Synchronizer fixed tooth trislot milling clamp

A fixed tooth and synchronizer technology, applied in the direction of clamping, positioning devices, milling machine equipment, etc., can solve the problems of cumbersome operation, low precision of three-groove machining, trisection and unstable symmetry to the center, etc., and achieve processing The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

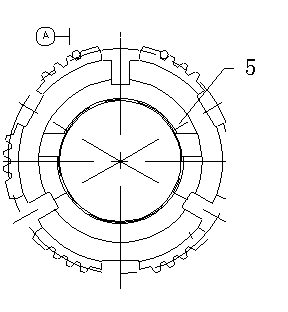

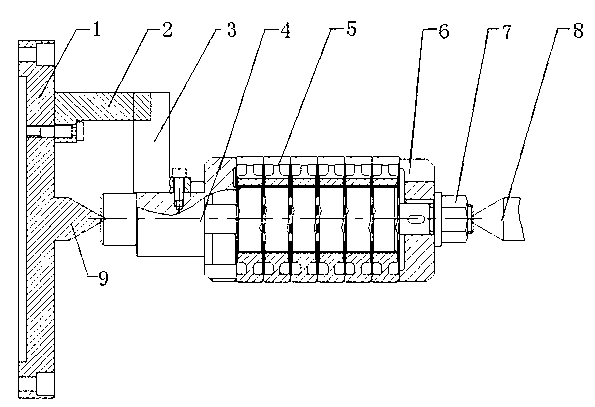

[0015] like figure 2 As shown, a three-slot milling fixture for fixed teeth of a synchronizer includes a fixed core shaft 4 and a nut 7 for passing through the center hole of the gear shell workpiece 5, and the nut 7 cooperates with the rear end of the fixed core shaft 4 to fix the teeth The shell workpiece 5 also includes a transition flange 1 installed on the dividing head. The center of the transition flange 1 is provided with a front tip 9 for positioning and clamping the front end of the fixed mandrel. The end is provided with a tail tip 8 for positioning and clamping the rear end of the fixed mandrel. The nut 7 is a shoulder nut. It also includes a positioning seat 2 and a positioning body 3 which are arranged perpendicular to each other and play an orientation role during clamping. The positioning seat 2 is vertically connected to the upper part of the transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com