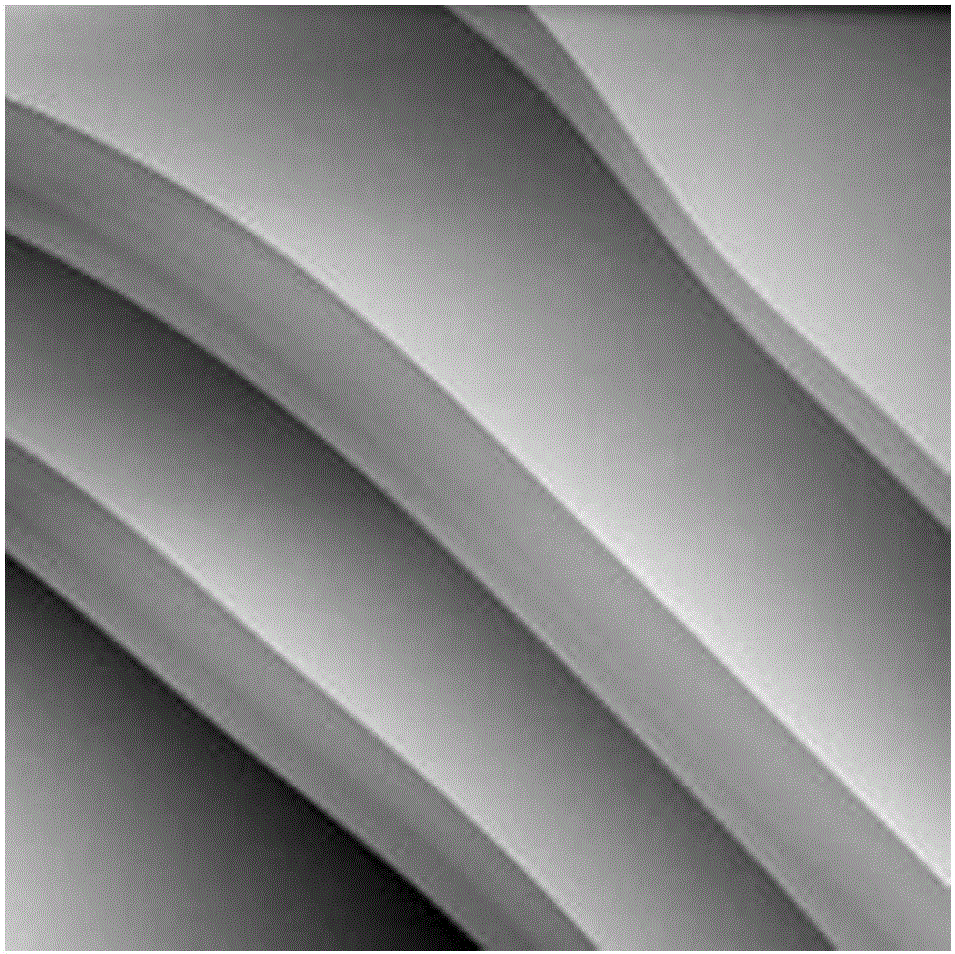

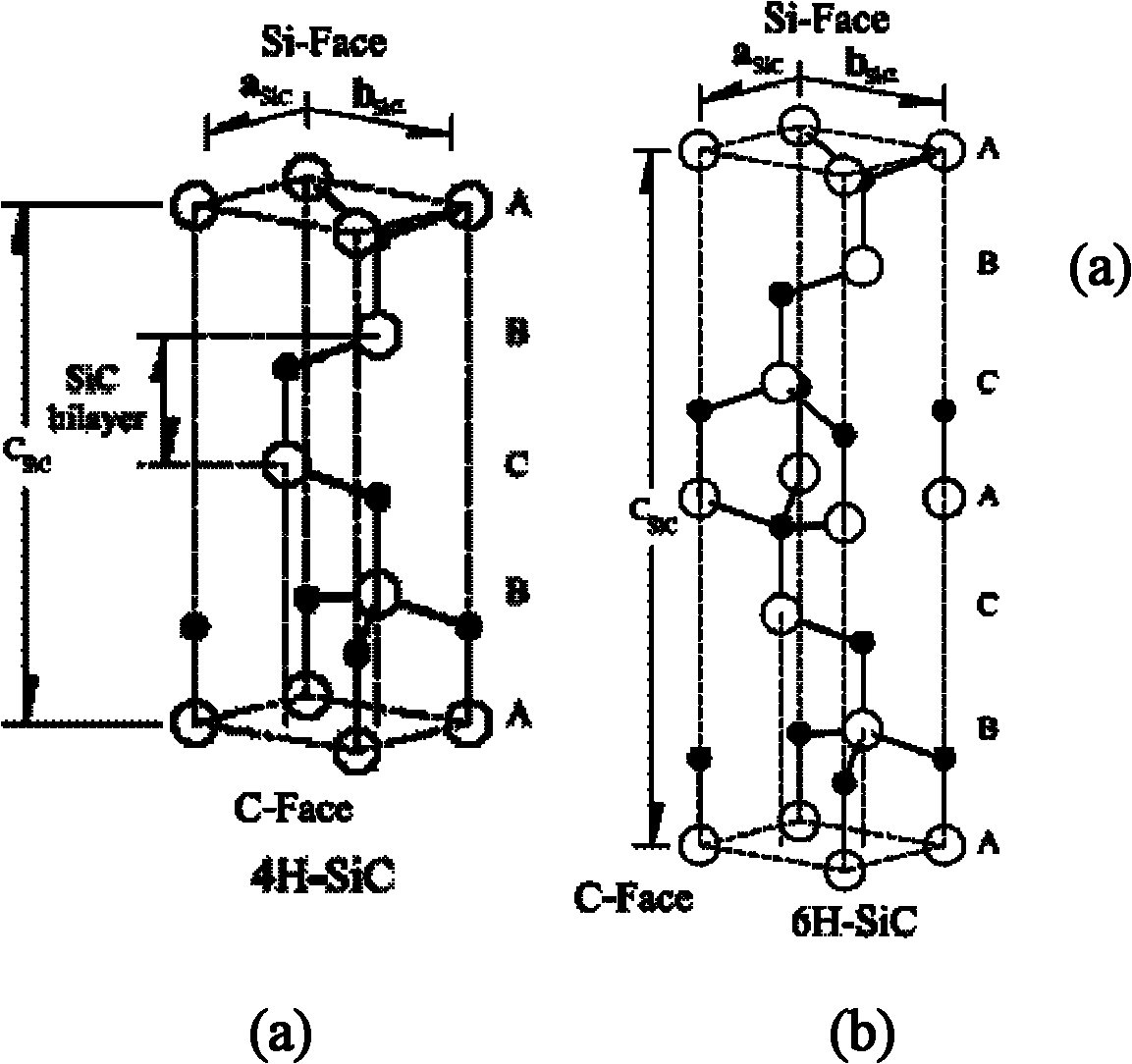

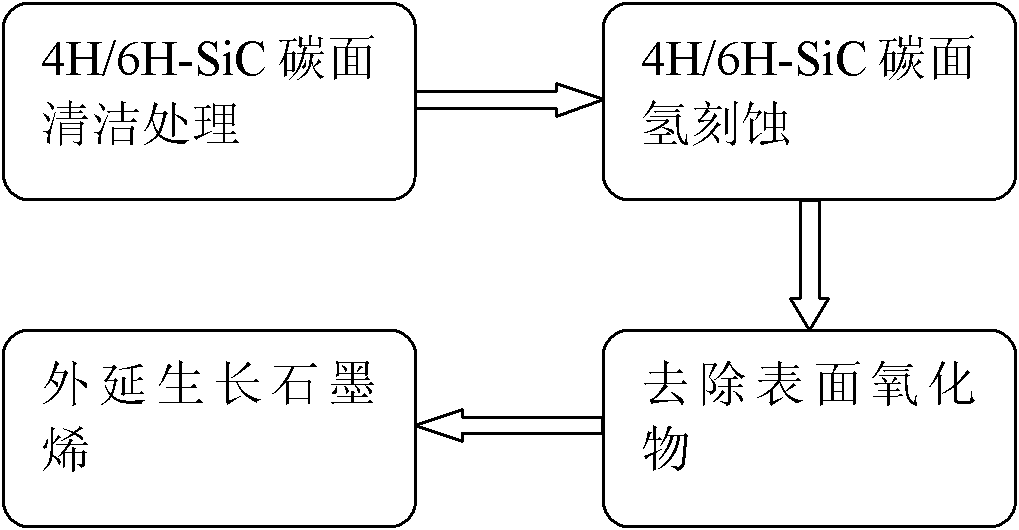

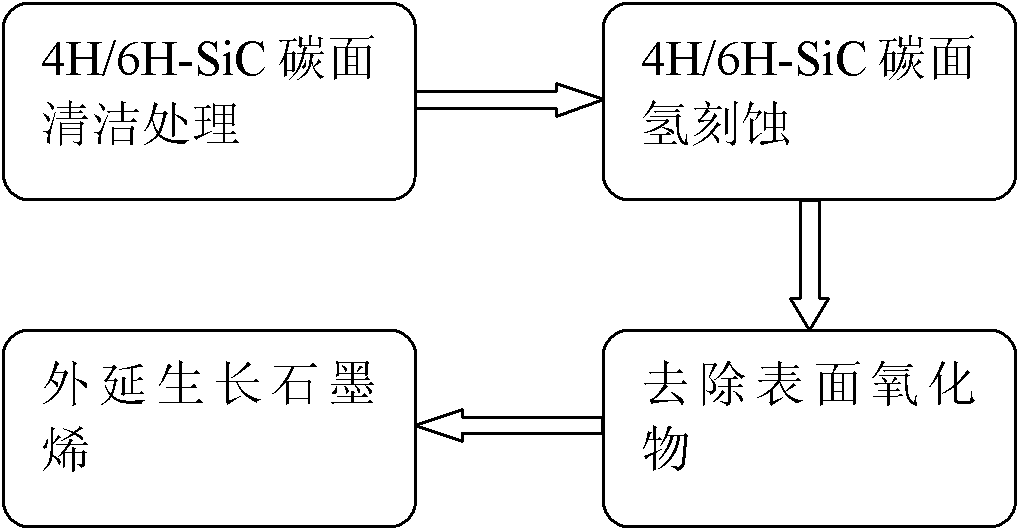

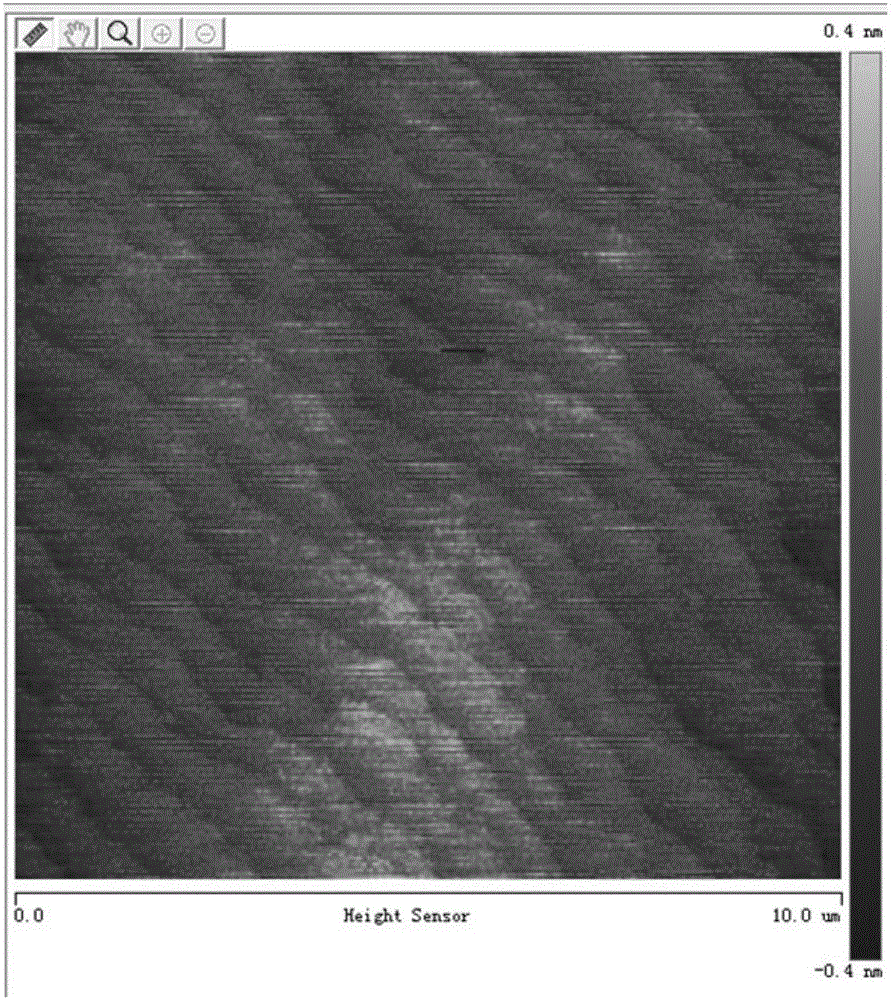

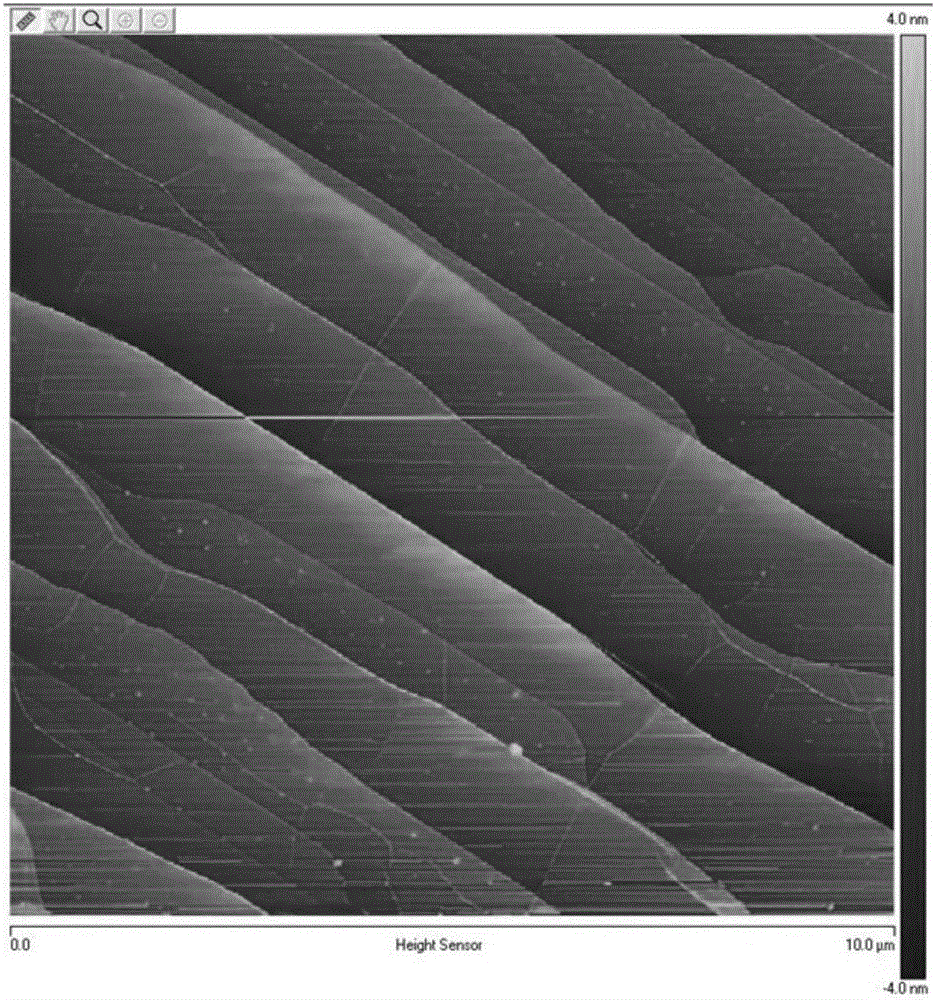

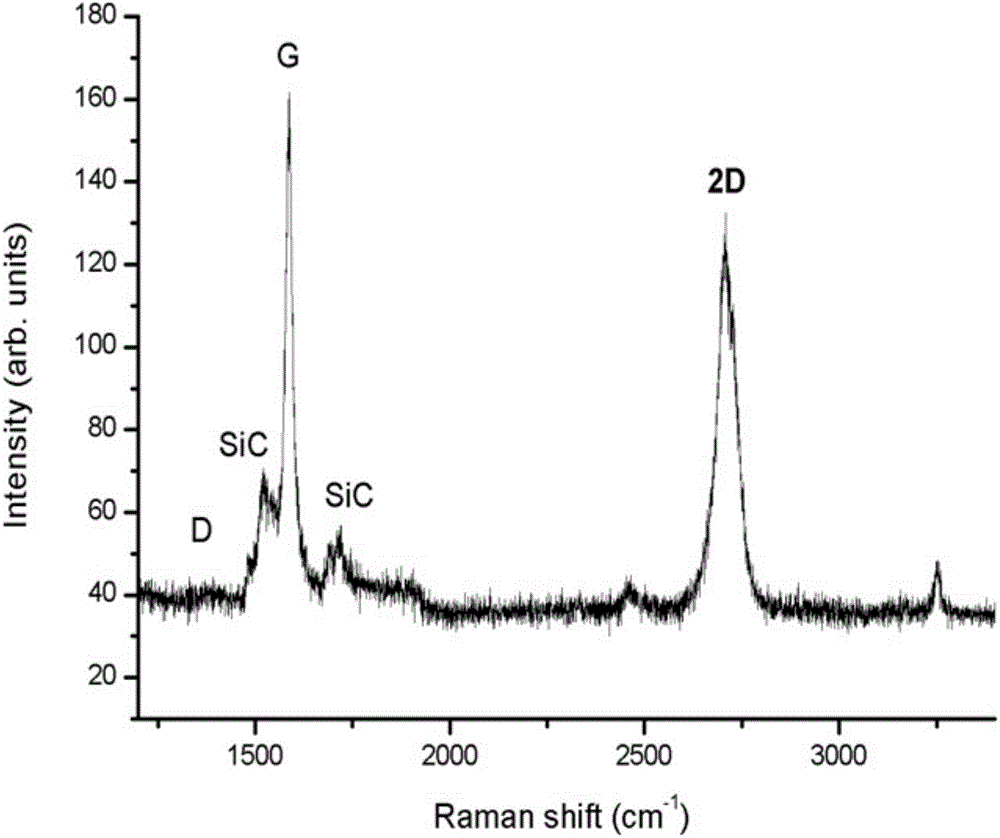

Method for epitaxial growth of wafer-level graphene on 4H/6H-SiC (0001) surface

InactiveCN102433586AEasy to cleanIncrease the areaPolycrystalline material growthFrom chemically reactive gasesHydrogenSilanes

The invention discloses a method for epitaxial growth of wafer-level graphene on a 4H / 6H-SiC (0001) surface. The method mainly solves the problem that based on the prior art, during epitaxial growth of graphene on a 4H / 6H-SiC surface, a graphene area is small and graphene uniformity is low. The method comprises the following steps of 1, cleaning a 4H / 6H-SiC (0001) surface to remove organic residues and ionic pollutants on the 4H / 6H-SiC (0001) surface, 2, feeding hydrogen, and carrying out hydrogen etching of the cleaned 4H / 6H-SiC (0001) surface to remove surface scratches so that regular bench-shaped stripes are formed, 3, feeding silane to remove oxides which are formed on the 4H / 6H-SiC (0001) surface by the hydrogen etching, and 4, heating in a low-argon pressure environment to evaporate silicon atoms so that carbon atoms are rearranged on the 4H / 6H-SiC (0001) surface by a sp2 method to form epitaxial graphene. Graphene obtained by the method has a large area and good uniformity and can be utilized for preparation of a wafer-level epitaxial graphene material.

Owner:XIDIAN UNIV

Method for selectable single-side growth of graphene on SiC substrate

ActiveCN105951179AIncrease the areaQuality improvementPolycrystalline material growthFrom chemically reactive gasesHydrogenHydrogen etching

The invention relates to a method for selectable single-side growth of graphene on a SiC substrate. The method comprises the following steps: horizontally placing the SiC substrate in a graphite crucible, allowing the side of C to be downward or the side of Si to be downward, and overlaying a cover sheet on the upward side of the SiC substrate, wherein the cover sheet is a Si atom donor or a C atom absorber; vacuumizing the chamber of a heating furnace for heating, then introducing high-purity H2, and subjecting the surface of the SiC substrate to hydrogen etching so as to form a regular SiC step structure; and closing H2, introducing Ar gas, continuing heating the heating furnace to 1500 to 1800 DEG C, and maintaining the temperature so as to complete the growth of graphene. The graphene grown by using the method provided by the invention has greatly-improved quality and surface morphology, and can be extensively applied in the fields of logic circuits, laser Q modulation, high-frequency nanometer radio frequency devices, etc.

Owner:SHANDONG UNIV

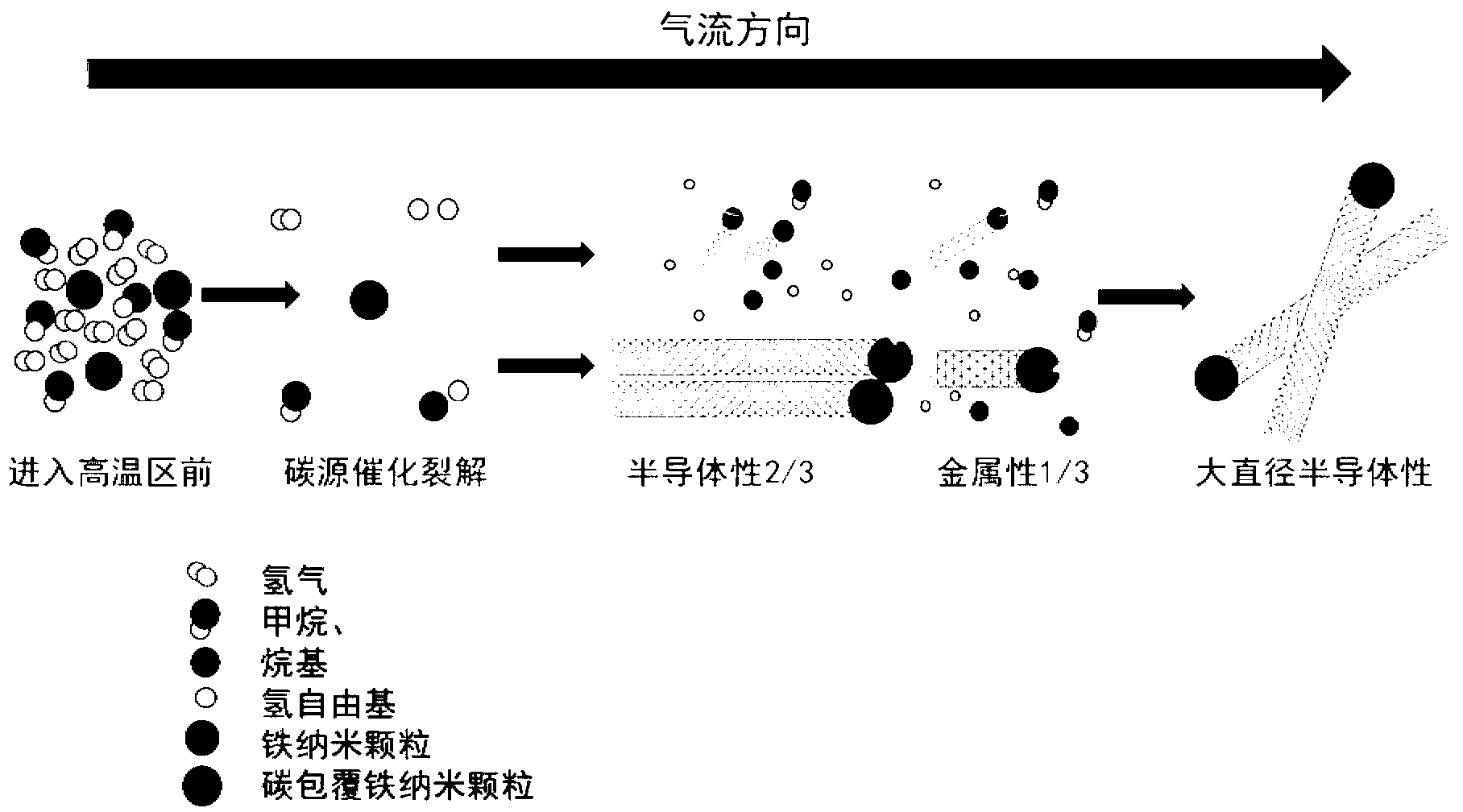

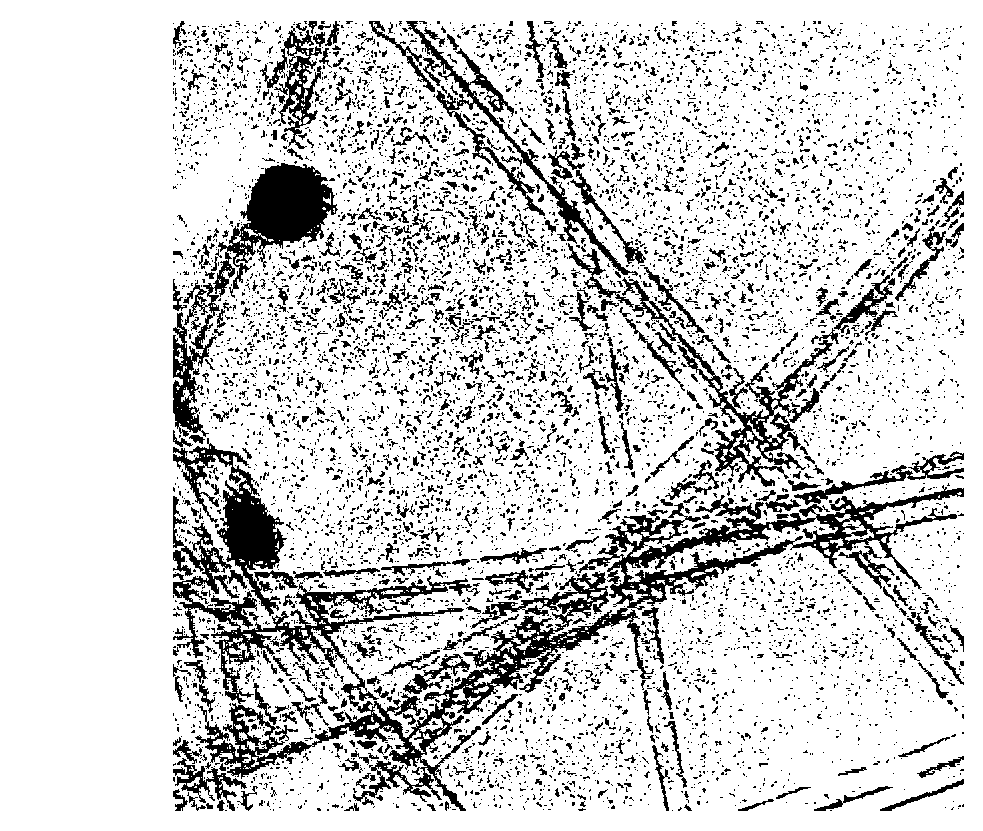

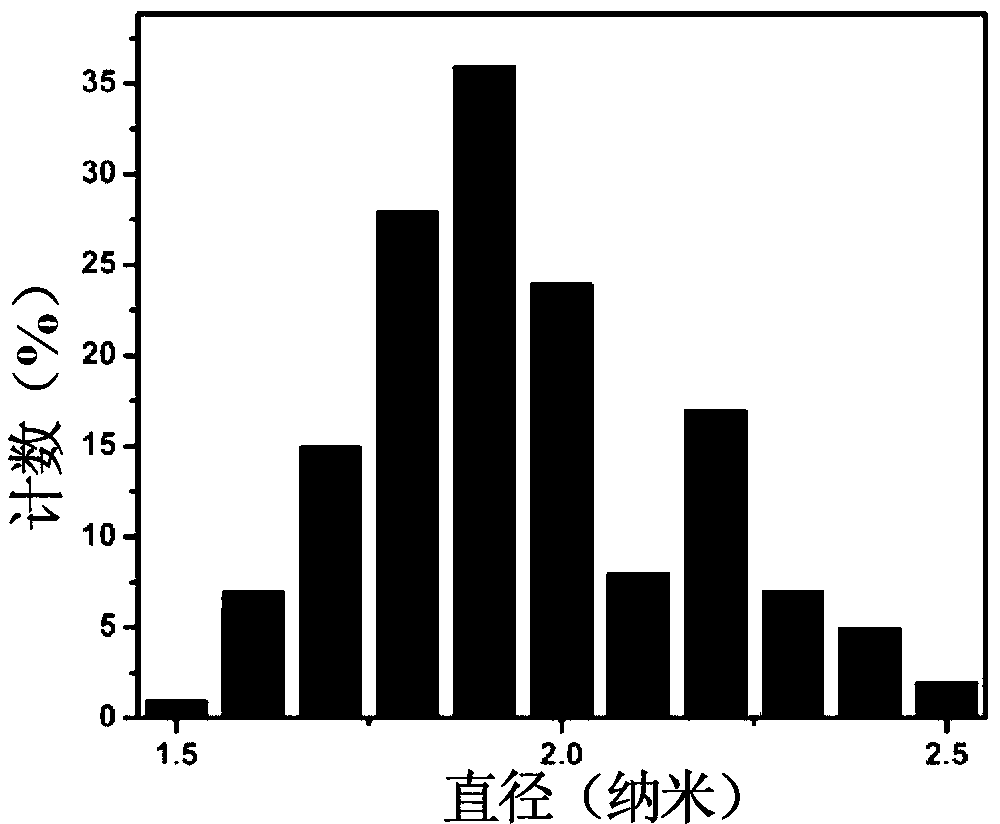

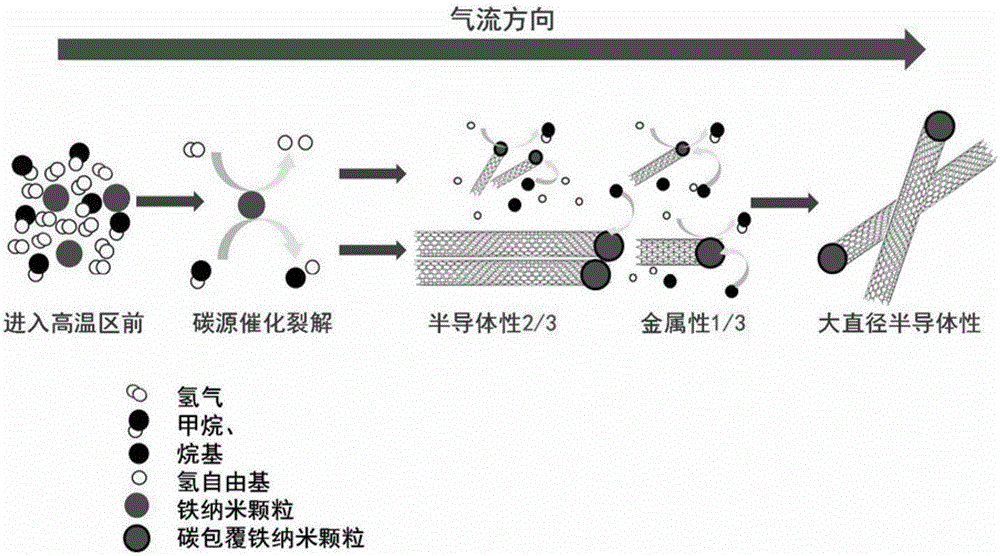

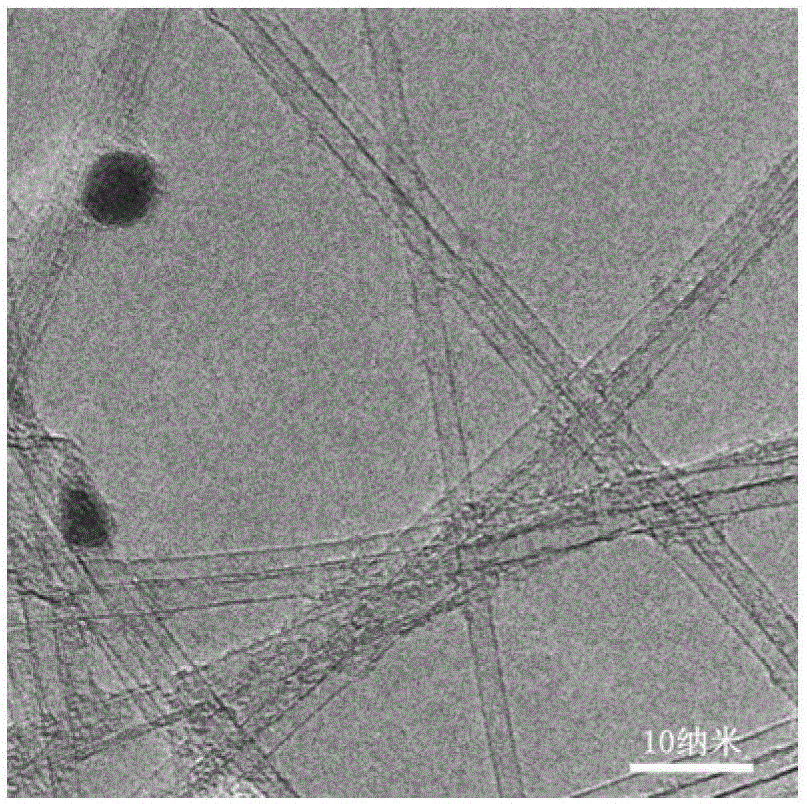

Method for growing high-quality semiconductor single-walled carbon nanotube through in-situ weak hydrogen etching

ActiveCN103011130AQuality improvementGood semiconductor performanceCarbon nanotubesNanotechnologyHydrogenSulfur

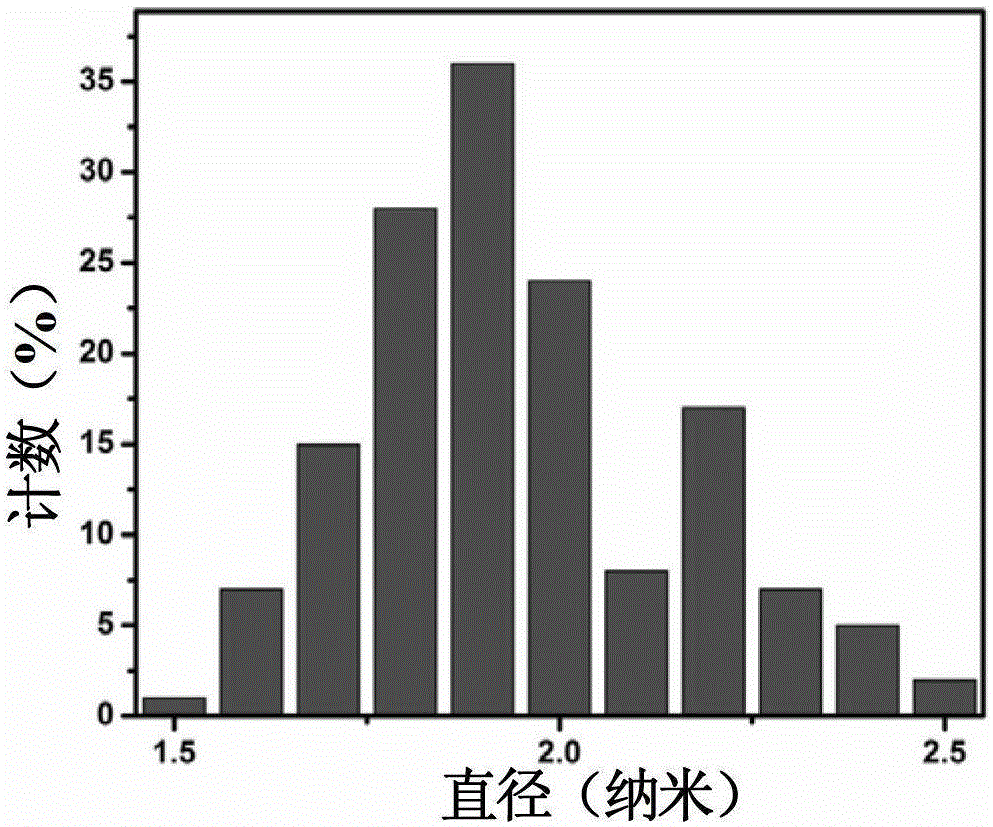

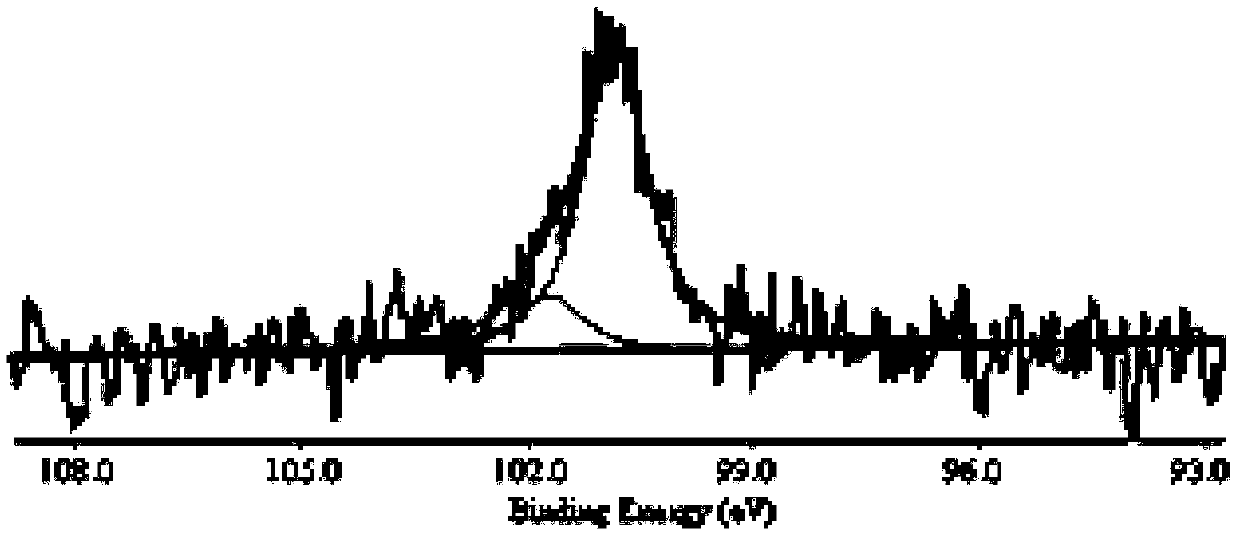

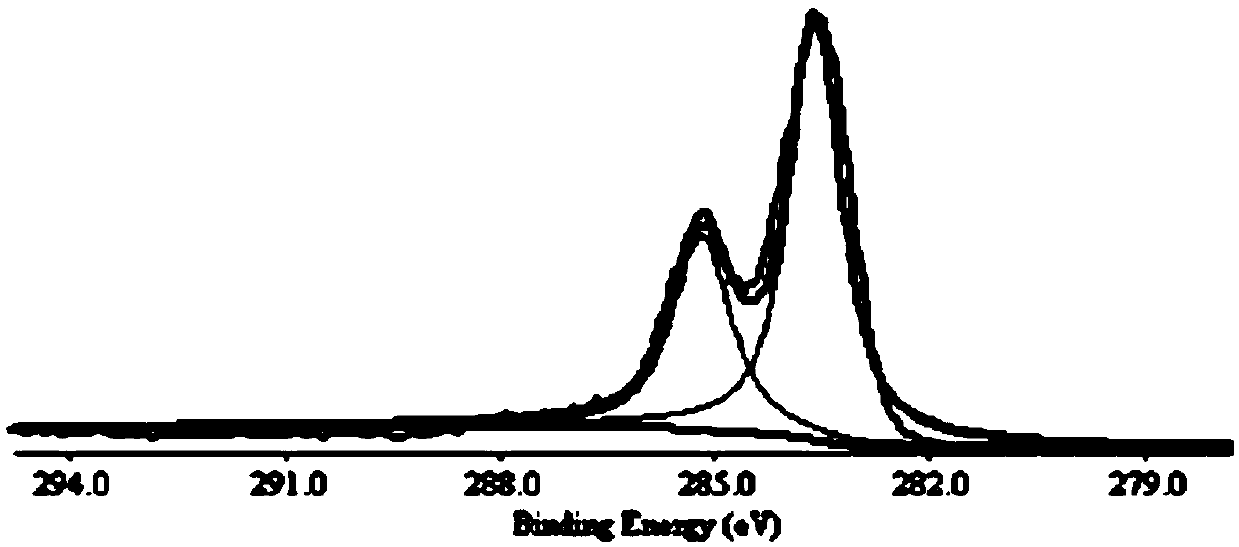

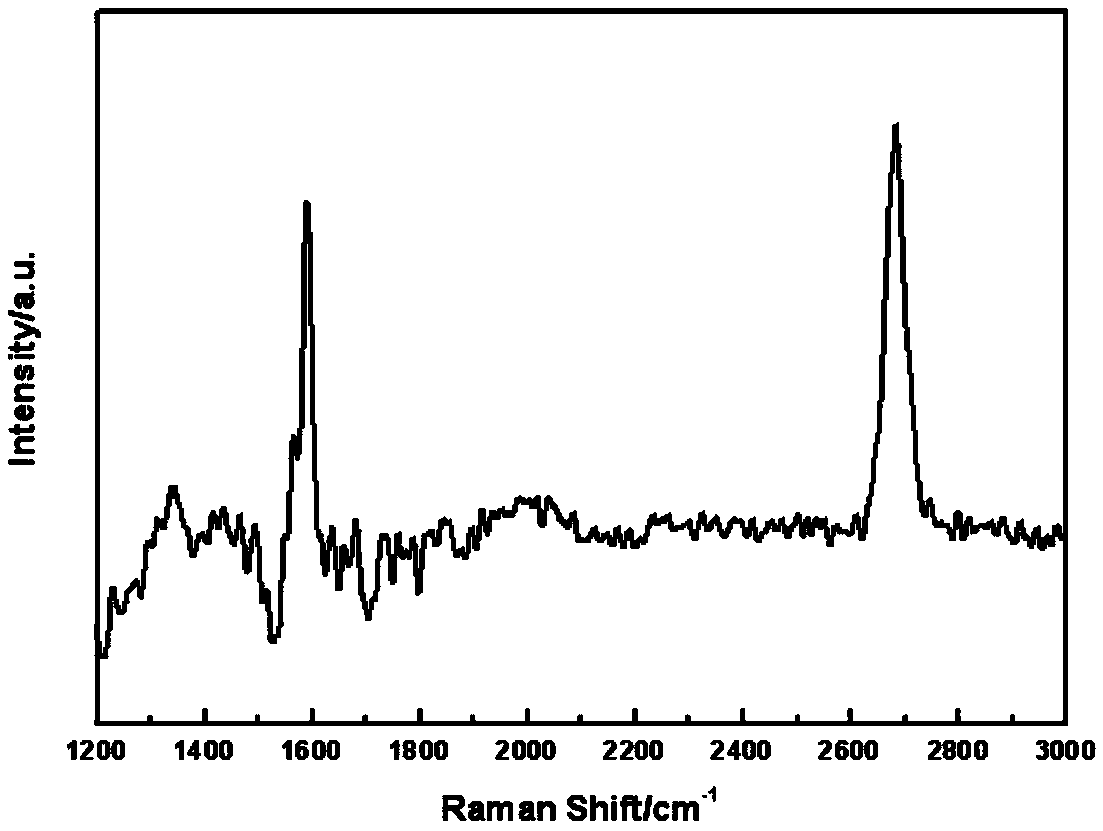

The invention relates to the field of fabrication of a high-quality semiconductor single-walled carbon nanotube, in particular to a method for directly growing the high-quality semiconductor single-walled carbon nanotube through in-situ weak hydrogen etching. A metallic and small-diameter single-walled carbon nanotube can be etched in situ at a certain reaction temperature by regulating and optimizing a flow of carrier gas, namely hydrogen and under the conditions of taking dicyclopentadienyl iron as a catalyst precursor, sulfur powder as a growth promoter and organic low-carbon hydrocarbon as a carbon source; and the high-quality semiconductor-superior single-walled carbon nanotube is finally obtained. The content of the semiconductor single-walled carbon nanotube is greater than or equal to 91wt%, the diameter distribution is between 1.5nm and 2.5nm, and the highest concentrated oxidation temperature reaches 800 DEG. With the adoption of the method, the massive, fast and low-cost controlled growth of the semiconductor single-walled carbon nanotube with the narrower diameter distribution and the high quality is realized, and the problems such as serious damages to a sample due to a strong etching agent, complexity of a fabrication process, low output and high cost during a selective fabrication course of a conduction-superior single-walled carbon nanotube can be effectively solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for realizing epitaxial growth of wafer level graphene on 4H/6H-SiC carbon surfaces

The invention discloses a method for realizing epitaxial growth of wafer level graphene on 4H / 6H-SiC carbon surfaces, which aims to realize that when epitaxial growth of wafer level graphene is realized by an existing method, the area of produced graphene is too small and uniformity of the graphene is low. The method includes steps of cleaning and treating the 4H / 6H-SiC carbon surfaces to remove organic residues and ion pollutant on the surfaces, filling hydrogen to realize hydrogen etching for the 4H / 6H-SiC carbon surfaces to remove scratches of the surfaces, and forming regular step-shaped strips; feeding silane to remove oxide caused by hydrogen etching on the surfaces; feeding argon flow to realize sublimation of silicon atoms under the condition of pressure of 2mbar by the aid of heating, and realizing reconstitution of surfaces of substrate in a sp2 mode by the aid of carbon atoms to form epitaxial graphene. The graphene prepared by the aid of the process method has larger area and fine uniformity, and the method can be applied to preparing wafer level epitaxial graphene materials.

Owner:XIDIAN UNIV

Method for reducing scratches on surface of epitaxial wafer

ActiveCN106783540AReduce processing timeReduce epitaxy defectsSemiconductor/solid-state device manufacturingLow speedHydrogen etching

The invention discloses a method for reducing scratches on the surface of an epitaxial wafer. The method comprises the following steps of (1) putting a silicon carbide substrate on a graphite substrate in a reaction chamber of a silicon carbide epitaxial system; (2) replacing a gas in the reaction chamber with argon for multiple times, and then introducing hydrogen into the reaction chamber, gradually increasing the flow of the hydrogen to 20-40L / min, setting the pressure of the reaction chamber to be 700-1,000mbar and gradually heating the reaction chamber to 1400-1500 DEG C; and (3) after reacting a set temperature, keeping all parameters invariable and carrying out in-situ hydrogen etching treatment on the silicon carbide substrate for 10-60 minutes. According to the method disclosed by the invention, the substrate is treated by adopting low-speed hydrogen etching which tends to be isotropic under the conditions of a relatively low temperature, high pressure of the reaction chamber and low-flow hydrogen, so that the scratches on the surface of the substrate can be effectively reduced and weakened, other epitaxial defects derived from the scratches in an epitaxial layer are reduced, the method is compatible with an existing epitaxy process and core process parameters do not need to be modified.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

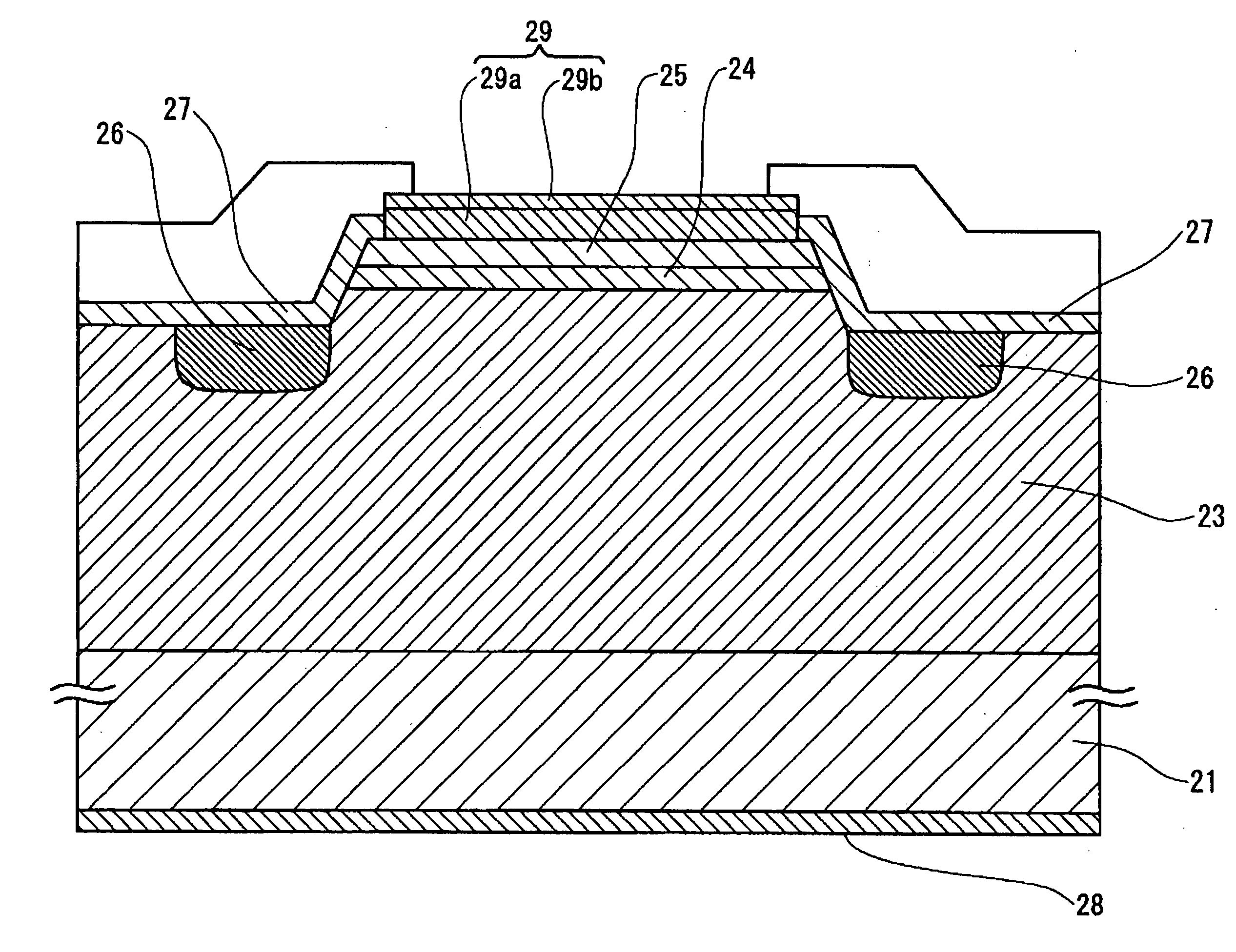

Bipolar semiconductor device and process for producing the same

Production of a bipolar semiconductor device having at least part of a region wherein at current passage electrons and holes re-couple with each other formed of an epitaxial layer of silicon carbide grown from a surface of silicon carbide substrate, wherein the epitaxial layer is formed by first performing hydrogen etching of a surface of silicon carbide substrate and thereafter effecting epitaxial growth of silicon carbide from the etched surface. Further propagation of a basal plane dislocation to the epitaxial layer can be reduced by subjecting the surface of silicon carbide substrate to chemical mechanical polishing prior to the hydrogen etching.

Owner:THE KANSAI ELECTRIC POWER CO +1

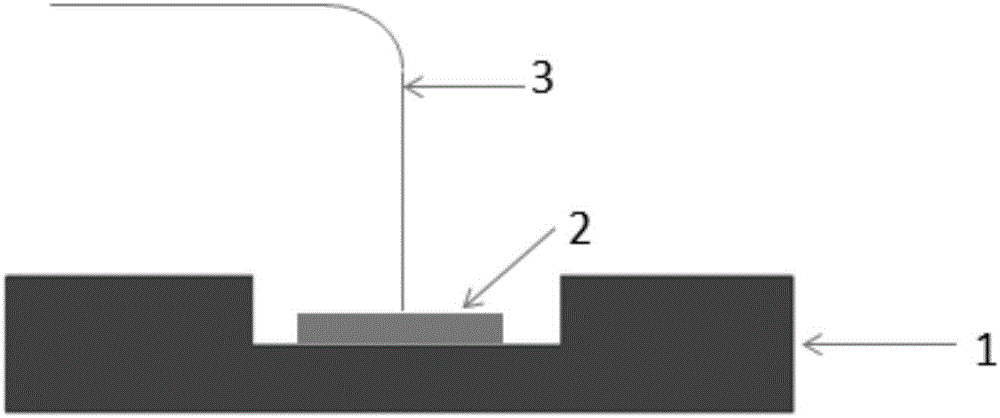

Method for preparing single-layer graphene without buffer layer on SiC substrate

ActiveCN107344868AAddressing Issues Affecting Graphene MobilitySolve the transfer problemHydrogen atomHydrogen etching

The invention relates to a method for preparing single-layer graphene without a buffer layer on a SiC substrate. The method comprises the following steps: performing hydrogen etching on a silicon surface of the SiC substrate to form regular step morphology; introducing argon gas and growing a graphene buffer layer; performing hydrogen annealing on the SiC substrate with only a layer of graphene buffer layer on the surface to insert the hydrogen atom between the graphene buffer layer and the SiC substrate, so that the graphene buffer layer becomes single-layer graphene. According to the method provided by the invention, a problem that the graphene migration rate is influenced by the buffer layer formed when graphene is grown on the silicon surface of the SiC substrate in a SiC pyrolysis method is solved; meanwhile, real single-layer graphene without a buffer layer is obtained and can be directly applied to a radio-frequency device.

Owner:SHANDONG UNIV

Preparation method of epitaxially-growing silicon carbide-graphene film

InactiveCN106435723AReduce defectsQuality improvementPolycrystalline material growthFrom chemically reactive gasesHydrogen etchingCvd graphene

The invention relates to the technical field of function materials, in particular to a preparation method of an epitaxially-growing silicon carbide-graphene film. The preparation method of the epitaxially-growing silicon carbide-graphene film comprises steps as follows: (1) preparation of silicon carbide-graphene; (2) epitaxial growth of the silicon carbide-graphene film. Continuous growth of silicon carbide-graphene is realized, so that conventional common steps of hydrogen etching and silicon enrichment reproduction required for growing graphene on silicon carbide are omitted, the phenomena of lattice imperfection and severe reduction of surface silicon enrichment due to hydrogen etching are reduced, and graphene has fewer defects, has about four layers distributed uniformly and has better crystal quality.

Owner:SHAANXI JUJIEHAN CHEM CO LTD

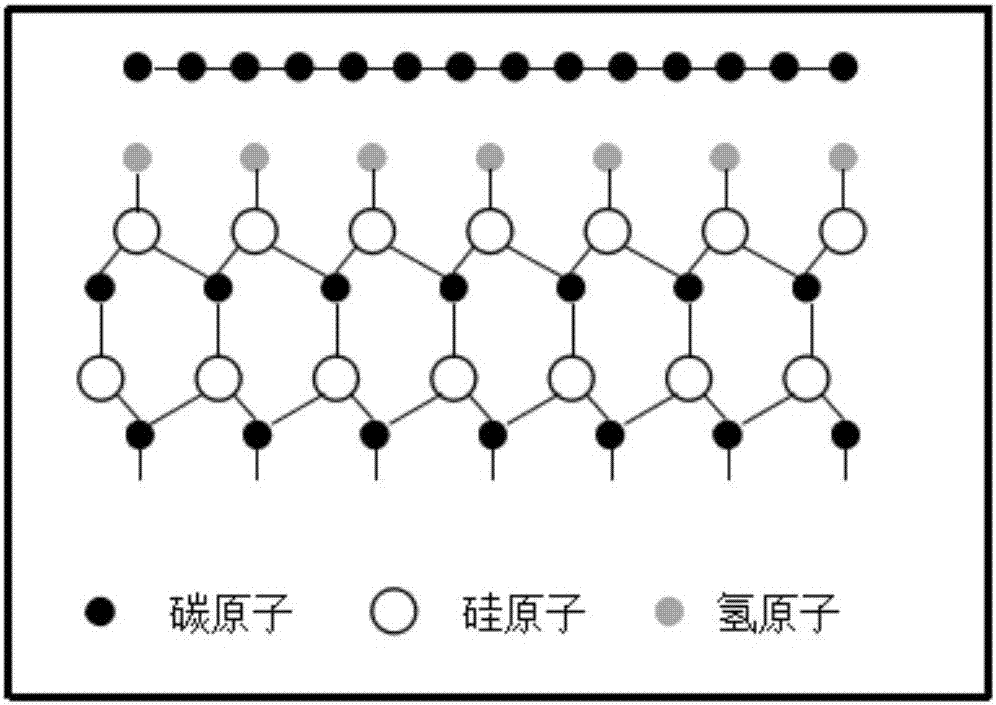

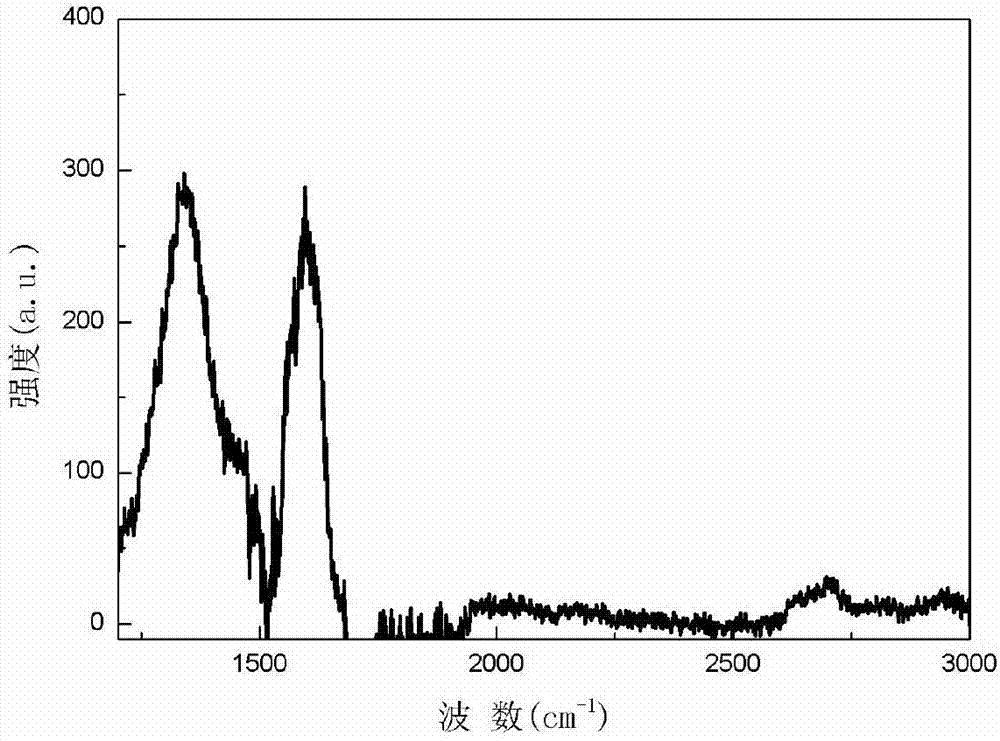

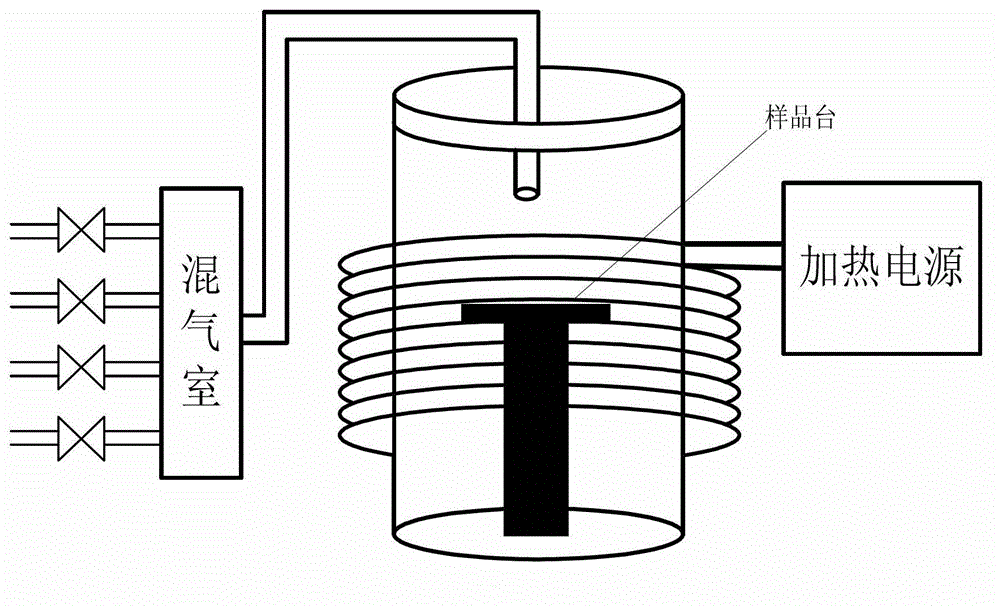

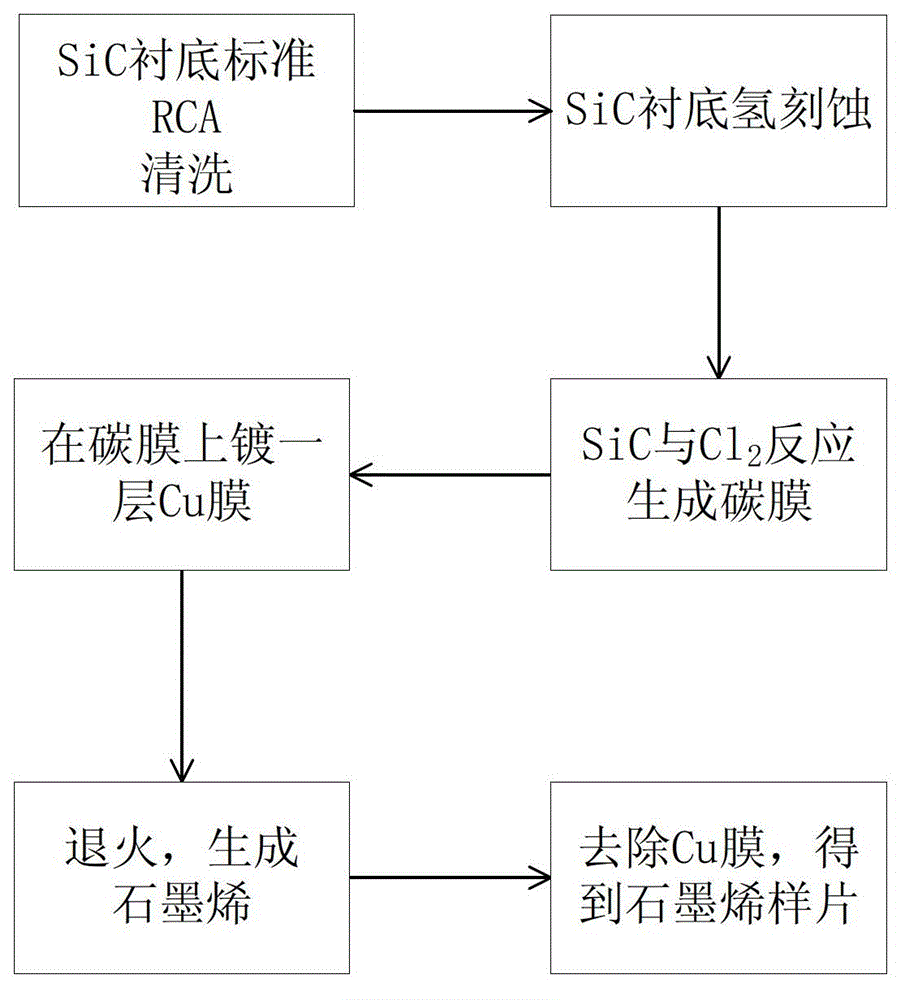

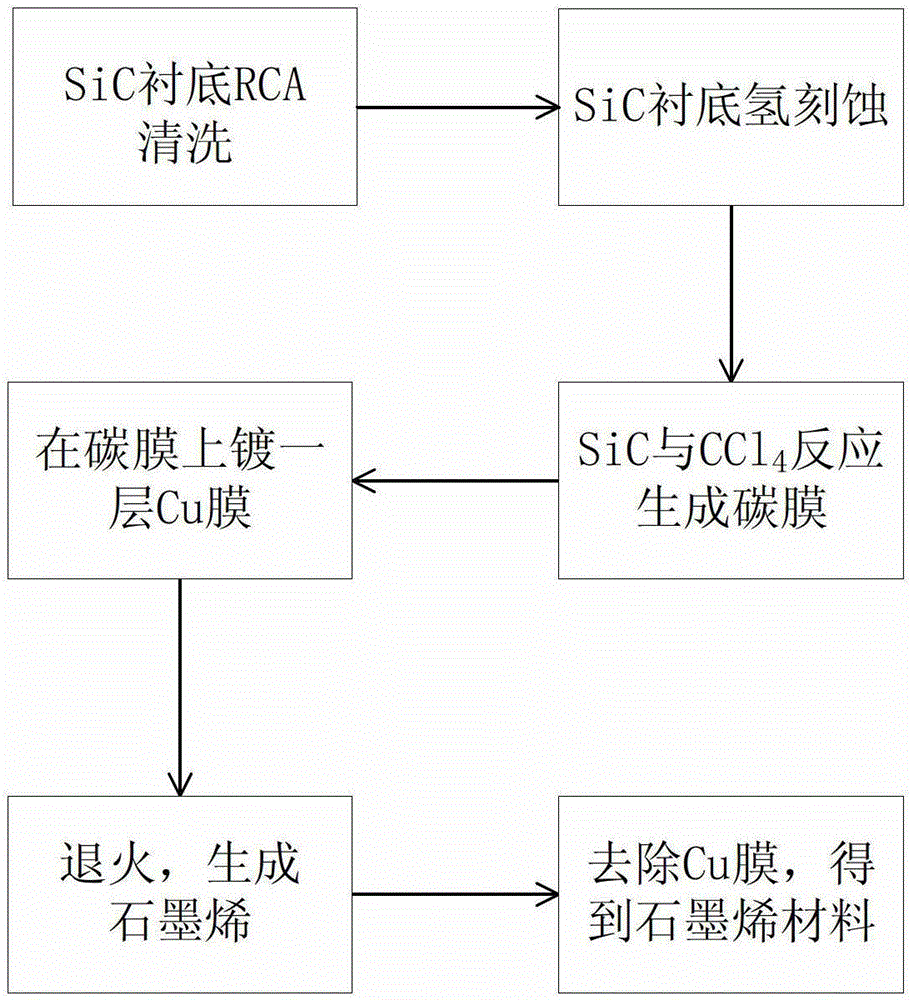

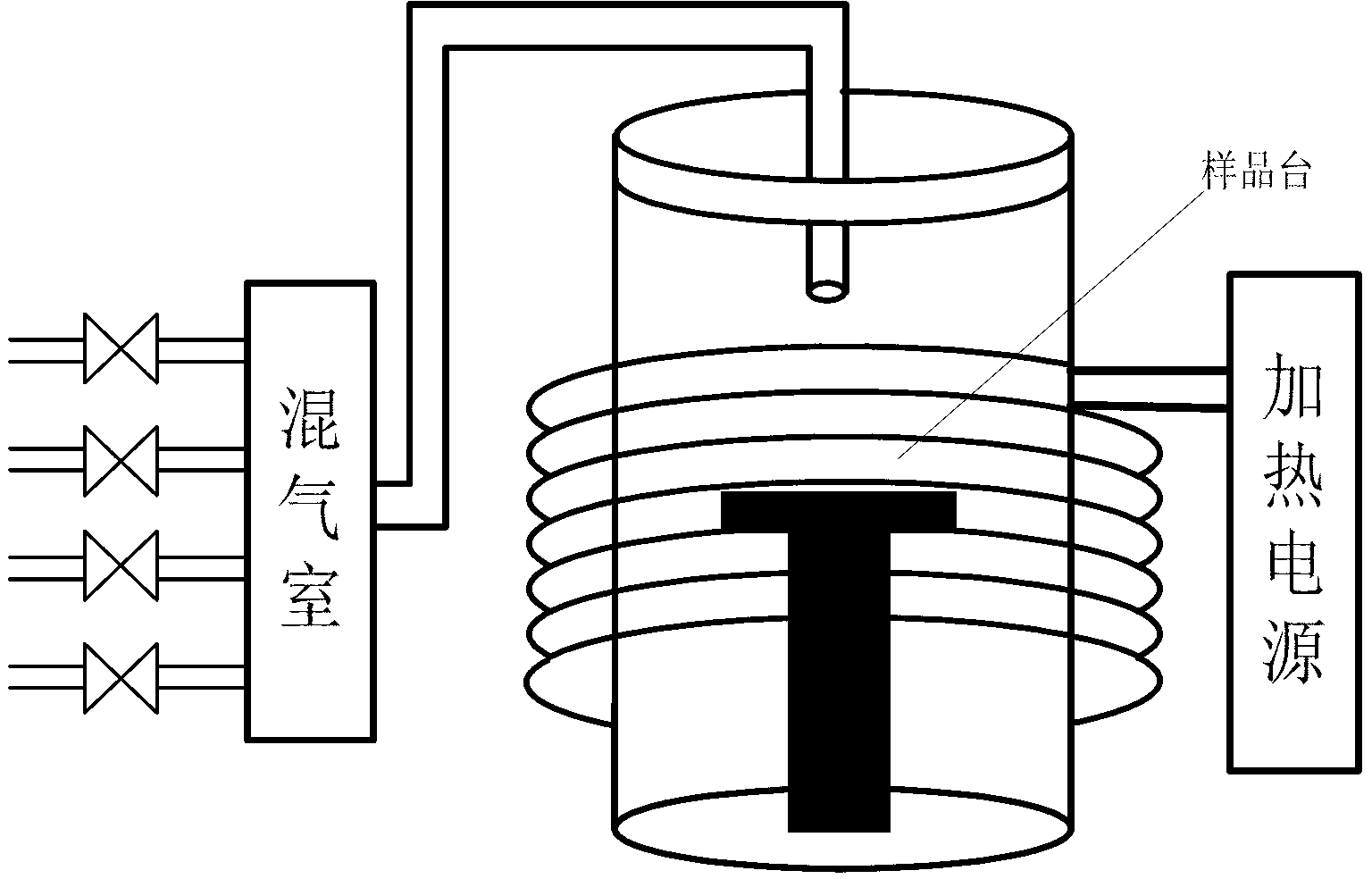

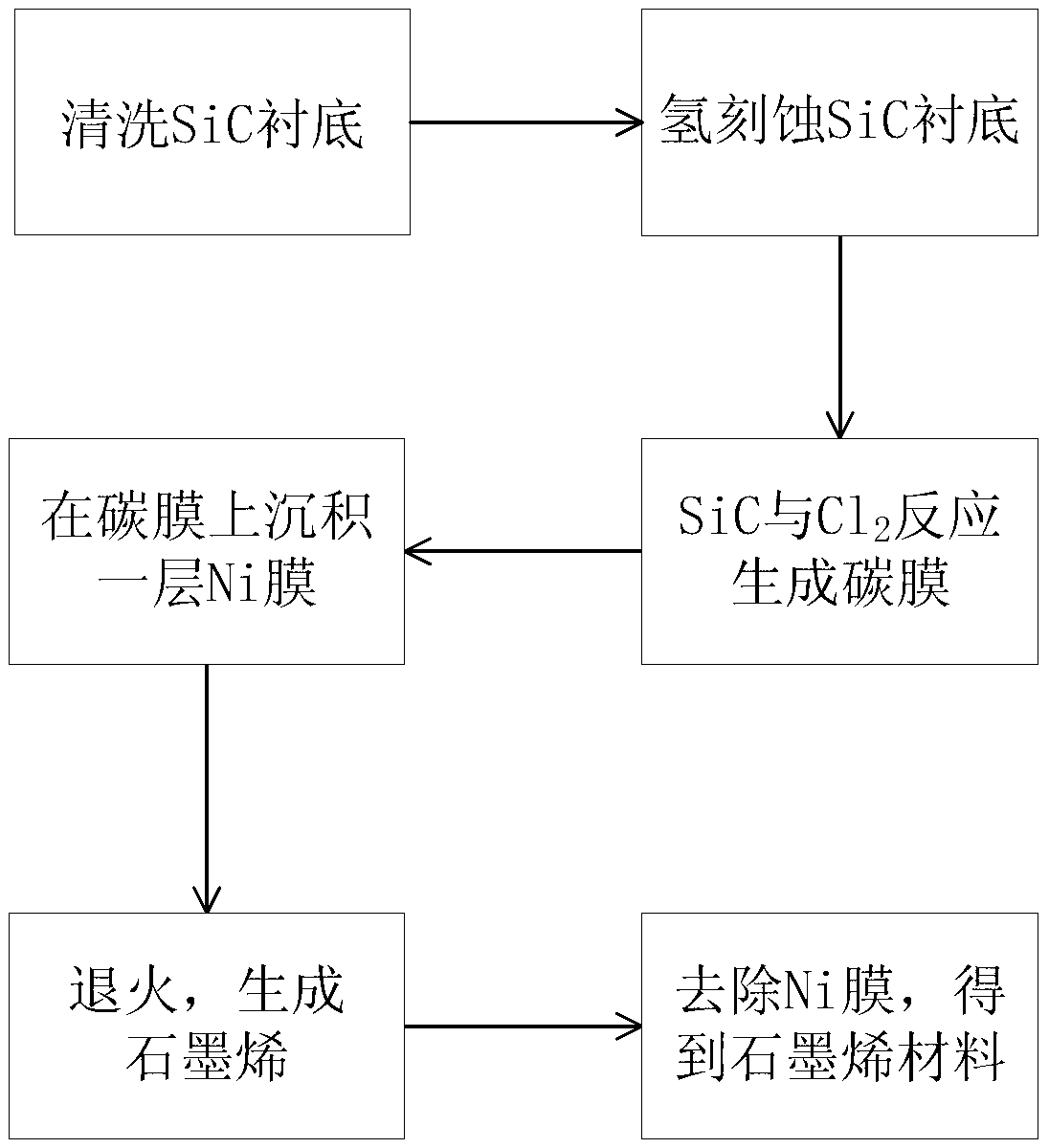

Preparation method of graphene on SiC substrate based on Cu film annealing and chlorine reaction

The invention discloses a preparation method of graphene on an SiC substrate based on Cu film annealing and chlorine reaction and mainly solves the problem that graphene prepared in the prior art has small area, can not be used for large-scale production and has non-uniform layers, multiple defects and unstable carrier mobility. The preparation method comprises the following steps: cleaning an SiC sample sheet; (2) putting the cleaned SiC sample sheet into graphene growth equipment and carrying out hydrogen etching on the SiC sample sheet; (3) introducing mixed gas of Ar gas and Cl2 into a reaction chamber and reacting SiC with Cl2 for 4-10 minutes at the temperature of 700-1,100 DEG C to generate a carbon film; (4) plating a Cu film on the generated carbon film; (5) putting a carbon film sample sheet plated with the Cu film into Ar gas and annealing for 15-25 minutes at the temperature of 900-1,200 DEG C to generate the graphene; and (6) removing the Cu film from a graphene sample sheet. The graphene prepared by the method has the advantages of smooth surface, good continuity and low porosity and can be used in the fields of biology, micro-electronics, chemicals and the like.

Owner:XIDIAN UNIV

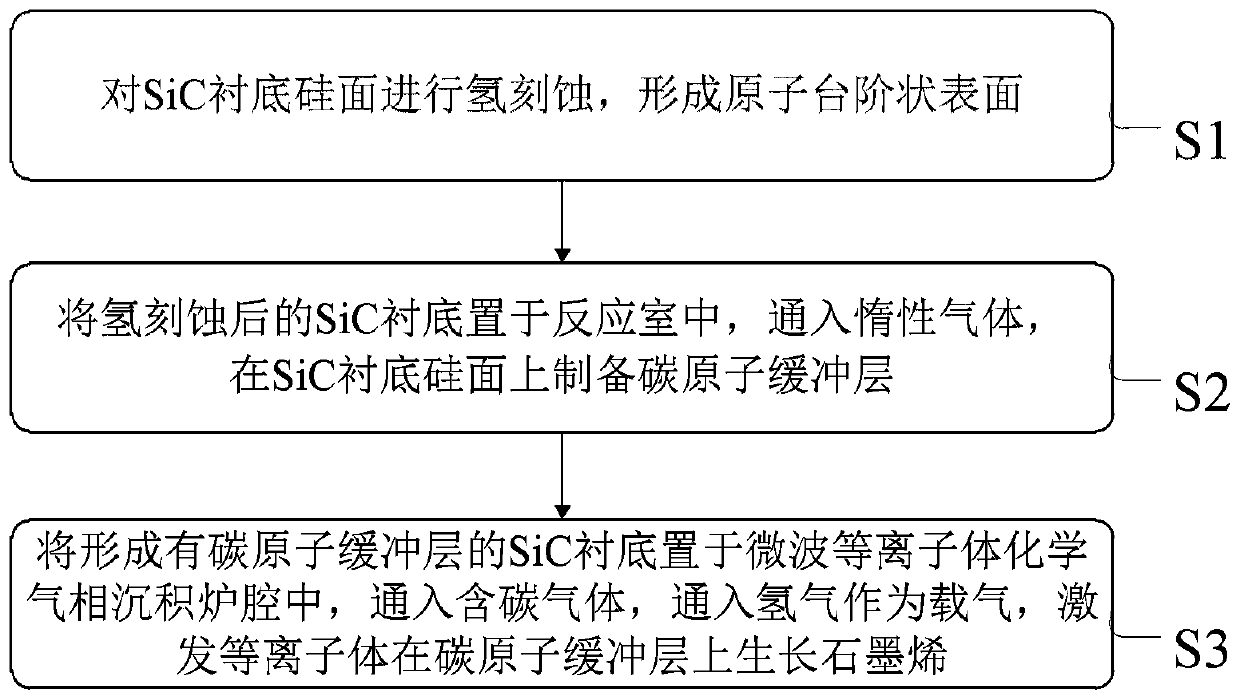

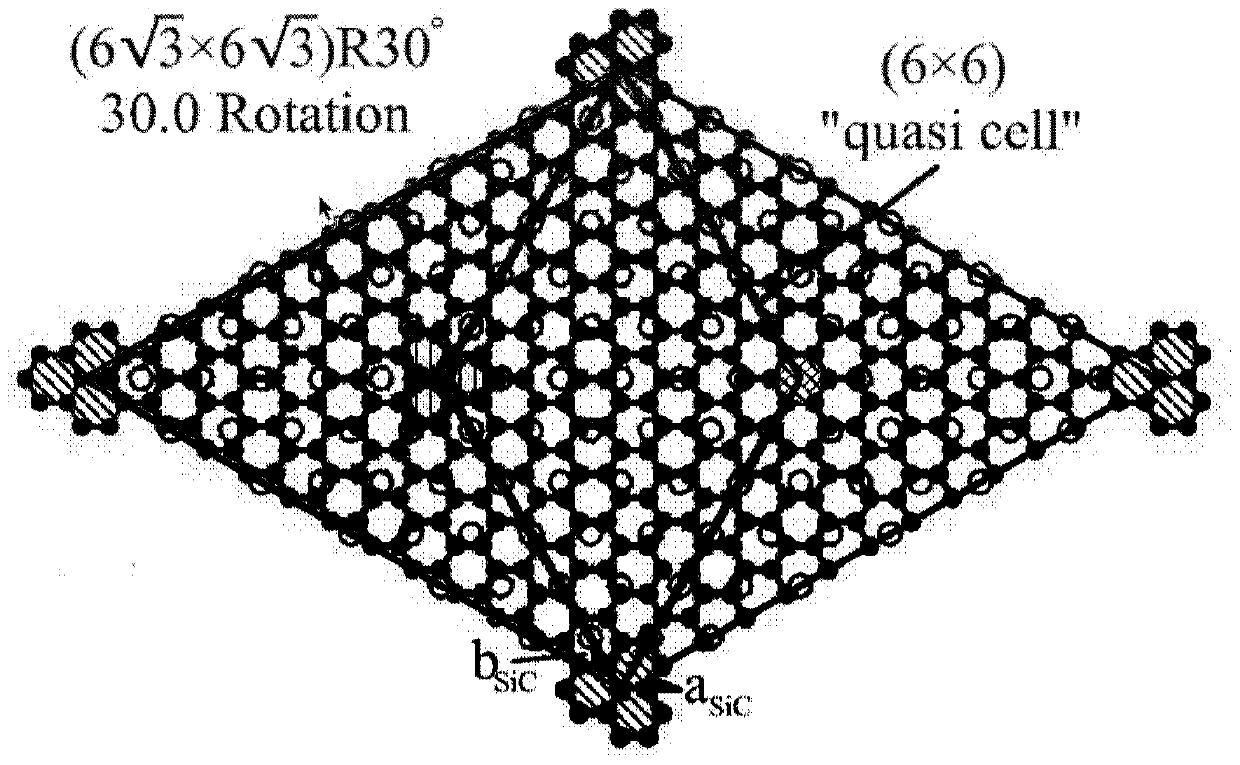

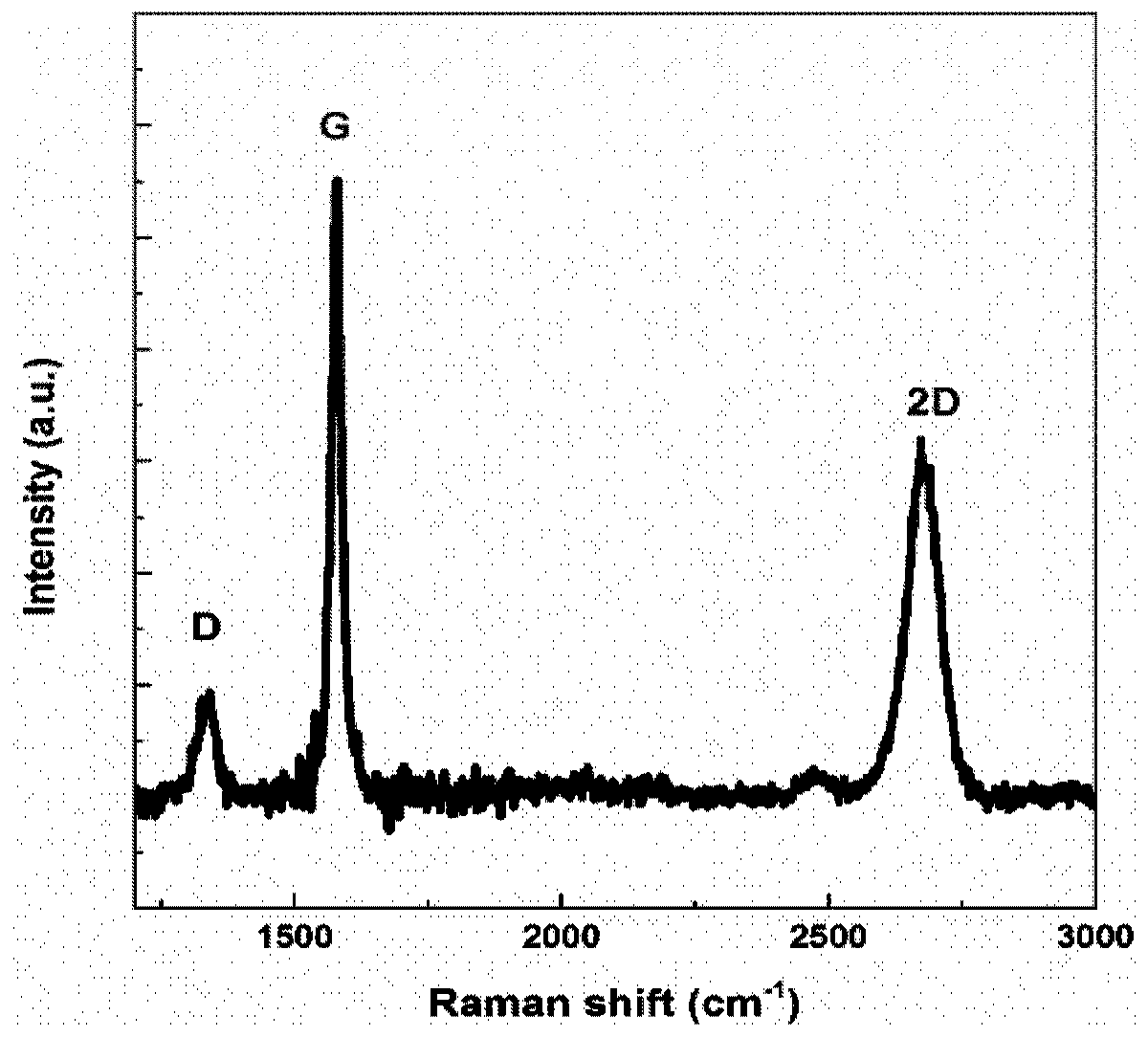

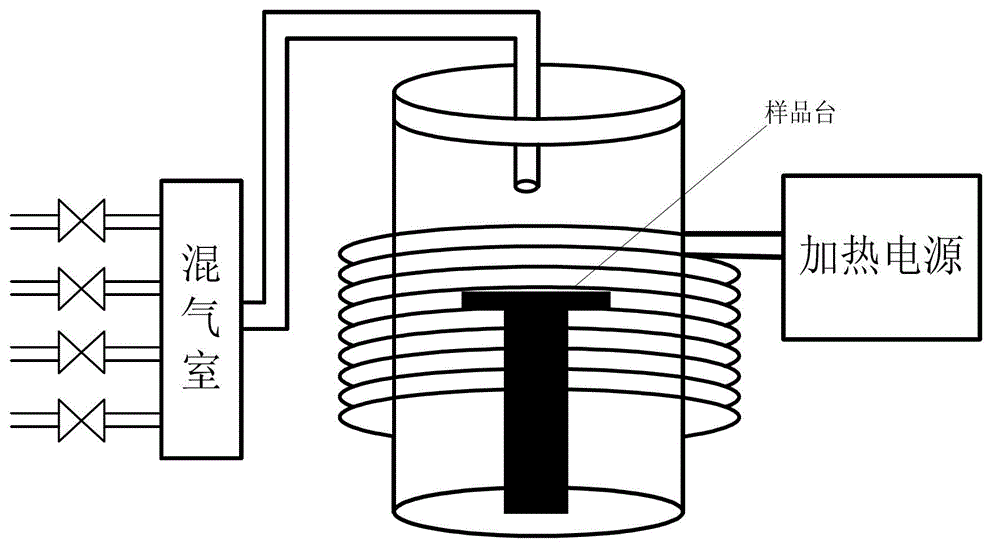

Graphene preparation method based on microwave plasma chemical vapor deposition

ActiveCN109852944AThe preparation process is easy to controlLow reaction temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingReaction rateReaction temperature

The invention provides a graphene preparation method. The graphene preparation method comprises the steps that hydrogen etching is carried out on a SiC substrate silicon face to form an atom step-shaped surface; a SiC substrate subjected to hydrogen etching is arranged in a reaction chamber, inert gas is fed into the reaction chamber, and a carbon atom buffer layer is prepared on the SiC substratesilicon face; and the SiC substrate on which the carbon atom buffer layer is formed is arranged in a microwave plasma chemical vapor deposition furnace chamber, carbon gas is fed with hydrogen serving as carrier gas, and plasma is stimulated to grow graphene on the buffer layer. The graphene prepared through the method can be directly manufactured into a device without transferring or following treatment, and device preparation is facilitated; by means of the application of the plasma, the thermal stress caused by a reaction temperature and the high temperature is reduced, preparation of thegraphene is more controllable, application of the graphene device is facilitated, the reaction time is effectively shortened, and the reaction rate is accelerated; and the carbon atom buffer layer serves as a middle layer, the defect that in a pyrolysis method, the migration rate of the graphene is reduced by the buffer layer is avoided, and the graphene quality is optimized.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

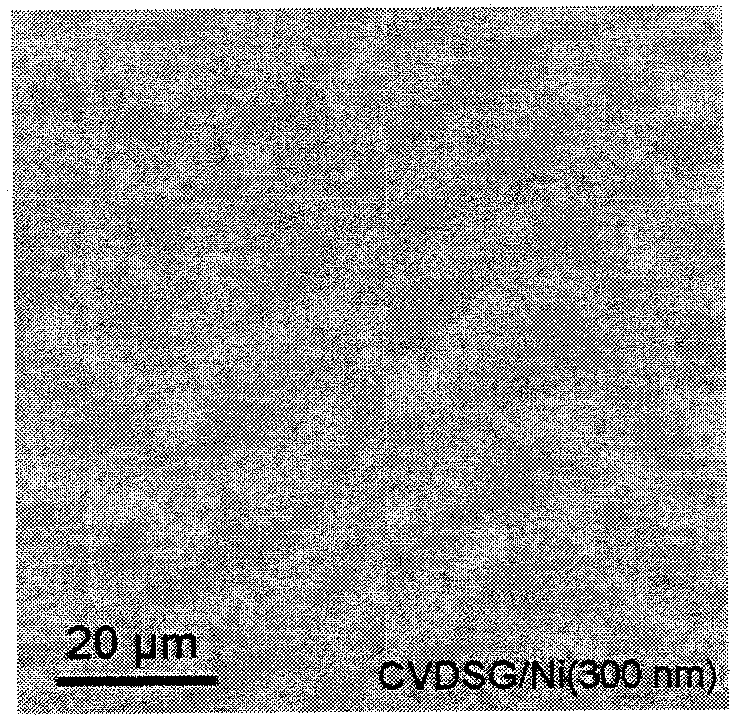

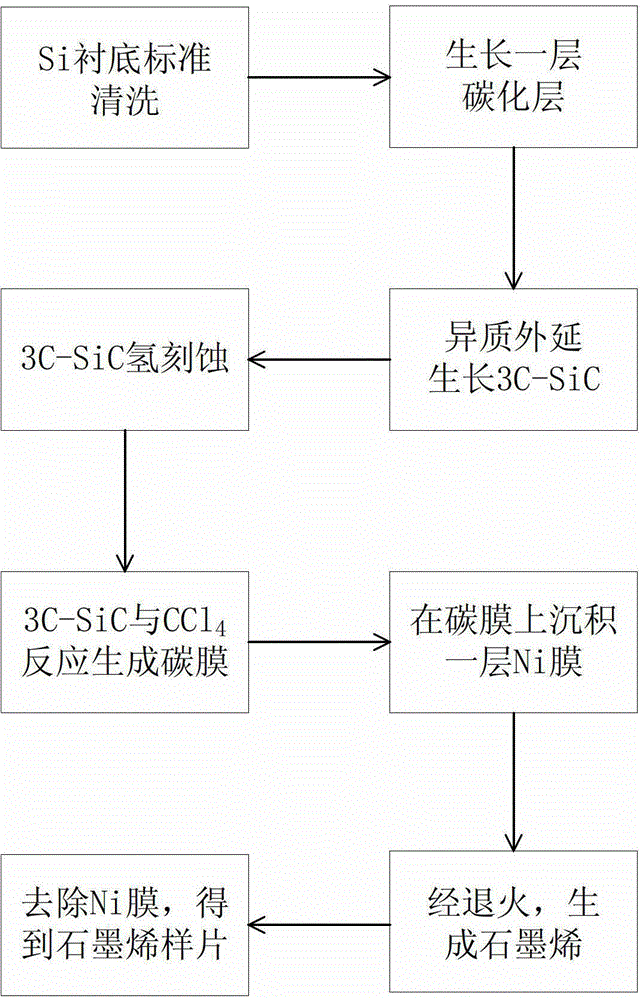

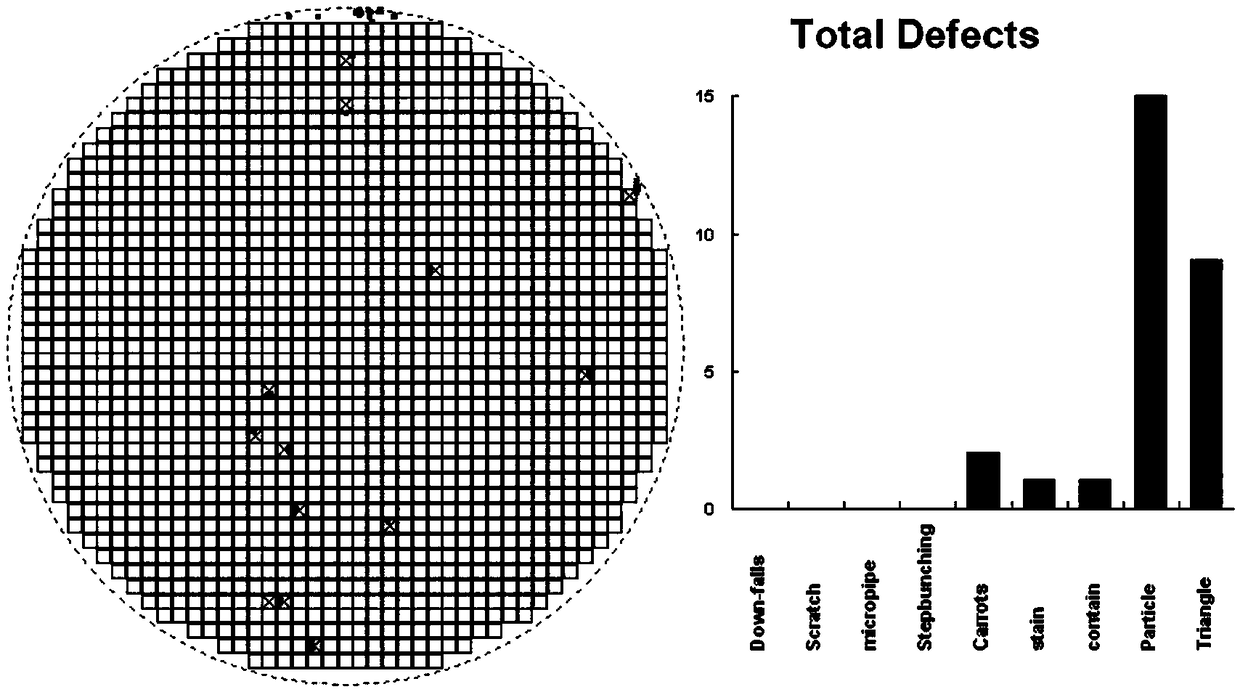

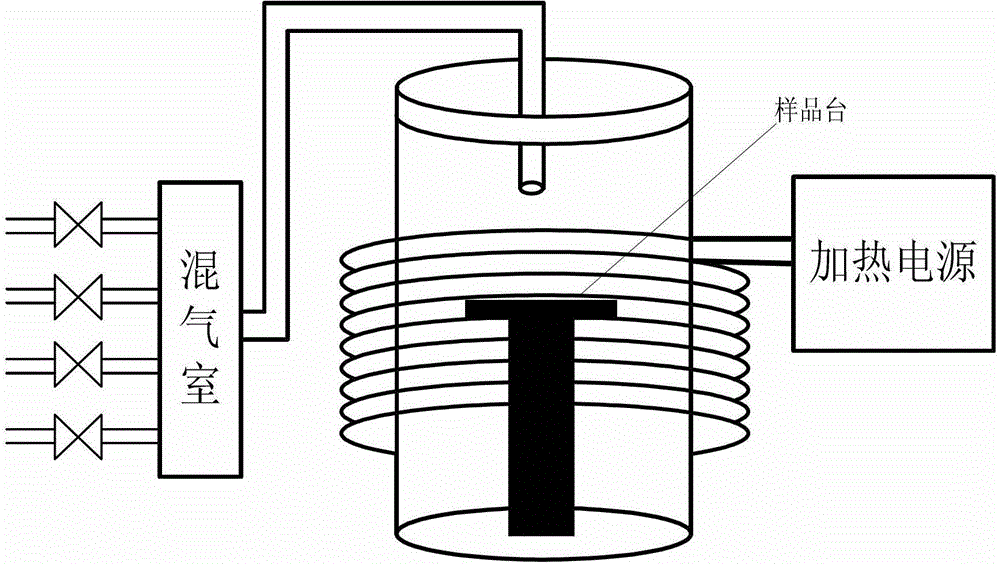

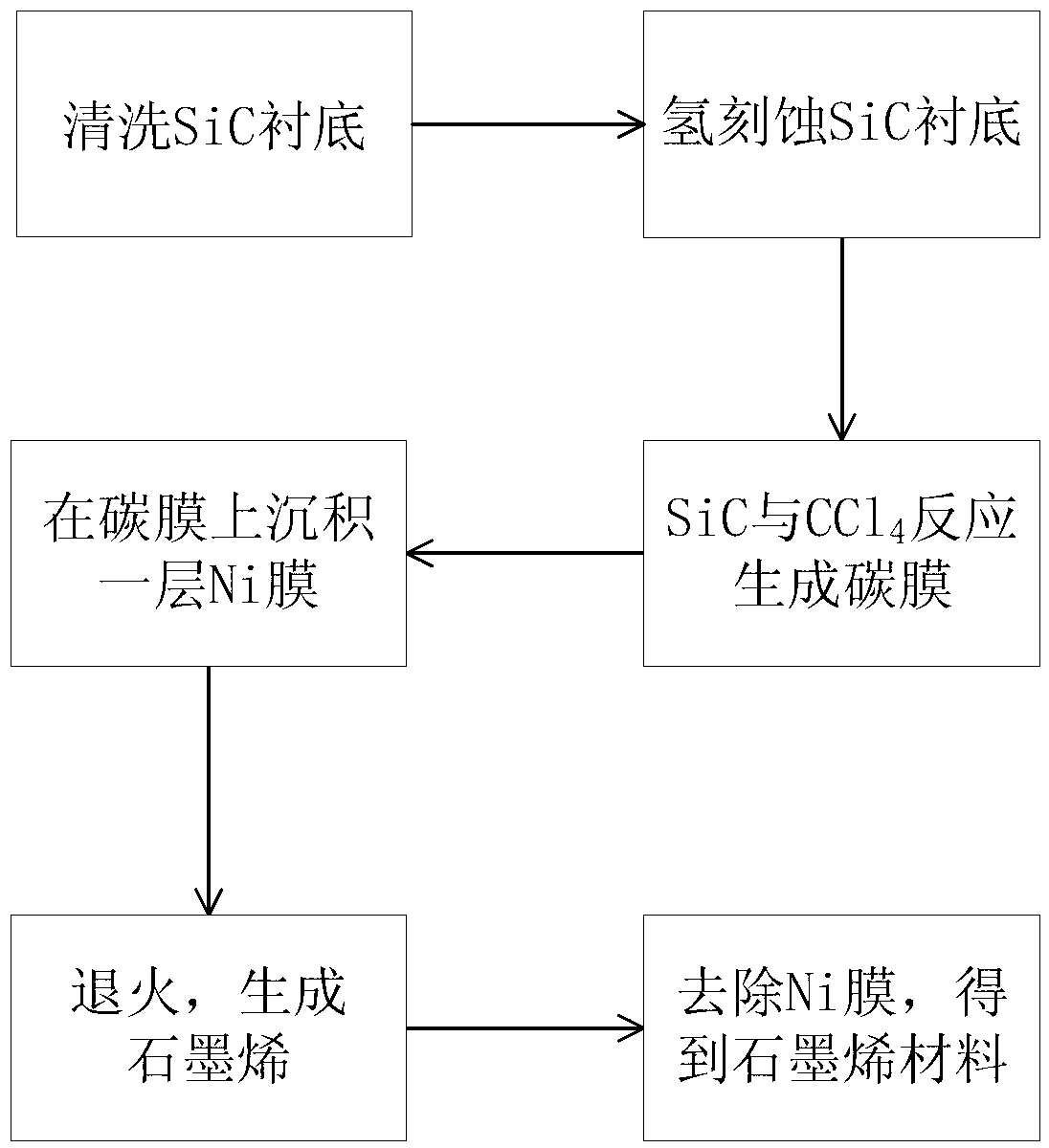

Preparation method of large-area graphene on Si substrate based on Ni film annealing

The invention discloses a preparation method of large-area graphene on an Si substrate based on Ni film annealing and mainly solves the problems of small area, poor continuity and non-uniform layers of graphene prepared in the prior art. The preparation method comprises the following implementation steps: growing a carburization layer on the 4-12-inch Si substrate to be used as a transition and growing a 3C-SiC heteroepitaxial film at the temperature of 1200 DEG C to 1350 DEG C by utilizing growth gas sources C3H8 and SiH4; carrying out hydrogen etching on the grown 3C-SiC film and removing a compound generated by etching; reacting 3C-SiC with gaseous CCl4 at a temperature of 800-1,000 DEG C to generate a carbon film; electron beam-depositing an Ni film on the carbon film, putting a sample sheet plated with the Ni film into Ar gas and annealing for 10-20 minutes at a temperature of 1,000-1,250 DEG C to generate a graphene sample sheet; and finally removing the Ni film from the graphene sample sheet. The graphene prepared by the method has the advantage that the area can reach 12 inches, the continuity is good, the surface is smooth, and the porosity is low. The graphene can be used for manufacturing microelectronic devices and biological sensors or sealing gas and liquid.

Owner:XIDIAN UNIV

Method for reducing the density of silicon carbide epitaxial surface defects

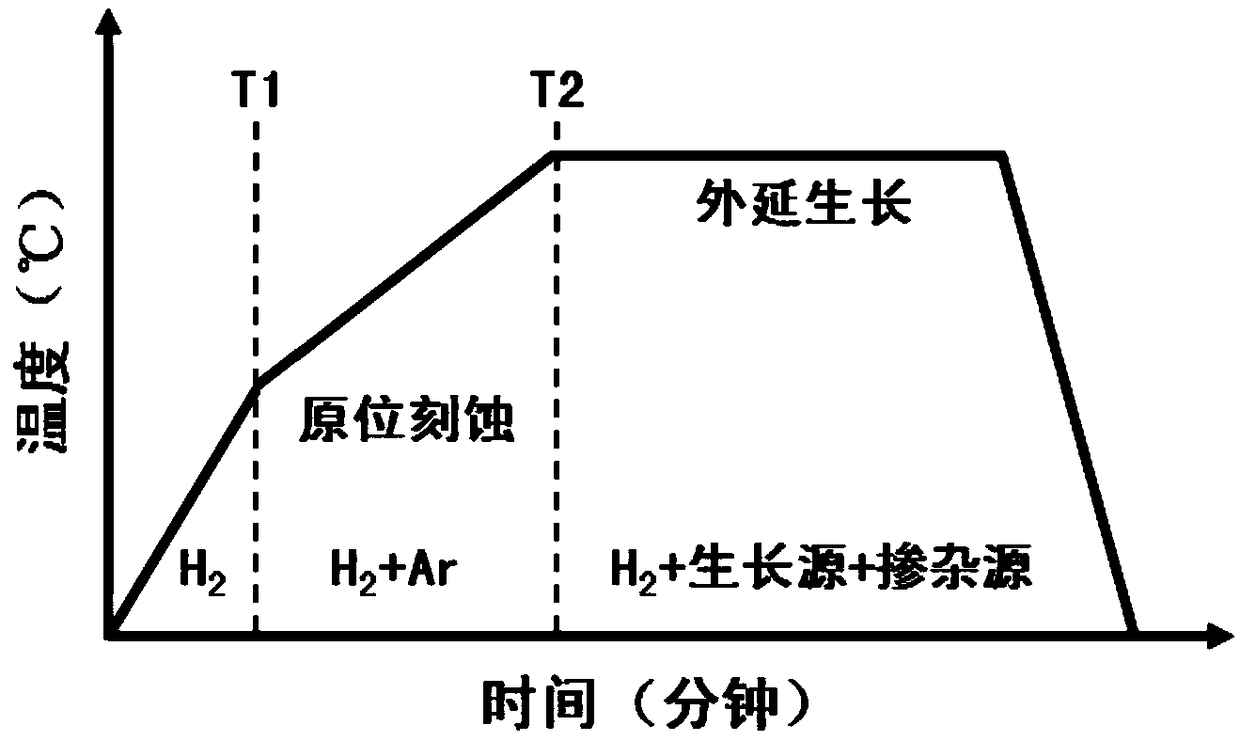

ActiveCN108878257AReduce unintentional injuriesReduce surface defect densitySemiconductor/solid-state device manufacturingHydrogenEtching

The invention discloses a method for reducing the density of silicon carbide epitaxial surface defects, a silicon carbide substrate is treated by in-situ composite etching with hydrogen-argon mixed atmosphere before epitaxial growth, by introducing relatively mild argon gas, the problem of large surface damage caused by pure hydrogen etching is solved, compared with pure hydrogen etching, the temperature field is more uniform, and the surface instability of the substrate in the initial epitaxial stage is reduced or even eliminated while the damaged layer introduced by the chemical mechanical polishing of the substrate is effectively treated, so that the defects of the surface extended into the epitaxial layer due to the substrate are greatly reduced, and the surface defect density in the epitaxial layer can be effectively reduced. The method of the invention is simple, feasible and compatible with the existing epitaxial process, and has high popularization value.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Cu film annealing based method for preparing large-area graphene on SiC substrate

The invention discloses a Cu film annealing based method for preparing large-area graphene on an SiC substrate, and mainly solves problems of poor continuity, high porosity and uneven layers of graphene prepared in the prior art. The method comprises the steps as follows: firstly, cleaning an SiC sample with an RCA cleaning method; secondly, performing hydrogen etching on the cleaned SiC sample; thirdly, feeding Ar gas and CCl4 gas into a gas mixing chamber for mixing, feeding the mixed gas into a reaction chamber, and enabling the CCl4 gas and the SiC to react and generate a carbon film; fourthly, plating a Cu film on the generated carbon film; fifthly, placing the sample plated with the Cu film in the Ar gas, annealing the sample at the temperature ranging from 900 DEG C to 1100 DEG C for 15 to 25 minutes, and enabling the carbon film to reconstruct the graphene; and sixthly, removing the Cu film from the graphene sample. The method has the advantages of good continuity and evenness and low porosity of the graphene and can be used in various fields of biology, optics, electricity, sensors and the like.

Owner:XIDIAN UNIV

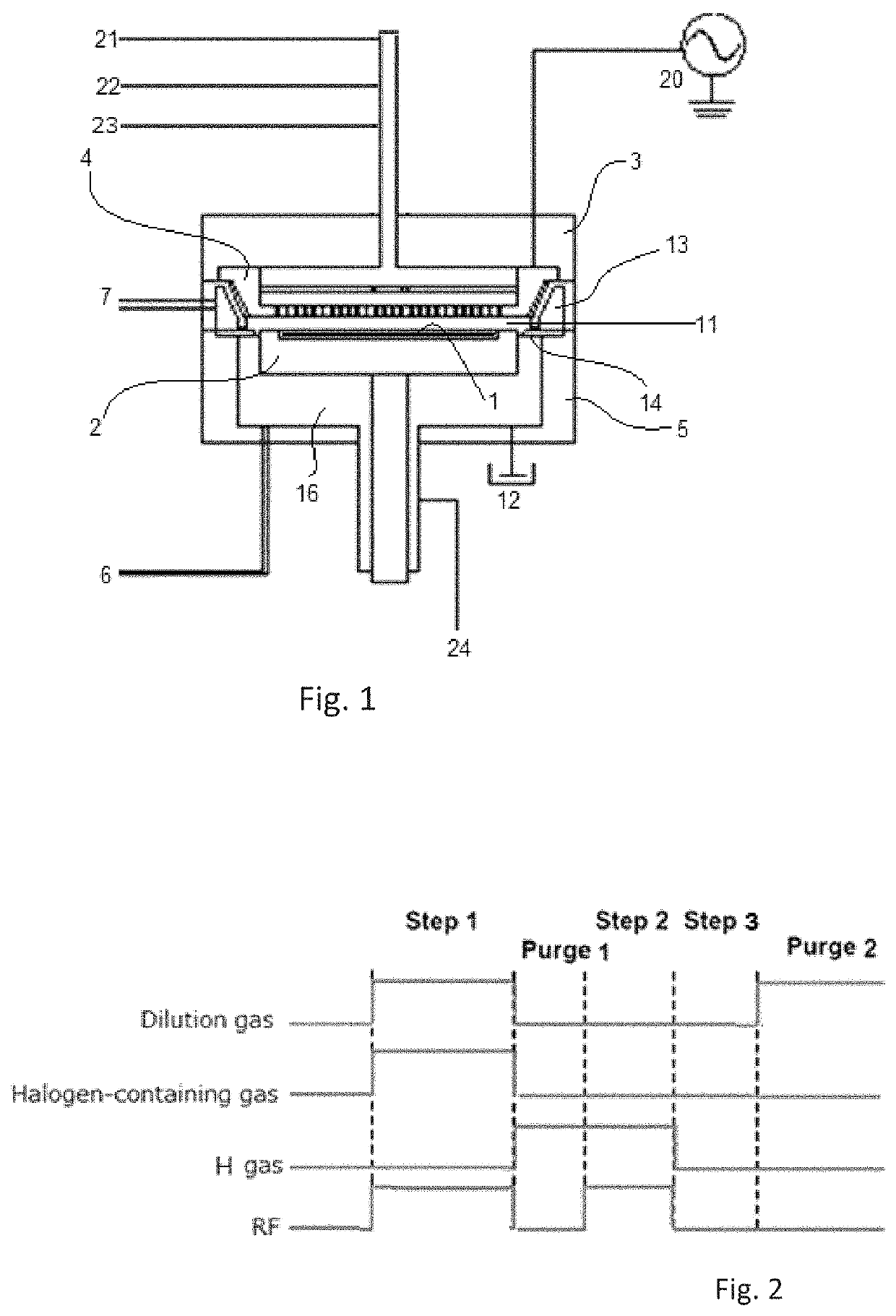

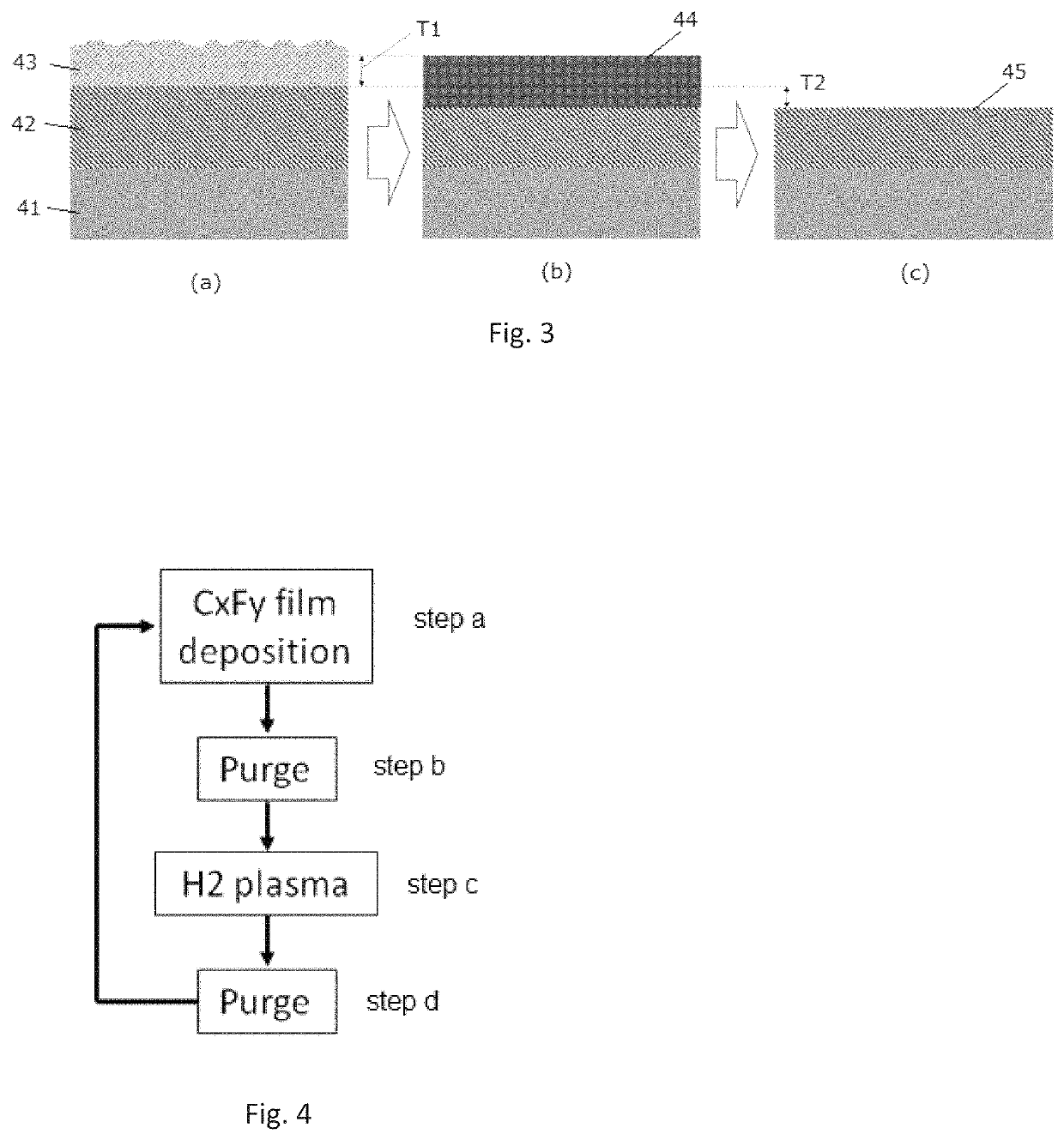

Method of atomic layer etching using hydrogen plasma

ActiveUS10504742B2Improve controllabilityEasy to operateSemiconductor/solid-state device manufacturingCarbon filmHydrogen halide

A method for etching a target layer on a substrate by a dry etching process includes at least one etching cycle, wherein an etching cycle includes: depositing a carbon halide film using reactive species on the target layer on the substrate; and etching the carbon halide film using a plasma of a non-halogen hydrogen-containing etching gas, which plasma alone does not substantially etch the target layer, thereby generating a hydrogen halide as etchant species at a boundary region of the carbon halide film and the target layer, thereby etching a portion of the target layer in the boundary region.

Owner:ASM IP HLDG BV

Method for preparing graphene on SiC substrate based on Ni film annealing and chlorine reaction

The invention discloses a method for preparing graphene on an SiC substrate based on Ni film annealing and chlorine reaction and mainly solves the problems of poor continuity and unsmooth surface of graphene prepared in the prior art. The preparation method comprises the following implementation steps: firstly, carrying out RCA cleaning on the SiC substrate; carrying out hydrogen etching on the cleaned SiC substrate and removing etching residues; introducing mixed gas of Ar gas and Cl2 into a quartz tube reaction chamber and reacting SiC with Cl2 for 3-8 minutes at the temperature of 700-1,100 DEG C to generate a carbon film; then electron beam-depositing an Ni film on the carbon film; putting a sample sheet deposited with the Ni film into Ar gas and annealing for 10-30 minutes at the temperature of 950-1,150 DEG C to generate the graphene; and finally removing the Ni film from a graphene sample sheet by utilizing mixed solution of hydrochloric acid and copper sulfate. The graphene generated by the method has the advantages of smooth surface, good continuity and low porosity and can be used for manufacturing microelectronic devices and biological sensors or sealing gas and liquid.

Owner:XIDIAN UNIV

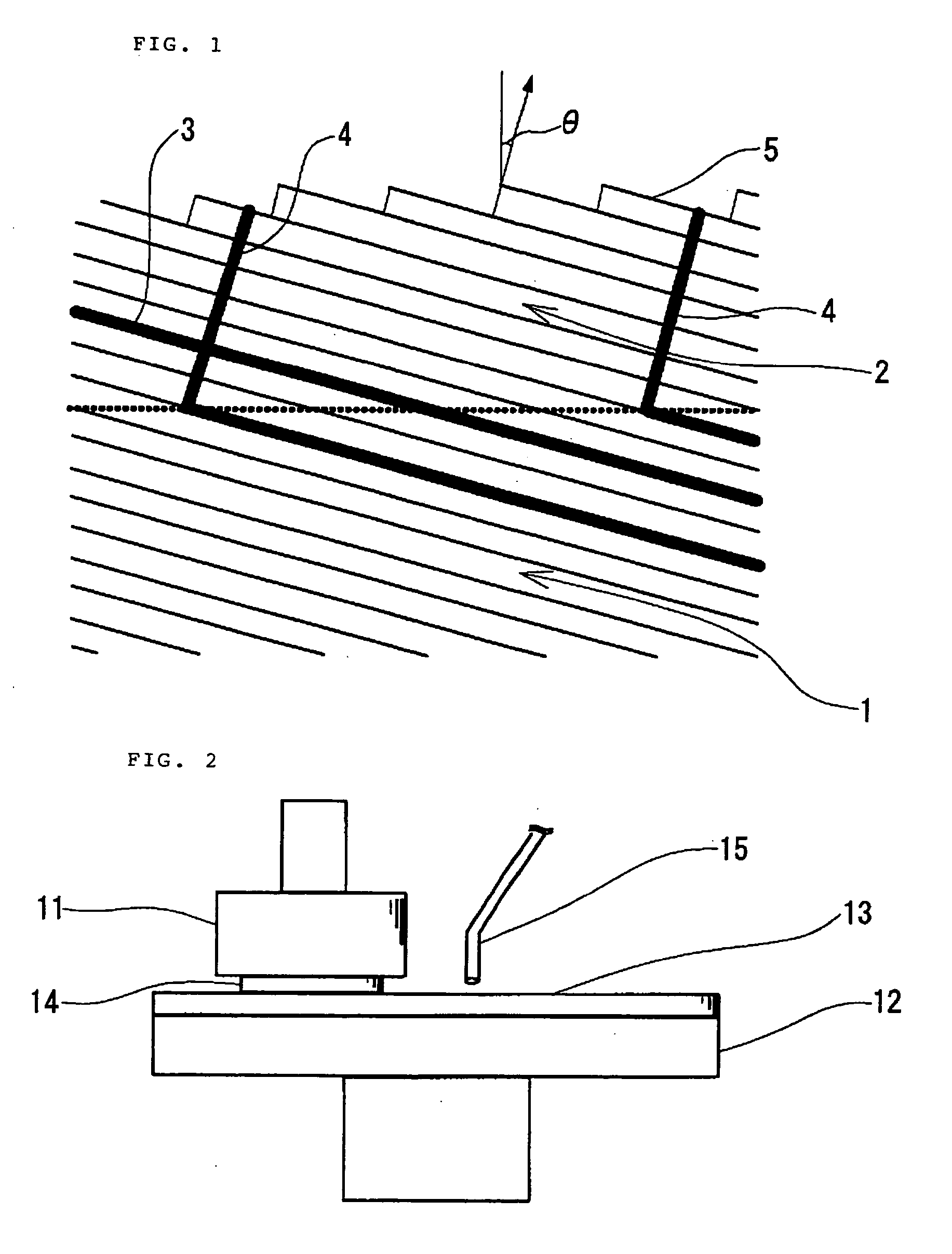

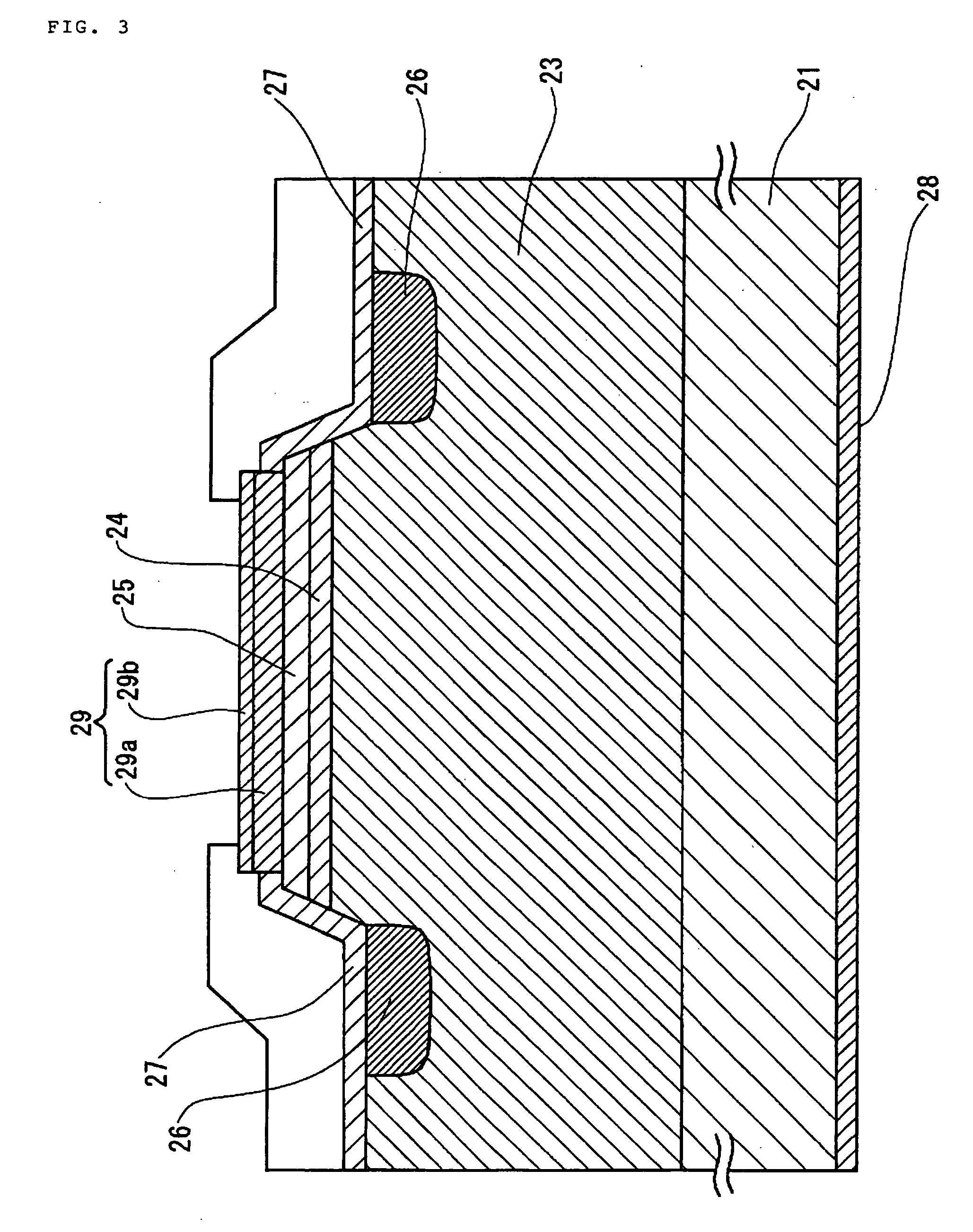

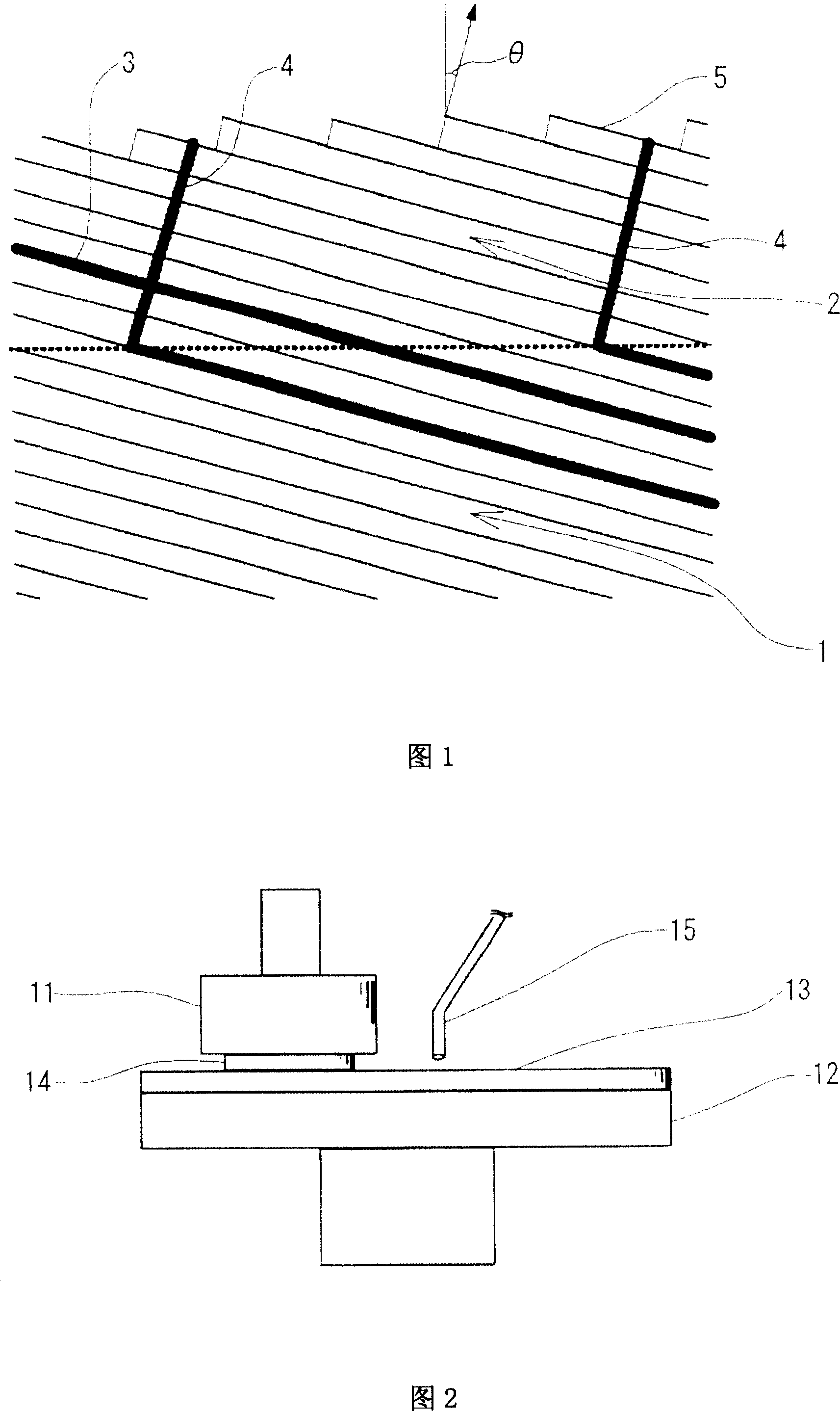

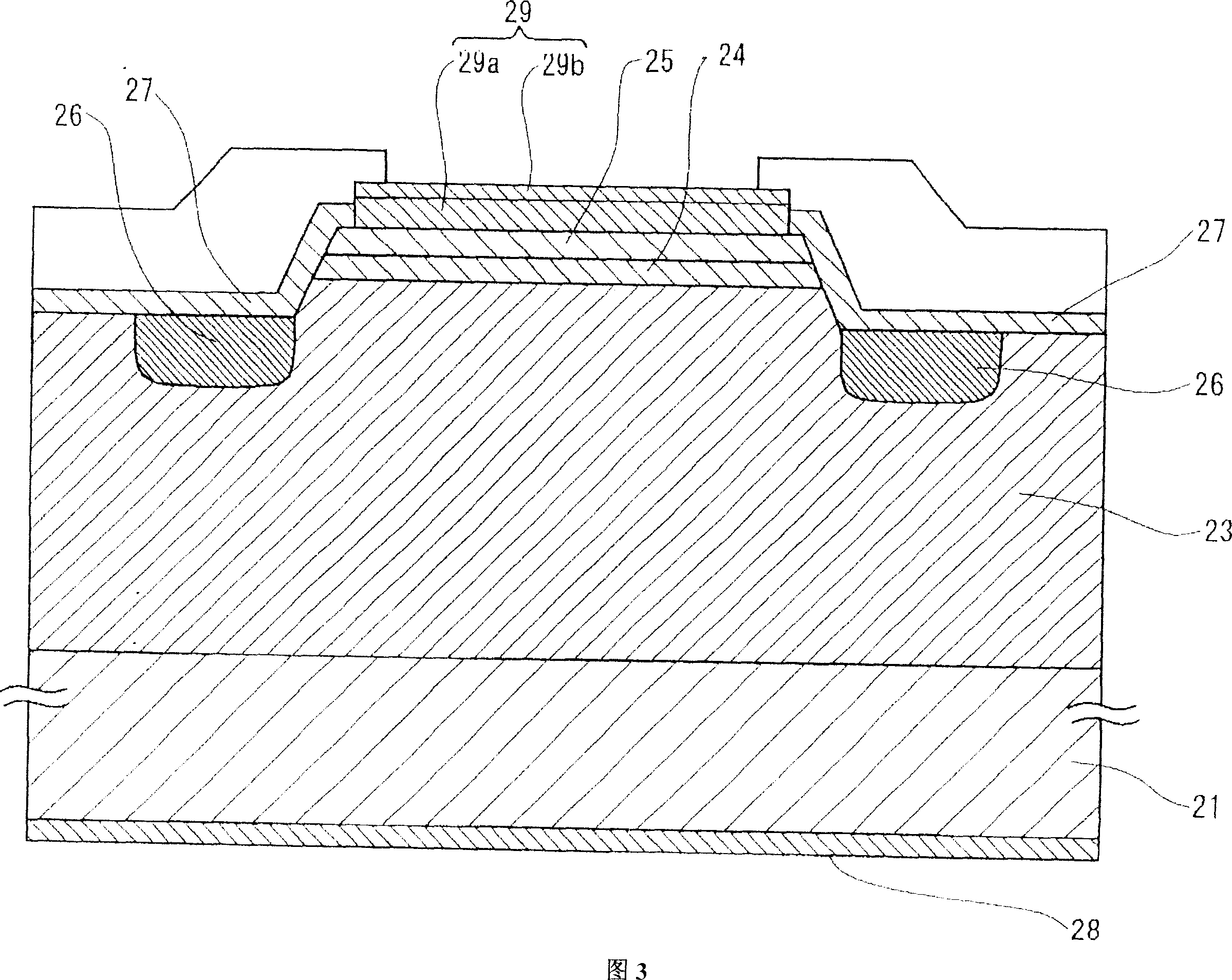

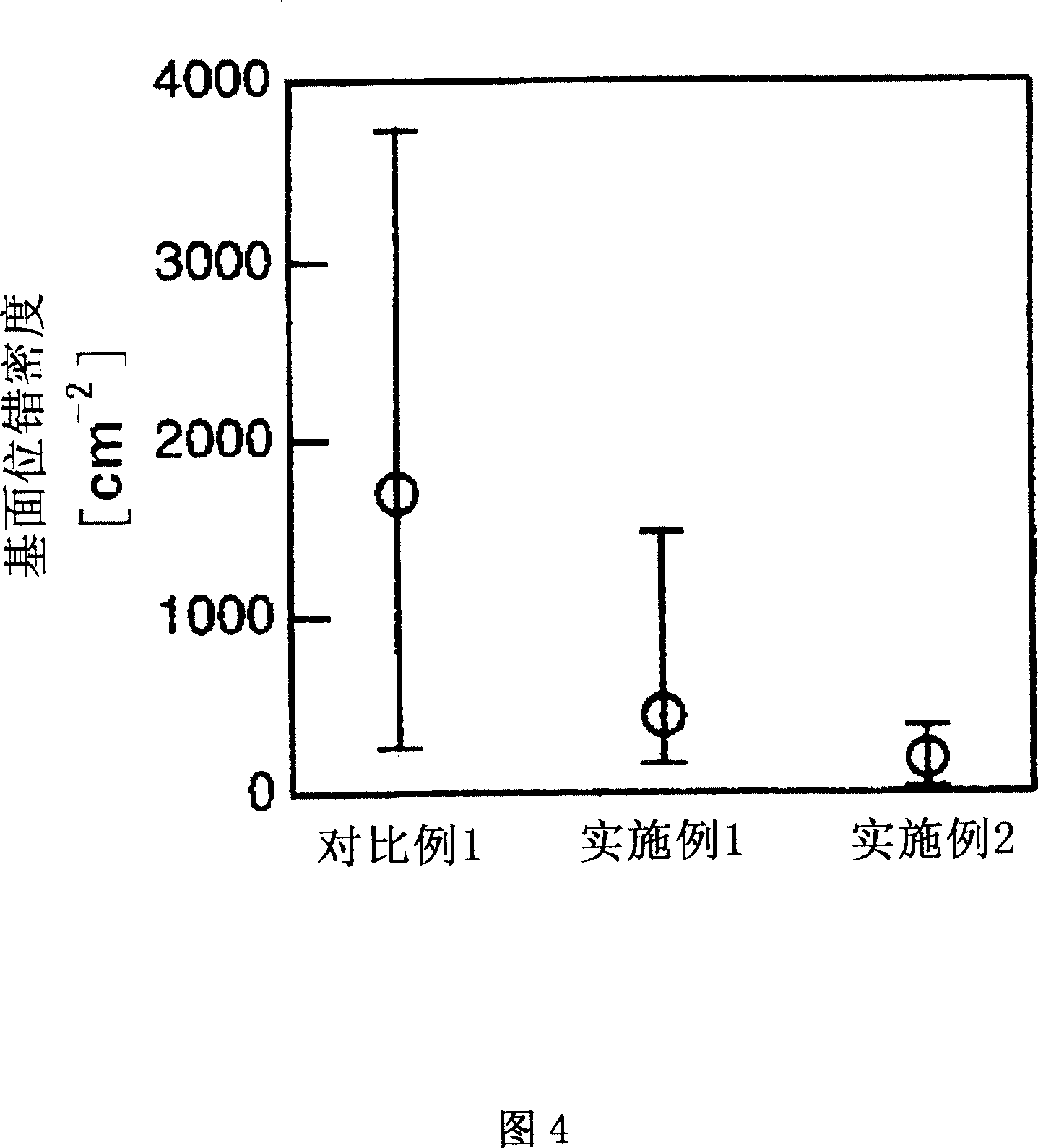

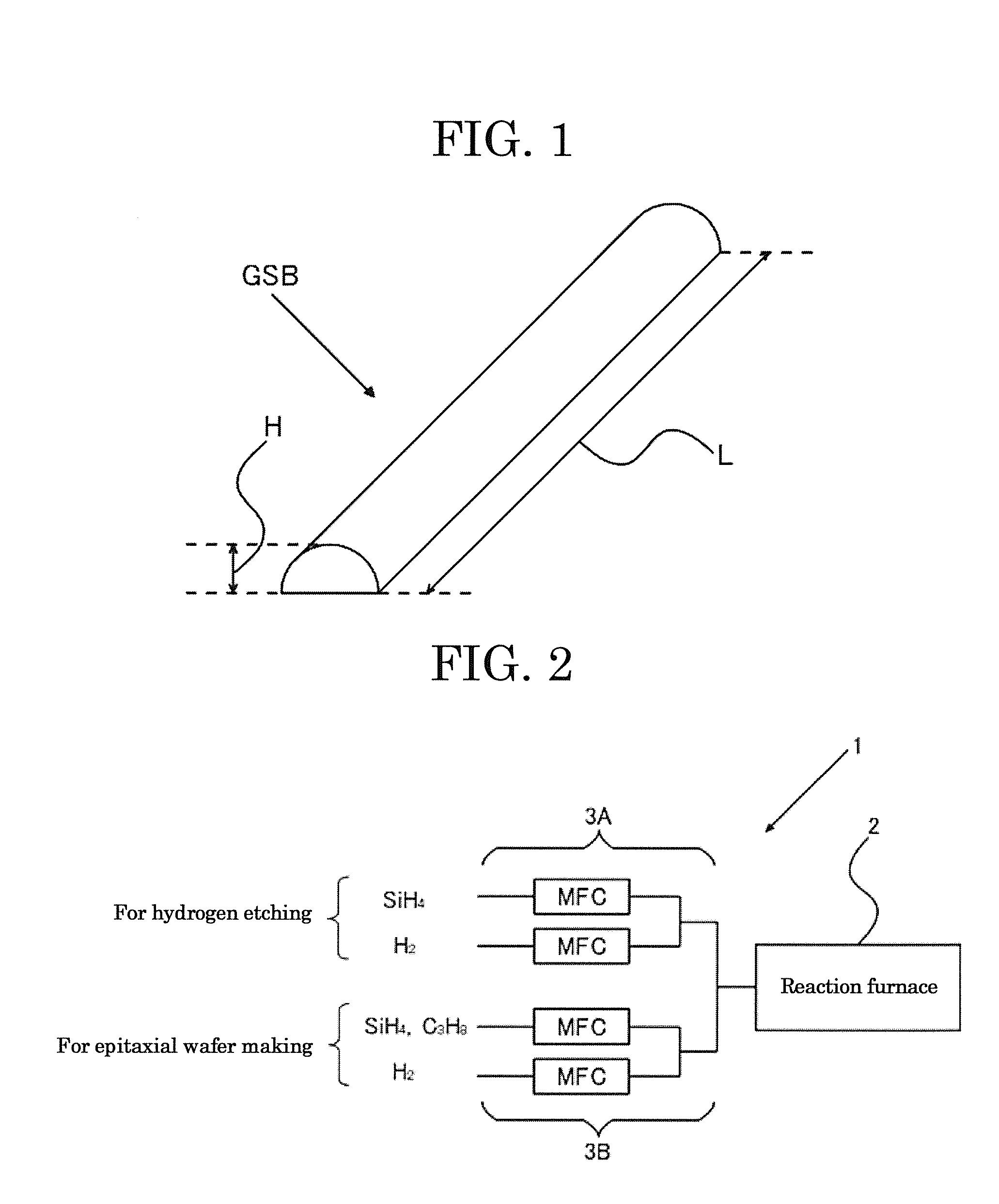

Silicon Carbide Epitaxial Wafer, Method for Manufacturing Silicon Carbide Epitaxial Wafer, Device for Manufacturing Silicon Carbide Epitaxial Wafer, and Silicon Carbide Semiconductor Element

InactiveUS20160168751A1Reduce surface defect densityImprove reliabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingWaferingHydrogen

To provide silicon carbide epitaxial wafer in which occurrence of giant step bunchings (GSBs) caused by basal plane dislocations (BPDs) that occur during hydrogen etching is suppressed on low off-angle silicon carbide substrate to decrease surface defect density of epitaxially grown layer to allow formation of silicon carbide semiconductor device having high reliability, method for manufacturing the wafer, and apparatus for manufacturing the wafer, and silicon carbide semiconductor device having the wafer.A silicon carbide epitaxial wafer of the present invention is such that epitaxially grown layer is disposed on silicon carbide substrate which has α-type crystal structure and in which (0001) Si face is tilted at greater than 0° and less than 5°, wherein surface defect density of the epitaxially grown layer based on giant step bunching caused by basal plane dislocation on substrate surface of the silicon carbide substrate is ≦20 / cm2.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Method for preparing graphene nanoribbon

InactiveCN106629686ASolve the problems that are not conducive to the later device processGrapheneGraphene nanoribbonsHydrogen etching

The invention discloses a method for preparing a graphene nanoribbon. The method comprises the following steps: (1) preparing a monoatomic layer step on a silicon carbide substrate: firstly, polishing a silicon carbide substrate sheet, and then pretreating the substrate sheet until the silicon carbide substrate with the periodic monoatomic layer step is obtained, wherein the pretreatment comprises chemical cleaning, hydrogen etching and oxide removal; (2) directly growing the graphene nanoribbon on the silicon carbide substrate with the monoatomic layer step, which is obtained in the step (1), through a silicon carbide epitaxial method. According to the method disclosed by the invention, by the use of the characteristics that silicon carbide has an atomic step and a flat cleavage surface, graphene is grown directly through the silicon carbide epitaxial method; by adjustment of conditions such as temperature and pressure intensity, the graphene can grow on the step into the graphene nanoribbon with an adjustable size; the requirement on equipment is low, and the prepared GNRs (Graphene NanoRibbons) contain less defects, are controllable in size, and do not need stripping; the problem that the graphene nanoribbon growing on a side surface is unfavorable for later device processing is successfully solved.

Owner:BEIJING HUAJINCHUANGWEI ELECTRONICS CO LTD

Method for located growing of big single crystal graphene on SiC substrate through point-seed way

ActiveCN106521618AUniform layersGood effectPolycrystalline material growthFrom chemically reactive gasesHydrogenArgon atmosphere

The invention relates to a method for located growing of big single crystal graphene on a SiC substrate through a point-seed way. The method comprises the following steps: (1) polishing and cleaning SiC; feeding into a growing furnace; pumping vacuum; increasing the temperature to be 1200 to 1300 DEG C; charging argon and hydrogen; increasing the temperature to be 1500-1600 DEG C; performing hydrogen etching; closing hydrogen after etching; decreasing the temperature to be 1400 to 1500 DEG C, and maintaining the temperature; decreasing the temperature to be 800 to 1100 DEG C under argon atmosphere; placing a superfine heat conducting probe on the SiC substrate to form a local undercooling point; charging carbon source gas and hydrogen, wherein an active carbon source obtained by the decomposing of the carbon source gas can preferentially grow into graphene seed crystal at the undercooling point; (2) enabling continuous growing of graphene using the seed crystal on the SiC substrate as the center under the condition that the temperature is 800 to 1100 DEG C, the pressure is 800 to 900mbar, and carbon source gas is supplied, so as to obtain big single crystal graphene; and (3) charging argon after the growth, and decreasing the temperature, thus obtaining the big single crystal graphene. The method is free of a metal substrate, and the grown big single crystal graphene can be directly applied to micro-electronic appliance without being transferred.

Owner:山东本源晶体科技有限公司

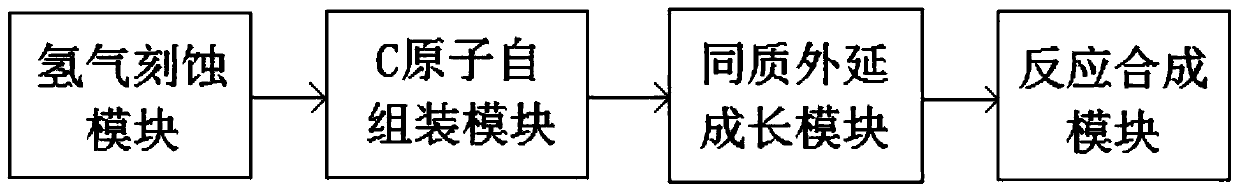

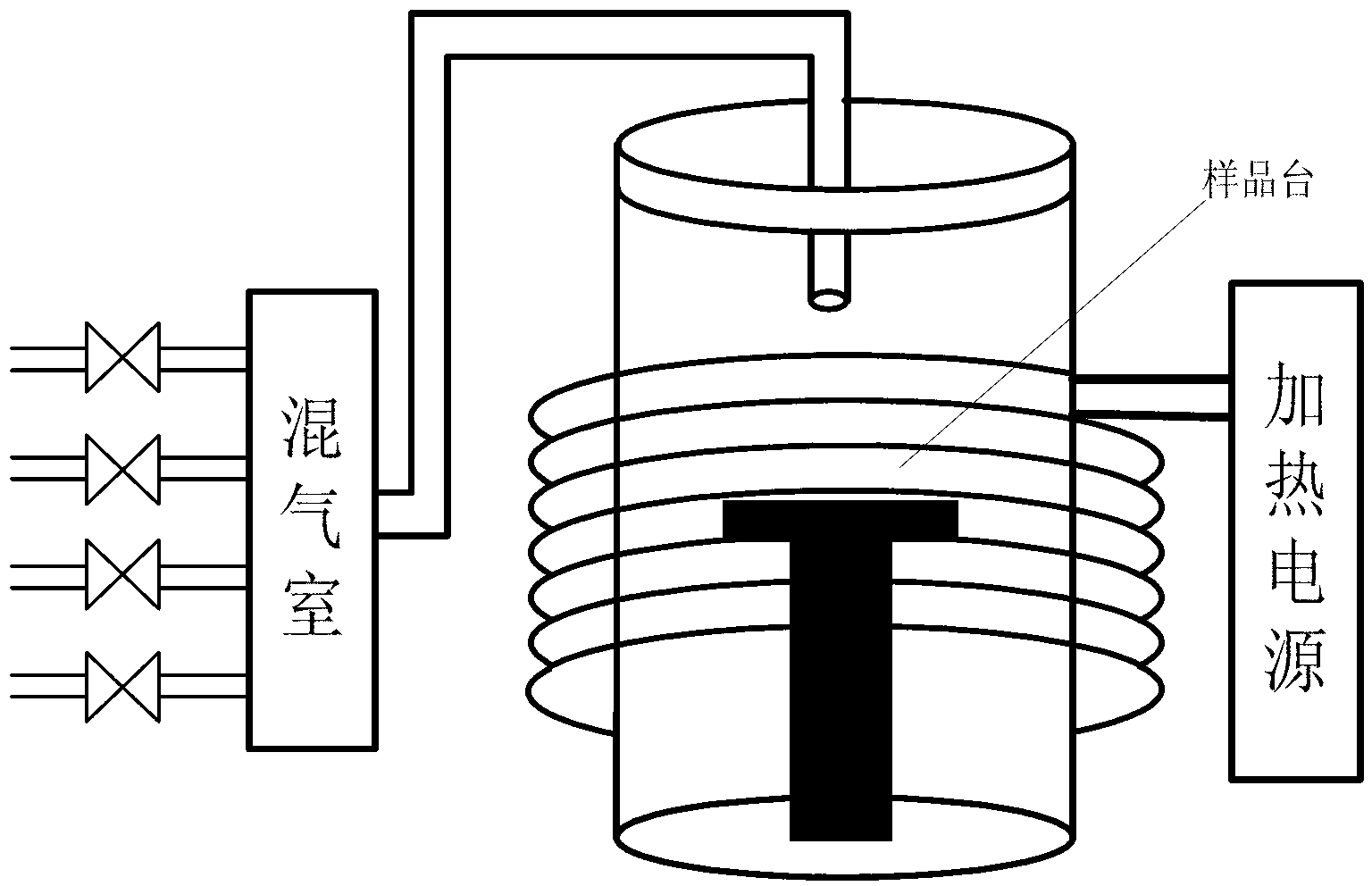

Graphene semiconductor preparation device and method

InactiveCN111410191AQuality improvementImprove uniformityGrapheneSemiconductor materialsHydrogen etching

The invention discloses a graphene semiconductor preparation device and method, and the method comprises the following steps: I, providing a SiC substrate, and etching the SiC substrate through hydrogen; II, heating the SiC substrate slice in an argon atmosphere; III, forming a hexagonal honeycomb-shaped graphene film in an ultrahigh vacuum environment; and IV, forming the graphene semiconductor composite material. A graphene semiconductor preparation device comprises a hydrogen etching module; a C atom self-assembly module; a homoepitaxy growth module; reaction synthesis module. According tothe method, large-area and high-quality graphene can be obtained, and the obtained graphene has good uniformity and has good compatibility with a current integrated circuit technology; and meanwhile,by utilizing the advantages of the semiconductor material and the characteristics of the graphene, the preparation of the graphene and the compounding of the graphene and the semiconductor material are simultaneously carried out, and the applicability is wide.

Owner:山东华达新材料有限公司

Preparation method of large-area graphene on SiC substrate based on Ni film annealing

The invention discloses a preparation method of large-area graphene on an SiC substrate based on Ni film annealing and mainly solves the problems of poor continuity, unsmooth surface and non-uniform layers of graphene prepared in the prior art. The preparation method comprises the following realization steps: firstly, cleaning the SiC substrate by using mixed solution of ammonia water and hydrogen peroxide and mixed solution of hydrochloric acid and hydrogen peroxide; then carrying out hydrogen etching on the cleaned SiC substrate and removing a generated Si compound; putting the cleaned SiC substrate into reaction equipment, so that SiC reacts with gaseous CCl4 at the temperature of 750-1,150 DEG C to generate a carbon film; then electron beam-depositing an Ni film on the carbon film, putting a sample sheet plated with the Ni film into Ar gas with the temperature of 900-1,200 DEG C and annealing for 10-20 minutes to generate the graphene; and finally removing the Ni film from a graphene sample sheet by using mixed solution of hydrochloric acid and copper sulfate. The graphene prepared by the method has the advantages of large area, good continuity, smooth surface and low porosity and can be produced in a large scale.

Owner:XIDIAN UNIV

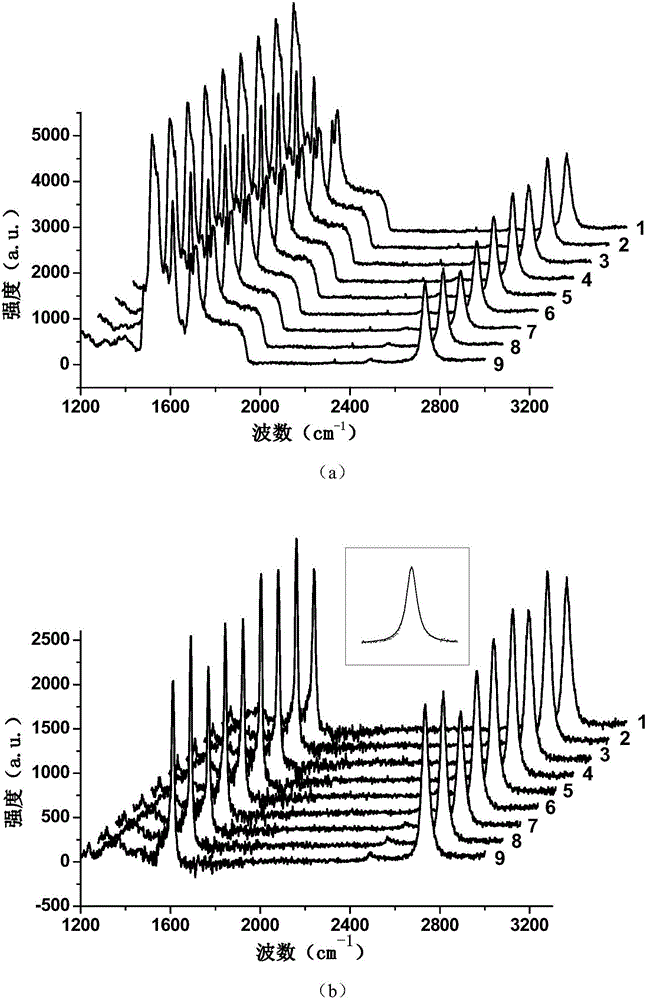

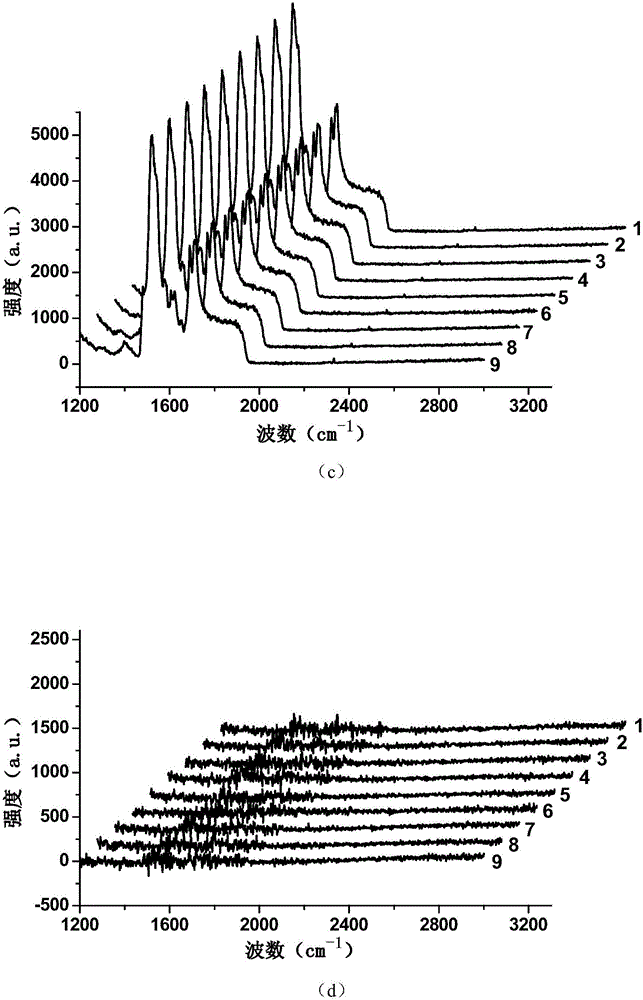

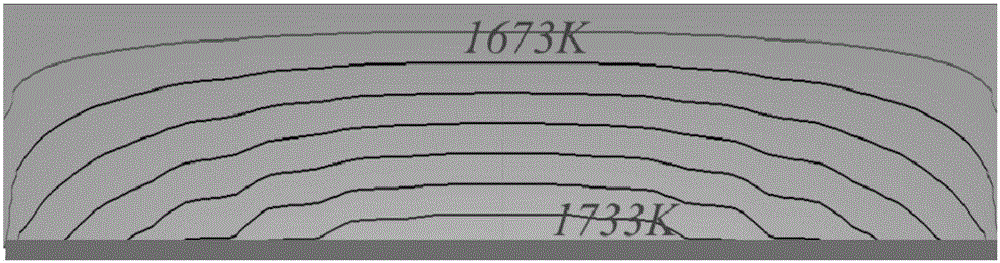

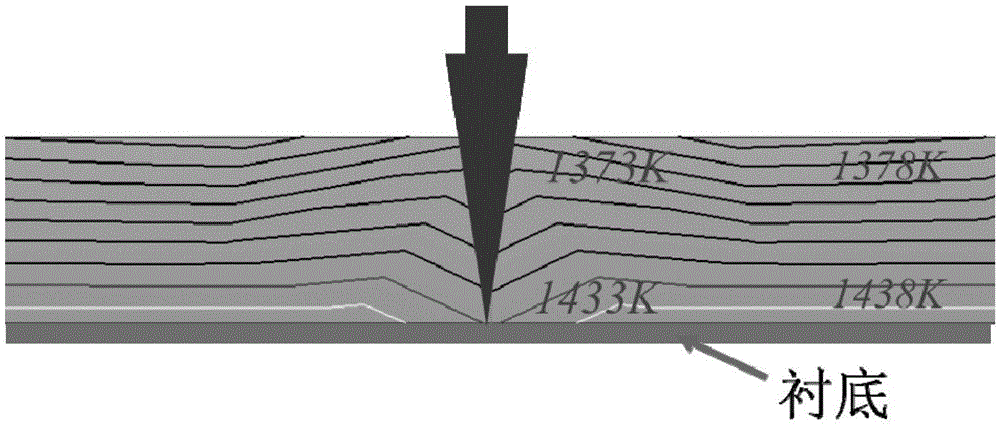

Substrate controllable step morphology pre-processing method of silicon carbide pyrolysis prepared graphene

ActiveCN108183064ASame supply speedUniform growthGrapheneSemiconductor/solid-state device manufacturingEtchingPretreatment method

The present invention discloses a substrate controllable step morphology pre-processing method applied to the silicon carbide pyrolysis prepared graphene. The method comprises the following steps of (1) placing a silicon carbide substrate on a pedestal in a chemical vapor deposition (CVD) device; (2) setting the pressure in a reaction chamber and the hydrogen flow, and warming to a beginning etching temperature under the hydrogen atmosphere; (3) keeping the pressure and the H2 flow to be constant, letting in the small flow carbon source auxiliary etching while continuously warming to a final etching temperature; (4) after warming to the final etching temperature, keeping the pressure, the temperature and the H2 flow to be constant, and improving the carbon source flow auxiliary etching slowly in a linear slowly varying manner; (5) closing a valve through which a carbon source gets in the reaction chamber, carrying out the pure H2 etching; (6) letting in the silane auxiliary H2 etchingtowards the reaction chamber; (7) cooling to a room temperature under the hydrogen atmosphere, and taking out a pre-processed silicon carbide substrate. The advantages of the present invention are that: a controllable technology window of the pure hydrogen etching is expanded, at the same time, the problem that due to the pure hydrogen etching, the steps on the surface of the substrate are difficult to control is solved. According to the present invention, a sub-damage layer on the surface of the substrate is removed effectively, the controllable, flat and straight steps having no defects alsocan be formed on the surface of the silicon carbide substrate, the dissociation speeds on the steps are consistent, and the supply speeds of the carbon atoms on the step surfaces are same, the growngraphene can be more uniform. The pre-processing method has a higher popularization value.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

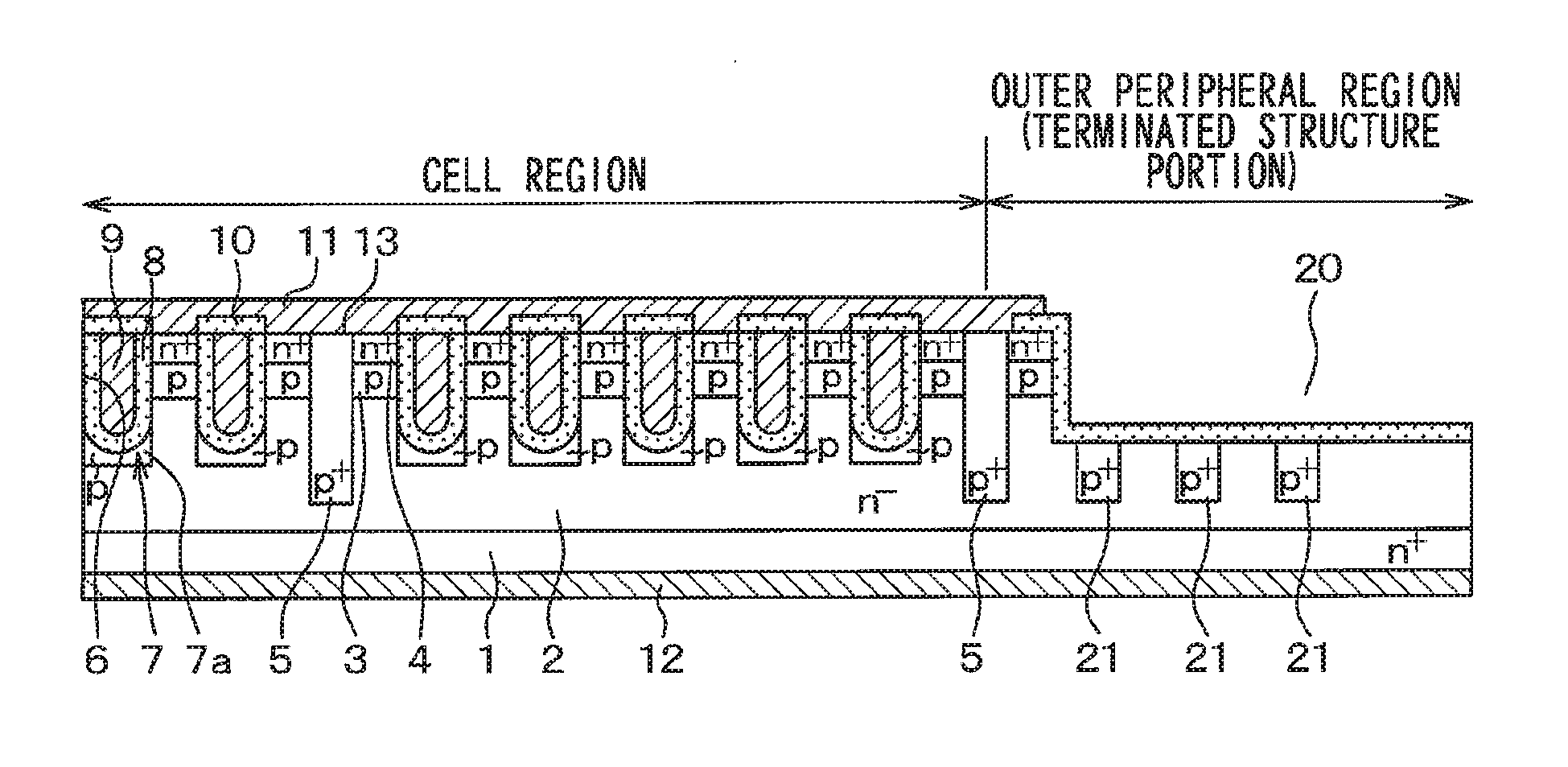

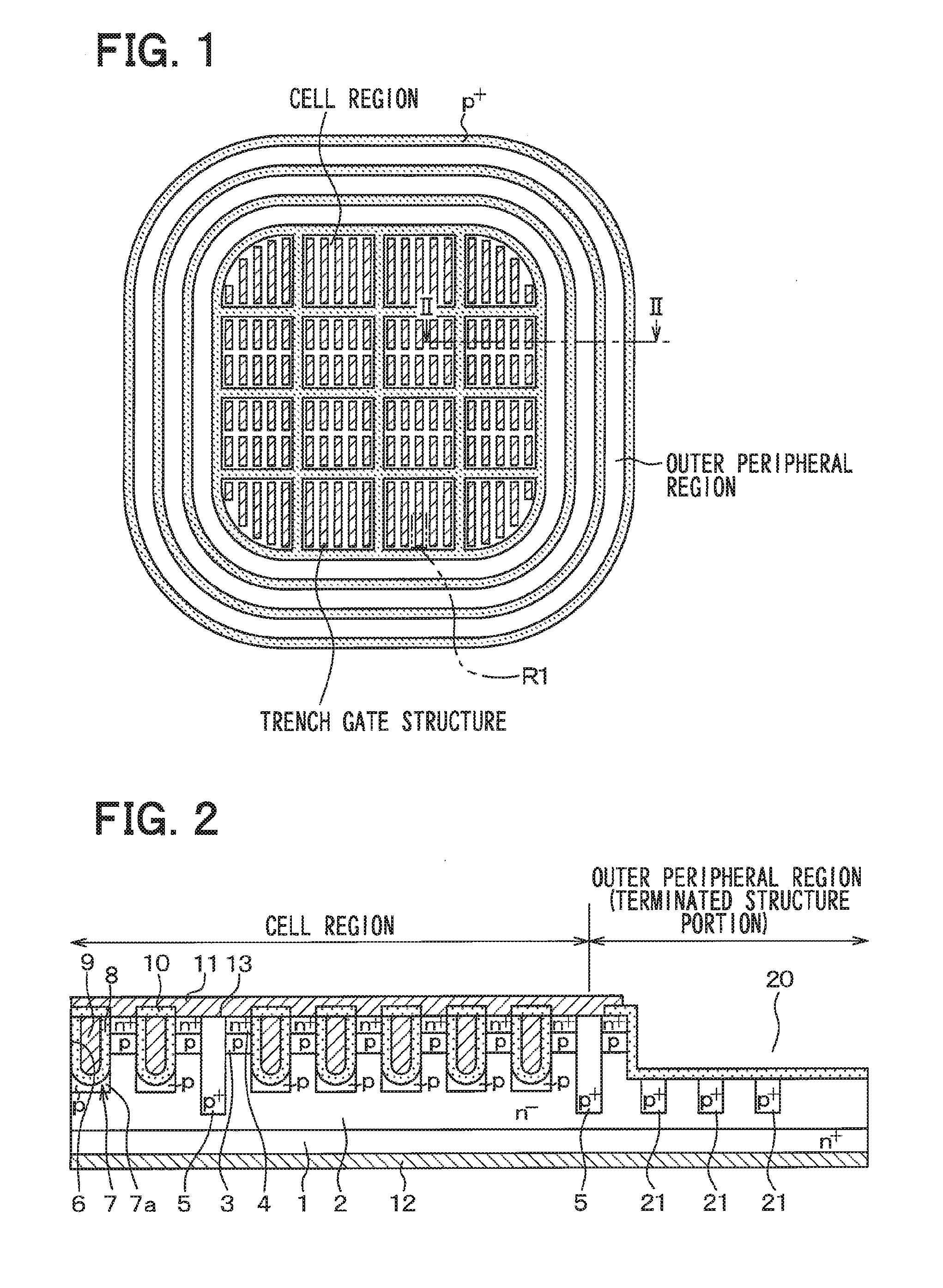

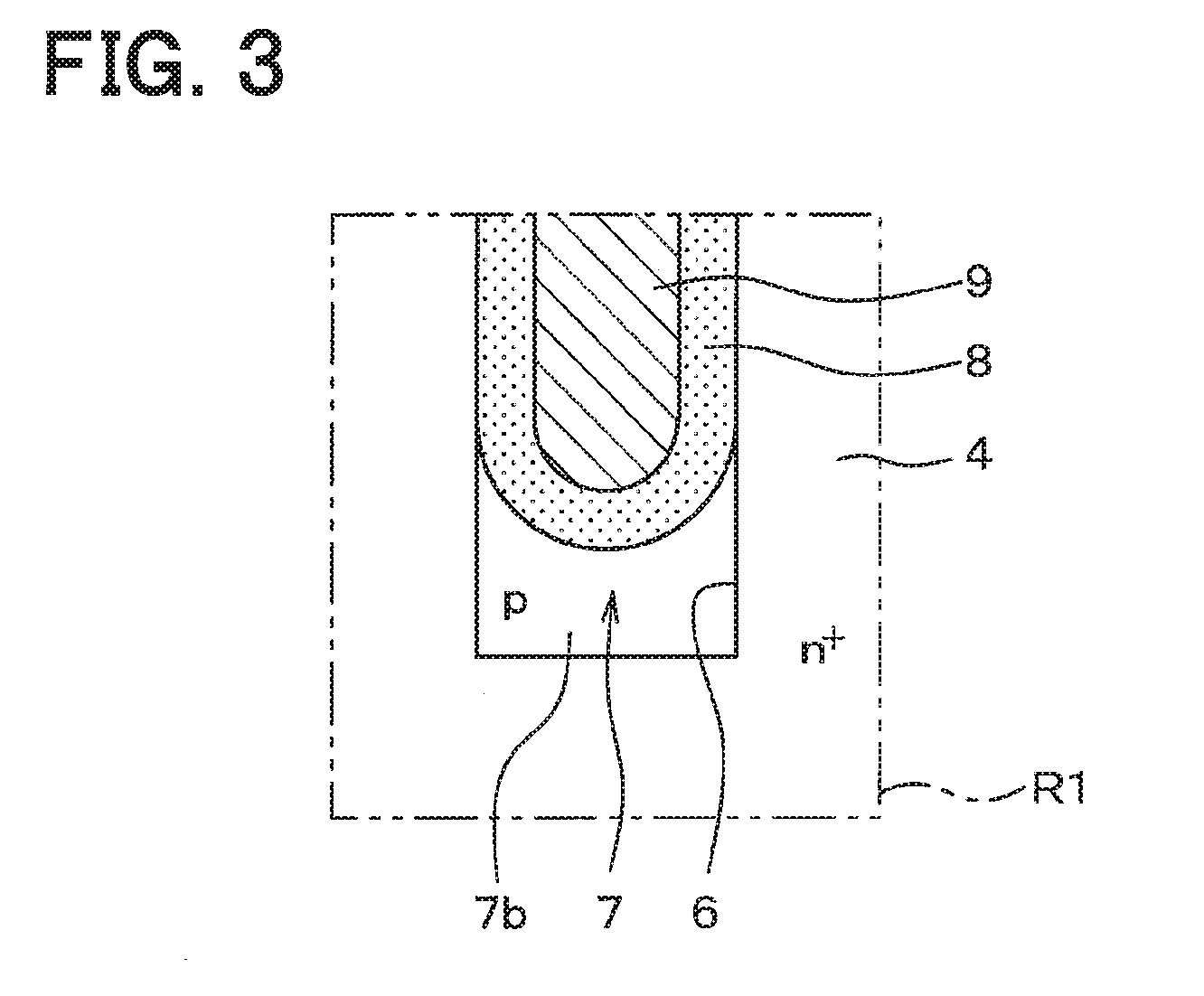

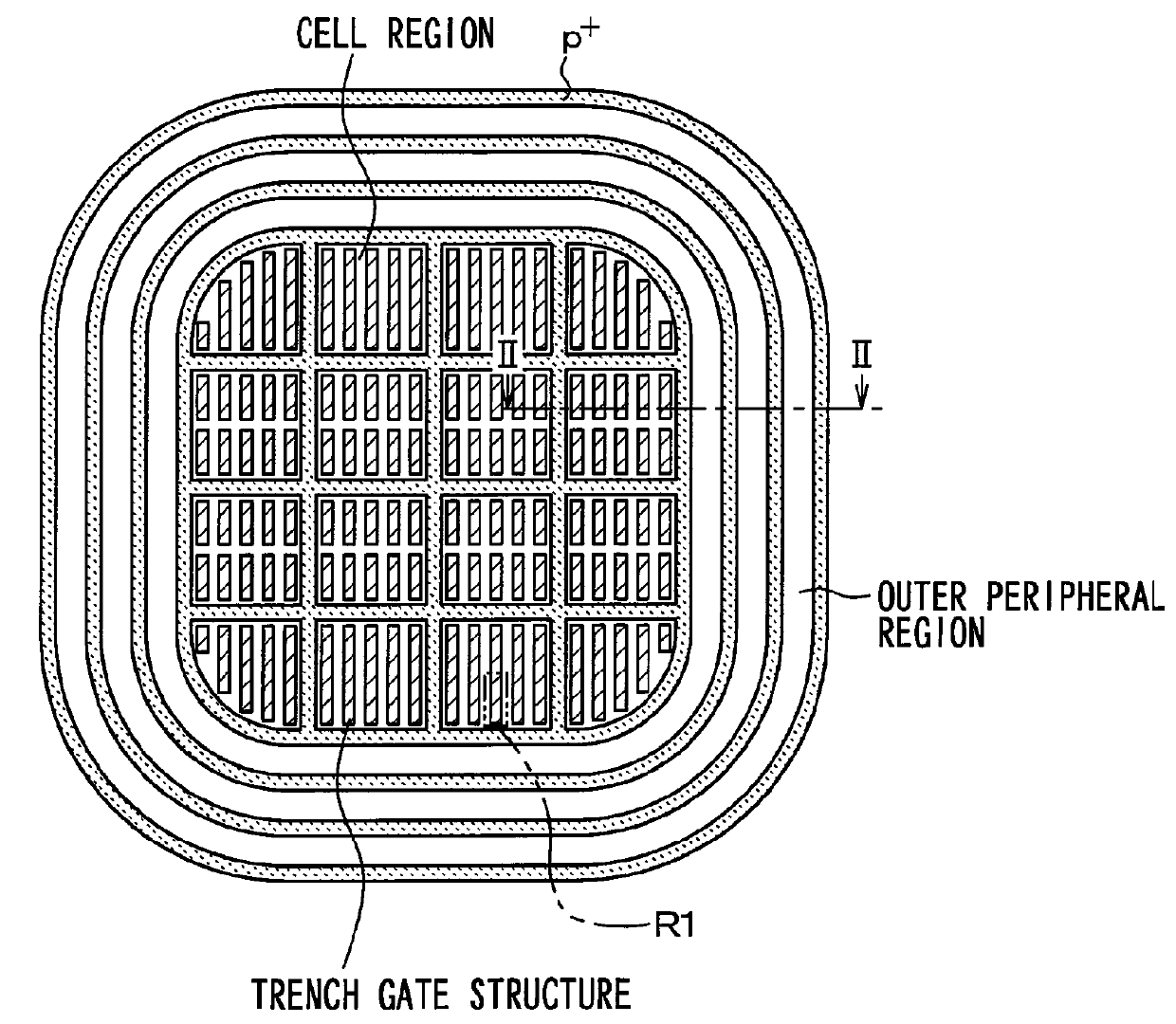

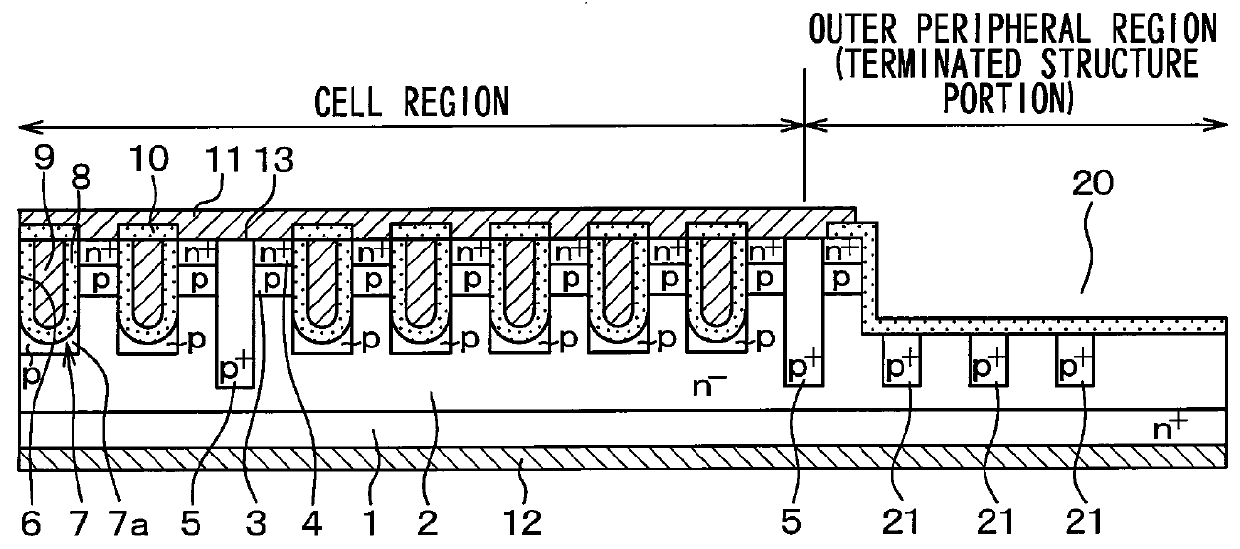

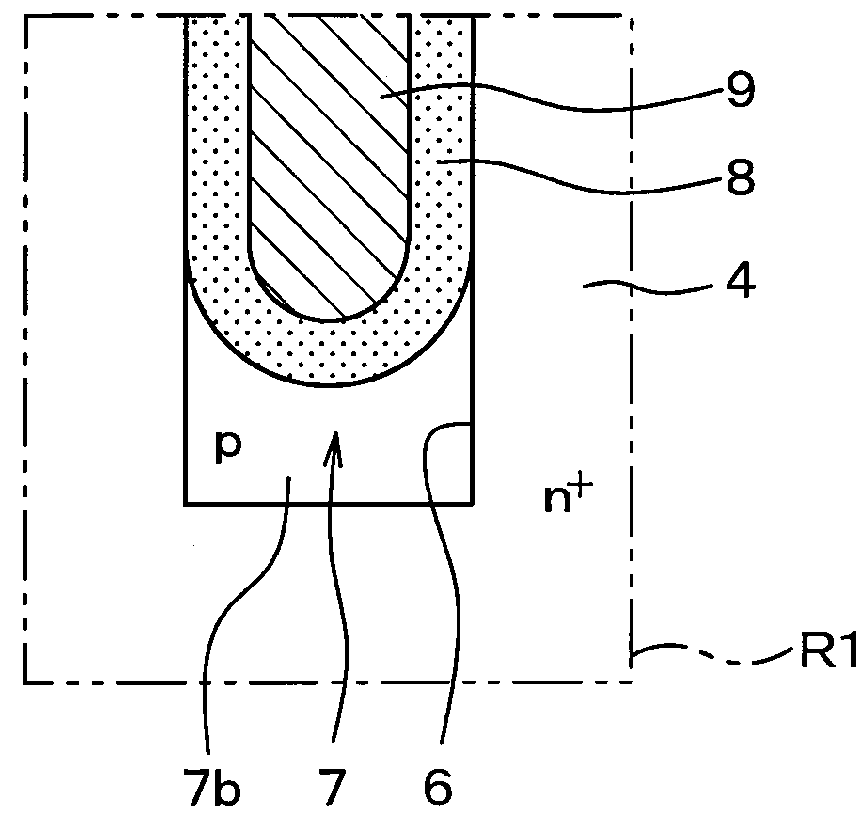

Silicon carbide semiconductor device and method for producing the same

ActiveUS20160163818A1Fast switching speedAccurately realize high withstand voltageSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialHydrogen etching

In a method for producing an SiC semiconductor device, a p type layer is formed in a trench by epitaxially growing, and is then left only on a bottom portion and ends of the trench by hydrogen etching, thereby to form a p type SiC layer. Thus, the p type SiC layer can be formed without depending on diagonal ion implantation. Since it is not necessary to separately perform the diagonal ion implantation, it is less likely that a production process will be complicated due to transferring into an ion implantation apparatus, and thus manufacturing costs reduce. Since there is no damage due to a defect caused by the ion implantation, it is possible to reduce a drain leakage and to reliably restrict the p type SiC layer from remaining on the side surface of the trench.

Owner:DENSO CORP +1

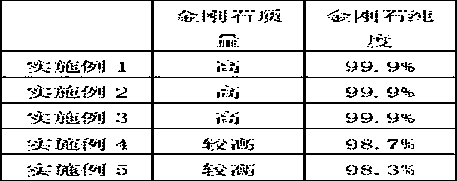

CVD monocrystalline diamond growth pretreatment method

InactiveCN109537052AQuality improvementHigh purityPolycrystalline material growthFrom chemically reactive gasesEtchingPretreatment method

The invention relates to the technical field of processing of a diamond substrate, and especially relates to a CVD single crystal diamond growth pretreatment method. The method can pre-treat a substrate before growth, remove contaminants on the surface of the substrate, and improve the quality and purity of the grown monocrystalline diamond; and comprises the following steps: (1) substrate selection; (2) ultrasonic cleaning; (3) first drying treatment; (3) chemical cleaning; (4) second drying treatment; (5) substrate transfer; (6) adjusting of parameters in cavity; (7) mixed etching; and (8) hydrogen etching.

Owner:西安碳星半导体科技有限公司

Silicon carbide semiconductor device and method for producing the same

ActiveUS9337298B2Fast switching speedAccurately realize high withstand voltageSemiconductor/solid-state device manufacturingSemiconductor devicesHydrogen etchingIon implantation

In a method for producing an SiC semiconductor device, a p type layer is formed in a trench by epitaxially growing, and is then left only on a bottom portion and ends of the trench by hydrogen etching, thereby to form a p type SiC layer. Thus, the p type SiC layer can be formed without depending on diagonal ion implantation. Since it is not necessary to separately perform the diagonal ion implantation, it is less likely that a production process will be complicated due to transferring into an ion implantation apparatus, and thus manufacturing costs reduce. Since there is no damage due to a defect caused by the ion implantation, it is possible to reduce a drain leakage and to reliably restrict the p type SiC layer from remaining on the side surface of the trench.

Owner:DENSO CORP +1

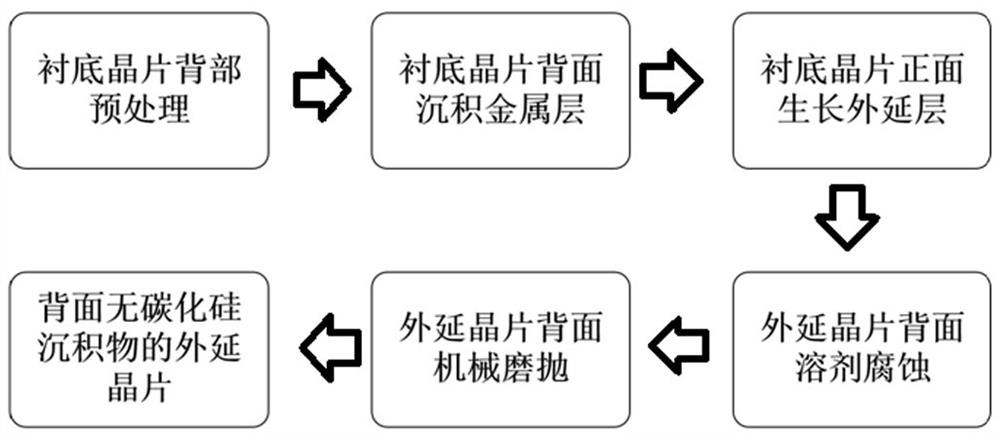

Method for rapidly removing sediments on back surface of wafer in epitaxial process of silicon carbide

ActiveCN113802184AReduce deposition rateConducive to cost controlPolycrystalline material growthSemiconductor/solid-state device manufacturingWaferingSingle crystal substrate

The invention discloses a method for rapidly removing sediments on the back surface of a wafer in an epitaxy process of a silicon carbide . The method comprises the following steps: S1) pretreating a substrate wafer: carrying out cleaning, hydrogen etching and / or polishing pretreatment on the back surface (non-epitaxial growth surface) of a silicon carbide single crystal substrate wafer; S2) forming a metal layer: depositing a metal or alloy on the back surface of the silicon carbide single crystal substrate wafer by adopting a magnetron sputtering method to form the metal layer; S3) forming a silicon carbide epitaxial wafer: growing a silicon carbide epitaxial layer on the epitaxial growth surface of the silicon carbide single crystal substrate wafer through a chemical vapor deposition method to obtain the silicon carbide epitaxial wafer; and S4) removing the metal layer: removing the metal layer on the back surface of the silicon carbide epitaxial wafer and the sediments attached to the surface of the metal layer in a solvent corrosion manner. According to the invention, after the method is adopted, the time of the process for removing the sediments on the back surface of the wafer is greatly shortened, the production efficiency can be effectively improved, and the cost control of the silicon carbide epitaxial wafer is facilitated.

Owner:DONGGUAN TIANYU SEMICON TECH

Method for growing high-quality semiconducting single-walled carbon nanotubes by in-situ weak etching with hydrogen

ActiveCN103011130BQuality improvementGood semiconductor performanceCarbon nanotubesNanotechnologyHydrogenSulfur

The invention relates to the field of fabrication of a high-quality semiconductor single-walled carbon nanotube, in particular to a method for directly growing the high-quality semiconductor single-walled carbon nanotube through in-situ weak hydrogen etching. A metallic and small-diameter single-walled carbon nanotube can be etched in situ at a certain reaction temperature by regulating and optimizing a flow of carrier gas, namely hydrogen and under the conditions of taking dicyclopentadienyl iron as a catalyst precursor, sulfur powder as a growth promoter and organic low-carbon hydrocarbon as a carbon source; and the high-quality semiconductor-superior single-walled carbon nanotube is finally obtained. The content of the semiconductor single-walled carbon nanotube is greater than or equal to 91wt%, the diameter distribution is between 1.5nm and 2.5nm, and the highest concentrated oxidation temperature reaches 800 DEG. With the adoption of the method, the massive, fast and low-cost controlled growth of the semiconductor single-walled carbon nanotube with the narrower diameter distribution and the high quality is realized, and the problems such as serious damages to a sample due to a strong etching agent, complexity of a fabrication process, low output and high cost during a selective fabrication course of a conduction-superior single-walled carbon nanotube can be effectively solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Production method of silicon carbide inorganic ceramic film

ActiveCN110124526AHigh temperature resistantResistant to chemical solventsMembranesSemi-permeable membranesHydrogenThin layer

The invention relates to a production method of a silicon carbide inorganic ceramic film, and the method comprises the following steps: (1) carrying out hydrogen etching on the surface of silicon carbide powder; (2) generating a graphene thin layer on the surface of the silicon carbide powder; (3) converting the generated graphene into graphene oxide; (4) swelling the generated graphene oxide; (5)molding the silicon carbide powder; (6) performing reduction and solidification of silicon carbide. The method takes the silicon carbide to epitaxially grow the graphene as a technical basis and provides an innovative silicon carbide inorganic ceramic film production process and method. The silicon carbide inorganic ceramic film prepared by the method has the advantages of small filtering aperture, high aperture distribution precision, good mechanical strength of the film body and high bending strength.

Owner:HUBEI UNIV OF TECH

Method for preparing graphene and graphene device by epitaxy of pretreated SiC substrate

ActiveCN110556283AQuality improvementInhibition of nucleation densitySemiconductor/solid-state device manufacturingHydrogenHydrogen etching

The invention relates to a method for preparing graphene and a graphene device by epitaxy of a pretreated SiC substrate. The method comprises the following steps: performing hydrogen etching on the SiC substrate and then performing oxidation treatment on the SiC substrate after hydrogen etching at a temperature of 800-1300 DEG C for the treatment time of 15-120min; and then rising the temperatureto 1450-1700 DEG C in an inert atmosphere on the pretreated SiC substrate for graphene growth. The SiC surface is passivated through oxidation pretreatment so that nucleation density of the graphene epitaxially grown on the SiC substrate is reduced, the graphene material with larger size and better performance is obtained, and the SiC epitaxial graphene wafer is subjected to deposition, photolithography, doping and integration procedures accordingly so as to prepare the corresponding graphene device.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com