Steam pocket applied to photo-thermal power generation system and steam generation system

A solar thermal power generation and steam drum technology, which is applied in the steam generation method, steam generation, steam generation method using solar energy, etc., can solve the problems of high equipment installation accuracy, reduced equipment life, noise pollution, etc., and achieves reduced processing. Difficulty and material cost, reduced installation accuracy, reduced footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

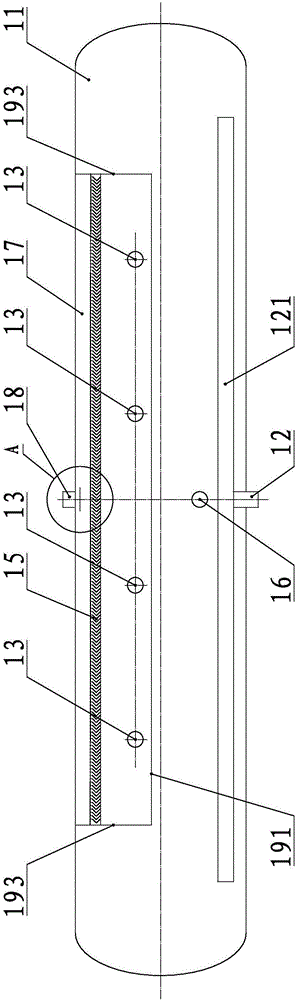

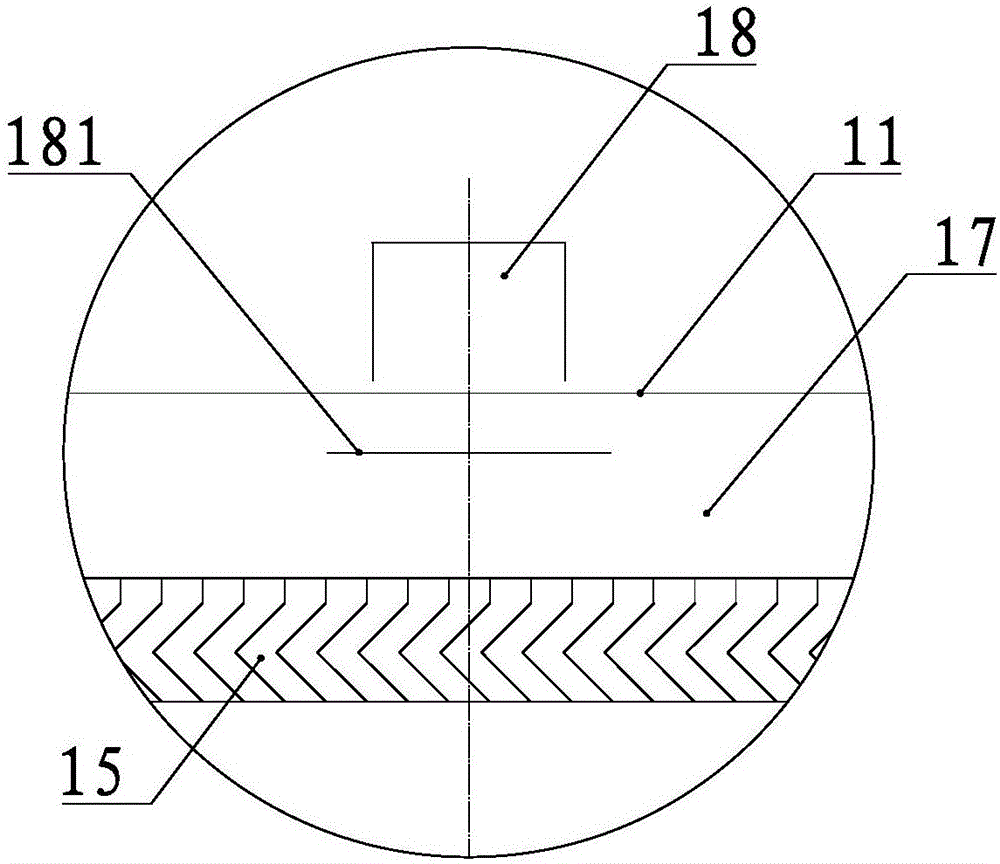

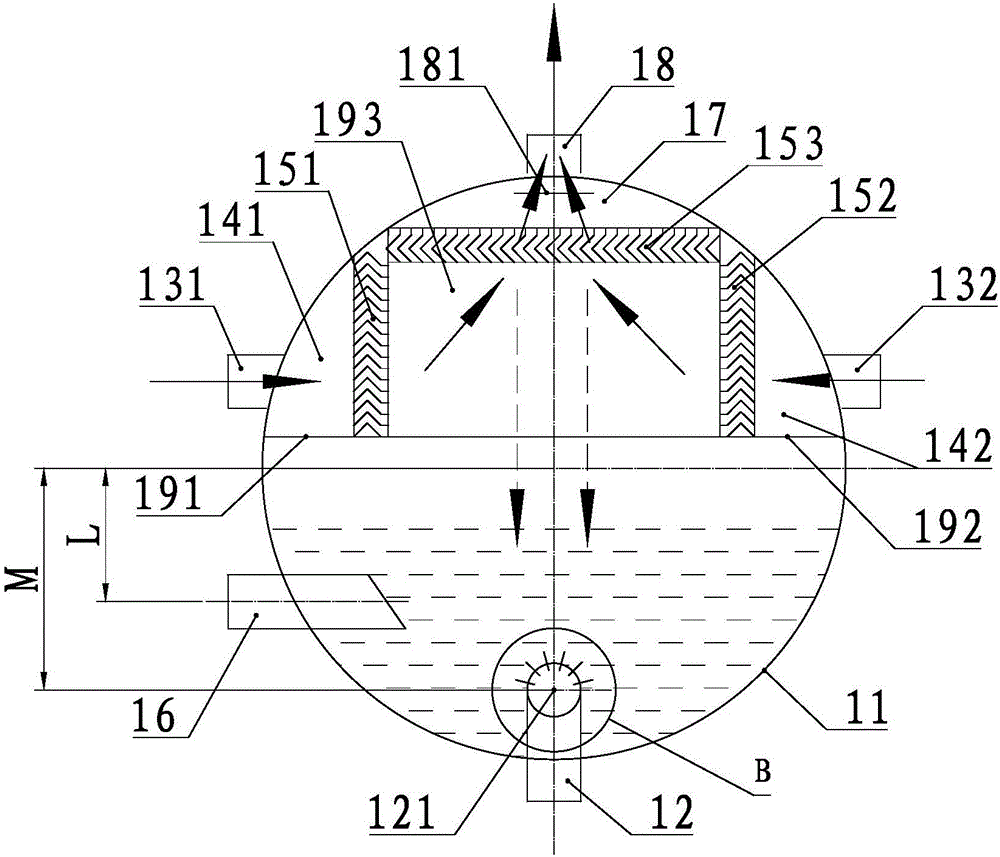

[0045] like Figure 1 to Figure 3 As shown, a steam drum 1 applied to a photothermal power generation system includes a first housing 11, the upper part of the inner cavity of the first housing 11 is provided with a steam-water separation device, and the steam-water separation device includes a first A steam-water separator 151 , a second steam-water separator 152 and a third steam-water separator 153 . The first steam-water separation device 151 and the second steam-water separation device 152 are arranged vertically, and the third steam-water separation device 153 is arranged between the first steam-water separation device 151 and the second steam-water separation device. between the separation devices 152 and arranged along the horizontal direction. The first steam-water separation device 151 , the second steam-water separation device 152 and the third steam-water separation device 153 together form a "gate" shape.

[0046]The upper ends of the first steam-water separator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com