Conical tube bundle support member and shell-and-tube heat exchanger adopting same

A technology for heat exchangers and supports, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as large shape resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The conical tube bundle support and the shell-and-tube heat exchanger using the tube bundle support of the present invention will be described in detail below with reference to the embodiments and drawings.

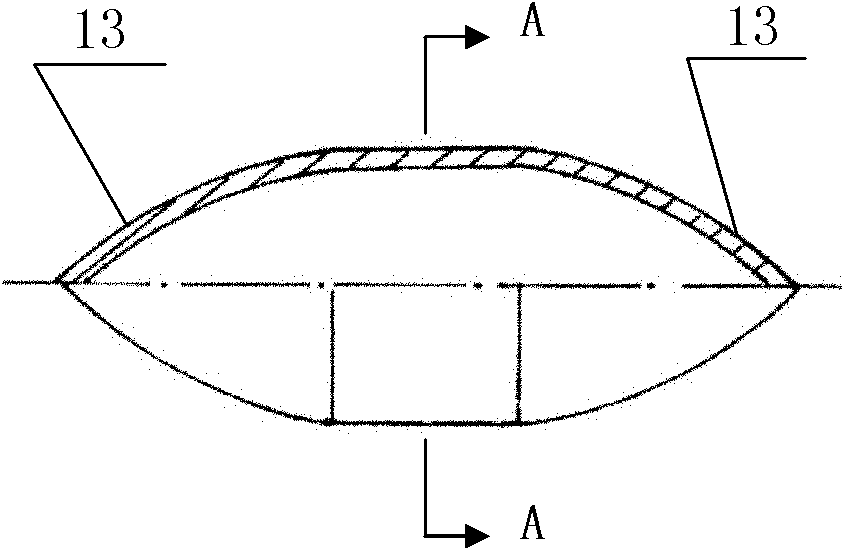

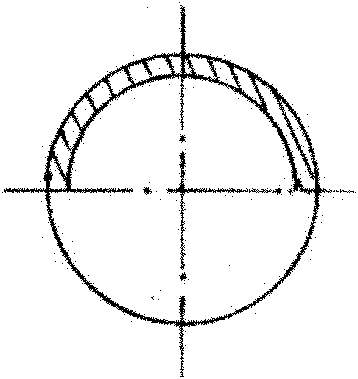

[0036] Such as figure 1 , figure 2 As shown, the cone-shaped tube bundle support structure for the shell-and-tube heat exchanger of the present invention is an olive-shaped structure with conical paraboloids 13 at both ends.

[0037] The cone angles of the conical paraboloids 13 at both ends of the olive-shaped structure are the same, or the cone angles of the conical paraboloids 13 at both ends of the olive-shaped structure are different.

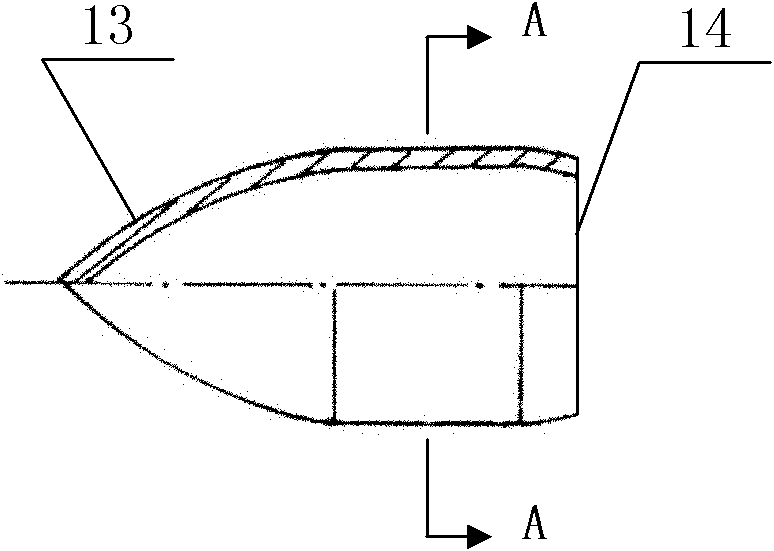

[0038] Such as image 3 , Figure 4 As shown, the structure of the cone-shaped tube bundle support for the shell-and-tube heat exchanger of the present invention is a bullet-shaped structure in which one end is a conical paraboloid 13 and the other end is a plane 14 .

[0039] Such as Figure 5 , Figure 6 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com