Stacking method of stack body and stacking arrangement of stack body

A technology of stacking and parallel arrangement, which is applied in the field of stacking of stacking bodies and stacking of stacking bodies, and can solve problems such as waste of time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

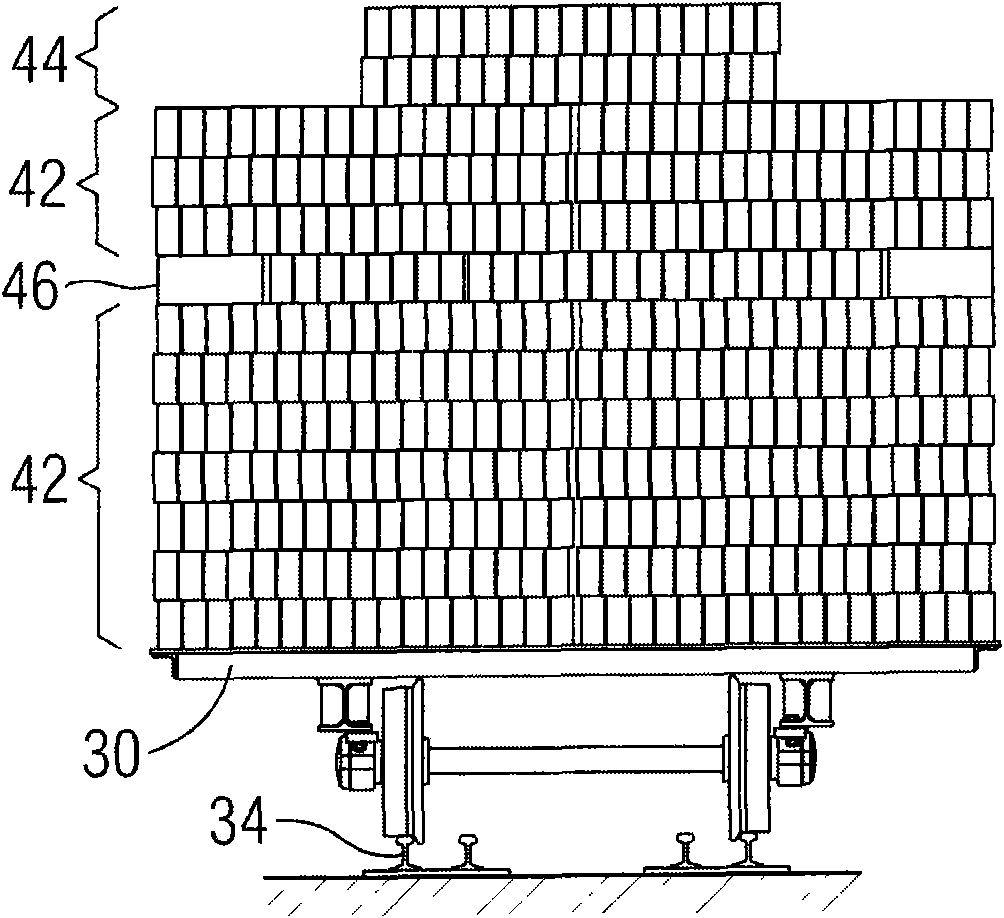

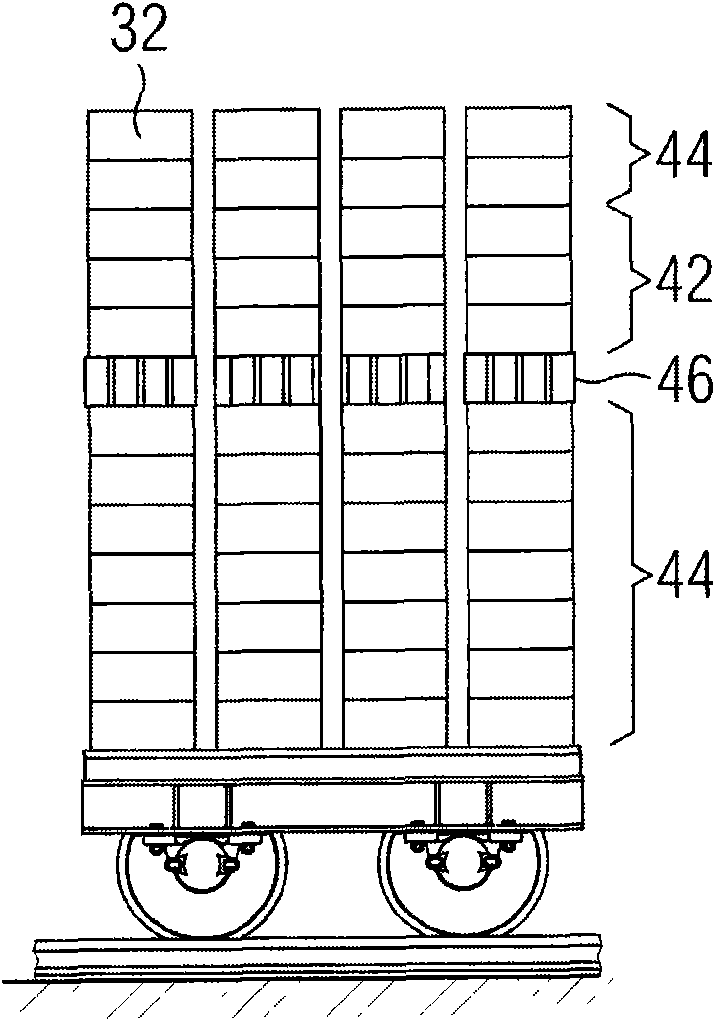

[0031]In the manufacture of square lime-sand bricks, lime-sand brick preforms are first produced by a brick press, which must then be given a hardening treatment. To transport these parisons to a hardening furnace or a hardening plant, so-called hardening trolleys 30 are used, which can be loaded with a large number of parisons 32 and are driven together on a track arrangement 34 into the hardening furnace.

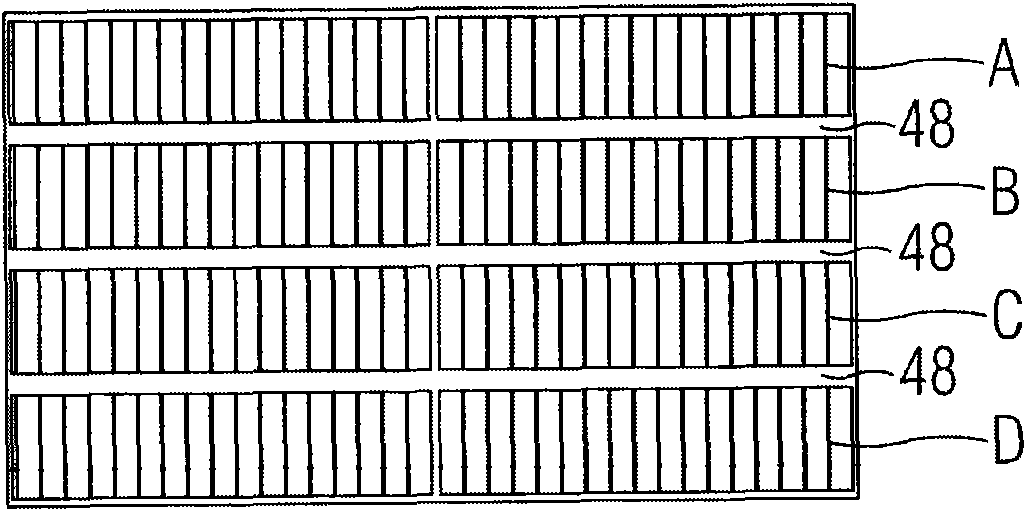

[0032] The loading of the hardening furnace car 30 is carried out by a stacking grab 36, which can pick up the double-row parisons 32 with its grab hand 38 from a lift table (not shown) and place them on the On the hardening car 30, each of said double rows carries a predetermined number of parisons 32, 17 in the example shown. The grab handle 38 of the stack grab 36 shown is rotatable on a vertical axis. The grab fingers 40 of the grab hand 38 can all be controlled individually, which allows the stacking grab 36 to pick up a total of 34 complete double-row parisons 32, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com