Patents

Literature

194results about How to "Reduce projected area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

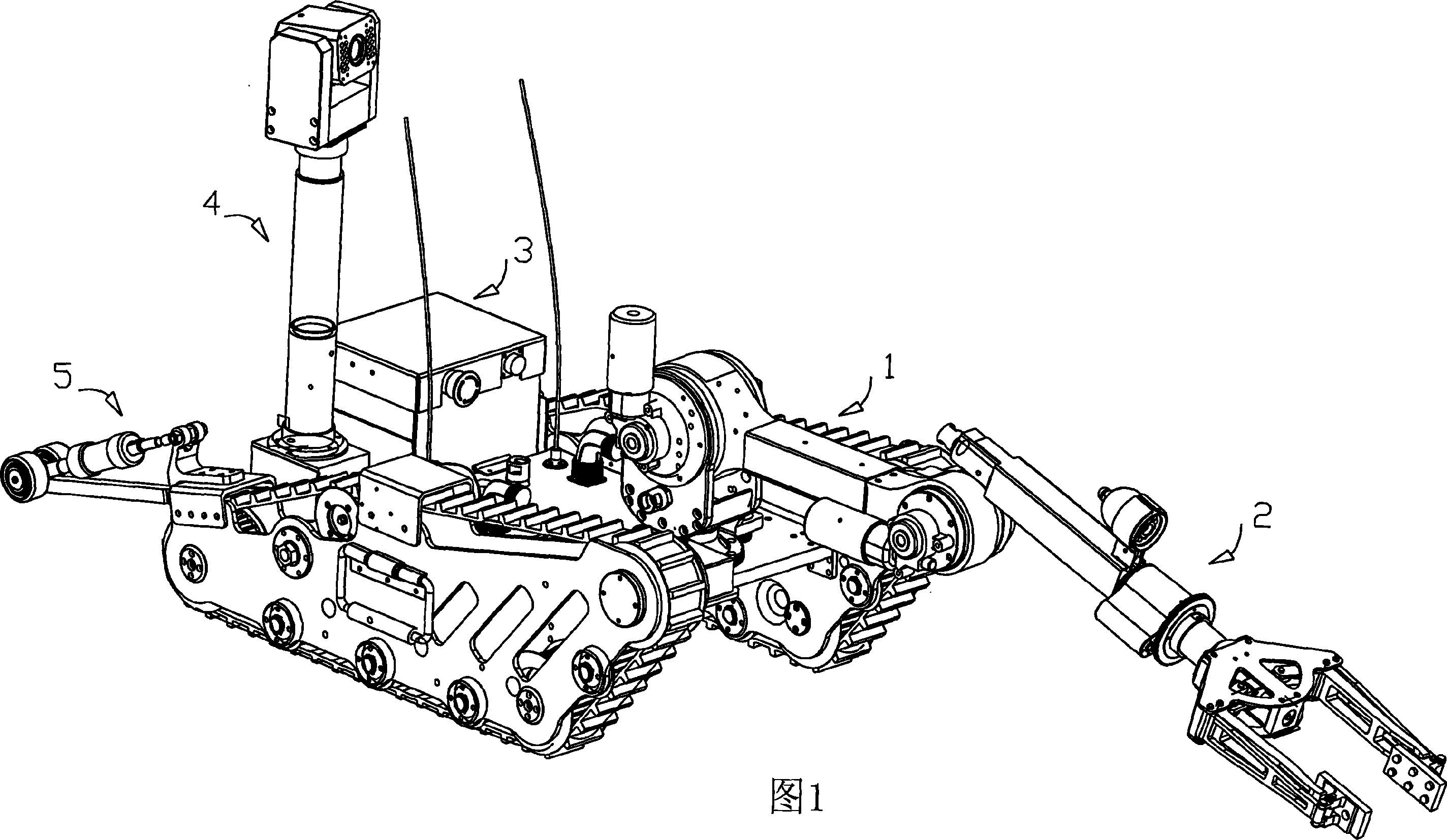

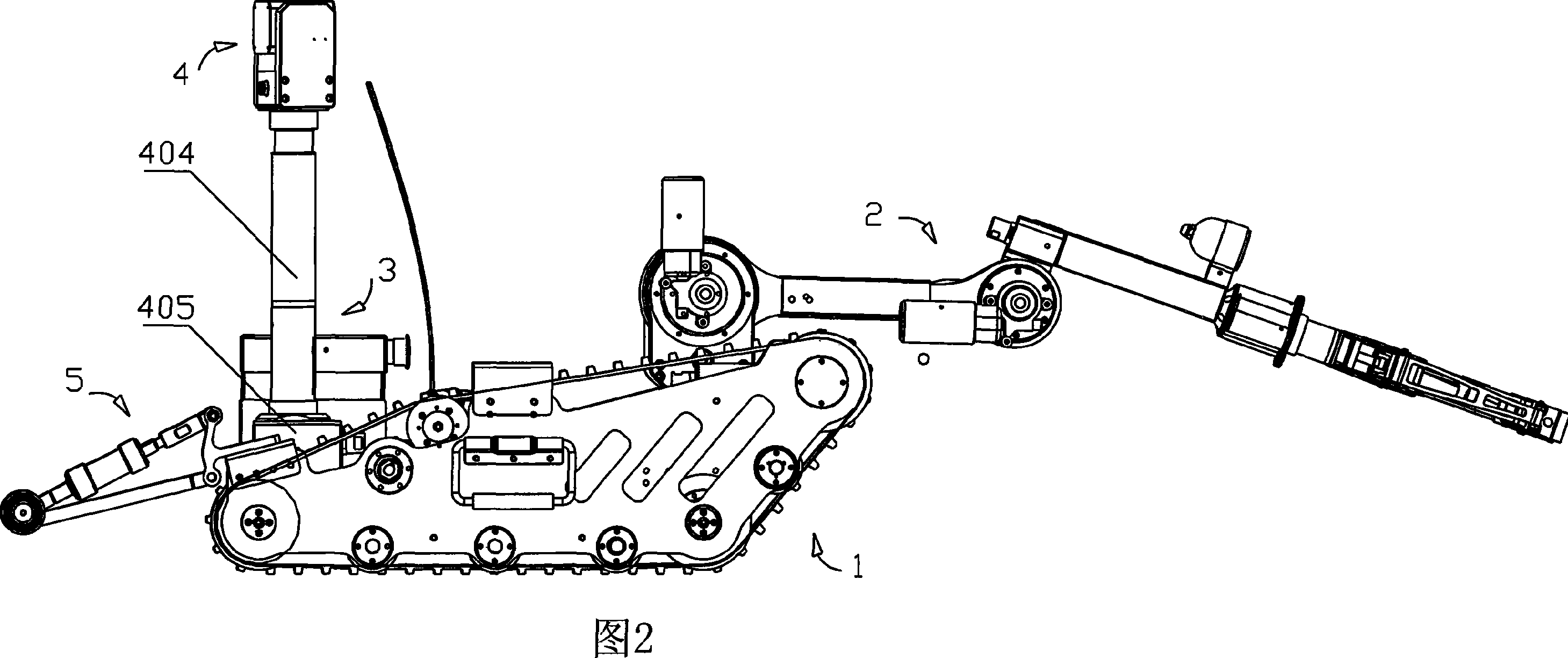

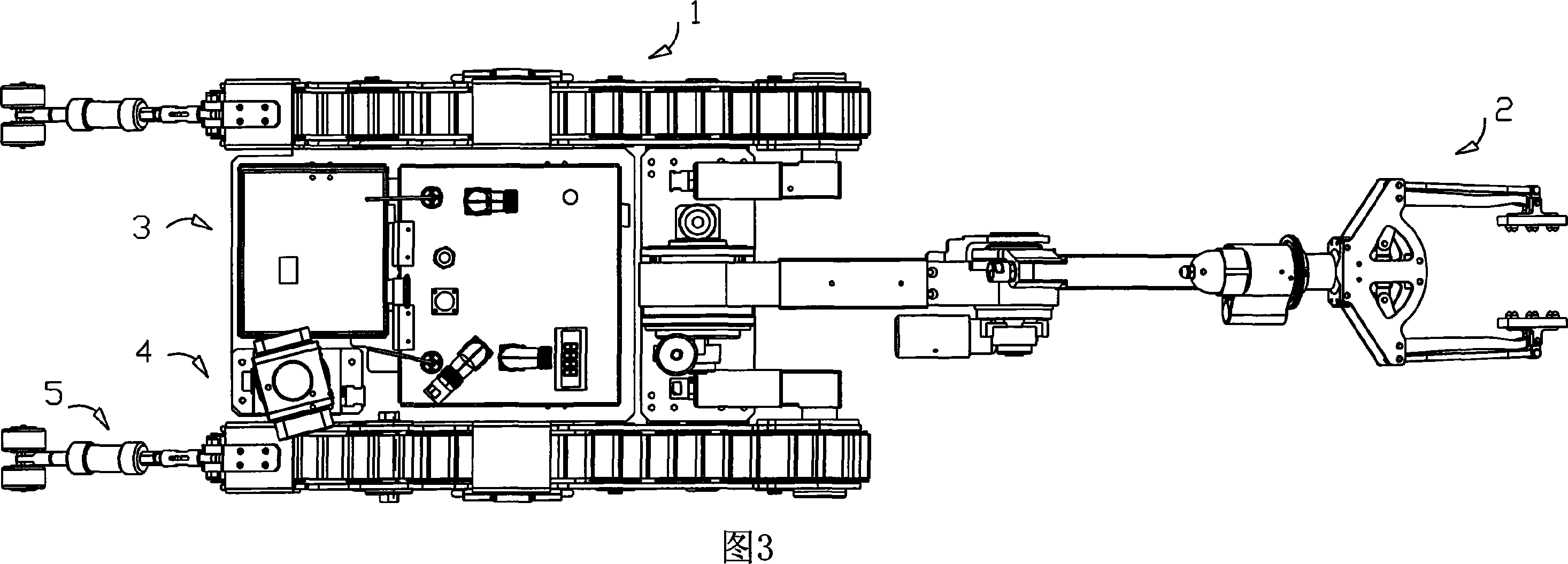

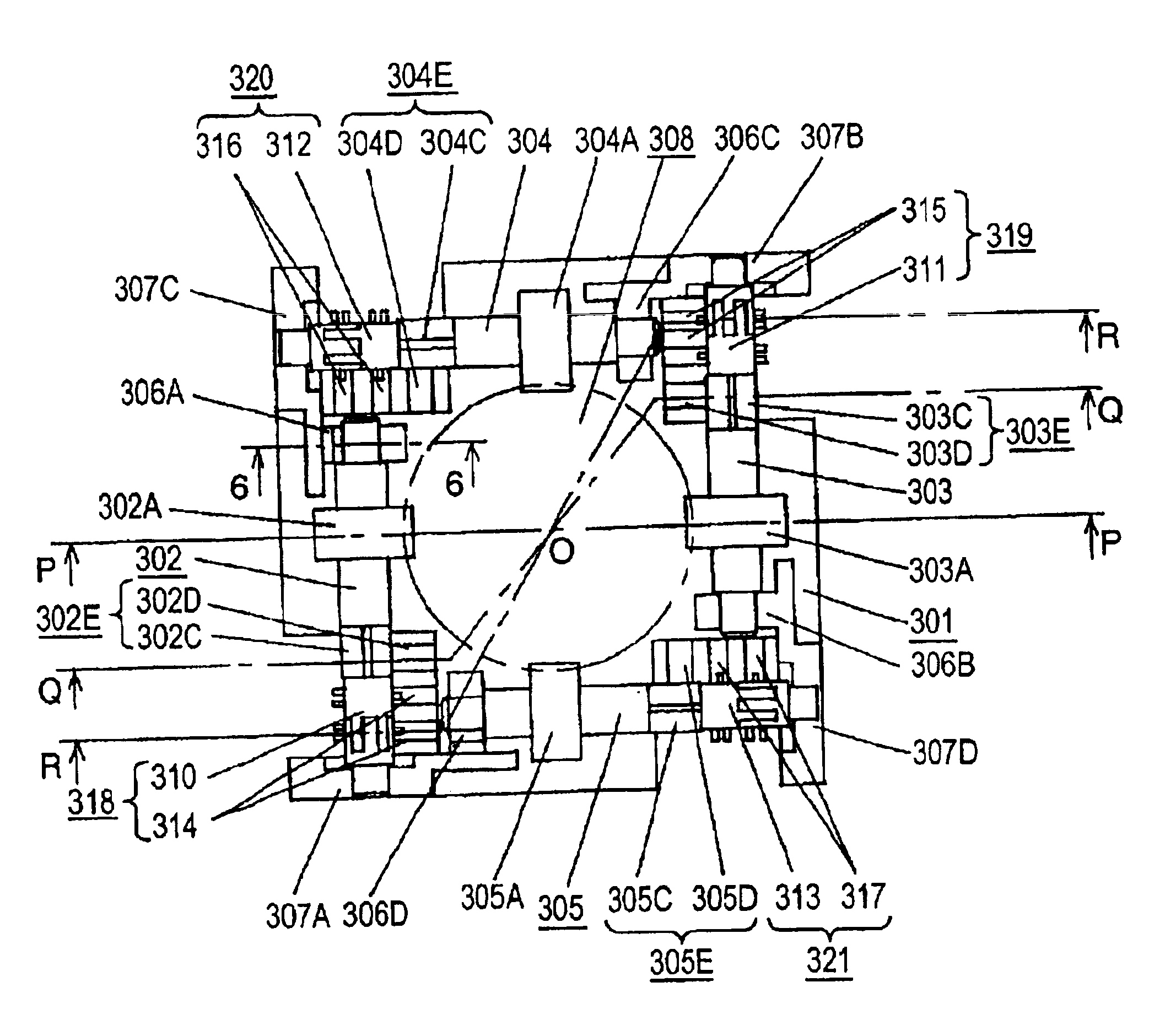

Robot for eliminating exploding and danger

The present invention relates to one kind of small explosive eliminating and hazardous article eliminating robot, which includes one running part, one manipulator part, one body part, one cradle part and one control part. The equipment compartment and battery compartment of the body part and the cradle part are set on the back chassis, the running part including one right part and one left part is connected symmetrically on two sides of the front chassis and the back chassis in the body part and has two tail supports, and the manipulator part set on the front chassis of the body part has multiple freedoms for sufficient grasping capacity and high capacity of passing through narrow space. The small explosive eliminating and hazardous article eliminating robot has functions similar to that of large robot, great topographic adaptability and high obstacle surmounting capacity, and may be applied directly for eliminating explosive and hazardous article.

Owner:BEIJING UNIVERSAL PIONEERING TECH

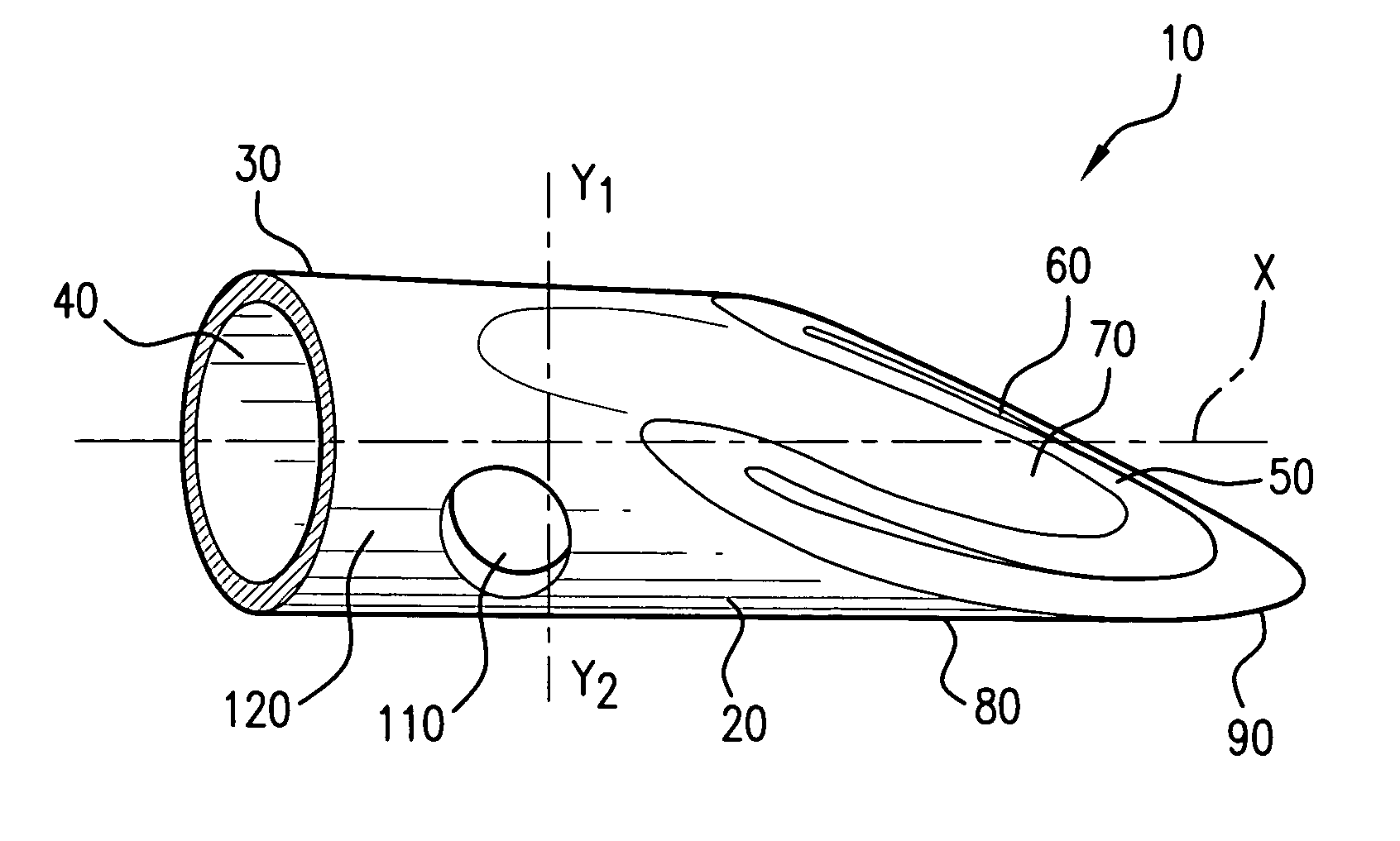

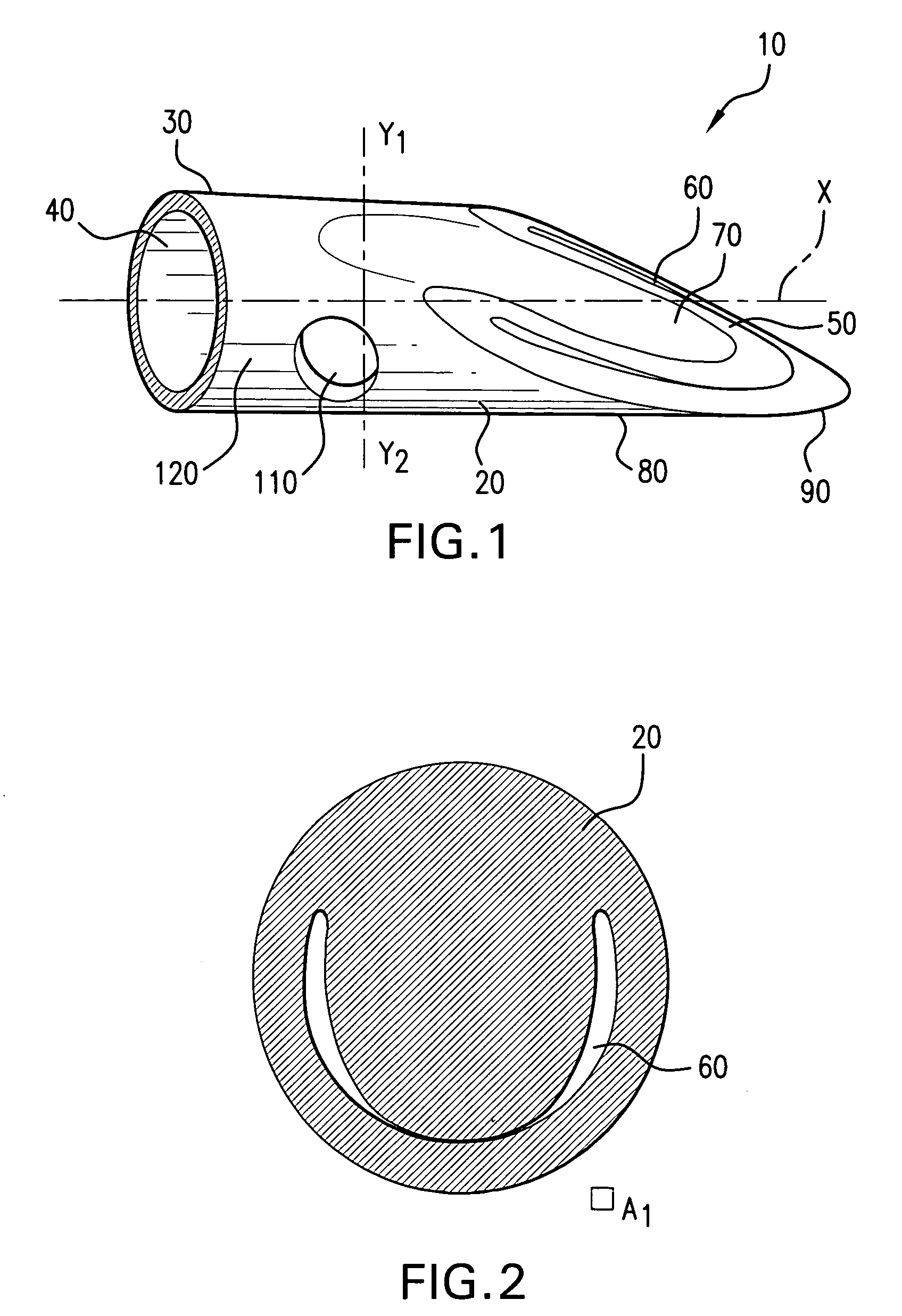

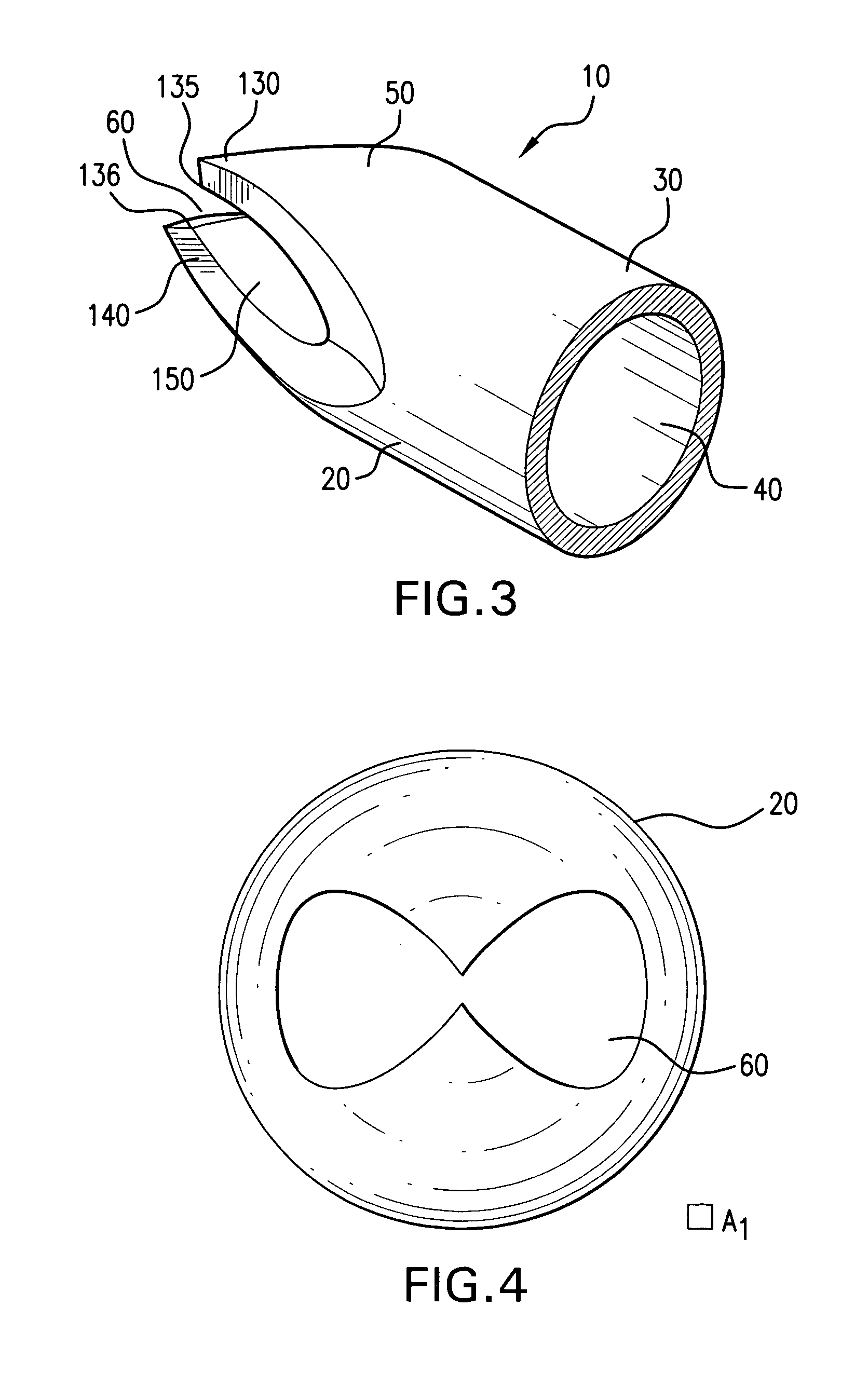

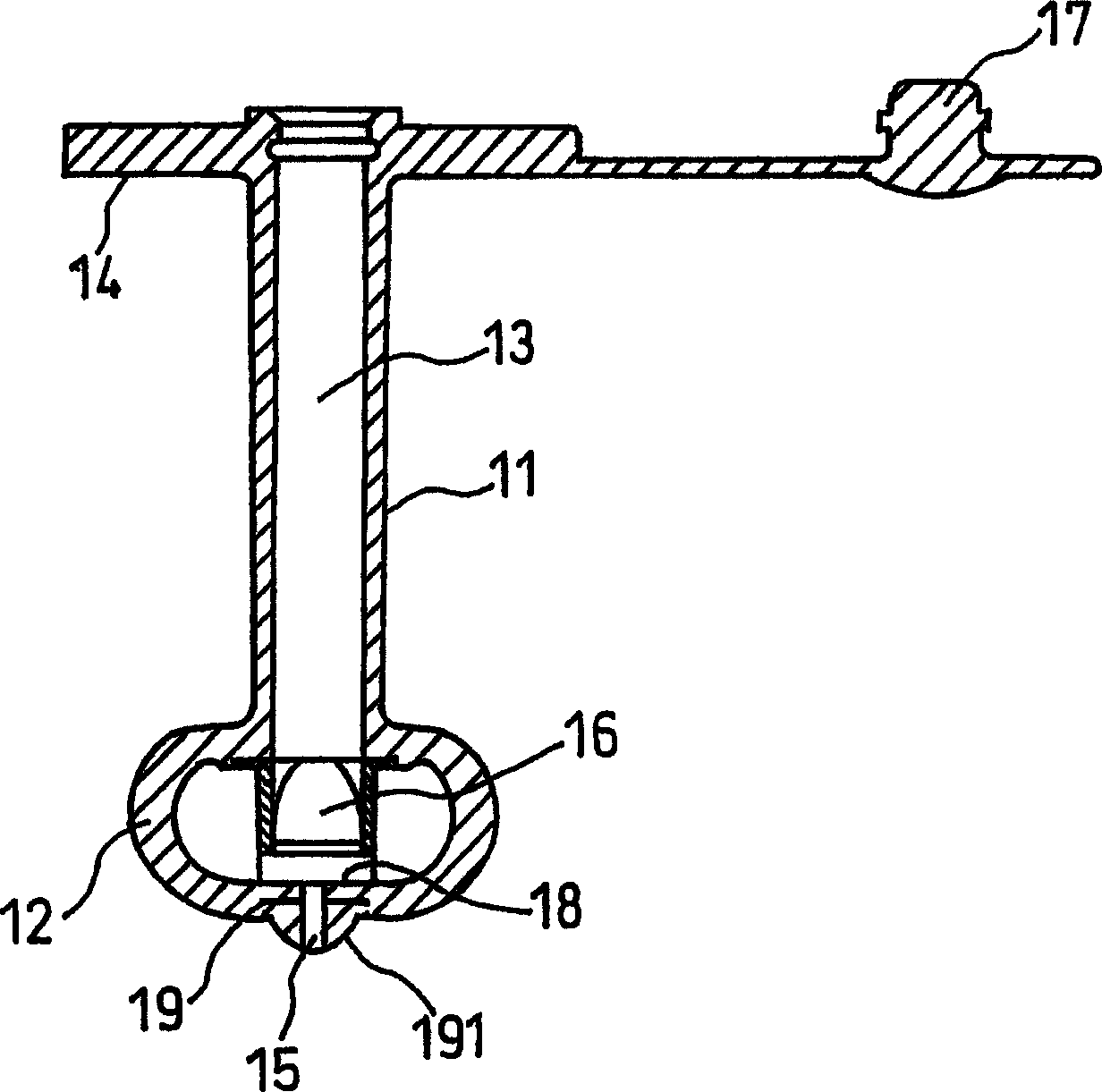

Needles and methods of using same

A needle having a shaft with a distal end defining a distal opening. The shaft has a longitudinal axis that extends through the distal opening and the distal opening has a projected area that is smaller than a cross-sectional area of a section of the shaft proximal to the distal end of the shaft. Also provided are methods of directly delivering a therapeutic agent to a target site using a Huber needle or pencil-point needle.

Owner:BOSTON SCI SCIMED INC

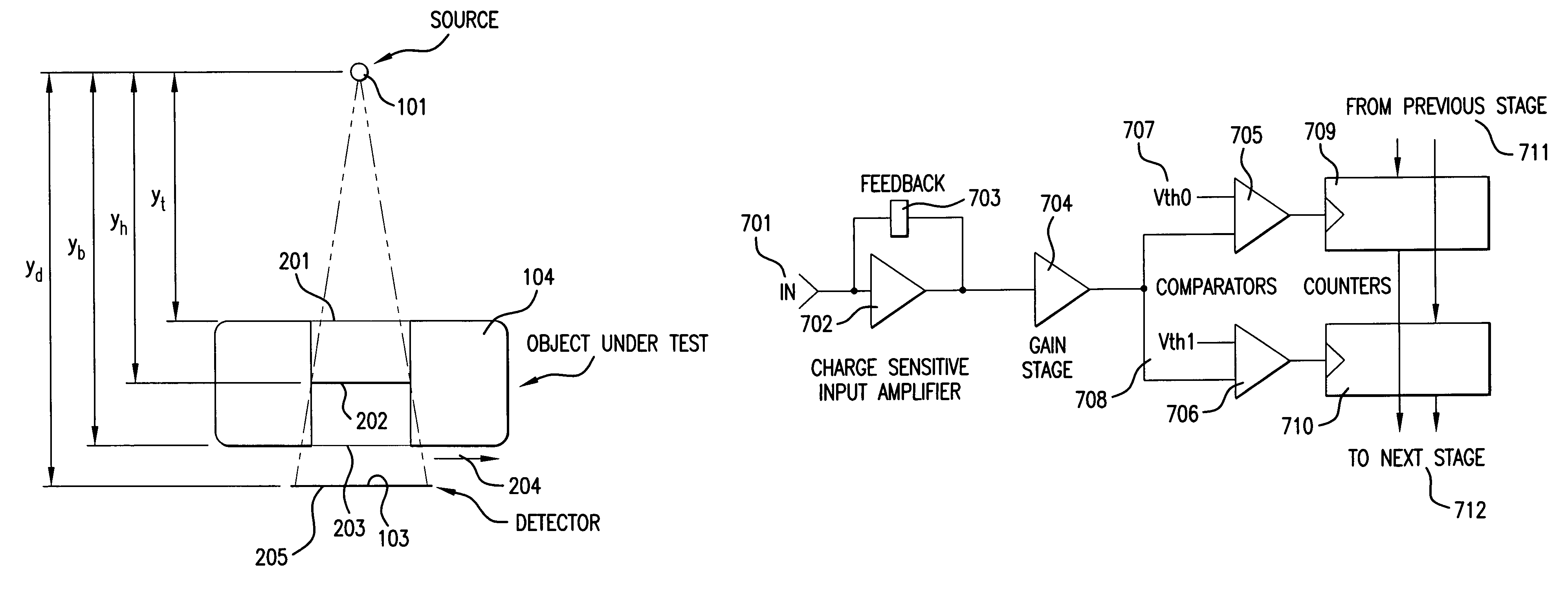

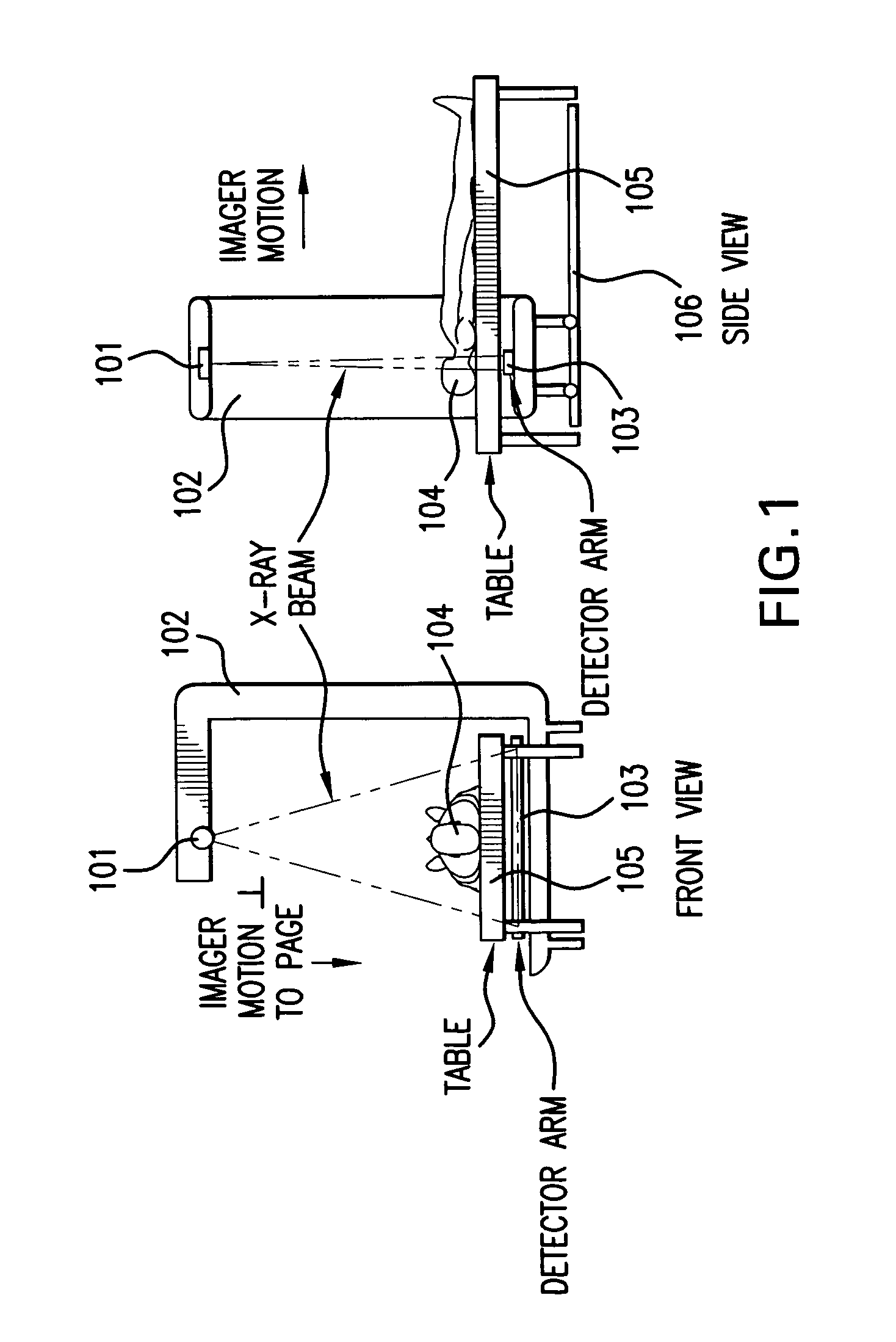

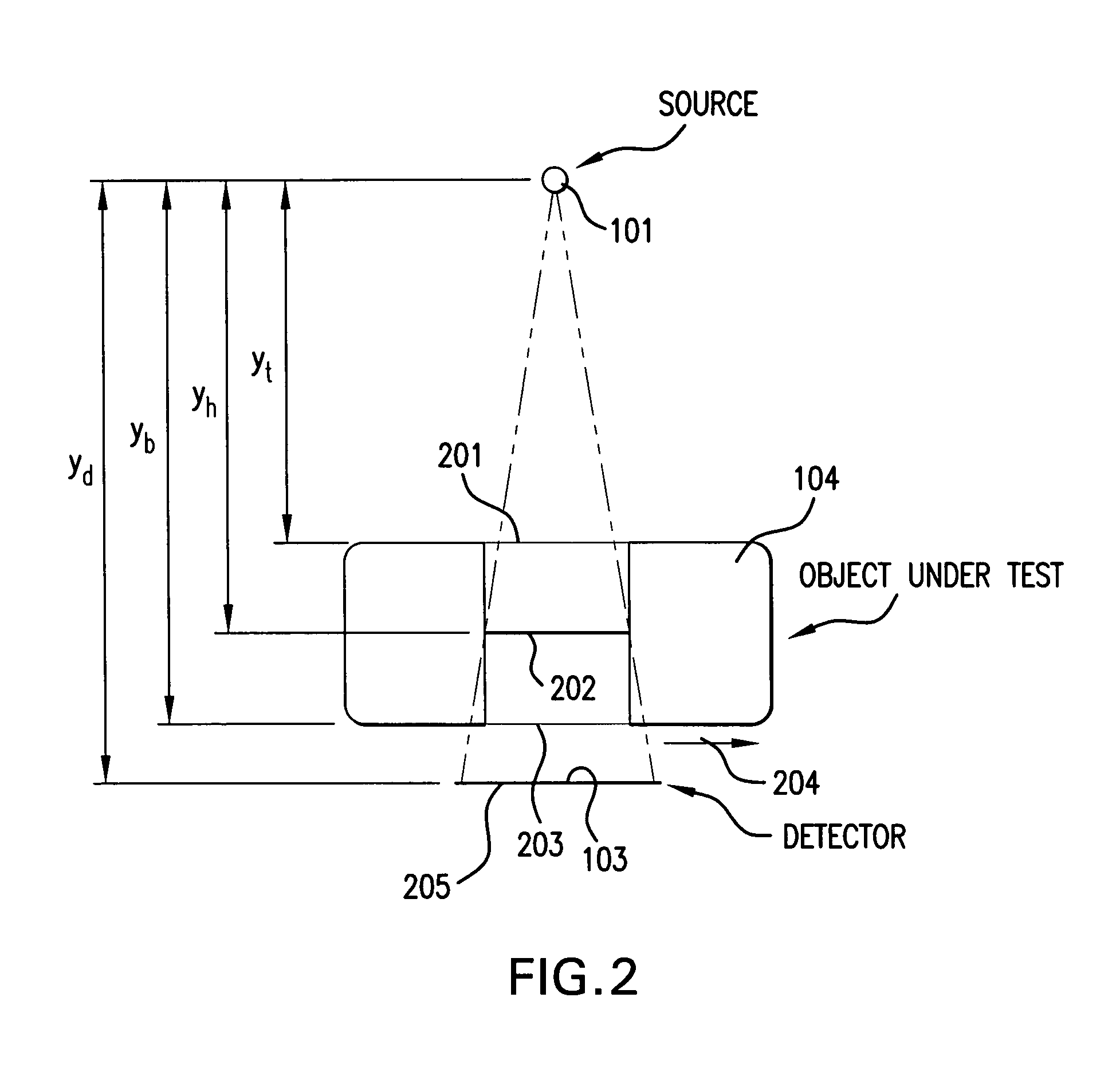

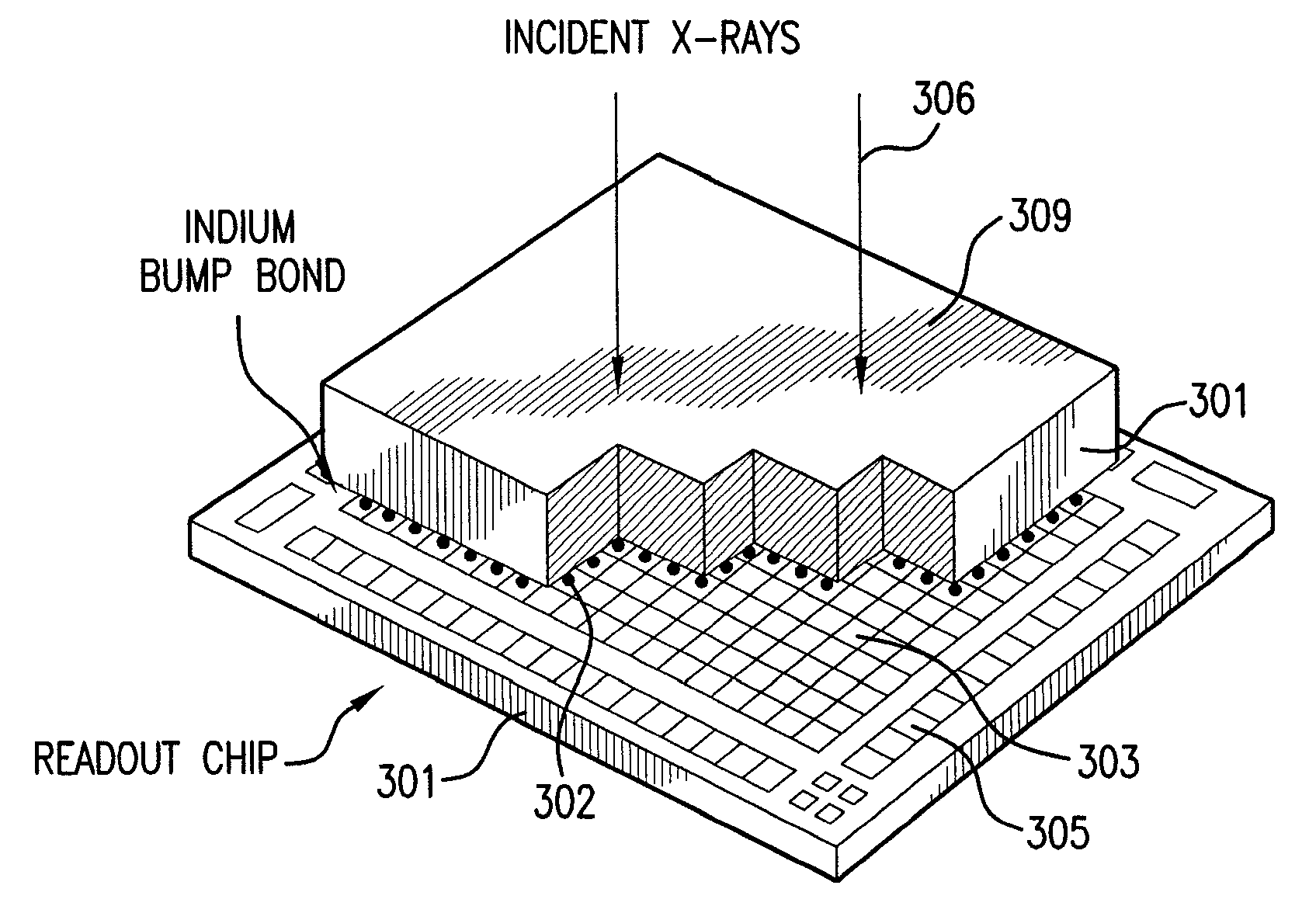

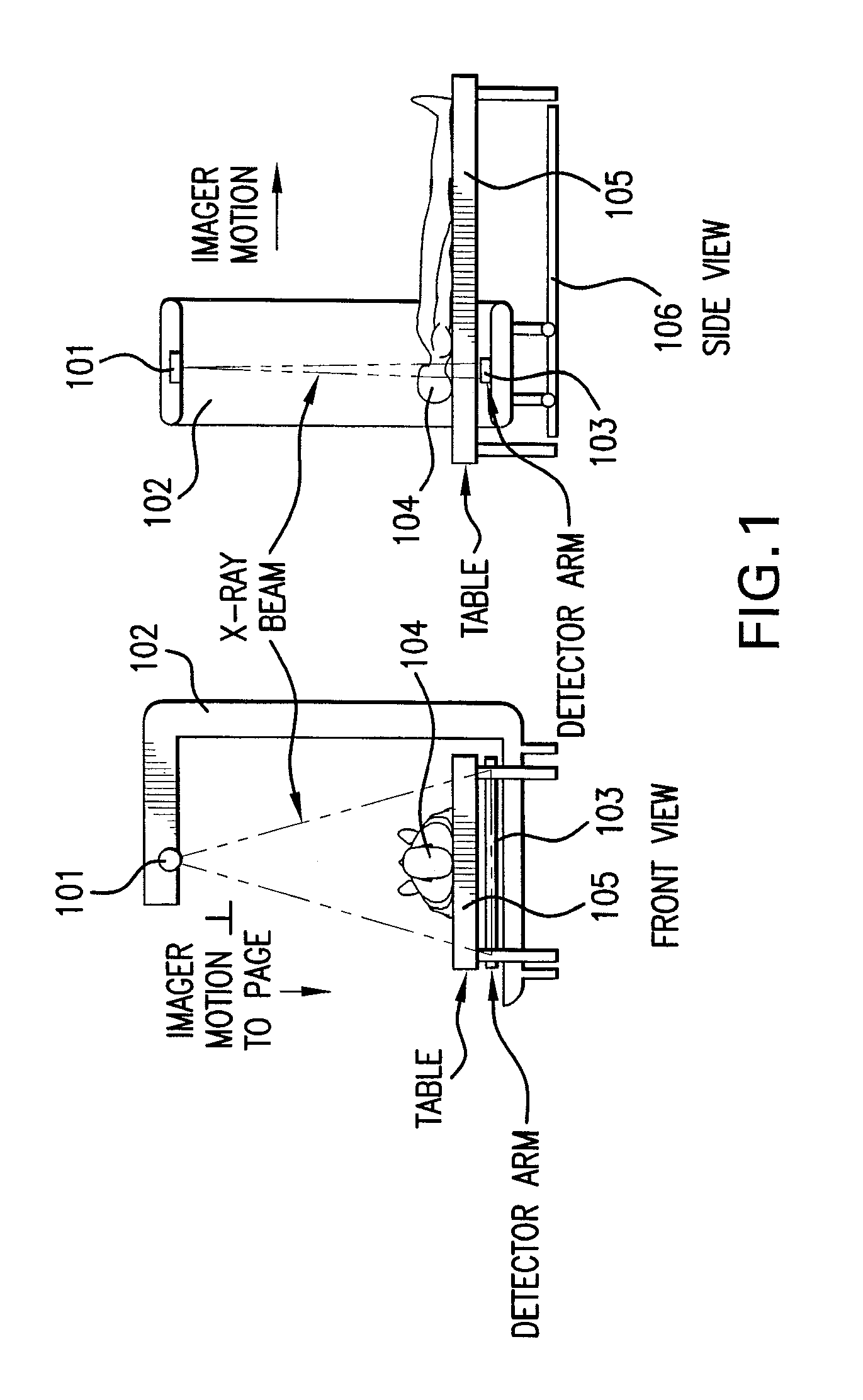

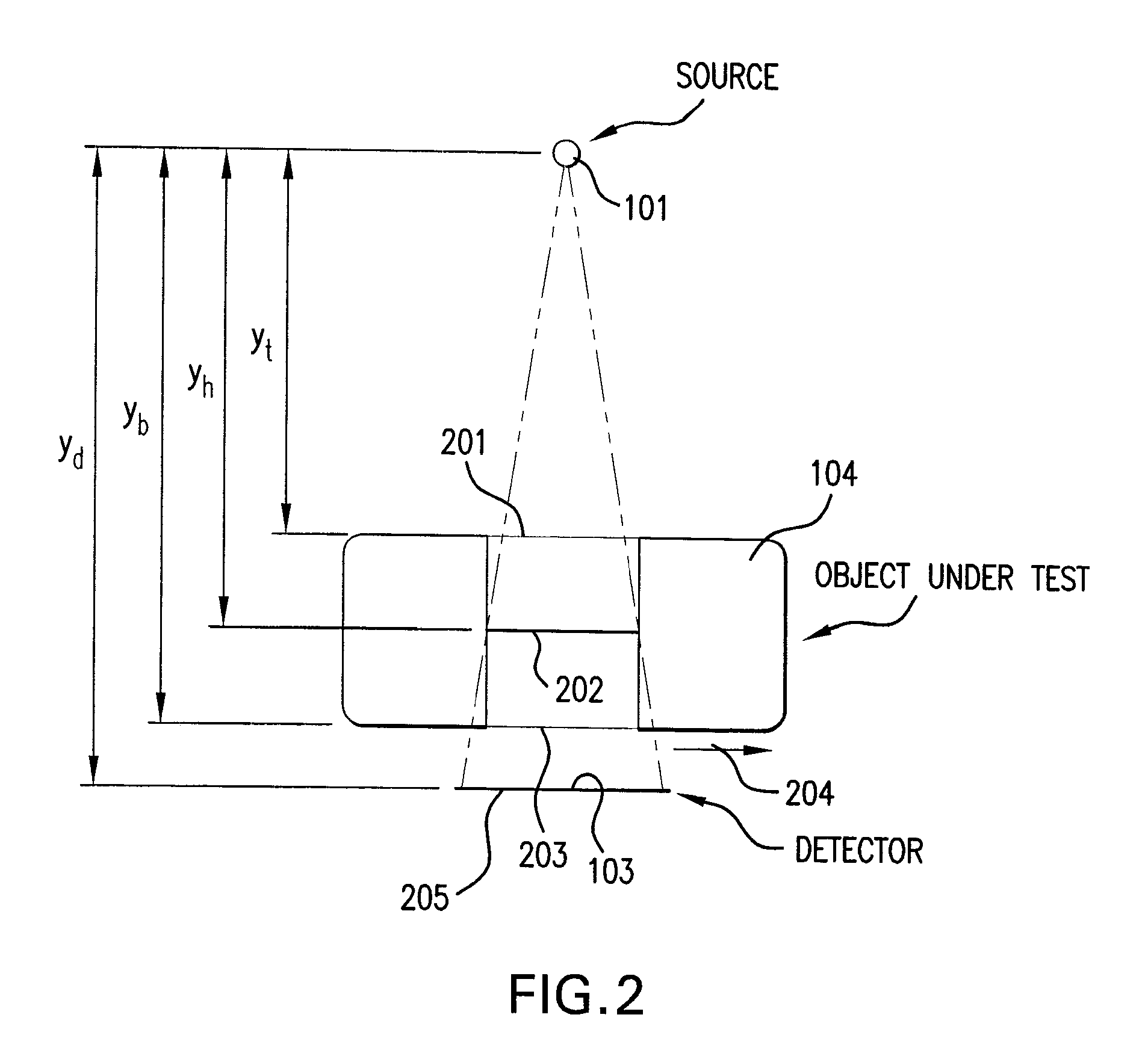

High resolution imaging system

ActiveUS7634061B1Reduce doseIncrease contrastSolid-state devicesMaterial analysis by optical meansLow noiseHigh resolution imaging

New sensors, pixel detectors and different embodiments of multi-channel integrated circuit are disclosed. The new high energy and spatial resolution sensors use solid state detectors. Each channel or pixel of the readout chip employs low noise preamplifier at its input followed by other circuitry. The different embodiments of the sensors, detectors and the integrated circuit are designed to produce high energy and / or spatial resolution two-dimensional and three-dimensional imaging for different applications. Some of these applications may require fast data acquisition, some others may need ultra high energy resolution, and a separate portion may require very high contrast. The embodiments described herein addresses these issues and also other issues that may be useful in two and three dimensional medical and industrial imaging. The applications of the new sensors, detectors and integrated circuits addresses a broad range of applications such as medical and industrial imaging, NDE and NDI, security, baggage scanning, astrophysics, nuclear physics and medicine.

Owner:NOVA R&D

High Resolution Imaging System

InactiveUS20100116999A1Reduce doseIncrease contrastPrinted circuit assemblingSolid-state devicesLow noiseHigh resolution imaging

New sensors, pixel detectors and different embodiments of multi-channel integrated circuit are disclosed. The new high energy and spatial resolution sensors use solid state detectors. Each channel or pixel of the readout chip employs low noise preamplifier at its input followed by other circuitry. The different embodiments of the sensors, detectors and the integrated circuit are designed to produce high energy and / or spatial resolution two-dimensional and three-dimensional imaging for different applications. Some of these applications may require fast data acquisition, some others may need ultra high energy resolution, and a separate portion may require very high contrast. The embodiments described herein addresses these issues and also other issues that may be useful in two and three dimensional medical and industrial imaging. The applications of the new sensors, detectors and integrated circuits addresses a broad range of applications such as medical and industrial imaging, NDE and NDI, security, baggage scanning, astrophysics, nuclear physics and medicine.

Owner:NOVA R&D

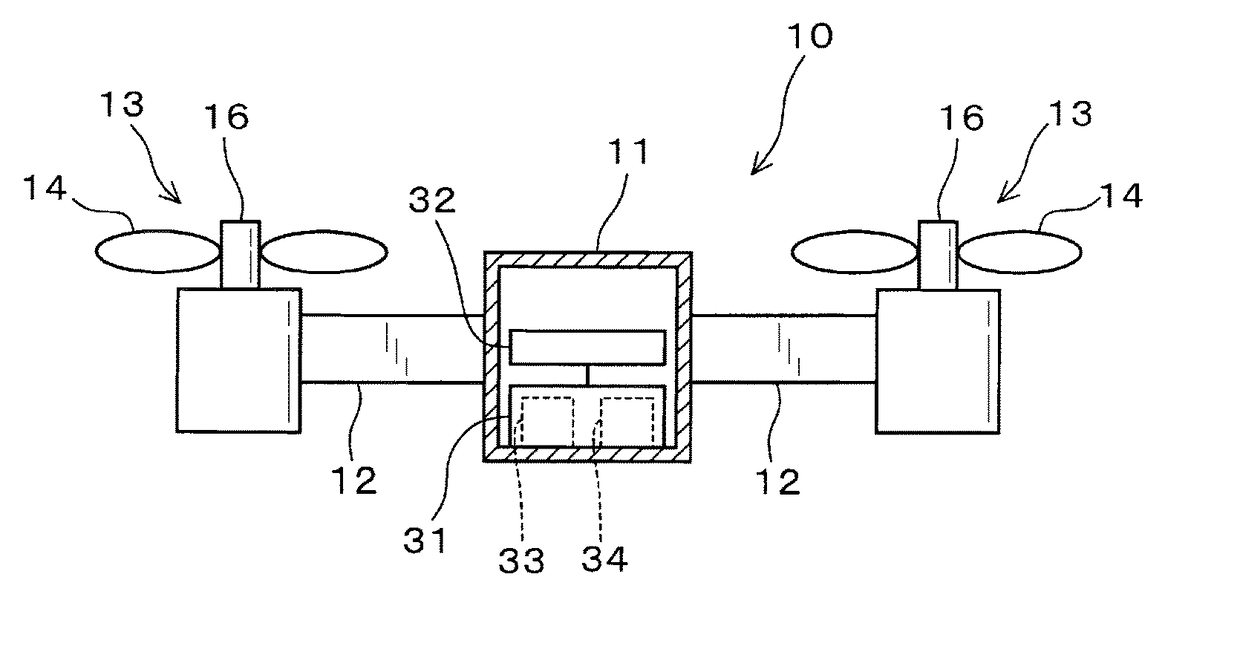

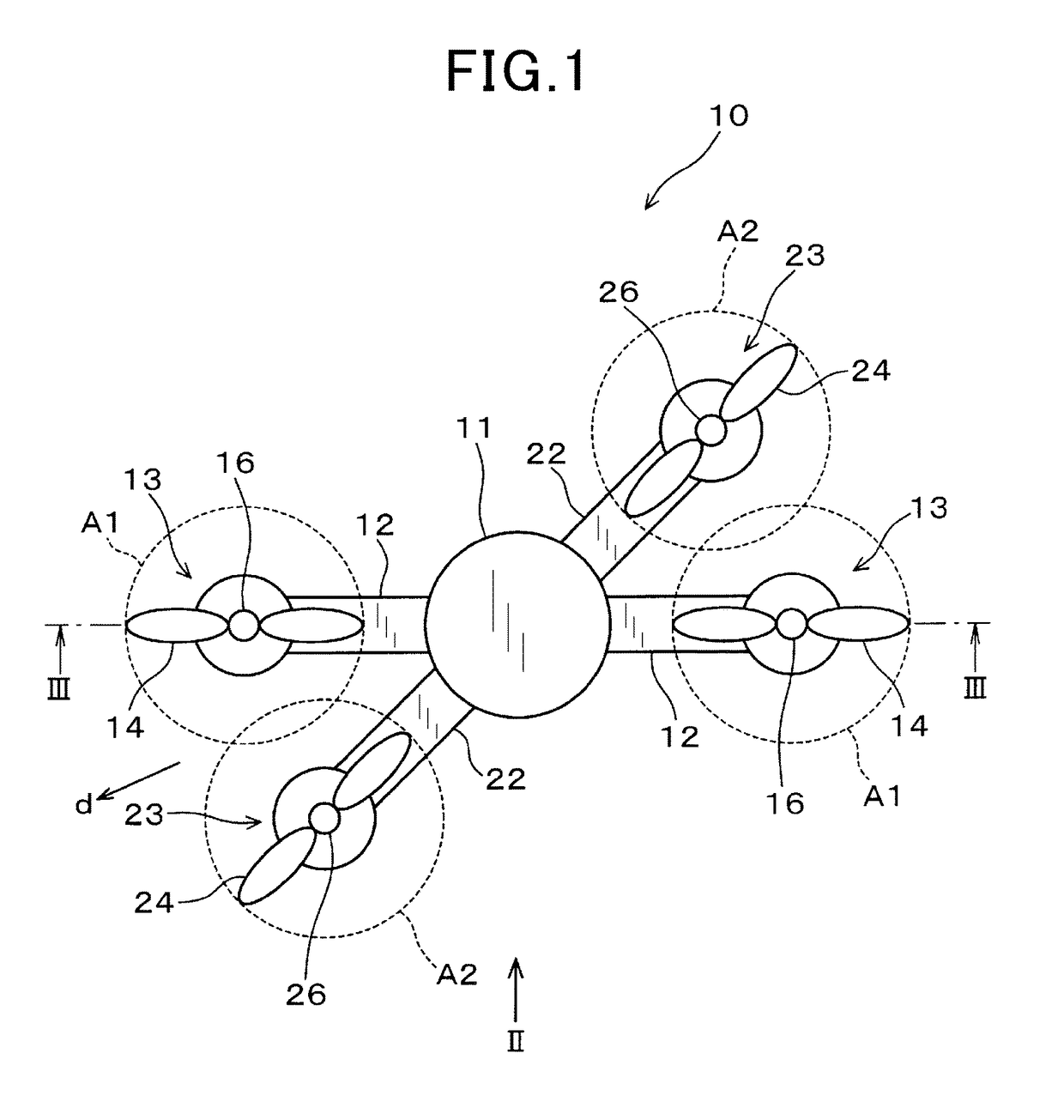

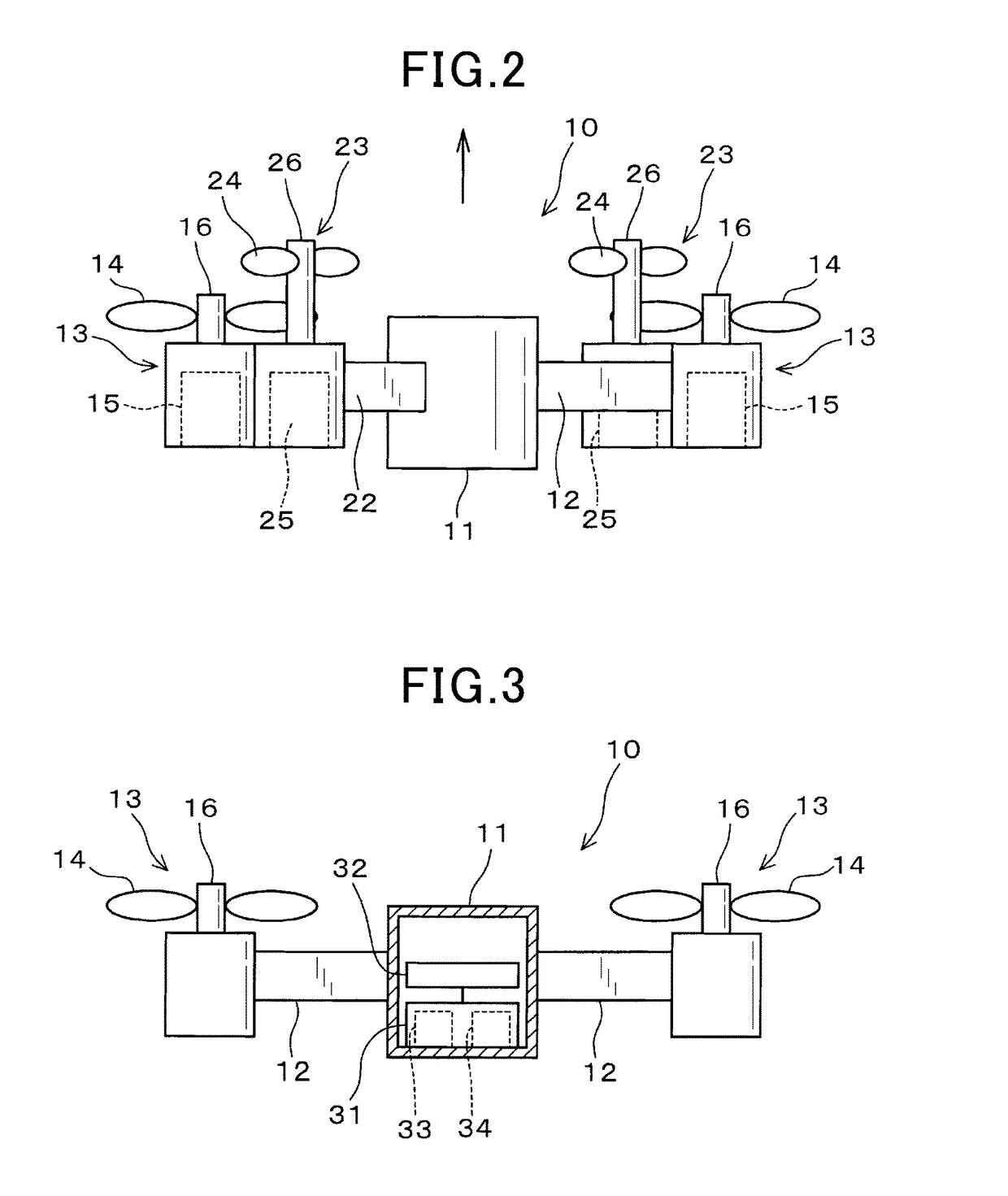

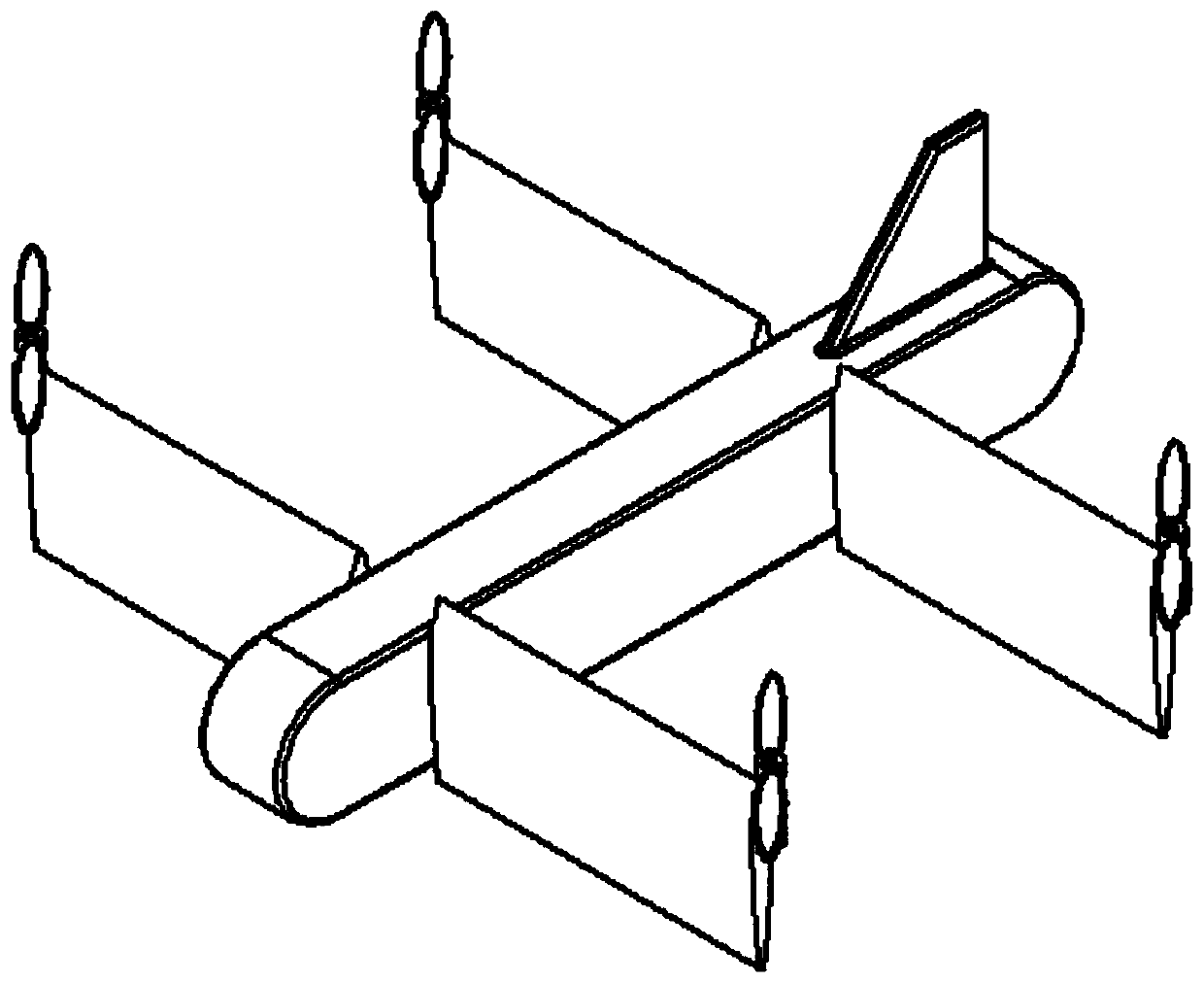

Aerial vehicle

InactiveUS20170174336A1Projection area decreaseDecrease spacingUnmanned aerial vehiclesRemote controlled aircraftFlight vehiclePropeller

An aerial vehicle is provided which includes first thrusters with first propellers and second thrusters with second propellers. Each of the first propellers has a first rotating region in which blades thereof rotate. Similarly, each of the second propellers has a second rotating region in which blades thereof rotate. Each of the first rotating regions is located to overlap one of the second rotating regions, as viewed in a direction of a yaw axis of the aerial vehicle. The first rotating regions are located away from the second rotating regions in the direction of the yaw axis. Such layout of the first and second propellers eliminates physical interference therebetween. The overlap between the first and second propellers results in a decreased cross-sectional area of projection of the aerial vehicle from the front view in a flight direction thereof.

Owner:NIPPON SOKEN +1

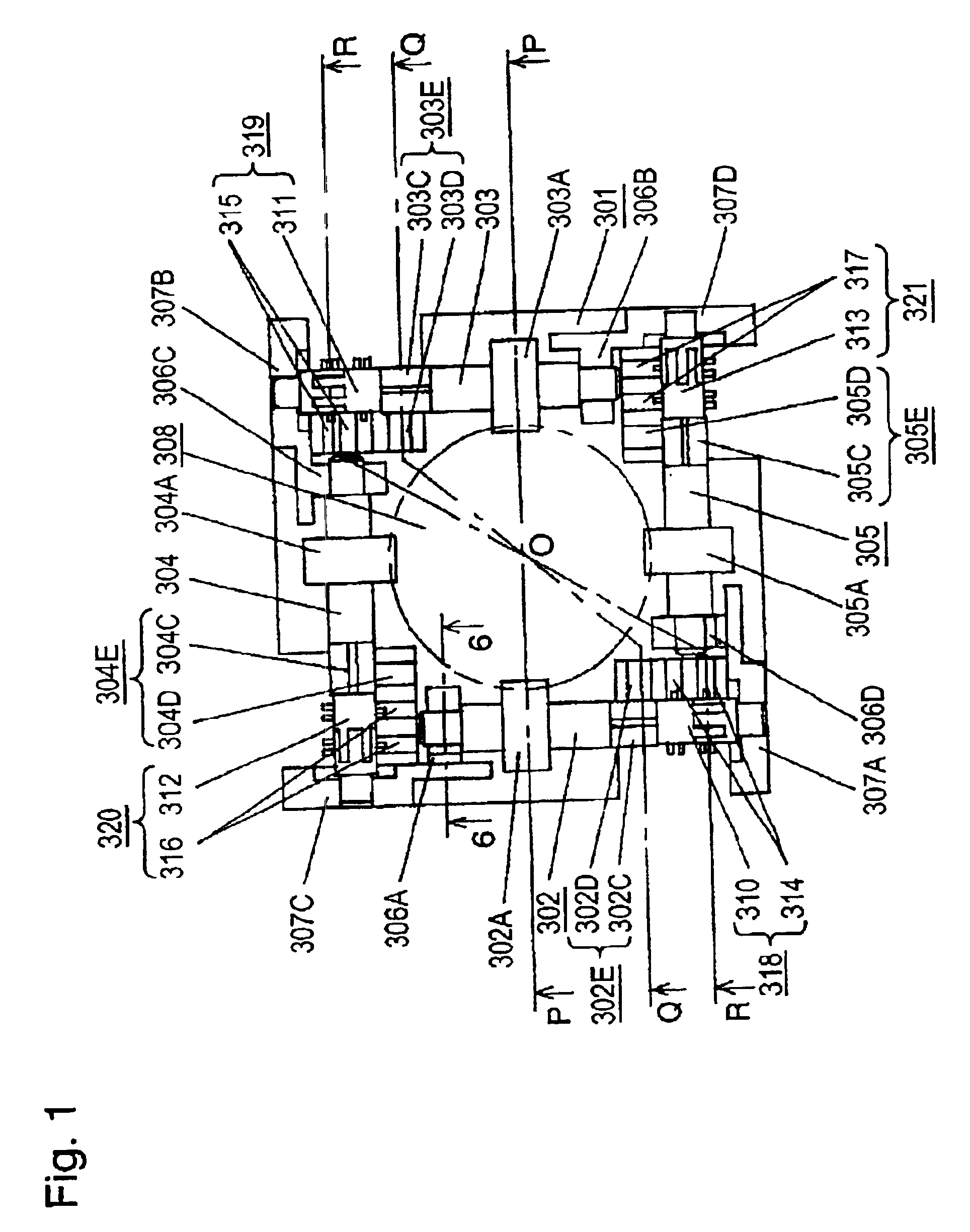

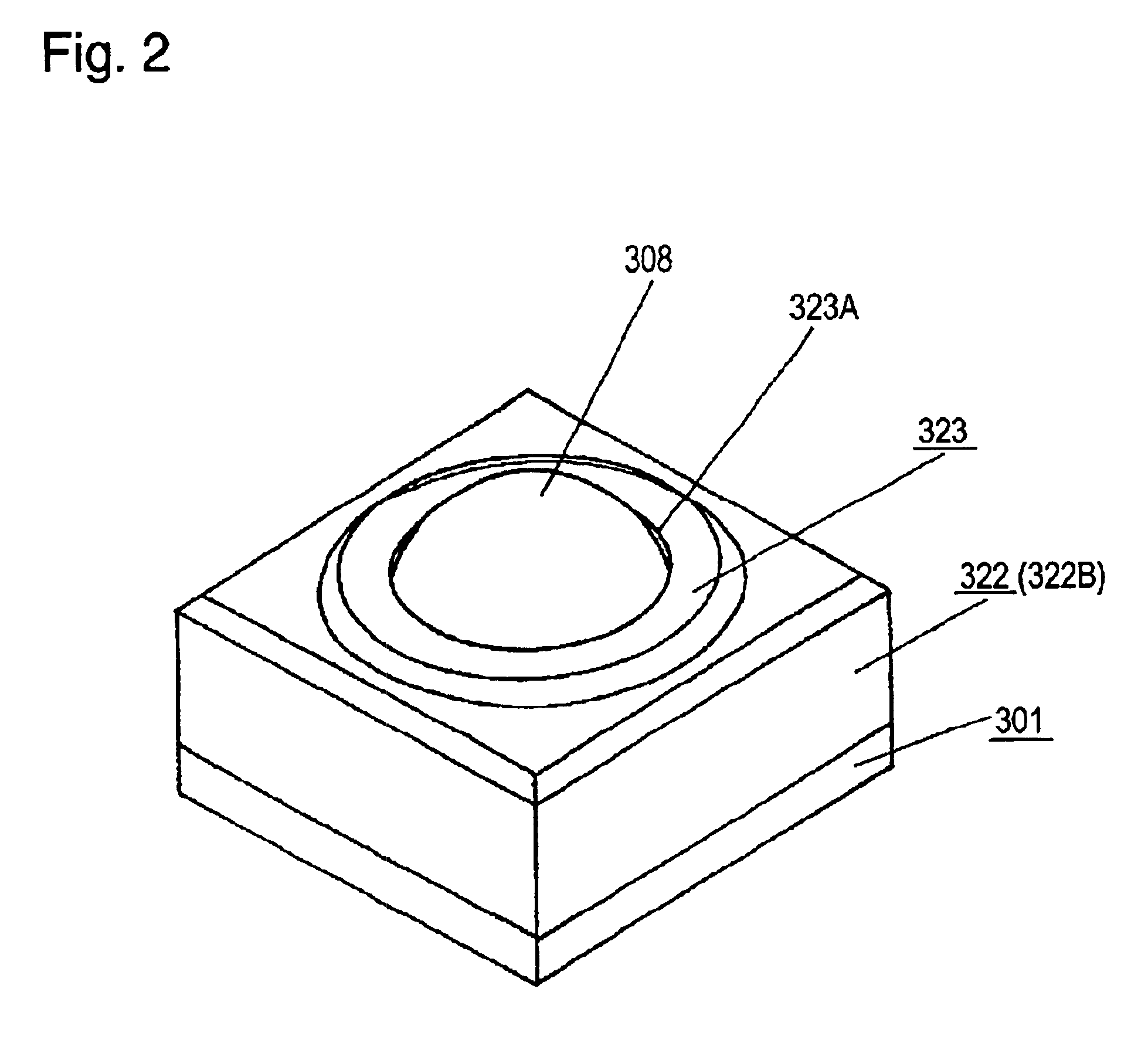

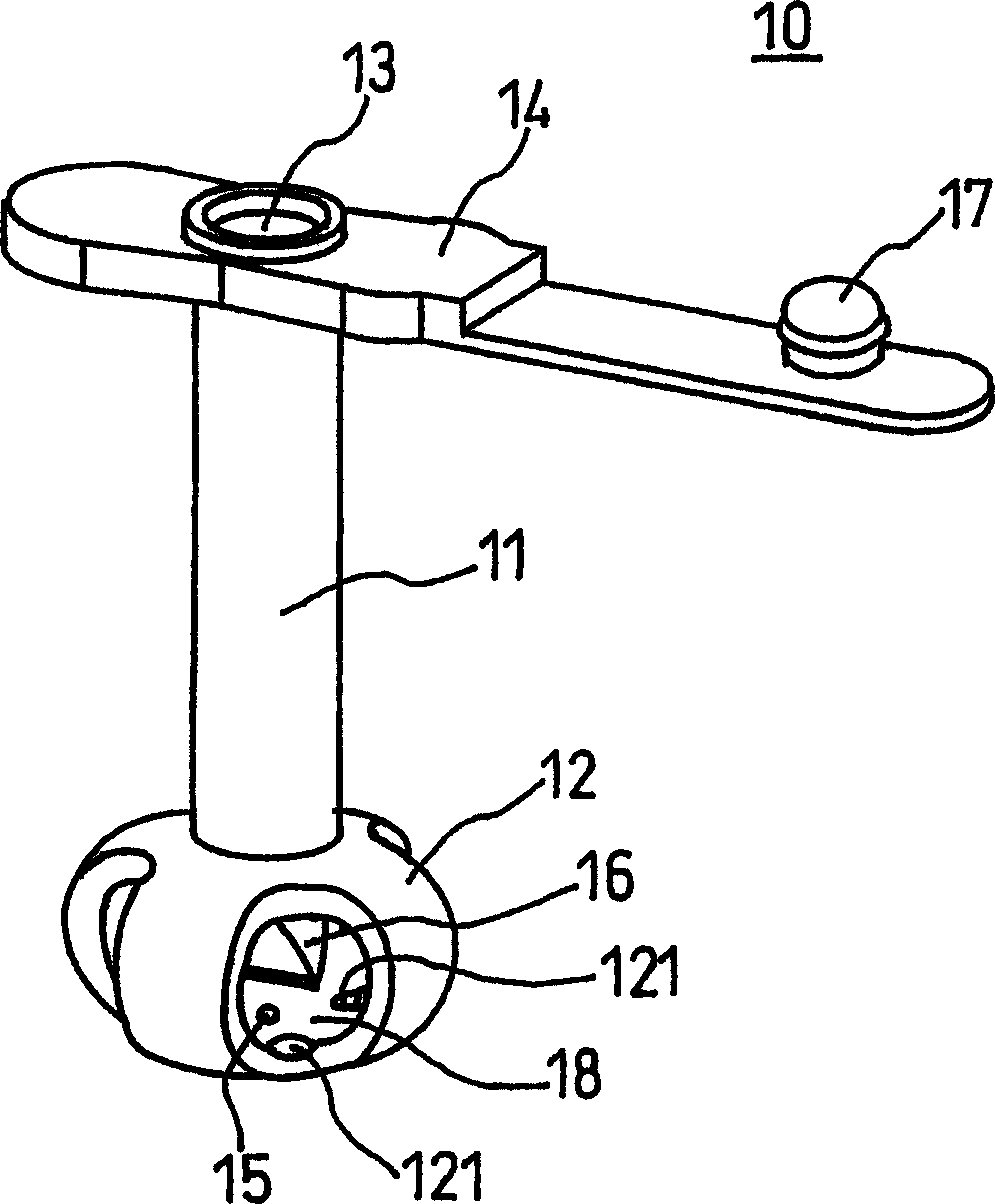

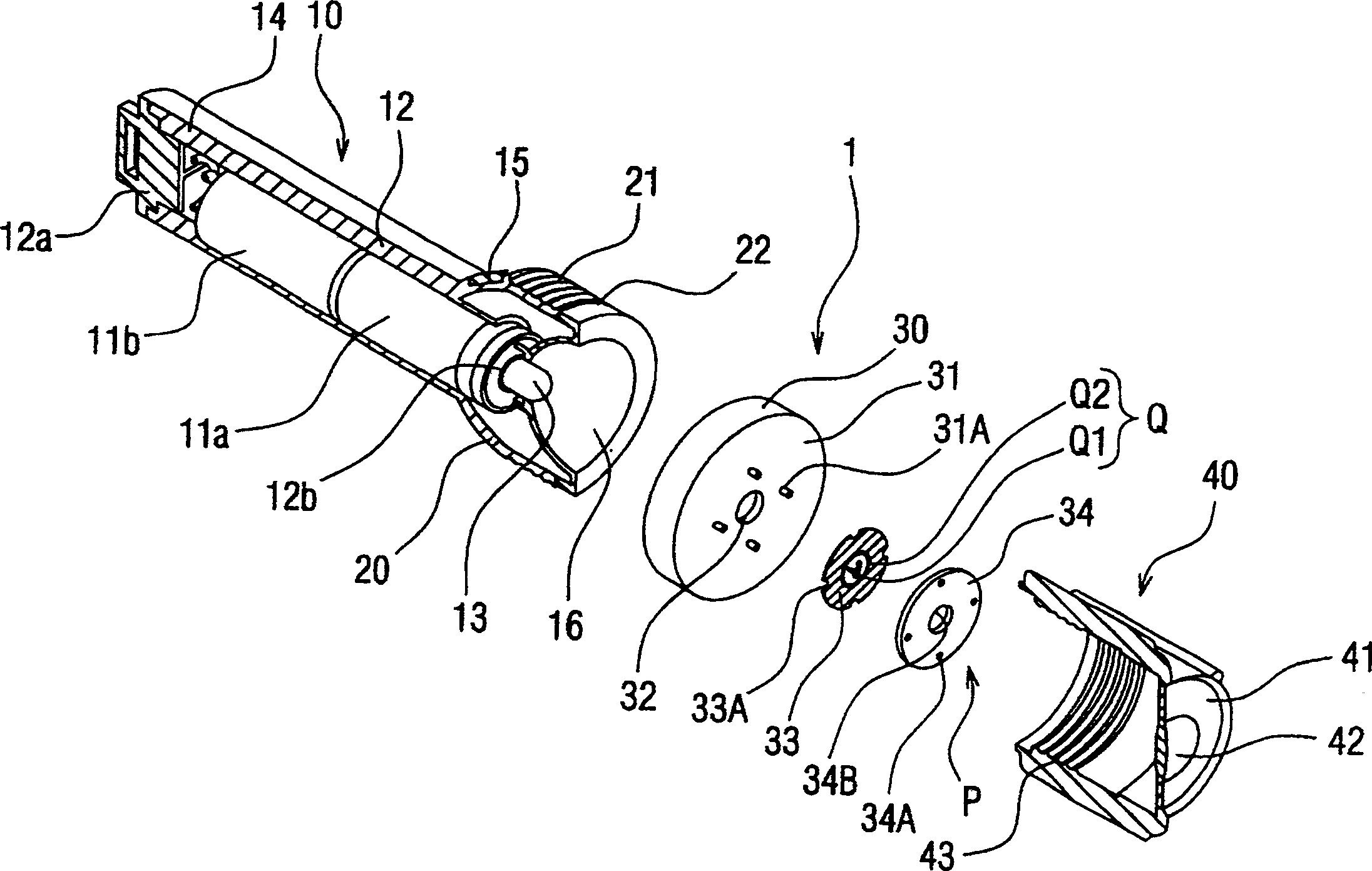

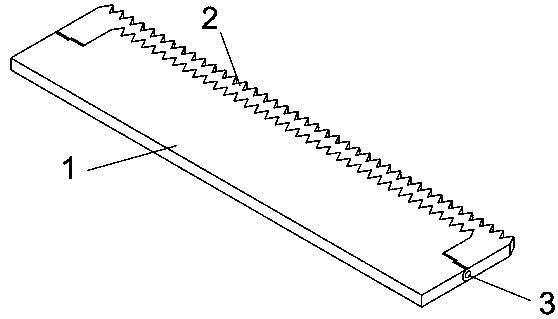

Track ball device and electronic apparatus using the same

InactiveUS6909422B2Reduce projected areaGuaranteed uptimeCathode-ray tube indicatorsInput/output processes for data processingMechanical engineeringSerration

Relating to a track ball device for manipulating a cursor moving on a display screen of an electronic apparatus, a track ball device being manipulated precisely while generating a click feel when a ball is rotated, having a small play angle and small size is presented. Beneath the center of the ball, the ball is rotatably supported by four rollers. The section of a contacting portion of the rollers contacting with the ball is a circular sawtooth profile, and the directions of the sawtooth serrations of opposite rollers are reverse to each other. Rollers 2 to 5 have switches as rotation amount detecting units. Further, X roller and Y roller contacting with the outer circumference in the orthogonal direction as seen from above the ball, and third roller hold the ball rotatably. Plural undulations are formed on the outer circumference of large-diameter contacting portions of the X roller and Y roller 3 of circular shaft shape. Rotary encoders are coupled to individual rollers.

Owner:PANASONIC CORP

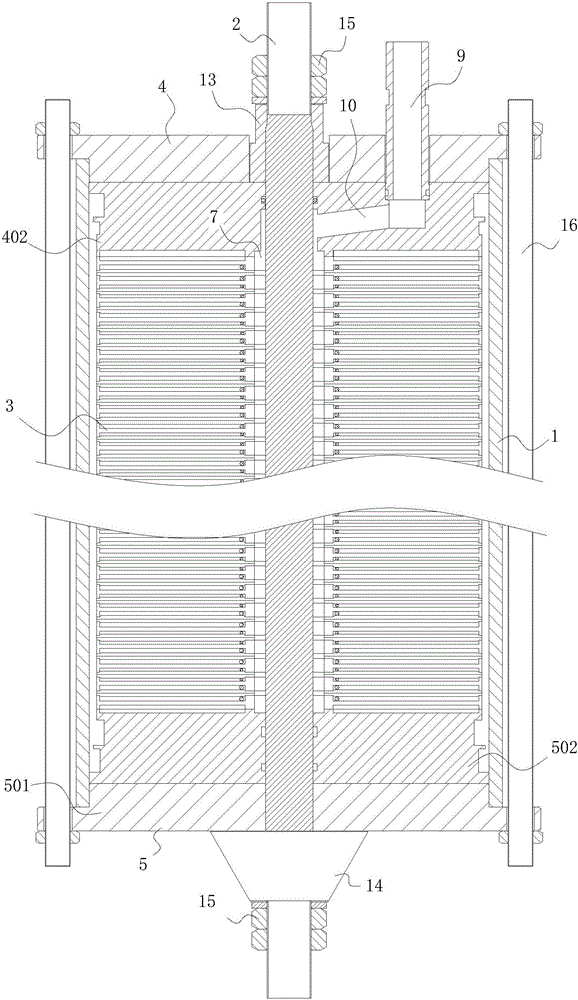

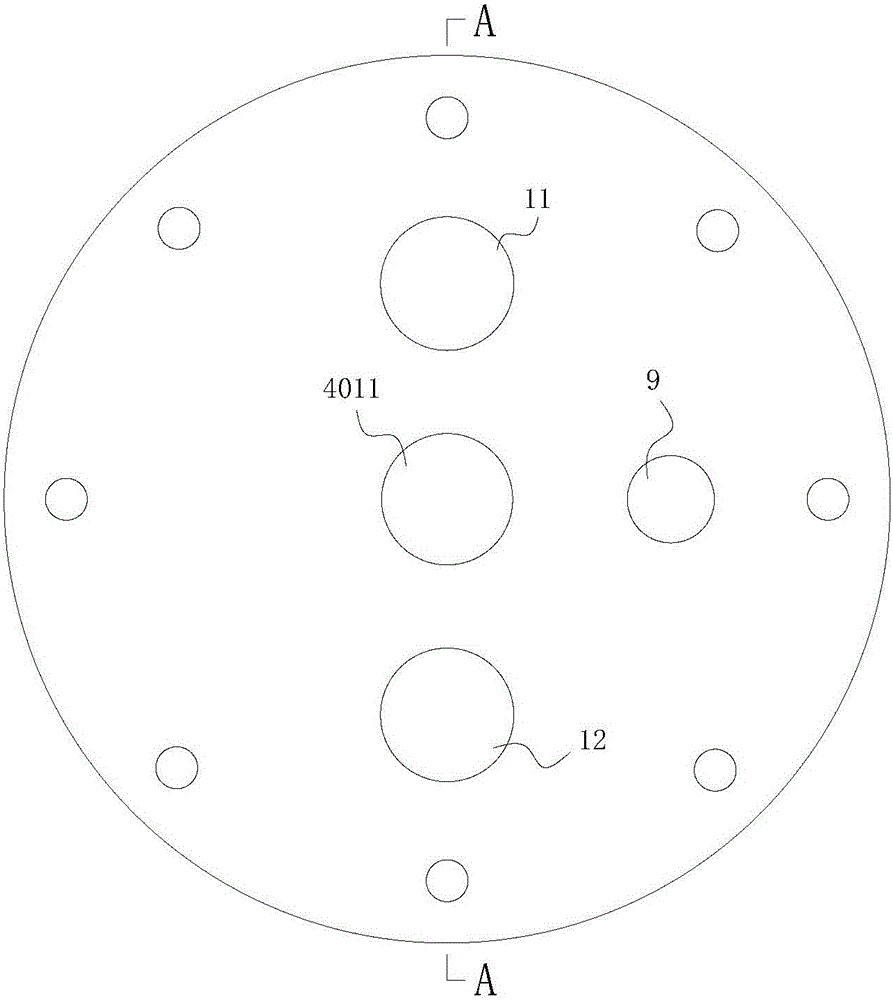

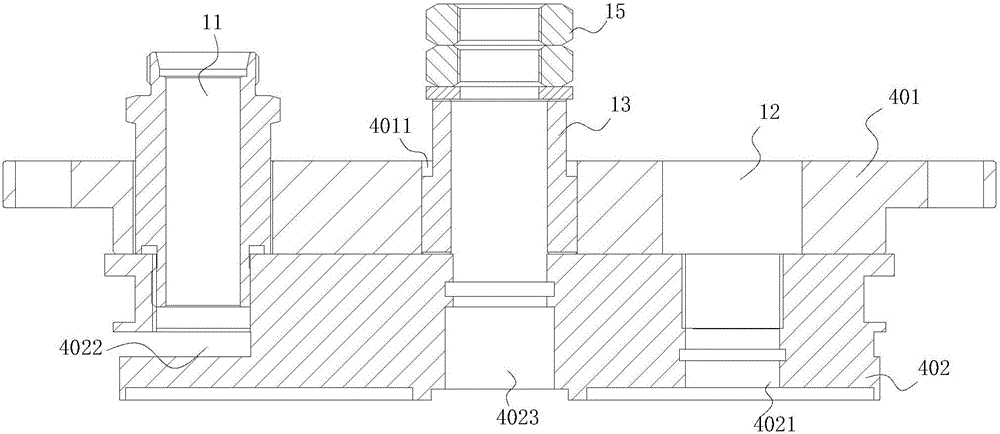

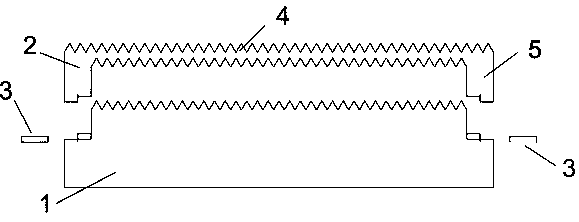

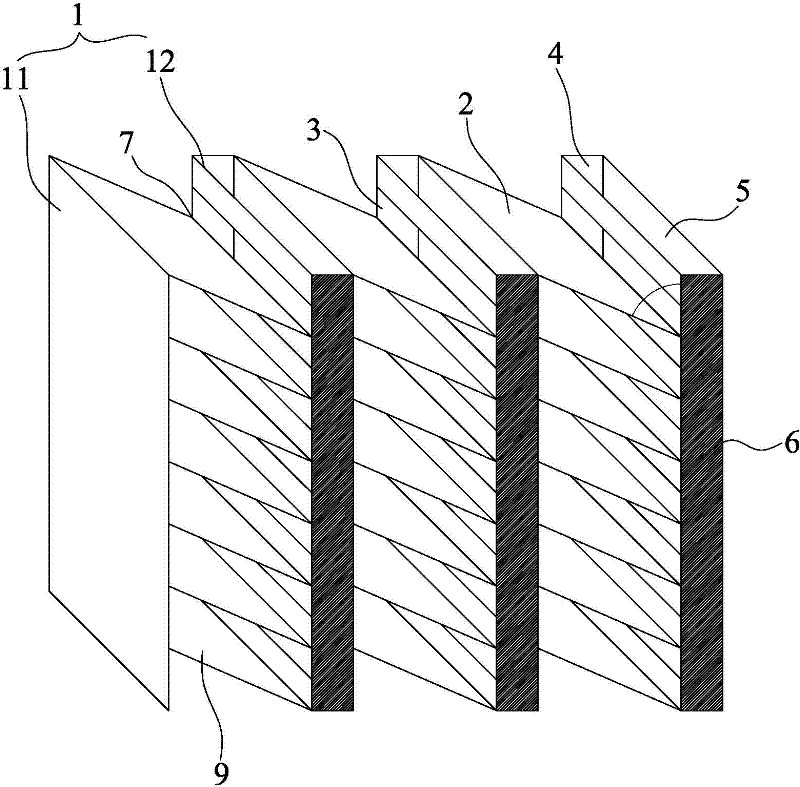

Membrane filtration assembly

InactiveCN105771666AReduce filtration efficiencyImprove filtration efficiencyMembranesReverse osmosisNanofiltrationMembrane configuration

The invention relates to a membrane filtration assembly, in particular to a nanofiltration or reverse osmosis membrance filtering assembly in the water treatment field. The invention discloses the membrane filtration assembly high in filtering efficiency in order to overcome the defect that an existing membrane filtration assembly is low in filtering efficiency. The assembly comprises a shell, a mandrel, a filtering structure, an upper cover assembly and a lower cover assembly. The upper cover assembly is arranged at the upper end of the mandrel, the lower cover assembly is disposed at the lower end of the mandrel, the mandrel is sleeved with the filtering structure, the filtering structure is axially pressed between the upper cover assembly and the lower cover assembly through a fastening structure, and the shell is arranged outside the filtering structure and connected with the upper cover assembly and the lower cover assembly. The filtering stricture comprises a plurality of flow guide discs and membranes, the flow guide discs and the membranes are sequentially sleeved with the mandrel in the axial direction of the mandrel. Each membrane is installed between every two adjacent flow guide discs. By selecting and combining some key parameters of the membranes through the membrane filtering assembly, filtering efficiency of the membrane filtering assembly can be higher, and the filtering rejection rate is unexpectedly good.

Owner:CHENGDU MEIFUTE MEMBRANE TECHNOLOGY CO LTD

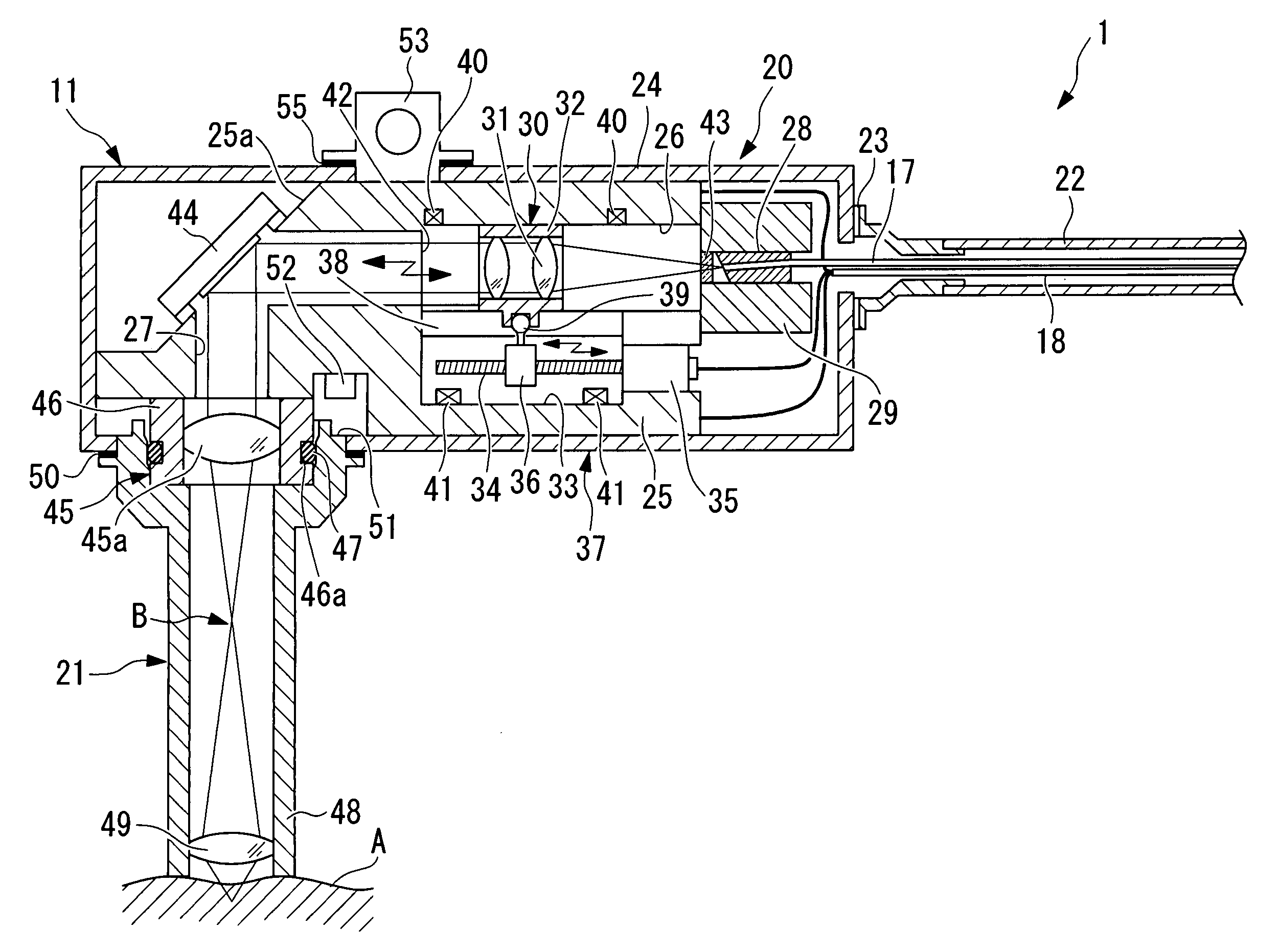

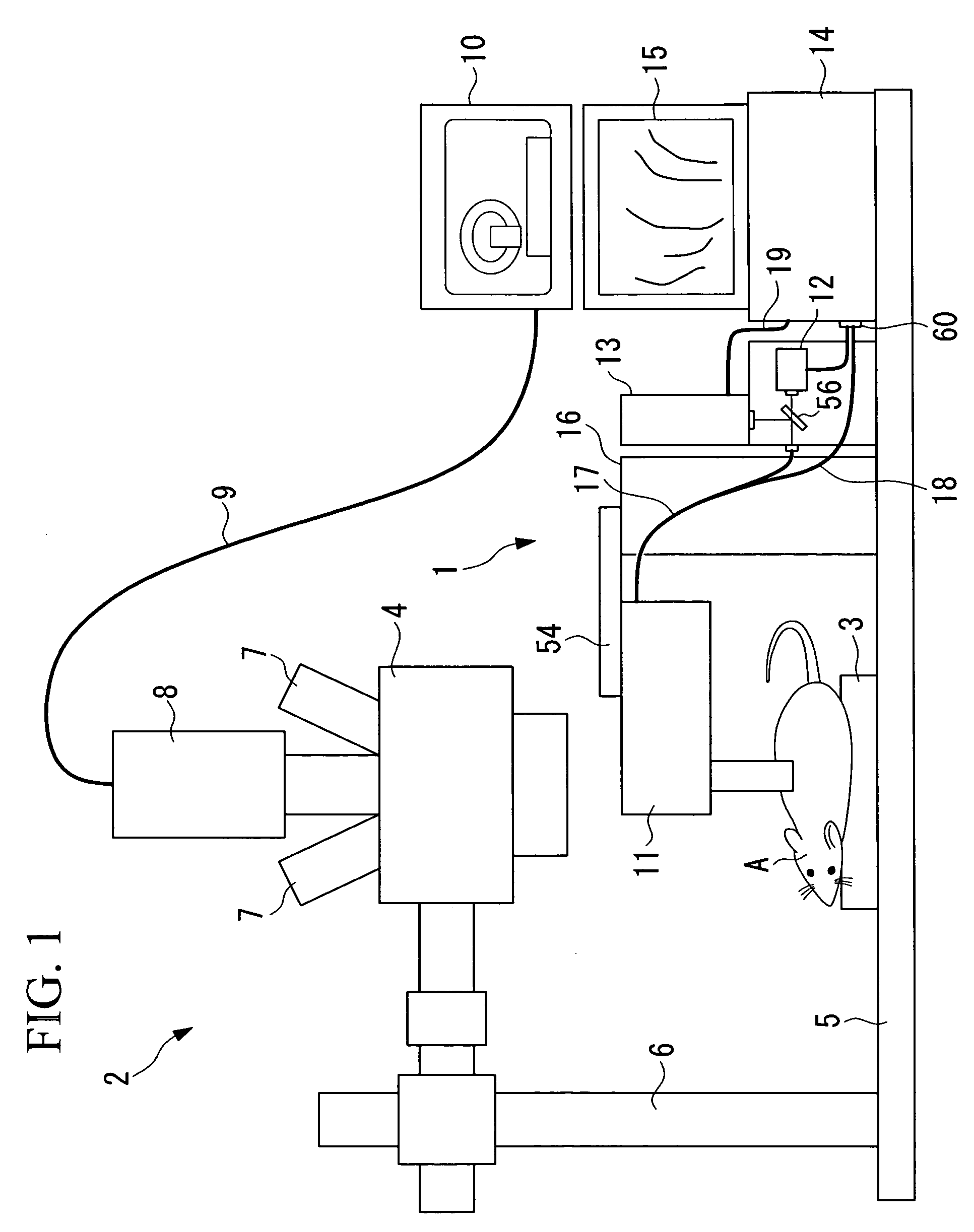

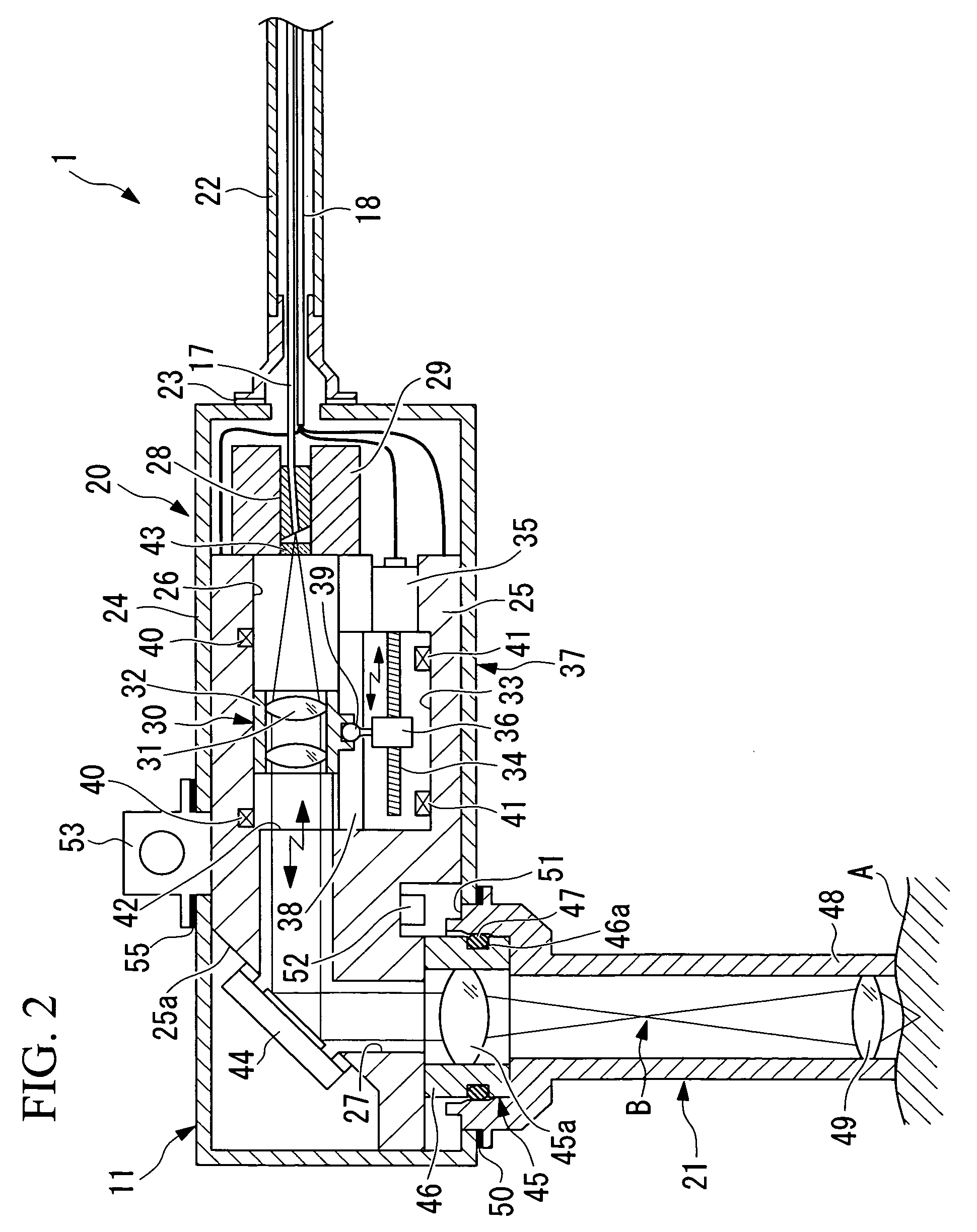

Optical-Scanning Microscope Examination Apparatus

InactiveUS20080130103A1Interfering with observationReduce projected areaDiagnostics using lightSurgeryBeam scanningPupil

A clear image having suppressed blurring due to pulsing is obtained by in-vivo examination of biological tissue or various internal organs of mammals, including small laboratory animals. The invention provides an optical-scanning microscope examination apparatus including a light source; a light-transmitting member for transmitting light from the light source; a collimator optical system for converting the transmitted light to a collimated beam; a beam-scanning unit for scanning the collimated beam on a subject; a focusing optical system for focusing the scanned beam onto the subject; a pupil-projection optical system; a light detector for detecting return light returning from the subject via the focusing optical system, the pupil-projection optical system, the beam-scanning unit, the collimator optical system, and the light-transmitting member; an actuator for moving the collimator optical system in an optical-axis direction; a control apparatus for controlling driving thereof; and a deflecting mechanism for deflecting the light issuing from the light-transmitting member in a direction intersecting the optical axis thereof, wherein the actuator is disposed in a space parallel to a plane including optical axes before and after deflection by the deflecting mechanism.

Owner:OLYMPUS CORP

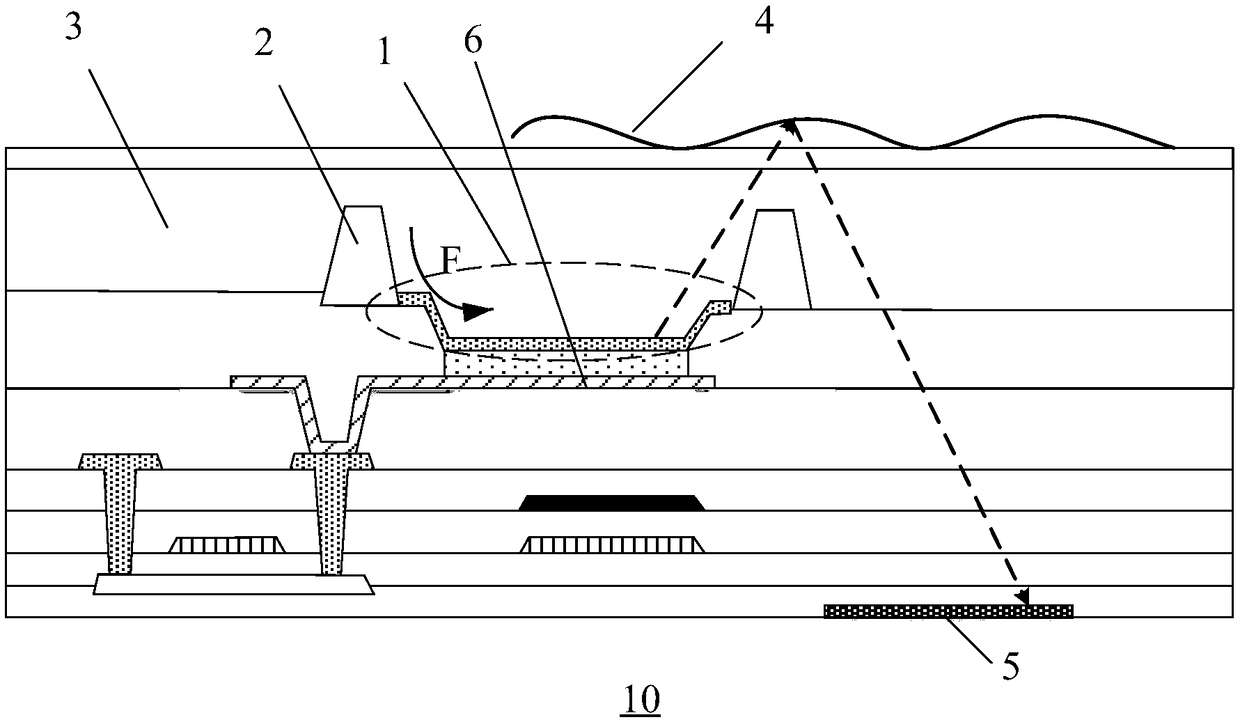

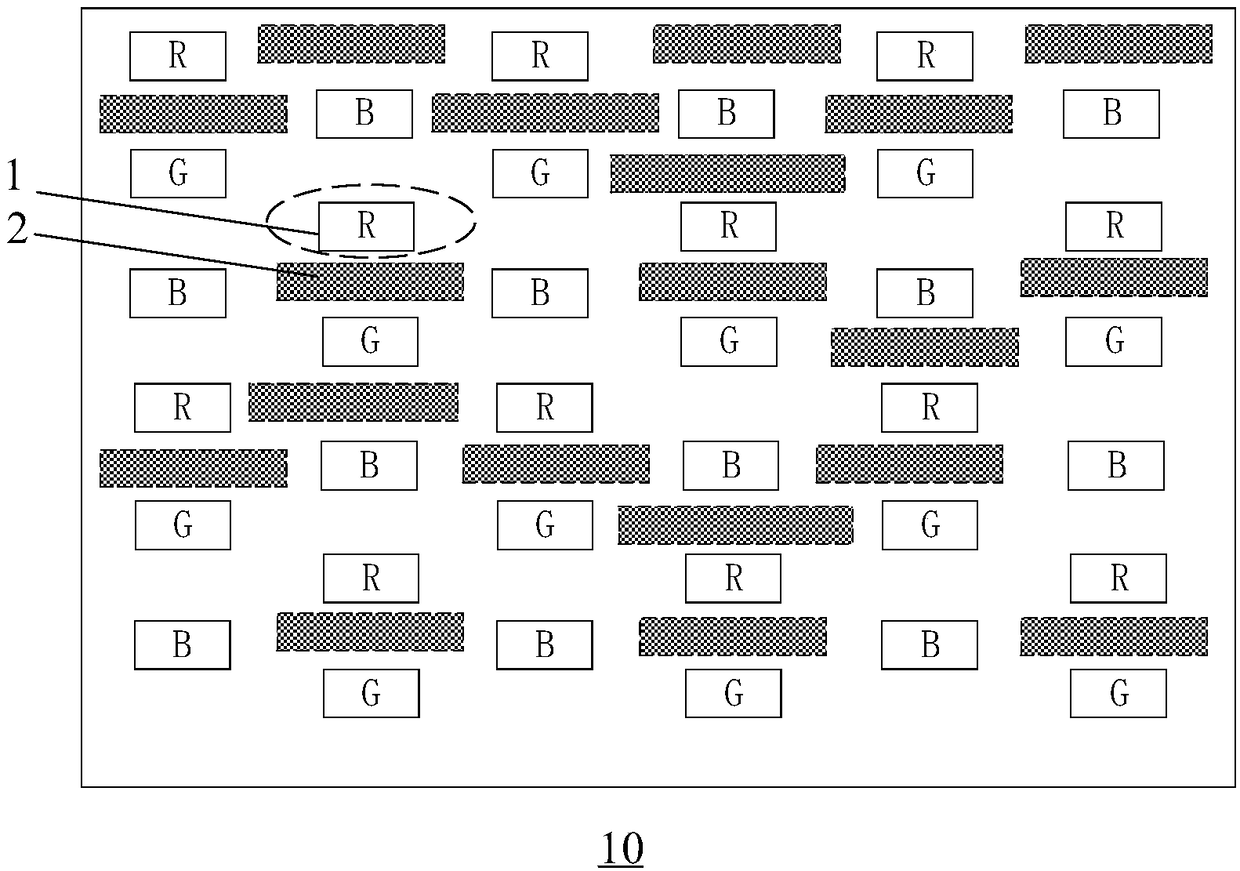

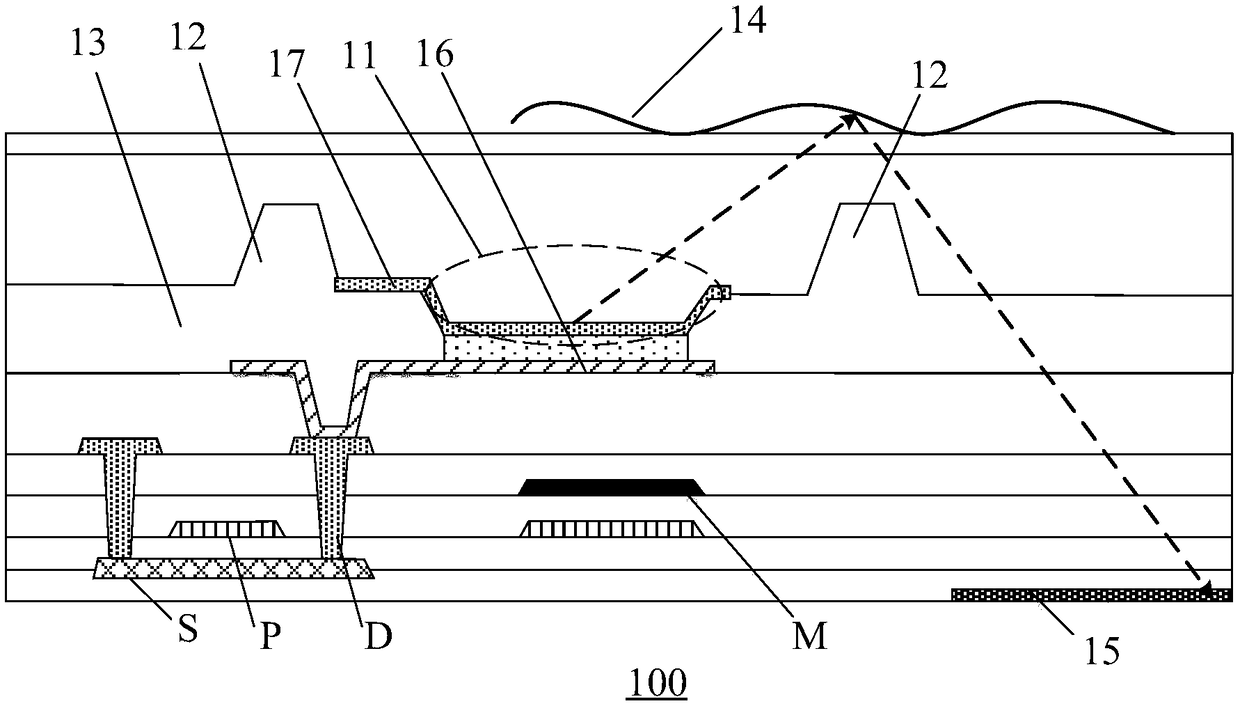

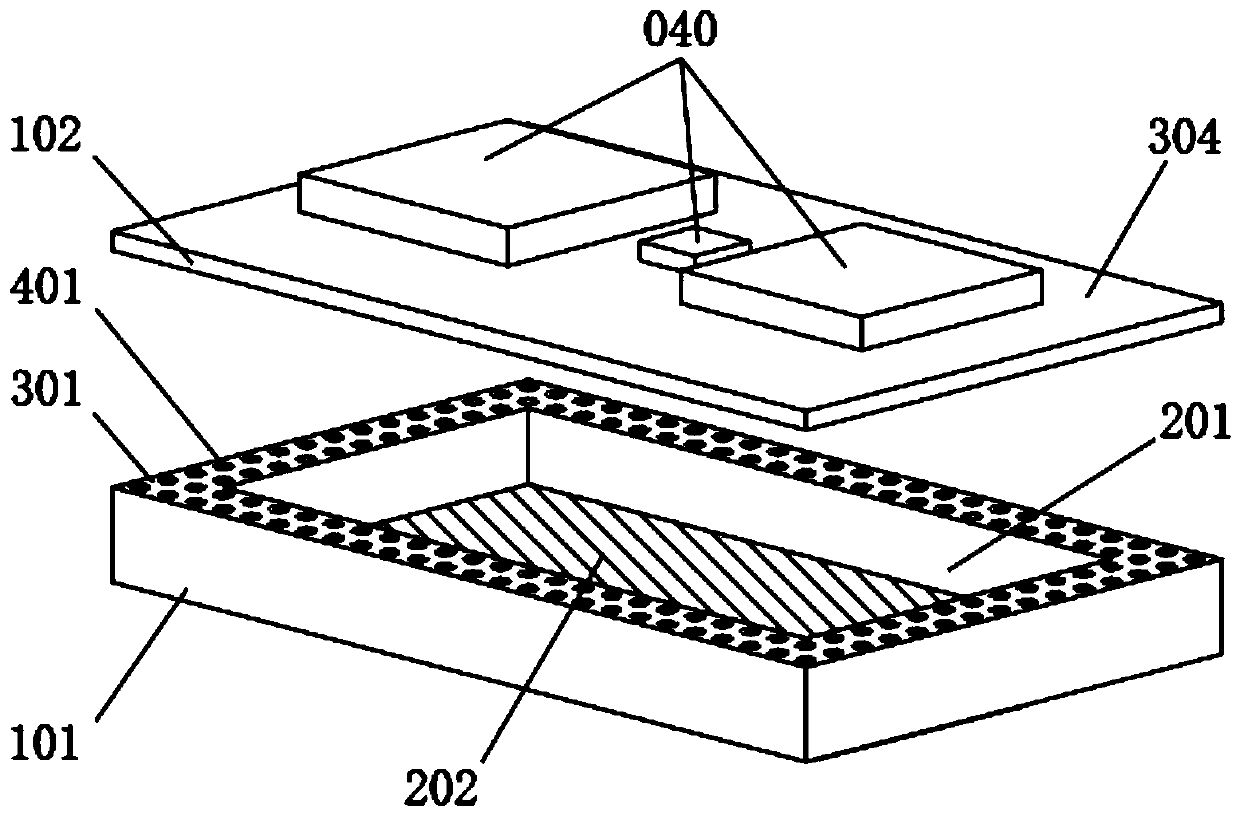

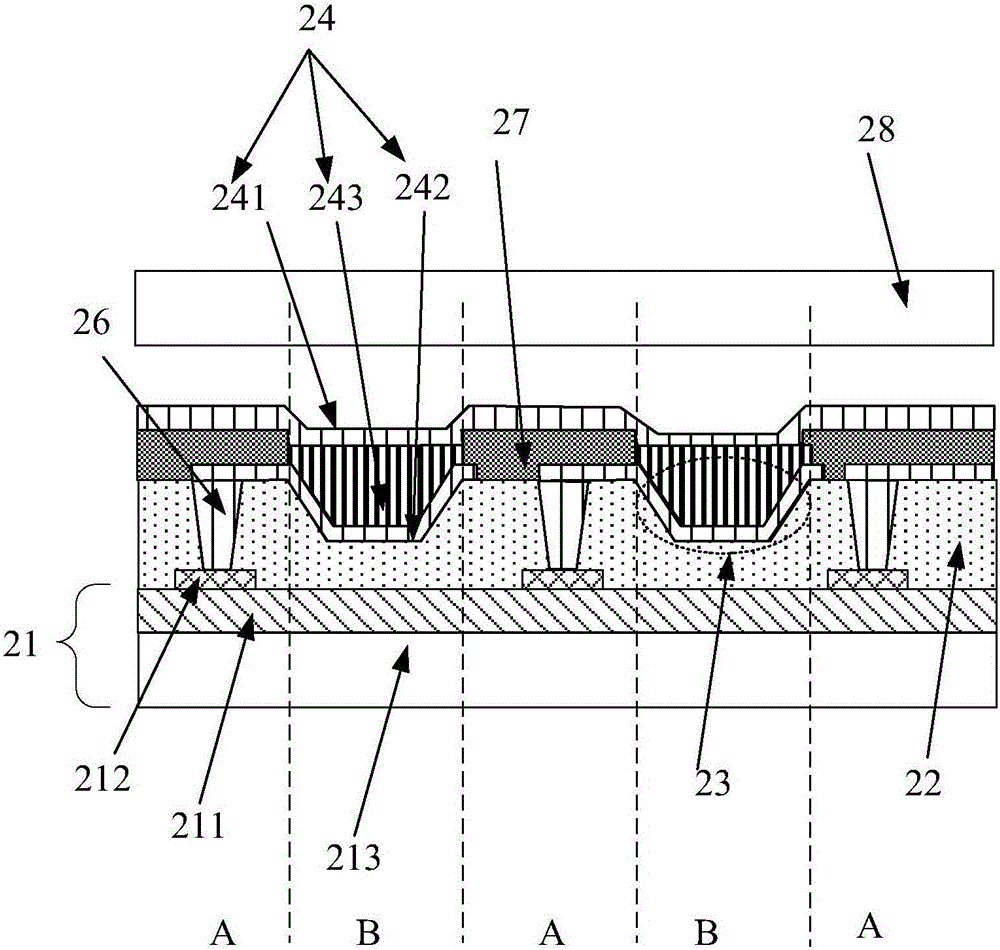

Display panel and display device

ActiveCN108598136AIncrease the effective light transmission areaReduce projected areaSolid-state devicesPrint image acquisitionLight sensingTransmittance

The embodiment of the invention provides an organic light emitting display panel and a display device. By means of distributed arrangement of supporting units in the display panel and the position adjustment of an opening area of a light emitting unit, on one hand, in the embodiment of the invention, an edge corner area of the supporting unit is close to the opening area of the light emitting unitas much as possible by reducing a relative side length of the supporting unit and the opening area of the light emitting unit, so that the distance between the supporting unit and the opening area ofthe light emitting unit is increased, as a result, the projection area of the supporting unit in the opening area of the light emitting unit is decreased, in this way, when the supporting unit generates deformation and even collapse due to an external pressure, the damage to the opening area of the light emitting unit is reduced. On the other hand, in the embodiment of the invention, by means ofthe distributed arrangement of the supporting units and the position adjustment, the supporting units are arranged in a non-transparent area as much as possible, thus increasing an effective light transmission area on the display panel, and in this way, the overall light transmittance is greatly improved, and the sensitivity of light sensing fingerprint recognition is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

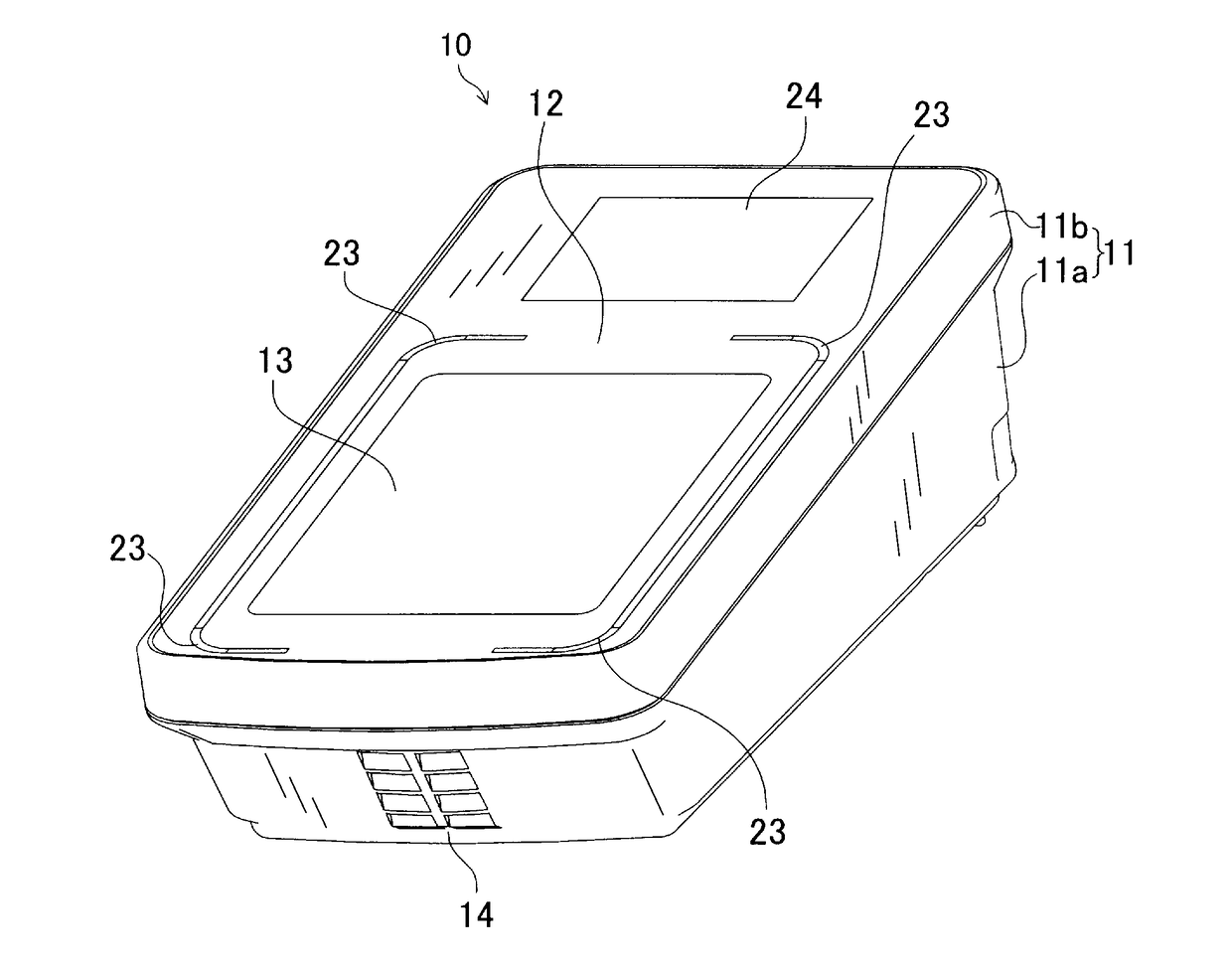

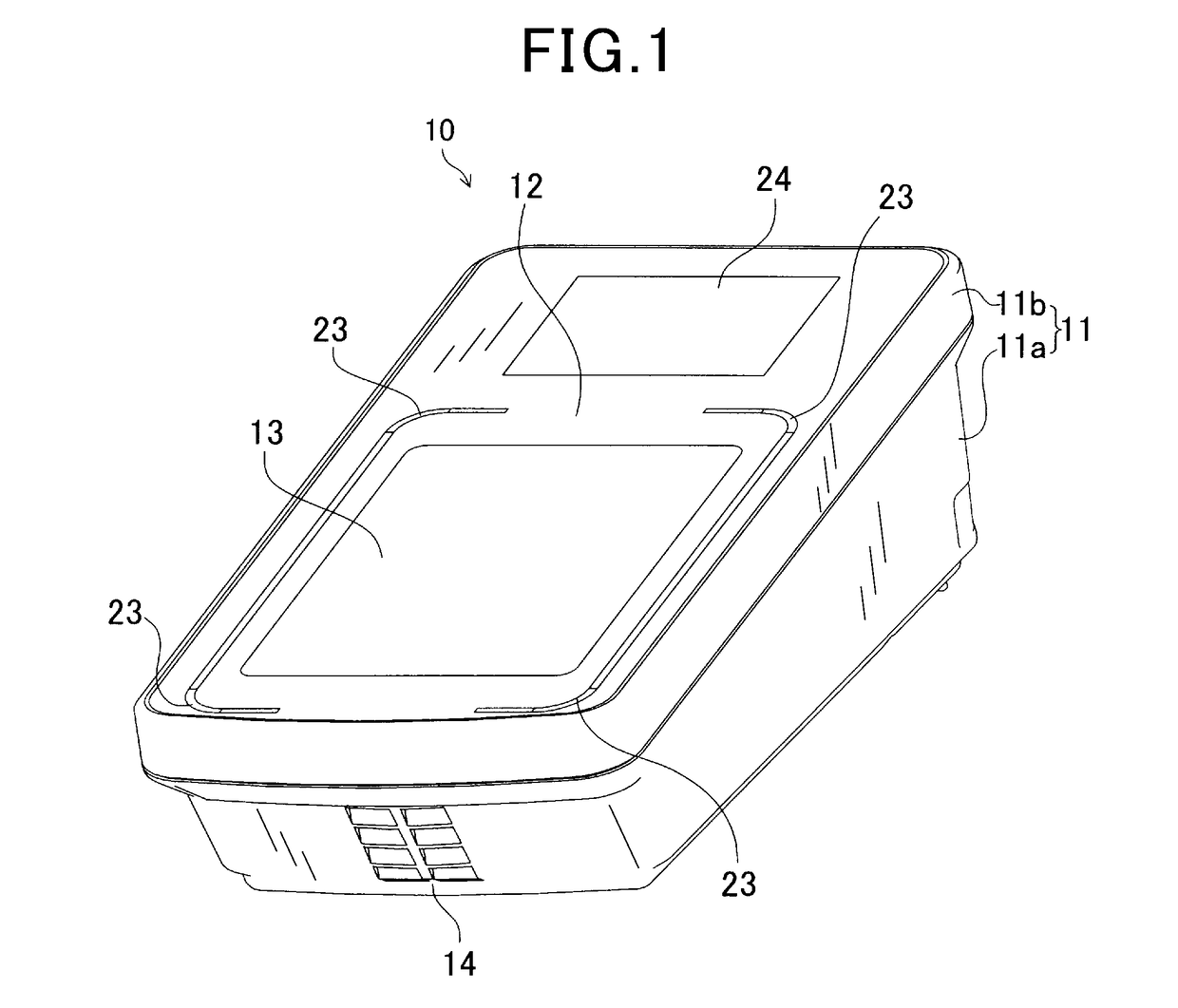

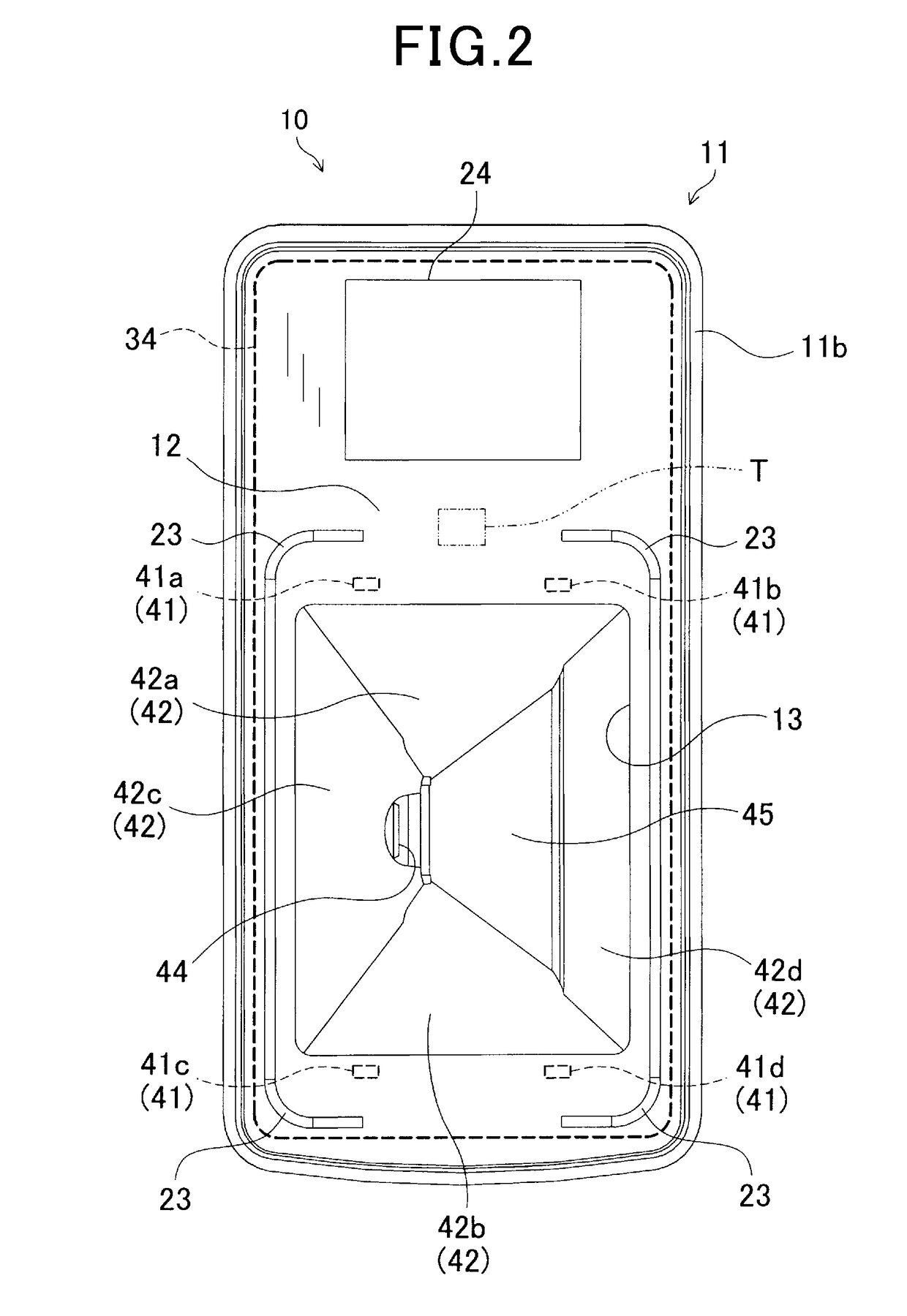

Information Reading Apparatus

ActiveUS20170278361A1Easy to collectImprove emission efficiencyMemory record carrier reading problemsCash registersDisplay deviceCommunications media

An information reading apparatus is provided. The information reading apparatus enables stable contactless communication with a contactless communication medium even when the apparatus includes a display device for displaying information associated with reading results, in addition to an information reading device and a contactless communication device. The information stored in the contactless communication medium held over a reading surface is read by the contactless communication device according to transmission / reception of electromagnetic waves via an antenna. The reading surface includes a reading port on the inside of the antenna in plan view of the reading surface, and includes a mark arranged not to overlap the antenna.

Owner:DENSO WAVE INC

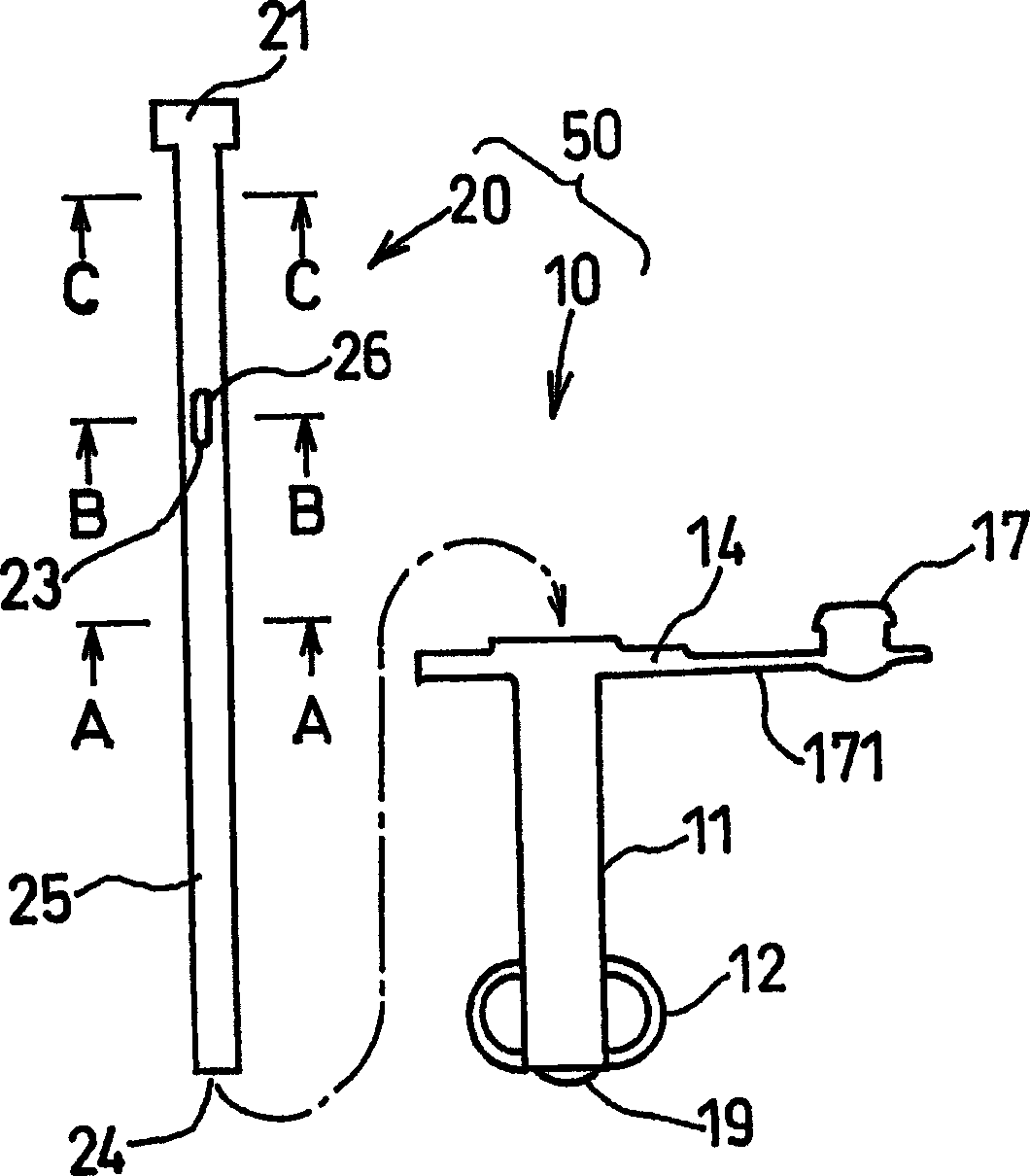

Catheter kit for burrow

Disclosed is a catheter tool for fistula with excellent operability including a catheter and a sealing device. The catheter has a flexible tube and an indwelling part in the body. The flexible tube extends along the wall of the fistula hole. A nutrition passage is provided inside the fistula hole to introduce nutrition or medicinal liquid into the stomach. The indwelling part in the body is attached to the soft tube. The protruding shape of the front end of the tube is a non-balloon indwelling part in the stomach in the body buried state while shrinking from the protruding state due to the external force caused by the sealing device. The sealing device is pulled out A sealing device that may be matched to the aforementioned catheter, which has a guide wire passage and an operation part, the guide wire passage is used to insert the guide wire attached from the front end to the middle of the guide wire, and the operation part is used to insert the guide wire attached to the rear end of the guide wire passage. The indwelling part in the body transmits the external force, and the rear end part of the guide wire channel and the operation part are arranged in a separated state.

Owner:SUMITOMO BAKELITE CO LTD +1

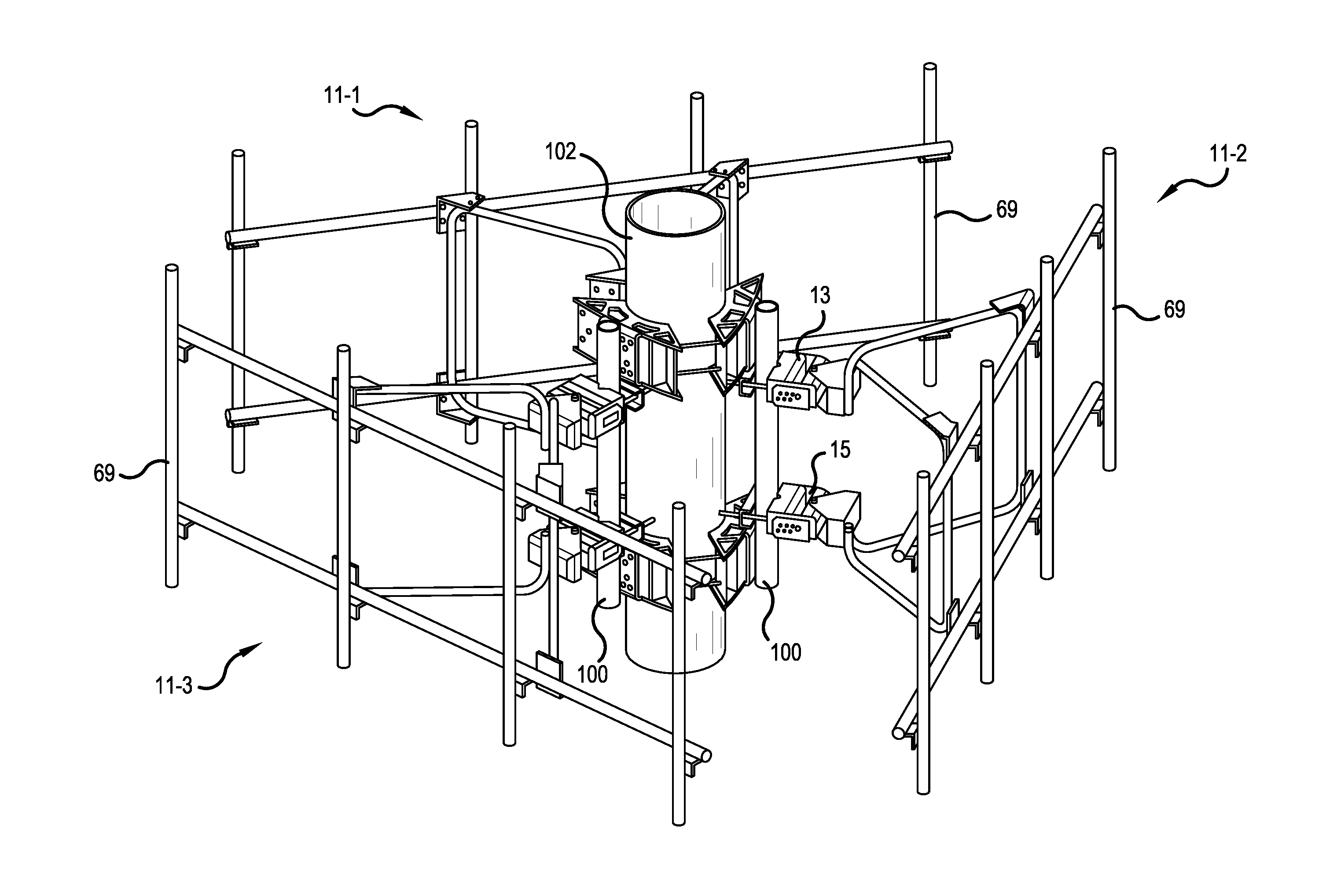

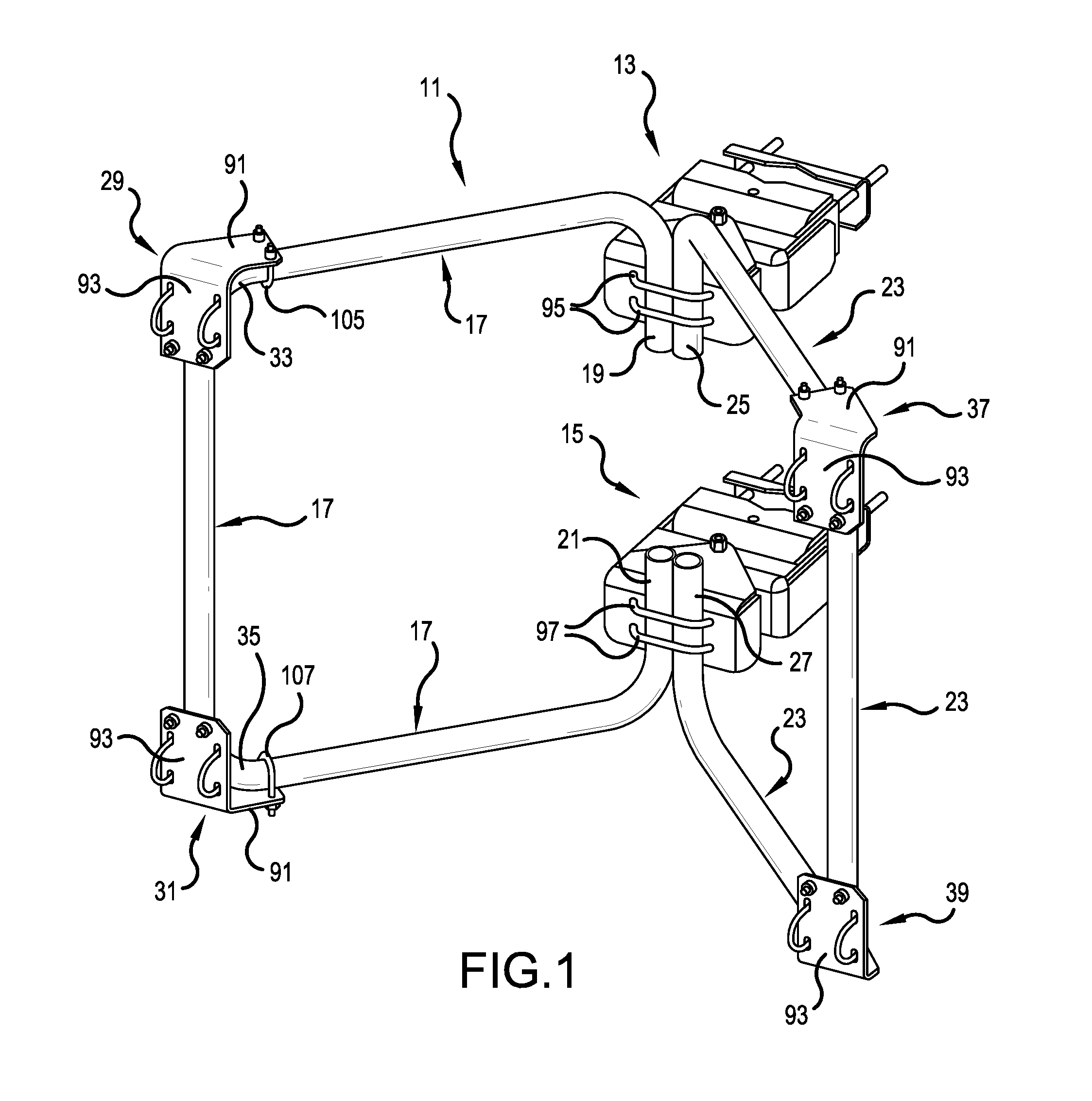

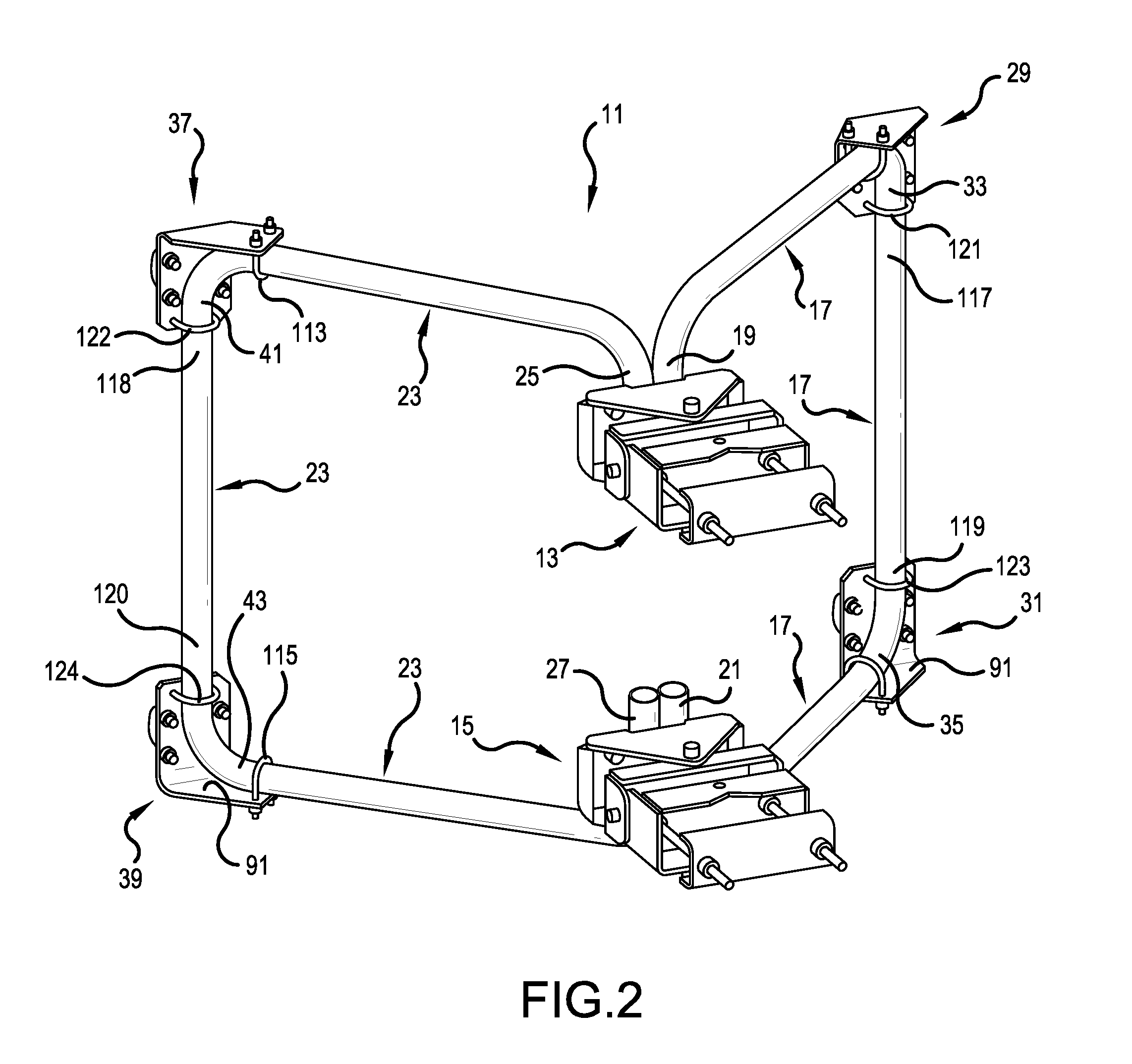

High capacity sector mount

InactiveUS20160211569A1Reduce weightReduce amountAntenna supports/mountingsStands/trestlesEngineeringTower

An antenna mount includes first and second tower mounting brackets. A first frame has first and second portions attached to the first and second tower mounting brackets, respectively. A second frame has third and fourth portions attached to the first and second tower mounting brackets, respectively. First and second equipment brackets are attached to the first frame, and third and fourth equipment brackets are attached to the second frame. Optionally, the first and second frames may each be formed as a one-piece continuous bent tube. Optionally, the first portion and the third portion are located side-by-side and clamped to the first tower bracket by a same first clamp, and the second portion and the fourth portion are located side-by-side and clamped to the second tower bracket by a same second clamp. Optionally, each equipment bracket has a frame face and an equipment face, wherein the frame face is orthogonal to the equipment face and extends in a direction which intersects a plane containing the equipment face at an angle of approximately 10 to 80 degrees.

Owner:COMMSCOPE TECH LLC

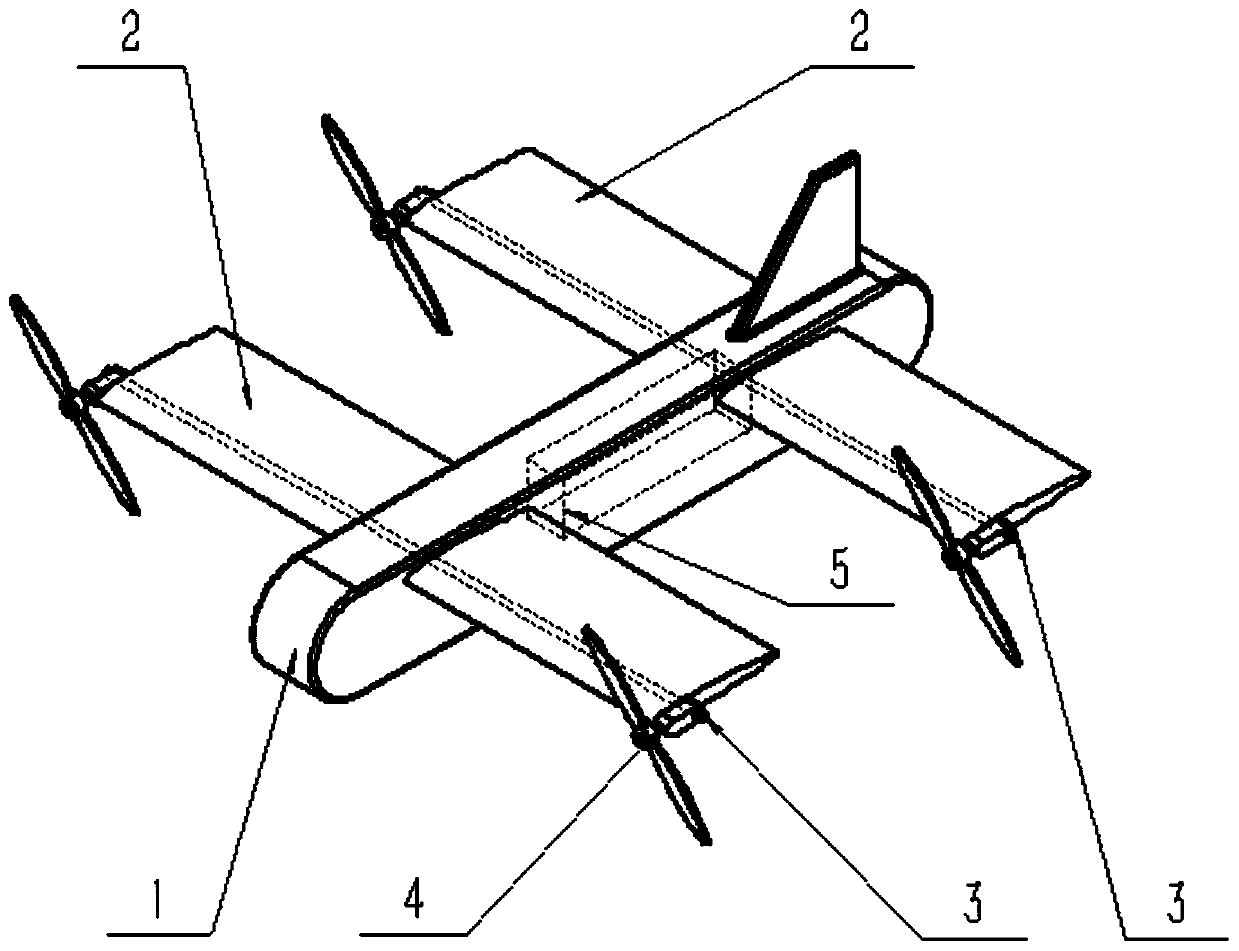

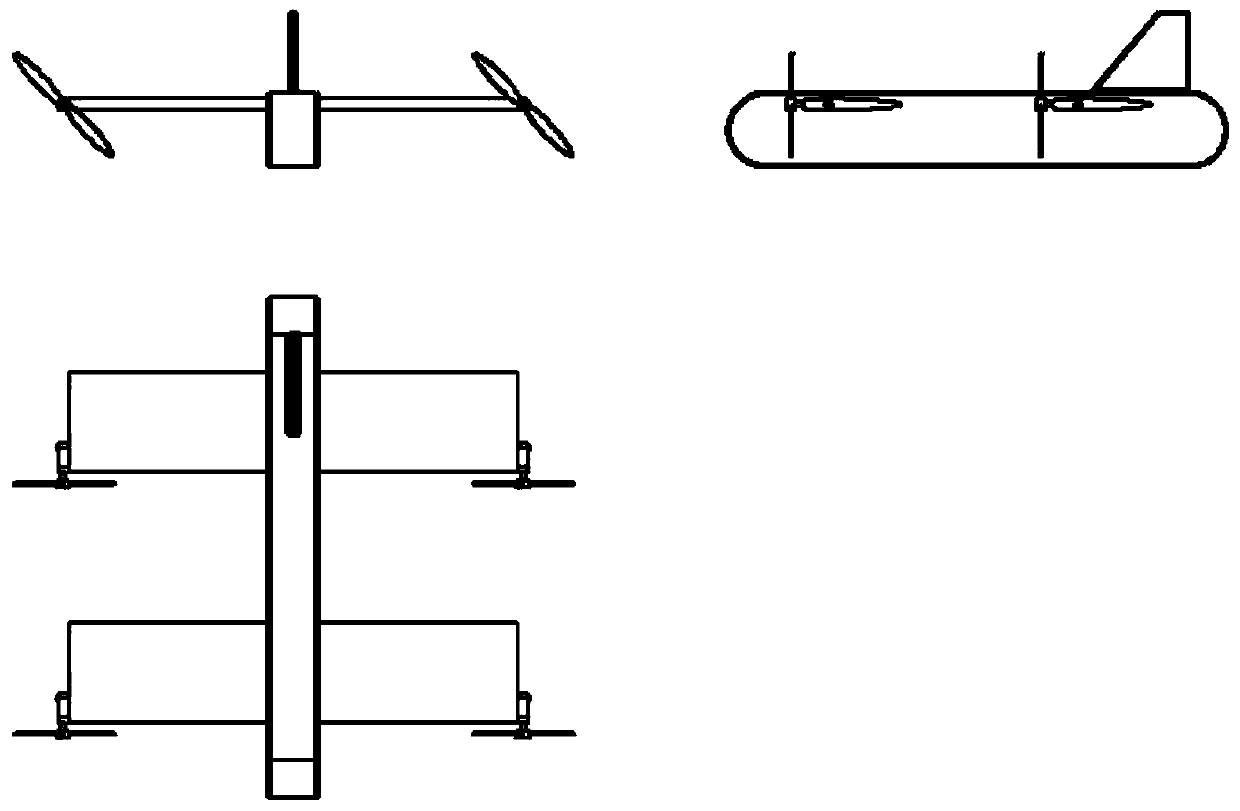

Layout and control method of tilting rotor-wing vertical take-off and landing aircraft

InactiveCN111516869AReduce the windward areaReduce projected areaWing adjustmentsVertical landing/take-off aircraftsLevel flightFlight vehicle

The invention relates to a layout and control method of a tilting rotor-wing vertical take-off and landing aircraft. Tandem wing layout is adopted; the wing tips of two sides of front wings and rear wings are each provided with one set of rotor wings, and altogether, four sets of rotor wings are adopted, so that a power system can be formed; the wings and the rotor wings can rotate around rotatingshafts penetrating through the interiors of the wings within a certain angle range, so that the respective tilting of the rotor wings and the wings is achieved. According to the control method, the vertical take-off and landing and high-speed level flight of the aircraft can be achieved; the angles of the rotor wings and the wings can be properly adjusted in all stages of flight, and the overallefficiency of the aircraft is optimized; the rotor wings and the wings can tilt respectively, resistance is small in vertical take-off and landing stages, and airflow interference between the rotor wings and the wings is small; when the aircraft is switched between a vertical take-off mode and a landing mode, the utilization efficiency of the wings is high, the burden of the power system is low; and flight control over a whole flight process is simple. The vertical take-off and landing aircraft has a wide application prospect.

Owner:BEIHANG UNIV

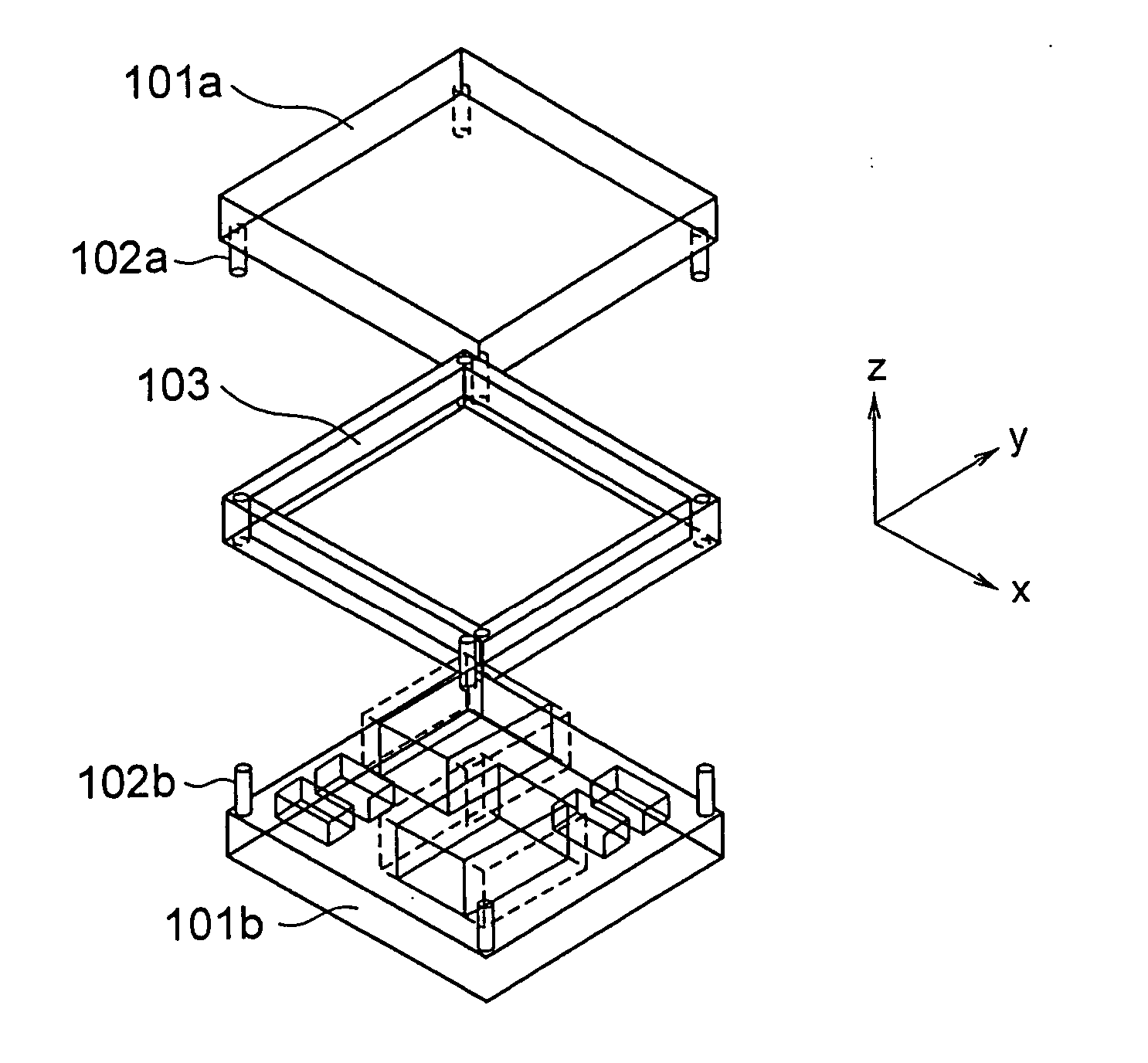

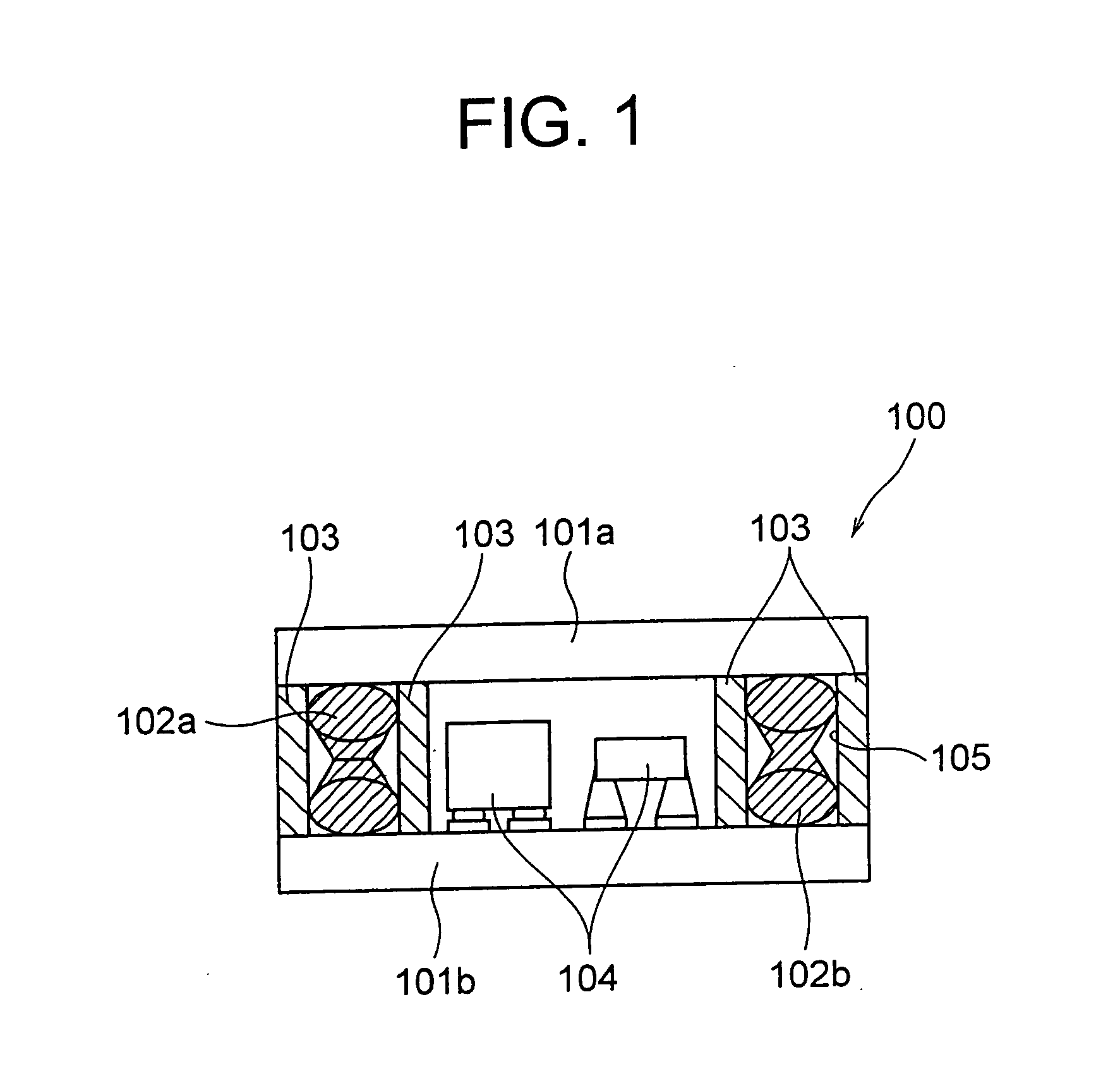

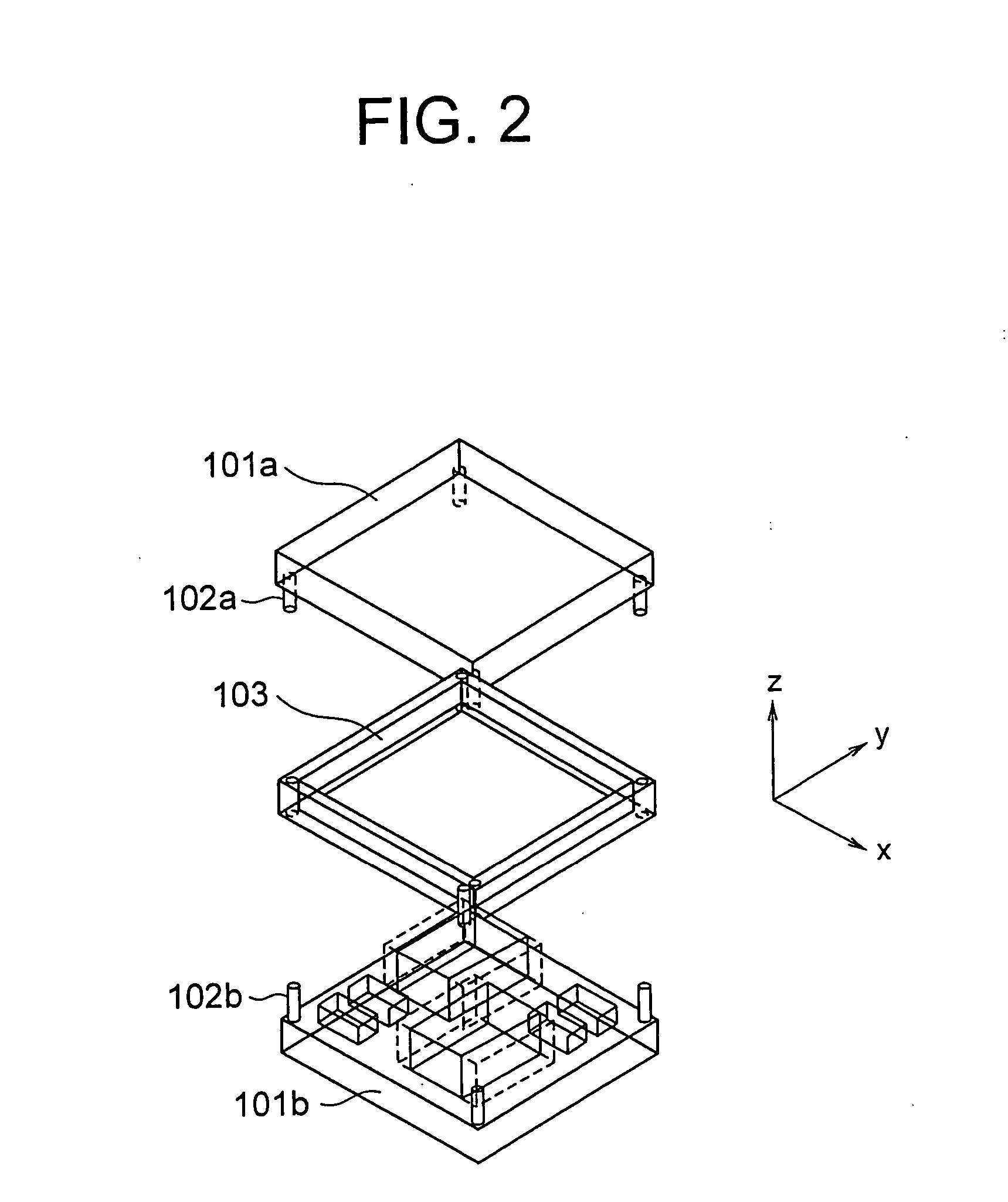

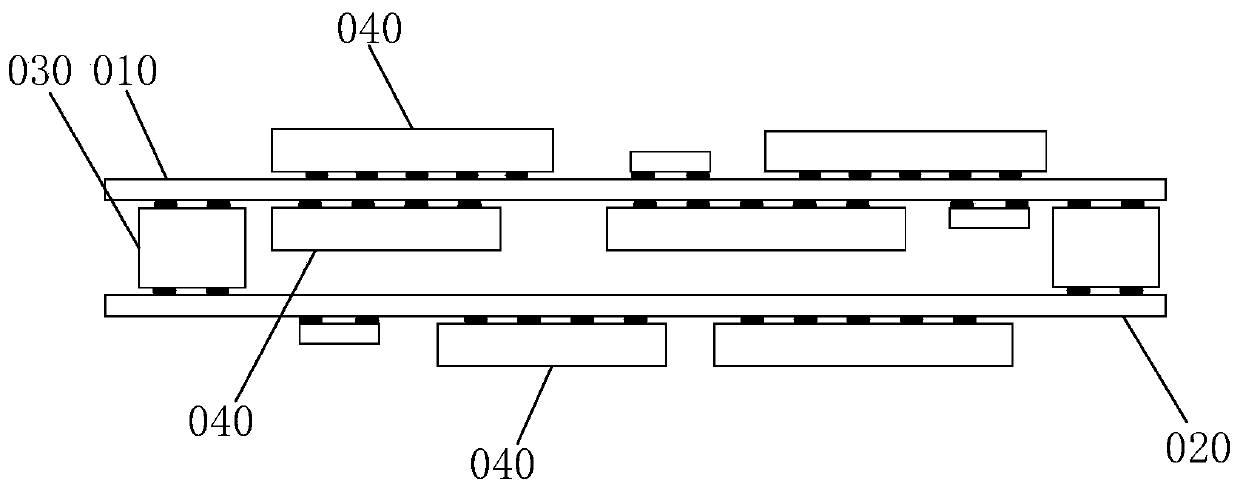

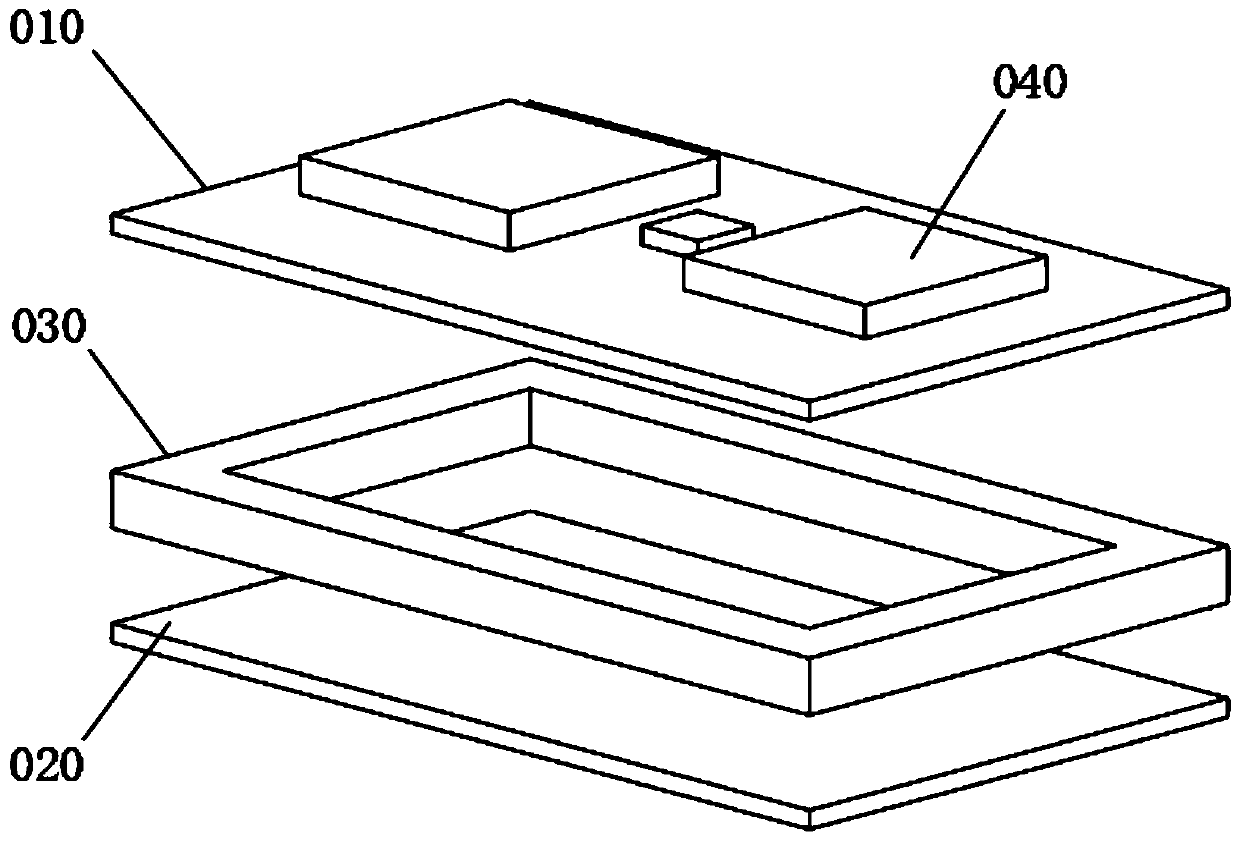

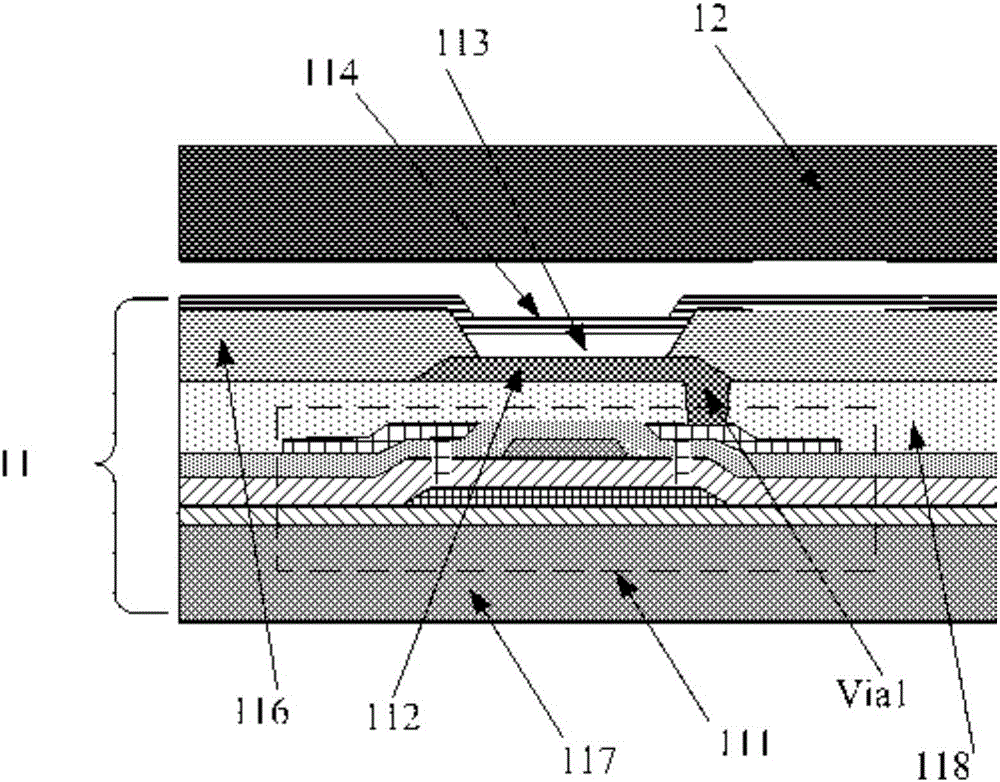

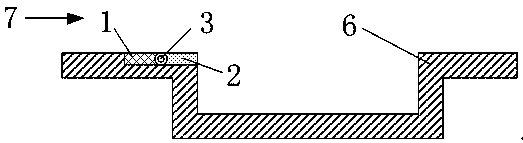

Stacked mounting structure

ActiveUS20070164444A1Increase productionLow costSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A stacked mounting structure includes at least two substrates namely a first substrate on which a first protruding electrode is formed and a second substrate on which a second protruding electrode is formed, and an intermediate substrate which is disposed between the first substrate and the second substrate, and which connects the first substrate and the second substrate by leaving a predetermined gap between the first substrate and the second substrate. Mounted components are disposed in the gap between the first substrate and the second substrate. The first protruding electrode and the second protruding electrode are connected in an opening which is provided in the intermediate substrate.

Owner:OLYMPUS CORP

High-temperature alloy disc die forging method

ActiveCN104707929AReduce projected areaReduced tonnage requirementsWheelsHeating/cooling devicesSuperalloyTurbine

The invention belongs to the technical field of high-temperature alloy die forging, and particularly relates to a high-temperature alloy turbine disc forge piece organization and performance thermal machining method. A performing die forging plus bearizing plus die forging method includes the steps that the specification and size of the wild shape required by finish forging are determined, a finish forging die and a performing die forging die are prepared, performing die forging is conducted, bearizing is conducted till the wild shape required by the finish forging is formed, and the finish forging is conducted; an annular blank is determined according to the forge piece shape to serve as the wild shape; first-fire forging of a titanium alloy bar is forged through the performing die, and the heating number integrates traditional upsetting, punching and saddling processes; preformed forge piece core materials generated after forming die forging is conducted are removed; bearizing is conducted on a performing forge piece till the wild shape size required by finish forging is formed; one-fire finish forging is conducted till forming is finished. According to the method, the problems that the final forge piece of the high-temperature alloy turbine disc forge piece is uneven in organization and residual stress due to the blank making process of more heating numbers and smaller deformation are avoided.

Owner:SHAANXI HONGYUAN AVIATION FORGING

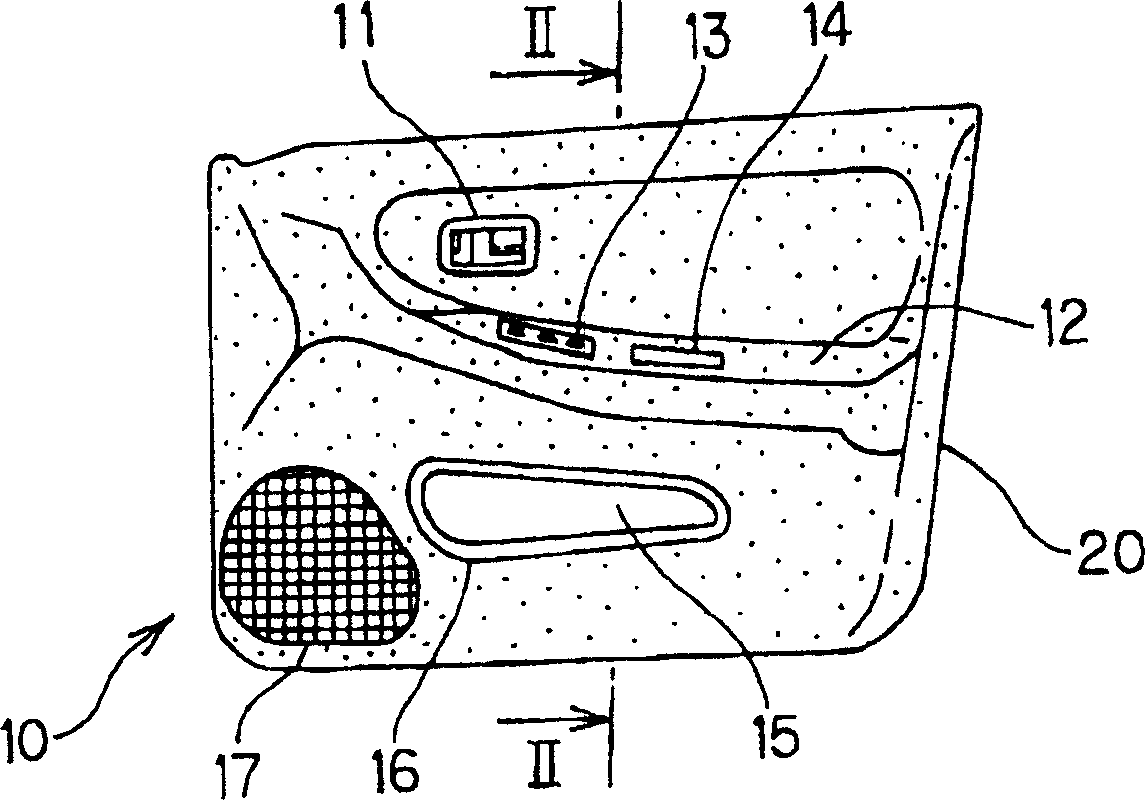

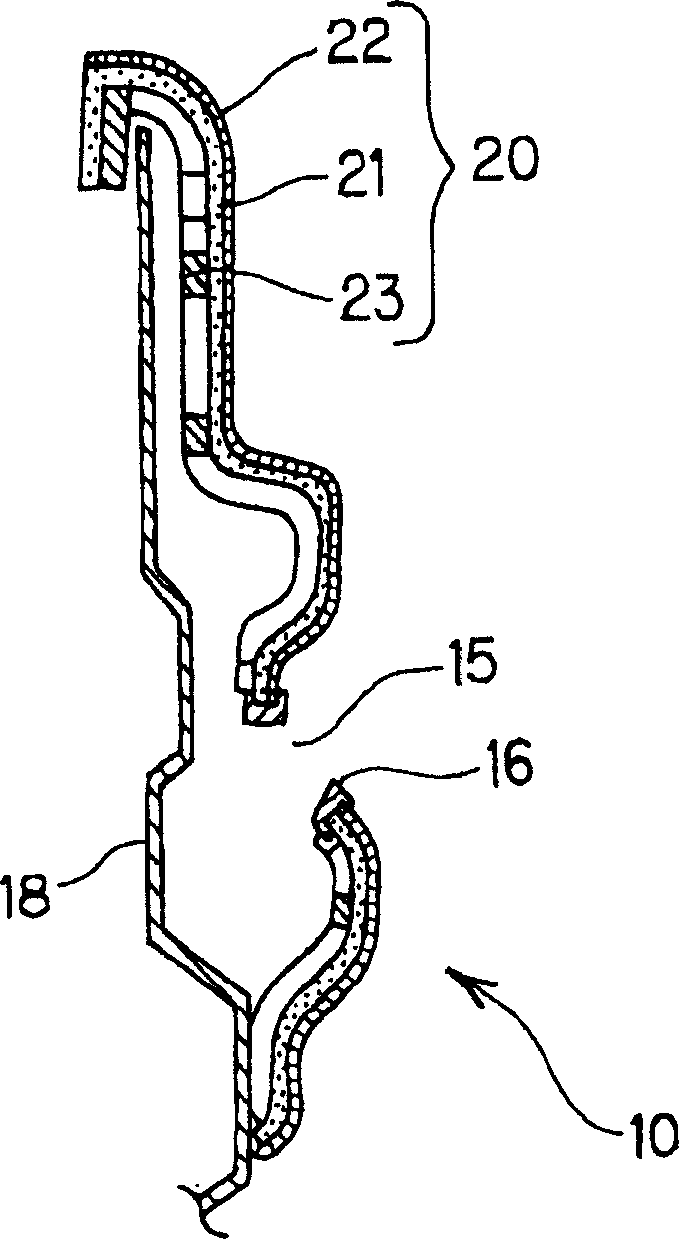

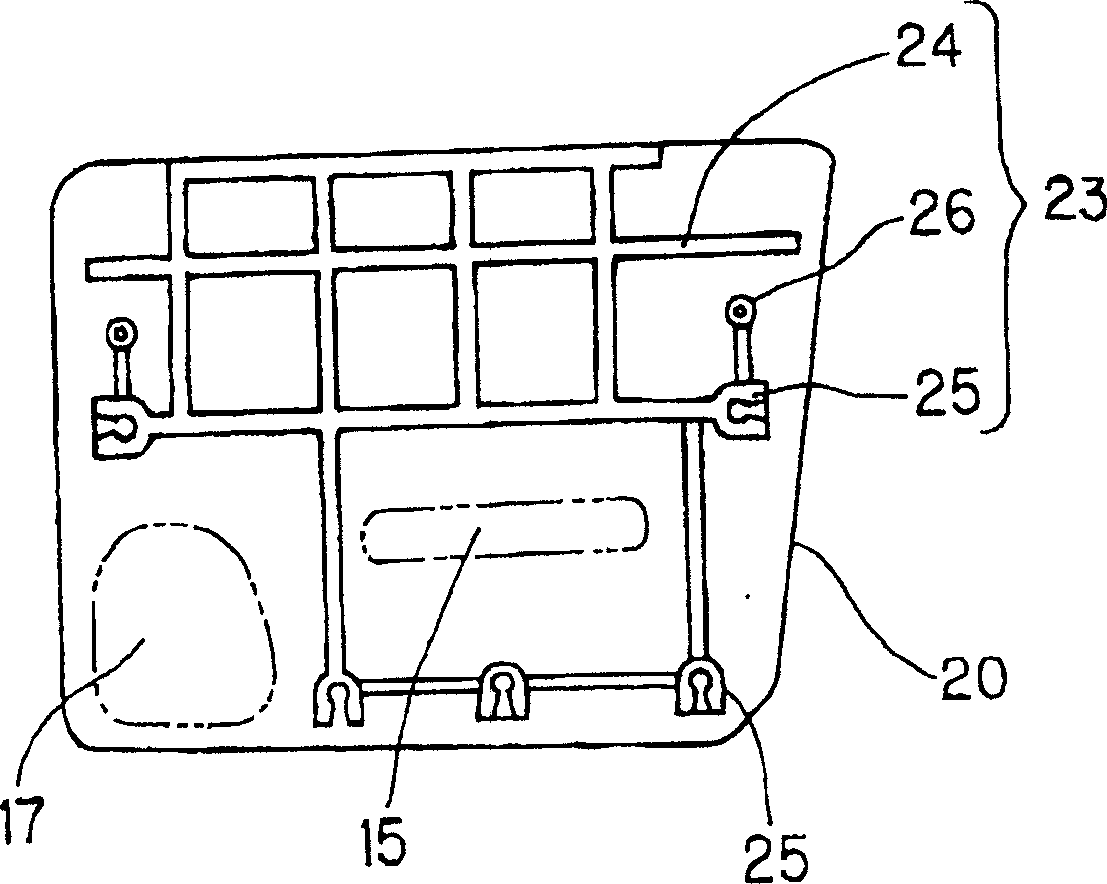

Interior decoration part for automobile and method for manufacturing the same

Owner:KASAI KOGYO CO LTD

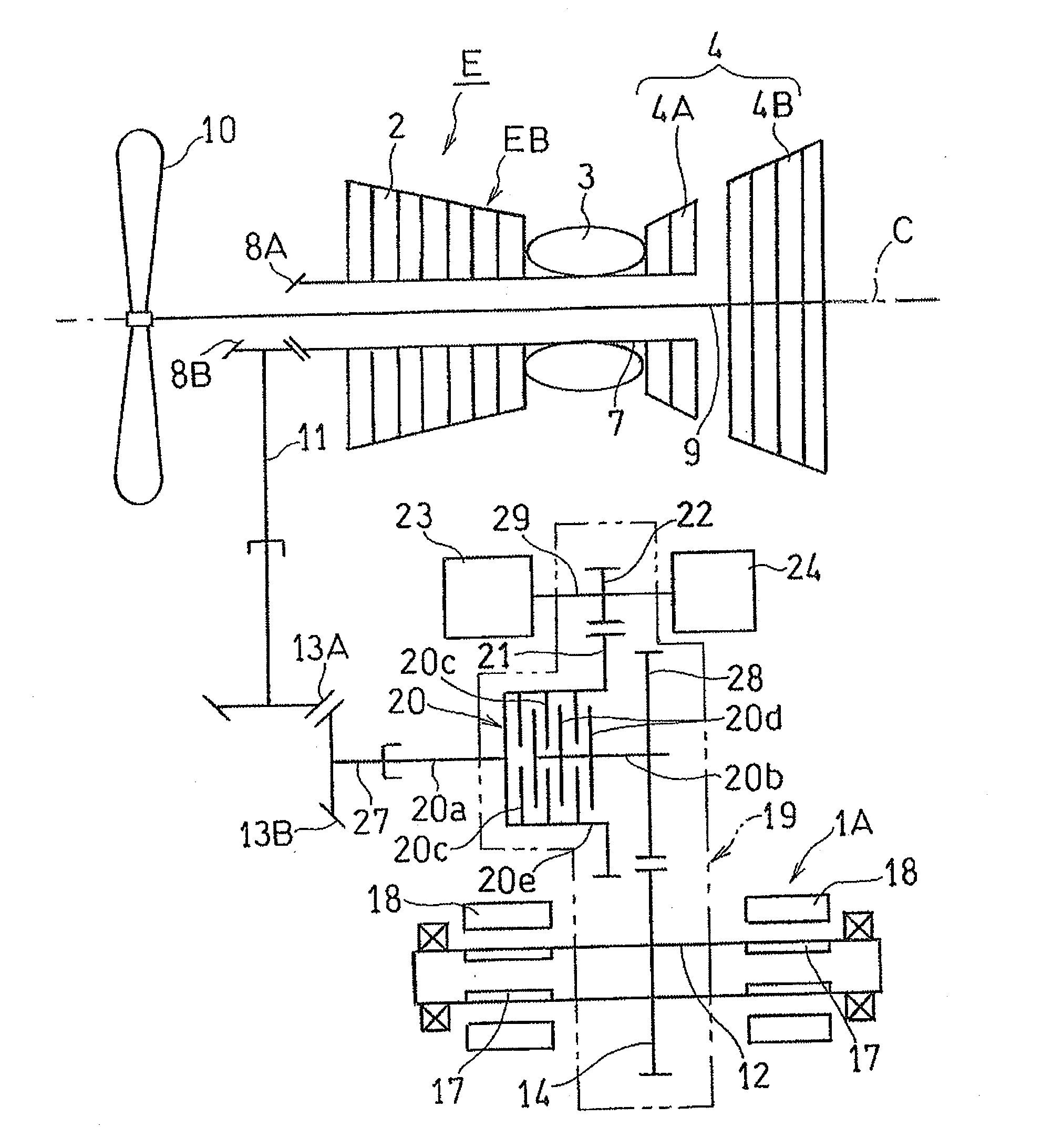

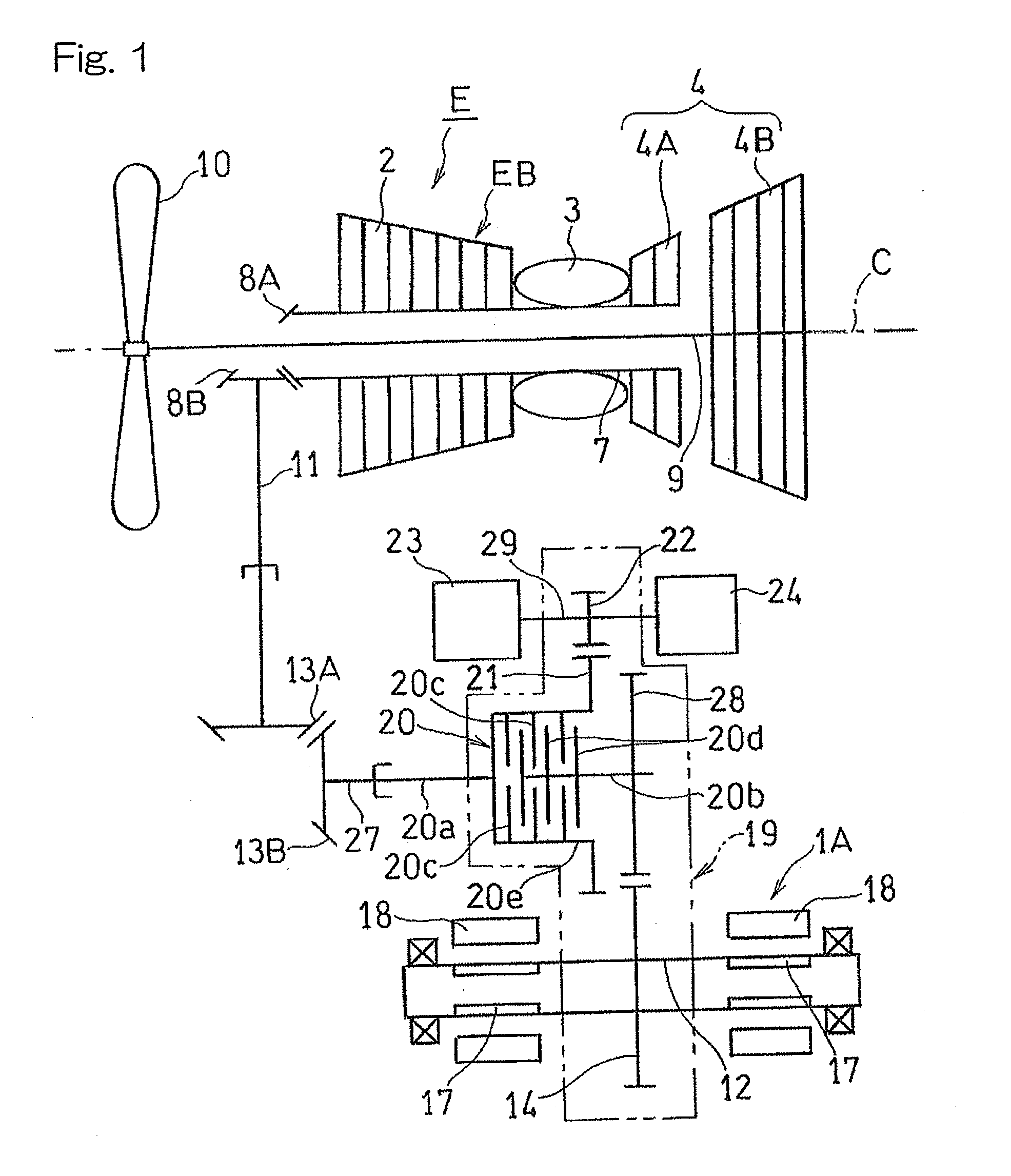

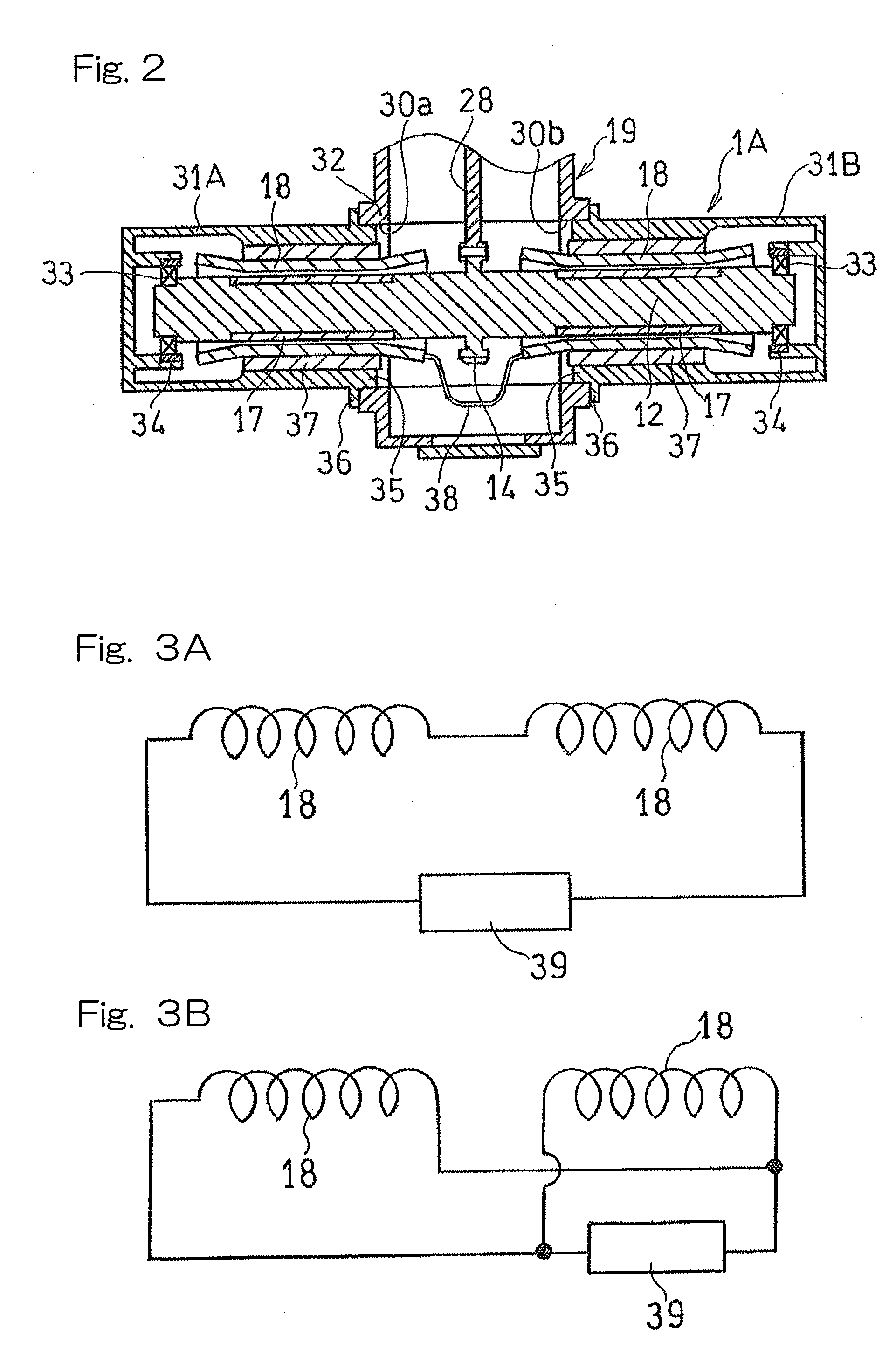

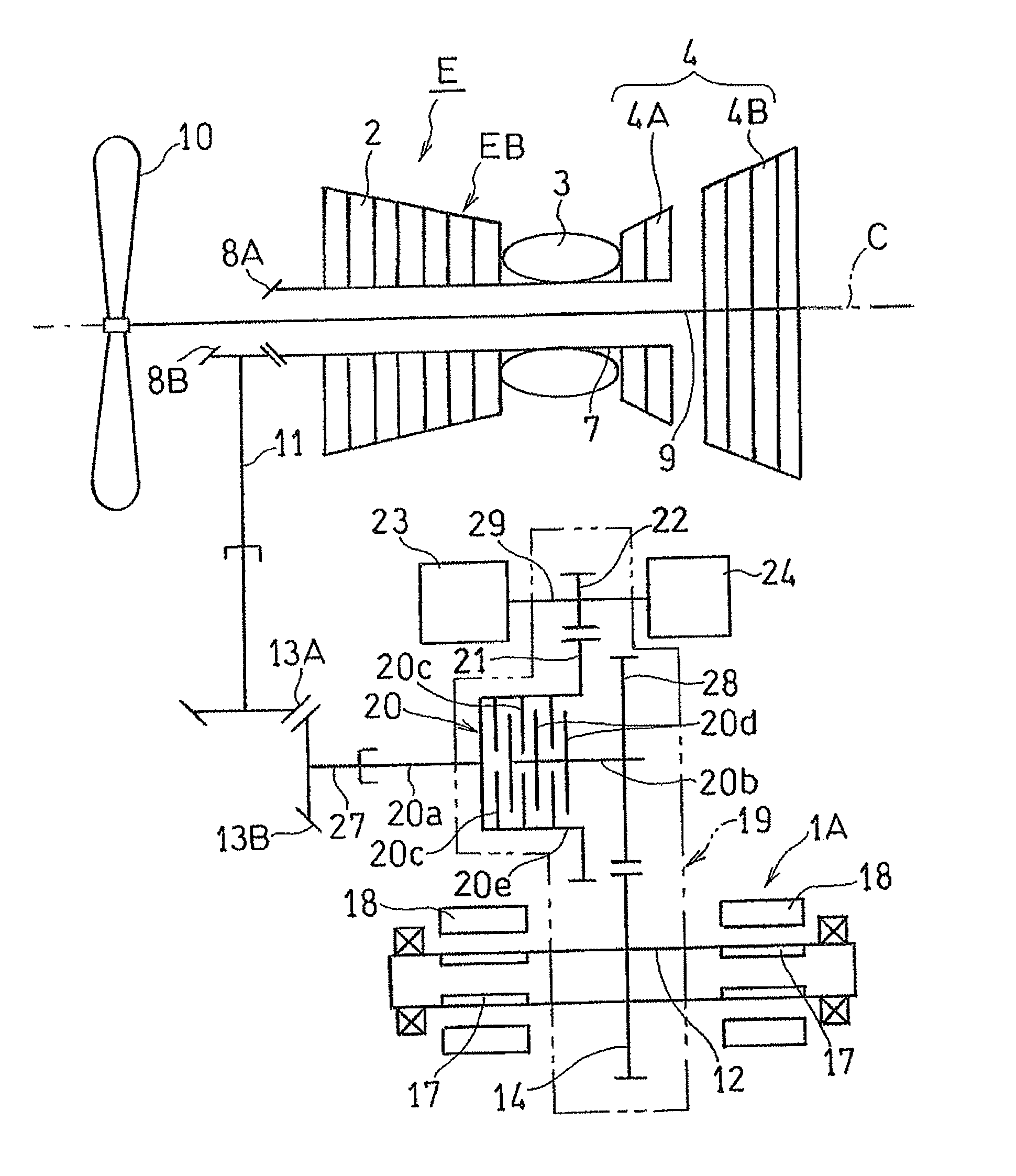

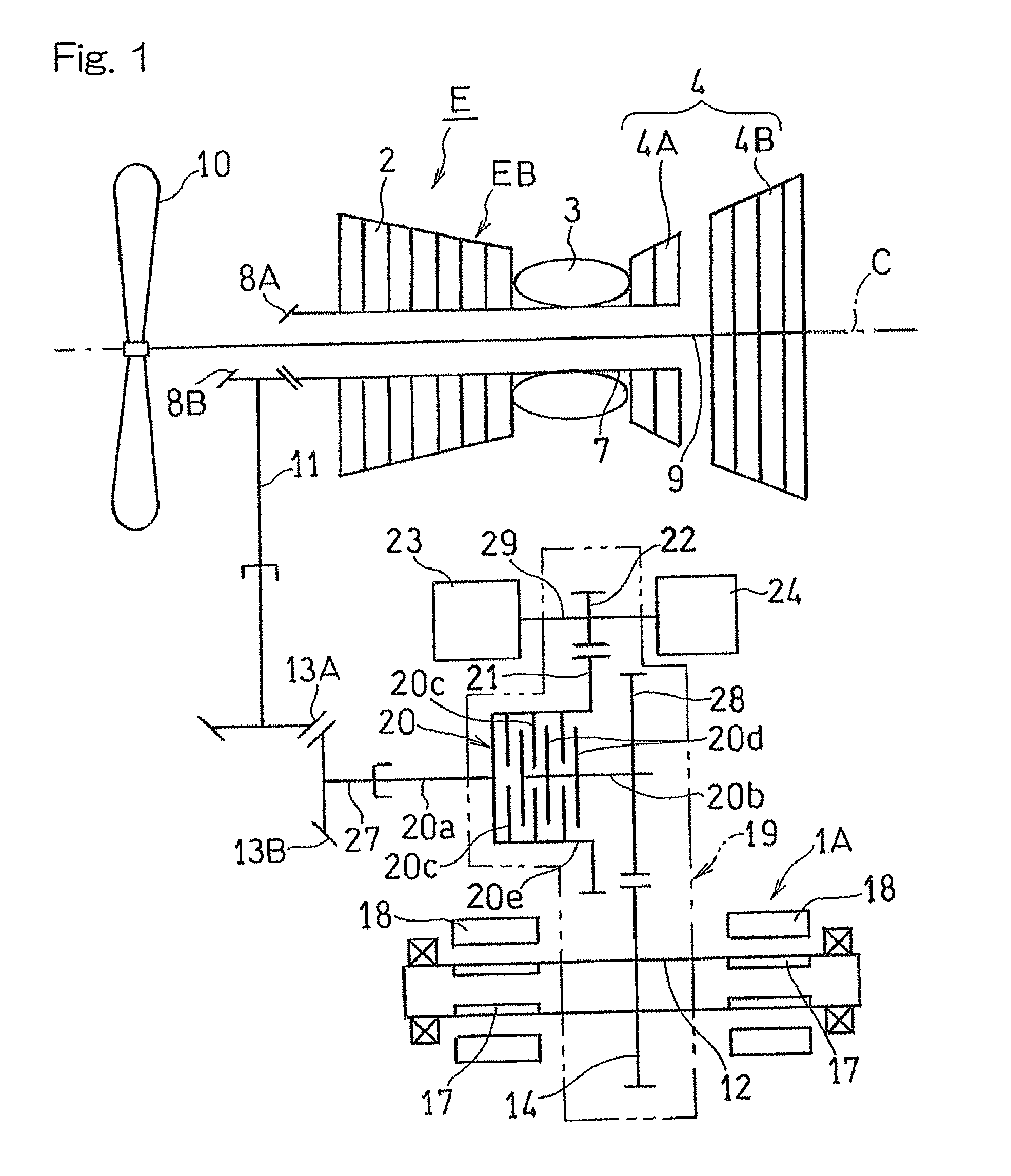

Power generation unit of integrated gearbox design for aircraft engine

ActiveUS20150311770A1Undesirable increase of be suppressReduce vibrationEngine fuctionsGas turbine plantsAirplaneMagnet

A power generation unit is connected with an engine rotary shaft via an accessory gearbox. A rotor extends through the accessory gearbox and a drive gear is disposed at an intermediate portion of the rotor for driving the latter. Permanent magnet elements are mounted on opposite side portions with the intermediate portion intervening therebetween, and stator coils are disposed so as to confront respective outer peripheries of the permanent magnet elements.

Owner:KAWASAKI HEAVY IND LTD

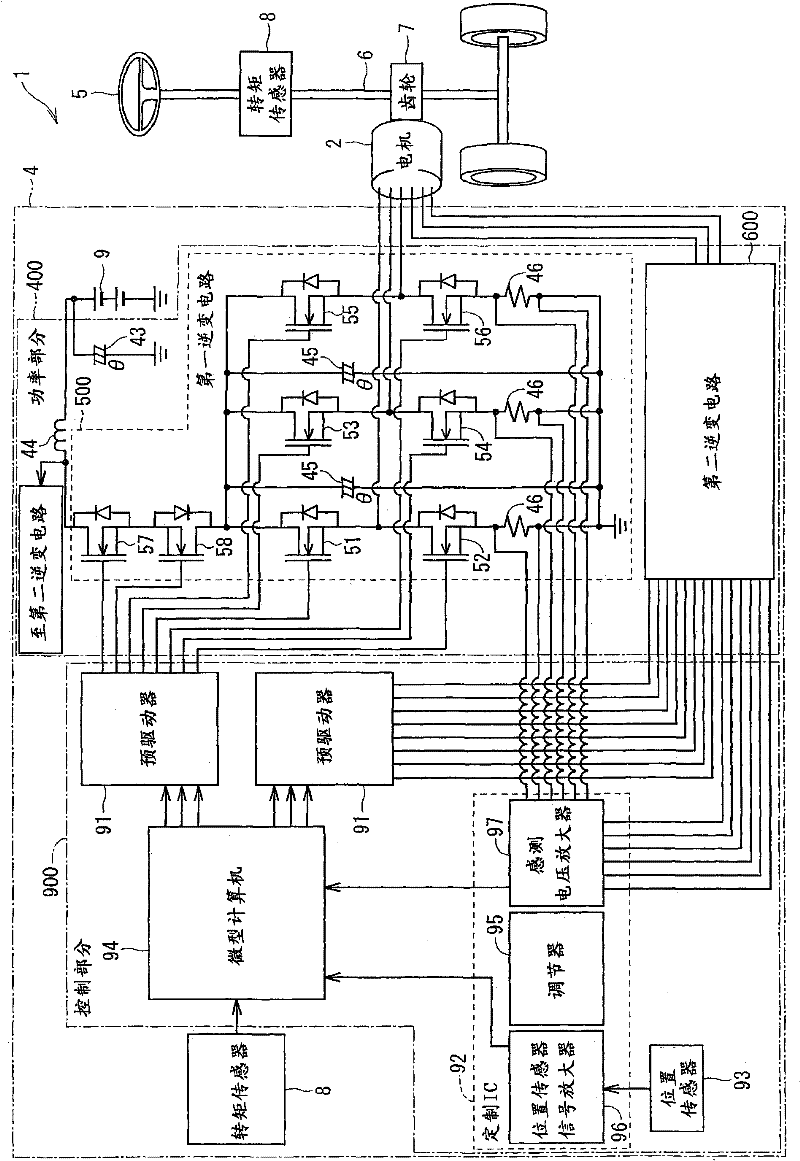

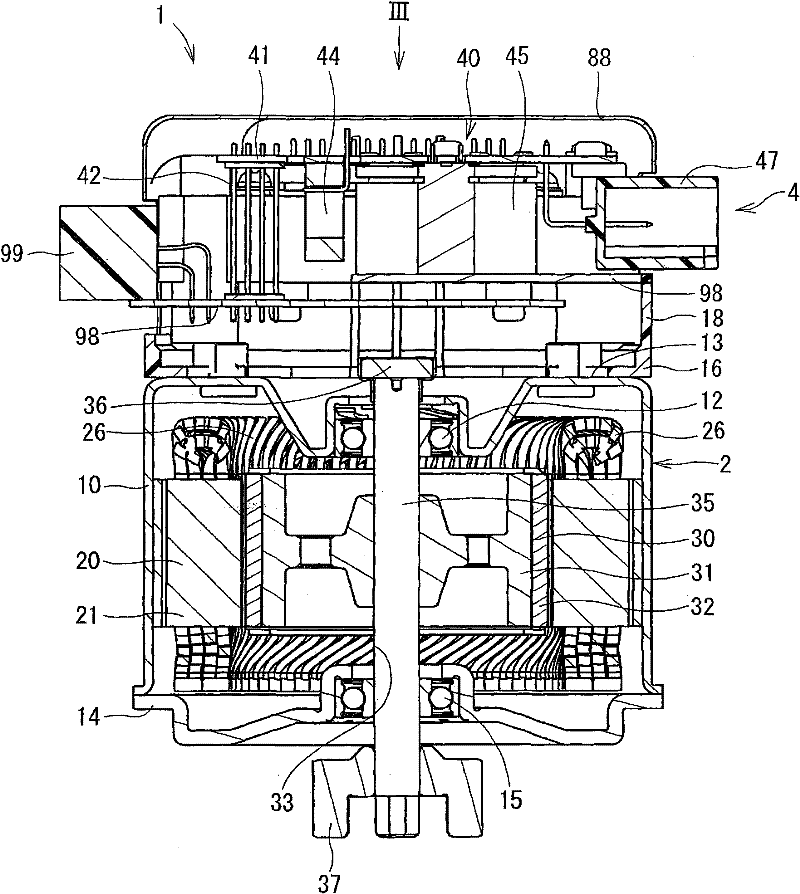

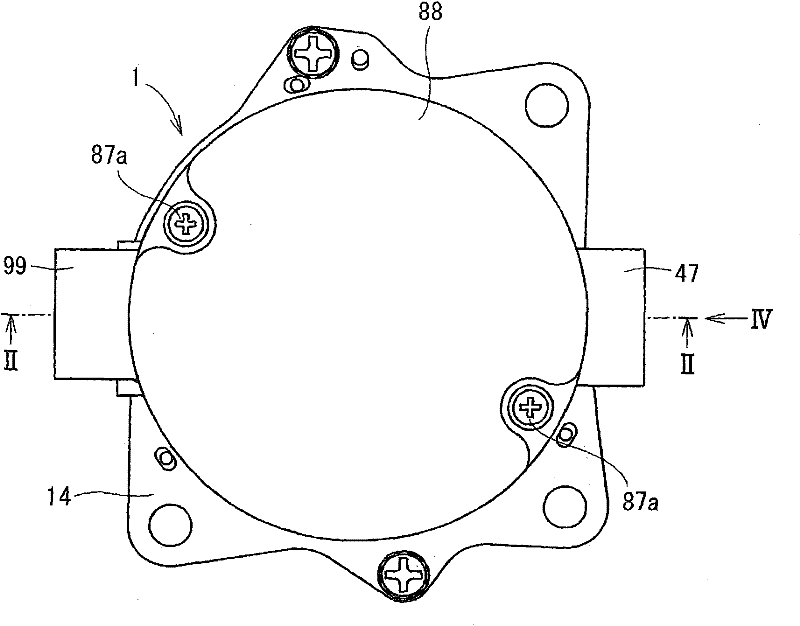

Inverter device and drive unit using the same

InactiveCN102255539ASmall sizeEfficient arrangementAC motor controlElectric devicesPower inverterElectric machine

The invention provides an inverter device and a drive unit using the same. In two systems of three-phase alternating-current inverter devices that drive a motor, power elements on power supply sides of bridge circuits are mounted on unit bases to constitute upper arm units. Power elements on ground sides of the bridge circuits are mounted on unit bases to constitute lower arm units. The upper arm units and the lower arm units are arranged separately on upper surfaces and outside surfaces of heat dissipation blocks of a heat sink. Heats generated by the power elements do not interfere with each other and are emitted to the heat sink, whereby heat dissipation performance of the power elements constituting the bridge circuits is improved.

Owner:DENSO CORP

Printed circuit board, manufacturing method thereof and electronic equipment

InactiveCN110149762AAvoid warpingAvoid the consequences of electrical connection failuresPrinted circuit assemblingPrinted circuits structural associationsSurface mountingEngineering

The embodiment of the invention provides a printed circuit board, a manufacturing method thereof and electronic equipment. The printed circuit board comprises a first printed circuit board. The firstprinted circuit board comprises a first surface and a second surface, and the first surface and the second surface are opposite in direction. The first printed circuit board is provided with a first groove, and an opening of the first groove faces the first surface. The first surface is provided with a first bonding pad. An electronic element is mounted on the second surface. The printed circuit board also comprises a second printed circuit board which comprises a third surface and a fourth surface, and the third surface and the fourth surface are opposite in direction. The third surface is provided with a second bonding pad, and the second bonding pad corresponds to the first bonding pad in position. The third surface and the fourth surface are respectively provided with electronic elements. The first printed circuit board and the second printed circuit board are welded through the first bonding pad and the second bonding pad to form a stacked structure. The printed circuit board provided by the invention is not likely to warp, has stronger stress deformation resistance, and can prolong the service life of electronic equipment.

Owner:HUAWEI TECH CO LTD

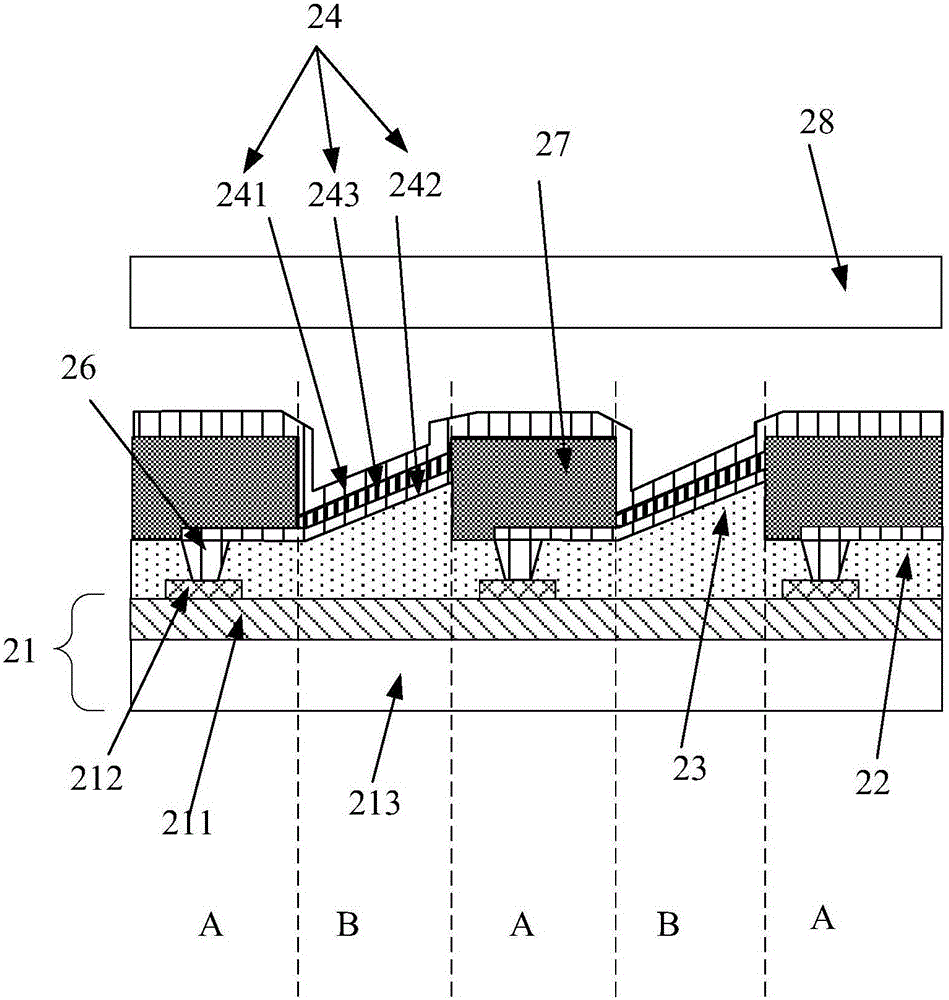

Display panel and manufacturing method thereof

ActiveCN106024807AIncrease surface areaIncrease the number ofSolid-state devicesSemiconductor/solid-state device manufacturingImage resolutionComputer science

The invention discloses a display panel and a manufacturing method. The display panel comprises a substrate, a planarizing layer and display units, wherein the planarizing layer is arranged on the surface of the substrate; the surface of the planarizing layer has adjusting structures; the planarizing layer comprises first regions and second regions; the surface of the first region is parallel to the substrate; the adjusting structure is located on the second region; the first regions and the second regions are alternately arranged at intervals; the display units cover the surfaces of the adjusting structures; and the adjusting structure is set to be a bump structure or a groove structure arranged in the second region. The adjusting structure is beneficial to an increase of the surface area of a light-emitting functional layer; the projection area of the light-emitting functional layer in the direction of the substrate is reduced; and the number of the display units is increased, so that the effect of improving the aperture ratio and the resolution ratio is achieved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

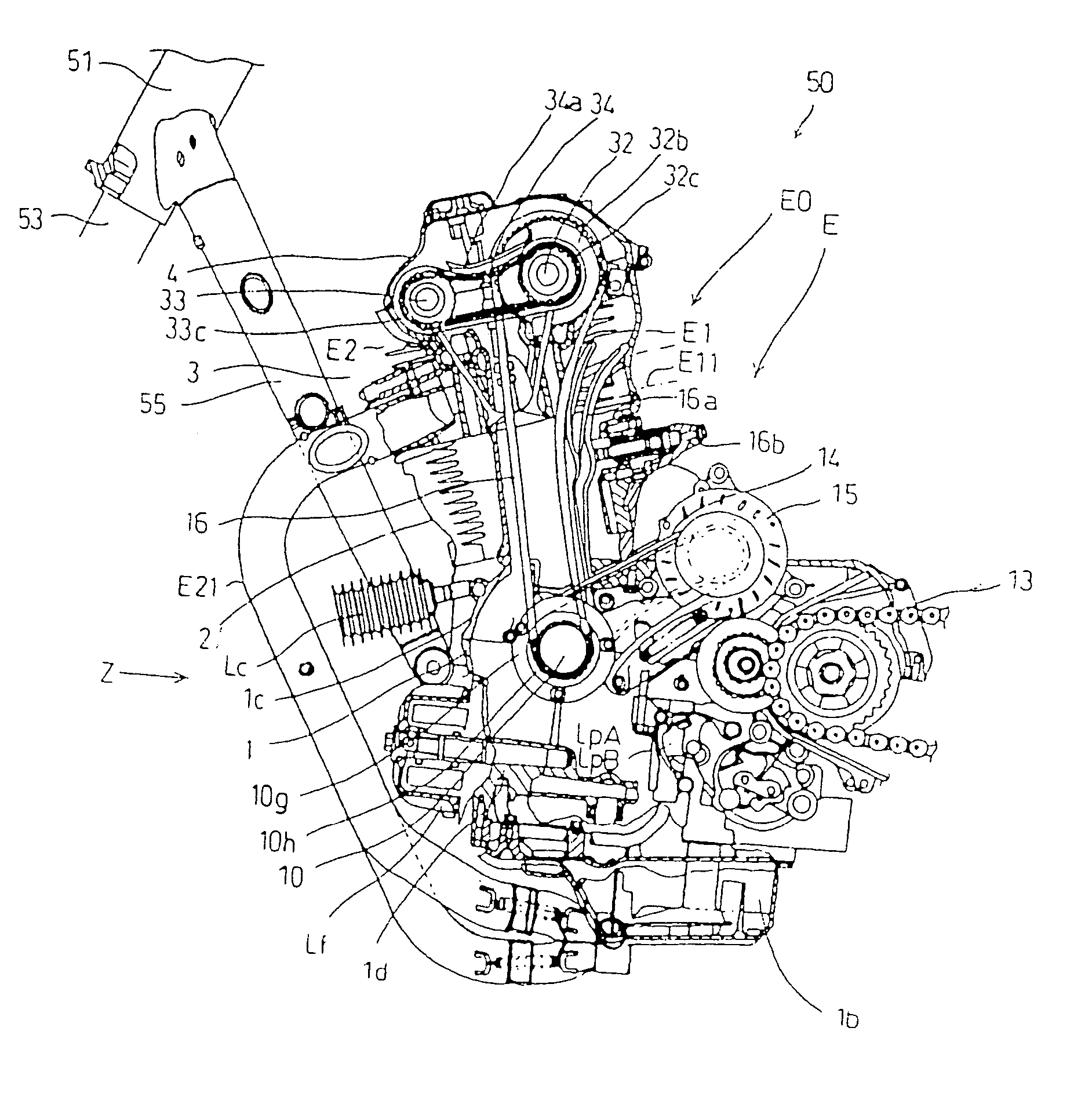

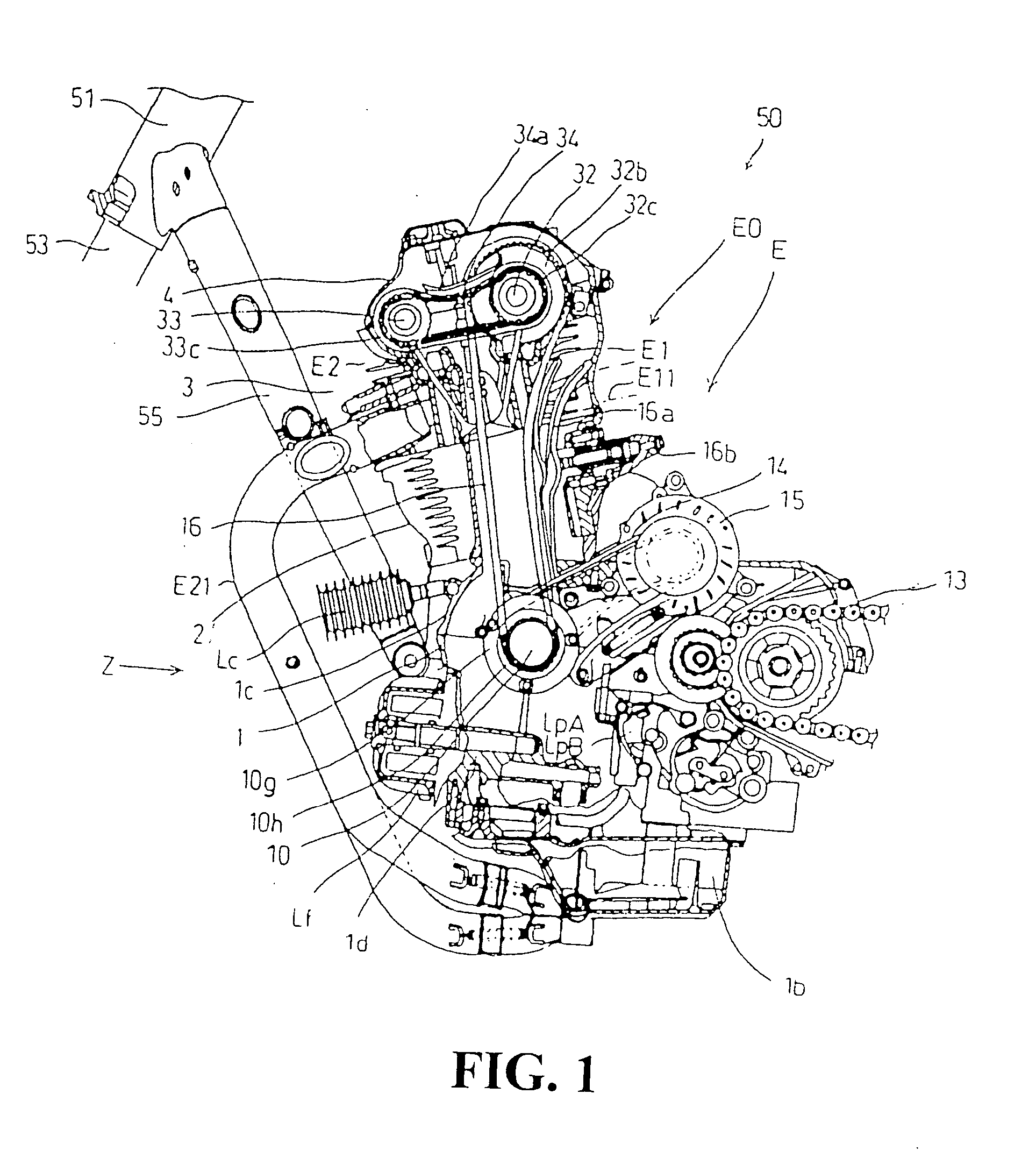

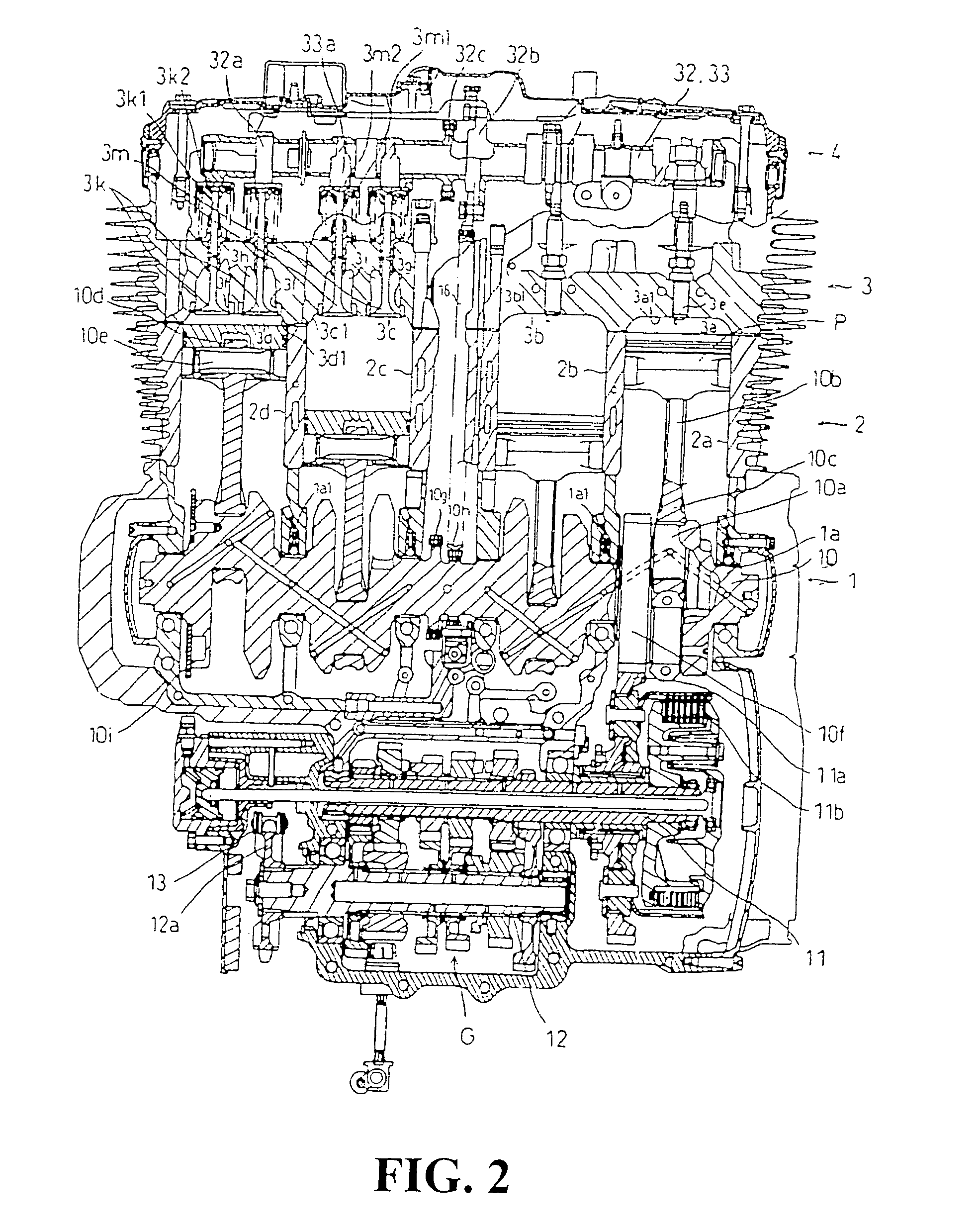

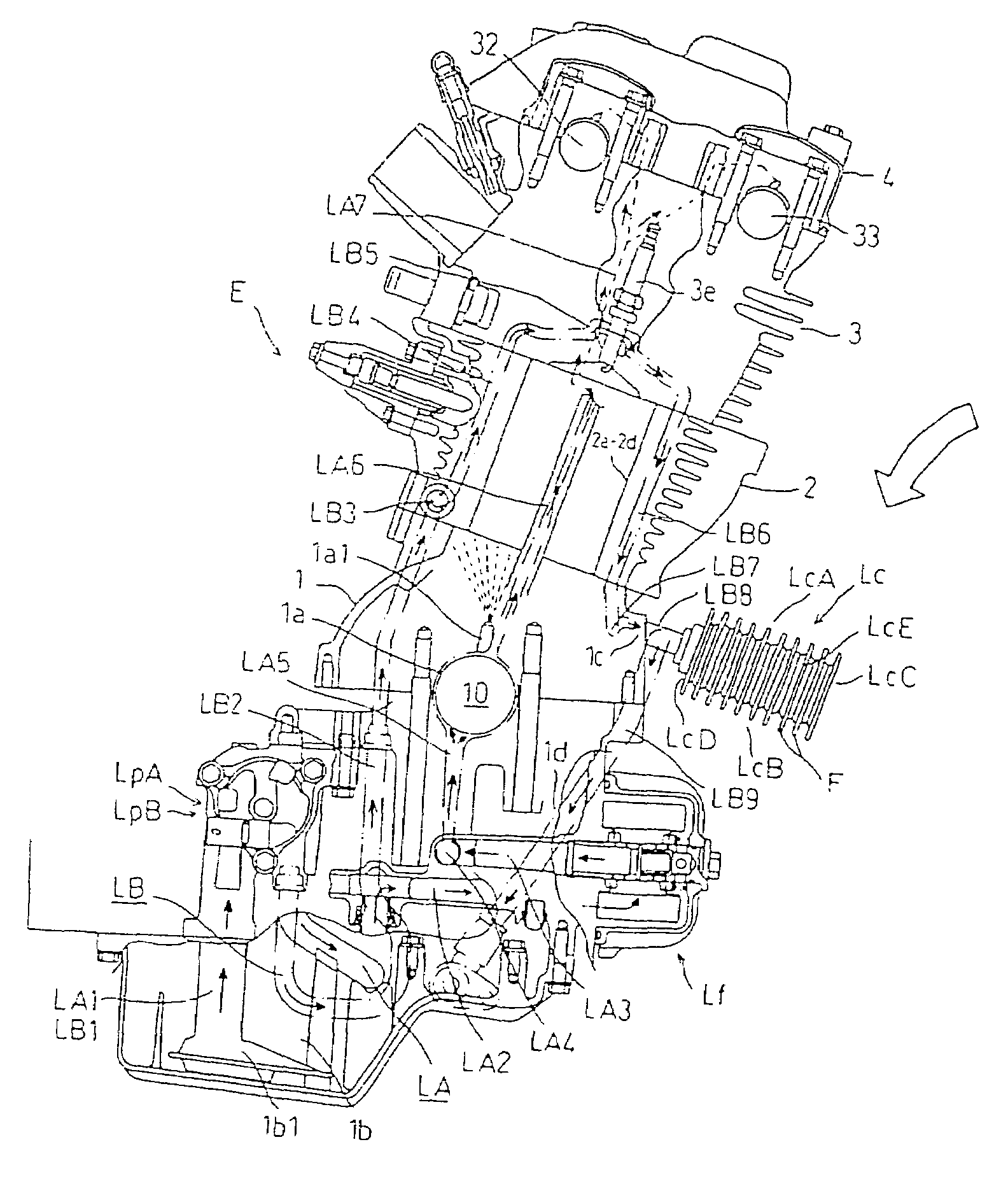

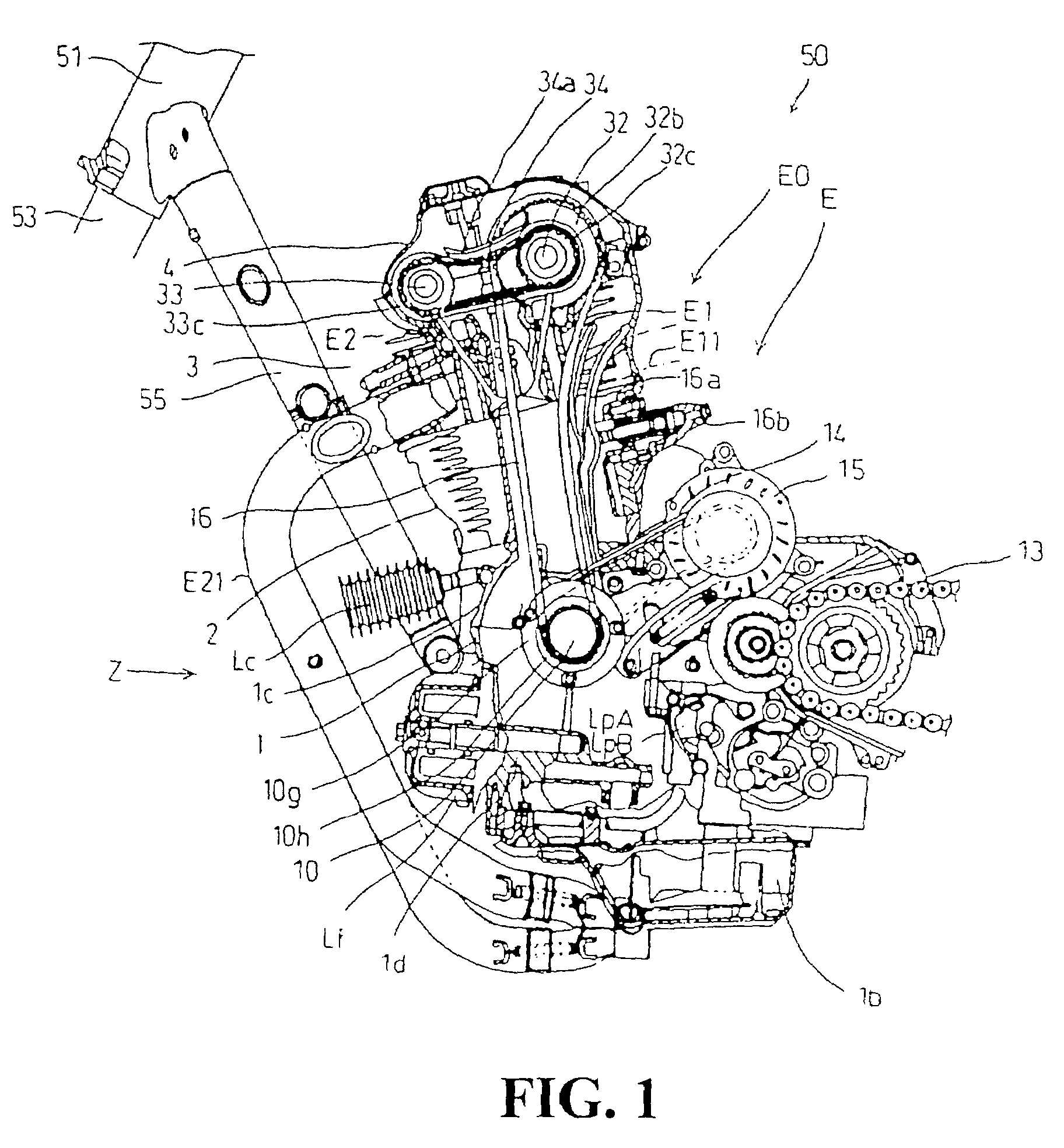

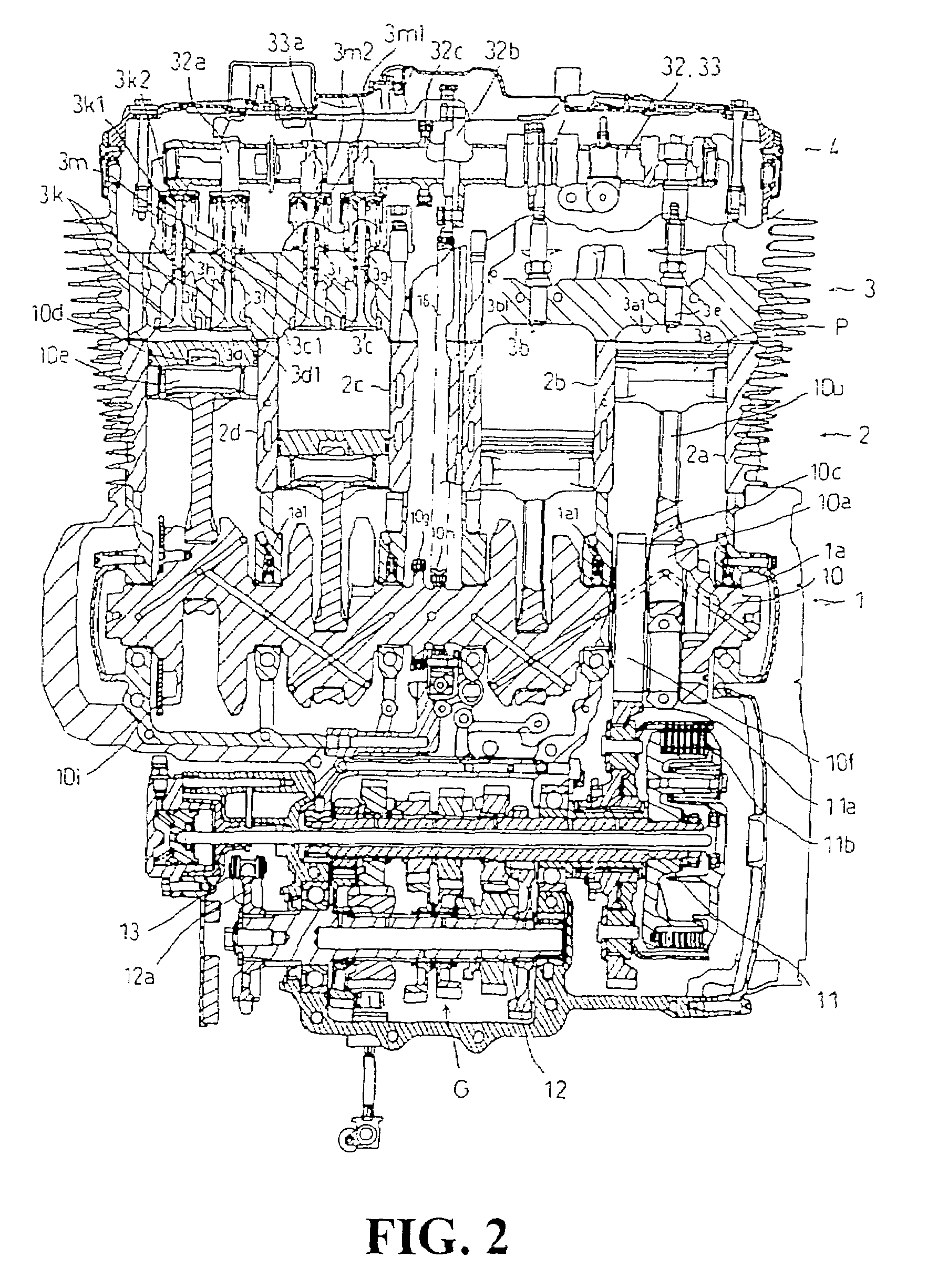

Disposition structure of heat exchanger in motorcycle

InactiveUS20050139403A1Improve cooling efficiencyMore air flowLiquid coolingCylinder headsEngineeringCrankcase

A disposition structure of a heat exchanger (oil cooler) in a motorcycle mounted in the central part in front of the upper part of the crankcase of an internal combustion engine E mounted on the motorcycle. When viewed from the front of the motorcycle, the oil cooler is located between the front forks. The oil cooler is disposed so that the fin surface of the cooling fins of the heat exchanger are perpendicular or substantially perpendicular to an air flow that goes between the front forks and above the front wheel. In the disposition structure so configured, cooling efficiency of the heat exchanger is improved.

Owner:HONDA MOTOR CO LTD

Power generation unit of integrated gearbox design for aircraft engine

ActiveUS9548639B2Increase in sizeReduce air resistanceEngine fuctionsGas turbine plantsRotational axisStator coil

A power generation unit is connected with an engine rotary shaft via an accessory gearbox. A rotor extends through the accessory gearbox and a drive gear is disposed at an intermediate portion of the rotor for driving the latter. Permanent magnet elements are mounted on opposite side portions with the intermediate portion intervening therebetween, and stator coils are disposed so as to confront respective outer peripheries of the permanent magnet elements.

Owner:KAWASAKI HEAVY IND LTD

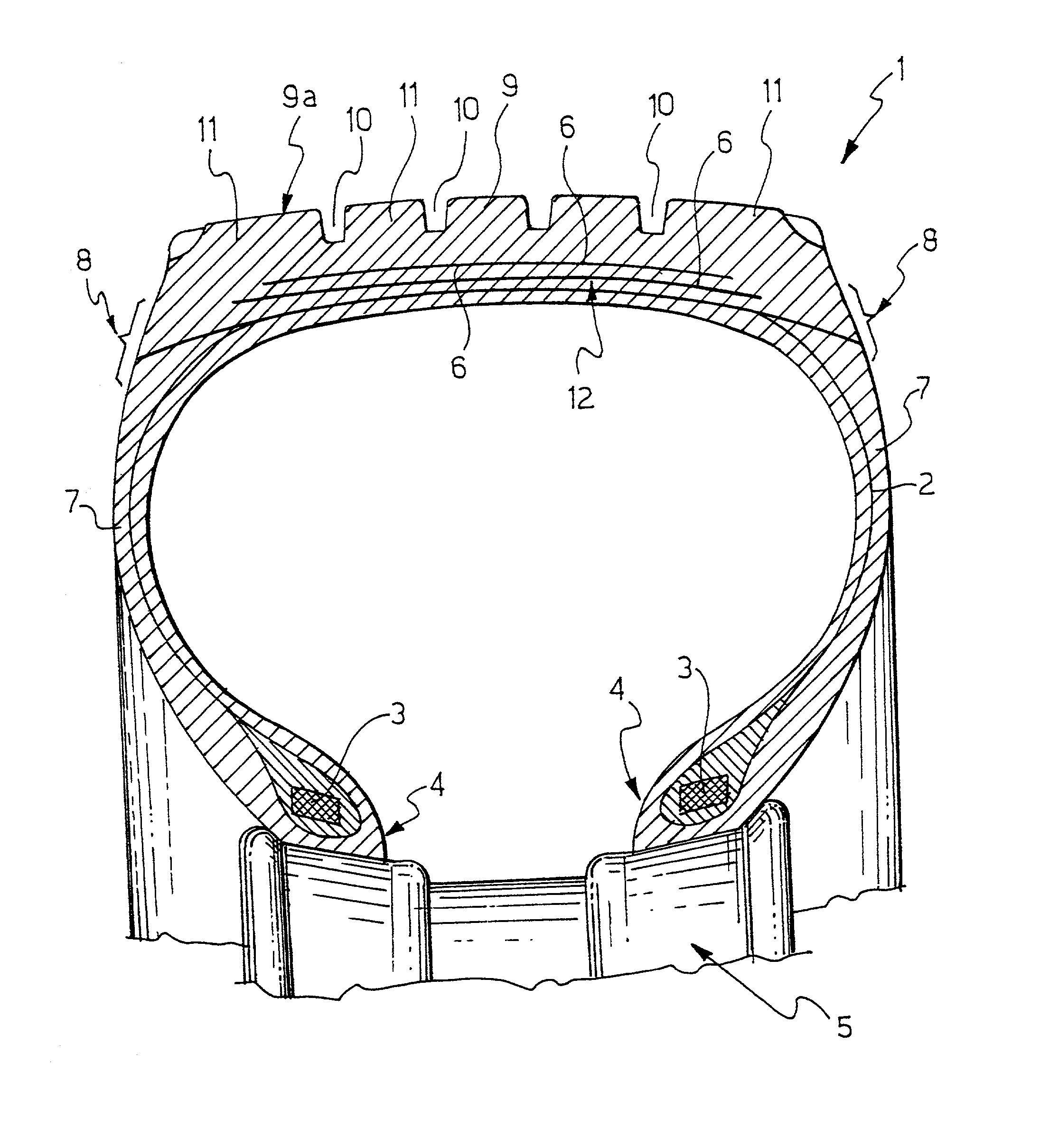

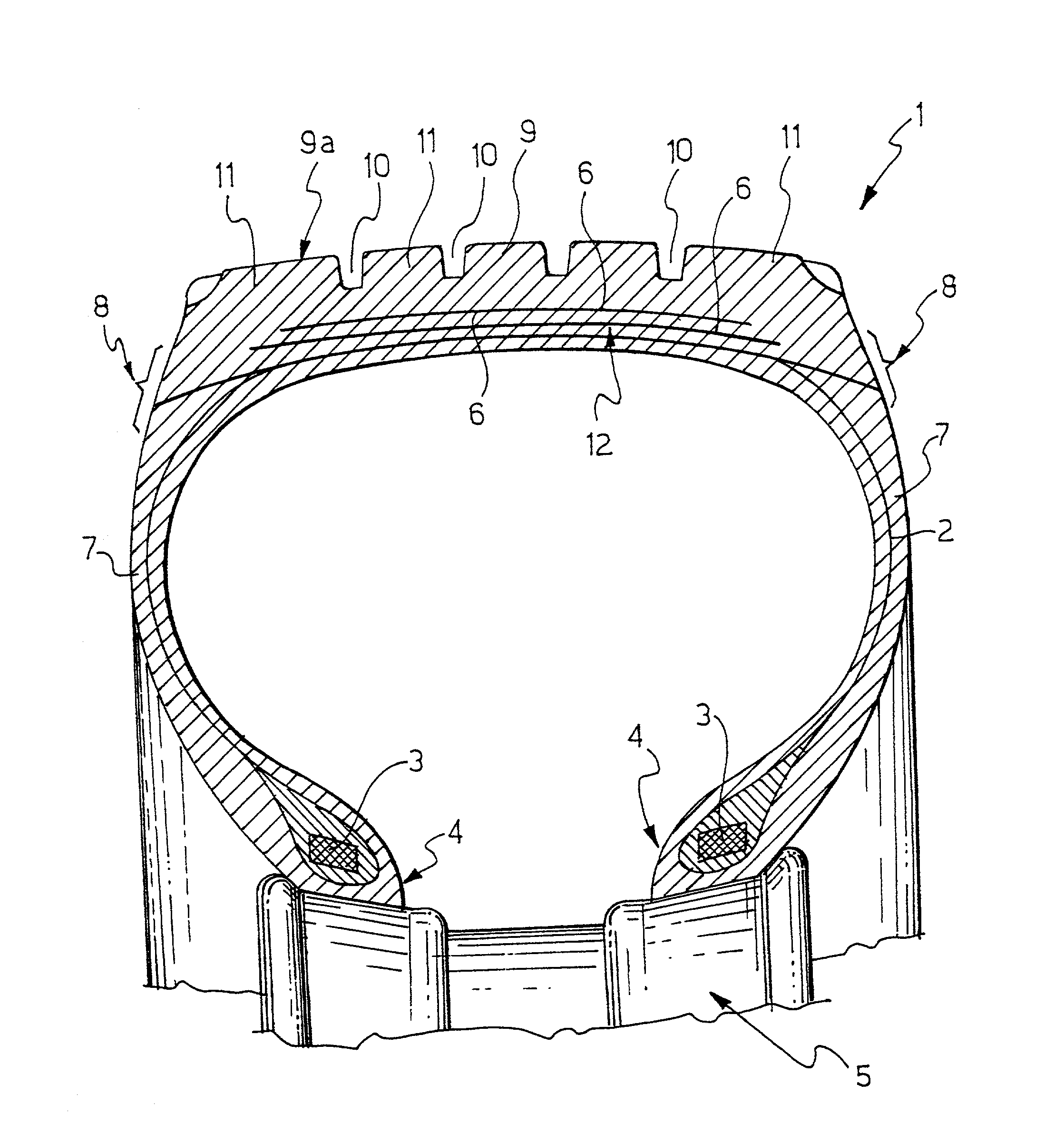

Low rolling resistance tire for vehicles

InactiveUS20020143096A1Reduce mixing actionLarge specific surface areaOther chemical processesSpecial tyresRolling resistanceProject area

A low rolling resistance tire (1) for vehicles is described which comprises a belt structure (12) coaxially extending around a carcass structure (2) and a tread (9), coaxially extending around the belt structure (12) and being externally provided with a rolling surface (9a) designed to get in touch with the ground, the tread (9) comprising a vulcanized polymer base including at least a first silica-based reinforcing filler, the tire being characterized in that the first silica-based reinforcing filler has: an average projected area of the aggregates as measured before incorporation into the polymer base lower than 20,000 nm2; a dispersion index in the vulcanized polymer base of the tread (9) not lower than 97%; and a projected area of the aggregates after incorporation into the polymer base comprised between 8500 and 18000 nm2. Advantageously, said tire has mechanical properties improved or at least comparable with respect to those of the known tires for the same type of use.

Owner:PIRELLI TYRE SPA

Disposition structure of heat exchanger in motorcycle

InactiveUS7377350B2Improve cooling efficiencyImprove cooling effectLiquid coolingCylinder headsCrankcaseHeat sink

A disposition structure of a heat exchanger (oil cooler) in a motorcycle mounted in the central part in front of the upper part of the crankcase of an internal combustion engine E mounted on the motorcycle. When viewed from the front of the motorcycle, the oil cooler is located between the front forks. The oil cooler is disposed so that the fin surface of the cooling fins of the heat exchanger are perpendicular or substantially perpendicular to an air flow that goes between the front forks and above the front wheel. In the disposition structure so configured, cooling efficiency of the heat exchanger is improved.

Owner:HONDA MOTOR CO LTD

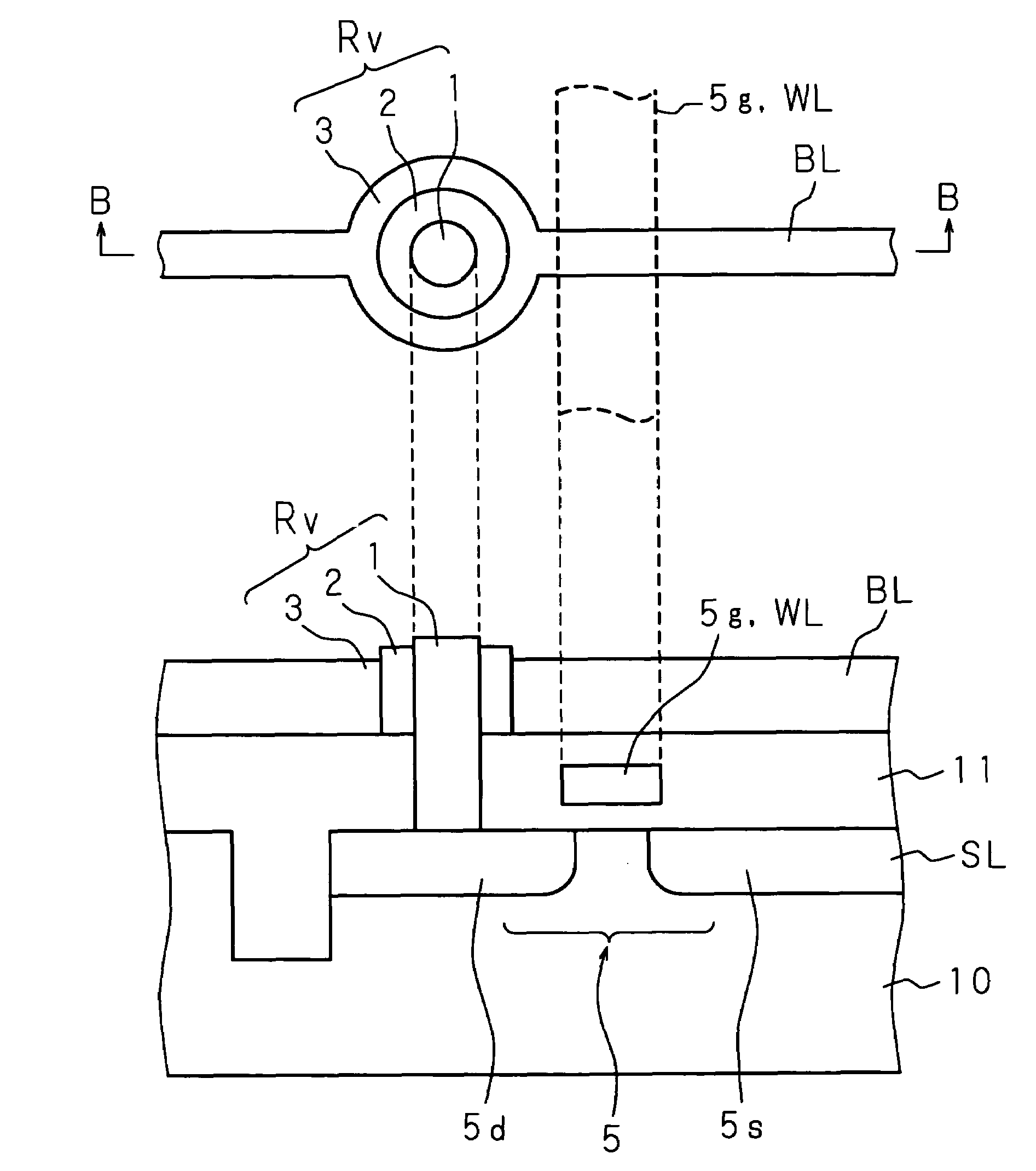

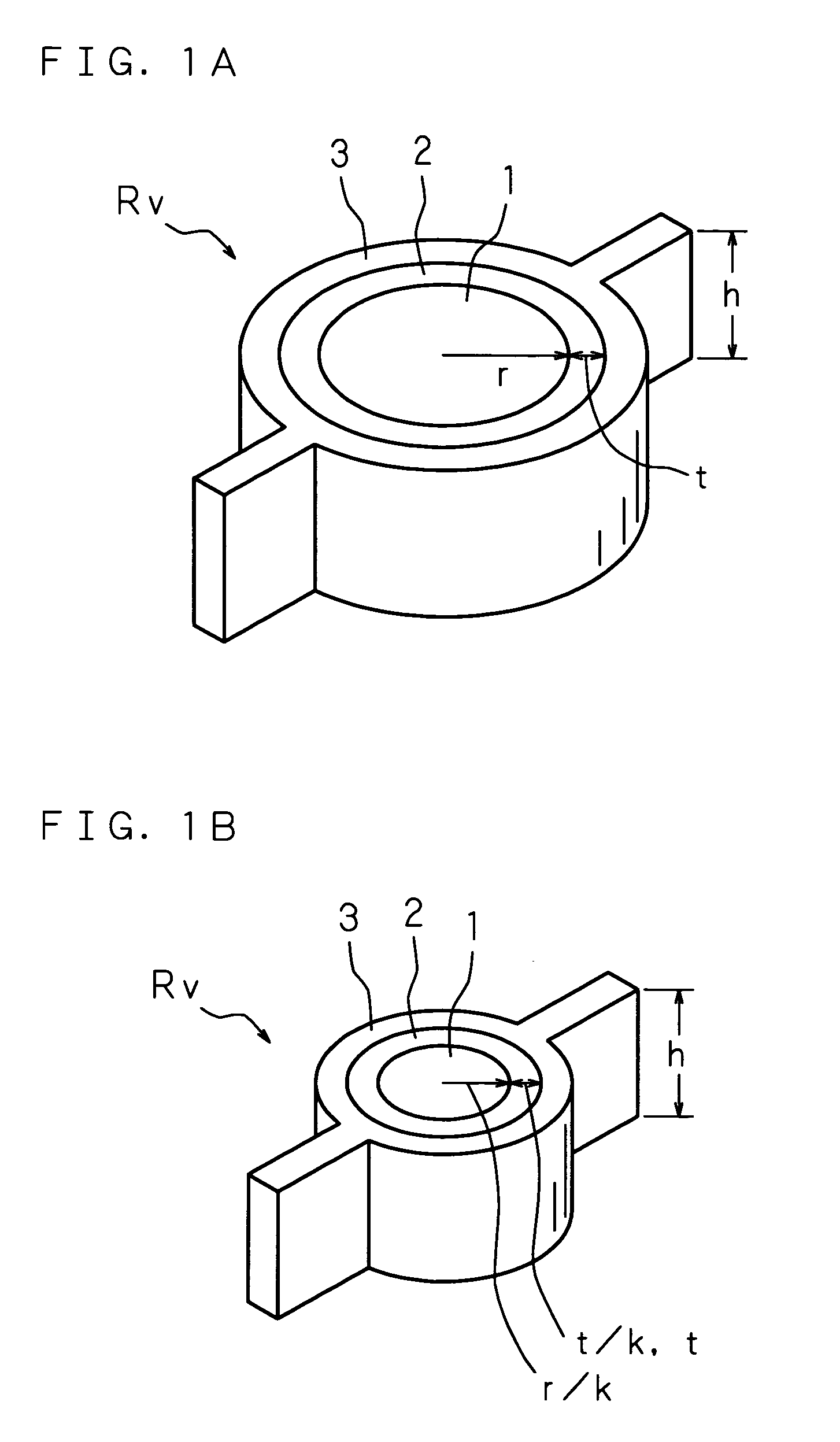

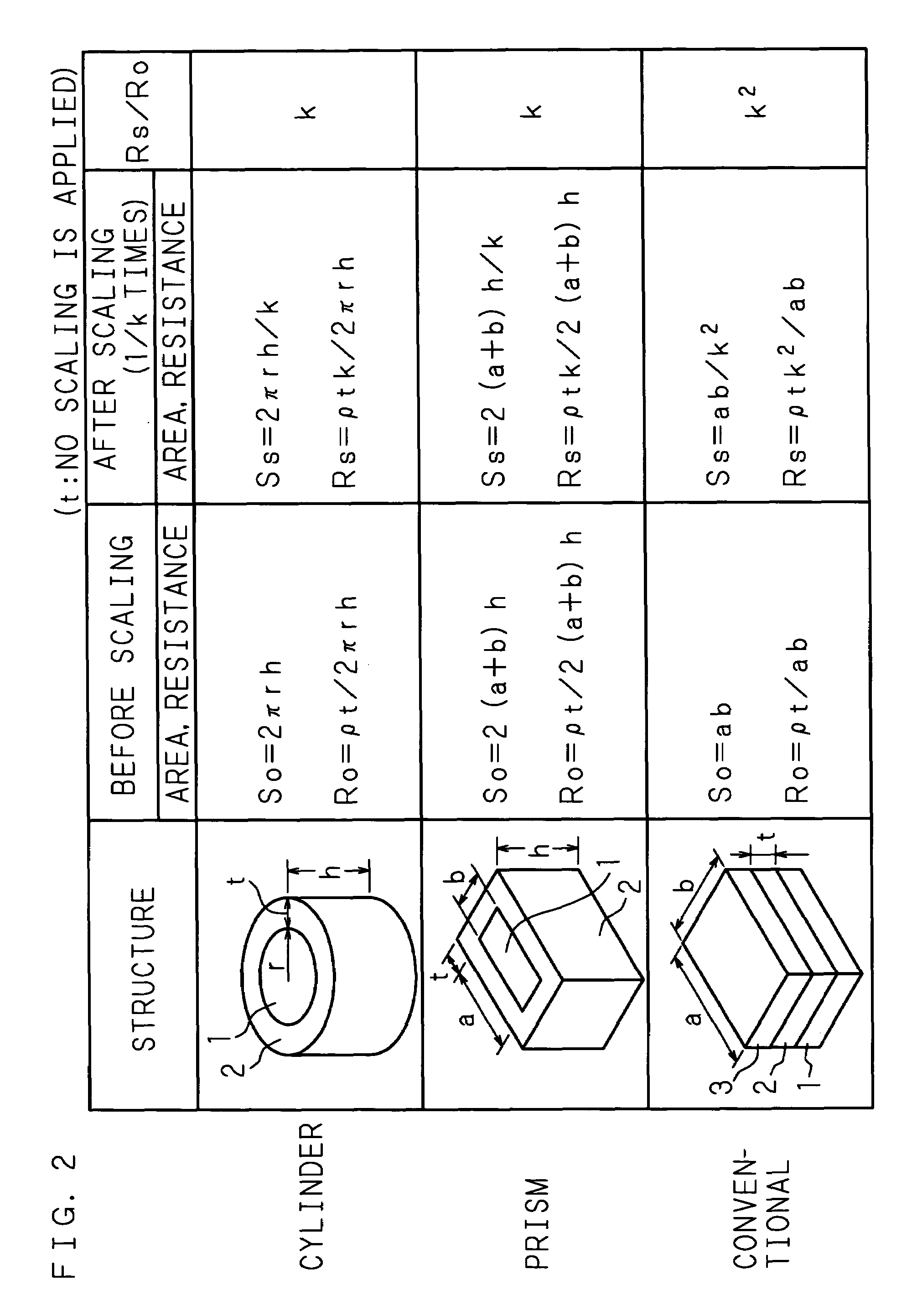

Nonvolatile variable resistor, memory device, and scaling method of nonvolatile variable resistor

ActiveUS7397688B2Reduce resistanceReduce decreaseSolid-state devicesRead-only memoriesElectrical resistance and conductanceProject area

Provided are a nonvolatile variable resistor with a structure capable of suppressing an increase in resistance in a case where scaling is applied to reduce a projected area on a plane, a memory device using the nonvolatile variable resistor, and a scaling method of a nonvolatile variable resistor. A first electrode and a second electrode formed on a substrate face each other in a direction of a surface of the substrate. The first electrode is used as an inner electrode, a nonvolatile variable resistance body is formed on an outer surface of the first electrode and the second electrode is formed as an outer electrode on an outer surface of the nonvolatile variable resistance body.

Owner:SAMSUNG ELECTRONICS CO LTD

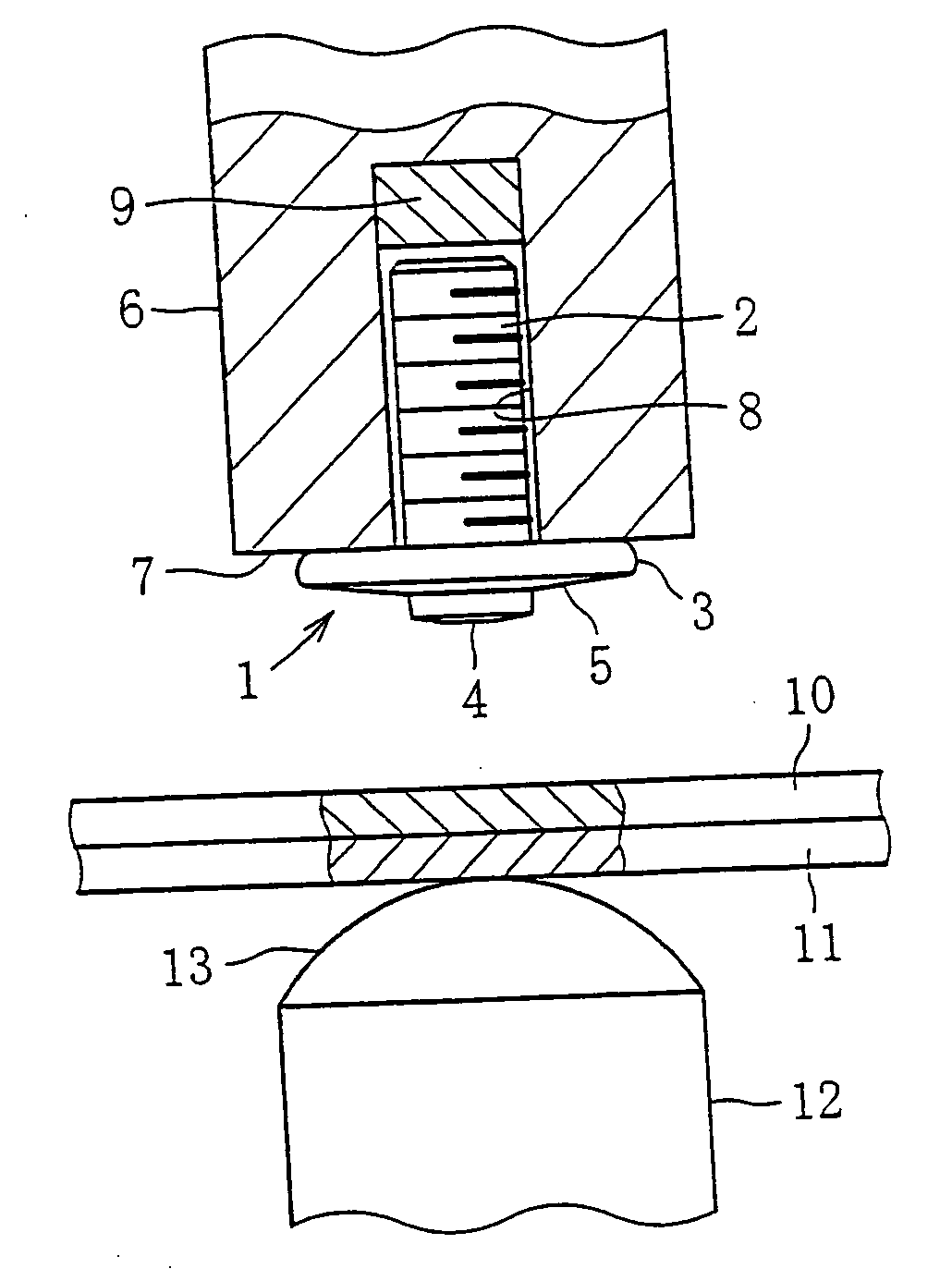

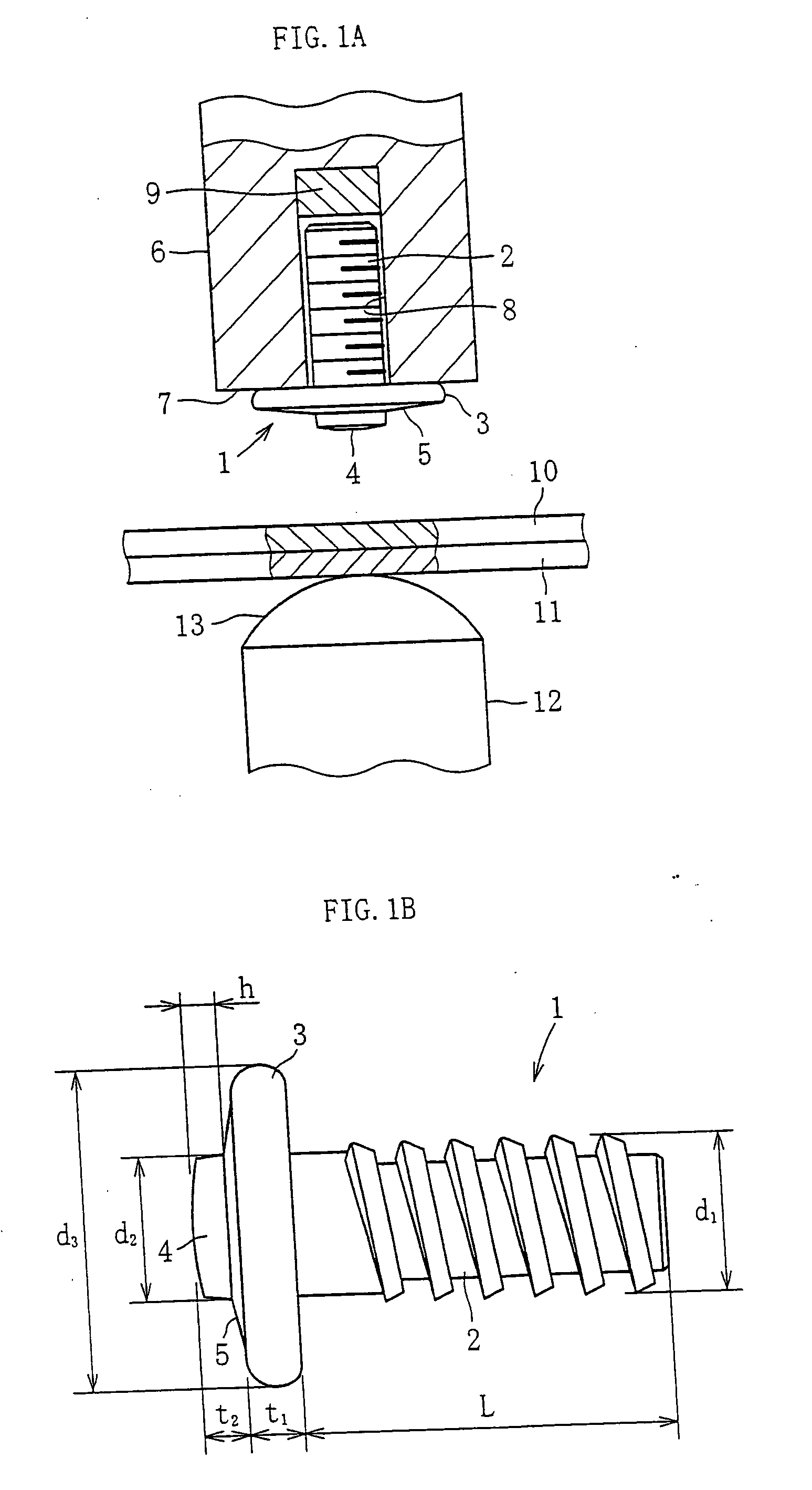

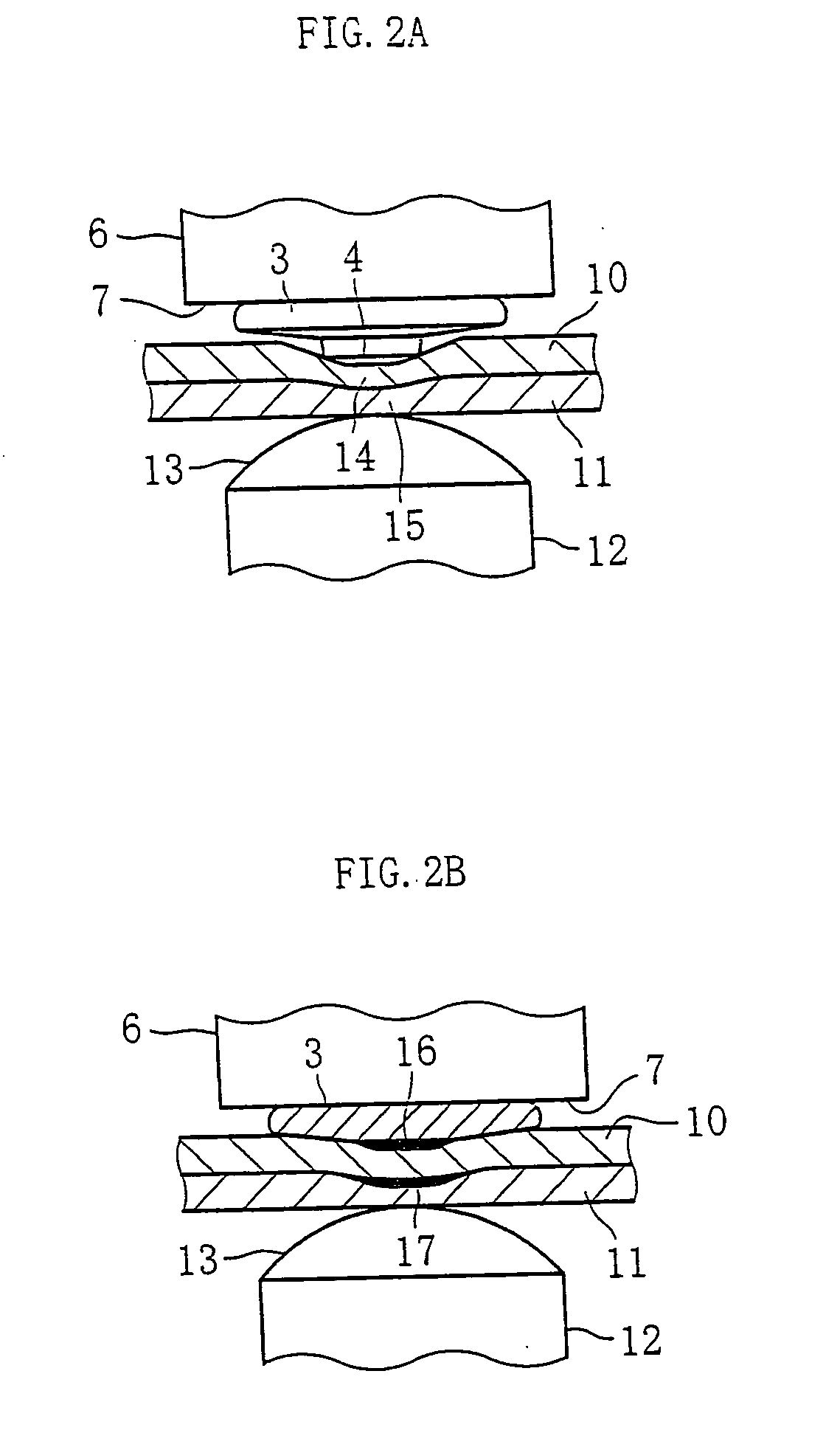

Method of welding shaft-like part on plurally piled steel plates

InactiveUS20060070981A1Reduce thicknessReliable startElectrode featuresElectrode supporting devicesFlangeSteel plates

A method of welding a shaft-like part to a stack of steel sheets is disclosed in which the saft-like part is composed of a stem portion (2), a flange (3) integrally formed on the stem portion (2), and a projection (4) disposed at the center of the flange (3) and smaller in diameter than the flange (3). The method comprises the steps of inserting the shaft-like part (1) at its stem portion (2) into a holding hole (8) in a movable electrode (6), stacking a plurality of steel sheets (10 and 11) so as to keep the stack in contact with a fixed electrode (12), advancing the movable electrode (6) to press the projection (4) against the steel sheet (10) so as to reduce the thickness of at least the steel sheet (10) pressed by the projection (4), and passing a welding current between the two electrodes (6 and 12) so that the welding of the shaft-like part (1) and the integration of a plurality of steel sheets (10 and 11) are reliably achieved.

Owner:KUBUSHIKI KAISHA AOYAMA

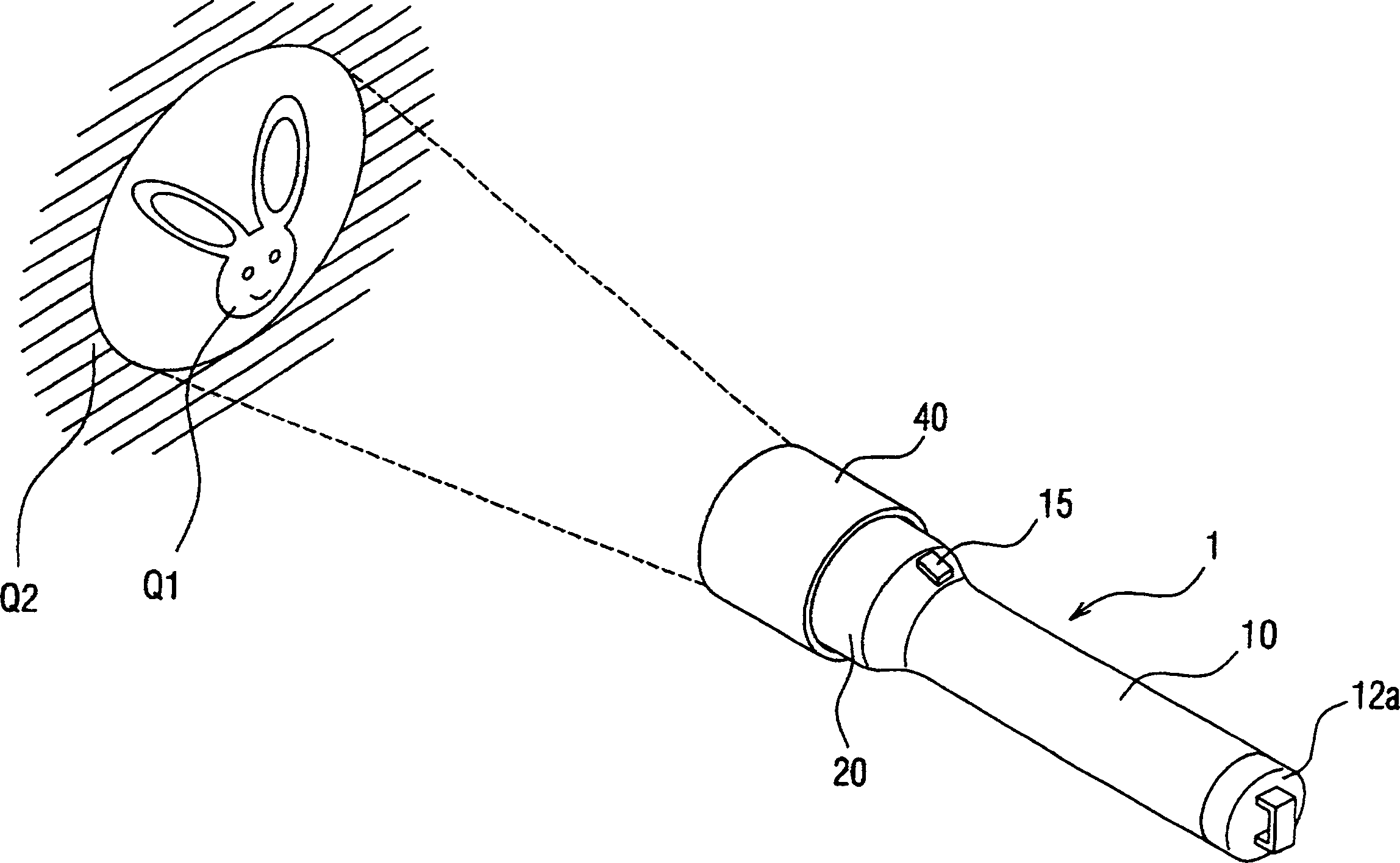

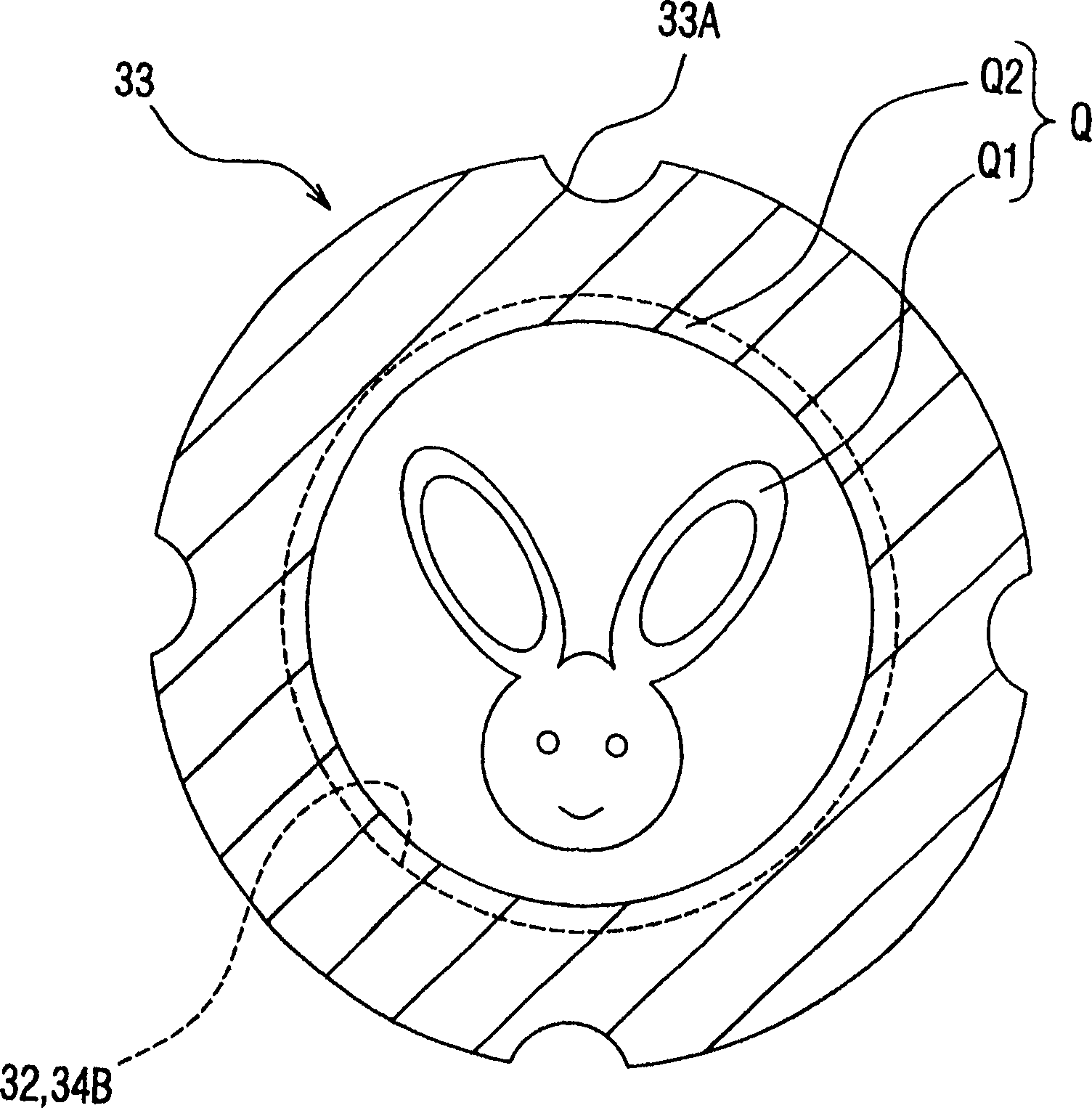

Projective lighting device and film component used therein

InactiveCN1389762AReduce projected areaSharp silhouetteProjectorsOptical elementsSurface patternEffect light

The present invention relates to a projection type lighting device and film component used therein. The device can easily form a clear silhouette having a distinct contour at the projected position by a lighted electric bulb. The present invention has a mask part 30, wherein a pattern with a inlay edge shape is composed by said Q2 part formed around inner surface patterns Q1 of the light transmission openings 32, simultantly the non-perspective display part Q2 is located at the inside circumference of the light transmission openings 32, and a film pressing means P is used to maintain a film member 33 at a light shielding plate 31 to the central part of the light transmission openings 32. The mask part 30 is detachably mounted to the front part of a hood casing part 20 formed on the lighting device main body 10. A cylindrical lens holder is mounted to the hood casing part 20 in a state of covering the whole part of the mask part. The film member 33 can be projected on a subscribed projection position by the light irradiated from the backside of the lighting device main body.

Owner:HALU

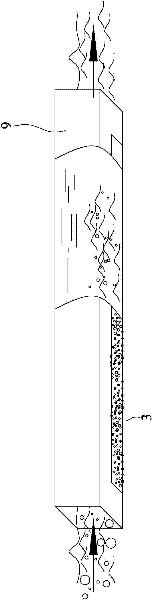

Sawtooth-shaped aircraft weapon cabin noise suppression device

ActiveCN108706092AImprove controlReduce aerodynamic dragFuselagesAir-flow influencersAerodynamic dragFlight vehicle

The invention discloses a sawtooth-shaped aircraft weapon cabin noise suppression device. The device comprises a spoiler arranged on the front edge surface of a weapon cabin. The spoiler comprises a bottom face base plate and a spoiler sheet connected with the bottom face base plate. The spoiler sheet can rotate around the bottom face base plate through connecting points. The included angle between the rotating spoiler sheet and the bottom face base plate is any angle between 0 degree and 90 degrees. The upper surface and the lower surface of a crossbeam of the spoiler sheet are each of a sawtooth-shaped structure, and an incoming flow control effect can be greatly improved. The projected area of the device in the incoming flow normal direction is reduced through a gap in the bottom of thespoiler sheet, so that the aerodynamic drag of an aircraft is reduced. The inclination angle between the spoiler sheet and the base plate is changed, so that it is guaranteed that the height of the spoiler sheet is equivalent to the boundary layer thickness, and the best noise reduction effect on a downstream cabin can be achieved under different speed conditions.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

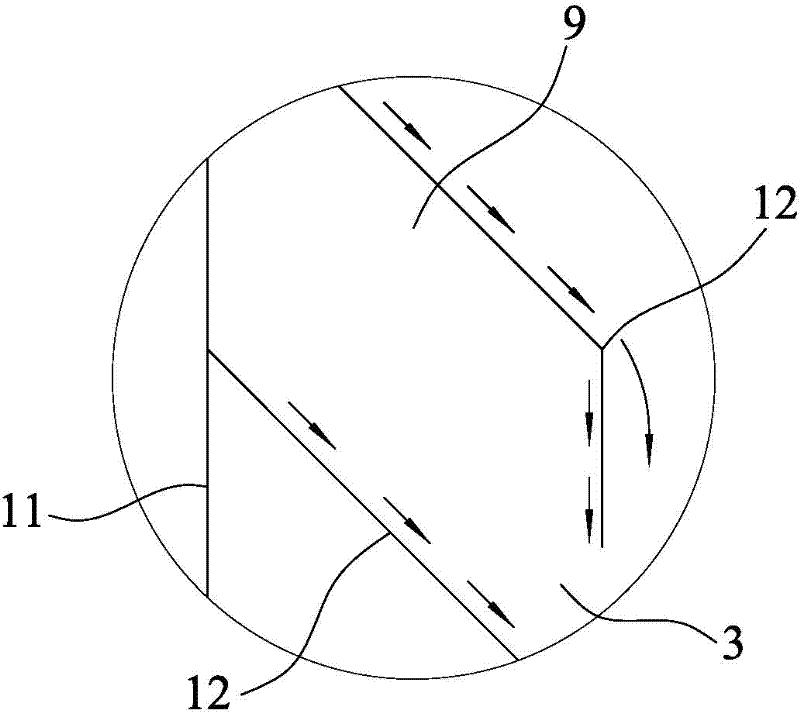

Multi-layer lattice precipitation separating device for V-shaped pipe

InactiveCN102553309AImprove sedimentation efficiencySimplify construction and construction difficultySedimentation settling tanksEngineeringPrecipitation

The invention discloses a multi-layer lattice precipitation separating device for a V-shaped pipe. The device is characterized by comprising multiple groups of parallel vertical plates, each group of parallel vertical plates is formed by a left vertical plate and a right vertical plate, a plurality of oblique clapboards are arranged between the left and right vertical plates, the left and right vertical plates and two adjacent clapboards form a water passage with a parallelogram-shaped cross section, a mud discharge hole is formed above the intersected part of the right vertical plate and the clapboard, a mud discharge passage is arranged between each right vertical plate and clapboards in another group of adjacent parallel vertical plates, and two ends of the mud discharge passage are sealed to form a static liquid area. As the vertical plates are adopted in the invention, the precipitation efficiency is improved, and simultaneously the vertical plates are more convenient to construct.

Owner:厦门飞华环保有限公司

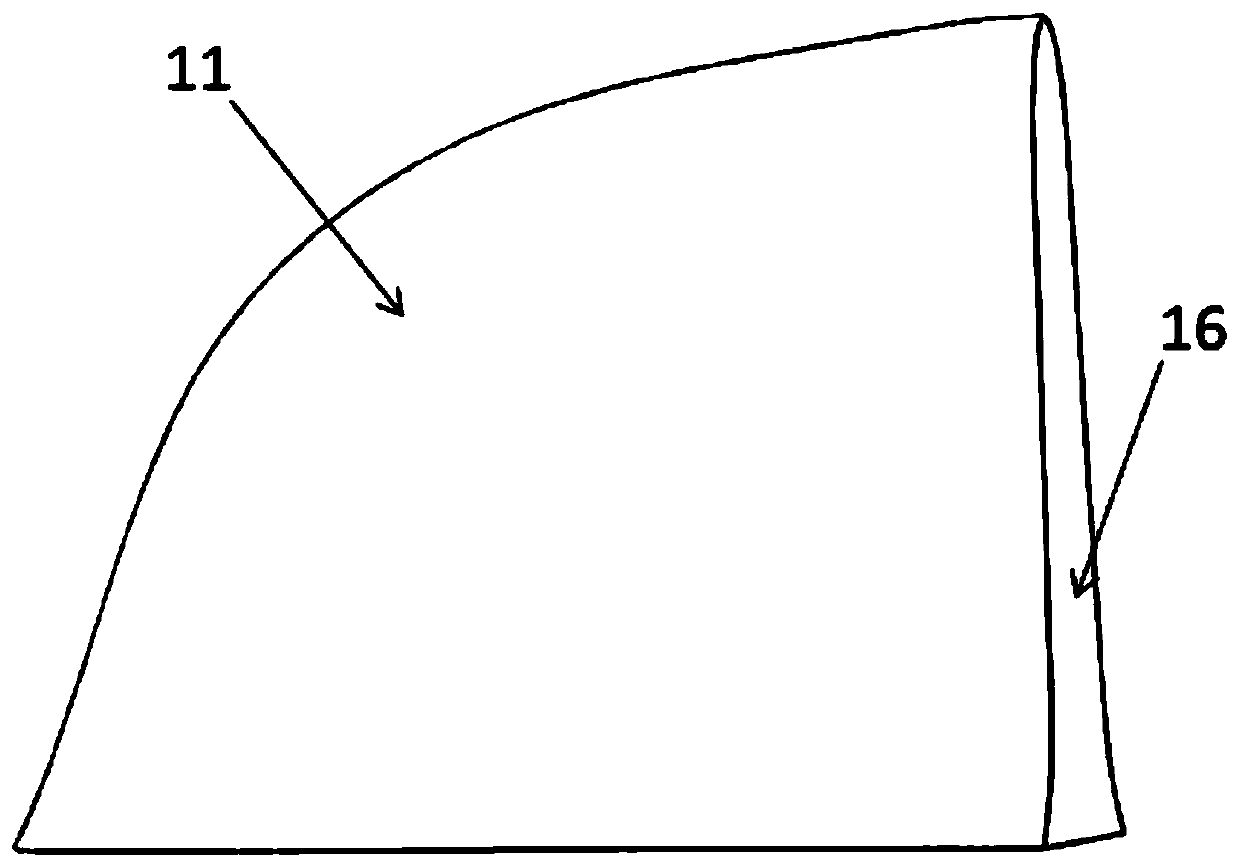

Novel vortex generator for wind turbine blade

InactiveCN110131096ALow flow resistanceReduce projected areaMachines/enginesEngine componentsLeading edgeHigh energy

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com