Multi-layer movable wall fluid resistance-reduction and propulsion device

A propulsion device and wall surface technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of limited drag reduction effect, large channel friction resistance, high polymer price, etc., and achieve the effect of eliminating fluid resistance and reducing friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

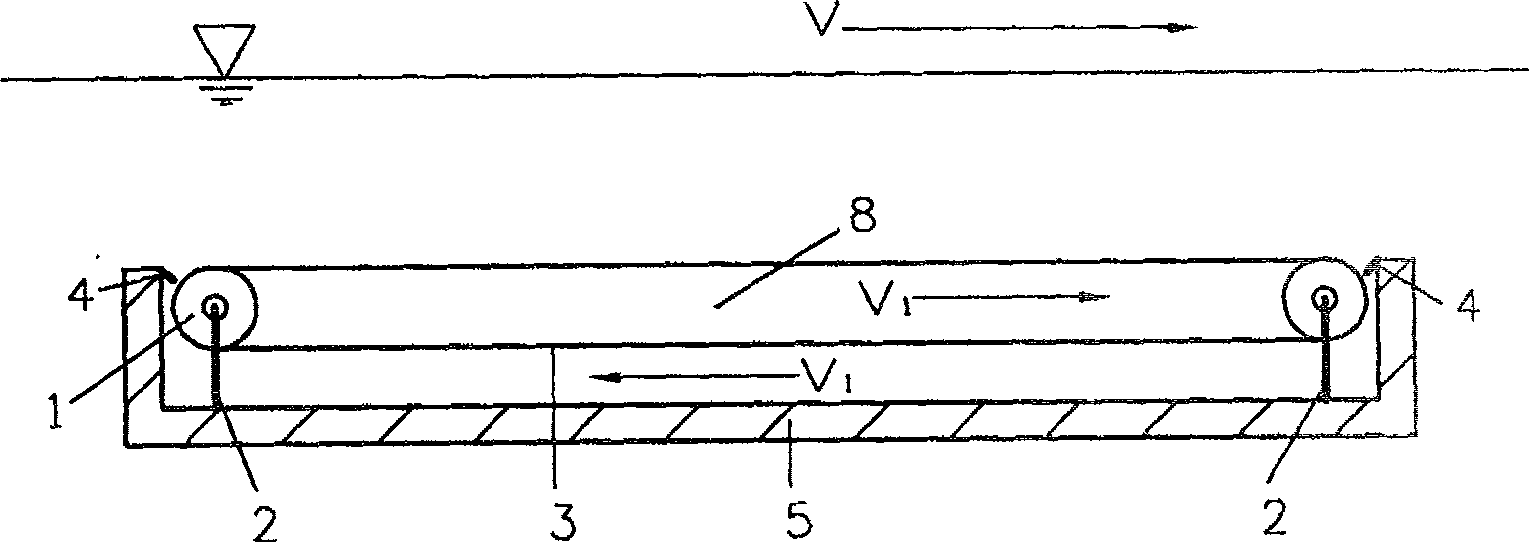

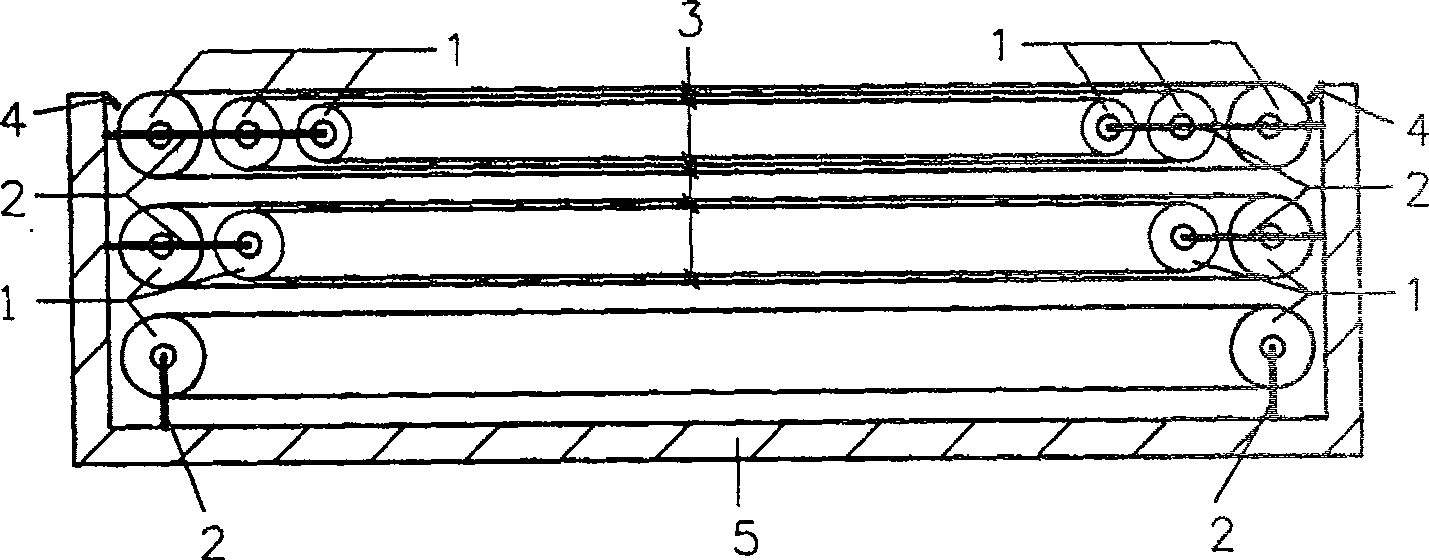

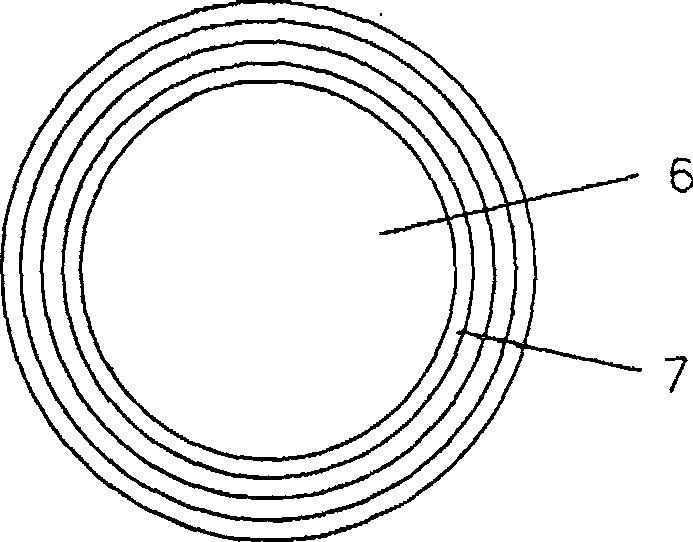

Embodiment 1

[0070] Figure 13 It is a schematic diagram of the division of oil pipeline drag reduction installation units and the positional relationship of each unit. If the pipe diameter is about 1100mm, the width of each unit is about 500~600mm. There are three layers, from the inside to the outside, they are one layer, two layer, and three layer. The average specific gravity of the movable wall is the same as that of petroleum or lubricating fluid, which can eliminate the sag caused by gravity. At the same time, it is pasted with a flexible composite magnetic strip to prevent or reduce its friction. Set up special joints at the joints of the pipelines, inside which are arranged driving drums, steering drums, etc., the movable wall surface steering method is the same Picture 9 As shown, the installation thickness of each movable wall (including its own thickness and the distance between the weights) is about 4mm, and the total thickness is about 4.4cm. It is equipped with a live button s...

Embodiment 2

[0072] Install the device of the present invention in a certain level (or a small slope) water delivery channel to reduce the frictional resistance of water to the channel wall, Figure 14 It is a schematic diagram of the division of the installation unit. When the unit width is too wide, it can be added. The top is air, so there is no drag reduction device; five movable walls are installed along the channel wall, and each layer is one, two, three, three, and five movable walls in order from the canal wall, with 100 meters as one installation For the length of the unit, recessed grooves are arranged in the canal wall every 100 meters, and the driving drum, the steering drum and the contact mechanism between each layer are arranged in the groove. The movable wall surface of the adjacent outermost layer of each installation unit is provided with a live button seal of the present invention, and a multi-stage dynamic seal is provided between the end baffle of each unit and the movable...

Embodiment 3

[0074] The present invention is applied to the surface of the underwater floating body of a small waterplane surface ship to reduce fluid resistance: suppose the floating body is a cylinder with a diameter of about 1.5 meters, which is divided into three installation units. The positional relationship section of the three installation units is the same as that of the first embodiment. The cross-sectional schematic diagram is very similar, the difference is that the hexagon surrounded by three units is outside the cylinder, and each unit is about 1 meter wide. The longitudinal cross-section shows the same Figure 4 Basically the same, pay attention to the arrangement of the three units at the intersection of the head and tail. Two of them are turned at right angles at the head and tail, and multiple movable walls are arranged on the outside to reduce the resistance when crossing the top. Each unit is arranged five The heavy movable wall, and the secondary movable wall on the return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com