A multi-purpose plate steam generator

A steam generator and multi-purpose technology, which is applied in the field of nuclear reactors, can solve the problems of increasing the manufacturing cost of a single steam generator, the design of the steam generator, the difficulty of manufacturing, the increase in the number and height of heat transfer tubes, etc. Low cost and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

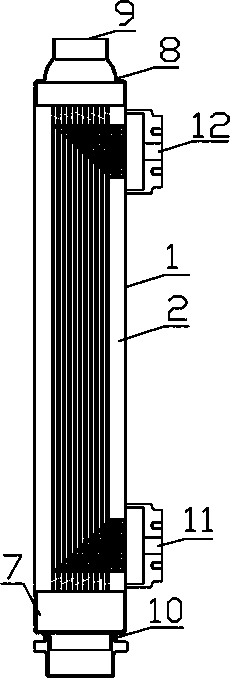

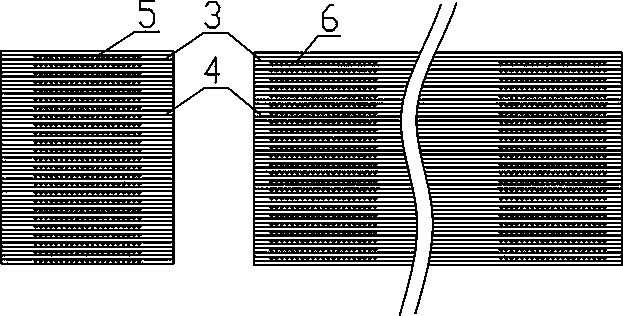

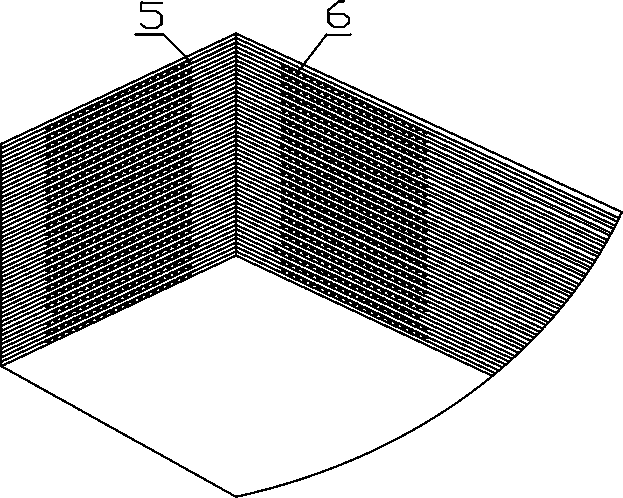

[0047] A kind of multi-purpose plate type steam generator of the present invention, as Figure 2-5 As shown, a multi-purpose plate steam generator includes a plate steam generating assembly 1, and the plate steam generating assembly 1 includes a heat exchange plate, and the heat exchange plate includes a heat exchange plate I3 and a heat exchange plate II4, and the heat exchange plate I3 and the heat exchange plate The heat plates II4 are alternately arranged, and the surface of the heat exchange plate I3 and the plate surface of the heat exchange plate II4 are connected by vacuum diffusion welding. Heat exchange channel 5 for reactor coolant is provided on heat exchange plate I3, and heat exchange channel 6 for secondary side medium is provided on heat exchange plate II4. The heat exchange channel 5 for the reactor coolant is a straight-through channel formed by matching the groove on the heat exchange plate I3 with the surface of the adjacent heat exchange plate II4, and the...

Embodiment 2

[0050] A kind of multi-purpose plate type steam generator of the present invention is further optimized on the basis of embodiment 1, as Figure 6~7 As shown, the reactor coolant outlet nozzle 10 of the plate steam generator includes an anti-leakage annular pipe 20 and an anti-bypass flow nozzle 21. The anti-leakage annular pipe 20 is welded to the bottom of the header 7, and the anti-bypass flow nozzle 21 is socketed On the outer side of the anti-leakage ring pipe 20 , a sealing ring 22 is provided between the anti-leakage ring pipe 20 and the anti-bypass nozzle 21 , and the outer bottom of the anti-bypass nozzle 21 fits and fixes with the groove of the support platform 19 . A spring 23 is provided between the anti-bypass nozzle 21 and the header 7, the central axis direction of the spring 23 is parallel to the axial direction of the plate steam generator, and a sleeve 24 is sleeved outside the spring 23, The spring 23 is provided with a positioning column 25, the upper end o...

Embodiment 3

[0052] A kind of multi-purpose plate steam generator that embodiment 2 provides is installed in the reactor pressure vessel, as Figure 8 As shown, the reactor pressure vessel barrel 13 is provided with a guide tube 15 , and the axis of the guide tube 15 coincides with the axis of the reactor pressure vessel barrel 13 . Four plate-type steam generators are evenly and symmetrically distributed in the annular space between the draft guide cylinder 15 and the reactor pressure vessel cylinder 13 . The feedwater inlet nozzle 11 and the feedwater inlet flange 17 on the reactor pressure vessel cylinder 13, and the steam outlet nozzle 12 and the steam outlet flange 18 of the reactor pressure vessel cylinder 13 are respectively sealed and connected by bolts. The upper port of 15 is communicated with the reactor coolant inlet 9 through the drainage assembly 16 . The drainage assembly 16 adopts a cross-shaped groove structure, such as Figures 9 to 11 As shown, the middle part of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com