Ship hydrodynamic comprehensive energy-saving device and installation method

An energy-saving device and hydrodynamic technology, which is used in transmission devices with synchronous propulsion components, ship propulsion, ship construction, etc., can solve the problems of turbulent drag wake, loss of propeller thrust, loss of vortex elimination effect of rudder ball, etc. The effect of sealing protection, increasing the thrust of the propeller, and improving the energy saving effect of the ship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

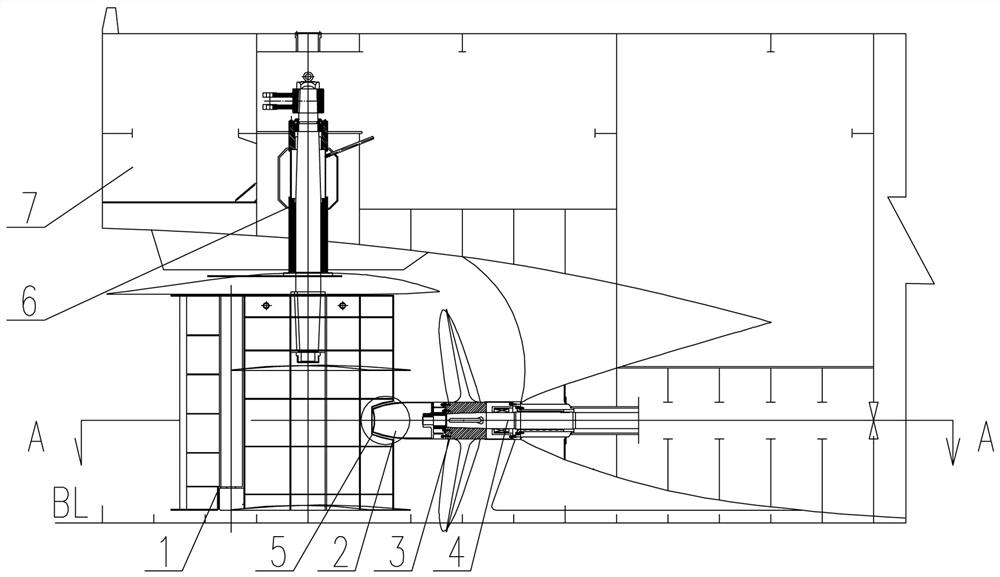

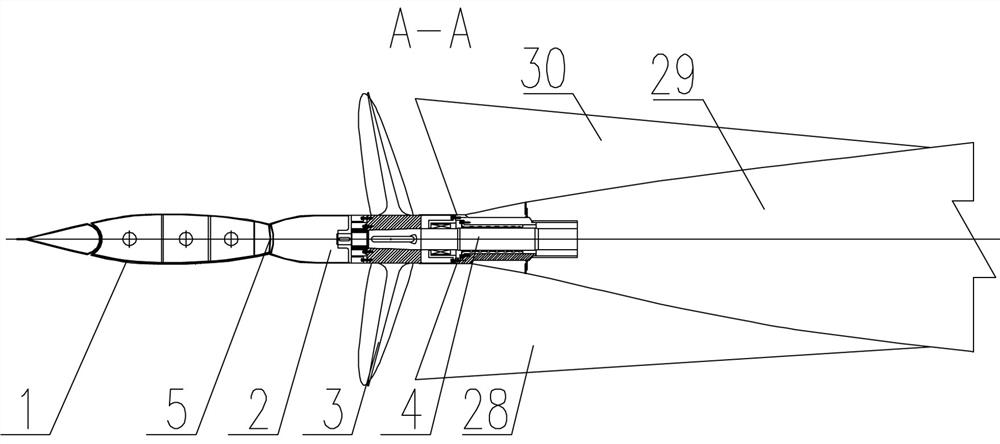

[0081] Such as Figure 1~26 Among them, a ship hydrodynamic comprehensive energy-saving device, which includes a propeller-rudder combined vortex-eliminating energy-saving device for dissipating the vortex generated by the propeller, and the propeller-rudder combined vortex-eliminating energy-saving device is fixedly installed on the tail of the propeller tail shaft 4, and Rotate with the rudder blade 1; include a combined energy-saving rectifying fin installed on the rudder blade 1 for vortex elimination and rectification; include a front rectifying fin structure installed on the double tail fin 29 of the ship body 7 and located in front of the propeller 3.

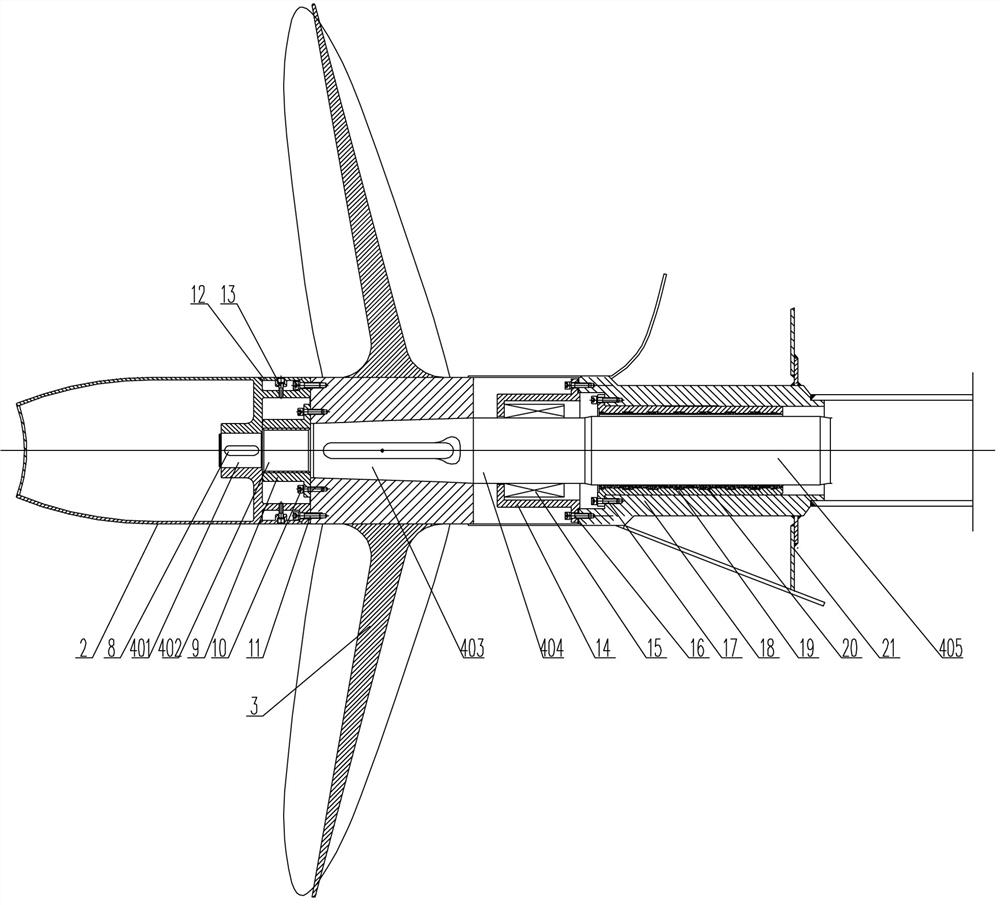

[0082] see Figure 1-9 Further, the propeller-rudder combination vortex elimination and energy-saving device includes a propeller tail shaft 4 installed at the tail of the ship body 7, a propeller 3 is installed on the propeller tail shaft 4, and a propeller tail shaft 4 is installed on the tail of the propeller tail sha...

Embodiment 3

[0090] The installation method of the propeller rudder combination vortex elimination and energy saving device comprises the following steps:

[0091] Step 1, positioning and installing the propeller 3 on the tapered shaft section 403 of the propeller tail shaft 4 through the thread retaining ring 9;

[0092] Step 2, the thread retaining ring 9 is fixedly connected to the propeller 3 through the first bolt assembly 10;

[0093] Step 3, the connecting bushing 208 of the vortex elimination device 2 is positioned and installed on the keyway shaft section 401 of the propeller tail shaft 4 through the flat key;

[0094] Step 4, the connecting flange 204 of the vortex eliminating device 2 is fixedly connected to the end face of the propeller 3 through the first bolt assembly 10;

[0095] Step 5, fixing the upper half circle 1201 and the lower half circle 1203 of the sealing ring assembly 12 on the outside of the vortex elimination shaft seat 203 through the radial bolt assembly 13,...

Embodiment 4

[0098] The specific structural dimensions of the vortex-eliminating device 2 are based on the diameter of the propeller of the ship and the diameter of the propeller shaft, wherein, the diameter of the propeller—D is known, and the diameter of the propeller shaft—d is known.

[0099] When specifically carrying out the size design of the vortex elimination device 2, calculate and determine relevant parameters according to the following formula:

[0100] Propeller hub diameter d 1 =0.18~0.20D mm;

[0101] Propeller hub length L=0.18~0.20D mm;

[0102] Vortex elimination device length l 1 =2~2.5Lmm;

[0103] Diameter of front end of vortex elimination device d 2 =D 1 mm;

[0104] The diameter of the rear end of the vortex elimination device d 3 = Thickness of the rudder blade where the vortex elimination device extends into the rudder blade, tmm;

[0105] The diameter of the inner hub of the vortex elimination device d 4 =0.5d;

[0106] Vortex elimination device inner h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com