Patents

Literature

39results about How to "Reduced shape resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Garments

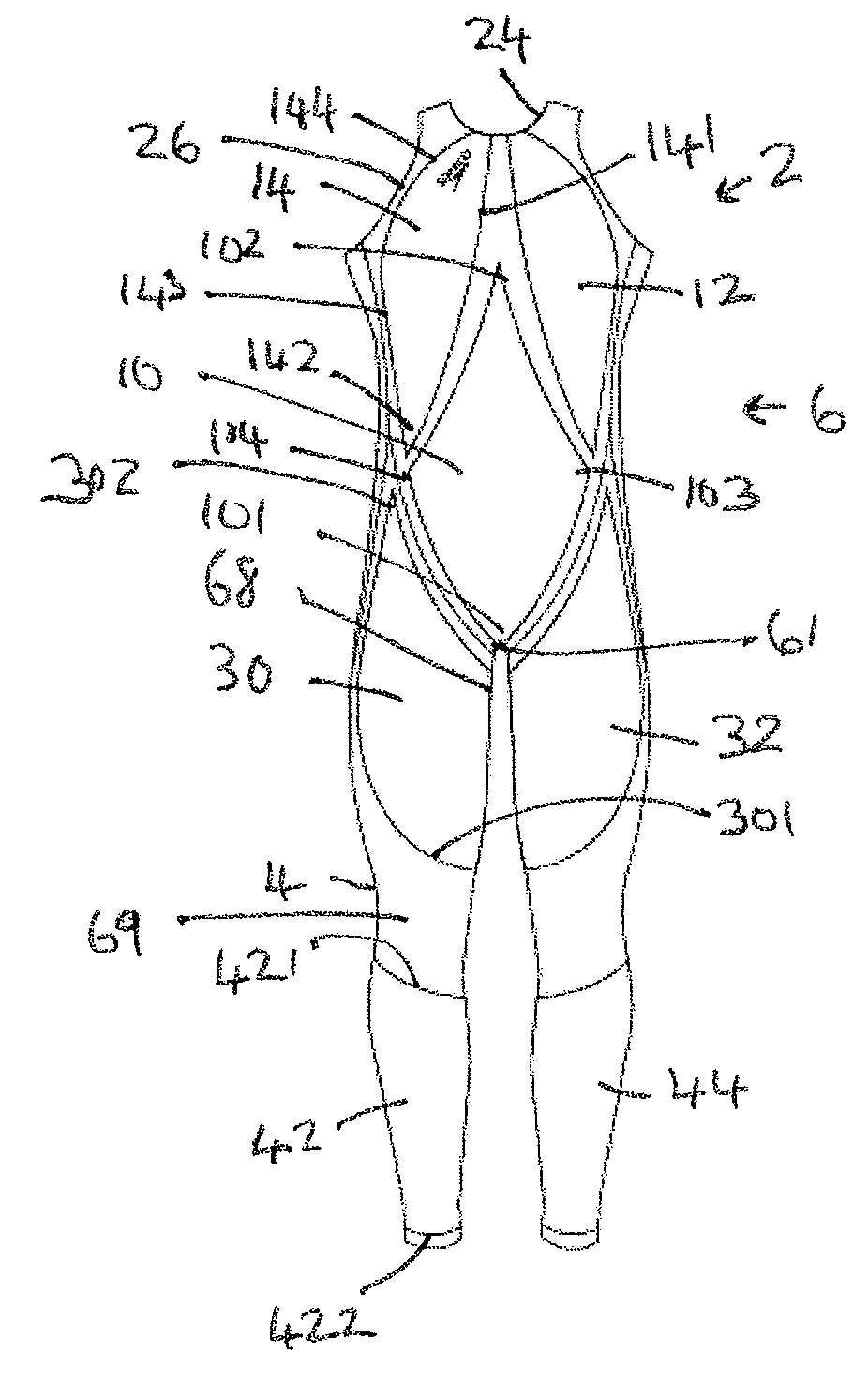

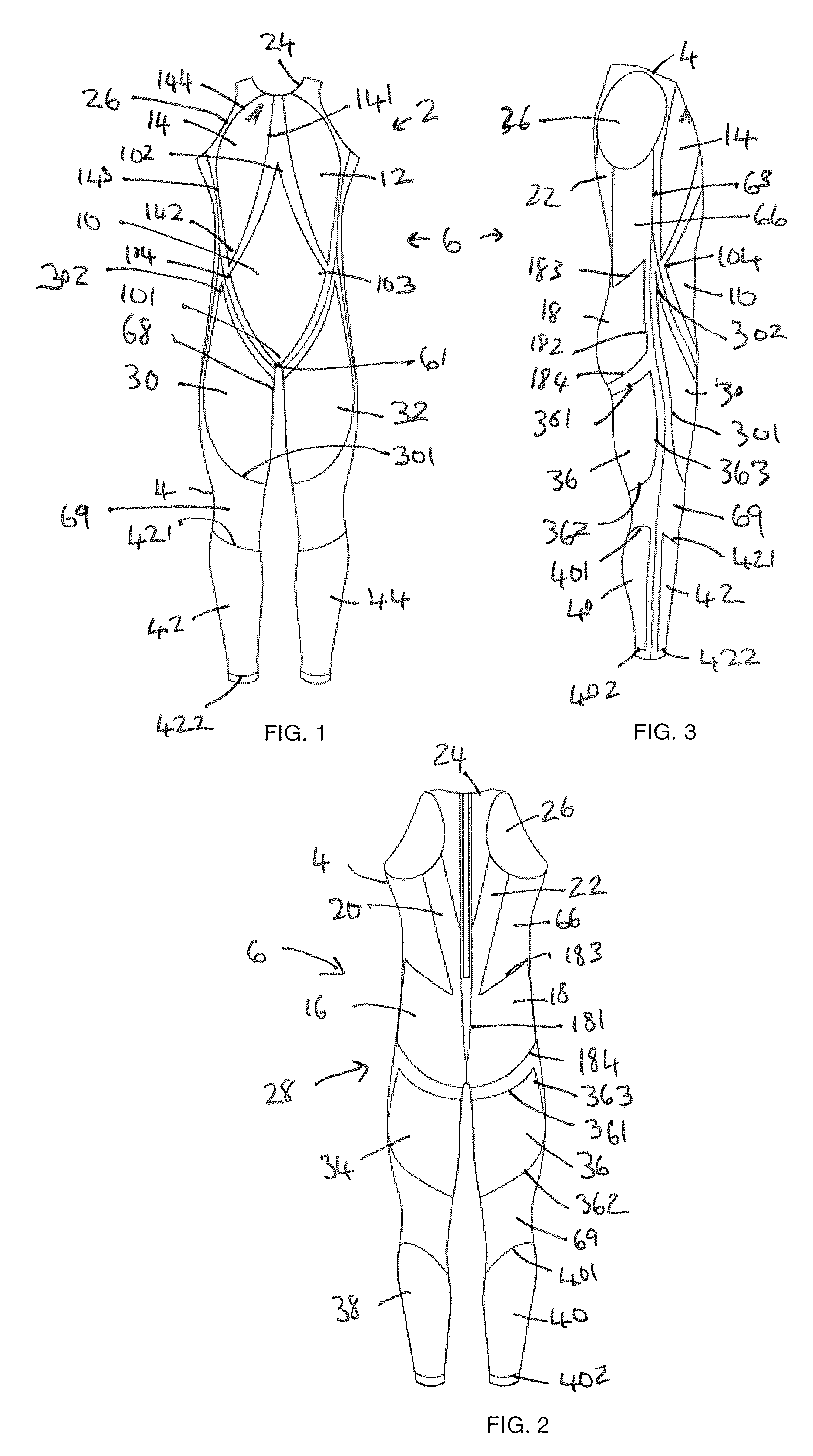

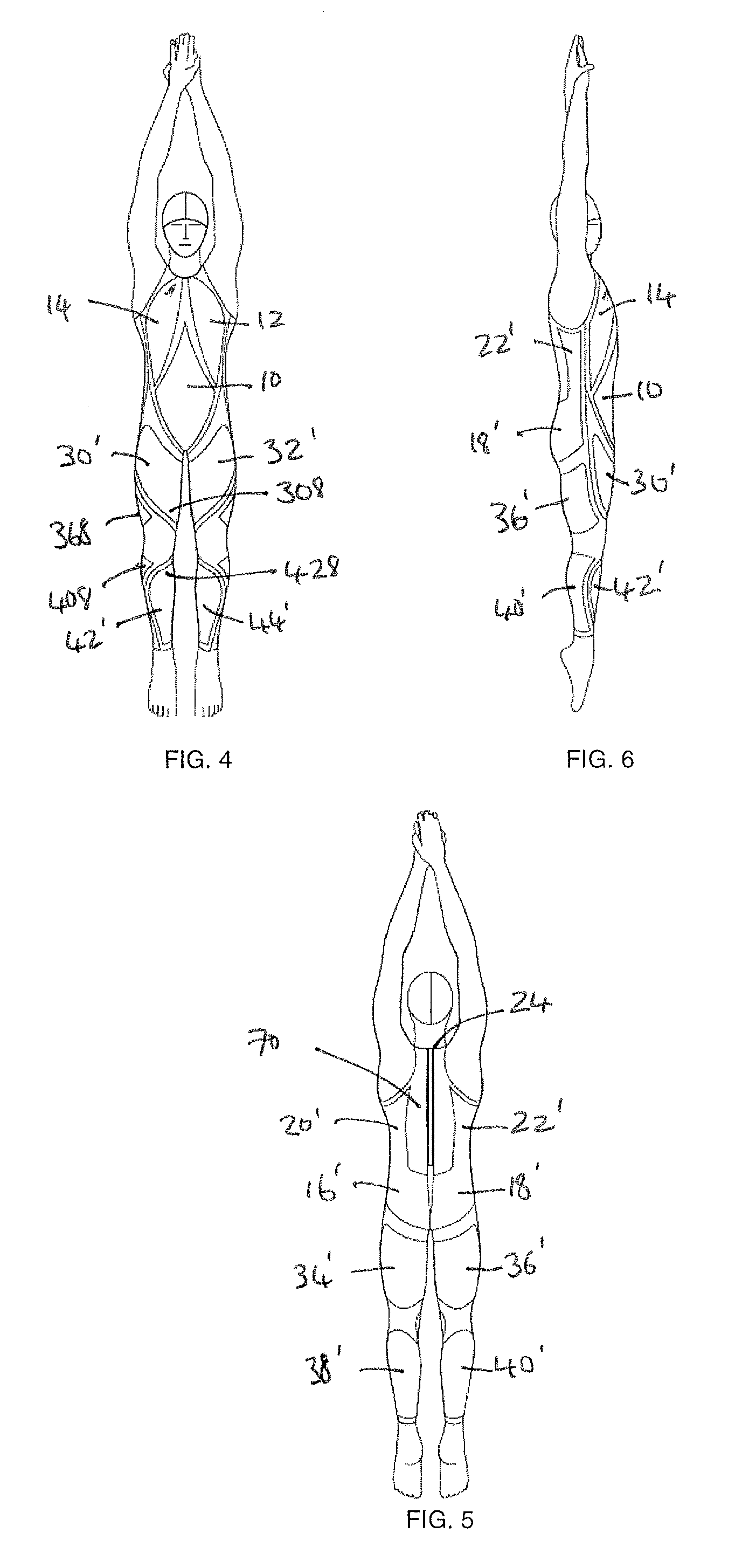

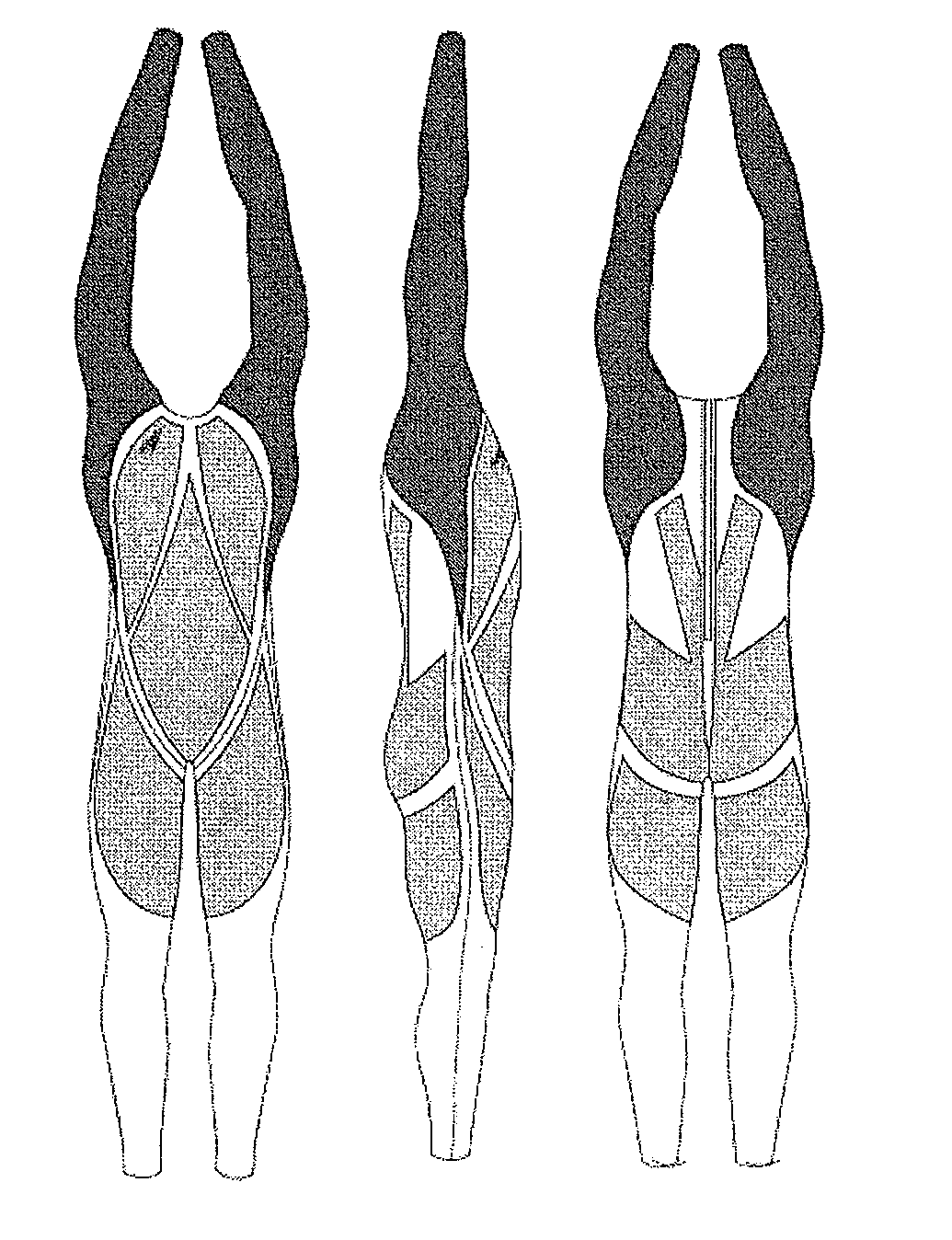

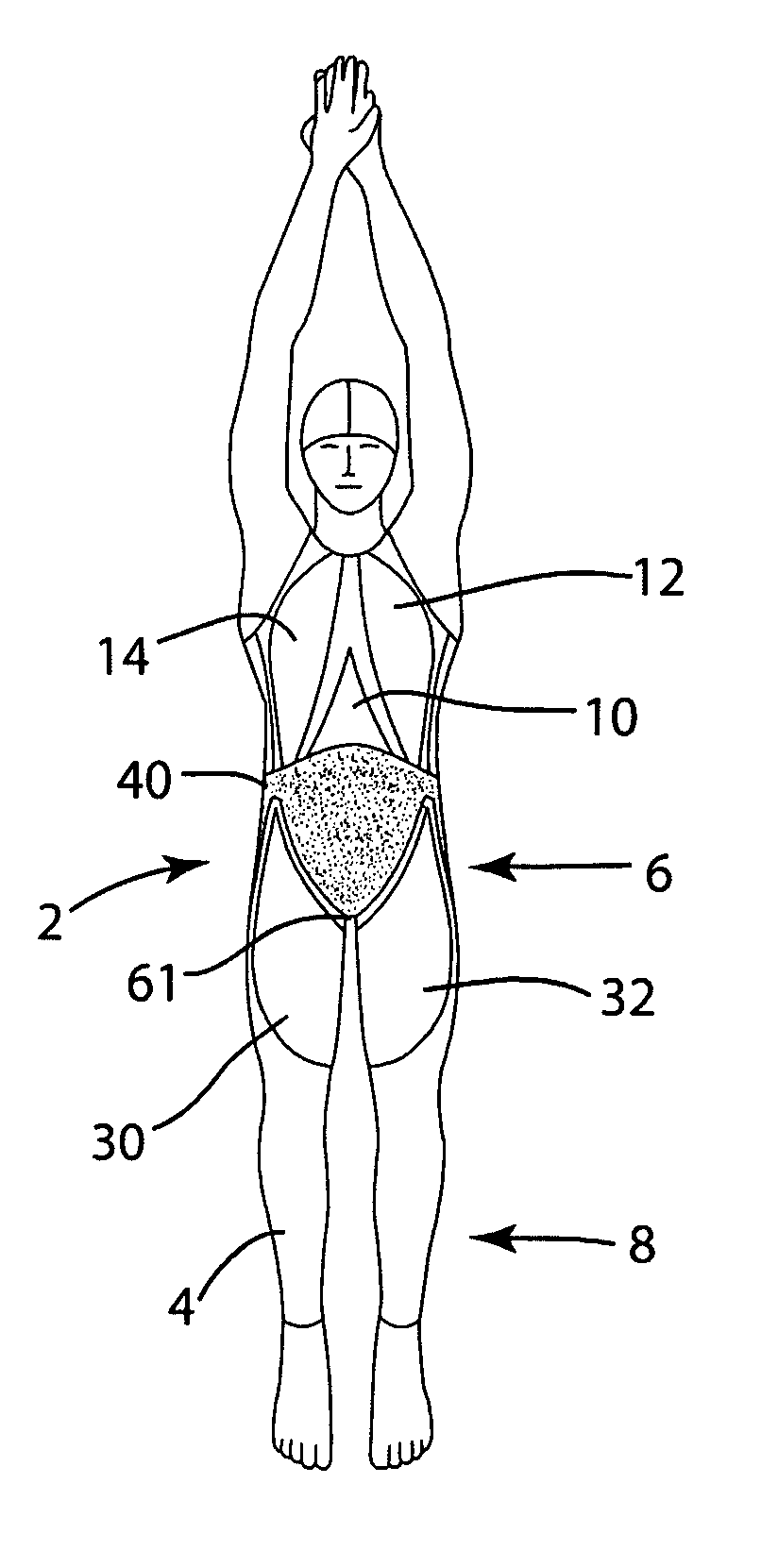

ActiveUS20080141430A1Improve performanceEnsure correct executionGarment special featuresProtective garmentEngineeringSurface drag

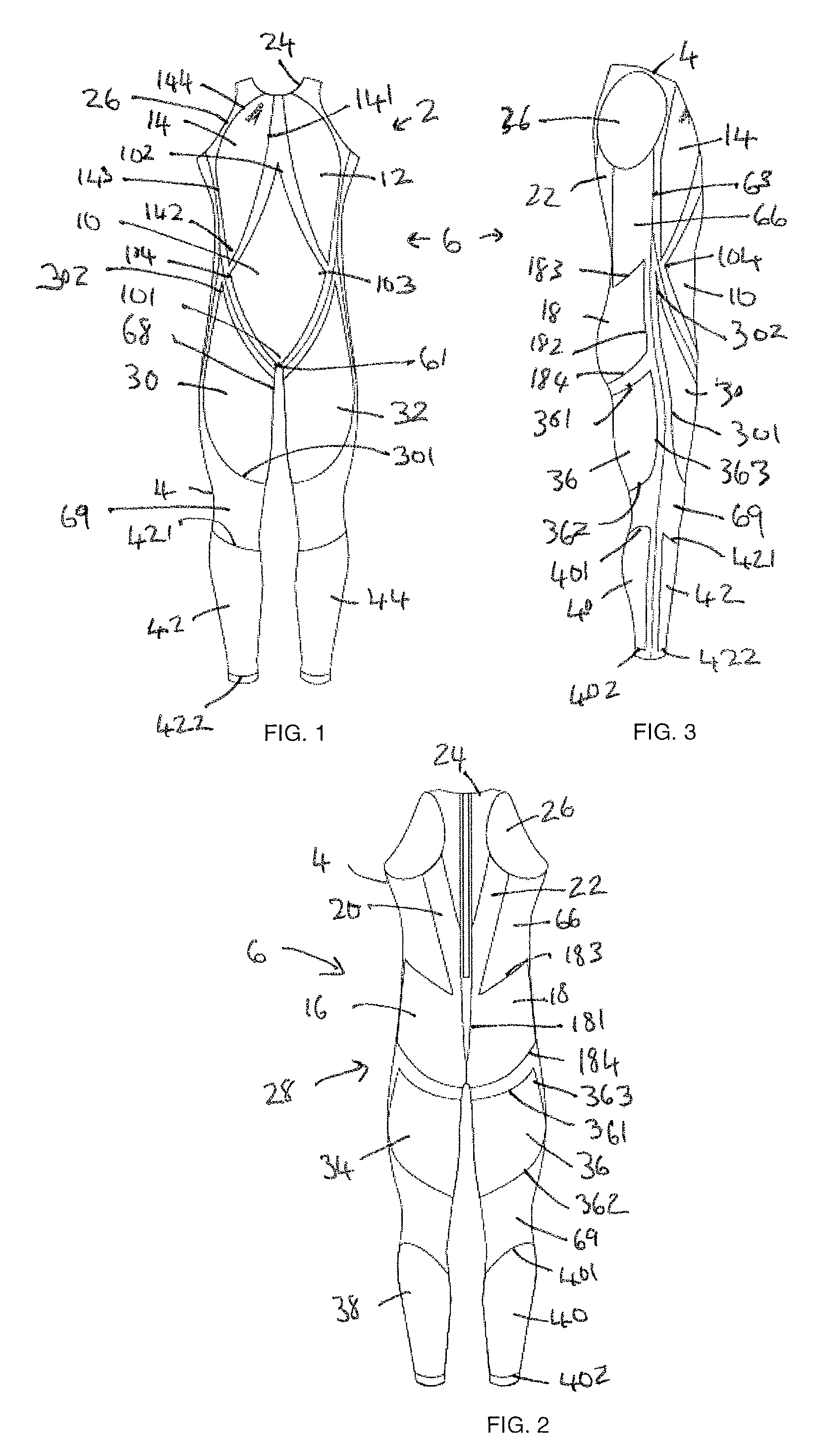

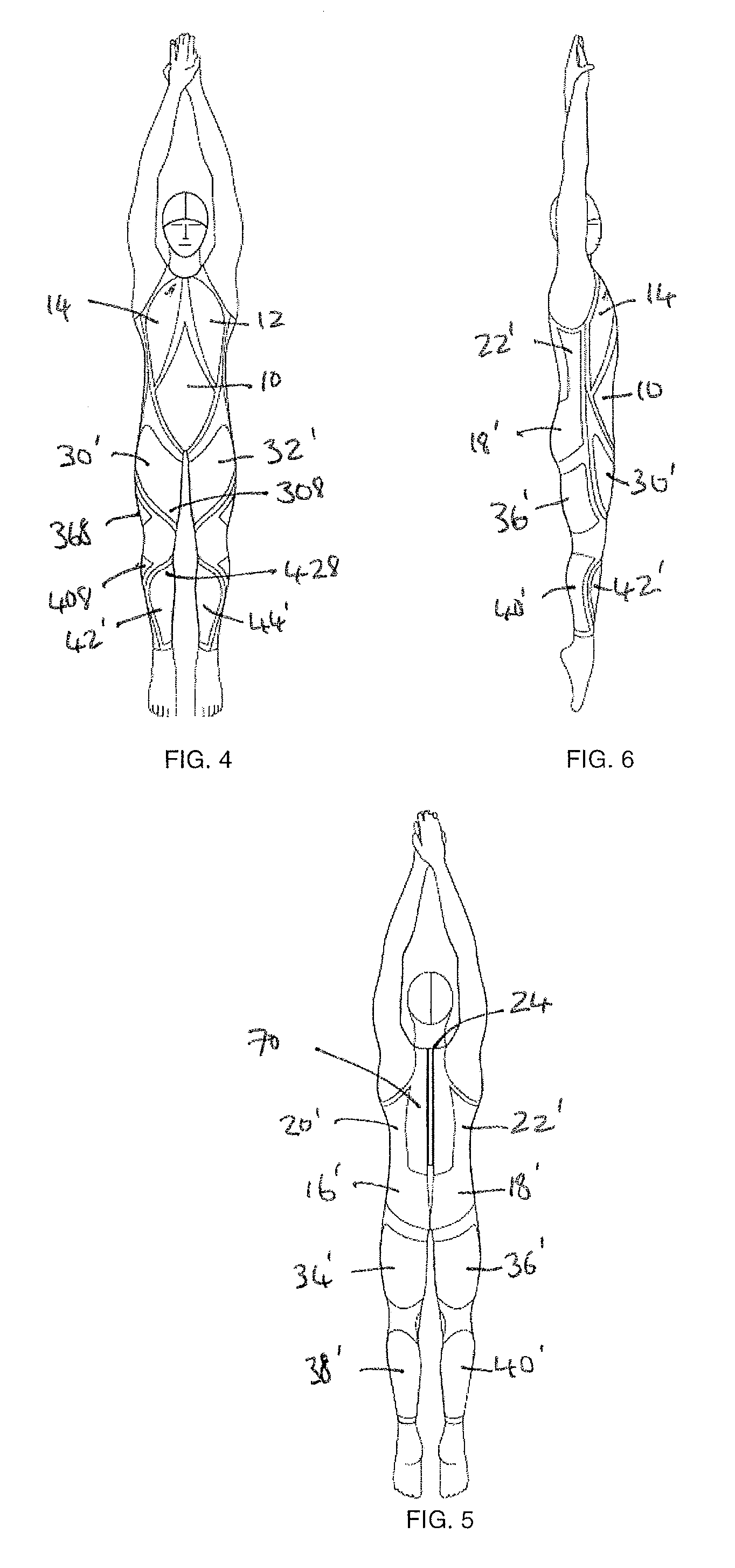

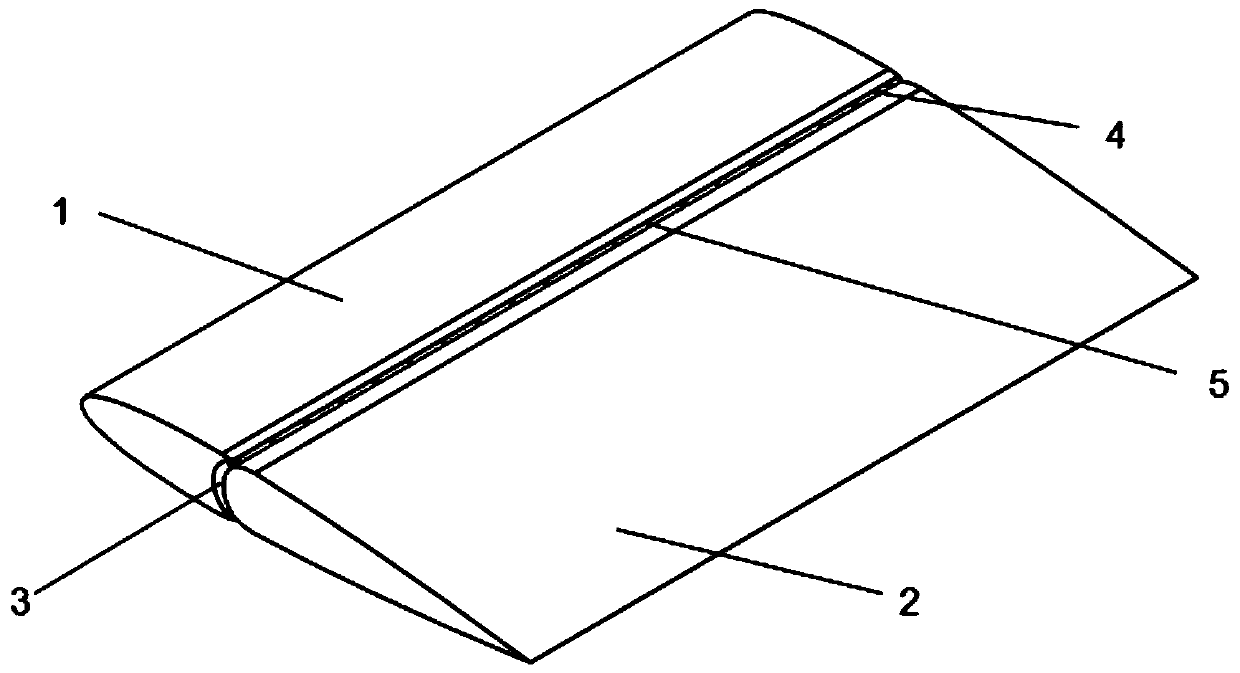

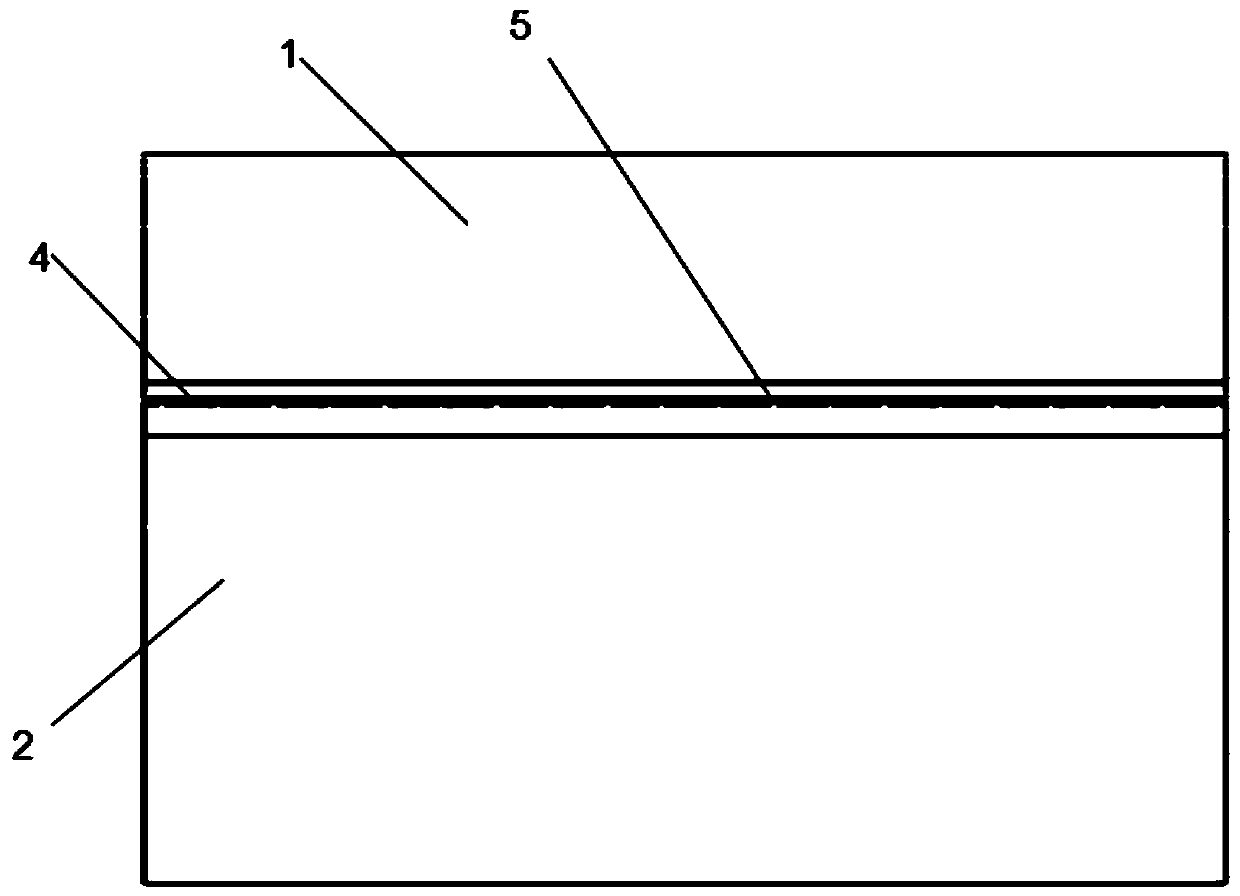

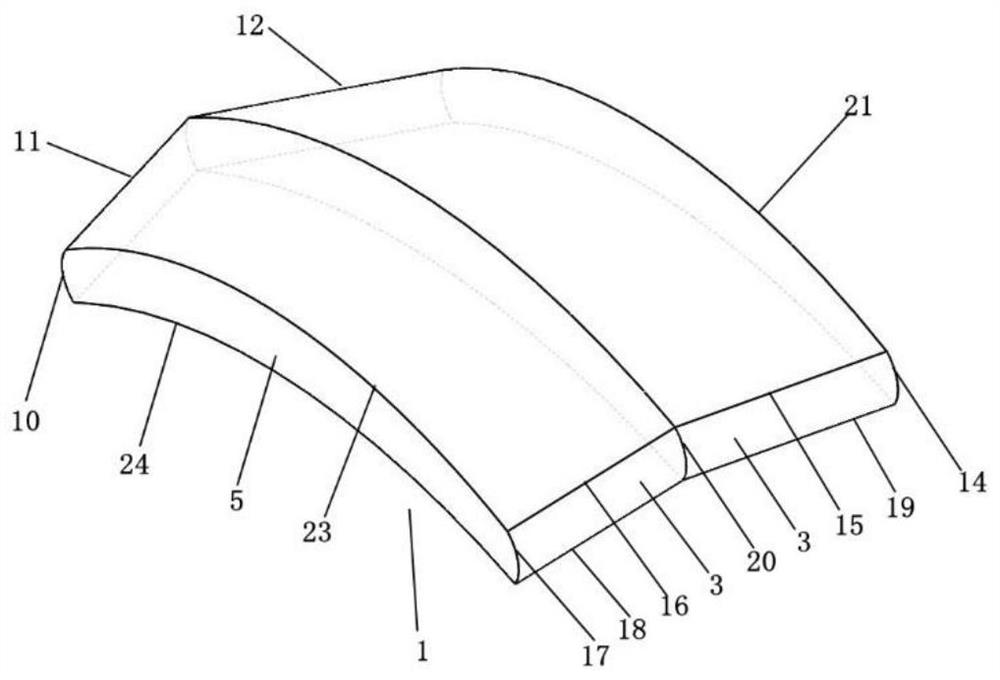

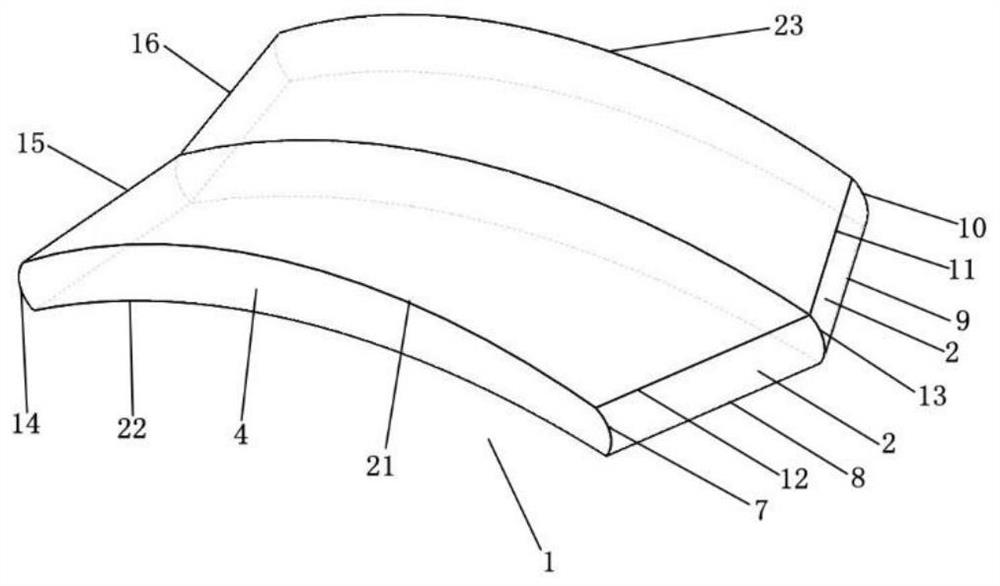

This application describes garments (2), for example swim suits or other sports or athletic garments, in which a plurality of panels (10-22&30-44) are laminated on the outer surface of a base layer (4) of stretchable elasticated fabric to offer (in the case of a swim suit) improved performance for competitive swimmers through a reduction in surface drag, a reduction in form drag and / or improved stability in the water.

Owner:SPEEDO INTERNATIONAL LIMITED

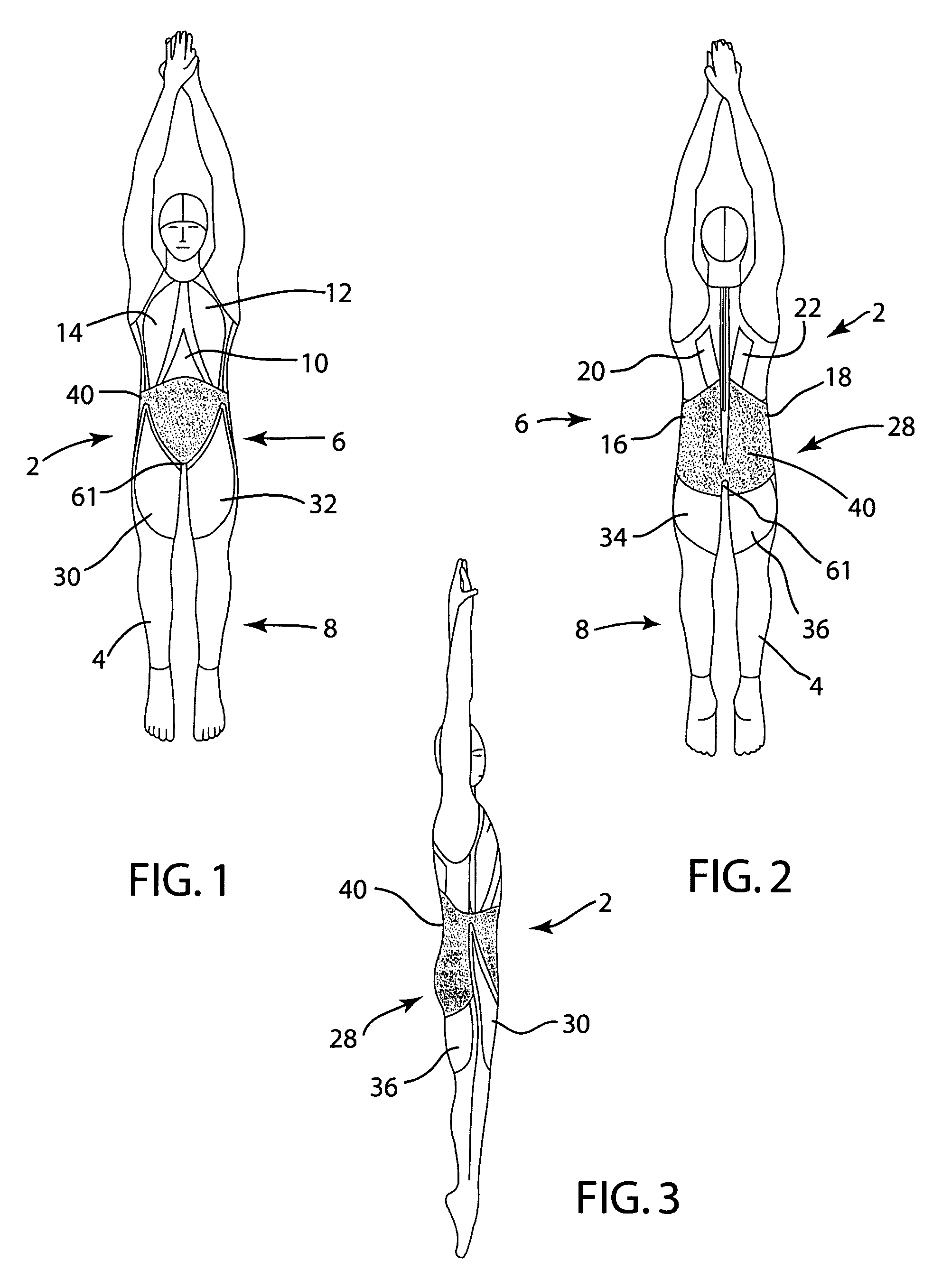

Garments

ActiveUS8286262B2Improve performanceEnsure correct executionGarment special featuresProtective garmentEngineeringSurface drag

Owner:SPEEDO INTERNATIONAL LIMITED

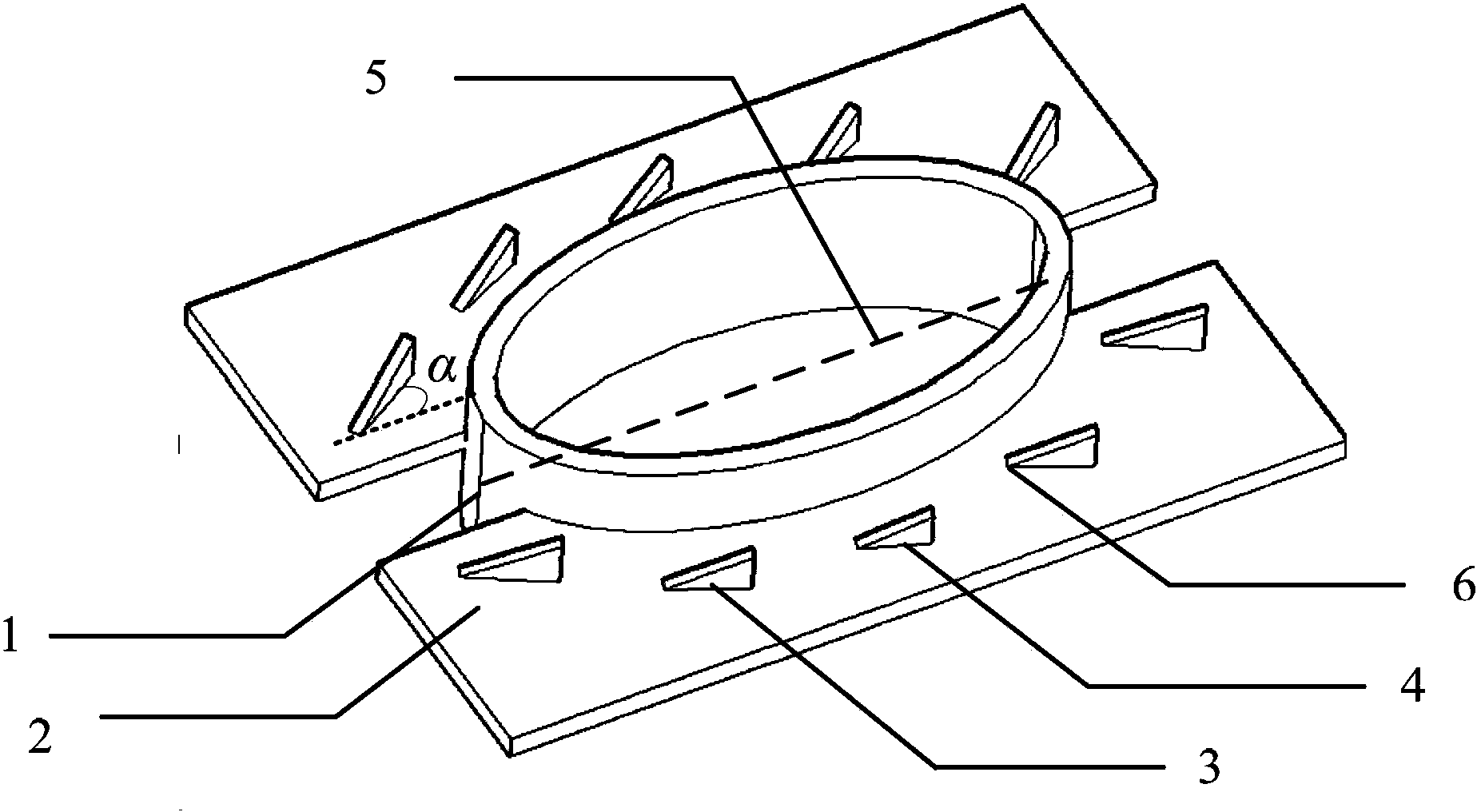

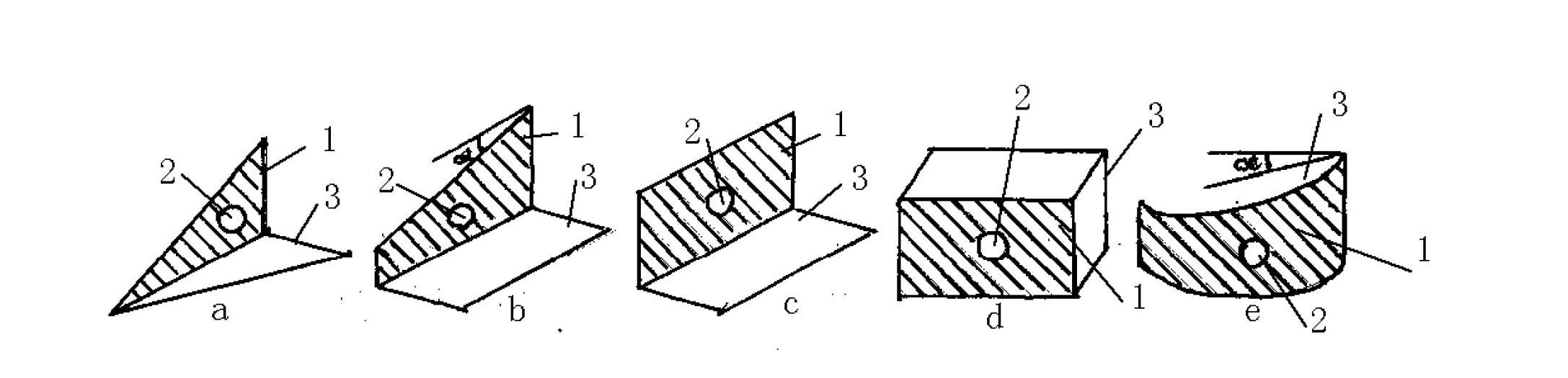

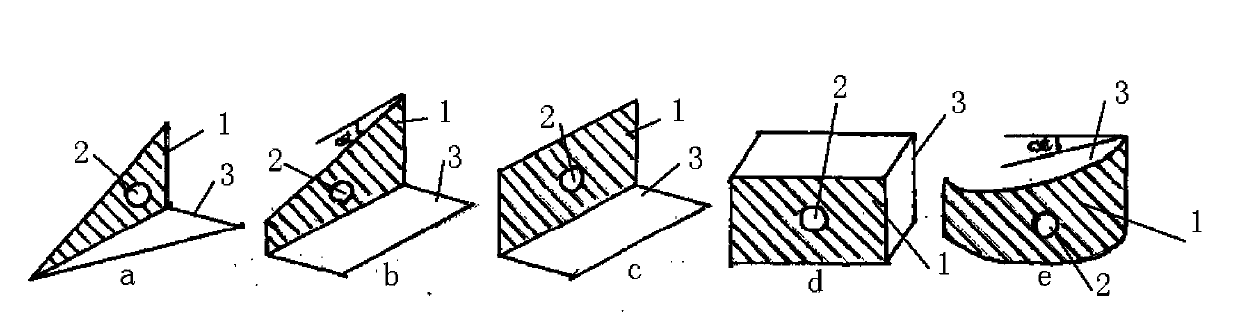

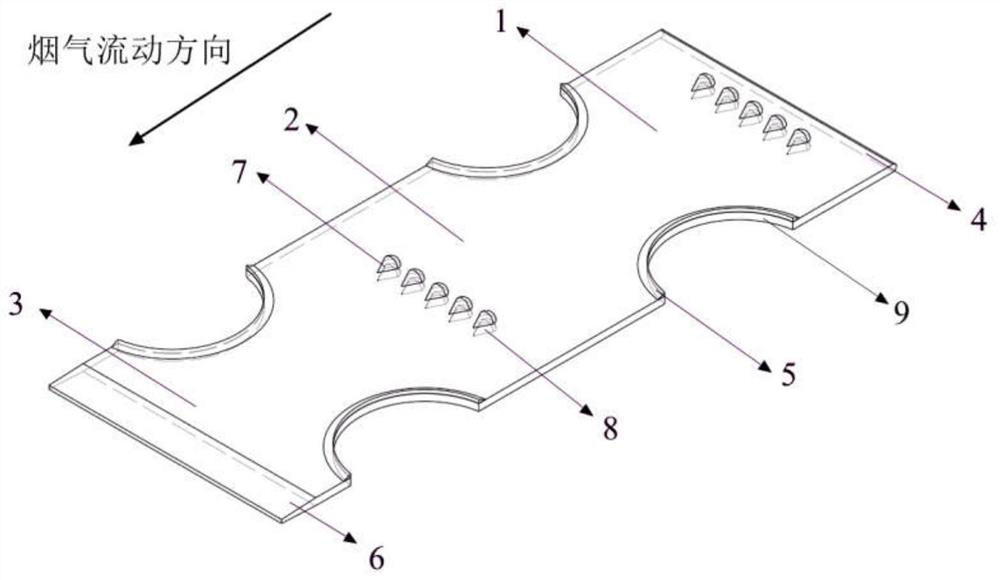

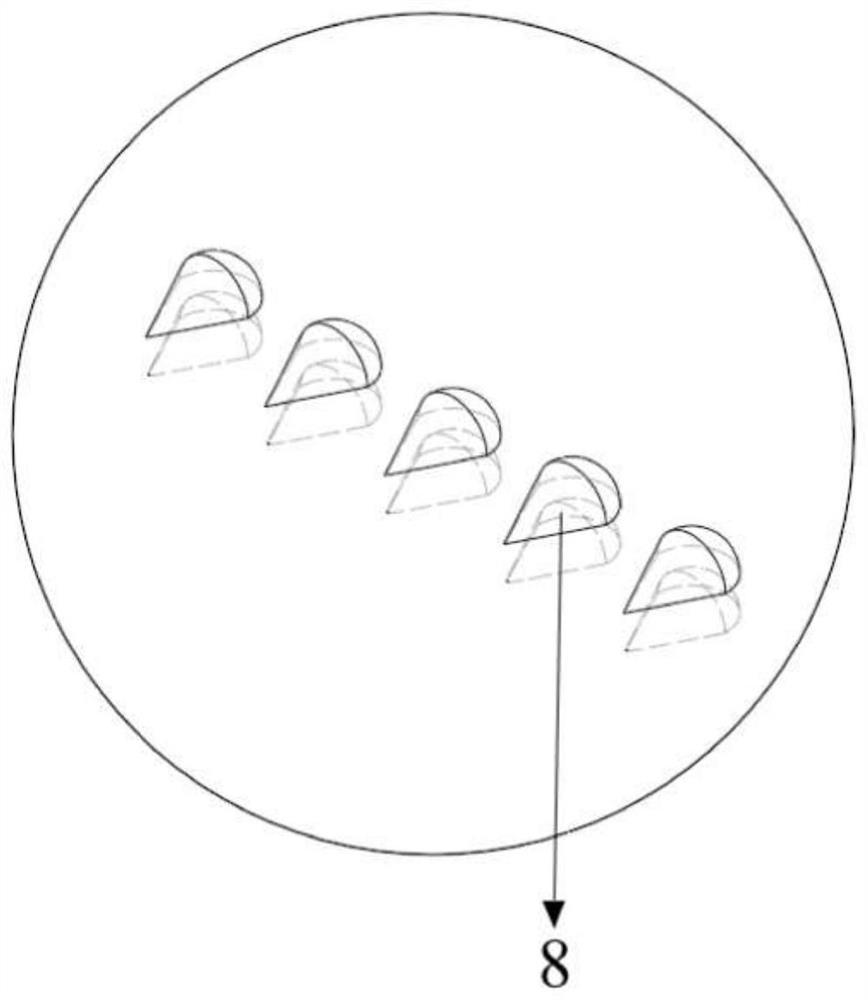

Reinforced heat transfer element of truncated cylindrical surface wing type vortex generator

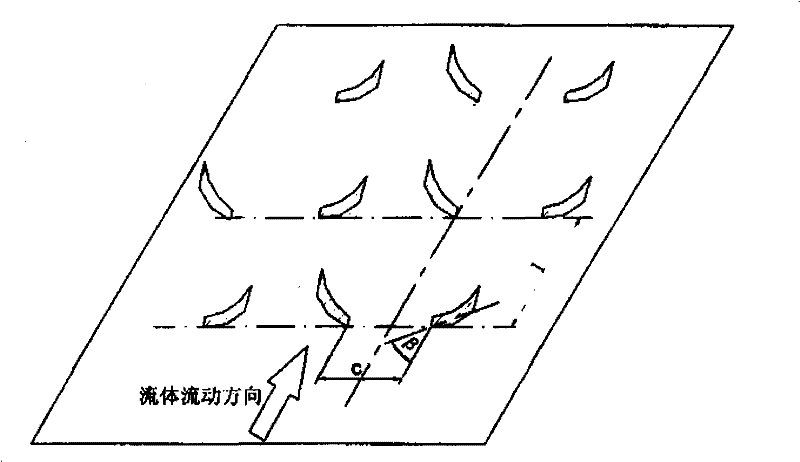

InactiveCN101532798AReduce transportation energy consumptionEnhanced convective heat transferHeat transfer modificationTransportation energyEngineering

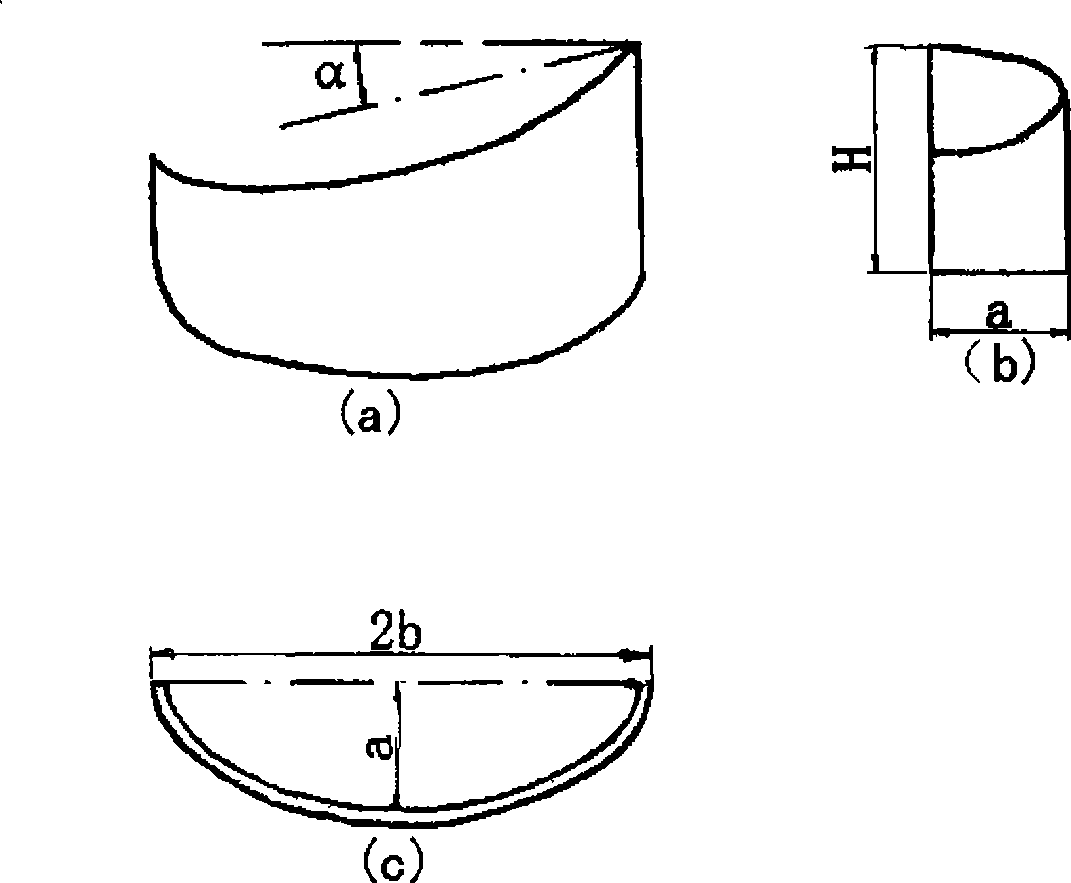

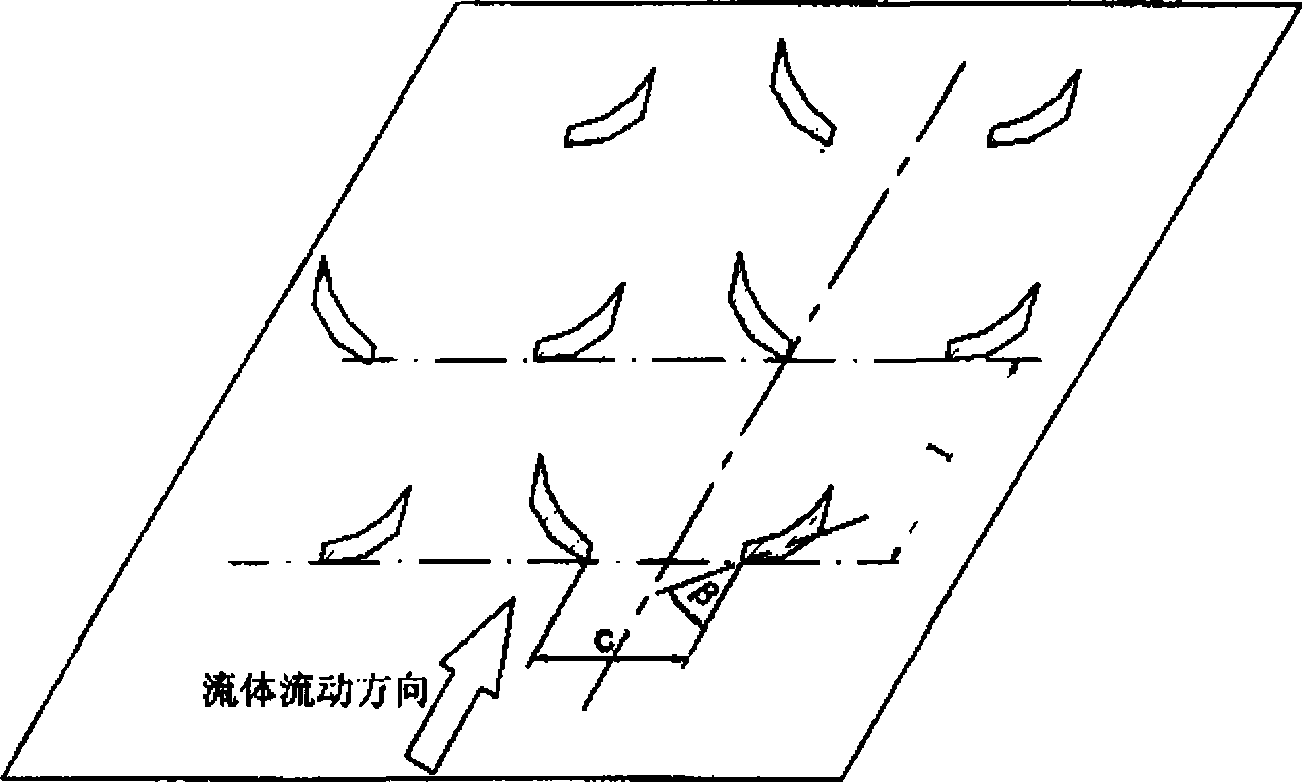

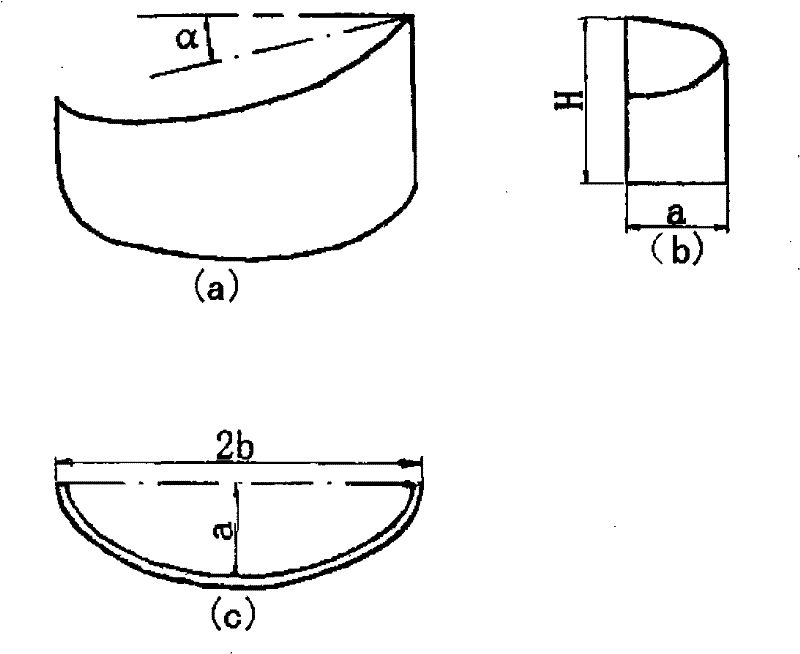

The invention discloses a reinforced heat transfer element of a truncated cylindrical surface wing type vortex generator, belonging to the field of heat transfer parts of heat exchanger. The vertical surface of a wing type vortex generator is bent into a semi cylindrical surface or a semi elliptic cylindrical surface to be arranged on a fin tube or a fin tube of a plate-fin heat exchanger or other passage flow heat exchanger plate surface in a certain incident flow impact angle and a certain array manner so as to induce the end longitudinal vortex and the root part horse shoe vortexes to couple to be thinned or destruct the boundary layer clinging to the wall face or reinforce the turbulence intensity to realize the passive reinforced heat exchange and improve the efficiency of the heat exchanger. In addition, due to the streamline surface, the shape resistance is reduced, thus lowering the flowing pressure loss and the fluid transportation energy consumption. The vortex generator can be manufactured by metal or other bendable molding materials, has the characteristics of simple manufacturing and convenient installation, and has extensive application prospect and promotion value in gas-liquid or gas-gas heat exchangers.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

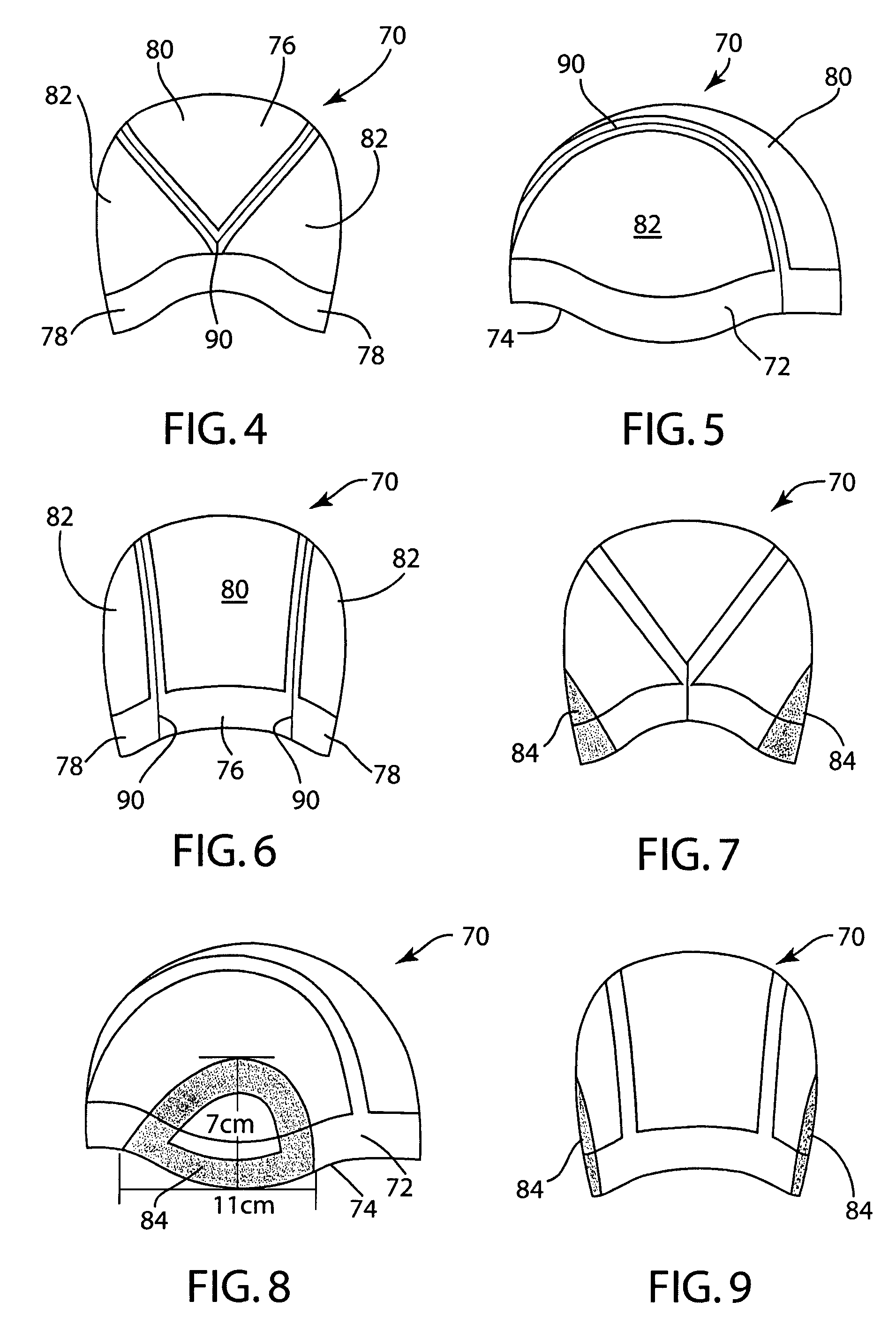

Garments

ActiveUS8196220B2Improve performanceReduce surface resistanceGarment special featuresSwim capsCore stabilityEngineering

This application describes a garment (e.g. a swim suit) having a base layer of stretchable elasticated fabric, the base layer having a torso portion that covers at least a part of the torso of a person when the garment is worn. An inner core layer of stretchable elasticated fabric is bonded to the inner surface of the base layer to extend around the abdomen and lower back regions of the garment. By providing a double layer of stretchable elasticated fabric in this manner, more compression is applied to the abdomen of the person (e.g. swimmer) wearing the suit, bringing about improvements in form drag. The additional support provided to the lower back and abdomen also improves core stability, which is of benefit in many sporting activities, including swimming.

Owner:SPEEDO INTERNATIONAL LIMITED

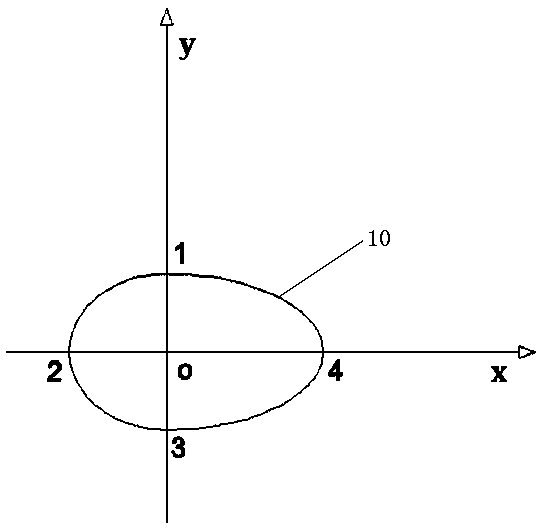

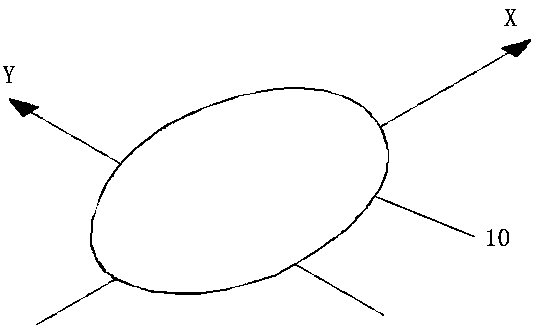

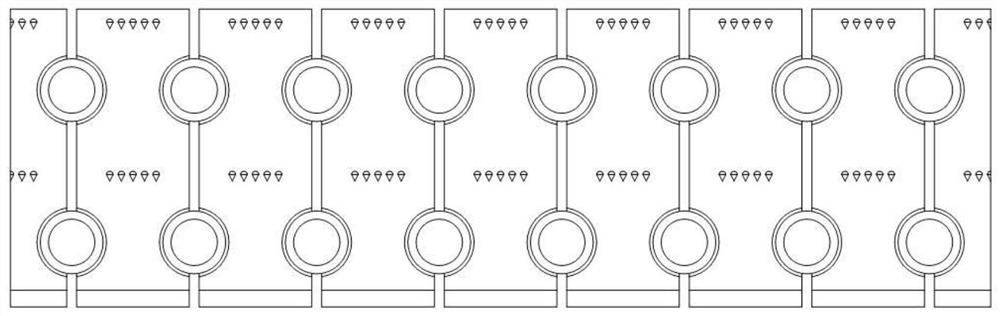

Elliptical tube H-shaped fin heat exchanger for waste heat recovery

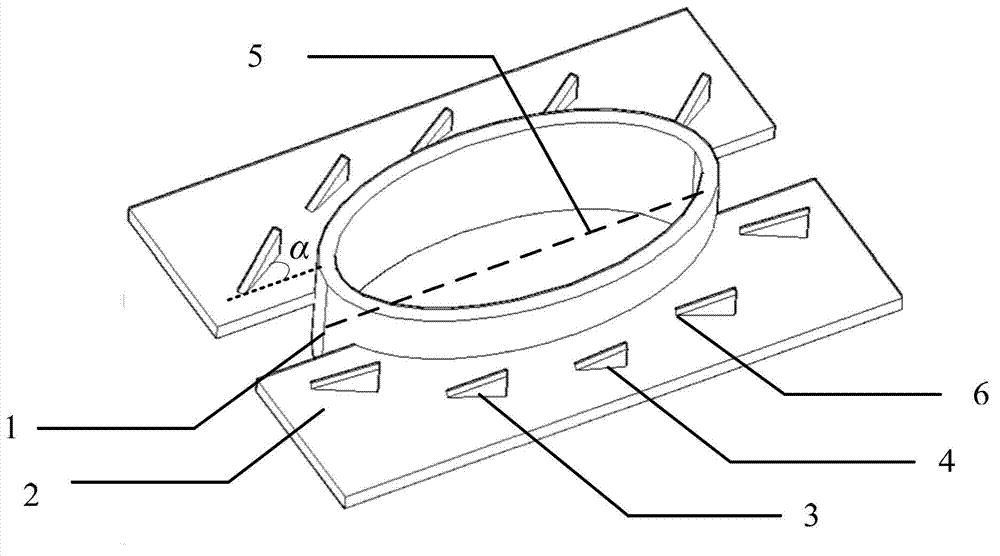

ActiveCN103438746AIncrease disturbanceIncrease the thermal resistance of heat transfer, reduce the wake zone" enhanced heat transfer principleTubular elementsParticle adhesionWaste heat recovery unit

The invention discloses an elliptical tube H-shaped fin heat exchanger for waste heat recovery. The elliptical tube H-shaped fin heat exchanger comprises an elliptical heat exchange tube, a plurality of groups of H-shaped fins and a heat exchanger surface, wherein the H-shaped fins are sleeved on the surface of the heat exchange tube; the heat exchanger surface consists of non-uniform triangular small wings, which are elliptically arranged, on the surfaces of the H-shaped fins around the elliptical heat exchange tube. When dusty flue gas flows through the surfaces of the H-shaped fins, the small wings disturb the fluid to enhance the heat exchange on the tube wall and the downstream side, and meanwhile, the deposition of particles on the tube wall is reduced; the pressure drop can be reduced by the elliptical tube while the particle adhesion is reduced. A plurality of longitudinal vortexes are arranged in a non-uniform manner; at the front and rear edges of the wing, the size of the small wings and the windward attack angle are larger; on the middle parts of the H-shaped fins, the size of the small wings and the attack angle are smaller; by using the device, the heat exchange surface in different flow states can be enhanced respectively, the heat exchange of the fins are effectively enhanced, the pressure drop is reduced, and the deposition of dust particles in the flue gas on the heat exchange surface is reduced, so that the heat exchanger can operate efficiently for a long time in the dusty flue gas.

Owner:XI AN JIAOTONG UNIV

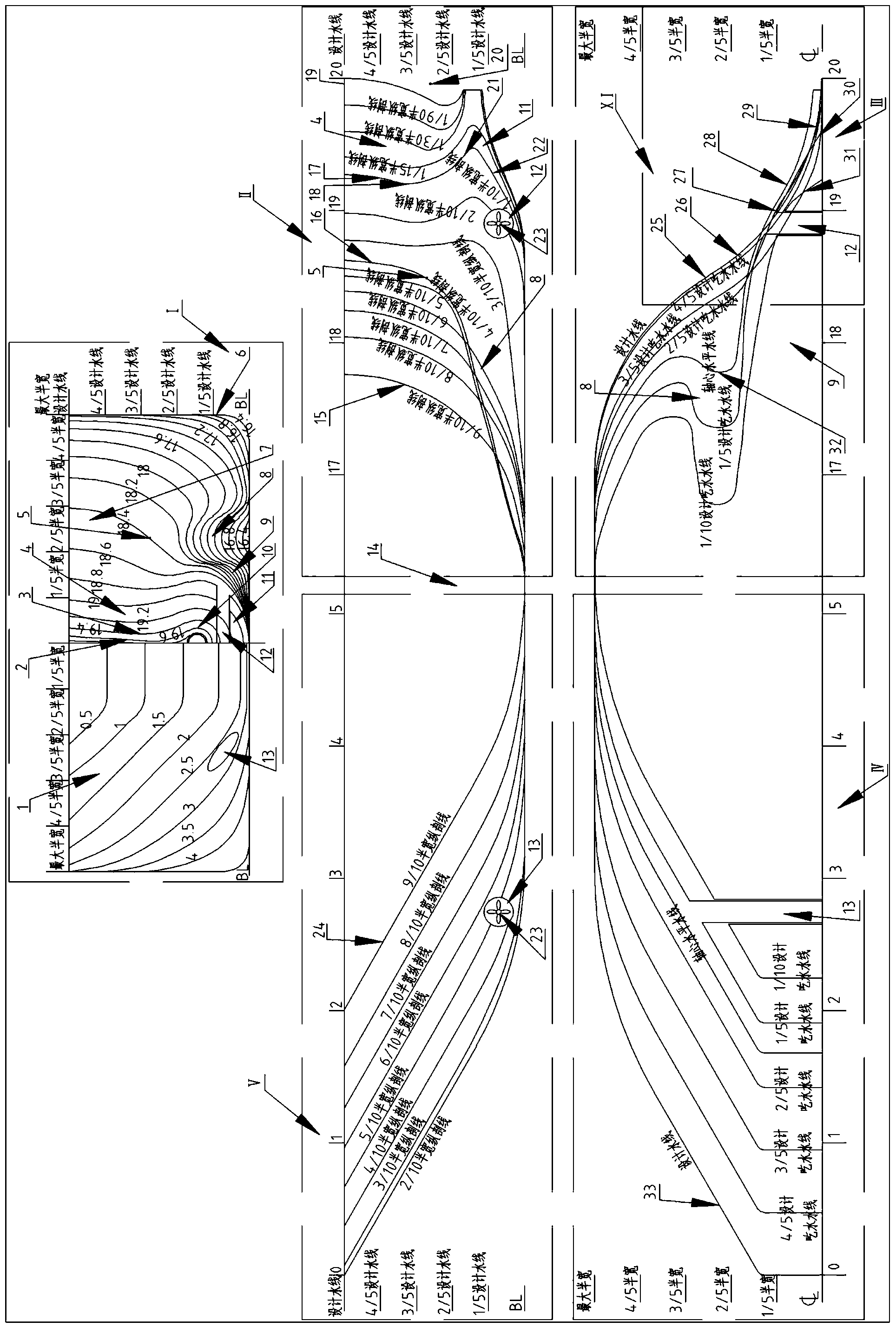

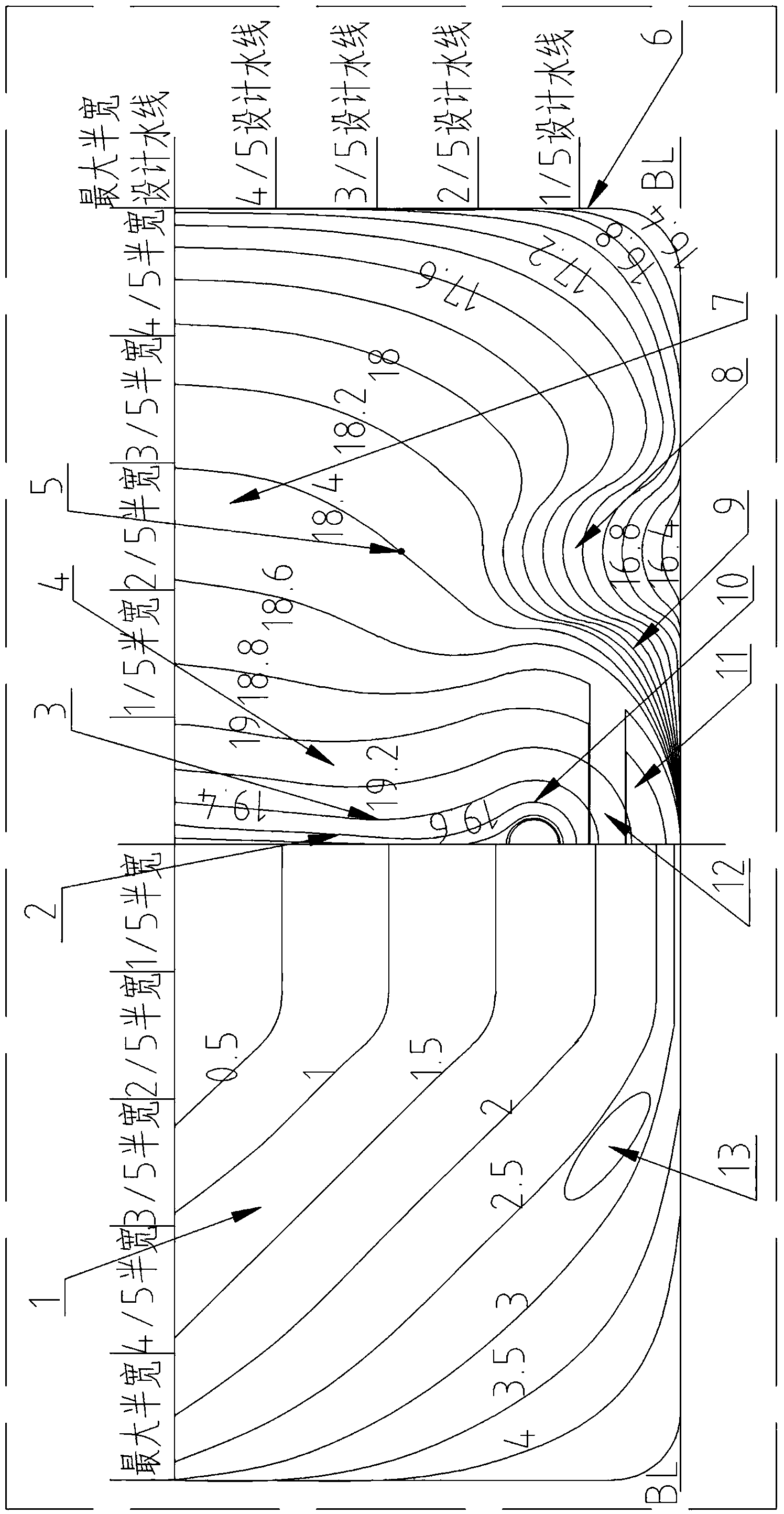

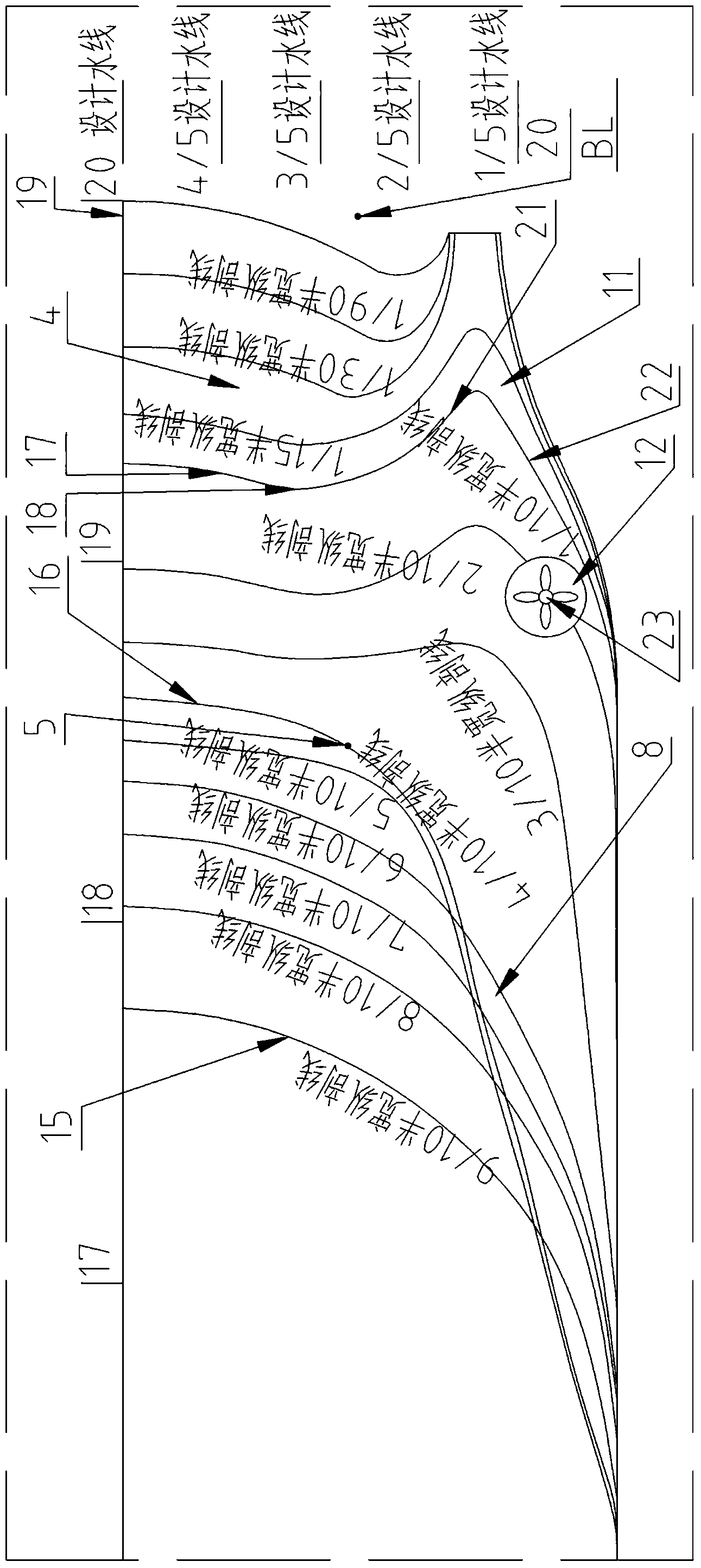

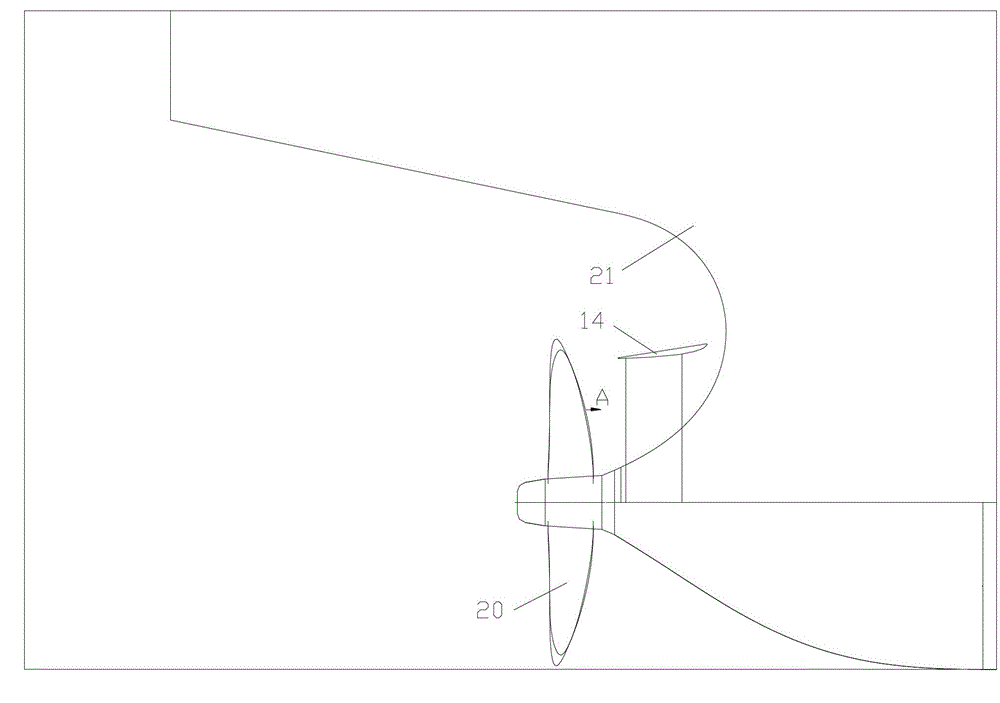

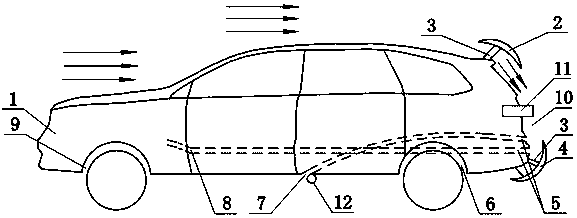

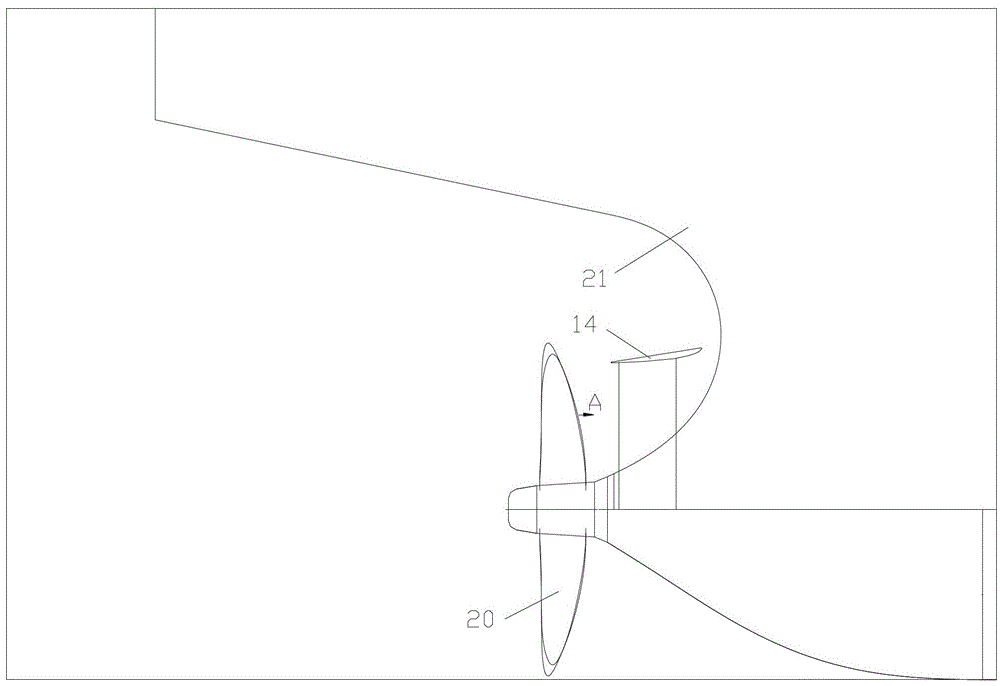

Low-resistance hull under designed waterline

InactiveCN103523152AReduced eddy current resistanceReduce wave resistanceHydrodynamic/hydrostatic featuresPropellerEngineering

The invention relates to a low-resistance hull under a designed waterline, belongs to the field of hull shape design, and mainly relates to the design of hulls under the designed waterline. A propeller is arranged on a ship bow, a shell bossing is designed to be in a spindly shape similar to a cone, the two sides of a transition position between the shell bossing and the hull above the shell bossing are respectively provided with an arc flow guide water groove, the bow waterline above the shell bossing is designed to be in a V shape with the big end up, and the V-shaped bow waterline has a flow guide effect. An area which has a small included angle between the surface normal of the bow and the navigation direction is designed to be close to one fourth to three fourths of ship width, two inclined flow guide water grooves are formed in the two sides of a main engine space located on the lower portion of the ship bow, a symmetric ship bow or an asymmetric ship bow is used, and the stern of the hull is designed to be a streamline reducing body. The bow and the stern are respectively provided with a flow channel which penetrates through the larboard and the starboard, and a spraying propelling unit is arranged in the hull to meet the steering requirement of the hull. Through linear bow and stern design and the propeller arranged on the bow, the head and wake flow fields of the hull are improved, adverse effects of water on ship navigation are weakened, and ship resistance is reduced.

Owner:何攀

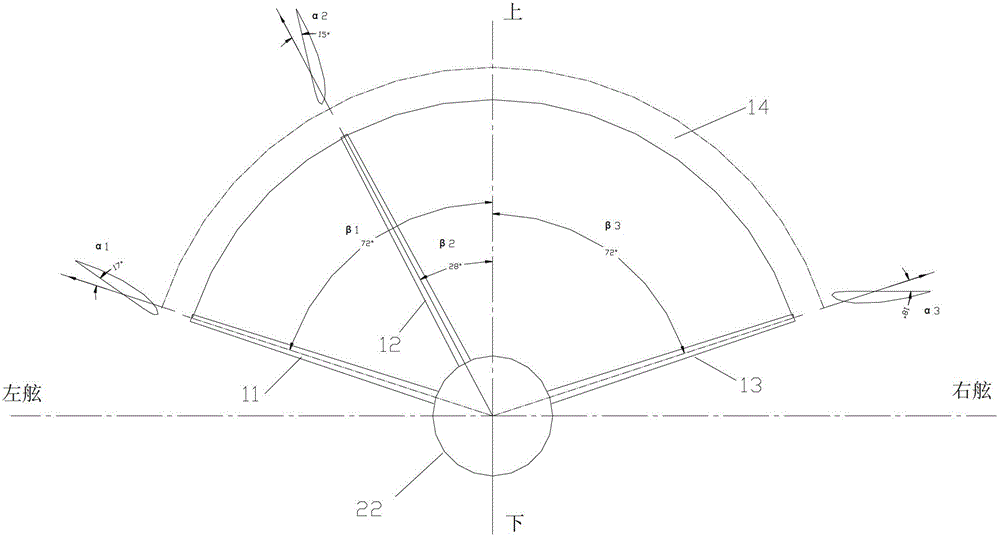

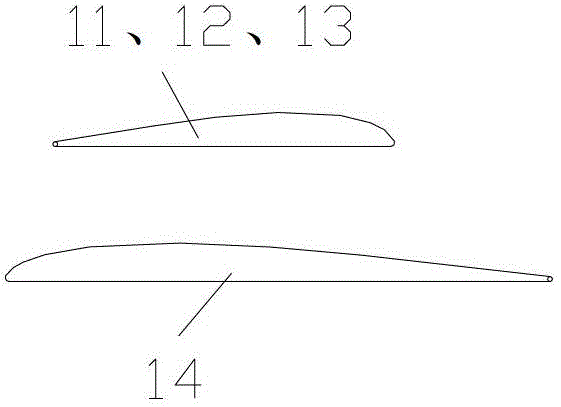

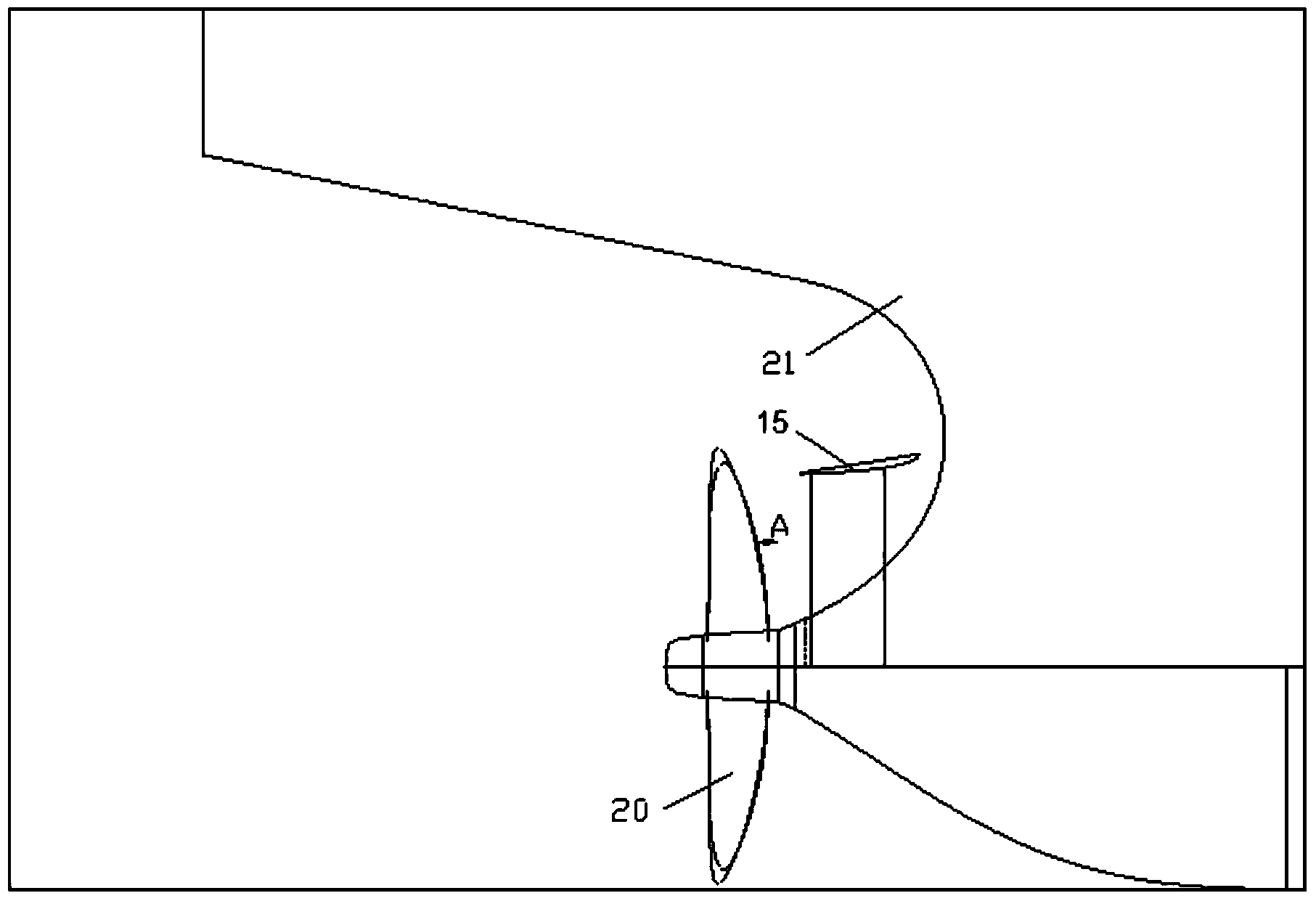

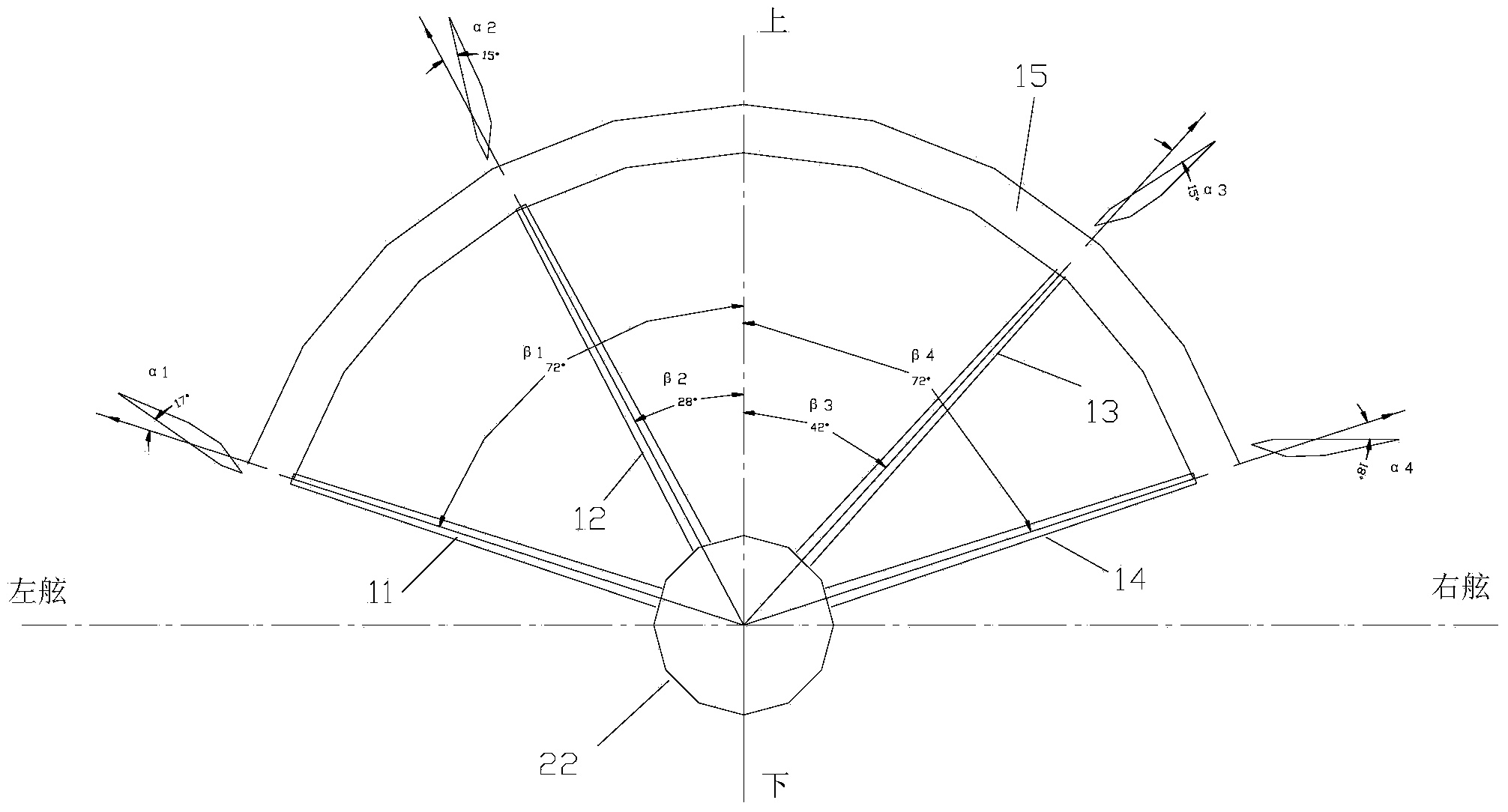

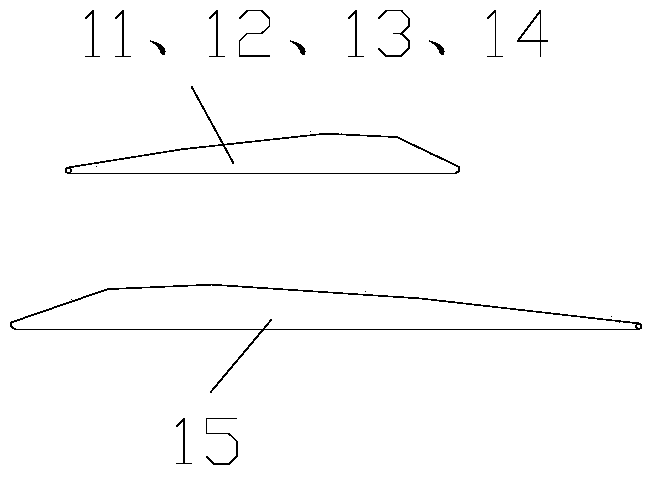

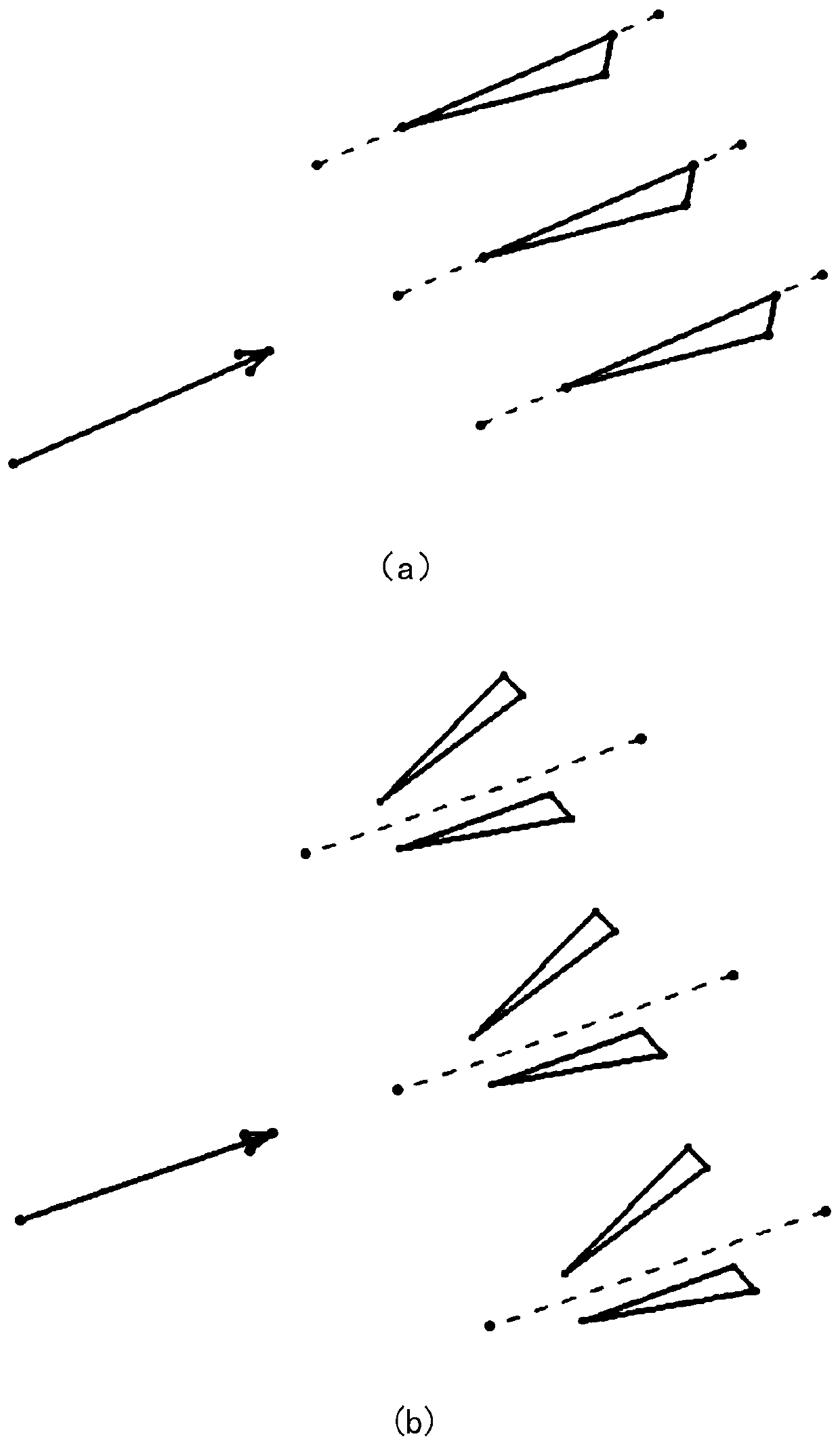

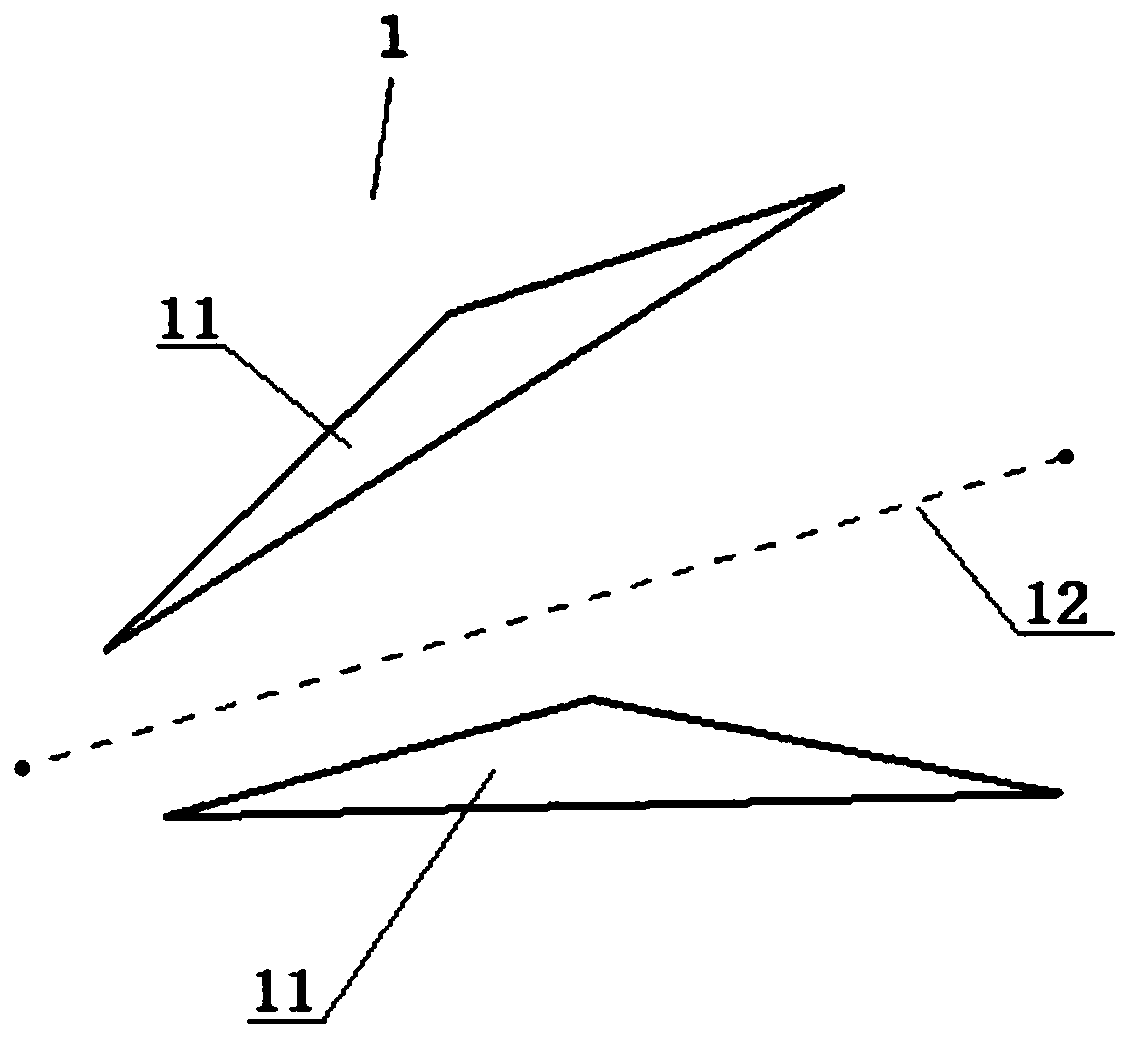

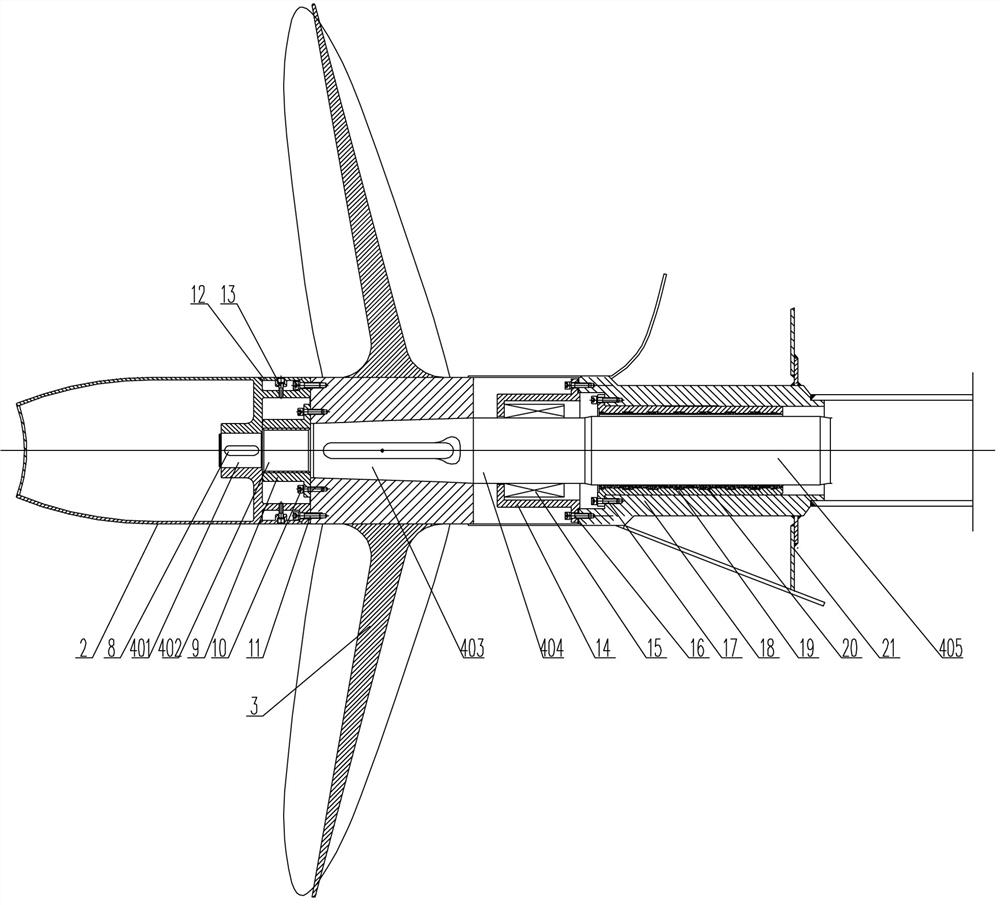

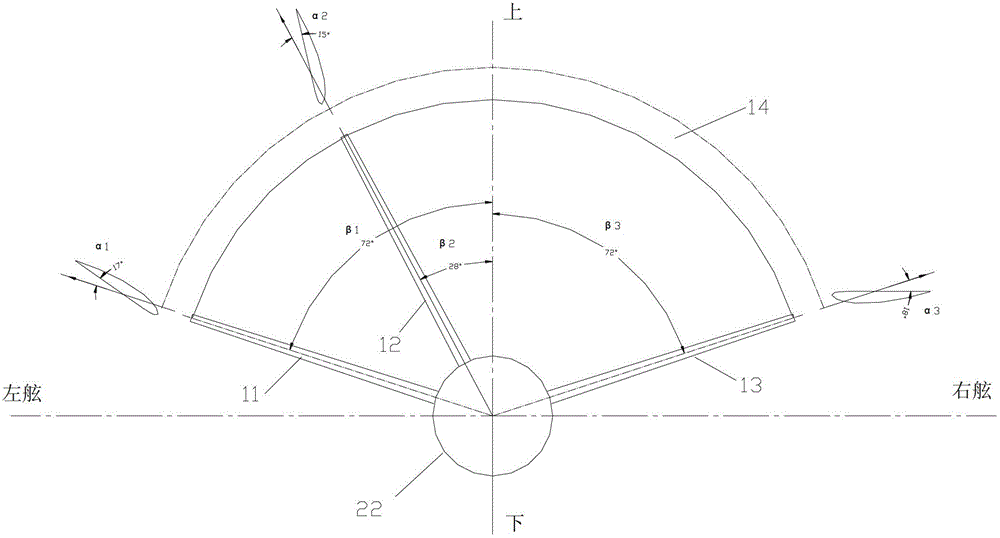

Pre-rotation triangular conduit for right-handed rotation single screw vessel

ActiveCN103332281AImprove rectification effectReduced wetted surface areaRotary propellersPropulsive efficiencyEngineering

The invention discloses a pre-rotation triangular conduit for a right-handed rotation single screw vessel. The pre-rotation triangular conduit has a fan-shaped structure; seen from the rear side of a screw propeller, a second blade and a first blade are arranged from top to bottom on the left side of a longitudinal central line of a propeller hub of the screw propeller, and a third blade is arranged on the right side; a blade back of a guide plate is fixedly connected with a blade tip of the first blade, a blade tip of the second blade and a blade tip of the third blade respectively; the included angle range of the first blade and the longitudinal central line of the propeller hub of the screw propeller is 70-75 degrees; the included angle range of the second blade and the longitudinal central line of the propeller hub of the screw propeller is 25-30 degrees; and the included angle range of the third blade and the longitudinal central line of the propeller hub of the screw propeller is 70-75 degrees. By using the principle of pre-rotation before the propeller and screw propeller upper inlet flow acceleration, the pre-rotation triangular conduit is a piece of body energy saving equipment with more uniform inlet flow of the screw propeller disk; and importantly, the energy lost due to rotation of a wake flow field of the screw propeller is reduced, the screw propeller propulsive efficiency is improved and the additional form resistance due to tail flow separation is reduced.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

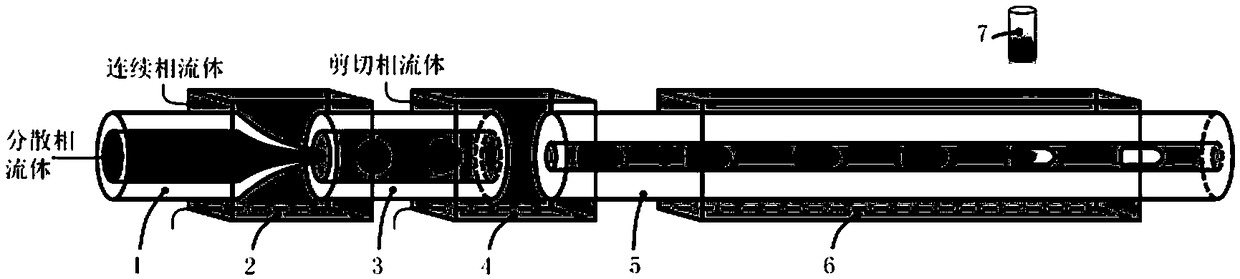

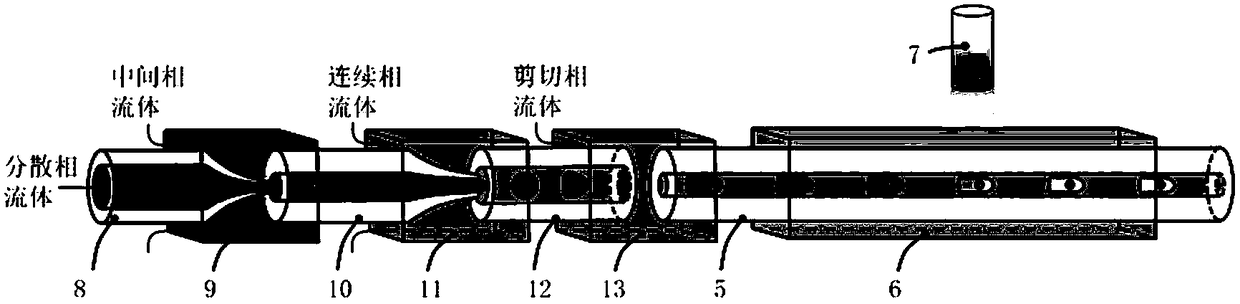

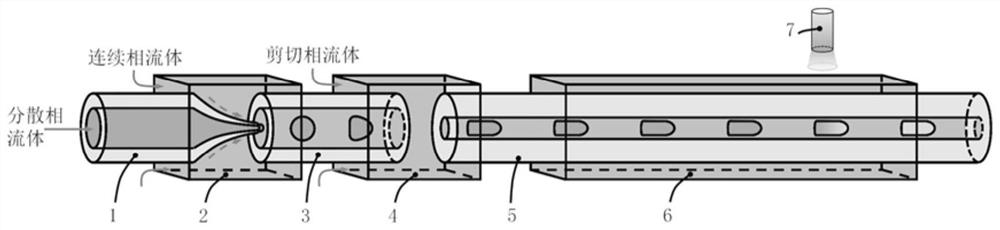

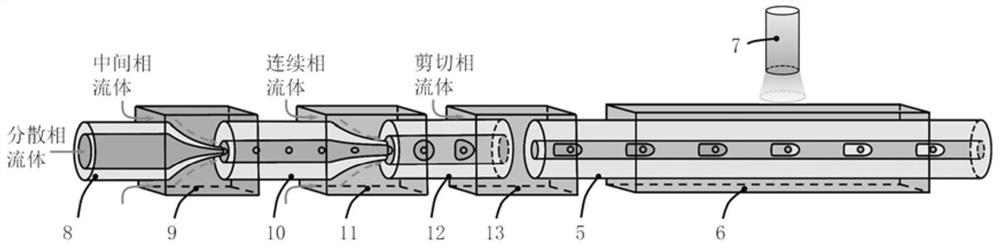

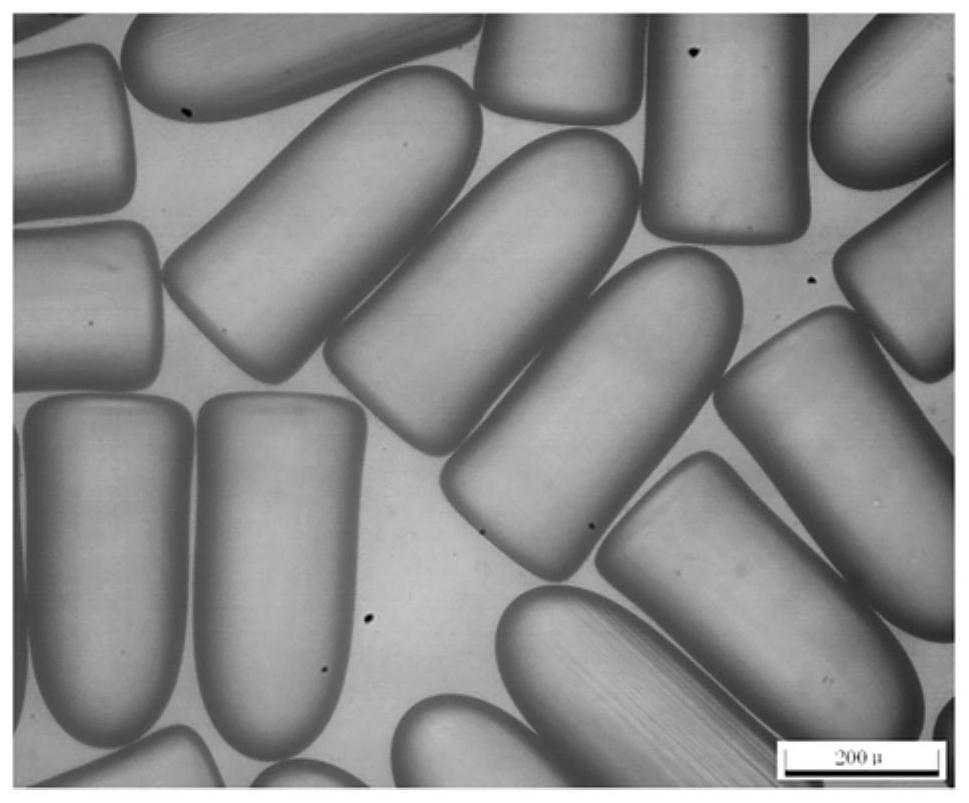

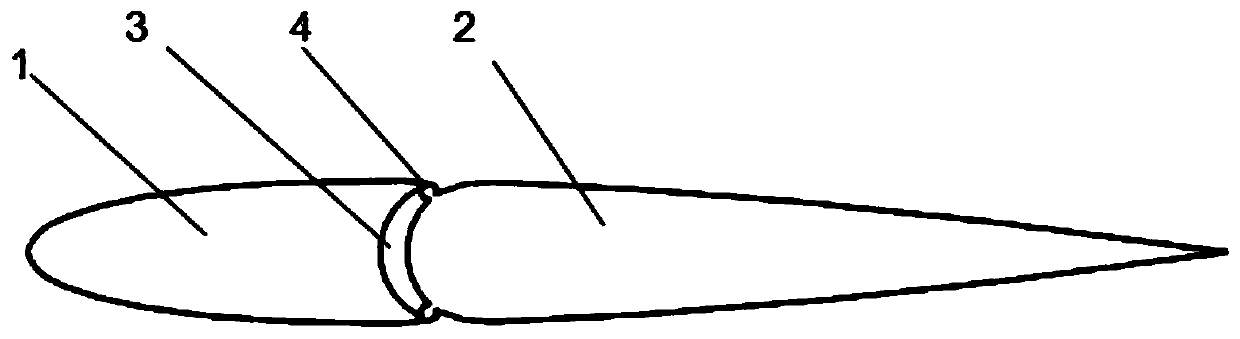

Bullet-shaped non-spherical micro-particle and microcapsule, and preparation method thereof

ActiveCN109482111AReduced shape resistanceImprove flow characteristicsPharmaceutical product form changePharmaceutical non-active ingredientsMicrofluidicsAgricultural engineering

The invention provides a bullet-shaped non-spherical micro-particle and microcapsule. A matrix of the micro-particle and micro-capsule is a polymerized photopolymerizable macromolecule, and the micro-particle and microcapsule is of an integrated bullet shape and consists of a similarly cone-shaped head portion and a cylindrical tail portion which are smoothly connected with each other; the microcapsule has at least one mutually independent chamber; and an oil phase solution is contained in the chamber. The invention further provides a method for continuously preparing the above bullet-shaped non-spherical micro-particle and microcapsule by using a microfluidic technique. The technical scheme provided by the invention can improve the flow characteristics and the movement rate of the microparticle and microcapsule in a channel, and improve the embedding effect of the microparticle and microcapsule. The microcapsule provided by the invention can realize entrapment and transport of activeingredients such as a drug.

Owner:四川大川合颐生物科技有限公司

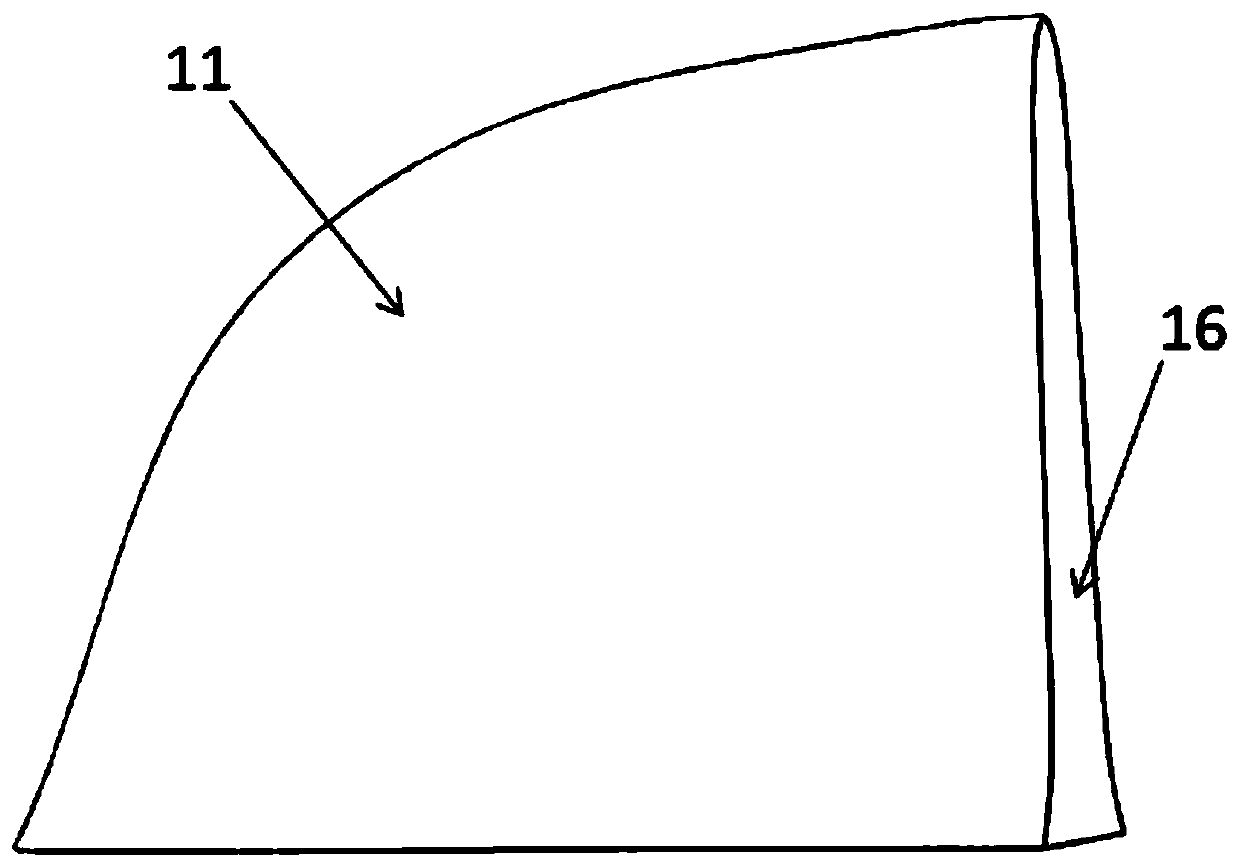

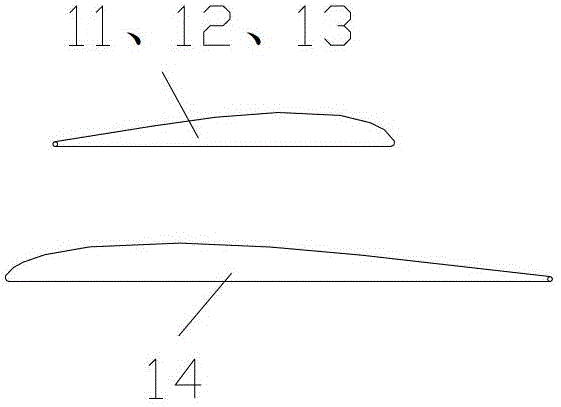

Novel vortex generator for wind turbine blade

InactiveCN110131096ALow flow resistanceReduce projected areaMachines/enginesEngine componentsLeading edgeHigh energy

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

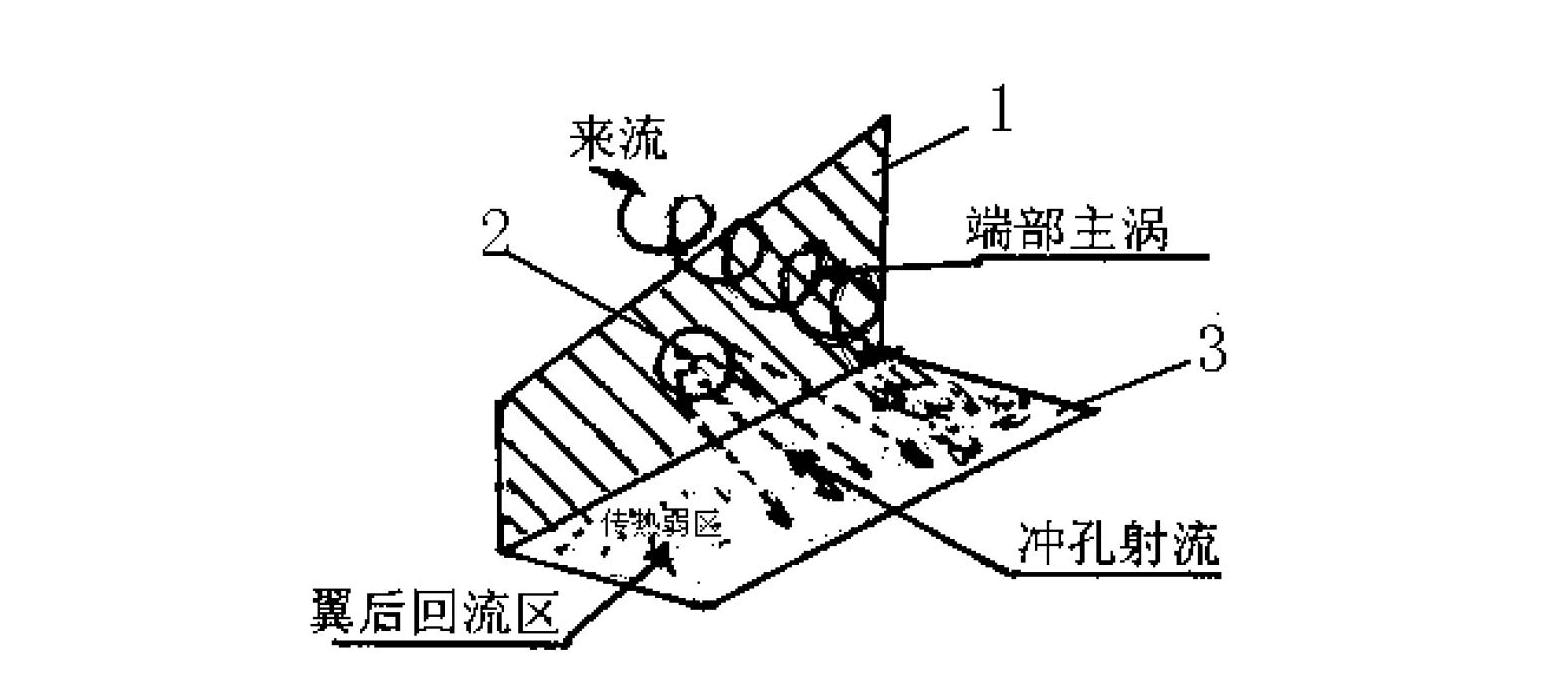

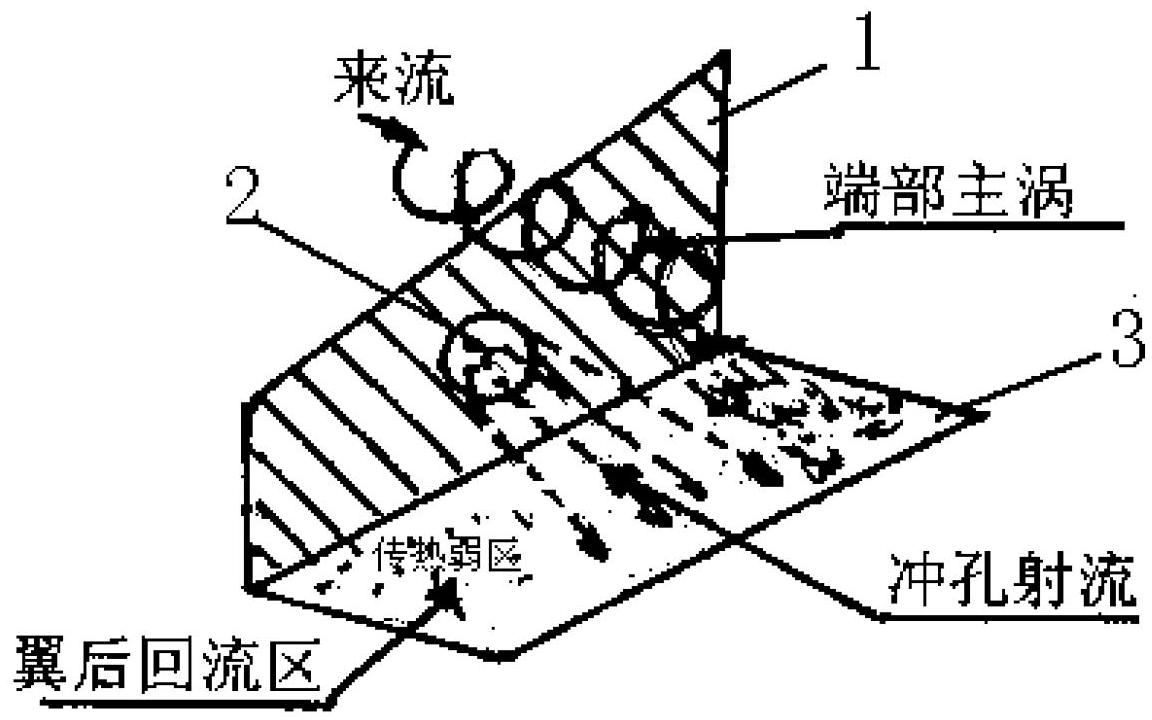

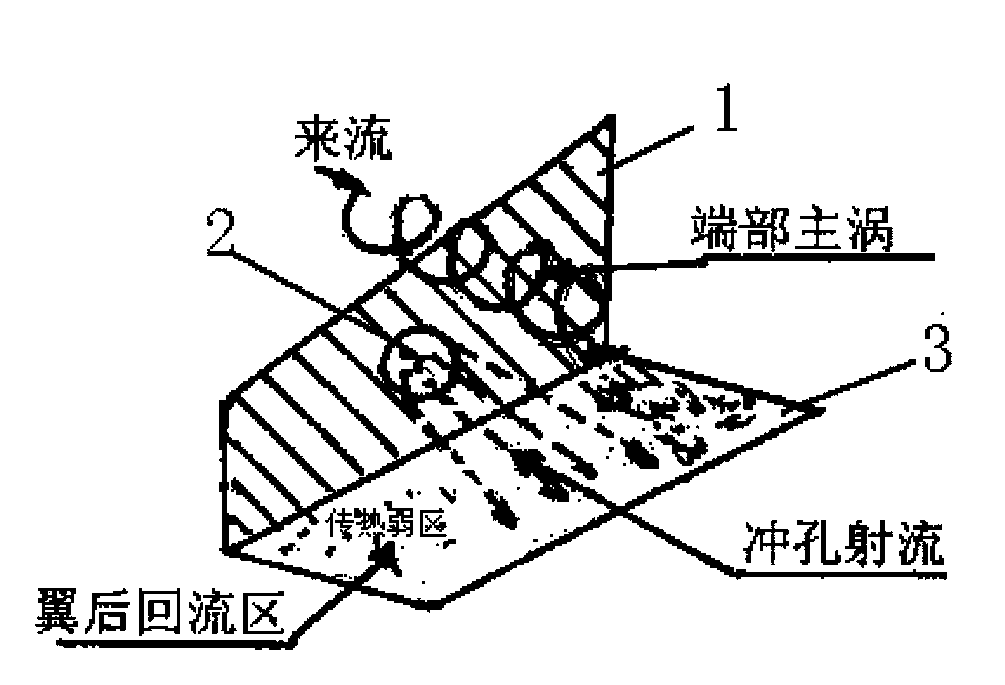

Method for improving heat exchange reinforcement effect of vortex generator by use of punching jet flow

InactiveCN102645118AImprove heat transfer effectReduce the windward areaHeat transfer modificationJet flowEngineering

The invention discloses a method for improving the heat exchange reinforcement effect of a vortex generator by use of punching jet flow, belonging to the field of heat exchange reinforcing technology. A hole is formed in a proper position on the windward surface of a wing-type or column-type vortex generator, thus the fluid at the front part of the vortex generator passes through the hole and scours the flow dead area or weak heat transfer area of the leeward surface of the vortex generator, thus the average flow rate and kinetic energy of the area are improved, the weak heat transfer area is eliminated, and the effects of heat exchange reinforcement and flowing resistance reduction of the vortex generator as well as the efficiency of the heat exchanger are further improved; and meanwhile, since the area of the windward surface of the vortex generator and the range of the flowing separation area are reduced by punching, the form resistance of the vortex generator is reduced, thus the flowing loss is reduced. The method has the characteristics of convenience in processing, simple manufacturing and obvious effect, and has wide application prospects and popularization values in the aspect of reinforcement gas-side heat exchange of a gas-liquid or gas-gas heat exchanger.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

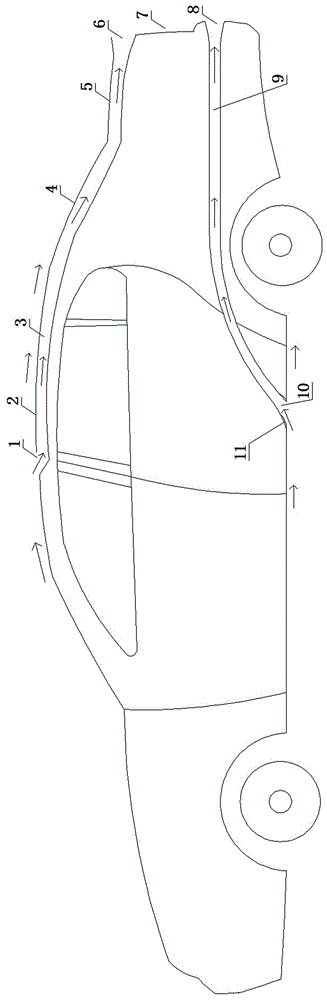

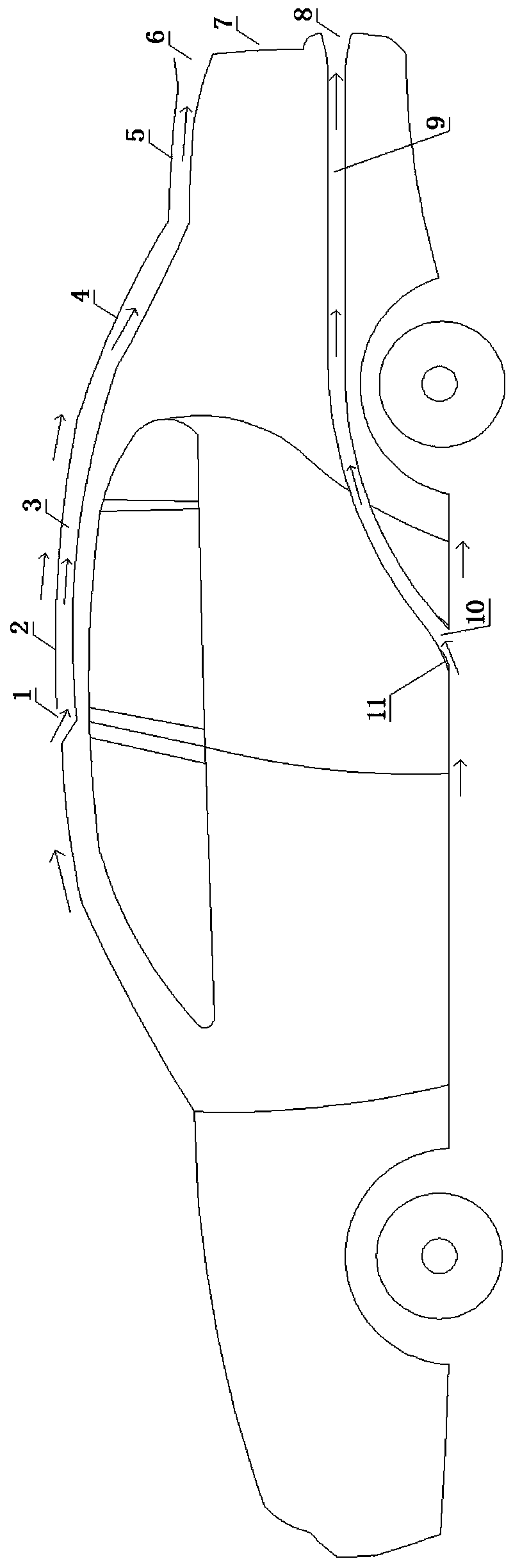

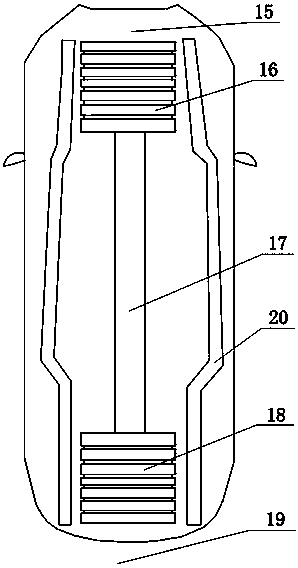

Electric vehicle for reducing lift force and resistance and increasing mileage

ActiveCN106379428AReduced lift effectEasy to separateVehicle body stabilisationElectric vehicleResistance force

The invention discloses an electric vehicle for reducing lift force and resistance and increasing mileage. The electric vehicle comprises air power structures arranged at the top tail and bottom of the electric vehicle. An air passage at the top tail of the vehicle weakens the separation of a gas boundary layer, reduces the rear wake area and finally leads the gas into the rear wake area, thus the shape resistance is reduced, and an effect of the electric vehicle of inhibiting gas separation through the air passage to increase the mileage is realized; since the air passage is arranged at the bottom of the electric vehicle, the air density at the vehicle bottom is reduced; the passage leads to left and right rear fenders, a rear bumper and a trunk cover, the air flow path is prolonged, the air speed is increased, and the vehicle lift force is reduced; the air is finally guided to the rear wake area, the wake area is downsized, the shape resistance is reduced, and the effects of the electric vehicle of reducing the vehicle lift force and increasing the mileage through the air passage are realized.

Owner:徐丹

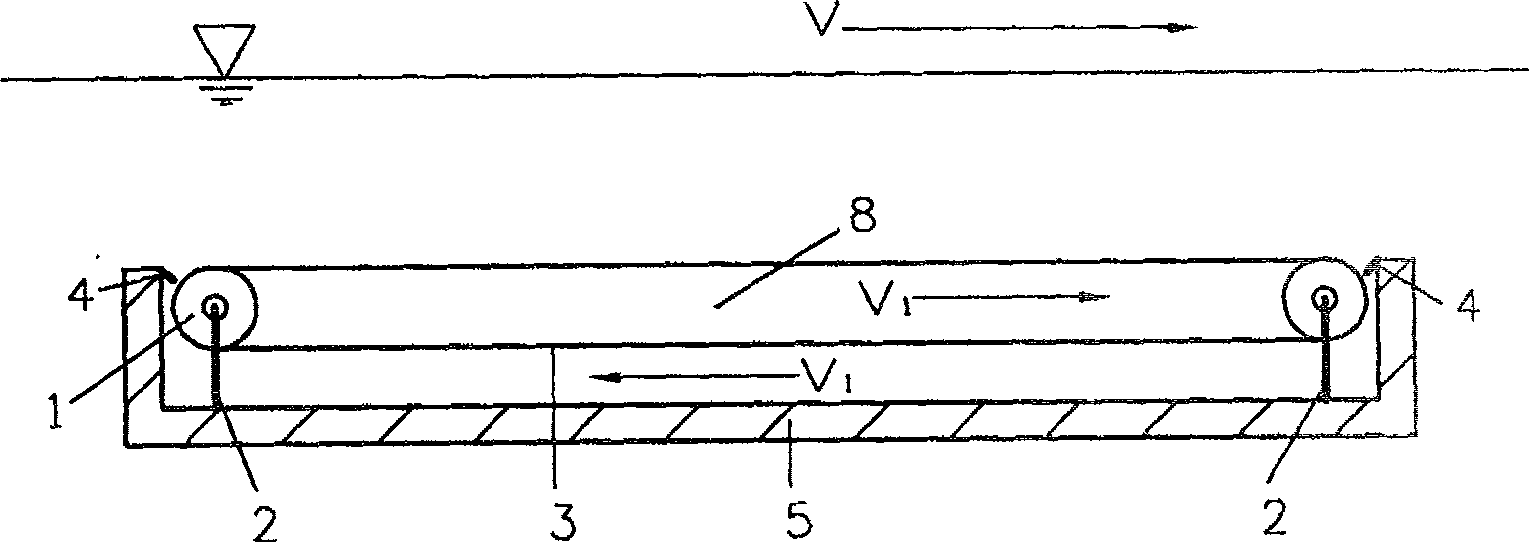

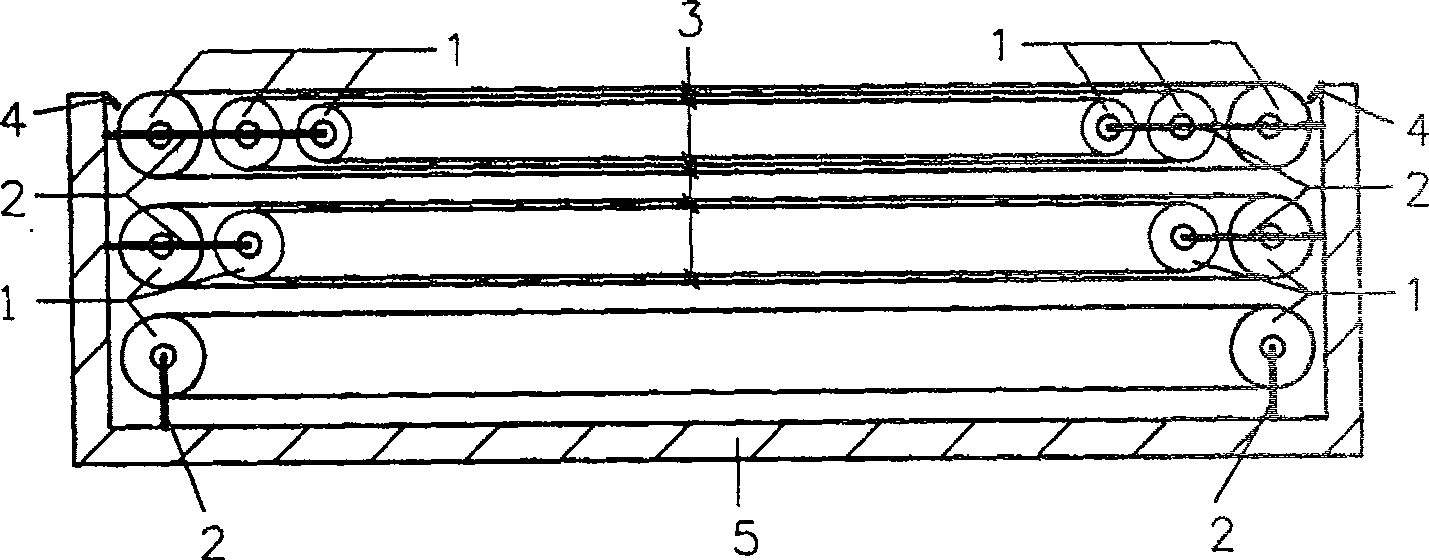

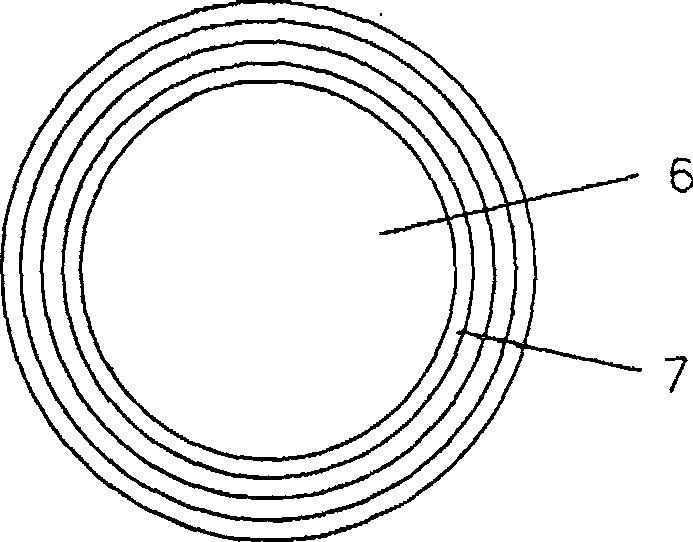

Multi-layer movable wall fluid resistance-reduction and propulsion device

InactiveCN100489318CLess expensiveEasy to control fluid state transitionFluid dynamicsPressure differenceEnergy consumption

The invention provides a fluid drag-reducing and propelling device with plural layers of active wall surfaces, able to reduce resistance to fluid, arranging one to plural layers of active wall surfaces able to circularly rotate on the surface of an object in the flowing direction of the fluid, where one to multiple active wall surfaces are arranged in the space formed by each layer of active wall surface, all the active wall surfaces moves with the fluid, reducing their relative speed to the fluid so as to reduce frictional resistance and energy consumption; by applying driving force to make the moving speeds of the active wall surfaces greater than that of the fluid, it can produce propelling force, able to reduce pressure difference between the two ends of the object and thus reducing shape resistance and making the frictional resistance disappear. And it can be widely applied to various drag reducing occasions of fluid.

Owner:邹立松

Elliptical tube H-shaped fin heat exchanger for waste heat recovery

ActiveCN103438746BIncrease disturbanceIncrease the principle of enhanced heat transferTubular elementsParticle adhesionWaste heat recovery unit

Owner:XI AN JIAOTONG UNIV

Prerotation fan-shaped conduit for right-handed single-screw ship

The invention discloses a prerotation fan-shaped conduit for a right-handed single-screw ship. The prerotation fan-shaped conduit comprises a first vane, a second vane, a third vane, a fourth vane and an arc guide plate; from the rear side of a screw propeller, the left side of a longitudinal central line of a screw impeller hub is sequentially provided with the second vane and the first vane from top to bottom, the right side is sequentially provided with the third vane and the fourth vane from top to bottom, an angle formed between the first vane and the longitudinal central line of the screw impeller hub is 70 to 80 degrees, an angle formed between the second vane and the longitudinal central line of the screw impeller hub is 25 to 30 degrees, an angle formed between the third vane and the longitudinal central line of the screw impeller hub is 35 to 45 degrees, and an angle formed between the fourth vane and the longitudinal central line of the screw impeller hub is 70 to 80 degrees. Compared with the three-vane prerotation triangular conduit, the third vane plays a role in supporting and reinforcing the prerotation and is also arranged outside an air bubble sensitive area, and the adverse impact on the air bubble performance can be avoided.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

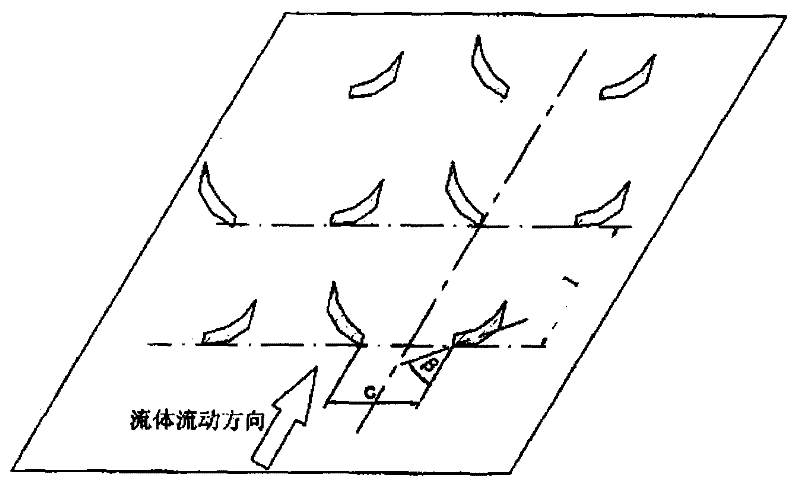

Enhanced heat transfer element of oblique truncated cylindrical wing vortex generator

InactiveCN101532798BReduce transportation energy consumptionEnhanced convective heat transferHeat transfer modificationEnhanced heat transferElliptic cylinder

The invention discloses an intensified heat transfer element for a vortex generator with oblique truncated cylindrical fins, which belongs to the field of heat transfer components of heat exchangers. It is to bend the facade of the airfoil vortex generator into a semi-cylindrical or semi-elliptical cylindrical form, and arrange it on the finned tube or the fin of the plate-fin heat exchanger or other channel flow heat exchange at a certain angle of attack and array. On the surface of the plate, the longitudinal vortex at the end is induced and the horseshoe vortex at the root is coupled to thin or destroy the boundary layer close to the wall or increase the turbulence intensity to achieve passive enhanced heat transfer and improve the efficiency of the heat exchanger. In addition, it is important that due to its streamlined surface, the shape resistance is reduced, thereby reducing the flow pressure loss and reducing the energy consumption of fluid transportation. This kind of vortex generator can be processed by metal or other flexible forming materials, has the characteristics of simple manufacture and convenient installation, and has broad application prospects and popularization value in gas-liquid or gas-gas heat exchangers.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Bullet-shaped non-spherical microparticles and microcapsules and preparation method thereof

ActiveCN109482111BReduced shape resistanceImprove flow characteristicsPharmaceutical product form changePharmaceutical non-active ingredientsPharmaceutical drugMicroparticle

Owner:四川大川合颐生物科技有限公司

An Electric Vehicle with Reduced Lift, Reduced Drag and Extended Range Simultaneously

ActiveCN106379428BReduced lift effectEasy to separateVehicle body stabilisationElectric vehicleMotive power

The invention discloses an electric vehicle for reducing lift force and resistance and increasing mileage. The electric vehicle comprises air power structures arranged at the top tail and bottom of the electric vehicle. An air passage at the top tail of the vehicle weakens the separation of a gas boundary layer, reduces the rear wake area and finally leads the gas into the rear wake area, thus the shape resistance is reduced, and an effect of the electric vehicle of inhibiting gas separation through the air passage to increase the mileage is realized; since the air passage is arranged at the bottom of the electric vehicle, the air density at the vehicle bottom is reduced; the passage leads to left and right rear fenders, a rear bumper and a trunk cover, the air flow path is prolonged, the air speed is increased, and the vehicle lift force is reduced; the air is finally guided to the rear wake area, the wake area is downsized, the shape resistance is reduced, and the effects of the electric vehicle of reducing the vehicle lift force and increasing the mileage through the air passage are realized.

Owner:徐丹

Vortex generator for vibration reduction and load reduction of wind turbine generator tower frame, wind turbine generator and tower frame

PendingCN111043112AAvoid separationChange the rear flow fieldEngine fuctionsWind motor supports/mountsClassical mechanicsTower

The invention discloses a vortex generator for vibration reduction and load reduction of a wind turbine generator tower frame, the wind turbine generator tower frame comprising vortex generators and awind turbine generator. Multiple groups of vortex generators are arranged at an outer surface of the tower frame, each group of vortex generators comprises one or two flat plates, each flat plate isof a triangular structure, a bottom edge of each triangle is connected with an outer surface of the tower frame, and two bottom angles of each triangle are smaller than 30 degrees; and when the two flat plates are arranged, the two flat plates are symmetrical about the central axis of a vortex generator. Multiple groups of vortex generators are spirally distributed on the outer surface of the tower frame. The vortex generator disclosed by the invention can adapt to various wind directions and can effectively inhibit airflow separation, so that a flow field behind the tower frame and corresponding aerodynamic force can be effectively changed, vortex-induced vibration of the tower frame is avoided by changing the frequency of the aerodynamic force acting on the tower frame, and vibration reduction and load reduction of the tower frame are truly realized from the source.

Owner:GUODIAN UNITED POWER TECH

Control plane cavitation effect suppression device

PendingCN110053752AIncrease kinetic energyLess prone to cavitationSteering ruddersWatercraft hull designCavitationBreather

The invention provides a control plane cavitation effect suppression device, including an air pump and a breather pipe. The air pump is arranged in a ship body and the breather pipe is located in thegap between a rudder horn and a rudder blade. The upper end of the breather pipe is fixed on a transom plate and communicates with the air pump. The lower end of the breather pipe is closed, and air holes for blowing air to the surface of a rudder blade are formed in the breather pipe. Through blowing to the control plane from the gap, control plane pressure increases and a cavitation effect is not prone to being produced. Kinetic energy of fluid near a boundary layer separation point can be increased to move the separation point back and decrease a separation area to achieve the effect of reducing form resistance. A laminar region can be extended, a critical Reynolds number can be increased and viscous resistance can be dramatically reduced under the critical Reynolds number.

Owner:HARBIN ENG UNIV

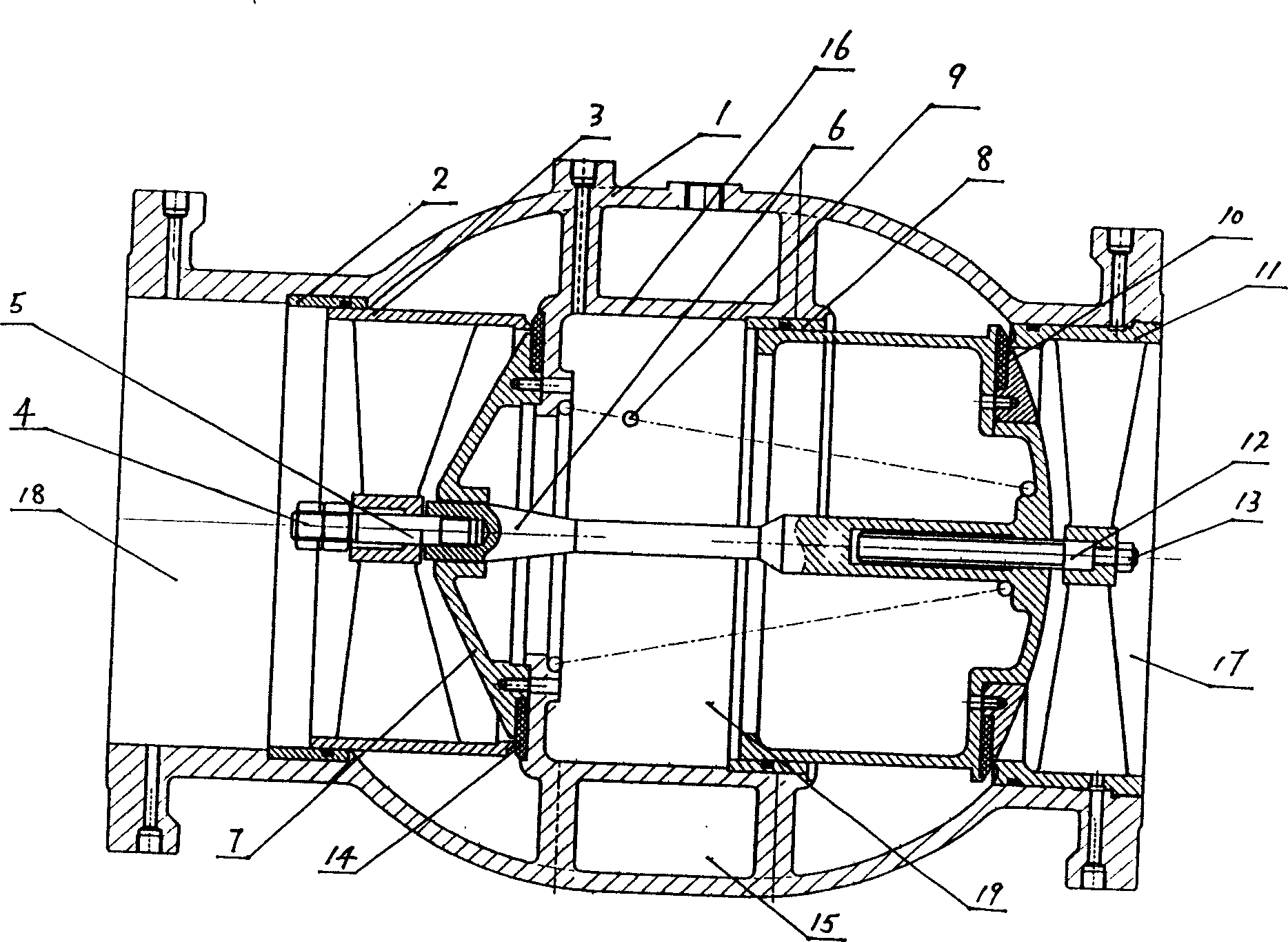

Conical tube bundle support member and shell-and-tube heat exchanger adopting same

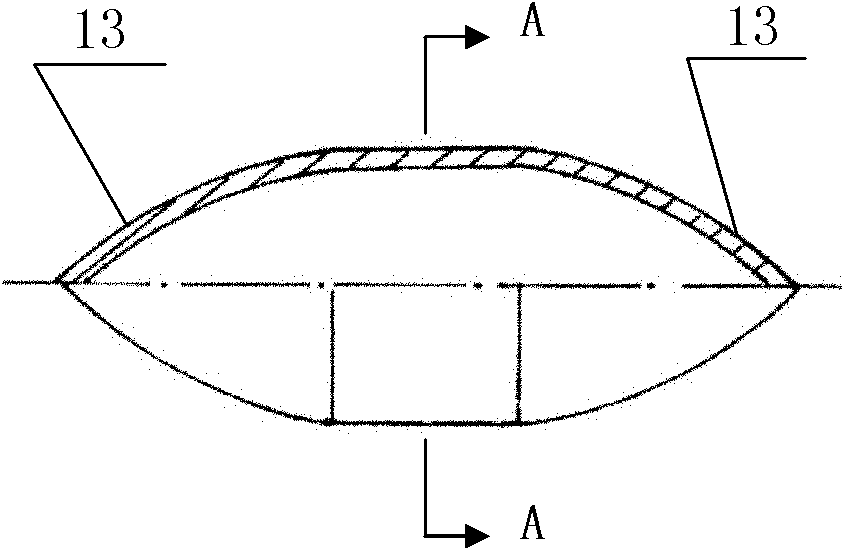

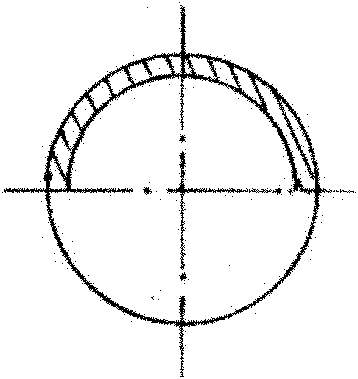

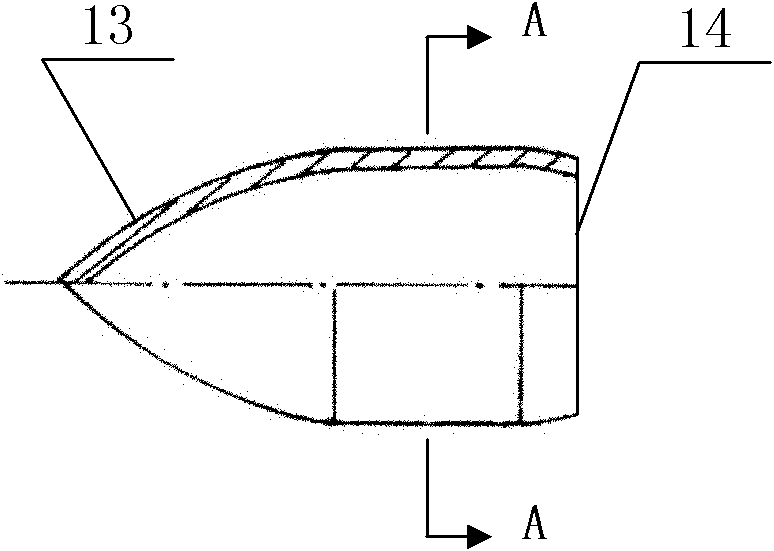

InactiveCN102147207ARealize pure countercurrent heat transferReduced shape resistanceHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The invention discloses a conical tube bundle support member and a shell-and-tube heat exchanger adopting the same. The support member is of an olivary structure with two ends being conical paraboloids, or a bullet structure with one end being a conical paraboloid and the other end being a plane. The shell-and-tube heat exchanger comprises a cylindrical shell and a plurality of heat exchange tubes, wherein two ends of the heat exchange tubes are axially arranged in the shell respectively through a left tube sheet and a right tube sheet; a plurality of conical tube bundle support members are arranged among the plurality of heat exchange tubes; and the plurality of heat exchange tubes and the plurality of conical tube bundle support members are drawn in and fixed by belt hoops. The plurality of heat exchange tubes are regularly distributed in a triangle or a square shape; and the conical tube bundle support members are arranged among the heat exchange tubes regularly distributed in the triangle or square shape. In the invention, the structure is simple, the manufacturing cost is low, and the single-shell side countercurrent heat exchange or double-shell side fluid heat exchange can be realized. The olivary support member changes the shell side fixed sectional area into shrink-expansion variable cross-section in axial flow, so that the heat convection capability of the shell side can be greatly improved.

Owner:TIANJIN UNIV

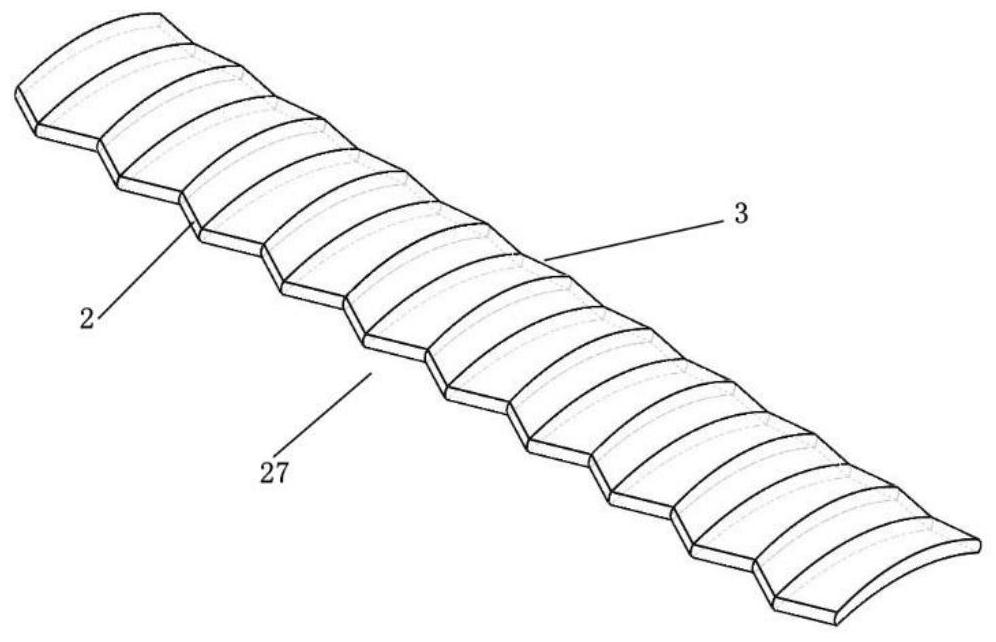

Cross-flow fan blade based on bionics

ActiveCN112049817AReduce energy consumptionEasy to movePump componentsRadial flow pumpsBiomimeticsFan blade

The invention discloses a cross-flow fan blade based on bionics. The blade is formed by arranging a plurality of blade units in the axial direction of an impeller, the front edges of the blade units protrude, the rear edges of the blade units are concave inwards, the middle portions of the sides, close to the front edges, of the upper surfaces of the blade units are higher than the two sides, themiddle portions of the sides, close to the rear edges, of the upper surfaces of the blade units are lower than the two sides, and the middle portions of the sides, close to the front edges, of the upper surfaces of the blade units are higher than the middle portions of the sides, close to the rear edges, of the upper surfaces of the blade units. By the adoption of the cross-flow fan blade based onbionics, airflow flowing of the front edge and rear edge of the blade can be improved, an eccentric vortex moves downwards, the efficiency of a cross-flow fan is improved, and energy consumption is reduced.

Owner:SOUTHEAST UNIV

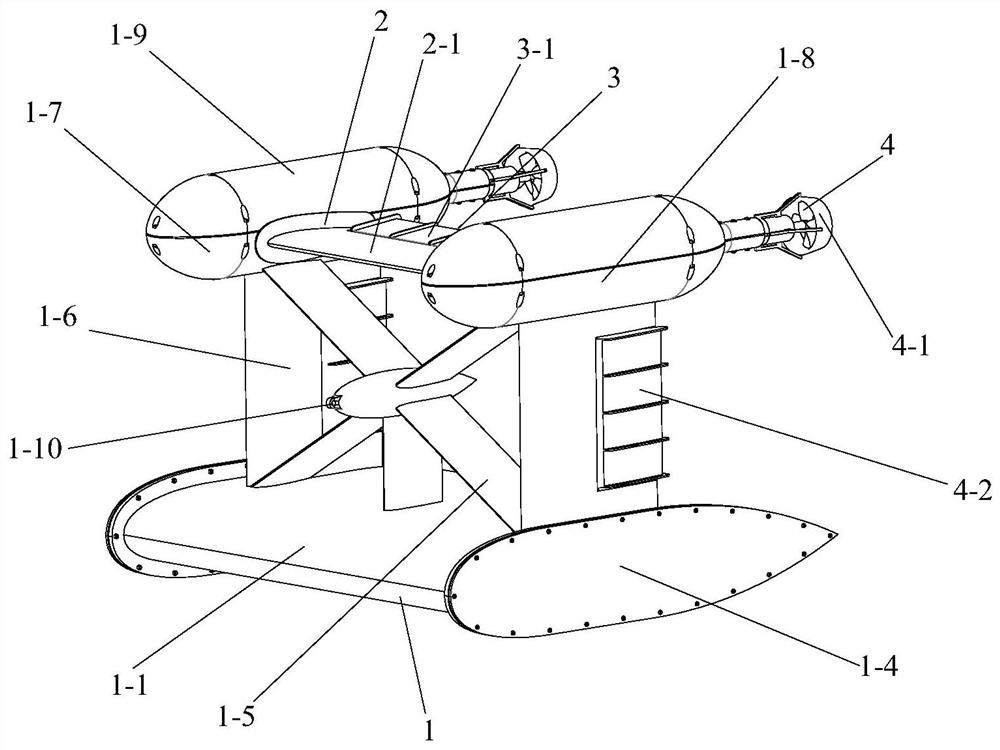

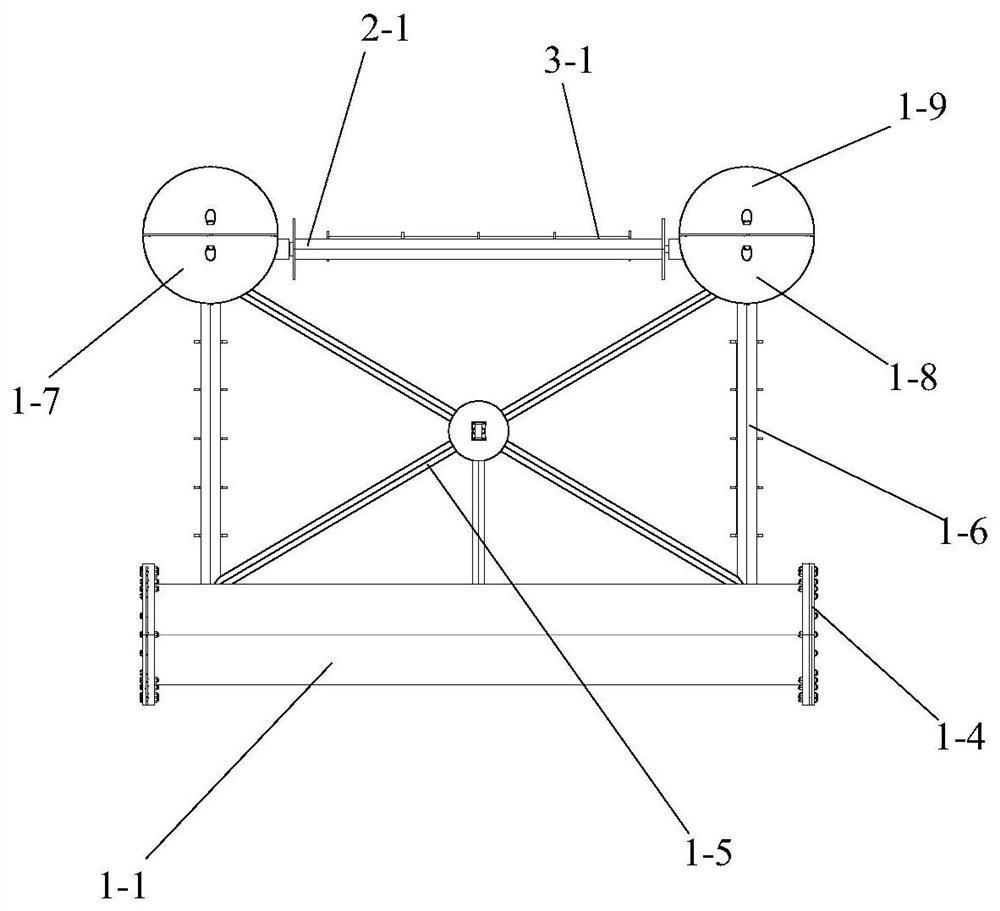

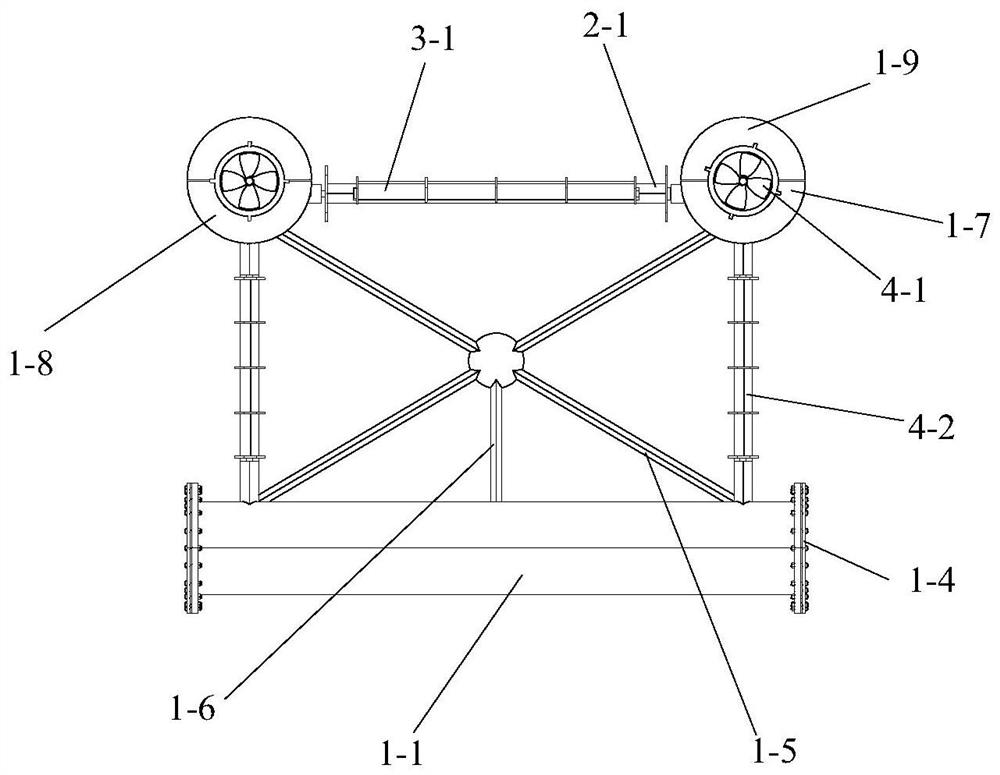

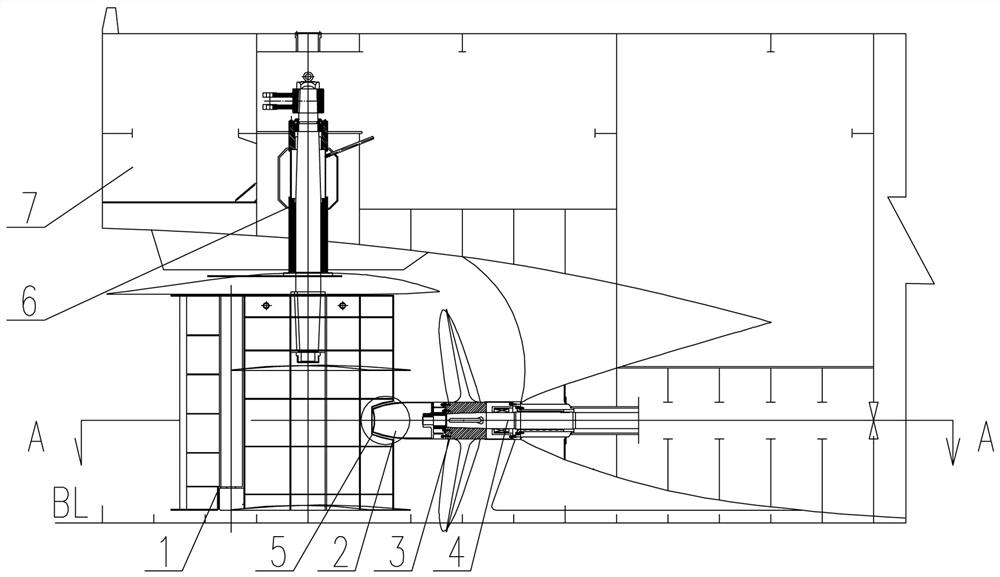

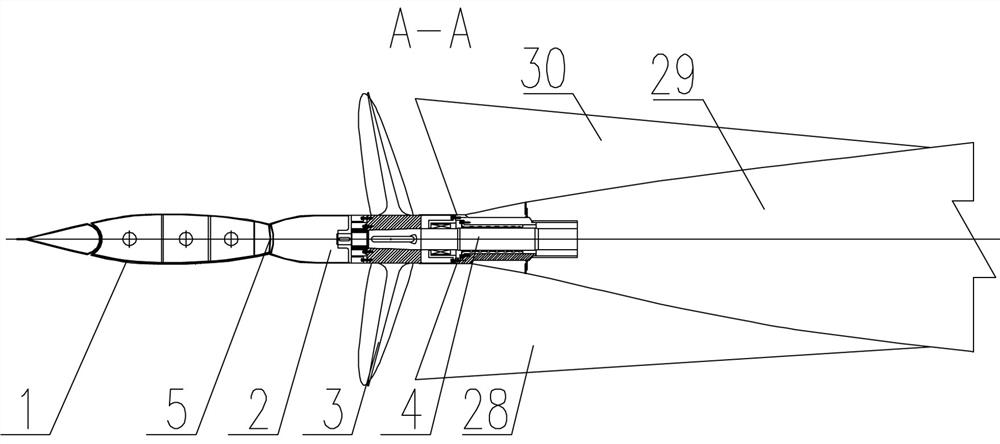

A controllable pod-type underwater towing body with stable attitude and multiple degrees of freedom

ActiveCN110435857BMany degrees of freedomControllable degrees of freedomUnderwater vesselsUnderwater equipmentDrive shaftTurbine

The invention discloses a stable-posture multi-degree-of-freedom controllable pod type underwater dragging body. The dragging body comprises a main body, a longitudinal inclination control mechanism,a heaving control mechanism and a bow changing control mechanism; the main body comprises a wing type pod, an inclined strut, a stand column, a longitudinal inclination control bin, a heaving controlbin and a cable hole; the wing type pod is of a water sealing cavity structure and is horizontally located at the lower portion of the main body, the longitudinal inclination control bin and the heaving control bin are each of a water sealing cavity structure and are arranged at the upper end of the wing type pod in a spaced mode through two stand columns, a heaving control hydrofoil of the heaving control mechanism is arranged in a gap of a longitudinal inclination control hydrofoil; the right end of the heaving control hydrofoil is in rigid connection with a heaving positioning shaft, and aheaving drive shaft penetrates through a through axle hole formed in the left side of the gap of the longitudinal inclination control hydrofoil and is in rigid connection with a heaving turbine; a heaving worm is meshed with the heaving turbine, and the heaving worm is connected with a heaving servo motor; the dragging body has the advantages that towing resistance is small, multiple degrees of freedom are controllable, the motion control posture is stable, and bin arrangement is reasonable.

Owner:SOUTH CHINA UNIV OF TECH +1

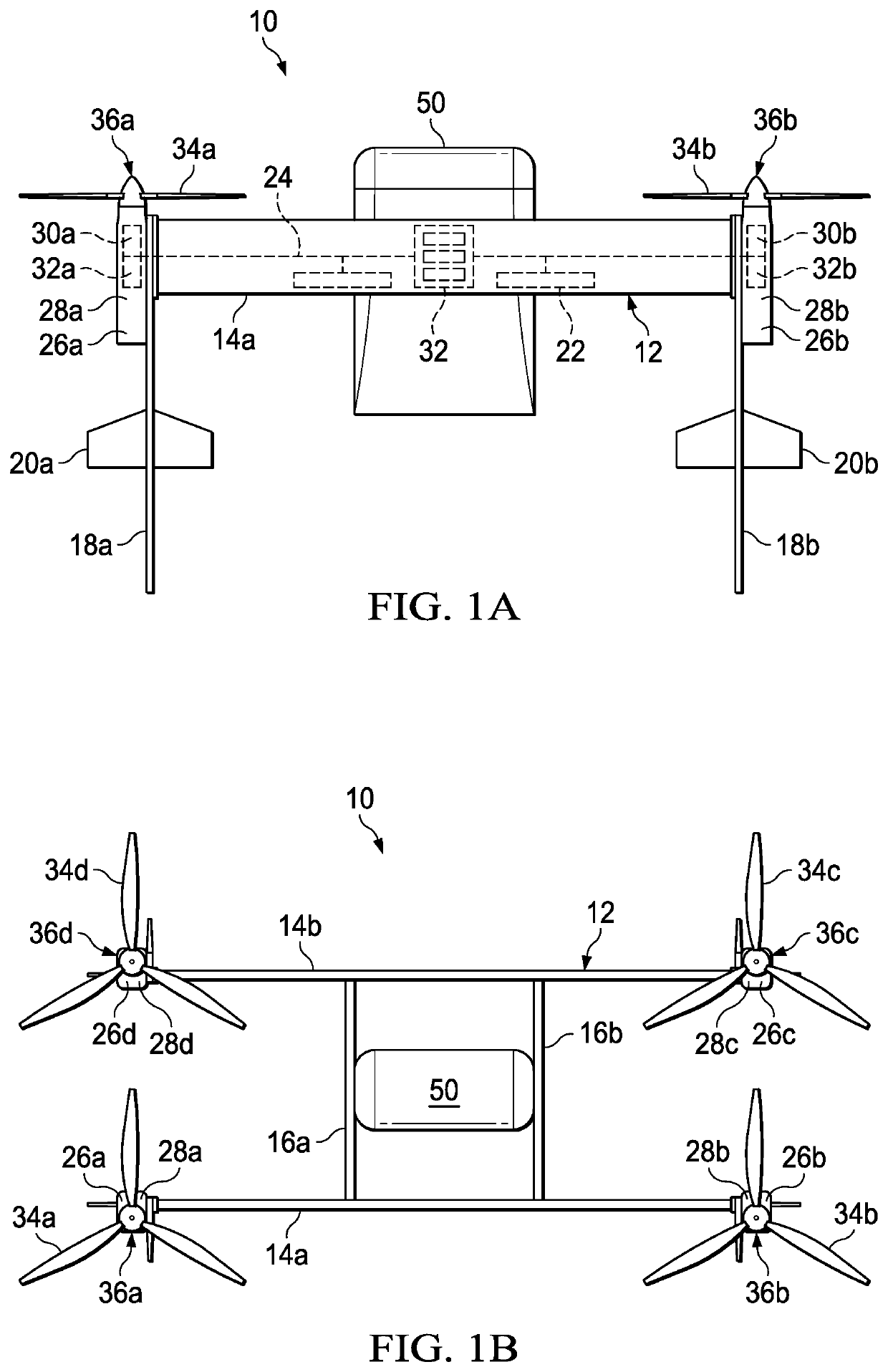

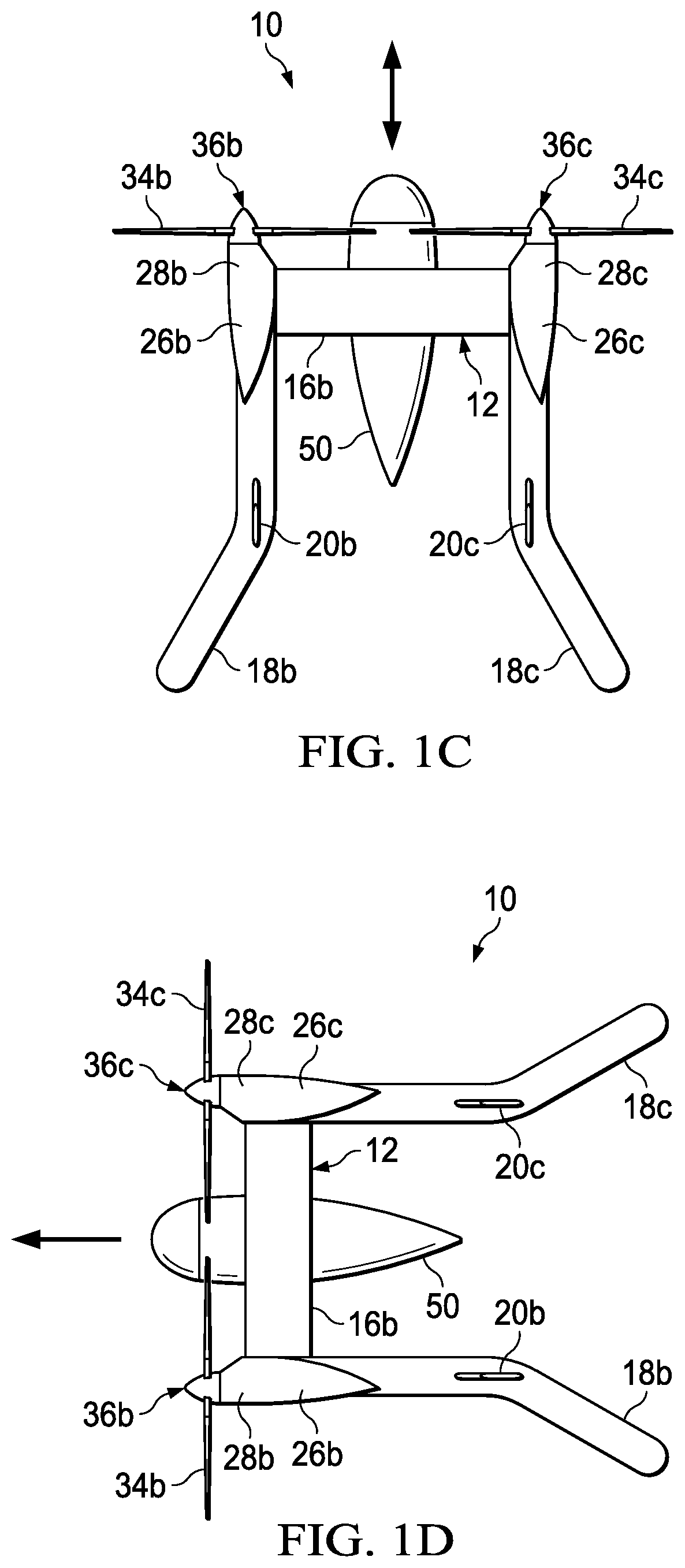

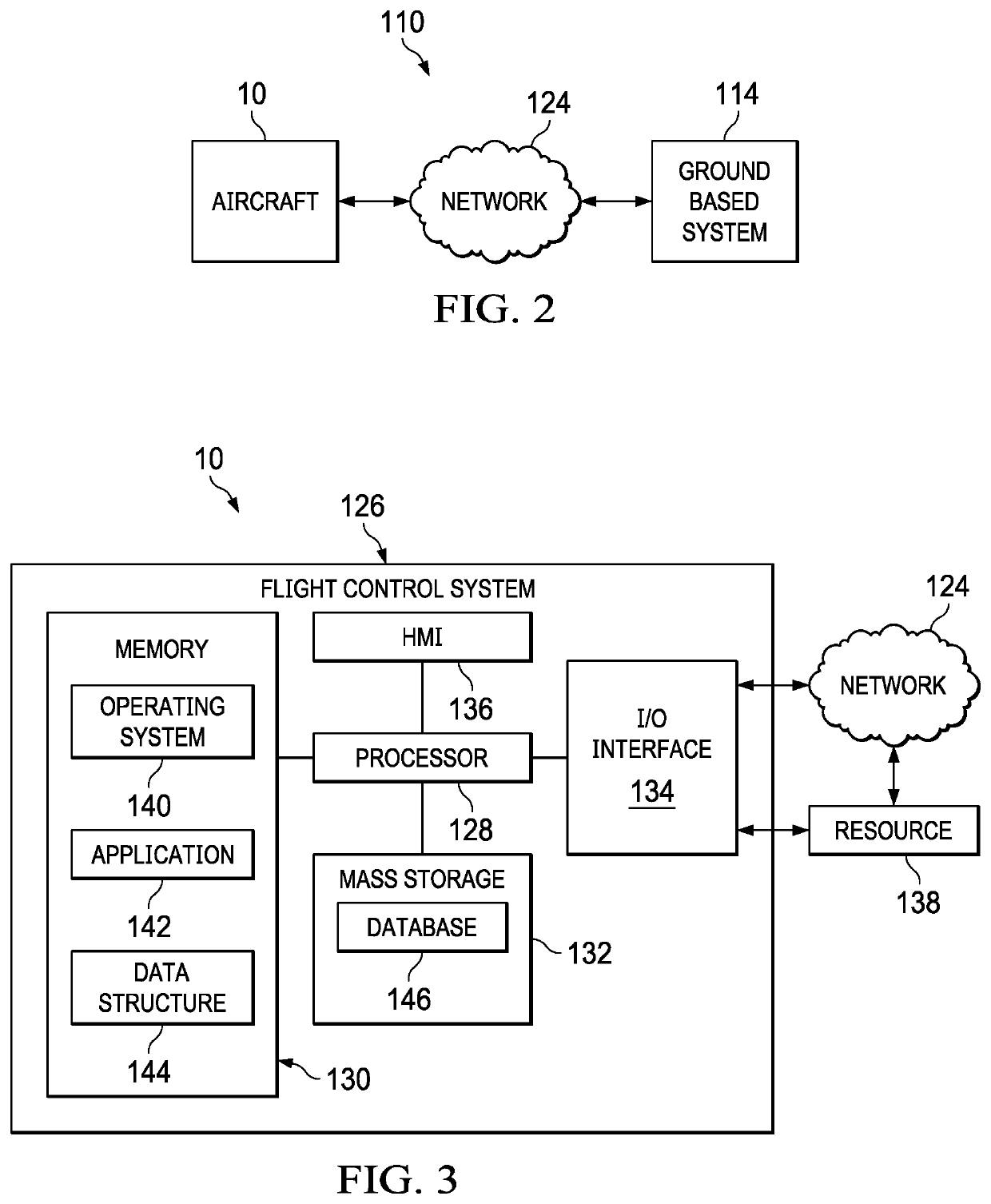

Turn Into Wind Method and System

PendingUS20220258851A1Reduced shape resistanceMinimize pitch angleActuated automaticallyVehicle position/course/altitude controlFlight vehicleClassical mechanics

A method for reducing form drag on a tailsitter aircraft during at least one of takeoff or landing includes vertically taking off from the ground in a tailsitter orientation. The method also includes determining an actual pitch of the tail sitter aircraft in the tailsitter orientation. The method also includes determining a difference between the actual pitch and a predetermined pitch. The method also includes adjusting a heading of the tailsitter aircraft based on the difference to minimize a pitch angle to reduce the form drag on the tailsitter aircraft.

Owner:TEXTRON INNOVATIONS

Method for improving heat exchange reinforcement effect of vortex generator by use of punching jet flow

InactiveCN102645118BImprove heat transfer effectReduce the windward areaHeat transfer modificationJet flowEngineering

The invention discloses a method for improving the heat exchange reinforcement effect of a vortex generator by use of punching jet flow, belonging to the field of heat exchange reinforcing technology. A hole is formed in a proper position on the windward surface of a wing-type or column-type vortex generator, thus the fluid at the front part of the vortex generator passes through the hole and scours the flow dead area or weak heat transfer area of the leeward surface of the vortex generator, thus the average flow rate and kinetic energy of the area are improved, the weak heat transfer area is eliminated, and the effects of heat exchange reinforcement and flowing resistance reduction of the vortex generator as well as the efficiency of the heat exchanger are further improved; and meanwhile, since the area of the windward surface of the vortex generator and the range of the flowing separation area are reduced by punching, the form resistance of the vortex generator is reduced, thus the flowing loss is reduced. The method has the characteristics of convenience in processing, simple manufacturing and obvious effect, and has wide application prospects and popularization values in the aspect of reinforcement gas-side heat exchange of a gas-liquid or gas-gas heat exchanger.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Ship hydrodynamic comprehensive energy-saving device and installation method

ActiveCN112124542BEliminate vortexImprove propulsion efficiencyRotary propellersTransmission with propulsive element synchronisationPropellerMechanical engineering

The invention provides a ship hydrodynamic comprehensive energy-saving device and an installation method thereof. The ship hydrodynamic comprehensive energy-saving device is characterized in that it includes a propeller-rudder combined vortex-eliminating energy-saving device for dissipating energy of the vortex generated by the propeller, and the propeller-rudder The combined vortex-elimination and energy-saving device is fixedly installed at the tail of the propeller tail shaft and rotates with the rudder blade; it includes a combined energy-saving rectifying fin installed on the rudder blade for vortex elimination and rectification; it includes the double tail fins installed on the ship body, and Front rectifier fin structure located in front of the propeller. This comprehensive energy-saving device aims at the shortcomings of the existing ship energy-saving technology, and adopts corresponding technical solutions to improve it in order to achieve the purpose of energy saving, and after organically and comprehensively utilizing all energy-saving methods, it can achieve the final energy-saving effect .

Owner:宜昌一凡船舶设计有限公司

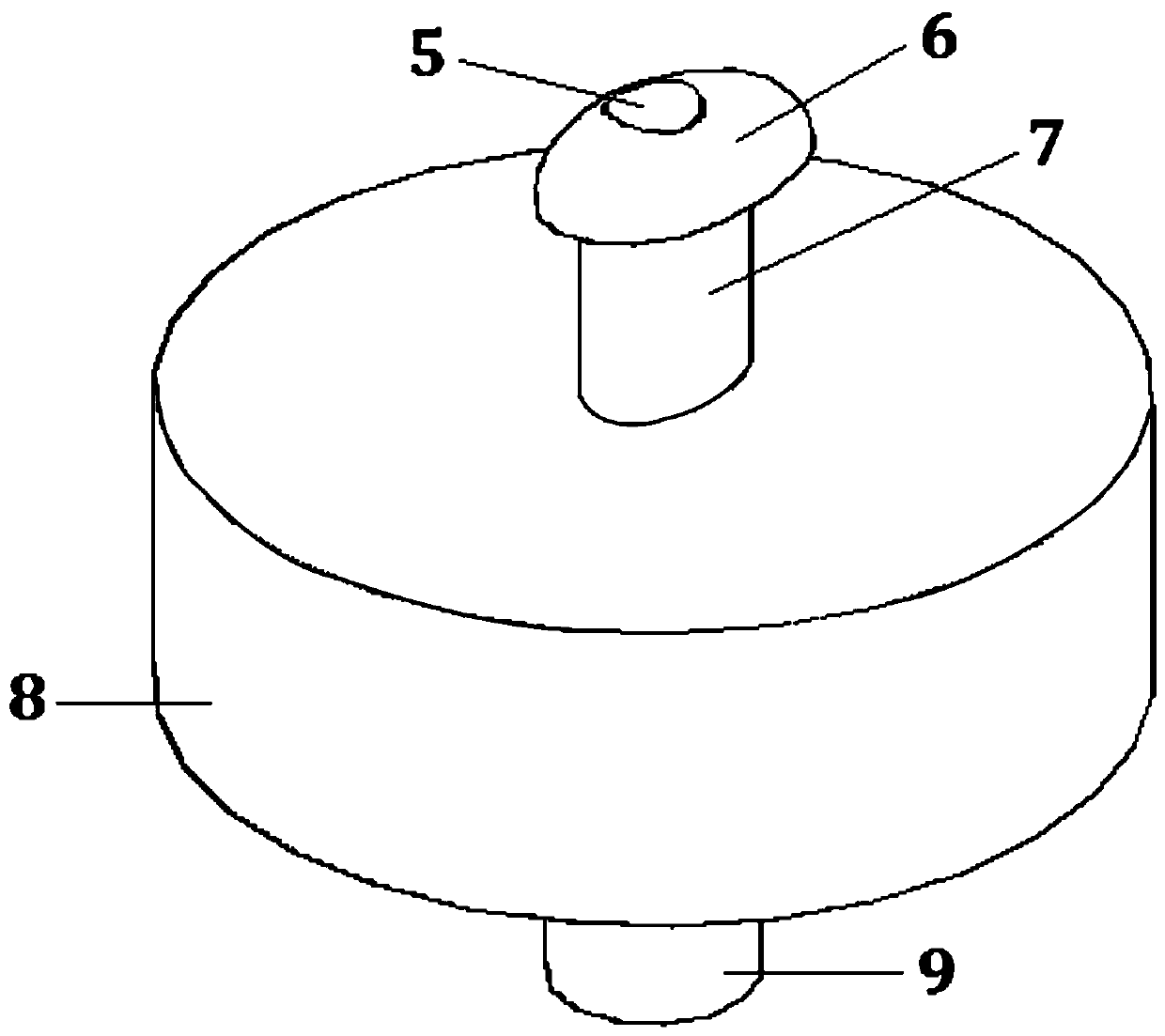

Double-ellipsoidal streamlined rotator irrigation emitter plug and mounting method thereof

ActiveCN110419417ASmooth flow separationReduced shape resistanceWatering devicesCultivating equipmentsIrrigationEngineering

A double-ellipsoidal streamlined rotator irrigation emitter plug comprises a plug back taper. A plug water inlet is formed in the upper end face of the plug back taper, the lower surface of the plug back taper is sequentially communicated with a plug taper neck, a dropper cavity and a dropper water outlet pipe from top to bottom, the contour line of the cross section of the plug back taper is a double-ellipsoidal streamlined curve, the contour line of the cross section of the plug taper neck is a double-ellipsoidal streamlined curve, and the area of the double-ellipsoidal streamlined curve ofthe upper end face is as same as that of the double-ellipsoidal streamlined curve of the lower end face. According to the double-ellipsoidal streamlined rotator irrigation emitter plug and a mountingmethod thereof, the problem of great local head loss can be solved, and the plug form resistance of an irrigation emitter is maximally reduced.

Owner:CHINA THREE GORGES UNIV

Heat exchange tube fin with corrugations

ActiveCN112797834AImprove heat transfer conditionsIncrease the areaTubular elementsFlue gasEngineering

The invention discloses a heat exchange tube fin with corrugations. Two sides of the fin are provided with grooves and extended chamfers, and the fin is divided into a windward area, an enhanced heat exchange area and a leeward area by the grooves along a flue gas flowing direction; the windward area and the enhanced heat exchange area are provided with a large number of streamline-structured corrugations; and the leeward area is fins with gradually-changed thickness. The structure is good in heat exchange performance, small in flowing resistance and good in flue gas waste heat recovery effect, the airflow separation and backflow phenomena occurring in the leeward area can be effectively improved, the fin temperature field and flue gas speed collaboration is enhanced, the heat exchange efficiency is improved, meanwhile, dust accumulation is effectively reduced, and flowing channel blockage is avoided.

Owner:XI AN JIAOTONG UNIV

Technology for reducing resistance force of DC waterproof pump controlling valve

InactiveCN101096961AReduce resistanceReasonable workmanshipPump componentsPump controlInlet valveEngineering

Owner:SHANGHAI SHANGLONG VALVE FACTORY

Electric passenger vehicle for reducing lift force and resistance and extending range through fluid equipment

PendingCN108016516AReduced shape resistanceReduce internal circulation resistanceVehicle body stabilisationAerodynamic dragInterference resistance

The invention discloses an electric passenger vehicle for reducing lift force and resistance and extending the range through fluid equipment. The electric passenger vehicle comprises a new vehicle body, air flow channels and fluid machines, wherein the air flow channels and the fluid machines are arranged on the two sides of a front compartment, a passenger compartment, a vehicle tail luggage compartment, a vehicle tail, a vehicle roof, a vehicle bottom and a vehicle body of the electric passenger vehicle. Form resistance, inner circulation resistance, interference resistance, induced resistance and lift force are reduced through the air flow channels and the fluid machines, and the effects that the electric passenger vehicle uses the air flow channels and the fluid machines for reducing air resistance and lift force and increasing the traveling mileage of the electric passenger vehicle are achieved.

Owner:徐丹

Pre-swivel triangular guide for right-handed single oar boats

ActiveCN103332281BImprove rectification effectReduced wetted surface areaRotary propellersPropulsive efficiencyEngineering

The invention discloses a pre-rotation triangular conduit for a right-handed rotation single screw vessel. The pre-rotation triangular conduit has a fan-shaped structure; seen from the rear side of a screw propeller, a second blade and a first blade are arranged from top to bottom on the left side of a longitudinal central line of a propeller hub of the screw propeller, and a third blade is arranged on the right side; a blade back of a guide plate is fixedly connected with a blade tip of the first blade, a blade tip of the second blade and a blade tip of the third blade respectively; the included angle range of the first blade and the longitudinal central line of the propeller hub of the screw propeller is 70-75 degrees; the included angle range of the second blade and the longitudinal central line of the propeller hub of the screw propeller is 25-30 degrees; and the included angle range of the third blade and the longitudinal central line of the propeller hub of the screw propeller is 70-75 degrees. By using the principle of pre-rotation before the propeller and screw propeller upper inlet flow acceleration, the pre-rotation triangular conduit is a piece of body energy saving equipment with more uniform inlet flow of the screw propeller disk; and importantly, the energy lost due to rotation of a wake flow field of the screw propeller is reduced, the screw propeller propulsive efficiency is improved and the additional form resistance due to tail flow separation is reduced.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com