Resistor element suction device of chip mounter and chip mounter

A technology of resistive components and placement machines, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of only absorbing components and not being able to adjust the orientation of components, so as to achieve high work efficiency, ensure stability, improve production capacity and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

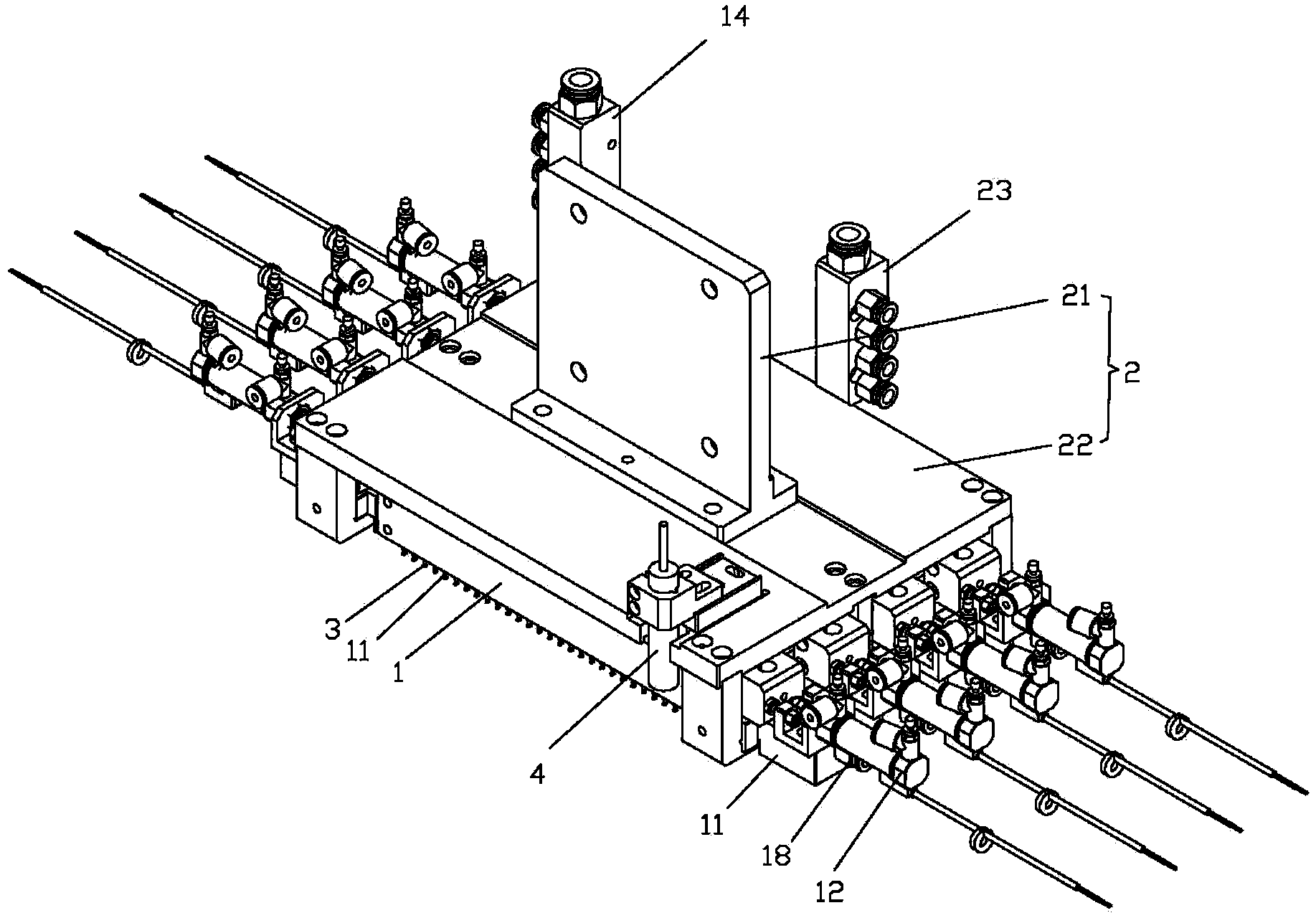

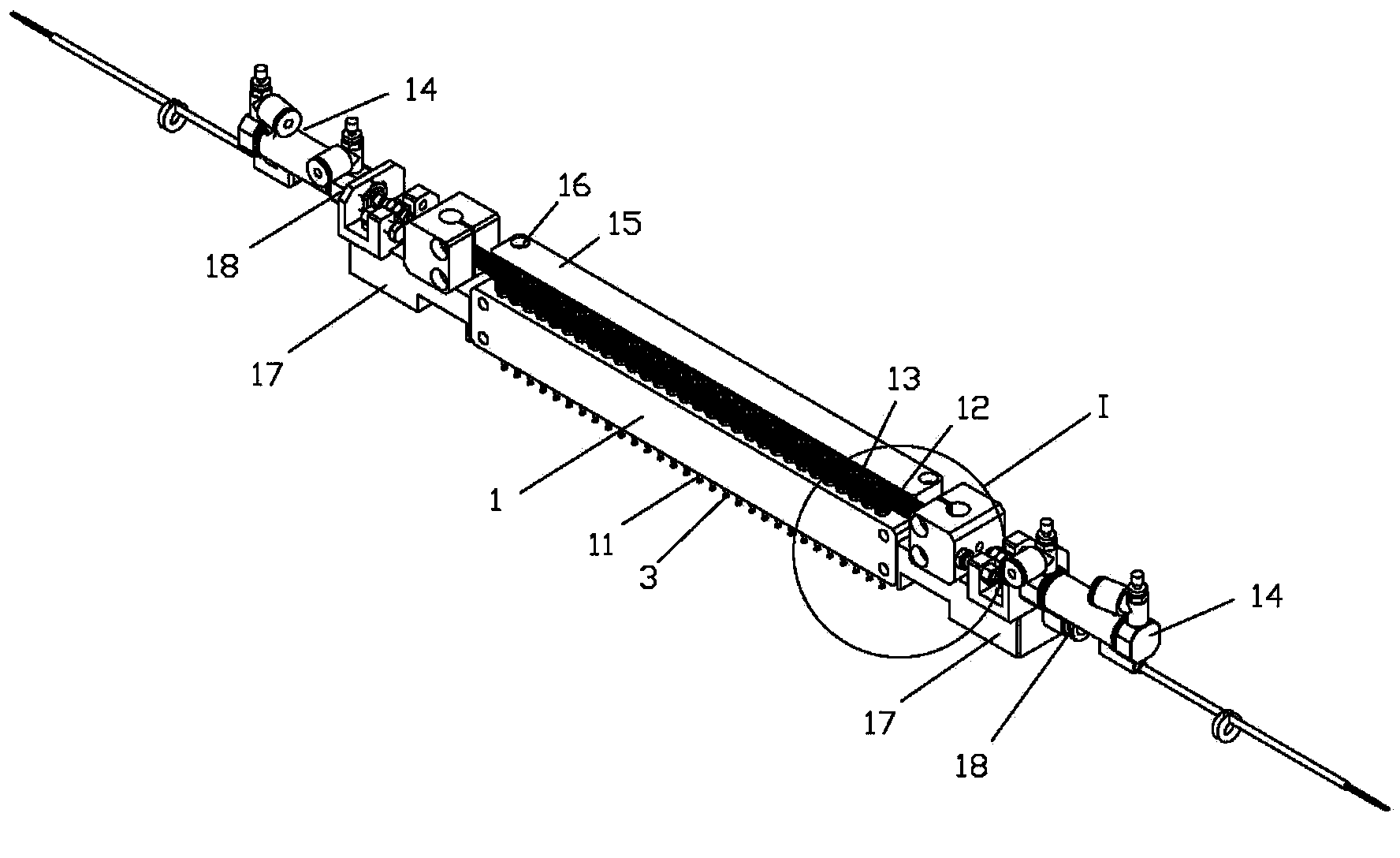

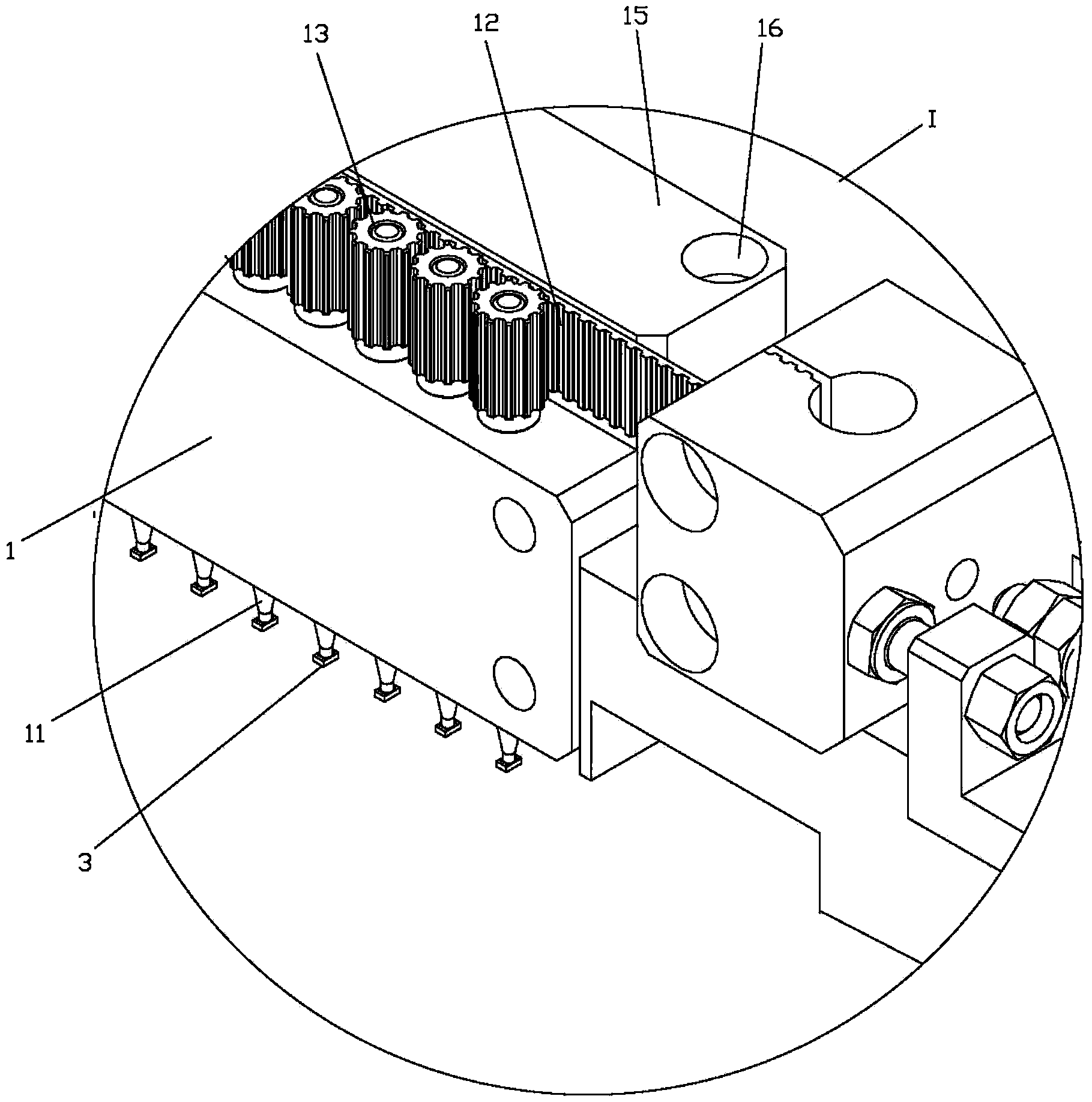

[0028] In the following, specific implementations of the high-efficiency placement machine of the present invention will be described with reference to the drawings.

[0029] Such as Figure 1 to Figure 3 As shown, a device for sucking resistive components of a chip mounter includes at least one nozzle tray 1 (four nozzle trays 1 are provided in this embodiment). The nozzle tray 1 is elongated and is on the nozzle tray 1. A plurality of suction nozzles 11 are installed to suck a plurality of resistive elements 3 (30 suction nozzles are installed on each nozzle plate 1 in this embodiment), and the plurality of suction nozzles 11 are arranged in a row along the length direction of the nozzle plate 1; The timing belt 12 and the rotating gear 13 that make the suction nozzle 11 rotate at a certain angle, the rotation gear 13 and the suction nozzle 11 are arranged in one-to-one correspondence, the rotation gear 13 is fixed to the corresponding suction nozzle 11, and the timing belt 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com