Graphene preparation method based on microwave plasma chemical vapor deposition

A microwave plasma and chemical vapor deposition technology, which is applied in gaseous chemical plating, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of high graphene growth temperature, lower graphene quality, stress and topological defects, etc. Achieve the effects of reducing thermal stress, controllable preparation, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

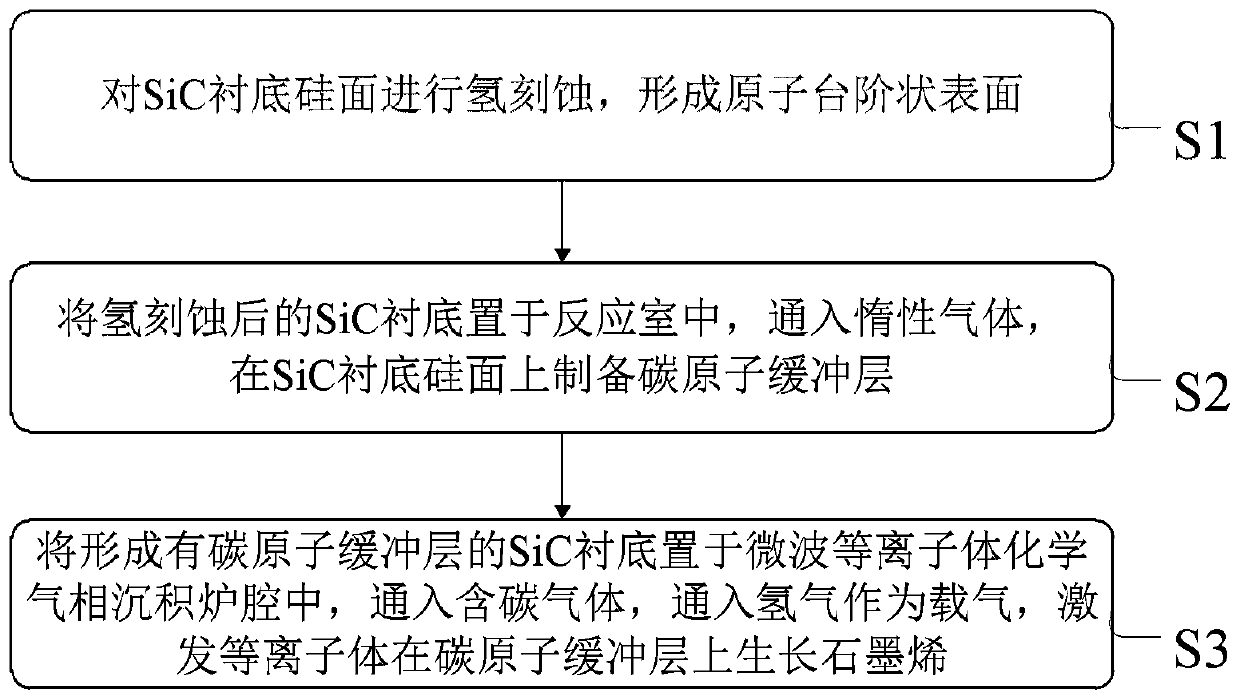

[0032] figure 1 Show the graphene preparation method flowchart based on microwave plasma chemical vapor deposition of the present invention, as figure 1 As shown, the methods include:

[0033] S1, performing hydrogen etching on the silicon surface of the SiC substrate to form an atomically stepped surface.

[0034] The silicon surface of the SiC substrate is etched with hydrogen by using a high-temperature annealing furnace or a microwave plasma chemical vapor deposition growth furnace. When using a high-temperature annealing furnace to perform hydrogen etching on the silicon surface of the SiC substrate, raise the temperature to 1200-1800°C and etch for 10-60 minutes; use a microwave plasma chemical vapor deposition growth furnace to perform hydrogen etching on the silicon surface of the SiC substrate During etching, the temperature is raised to 600-1000° C. and etched for 10-60 minutes. In the hydrogen etching process of SiC, high-purity hydrogen or a mixture of high-puri...

Embodiment 1

[0043] The method for preparing graphene on SiC substrate in the present embodiment comprises the following steps:

[0044] First, the surface treatment of the SiC substrate. Specifically, the SiC substrate is placed in a high-temperature annealing furnace, a pure hydrogen atmosphere is selected during the etching process, the chamber pressure is 600 Torr, and the treatment is performed at 1400° C. for 10 minutes. After hydrogen treatment, surface scratches can be removed and a substrate surface with regular atomic steps can be formed.

[0045] Then, a carbon atom buffer layer is prepared. Specifically, the SiC substrate after surface treatment is placed in a reaction chamber, and a high-purity argon atmosphere is selected as the gas. The carbon atom buffer layer can be obtained by growing at 1400°C and 600 Torr gas pressure for 10 minutes, and due to the low temperature, pyrolytic graphene will not be formed at this time.

[0046] Finally, epitaxially grow graphene on the ...

Embodiment 2

[0048] The difference between this embodiment and Implementation 1 is that the hydrogen etching method of the substrate is different, the graphene growth time is prolonged, and a graphene sample with more layers is obtained, which specifically includes the following steps:

[0049] First, the surface treatment of the SiC substrate. Specifically, the SiC substrate is placed in an MPCVD growth furnace, and a pure hydrogen atmosphere is selected during the etching process under the conditions of a pressure of 80 Torr and a temperature of 800° C. for 10 minutes. After hydrogen treatment, surface scratches can be removed and a substrate surface with regular atomic steps can be formed.

[0050] Then, a carbon atom buffer layer is prepared. Specifically, the SiC substrate after surface treatment is placed in a reaction chamber, and the gas is selected as pure argon atmosphere. The carbon atom buffer layer can be obtained by growing at 1400°C and 600 Torr gas pressure for 10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com