Multi-layer lattice precipitation separating device for V-shaped pipe

A technology of precipitation separation and vertical plate, applied in the direction of sedimentation tank, can solve the problems of reducing water flow area, reversible precipitation of suspended matter, unfavorable precipitation of suspended matter, etc., to achieve the effect of improving precipitation efficiency, simplifying construction and construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

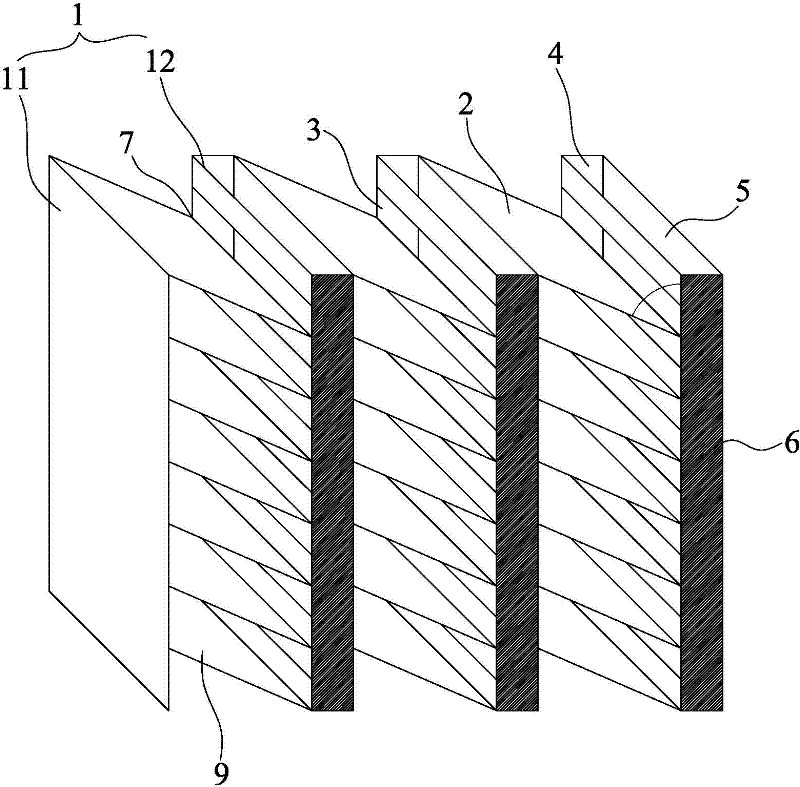

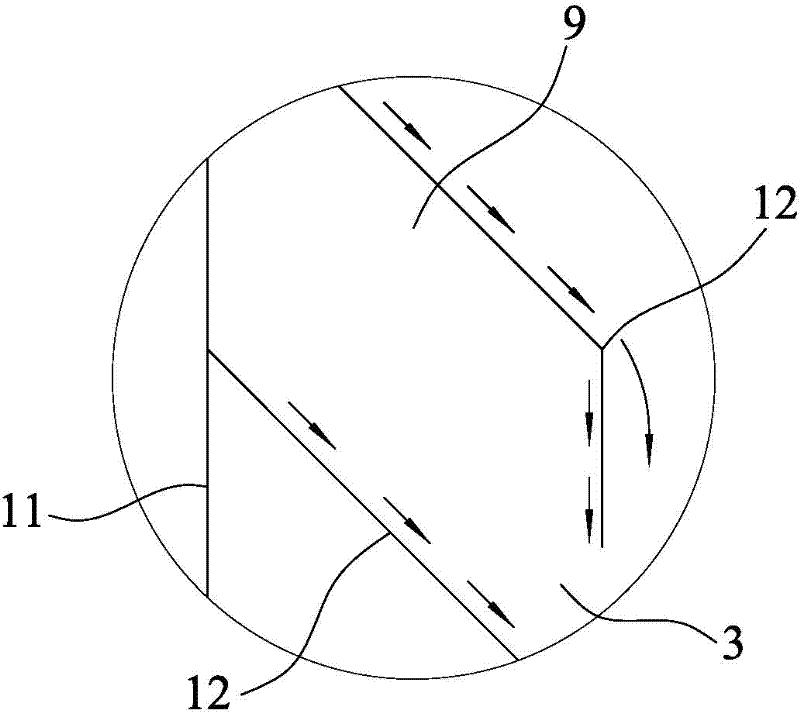

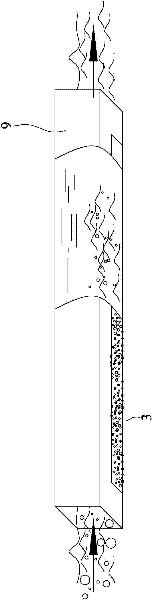

[0026] What the present invention discloses is a kind of V-shaped pipe multi-layer sedimentation separation device, such as Figure 2 to Figure 5 Shown is a preferred embodiment of the present invention. The V-shaped tube multi-layer sedimentation and separation device includes multiple groups of parallel vertical plates 1, each group of parallel vertical plates is composed of a left vertical plate 11 and a right vertical plate 12, and the angle between the left and right vertical plates 11, 12 and the horizontal plane 90 °, between the left and right vertical plates 11,12 is provided with a plurality of partitions 2, the partitions 2 are separated between the left and right vertical plates 11,12 several water flow channels 9 with a parallelogram in cross-section, the right vertical There is a mud discharge port 3 above the intersect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com