Fan

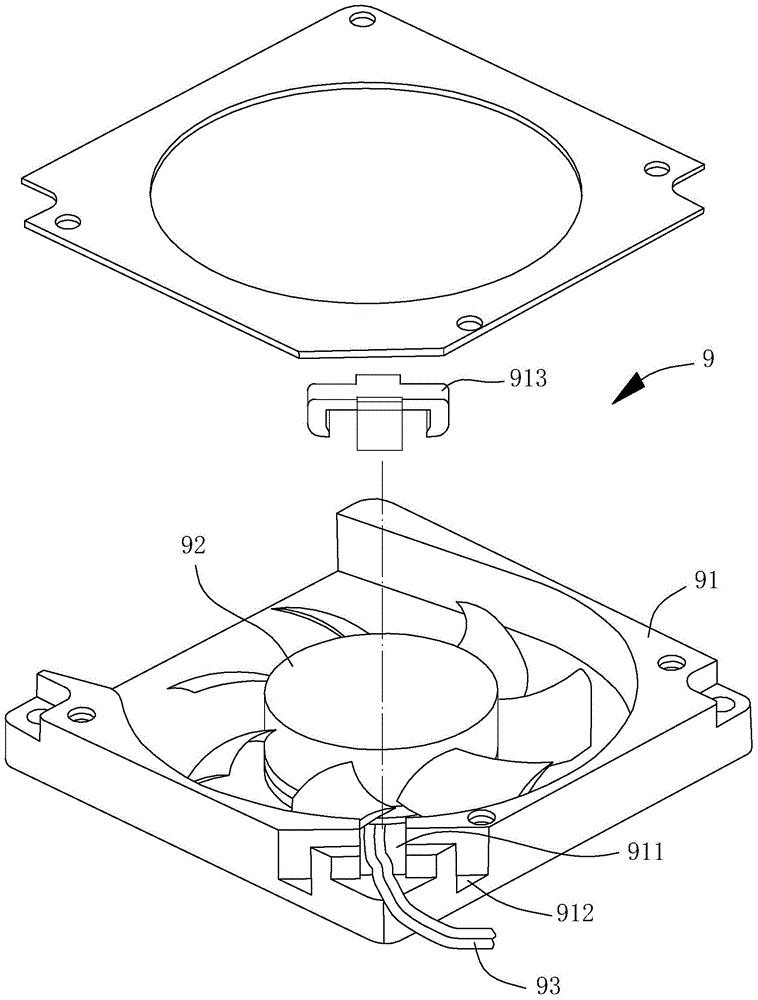

A fan and fan frame technology, which is applied in the field of fans provided with wireless power receiving coils, can solve the problems of increasing the structural complexity of the fan frame 91, the complex structure of the fan frame, and the short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the above-mentioned and other purposes, features and advantages of the present invention more obvious and easy to understand, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

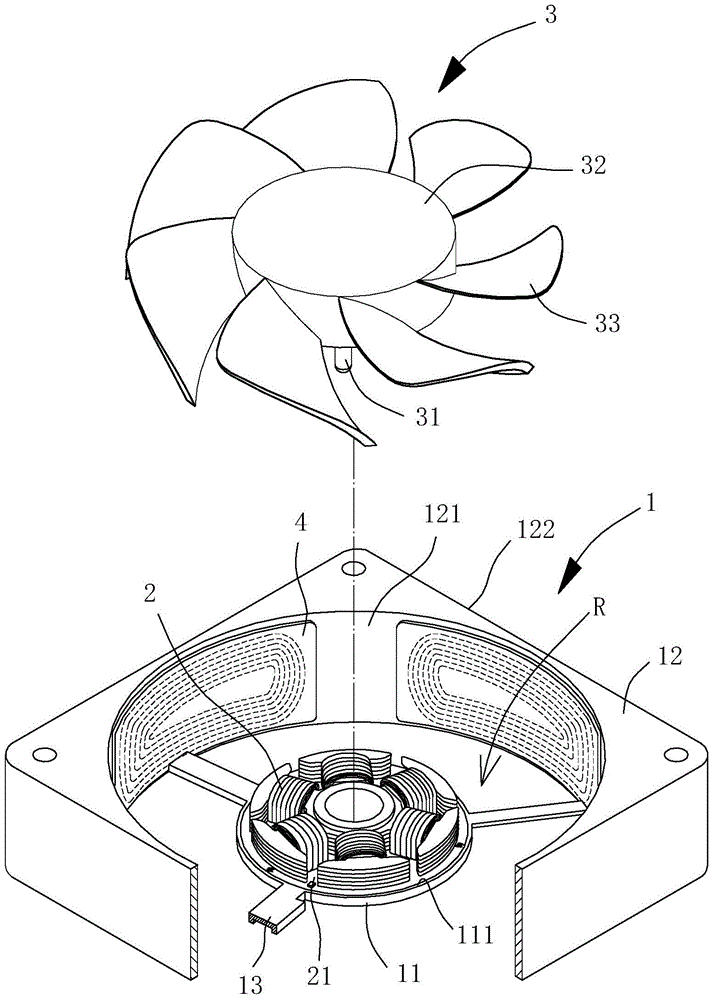

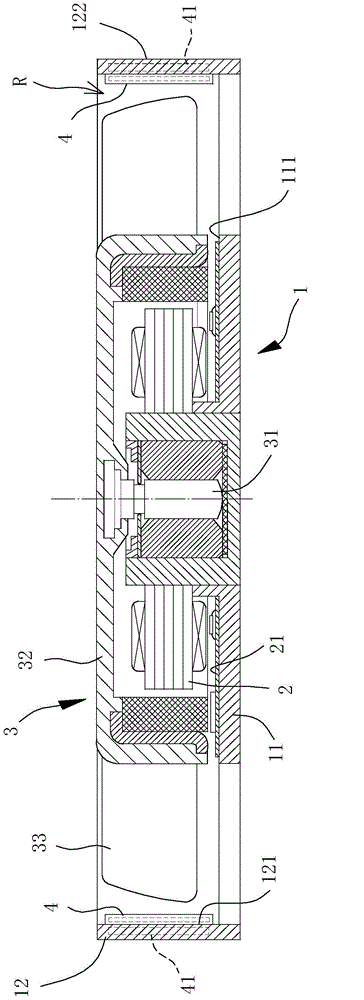

[0069] Please refer to figure 2 and 3 As shown, the fan according to the first embodiment of the present invention includes a fan frame 1 , a stator set 2 , a fan wheel 3 and a wireless power receiving coil 4 . The stator set 2 is disposed in the fan frame 1 ; the fan wheel 3 is rotatably combined with the stator set 2 ; and the wireless power receiving coil 4 is combined with the fan frame 1 . In this embodiment, the fan is an axial fan.

[0070] The fan frame 1 includes a base plate portion 11 and a surrounding wall portion 12 connected to each other. The surrounding wall portion 12 is arranged around the base plate portion 11, and the surrounding wall portion 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com