Method for located growing of big single crystal graphene on SiC substrate through point-seed way

A single crystal graphene, large-size technology, applied in the field of microelectronic materials, can solve the problems of uncontrollable single nucleation, difficulty in obtaining large-size single crystal graphene, and unavoidable damage and pollution of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

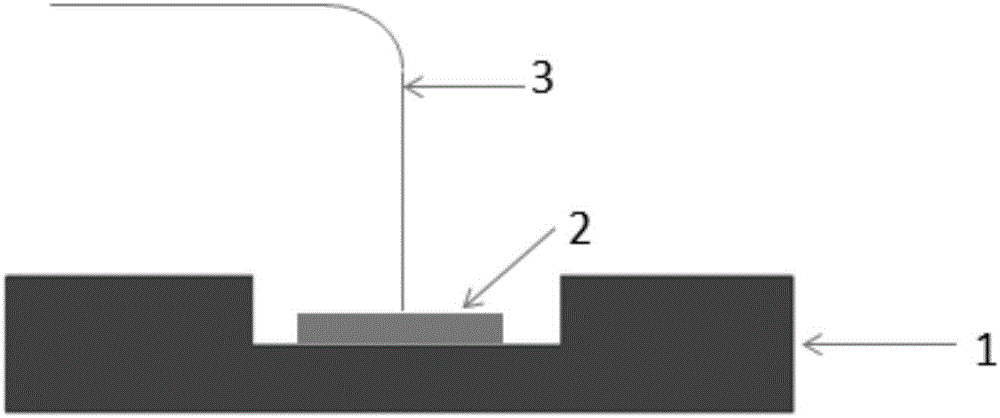

[0046] A method for growing large-area graphene by point seed crystal positioning on SiC, comprising the following steps:

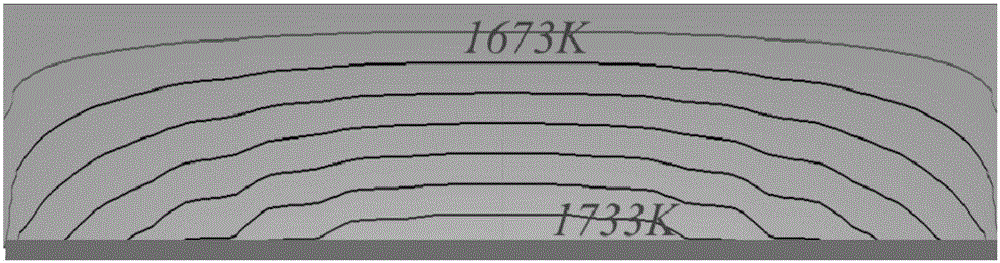

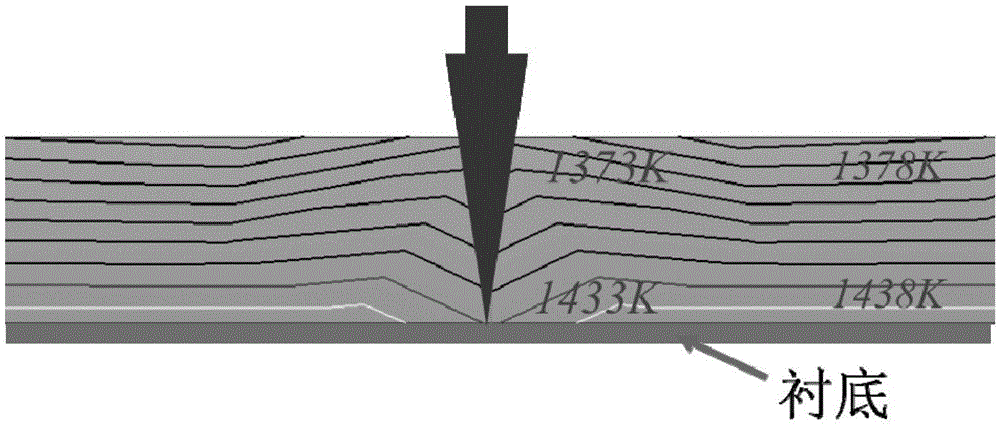

[0047] (1) After the SiC is polished and cleaned, it is placed flat in the heater in the high-temperature CVD graphene growth furnace, and the vacuum degree of the furnace chamber is 10 -3 Pa, the temperature is raised rapidly to 1200°C, and the heating rate is 10°C / min; high-purity argon and hydrogen are introduced, the flow rates are 40sccm and 40sccm, respectively, and the pressure is controlled at 800mbar, and then the temperature is slowly raised to 1500°C, and the heating rate is 2°C / min min, keep it warm for 10 minutes, and carry out hydrogen etching; after the etching, turn off the hydrogen, continue to flow argon, and then slowly lower the temperature to 1400°C, reaching the temperature at which the Si-C bond begins to break. The bond is partially broken and part of the silicon evaporates. The surface topography of the SiC atomic force microscop...

Embodiment 2

[0052] A method for growing large-area graphene by point seed crystal positioning on SiC, comprising the following steps:

[0053] (1) After the SiC is polished and cleaned, it is placed flat in the heater in the high-temperature CVD graphene growth furnace, and the vacuum degree of the furnace chamber is 10 -3 Pa, heat up to 1300°C quickly, with a heating rate of 10°C / min; feed high-purity argon and hydrogen with flow rates of 50sccm and 50sccm respectively, and control the pressure at 900mbar, then slowly raise the temperature to 1500°C, with a heating rate of 2°C / min min, keep it warm for 10 minutes, and carry out hydrogen etching; after the etching, turn off the hydrogen, continue to flow argon, and then slowly lower the temperature to 1400°C, reaching the temperature at which the Si-C bond begins to break. The bond is partially broken and part of the silicon evaporates.

[0054] Then, the temperature was lowered to 1000°C in an argon atmosphere, and the platinum micro-th...

Embodiment 3

[0059] A method for growing large-area graphene at SiC using point seed orientation, comprising steps as follows:

[0060] (1) After the SiC is polished and cleaned, it is placed flat in the heater in the high-temperature CVD graphene growth furnace, and the vacuum degree of the furnace chamber is 10 -4 Pa, heat up to 1200°C quickly, with a heating rate of 10°C / min; feed high-purity argon and hydrogen, with flow rates of 50sccm and 40sccm, respectively, and control the pressure at 850mbar, then slowly raise the temperature to 1600°C, with a heating rate of 5°C / min min, keep it warm for 10 minutes, and carry out hydrogen etching; after the etching, turn off the hydrogen, continue to flow argon, and then slowly lower the temperature to 1400°C, reaching the temperature at which the Si-C bond begins to break. The bond is partially broken and part of the silicon evaporates.

[0061] Then, the temperature was lowered to 1100 °C in an argon atmosphere, and the platinum micro-thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com