Pipe-in-pipe faucet water control valve

A technology for faucets and water control valves, applied to multi-way valves, valve devices, engine components, etc., can solve complex problems, achieve low production costs and reduce production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

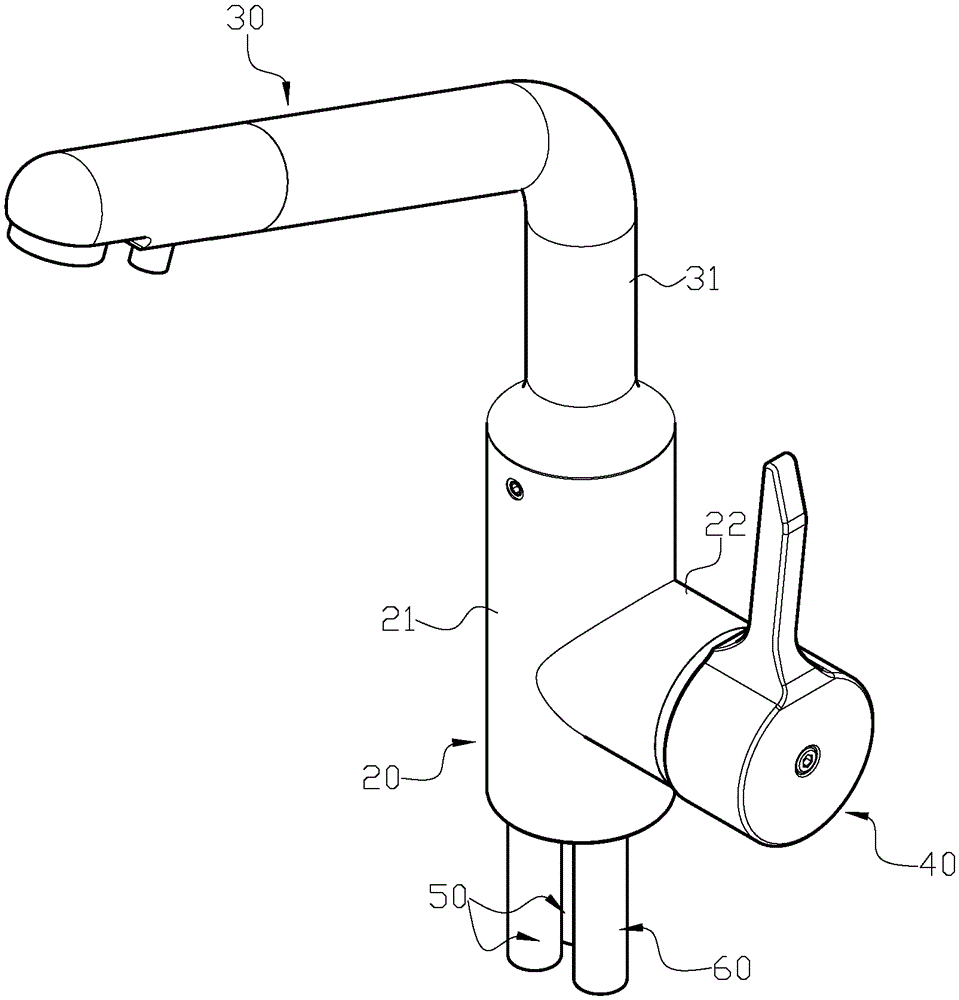

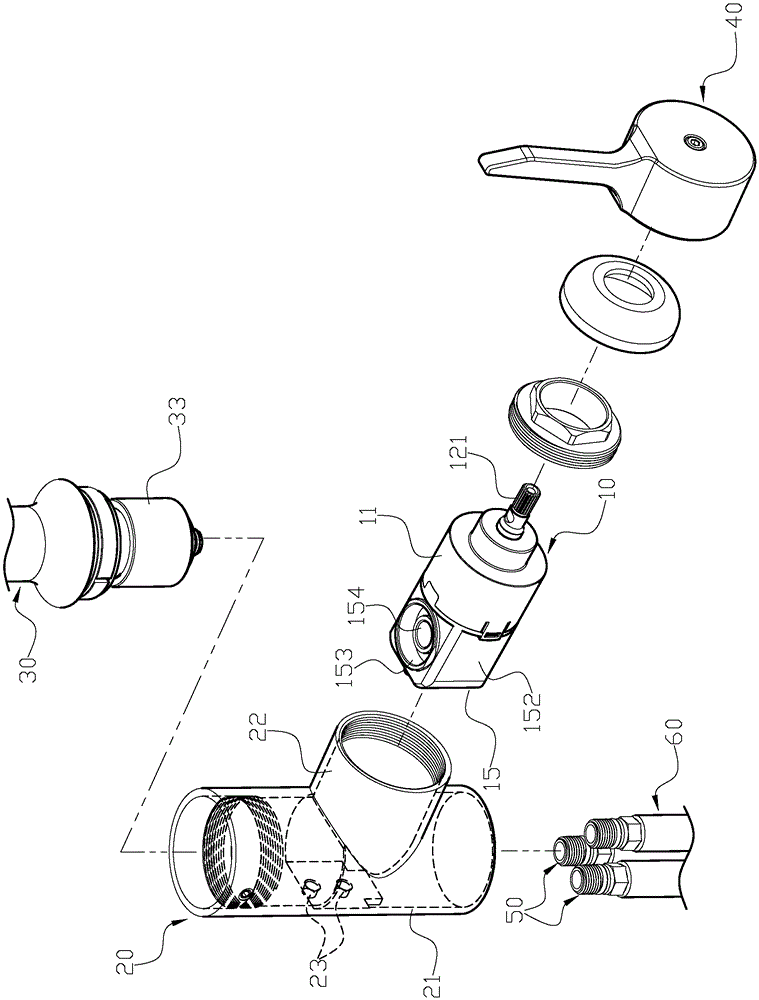

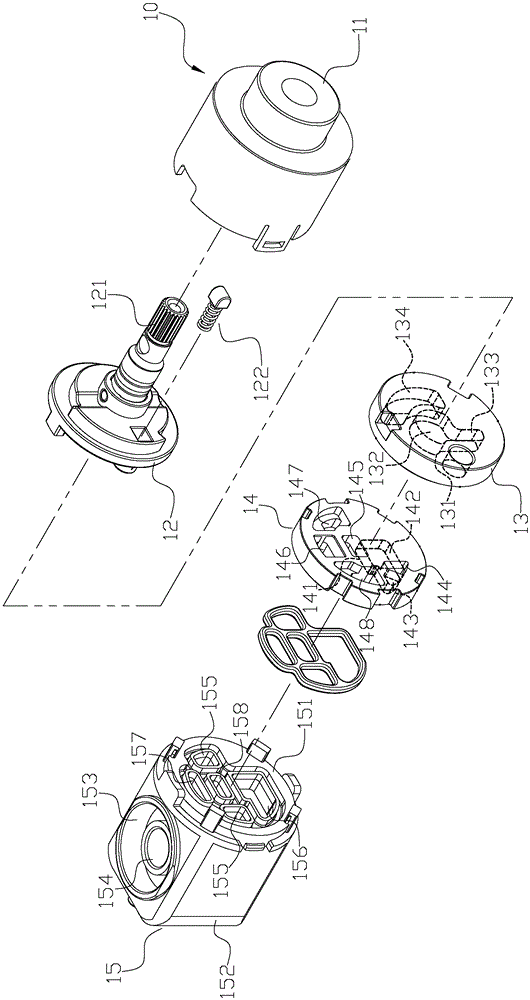

[0068] Usually according to the present invention, such as Figure 1 to Figure 7 As shown, the water control valve 10 is provided with a rotating seat 12, a movable valve plate 13 and a fixed valve plate 14 which are sequentially stacked in a valve housing 11, and the rotating seat 12 is also provided with an outwardly protruding valve. A valve stem 121 of the shell 11 is operated by the valve stem 121, and the movable valve piece 13 is embedded in the rotating seat 12 to rotate, and the change of the alignment relationship between the movable valve piece 13 and the fixed valve piece 14 can be used to control the faucet. Turn on and off the water, or change the mixing ratio of cold and hot water and the flow rate of the water. At the end of the valve housing 11, a combination of a valve seat 15 is used to block the fixed valve plate 14, the movable valve plate 13, the rotating seat 12, etc. Components fall out, and the water control valve 10 is used in conjunction with a fauce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com