Method and device for treating oil and gas field fracturing flow-back fluid by adopting ceramic membrane

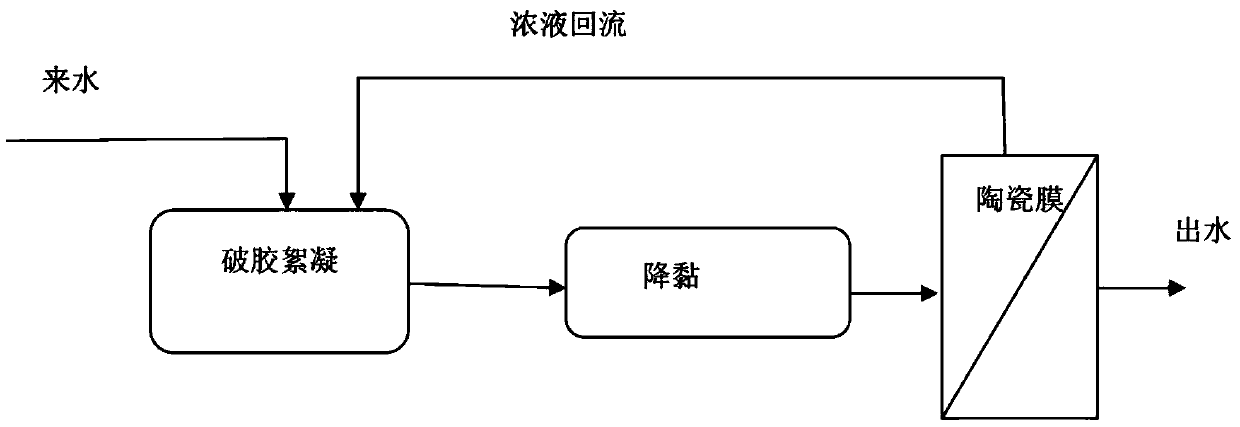

A fracturing flowback fluid and ceramic membrane technology, applied in the field of water treatment, can solve the problems of high treatment cost, large oxidant consumption, oxidation time process, etc., and achieve the effects of improving sedimentation efficiency, improving purification effect, and improving effluent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

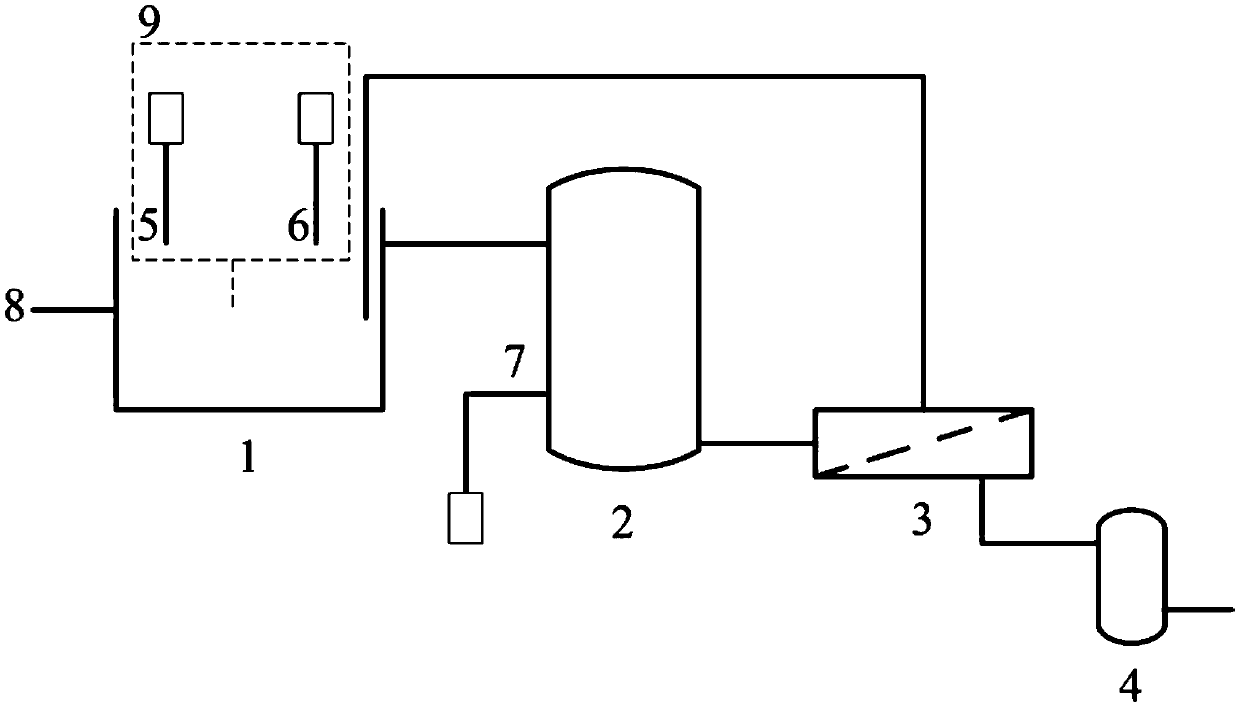

Method used

Image

Examples

Embodiment 1

[0049] Step 1: Carry out gel breaking and flocculation sedimentation on the fracturing flowback fluid; 2 S 2 o 8 / FeCl 2 / CaO compound formula, where Na 2 S 2 o 8 and FeCl 2 The concentration of CaO is 132mg / l and 258mg / l respectively, the dosage of CaO depends on the pH of incoming water; the reaction time is 30min.

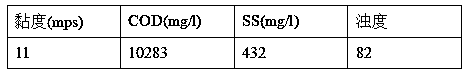

[0050] Step 2: Viscosity reduction treatment is performed on the effluent after gel breaking and flocculation, where O 3 The dosage is 112mg / l, and the reaction time is 15min. The properties of the processed feed liquid are as follows:

[0051]

[0052] Step 3: Use membrane equipment to treat sewage. The ceramic membrane used has an average pore size of 50nm, operates at different membrane surface flow rates, the transmembrane pressure difference is 0.3MPa, and the sewage temperature is 35°C. The sewage is cross-flow filtered in the membrane equipment, and the permeate is directly used for reinjection. The circulating fluid that has not passed throug...

Embodiment 2

[0072] In this example, the effect of using this process on the treatment of fracturing flowback fluid under different membrane pore diameter conditions is investigated.

[0073] Step 1: Carry out gel breaking and flocculation sedimentation on the fracturing flowback fluid; 4 ) 2 S 2 o 8 / FeCl 2 / Na 2 CO 3 The compound formula, where (NH 4 ) 2 S 2 o 8 and FeCl 2 The concentrations are 166mg / l and 289mg / l respectively, Na 2 CO 3 The dosage depends on the pH of the incoming water; the reaction time is 40 minutes.

[0074] Step 2: Viscosity reduction treatment is performed on the effluent after gel breaking and flocculation, where O 3 The dosage is 136mg / l, and the reaction time is 20min. The properties of the treated feed liquid are as follows:

[0075]

[0076] Step 3: Membrane equipment is used to treat sewage. Ceramic membrane filters with different average pore sizes are used. The membrane surface flow rate is 4m / s, the transmembrane pressure difference is ...

Embodiment 3

[0079] In this example, the effect of using this process on treating fracturing flowback fluid under different ceramic membrane filtration pressure conditions is investigated.

[0080] Step 1: Carry out gel breaking and flocculation sedimentation on the fracturing flowback fluid; 2 S 2 o 8 / Polyferric Sulfate / Na 2 CO 3 The compound formula, where K 2 S 2 o 8 and polyferric sulfate concentrations were 200mg / l and 300mg / l, Na 2 CO 3 The dosage depends on the pH of the incoming water; the reaction time is 40 minutes.

[0081] Step 2: Viscosity reduction treatment is performed on the effluent after gel breaking and flocculation, where O 3 The dosage is 350mg / l, and the reaction time is 30min. The properties of the treated feed liquid are as follows:

[0082]

[0083] Step 3: Use membrane equipment to treat sewage, using a ceramic membrane filter with an average pore size of 50nm, with a membrane surface flow rate of 3m / s, and filter under different transmembrane pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com