Patents

Literature

53results about How to "Compensation for degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

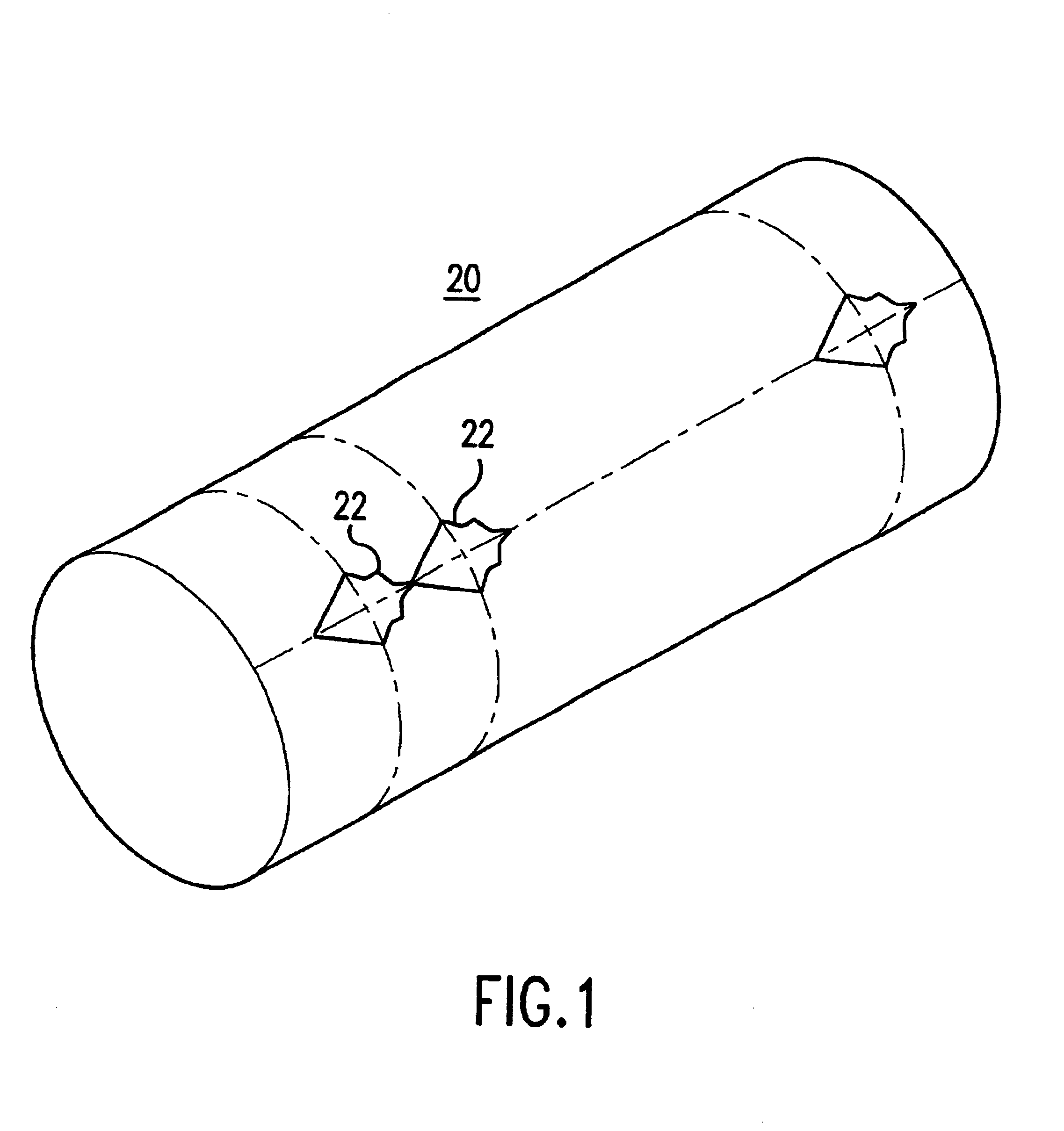

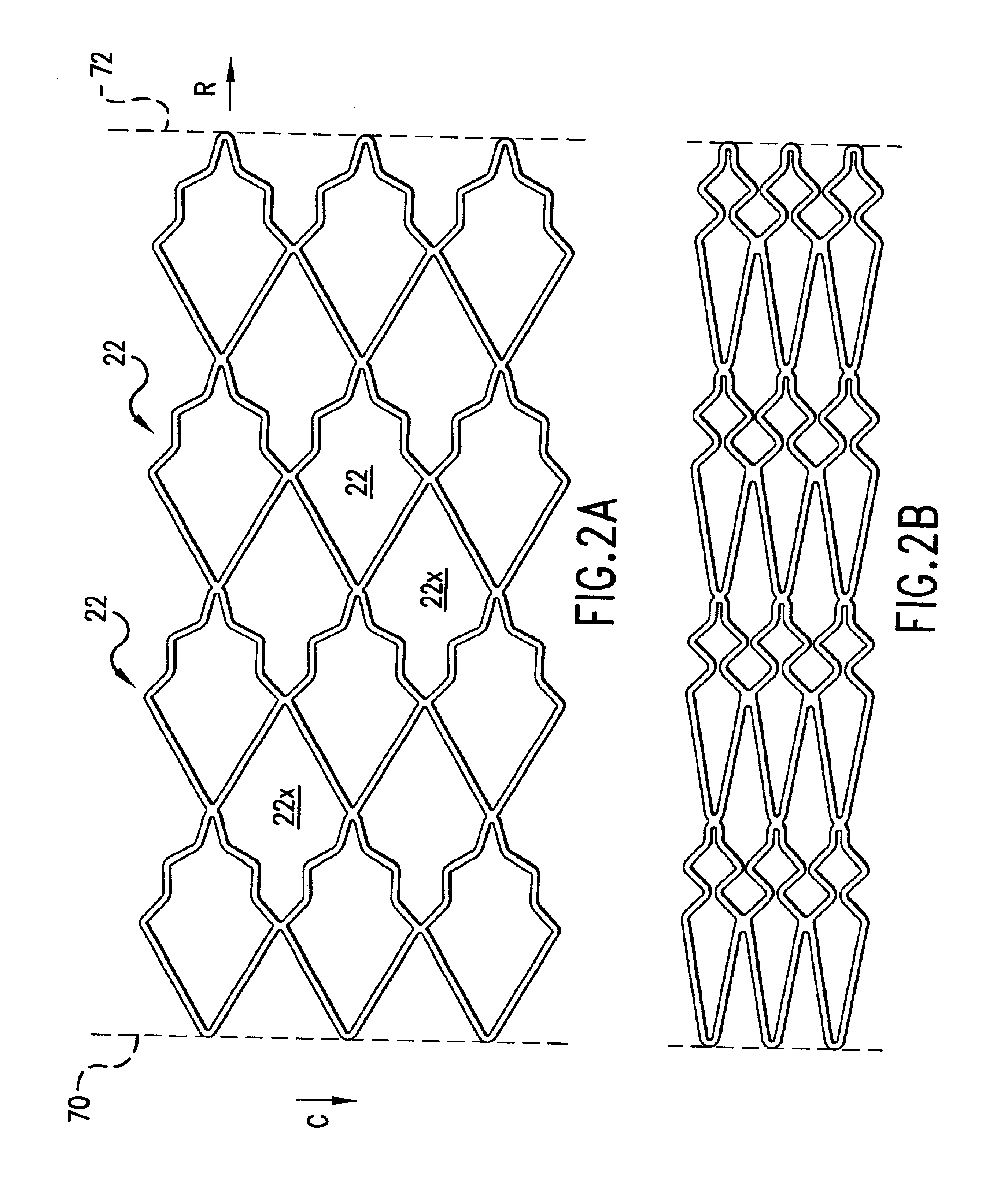

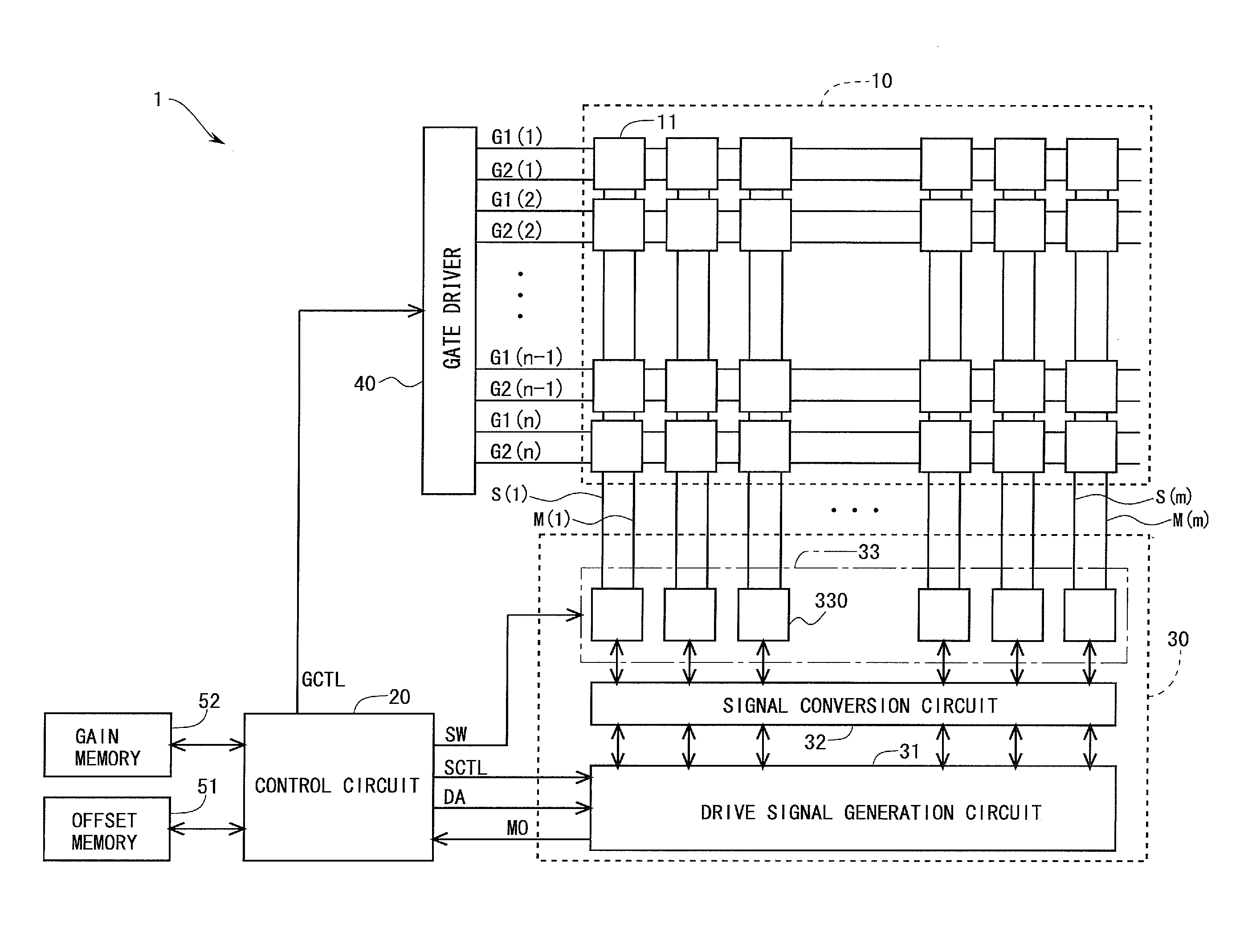

Display device and method for driving same

ActiveUS20150379940A1Keep for a long timeAvoid insufficient lengthSolid-state devicesCathode-ray tube indicatorsAcquired characteristicSignal correction

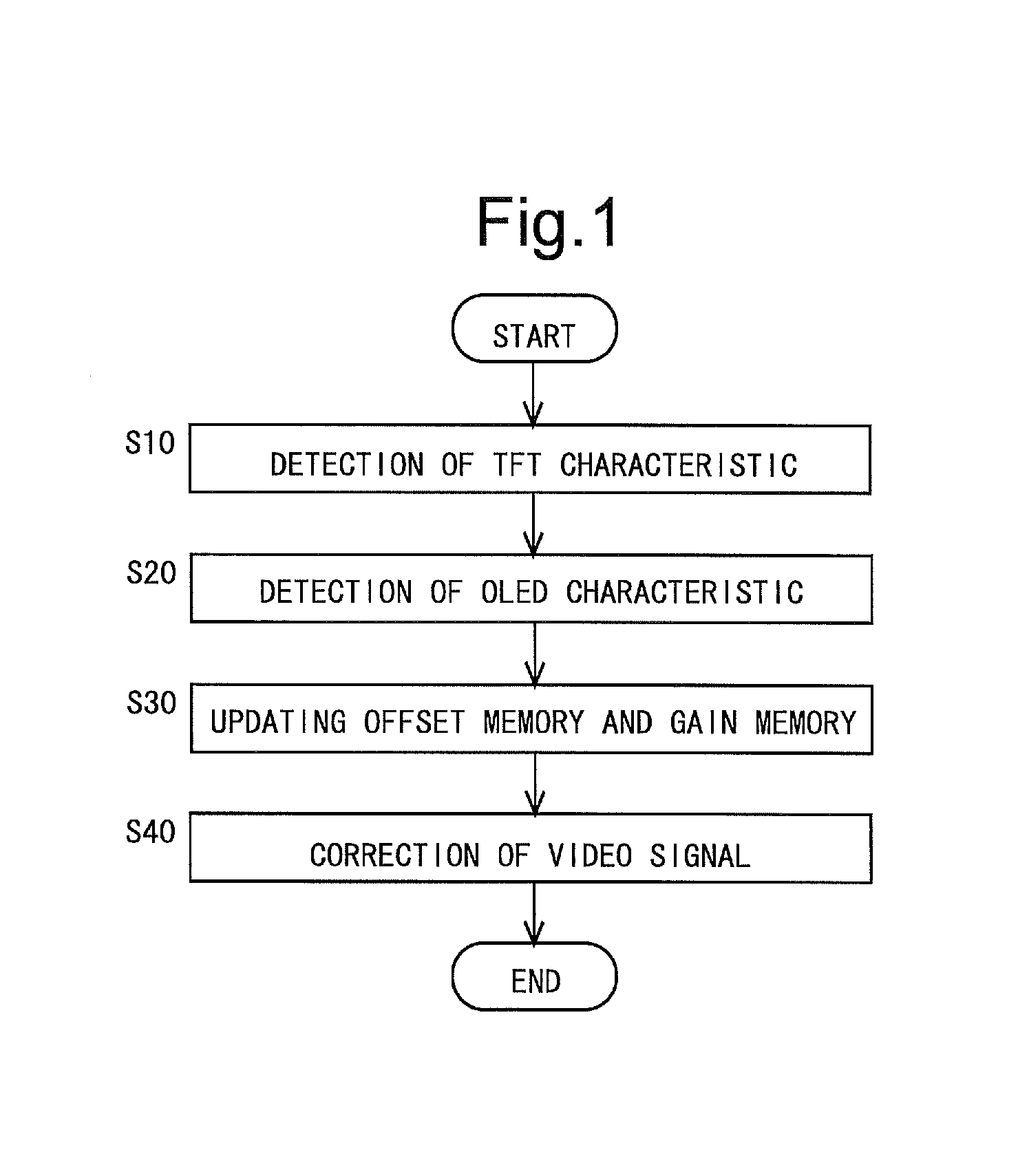

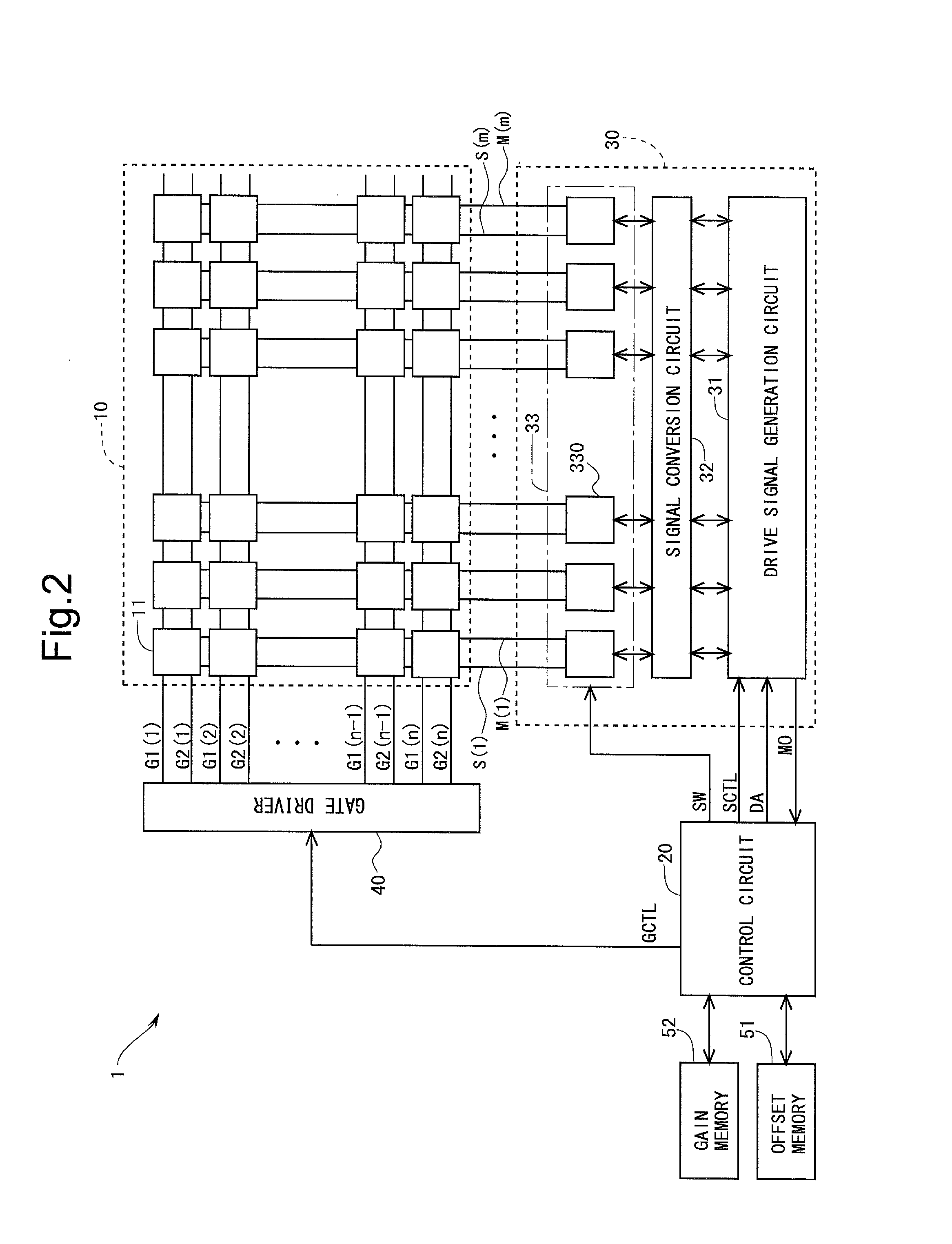

Provided is a driving method whereby it is possible to simultaneously compensate for both degradation of a drive transistor and degradation of a light-emitting element without causing special light emission at the time of detecting characteristics in a display device. In a display device which includes a pixel circuit including an electro-optic element and a drive transistor, a driving method includes: a first characteristic detection step for detecting a characteristic of the drive transistor; a second characteristic detection step for detecting a characteristic of the electro-optic element; a correction data storage step for storing characteristic data obtained based on detection results in the first and second characteristic detection steps as correction data; and a video signal correction step for correcting the video signal based on the correction data. The second characteristic detection step is performed in a light emission period.

Owner:SHARP KK

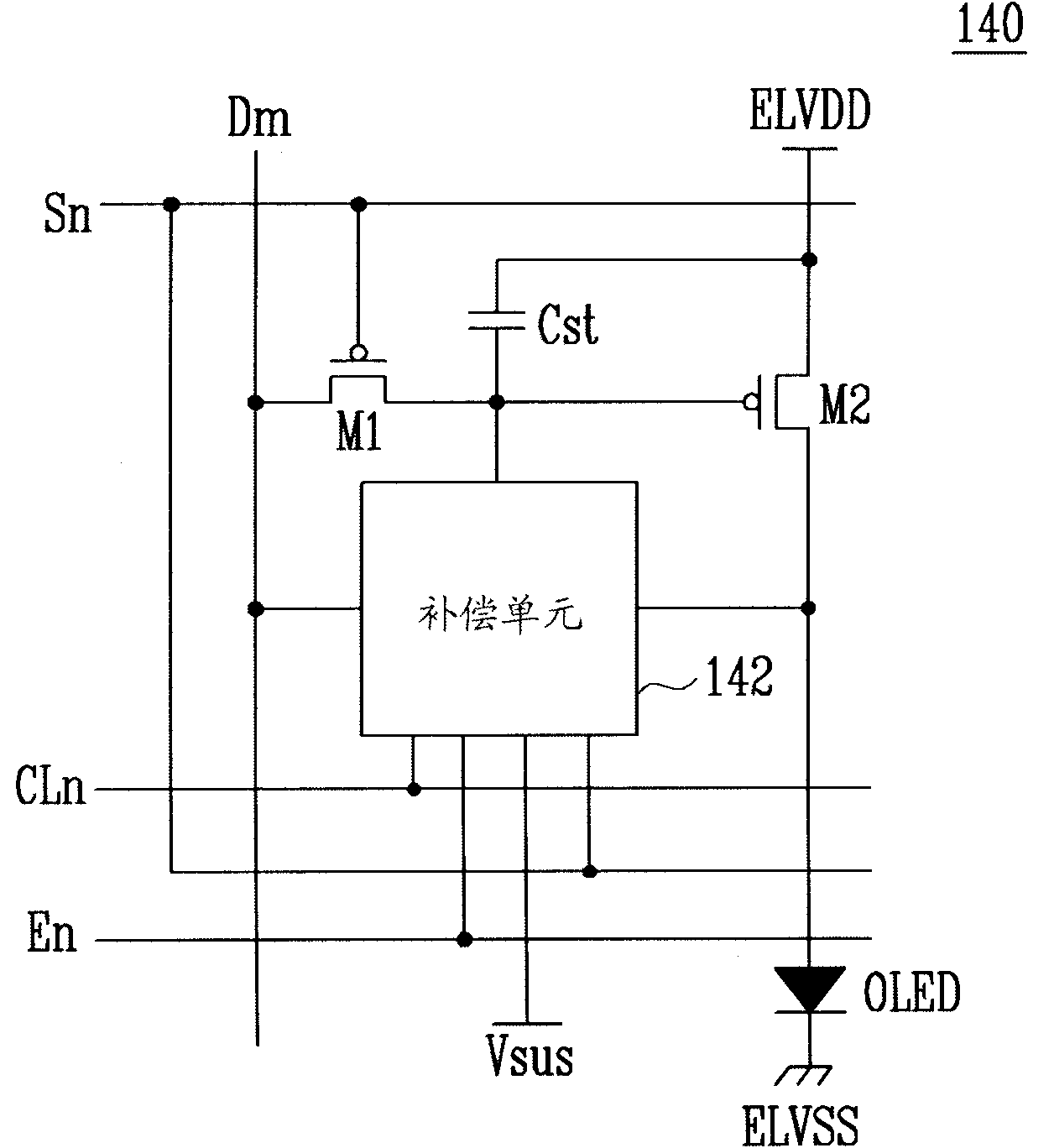

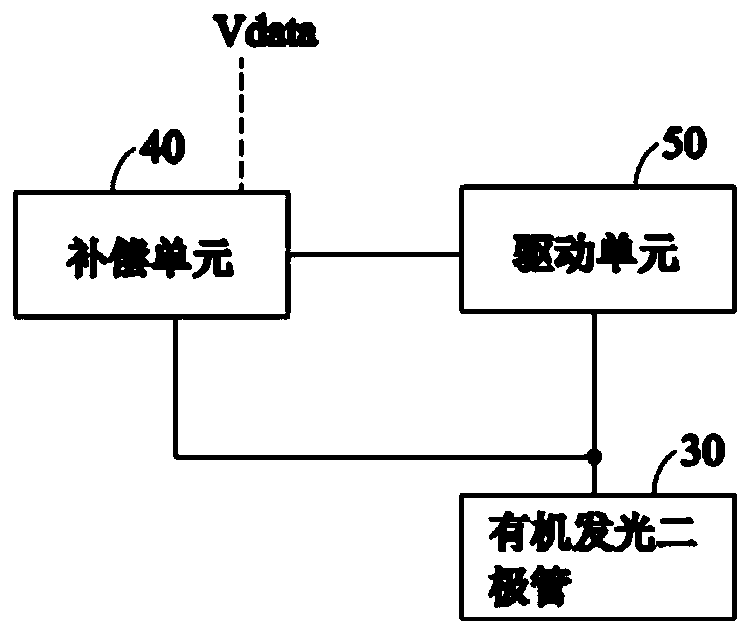

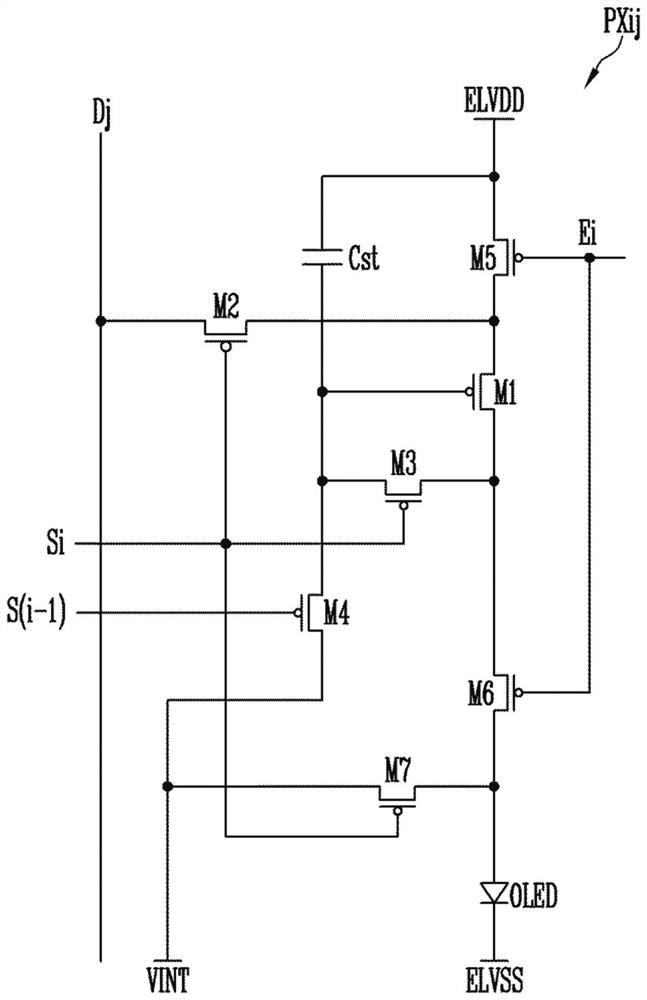

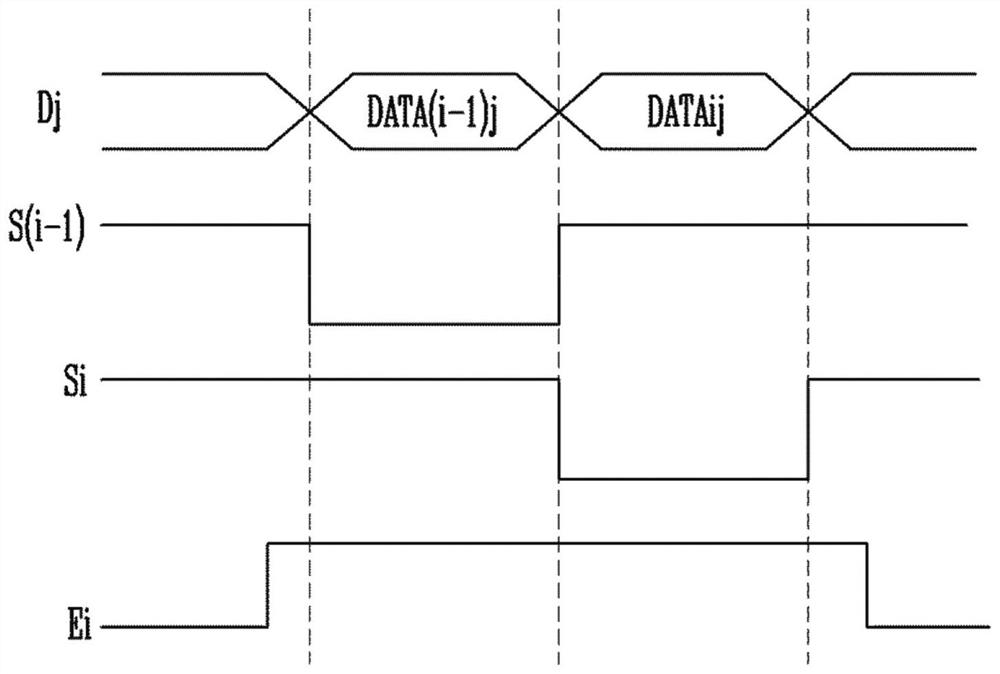

Pixel and organic light emitting display device using the same

InactiveCN101859536ACompensation for degradationUniform brightnessStatic indicating devicesSolid-state devicesDisplay deviceEngineering

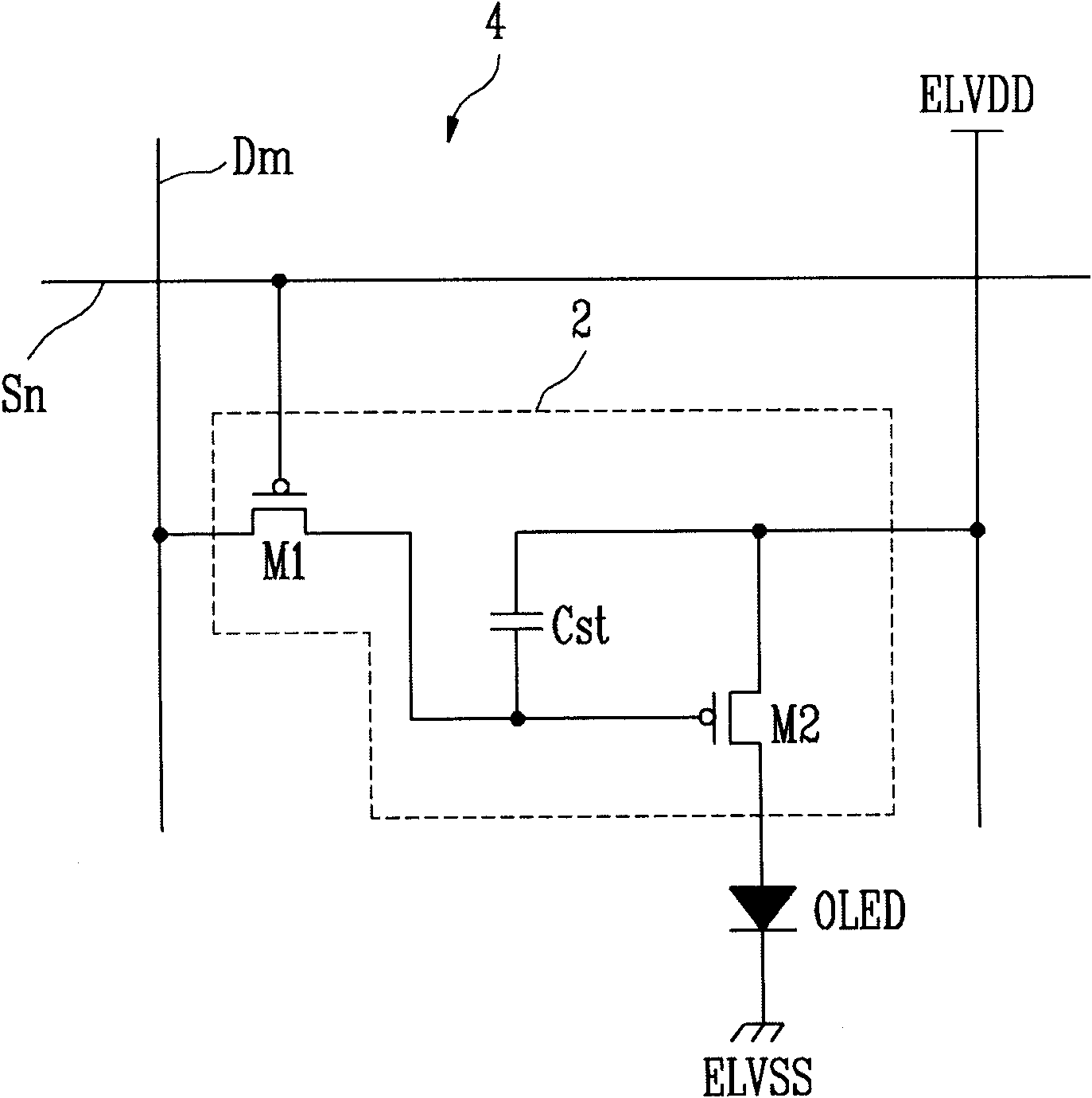

The invention provides a pixel and organic light emitting display device using the same. A display device displays an image having a substantially uniform brightness by compensating for variations of the threshold voltages of driving transistors and compensating for the deterioration of an organic light emitting diode. A pixel includes an organic light emitting diode, two transistors, a storage capacitor, and a compensation unit. A driving transistor supplies a current to an OLED corresponding to the voltage in the storage capacitor. The compensation unit controls a voltage of a gate electrode of the driving transistor corresponding to a deterioration of the organic light emitting diode, and couples one electrode of the driving transistor to the data line during a compensation period, during which a threshold voltage of the driving transistor is compensated.

Owner:SAMSUNG DISPLAY CO LTD

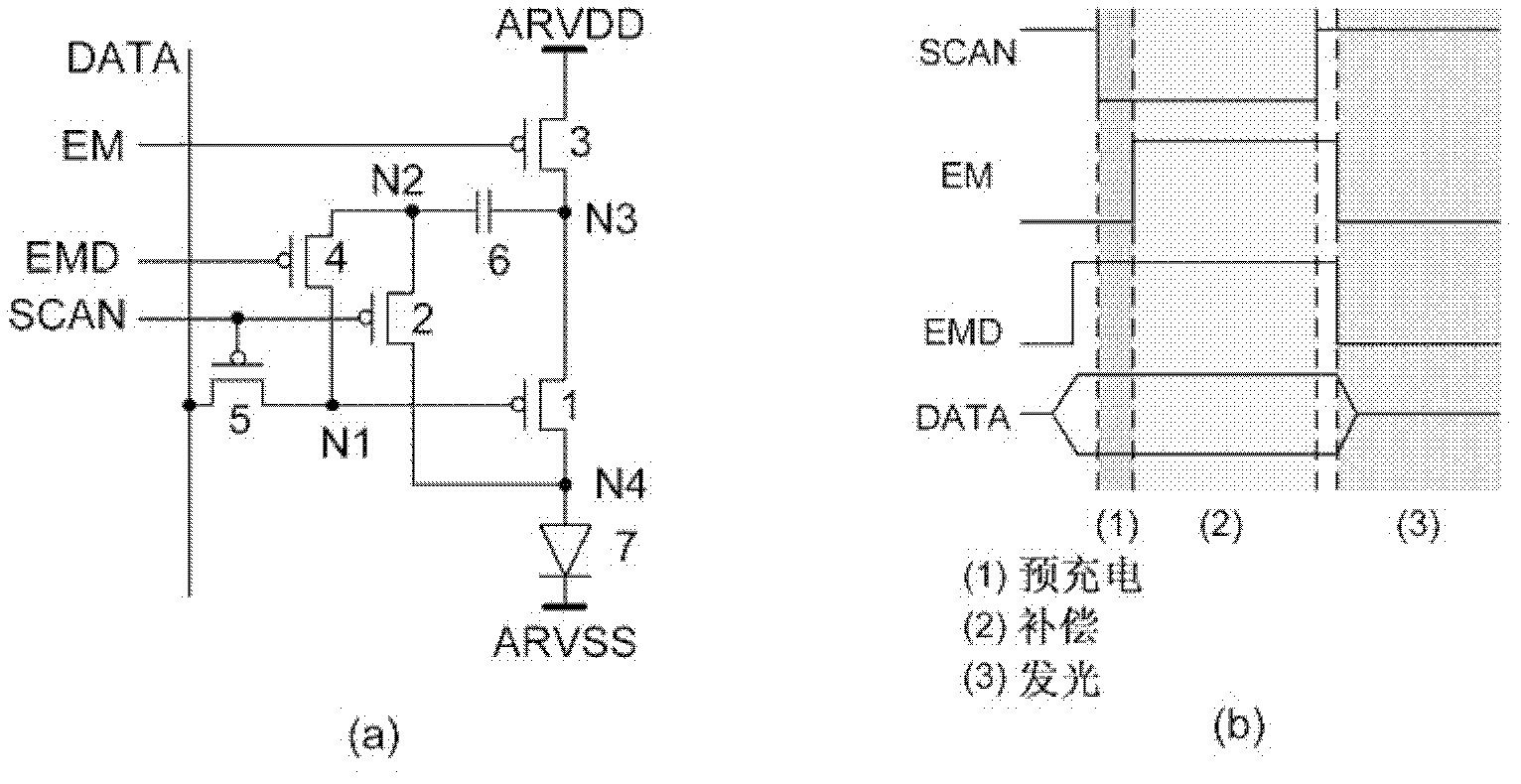

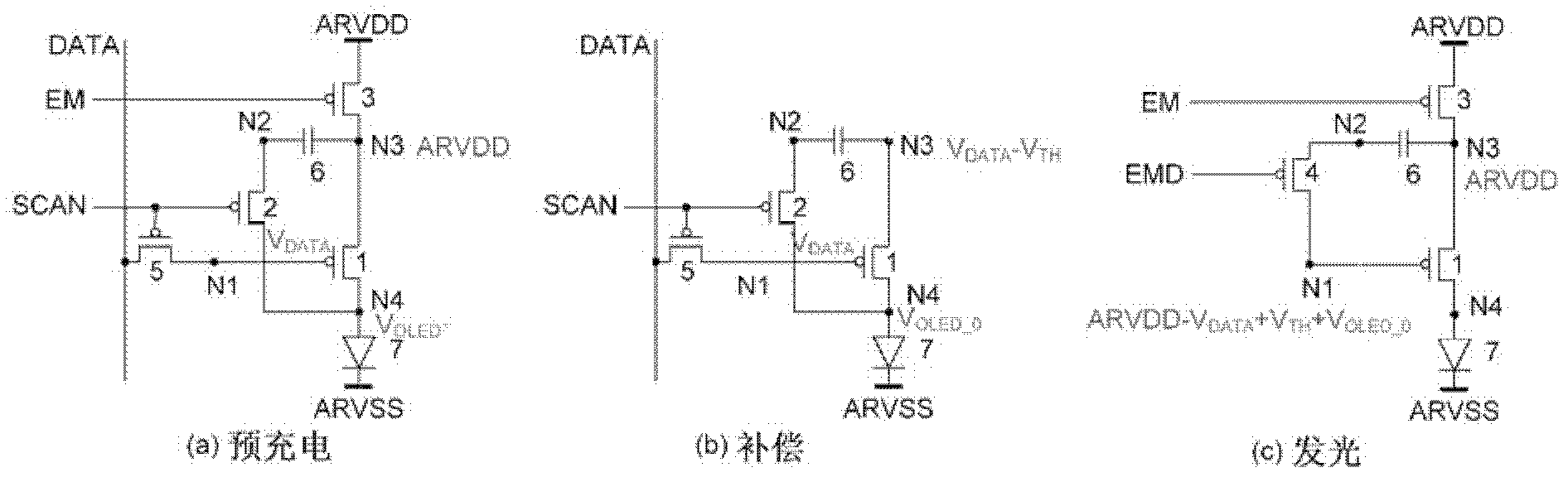

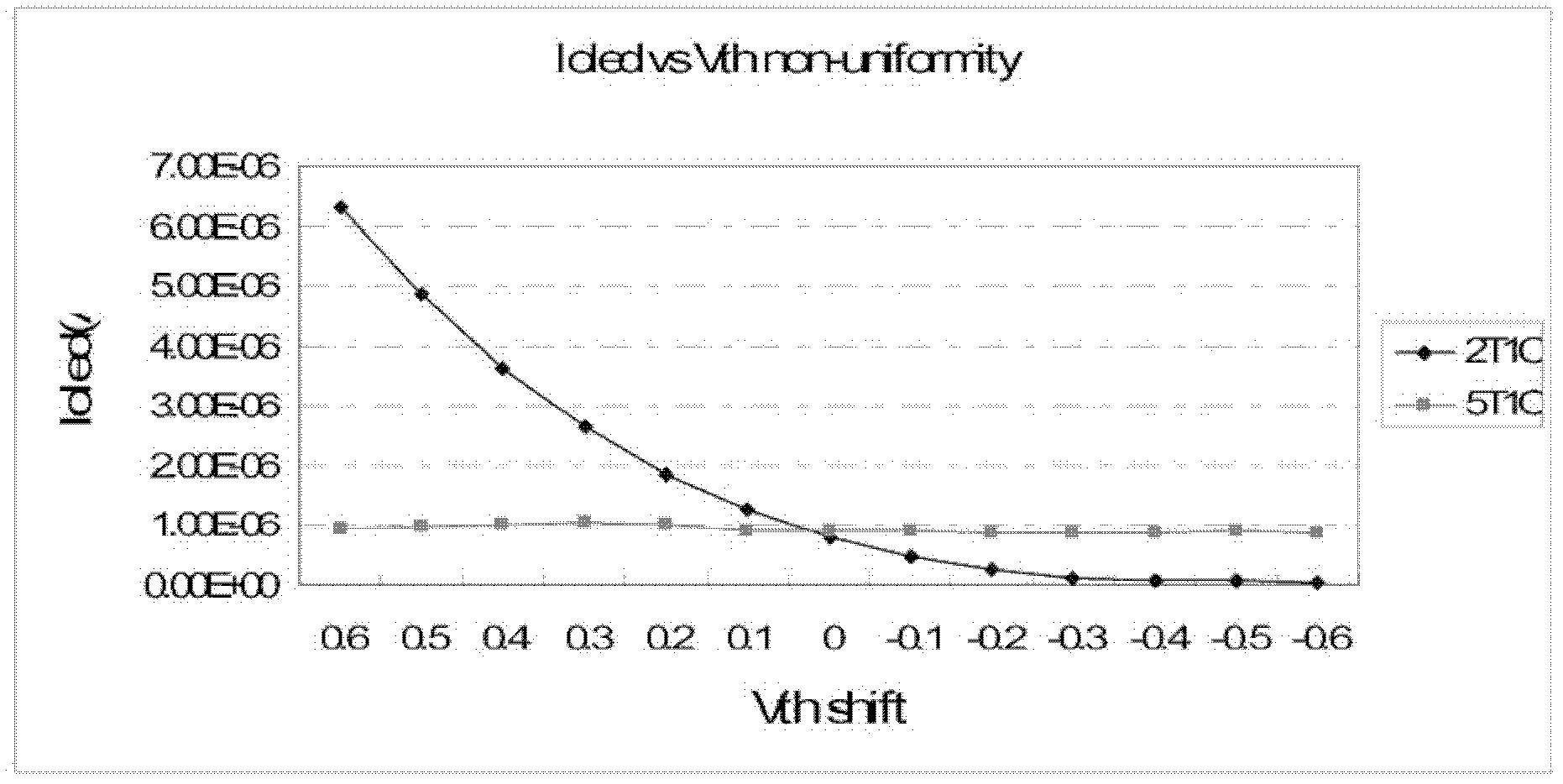

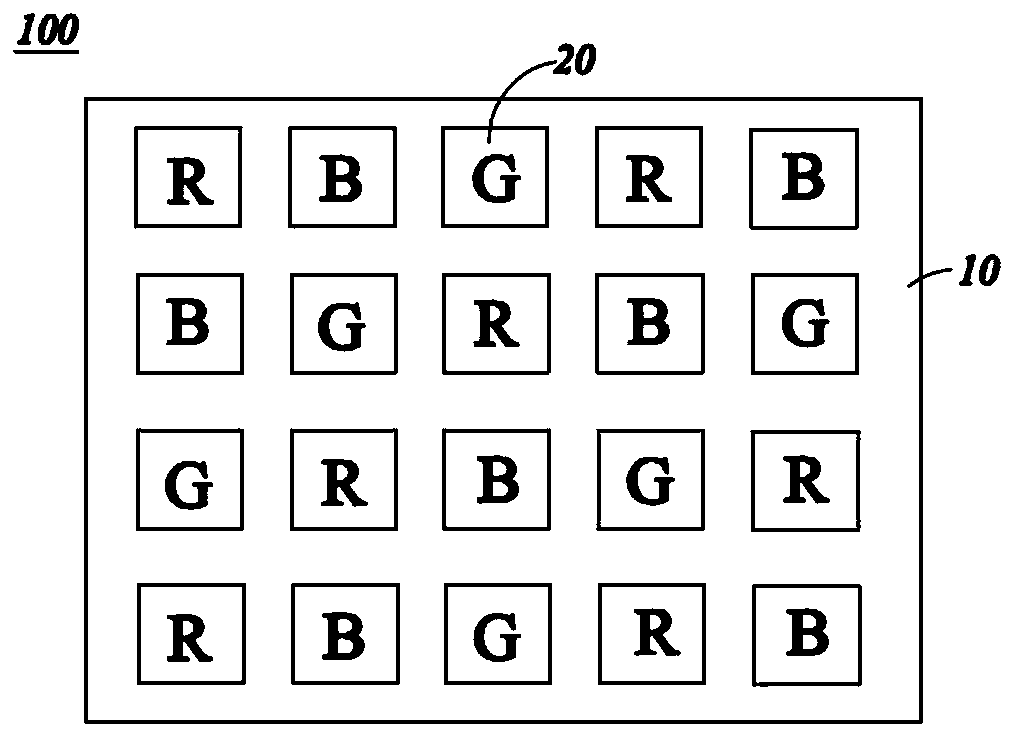

OLED (Organic Light Emitting Diode) pixel structure for compensating light emitting nonuniformity and driving method

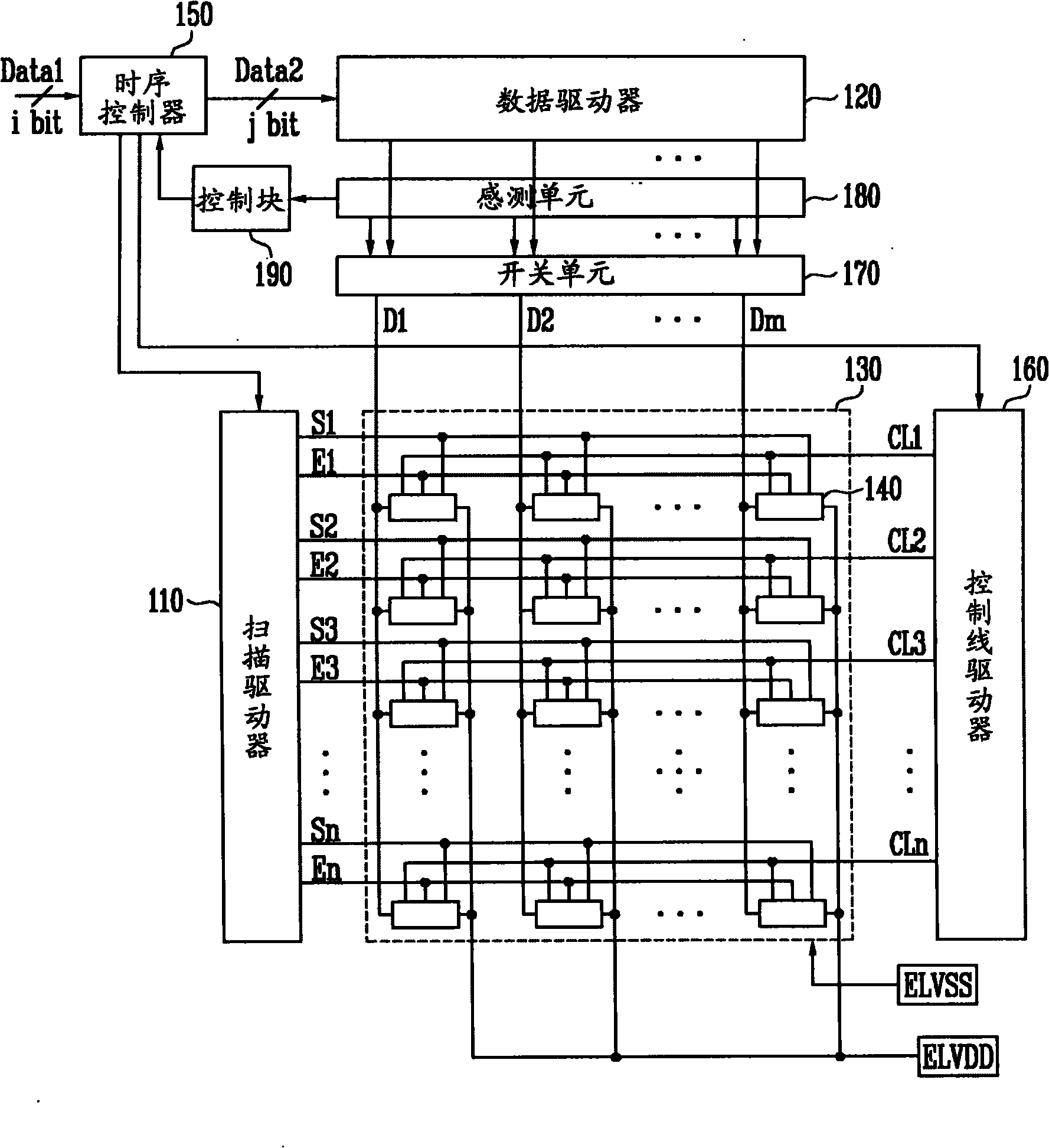

ActiveCN102651195ACompensation for degradationCompensation for threshold voltage non-uniformityStatic indicating devicesControl signalScan line

The invention provides an organic light emitting display pixel structure and a driving method thereof. The pixel structure comprises first to fifth thin film transistors, a capacitor and an OLED (Organic Light Emitting Diode) device, wherein the width to length ratio of the first thin film transistor is set to compensate the brightness loss caused by degradation of the OLED device. According to the pixel structure, the following steps are performed in the process of refreshing each frame image: in a precharging period, a scan line and a first control signal (EM) have low levels, and a second control signal (EMD) has a high level; in a compensating period, the scan line has a low level, and the first control signal (EM) and the second control signal (EMD) have high levels; and in a light emitting period, the scan line has a high level, and the first control signal (EM) and the second control signal (EMD) have low levels.

Owner:BOE TECH GRP CO LTD

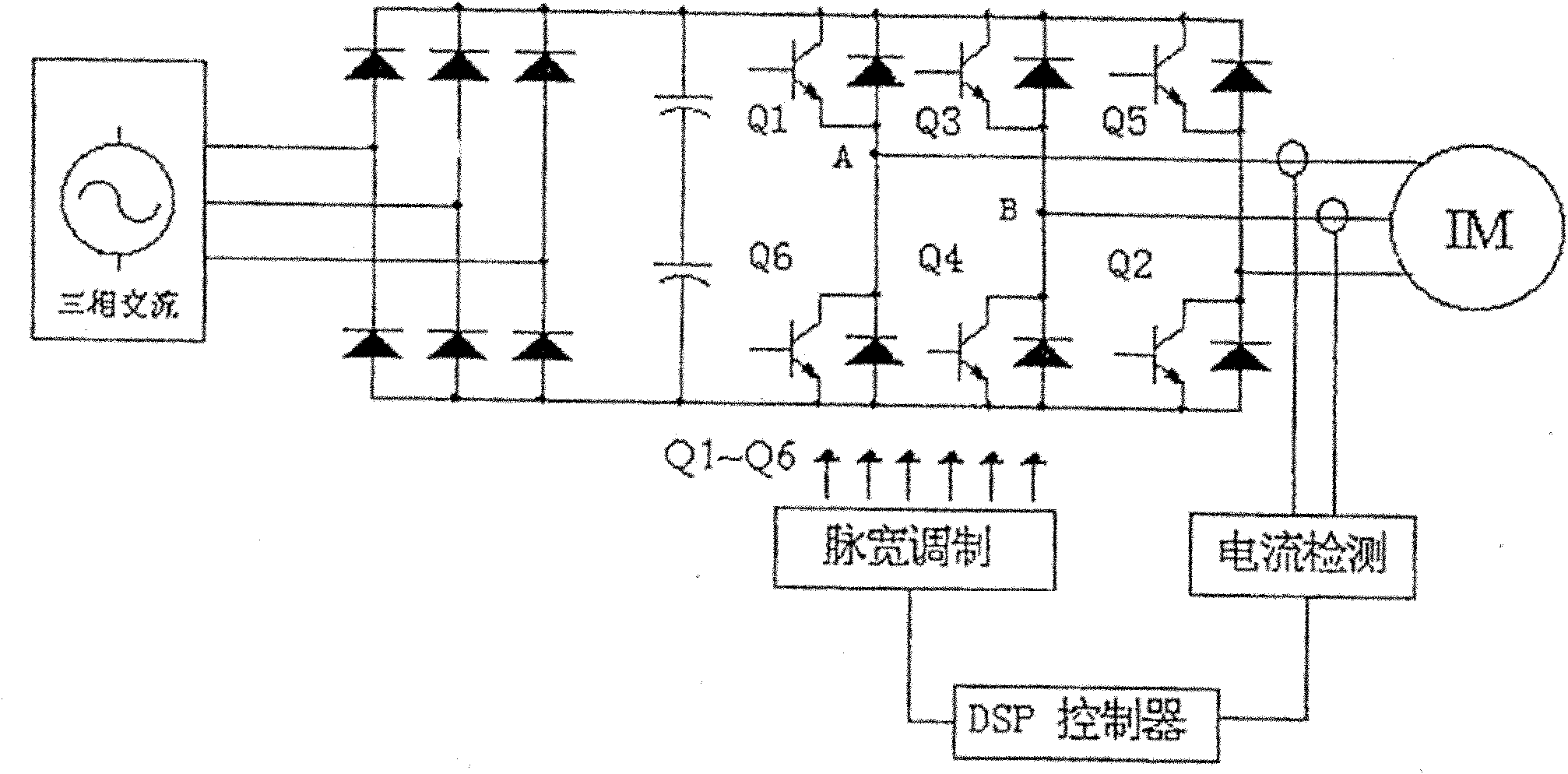

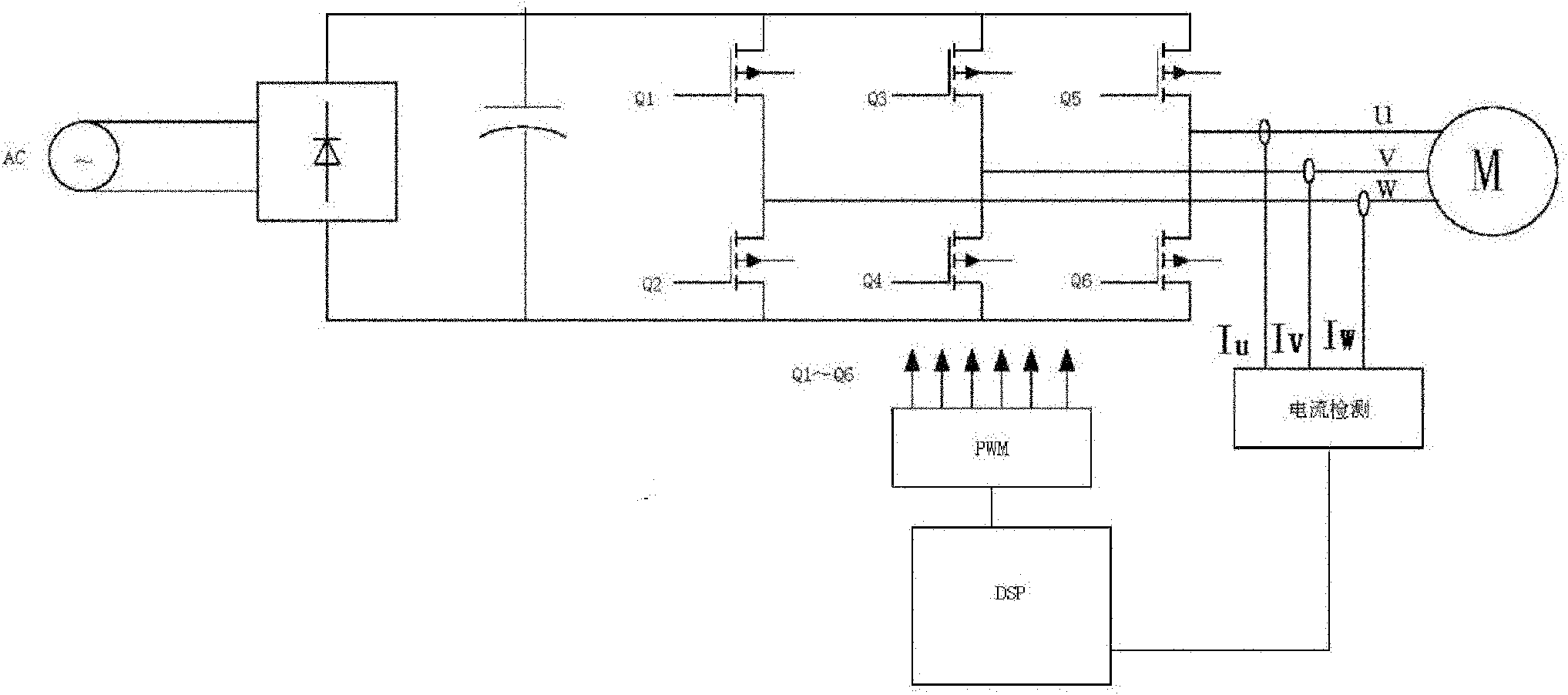

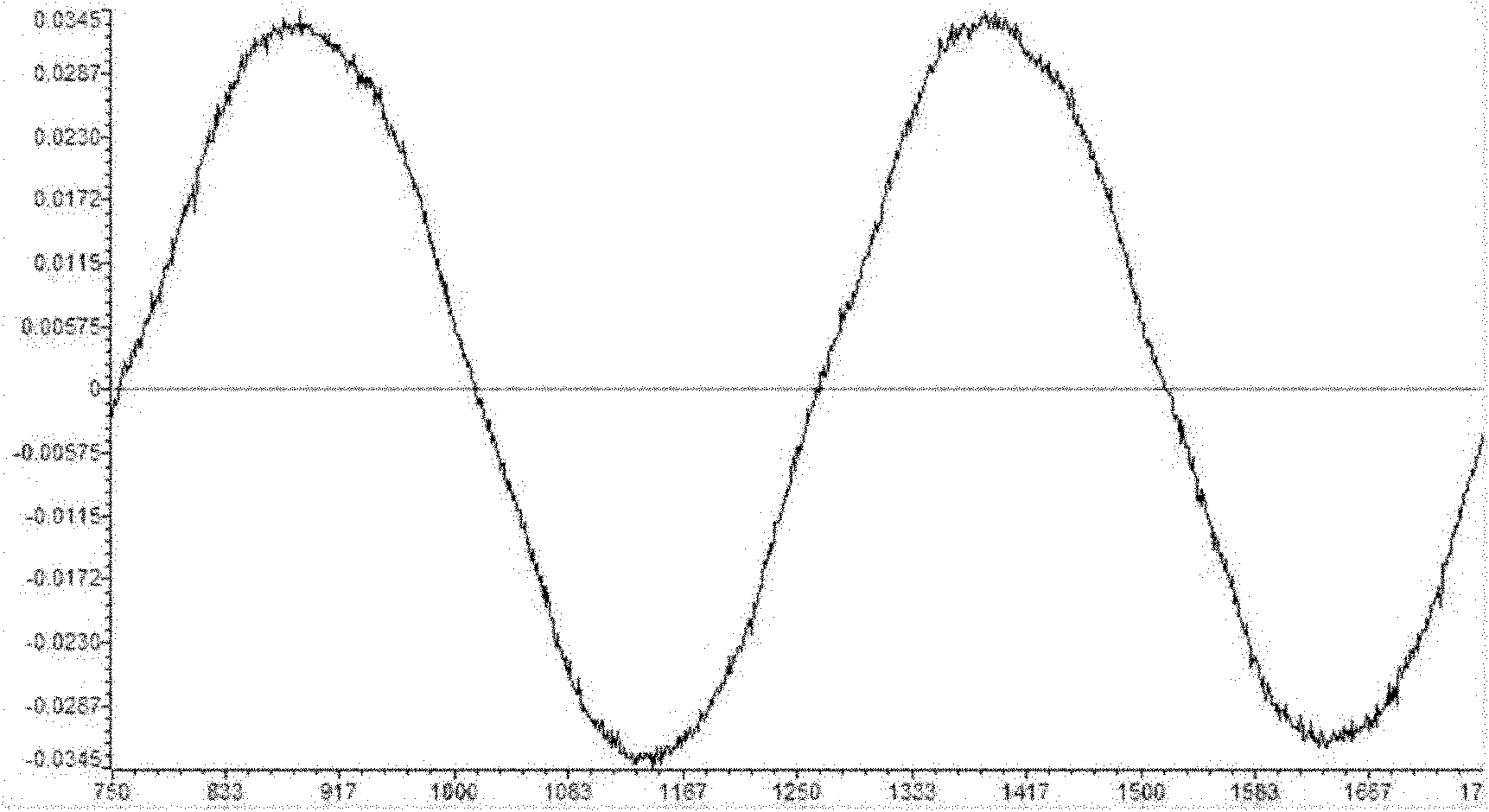

Method for compensating dead area of universal frequency transformer

InactiveCN101964592AReduce disturbanceReliable zero-crossing detectionAc-ac conversionTransformerFiltration

The invention discloses a method for compensating a dead area of a universal frequency transformer. The method comprises the following steps of: (1) acquiring three-phase current signals IU, IV and IW of a motor, and transmitting the signals to a digital signal processor to perform digital filtration by adopting a hardware filter; and (2) performing linear processing on the compensation magnitude according to the magnitude and positive and negative of the detected current, namely when the current of one phase is positive, correspondingly increasing a dead area time to the switch-on time of an upper bridge arm Qx of an inverting bridge corresponding to the current, and correspondingly reducing a dead area time from the switch-on time of a lower bridge arm Qy of the inverting bridge corresponding to the current; and when the current of the phase is negative, correspondingly reducing a dead area time from the switch-on time of the upper bridge arm Qx of the inverting bridge corresponding to the current, and correspondingly increasing a dead area time to the switch-on time of the lower bridge arm Qy of the inverting bridge corresponding to the current. The method is simple to compensate the dead area, has high compensation accuracy, and well overcome the defect of the conventional related compensation.

Owner:SHANGHAI BST ELECTRIC +1

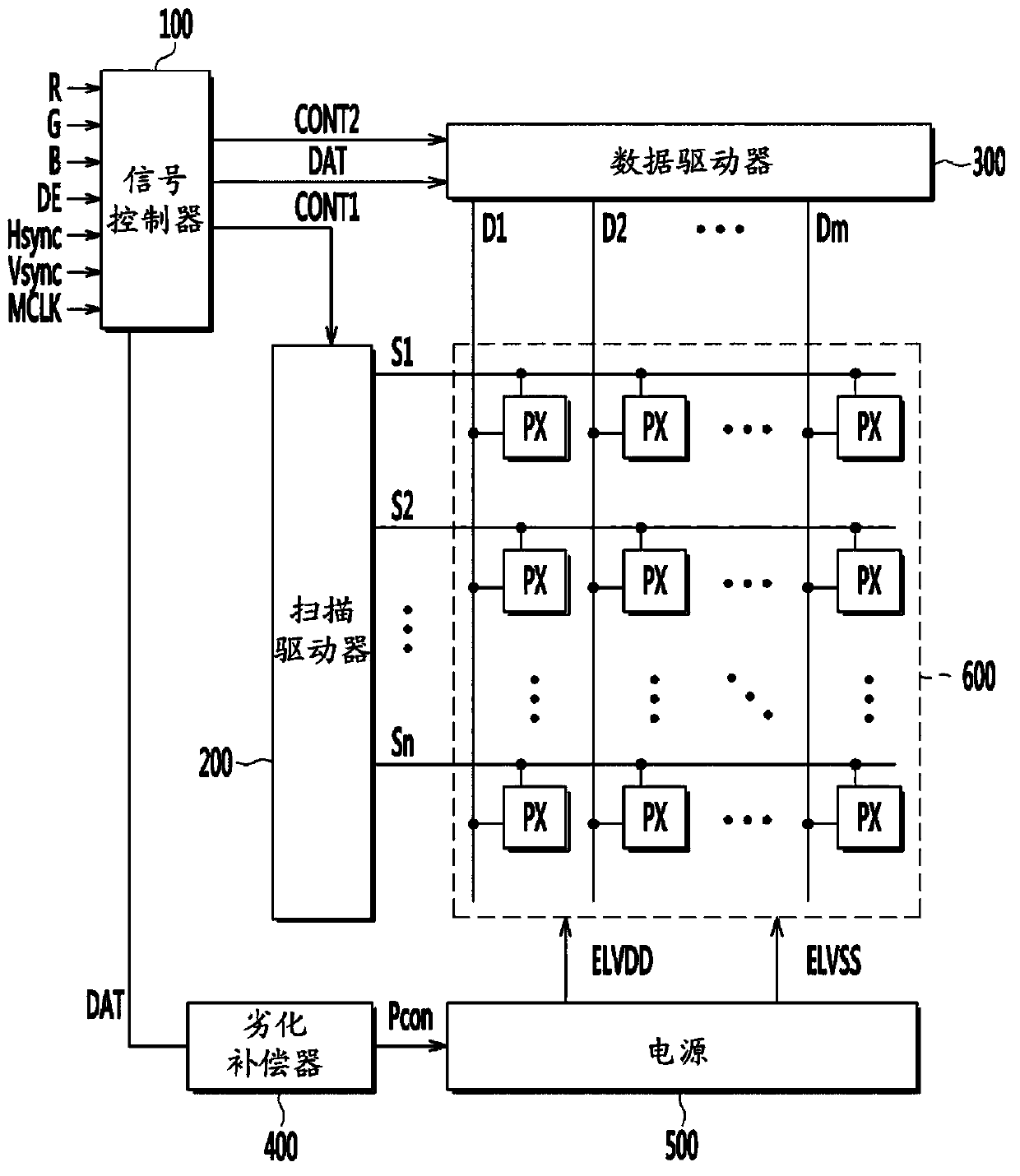

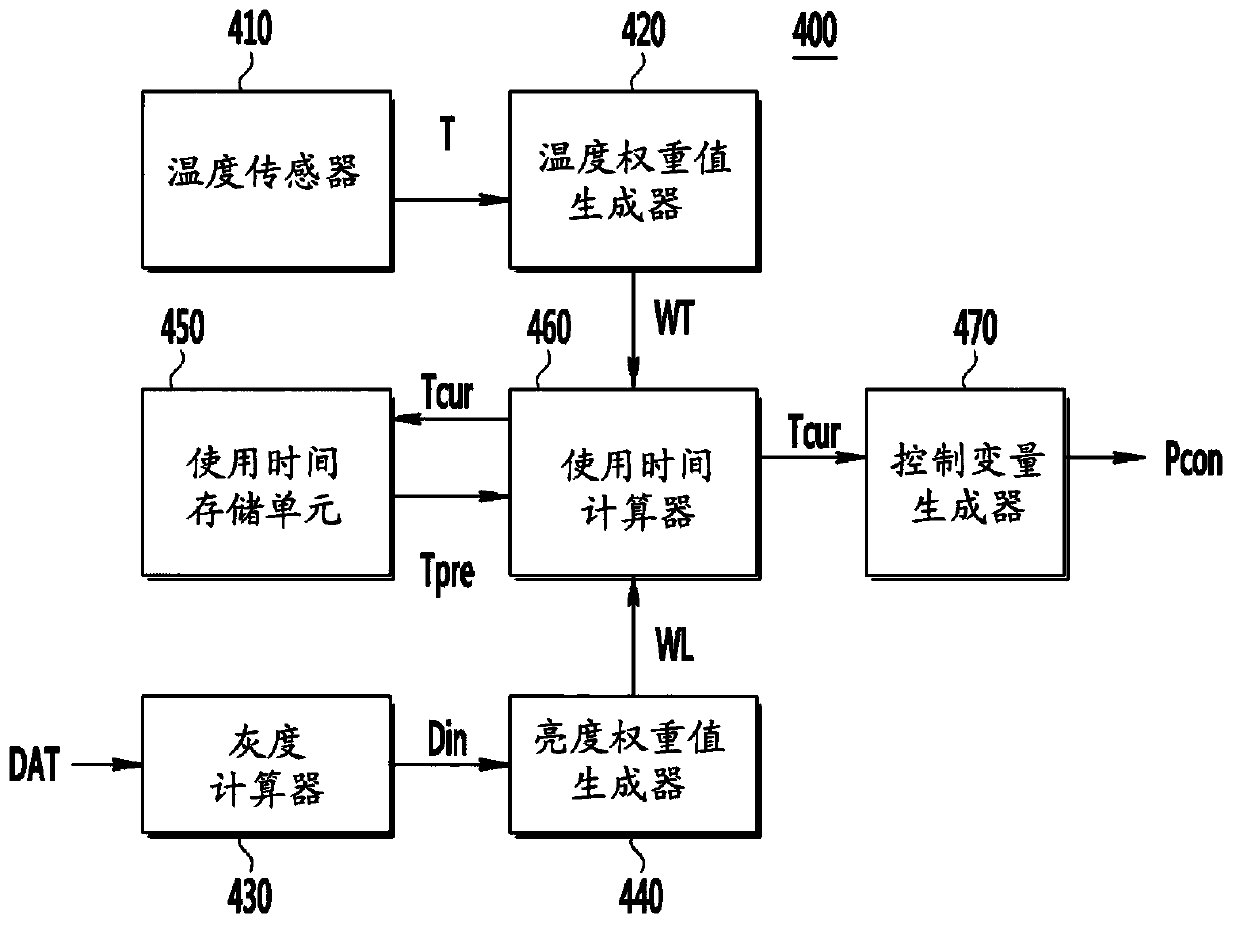

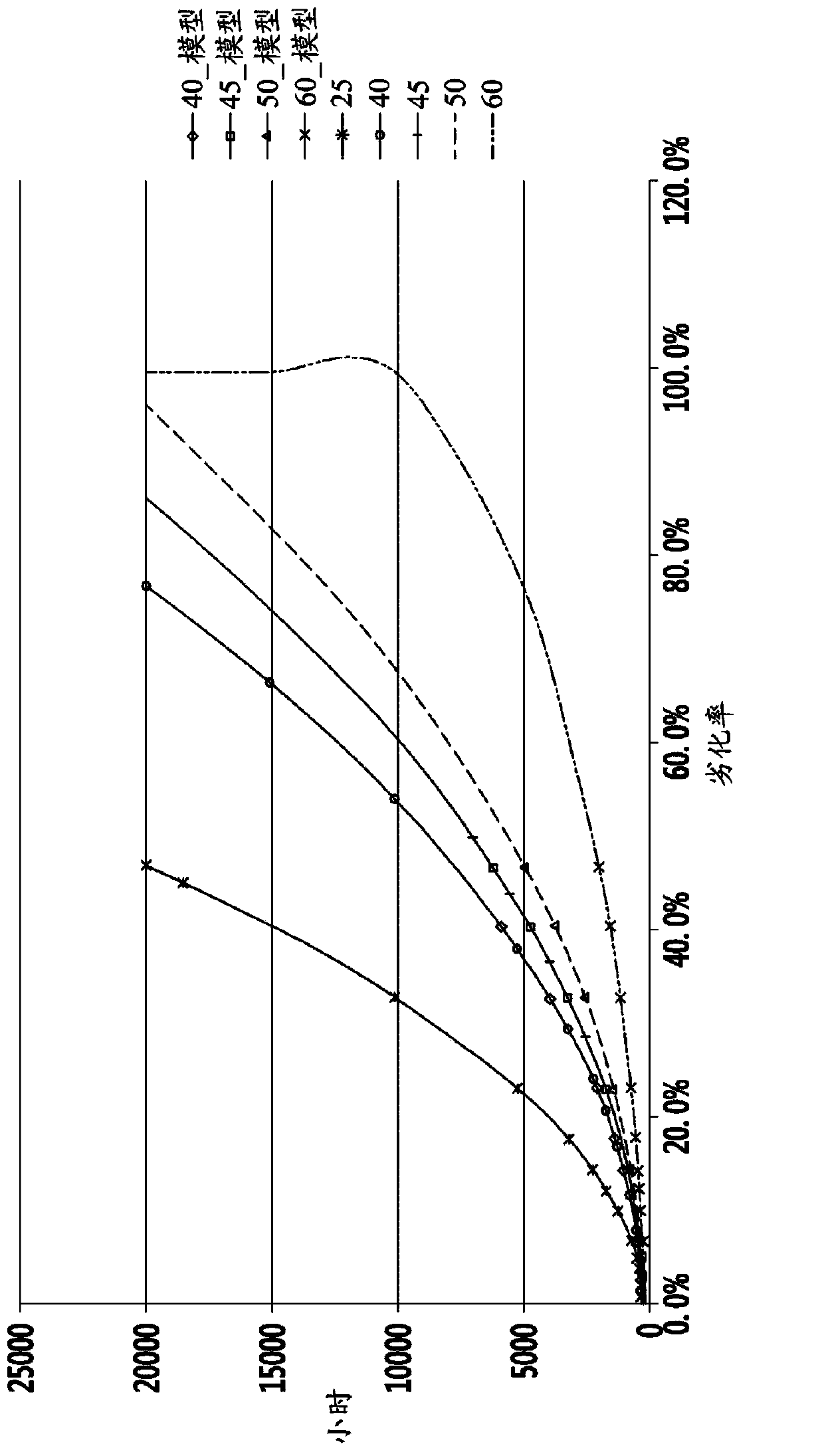

Display device, apparatus for compensating degradation and method thereof

ActiveCN103794174ACompensation for degradationReduce power consumptionStatic indicating devicesDriving currentDisplay device

The present invention discloses a display device, an apparatus for compensating degradation and a method thereof. The display device includes: a plurality of pixels; a degradation compensator for using a temperature weight value for a reference temperature, a luminance weight value for a reference luminance, and a material weight value for a reference material, for calculating a reference using time when a degradation rate of the pixels is changed to a reference degradation rate of a reference degradation curve, and for generating a control variable according to the reference using time; and a power supply for controlling a voltage difference between a first power source voltage for supplying a driving current to the pixels and a second power source voltage according to the control variable.

Owner:SAMSUNG DISPLAY CO LTD

Outgoing maintenance management method and system

InactiveCN105719068AAccurately grasp the locationIncrease authenticityResourcesRepair timeMaintenance management

The invention discloses an outgoing maintenance management method and a system. The method and the system are mainly used for management and monitoring of outgoing maintainers. When an outgoing maintainer gets an outgoing maintenance task, he / she can judge the initial situations of a fault and required tools for maintenance according to a picture provided by a client. The maintainer fills outgoing maintenance information in an outgoing maintenance application form, delivers the outgoing maintenance application form to an approver for approving and can departs for outgoing maintenance after the approver approves. During the outgoing maintenance process, a GPS positioning sub-module will automatically obtain working tracks of the outgoing maintainer and feedback the working tracks on a map sub-module. A time sub-module will obtain departure time, maintenance time and returning time of the outgoing maintainer. According to the invention, outgoing maintainers are prevented from make false declaration on expense and effects and loss of enterprises is reduced; enterprises can know working dynamic states of the outgoing maintainers; and management of the maintainers by the enterprises is enhanced.

Owner:CHENGDU JINWANTAI TECH CO LTD

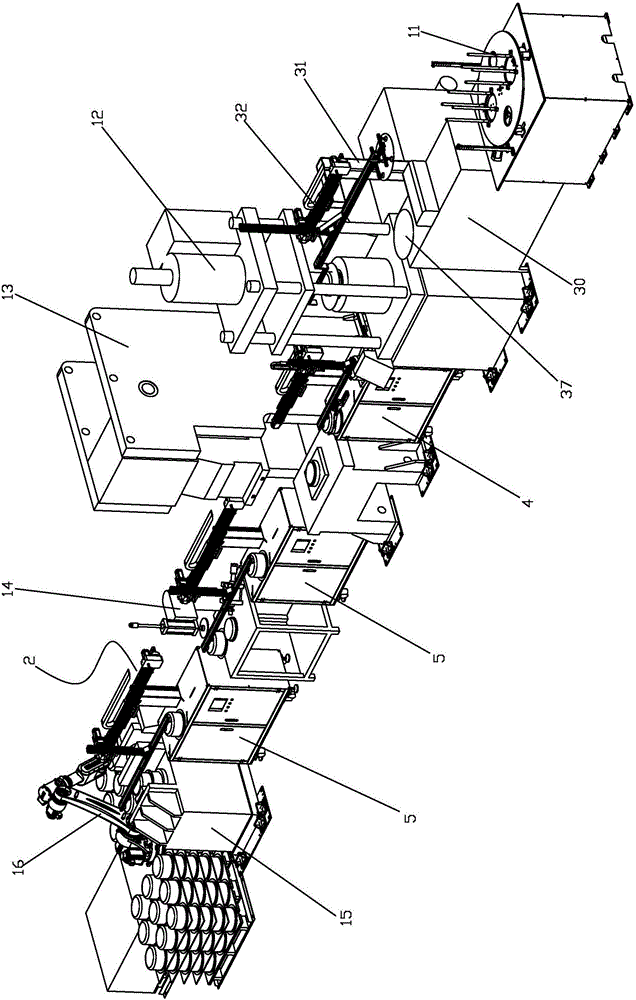

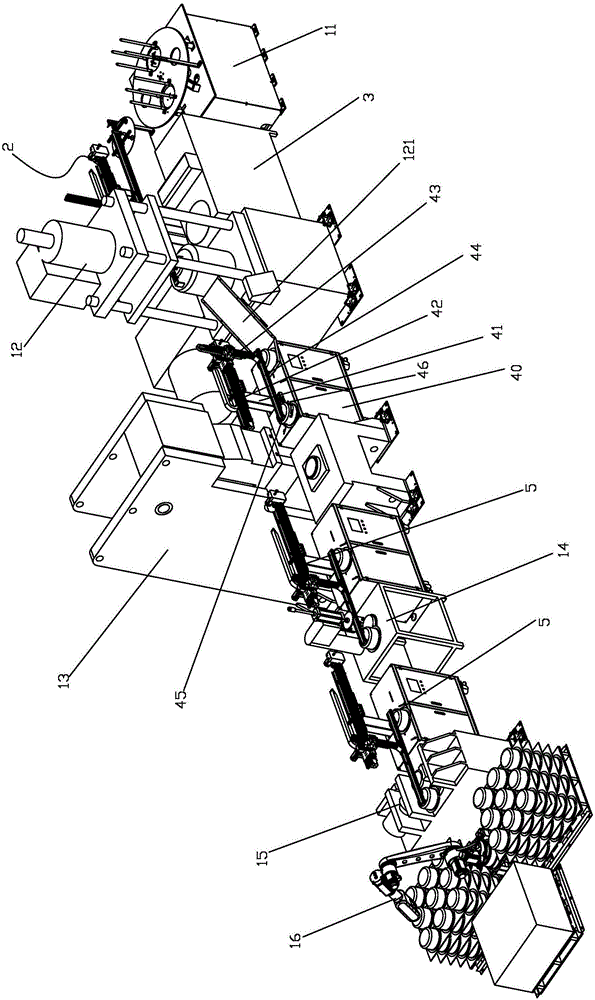

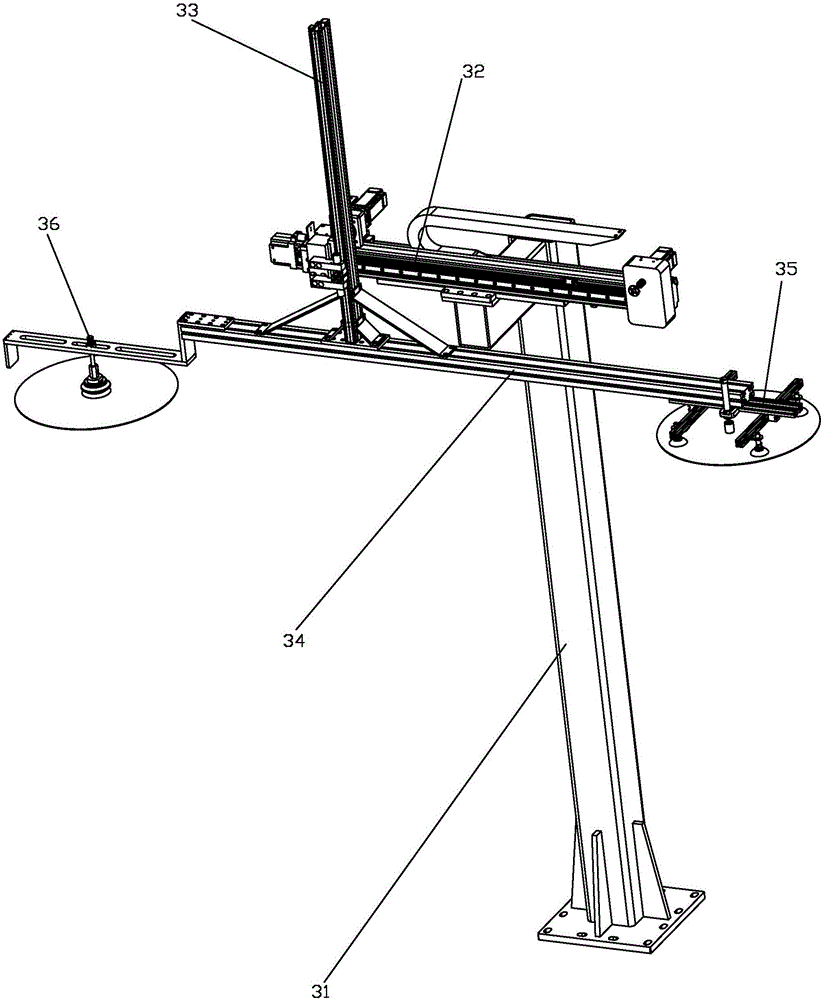

Full-automatic intelligent punching production system based on remote control

InactiveCN105834291AControllable production speedReduce the quantity in processMetal-working feeding devicesOther manufacturing equipments/toolsProduction lineAutomatic train control

The invention discloses a full-automatic intelligent punching production system based on remote control. According to the technical scheme, the full-automatic intelligent punching production system is characterized by comprising an automatic feeding device, an automatic drawing molding device, an automatic edge trimming device, an automatic edge curling device, an automatic labeling device and an automatic stacking device which are arranged in sequence, and further comprising an automatic control system used for controlling the production line to operate in a remote mode. The automatic control system comprises a first pushing robot, a second pushing robot and third pushing robots, wherein the first pushing robot is arranged between the automatic feeding device and the automatic drawing molding device and used for automatically transferring and pushing semi-finished products; the second pushing robot is arranged between the automatic drawing molding device and the automatic edge trimming device; and the third pushing robots are arranged between the automatic edge trimming device and the automatic edge curling device and between the automatic edge curling device and the automatic labeling device. According to the full-automatic intelligent punching production system based on remote control, unmanned automated operation can be realized in all manufacture procedures, the semi-finished products can be transferred automatically between the manufacture procedures, and therefore automatic production is achieved in a real sense.

Owner:GUANGDONG CLAW ROBOT CO LTD

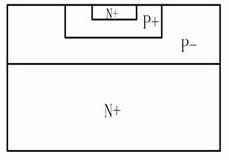

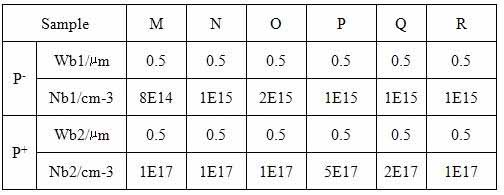

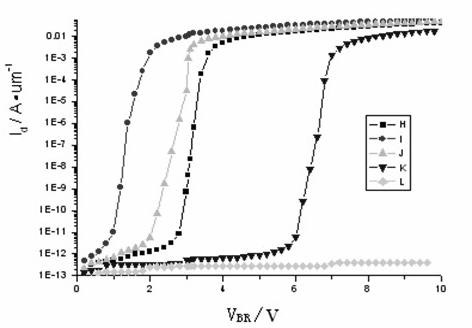

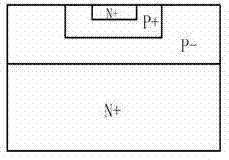

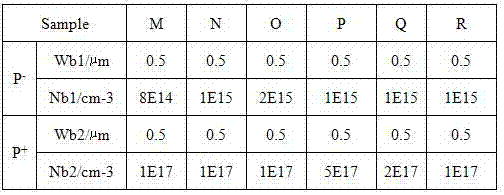

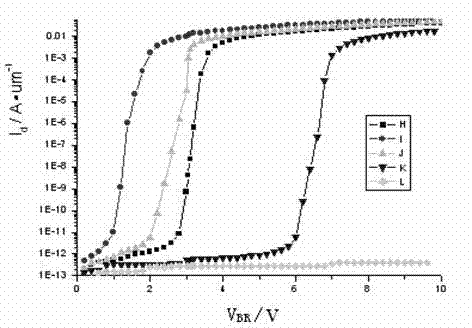

Manufacturing method of silicon epitaxial wafer for low voltage tvs

ActiveCN102290337ACompensation for degradationImprove gas phase conditionsSemiconductor/solid-state device manufacturingCooking & bakingHydrogen

The invention relates to a manufacturing method for a silicon epitaxial wafer, in particular to a manufacturing method for a silicon epitaxial wafer of a low-voltage TVS (transient voltage suppressor). In the technical scheme, when a P-shaped epitaxial layer is grown on an N-shaped substrate, HCl (Hydrogen Chloride) is adopted for gas corrosion of impurities and metal atoms on the surface of the substrate, high-temperature large-volume hydrogen is then adopts for blowing, hydrogen is adopted for high-temperature baking of impurity atoms on the N-shaped substrate, and finally a pre-pass P-typedopant (B2H6) is grown on the epitaxial layer. Therefore, the concentration of gas-phase impurities in an epitaxial reactor and the concentration of impurities absorbed to a base and the surface of the substrate can be reduced, the degree of compensation of N-type impurities and P-type impurities can be decreased, and a clean growth zone can be formed. Moreover, gas-phase conditions in the reactor can be improved, the stability of the thickness of the epitaxial layer can be guaranteed, and thus, the stability of protective voltage for devices can be ensured.

Owner:NANJING GUOSHENG ELECTRONICS

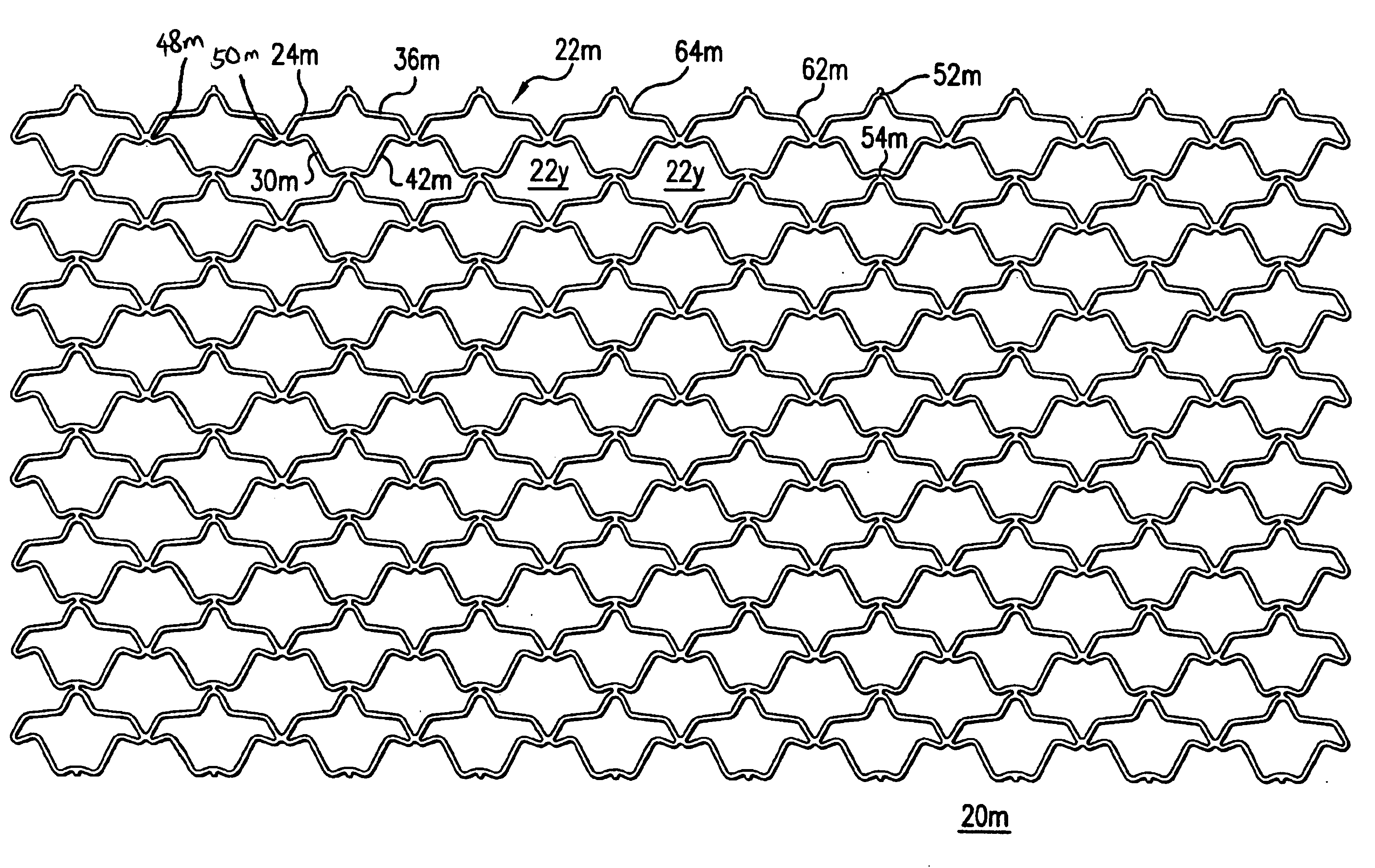

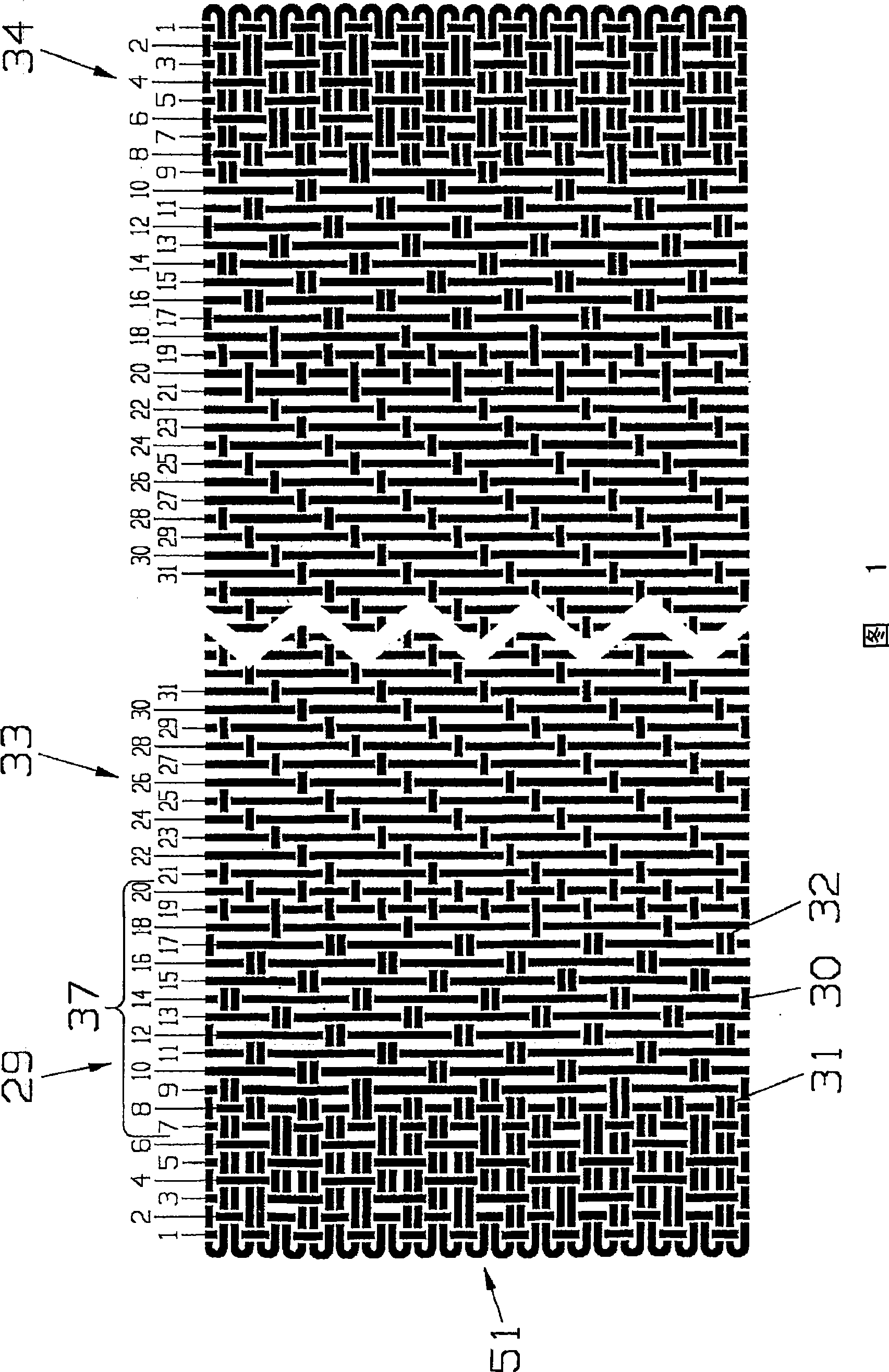

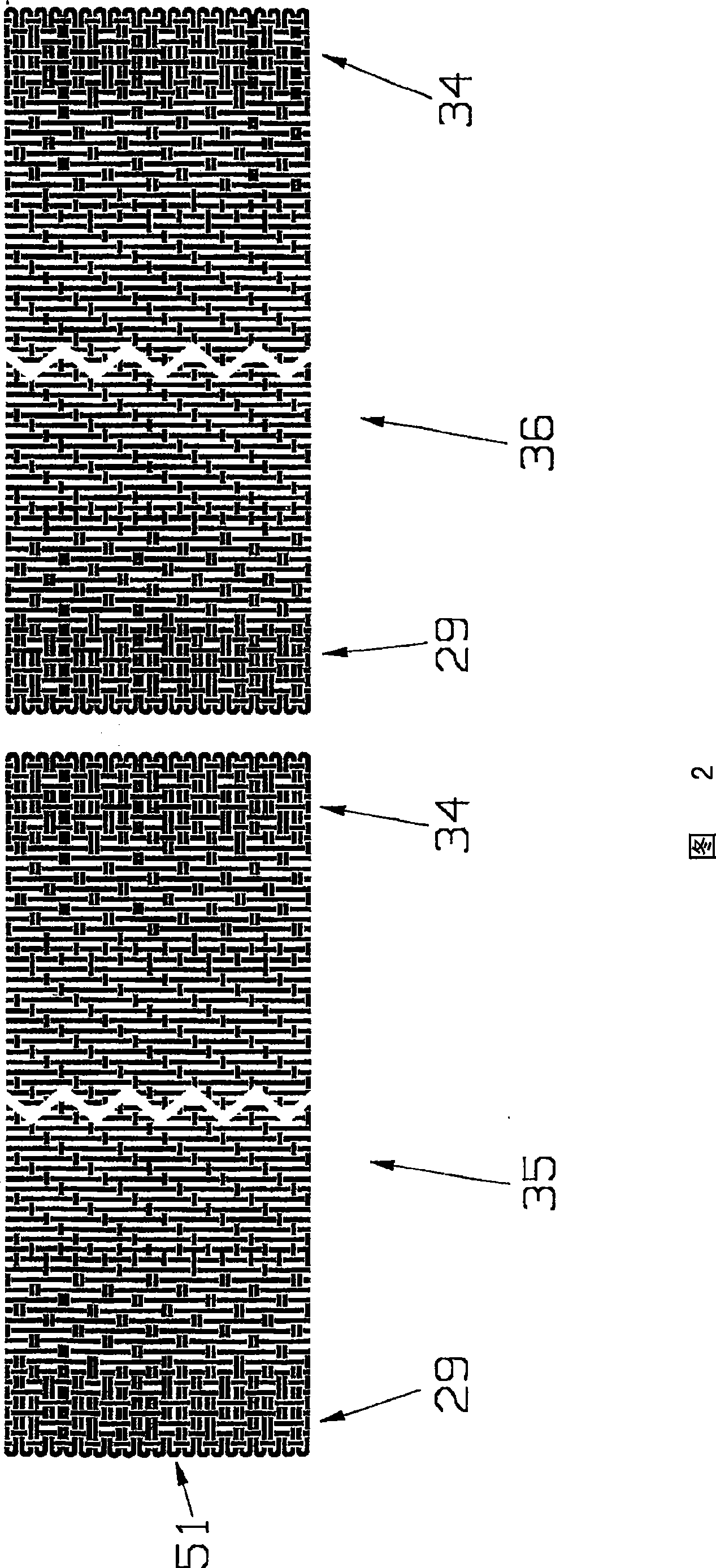

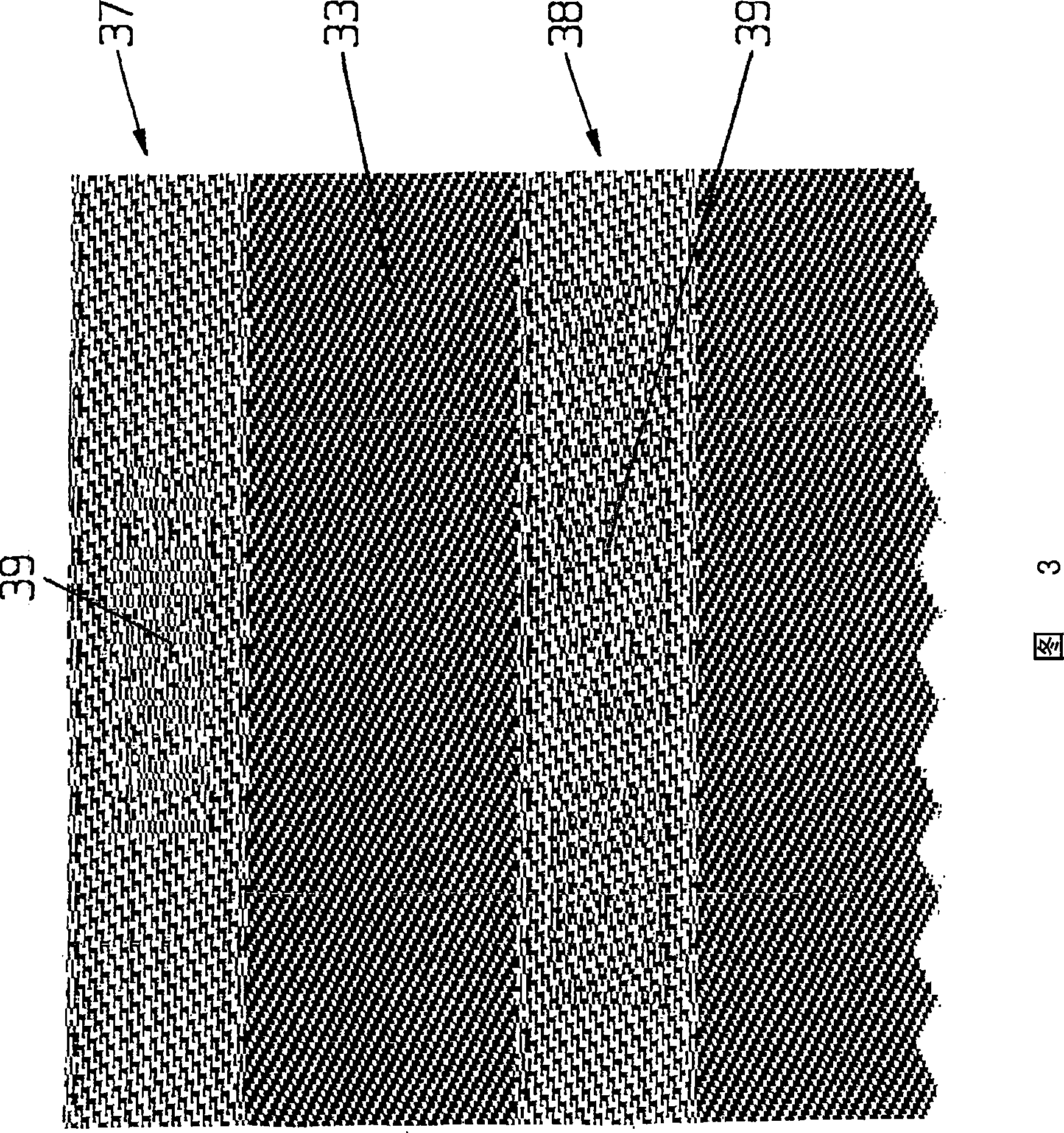

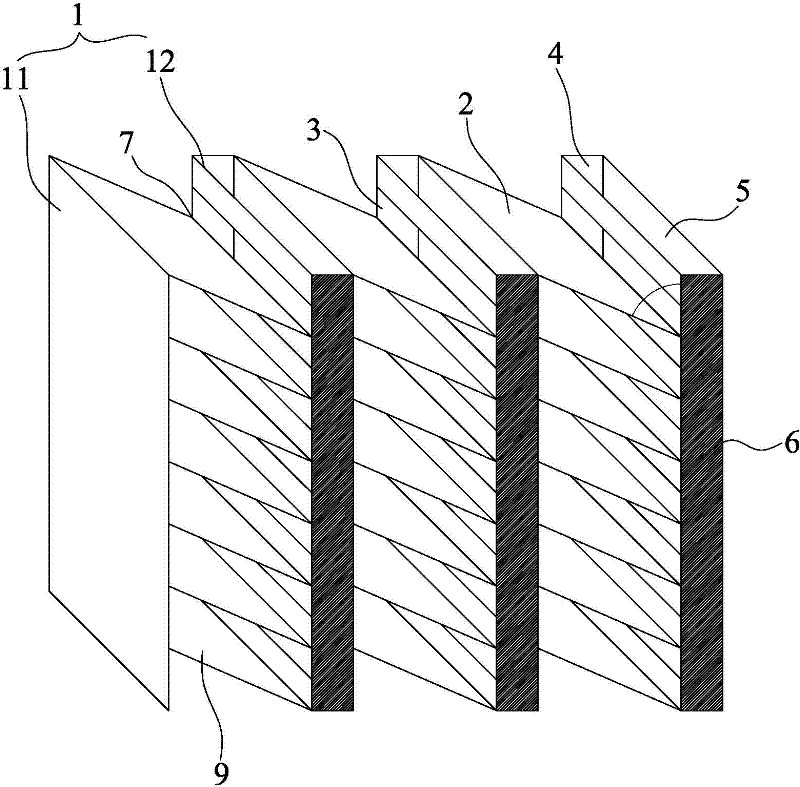

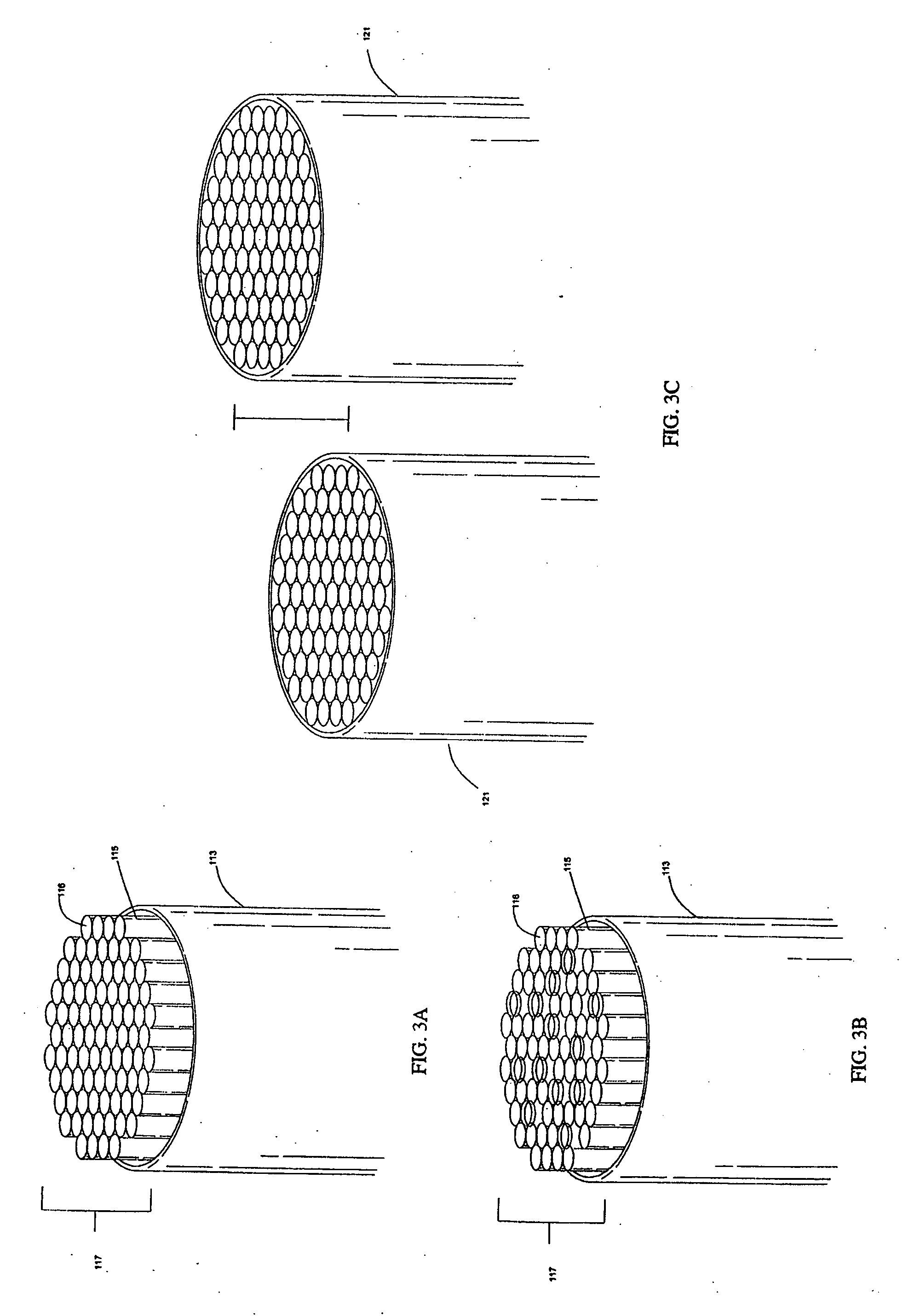

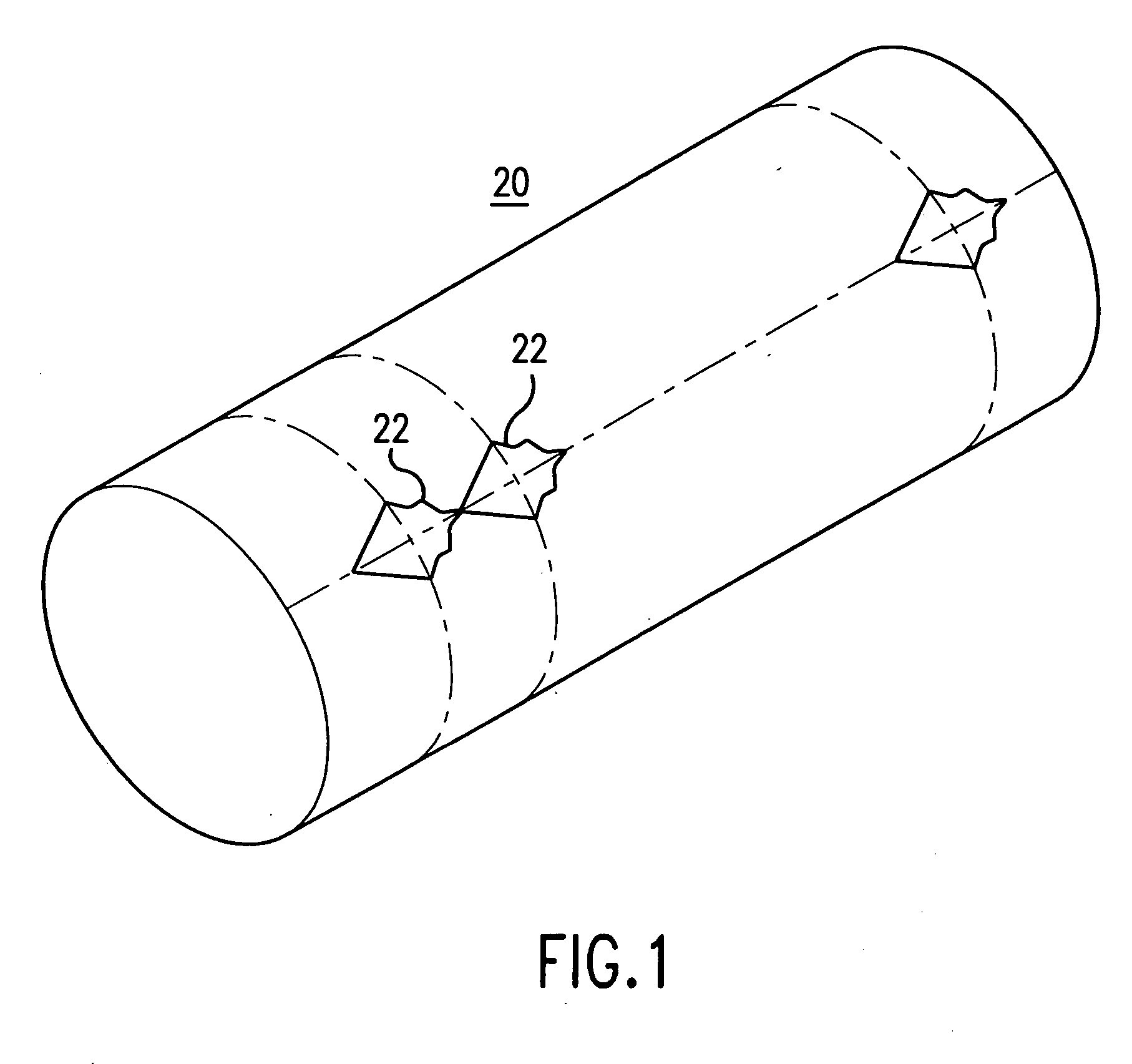

Tissue with an insert edge and use of said tissue

The invention relates to a tissue, in particular a jeans tissue, comprising a basic tissue (140) and a tucked selvedge (135). The terminal sections (138) of the weft threads (137) are folded over at the edge (147) of the tissue and then resupplied into the tissue. The ends (139) of the terminal sections of the weft threads (138) can be dispersed over a zone a and become a visual bore. A field (144) having alphanumeric signs, logos or at least one colour is woven into the tucked selvedge (135). The field (144) serves for publicity purposes and renders the ends (139) of the terminal sections of the weft threads (138) largely or completely invisible by covering the ends (139) on the upper and inner side of the tissue according to weave technology or present the same colour as the warp threads (109 to 117) in the region of the field (144).

Owner:LINDAUER DORNIER GMBH

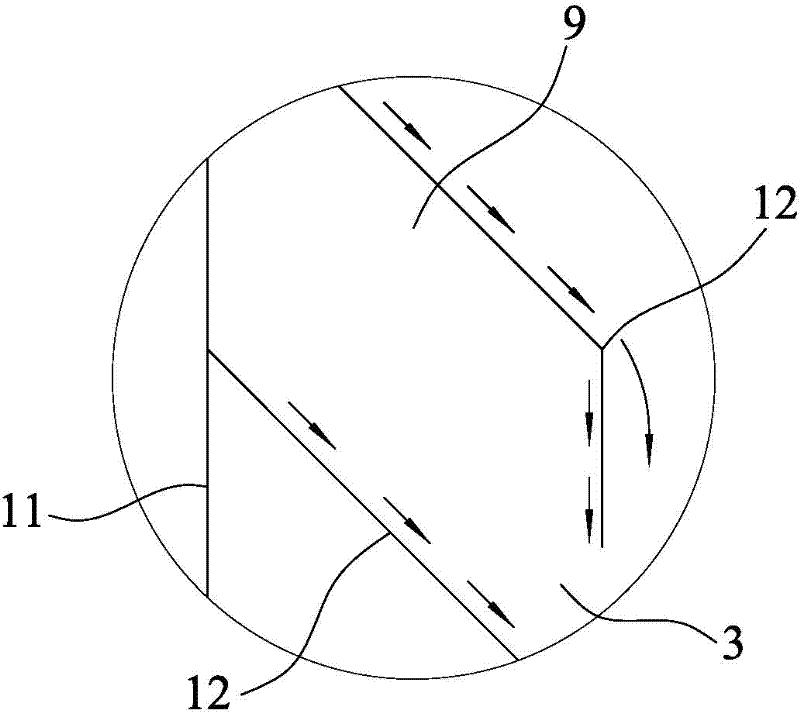

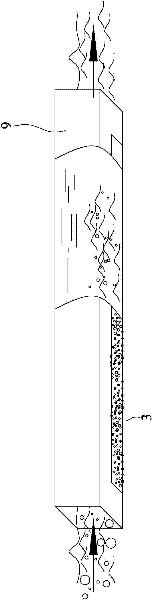

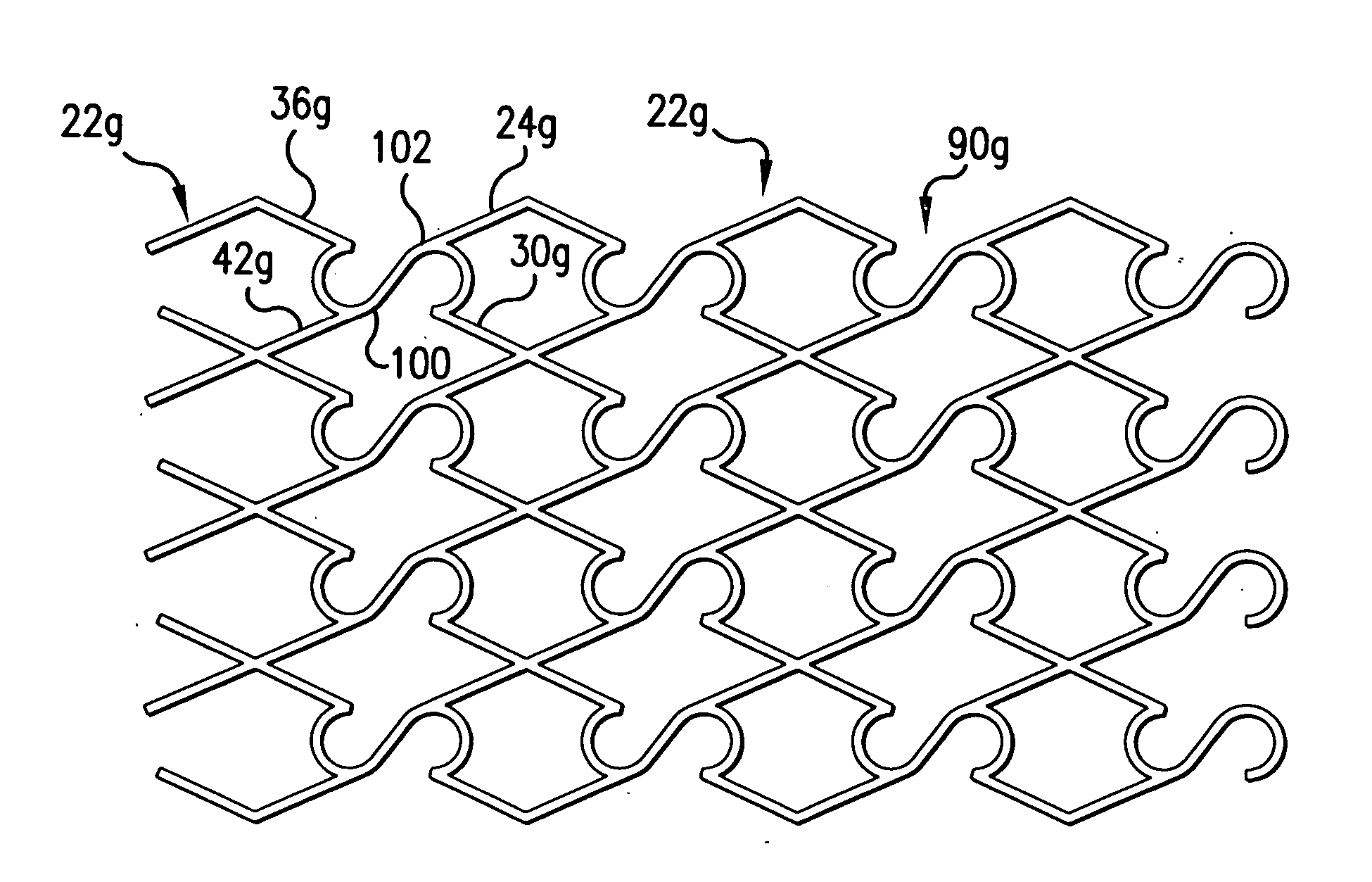

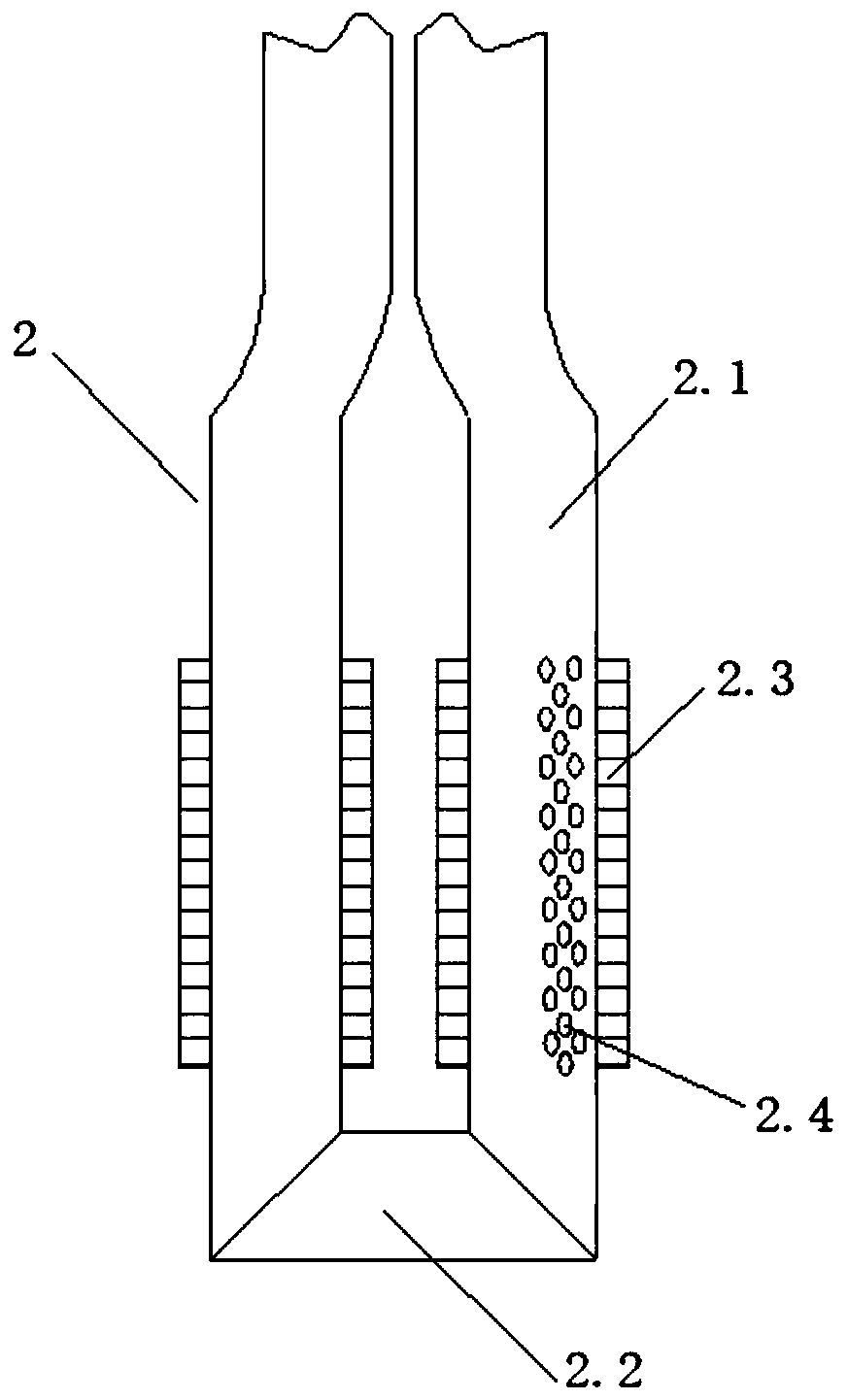

Multi-layer lattice precipitation separating device for V-shaped pipe

InactiveCN102553309AImprove sedimentation efficiencySimplify construction and construction difficultySedimentation settling tanksEngineeringPrecipitation

The invention discloses a multi-layer lattice precipitation separating device for a V-shaped pipe. The device is characterized by comprising multiple groups of parallel vertical plates, each group of parallel vertical plates is formed by a left vertical plate and a right vertical plate, a plurality of oblique clapboards are arranged between the left and right vertical plates, the left and right vertical plates and two adjacent clapboards form a water passage with a parallelogram-shaped cross section, a mud discharge hole is formed above the intersected part of the right vertical plate and the clapboard, a mud discharge passage is arranged between each right vertical plate and clapboards in another group of adjacent parallel vertical plates, and two ends of the mud discharge passage are sealed to form a static liquid area. As the vertical plates are adopted in the invention, the precipitation efficiency is improved, and simultaneously the vertical plates are more convenient to construct.

Owner:厦门飞华环保有限公司

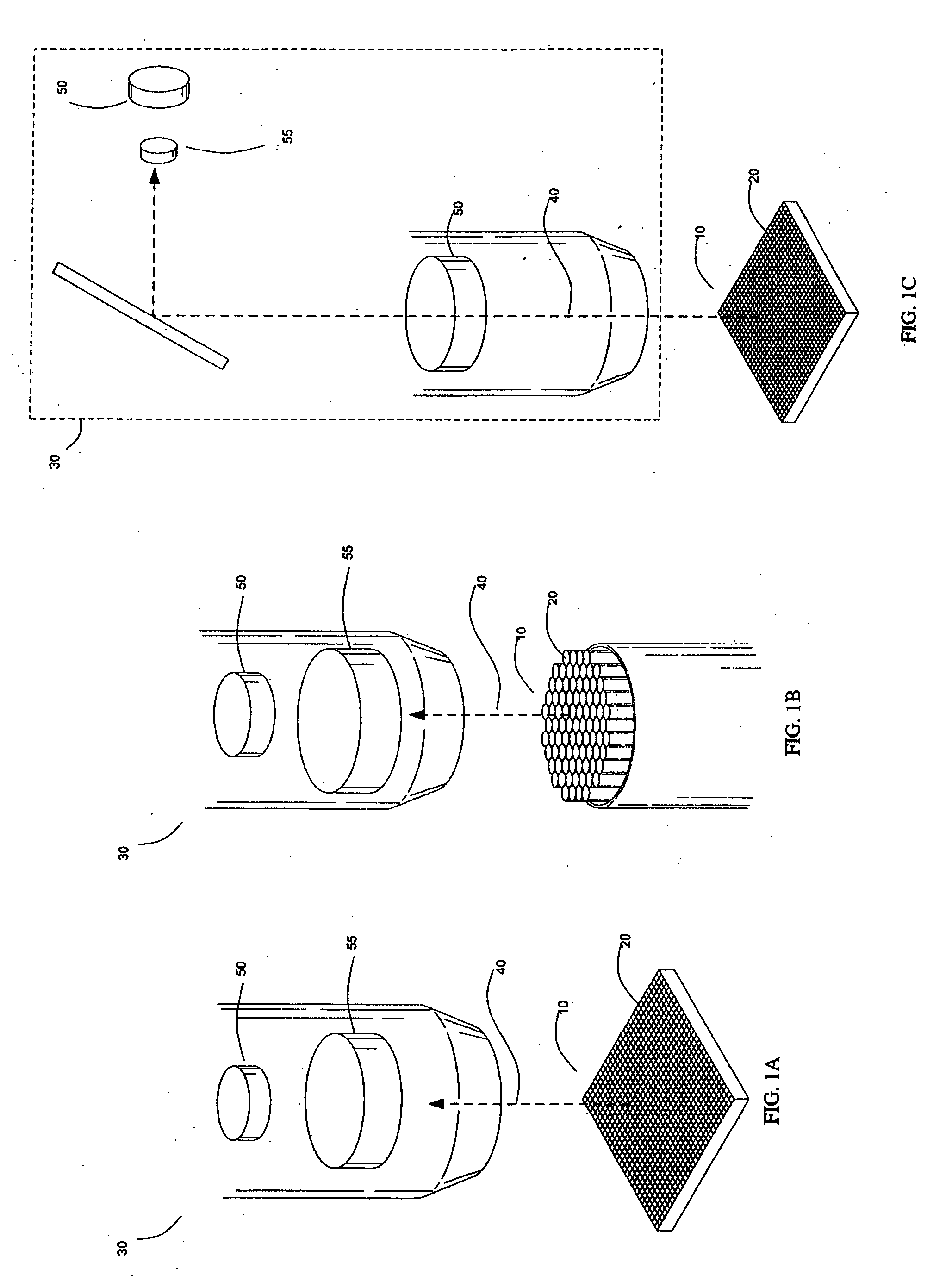

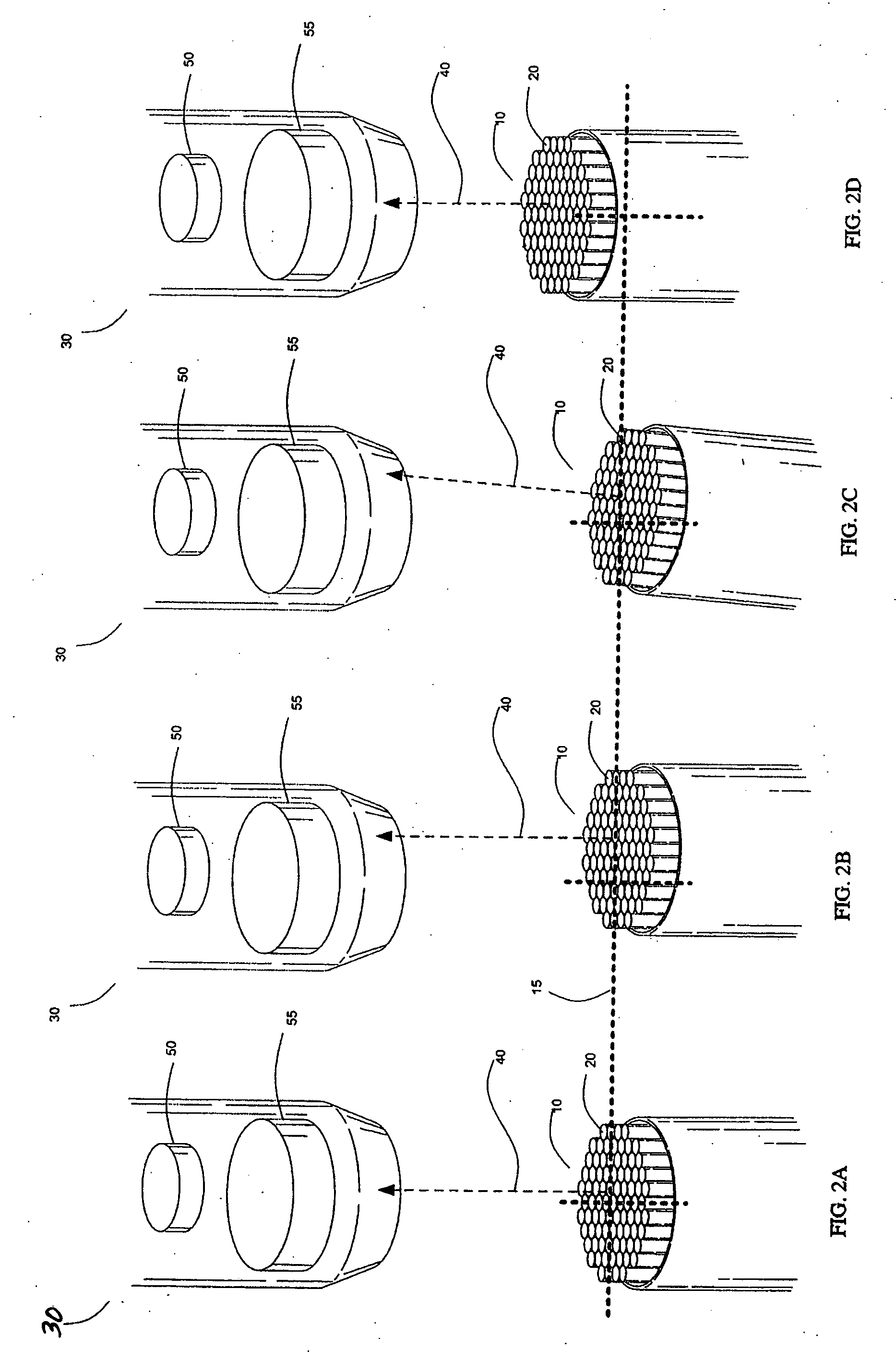

Multiaxis focusing mechanism for microarray analysis

InactiveUS20060094027A1Reduce target position errorReduce ambiguityMicrobiological testing/measurementAcquiring/recognising microscopic objectsLight beamMicroarray profiling

Systems and methods for positioning a multi-featured biological array relative to a signal acquisition device. Detection of the array's positional deviation may be achieved by a calibration beam reflected from the array surface and detected by a position sensitive detector (PSD). The PSD-measured positional deviation can be transformed and used in a control loop to correct for positional variations of the array. The calibration beam and PSD may also be used to detect the array or feature boundaries, thereby allowing lateral centering or positioning of the array relative to the signal acquisition device.

Owner:APPL BIOSYSTEMS INC

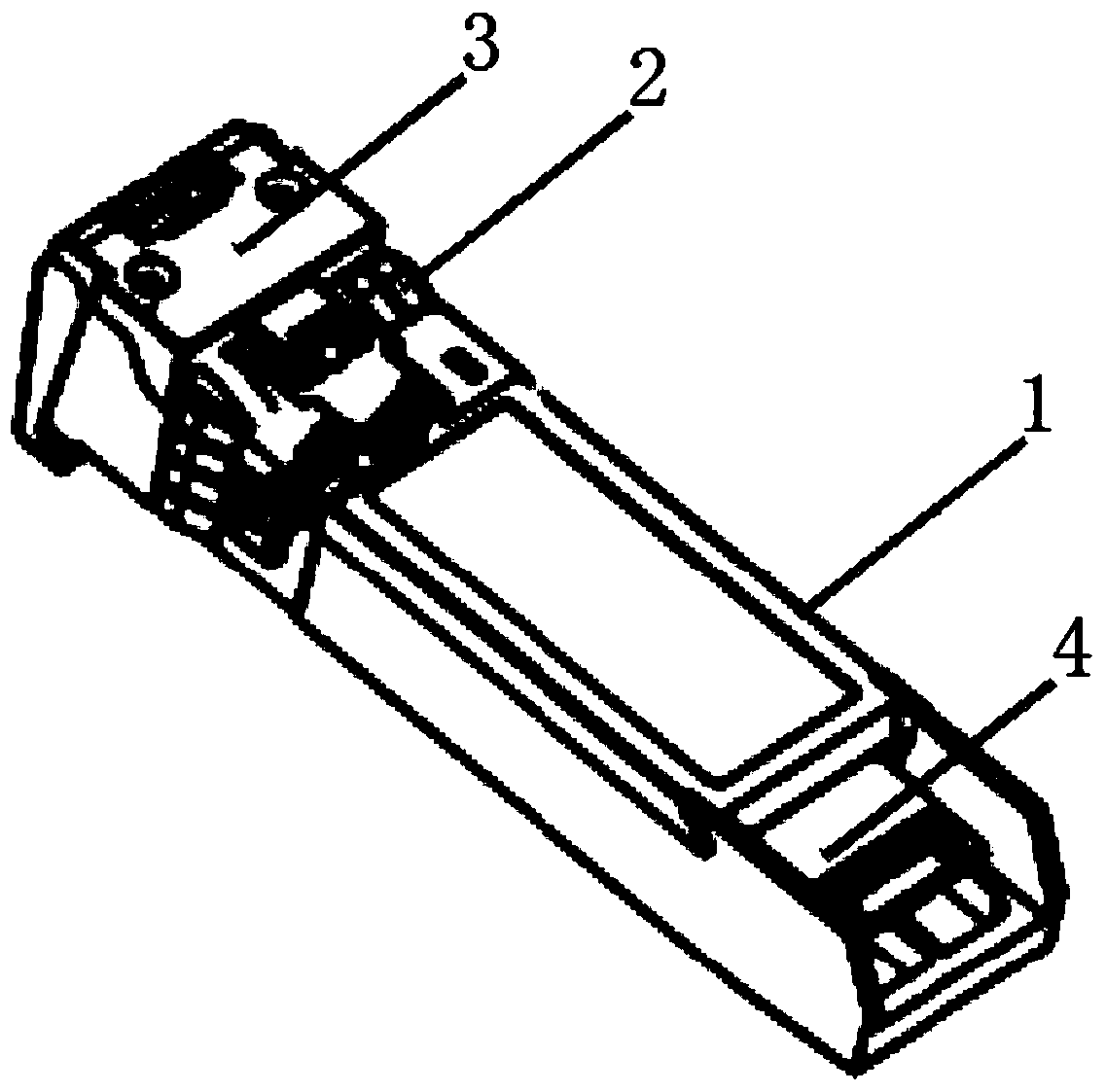

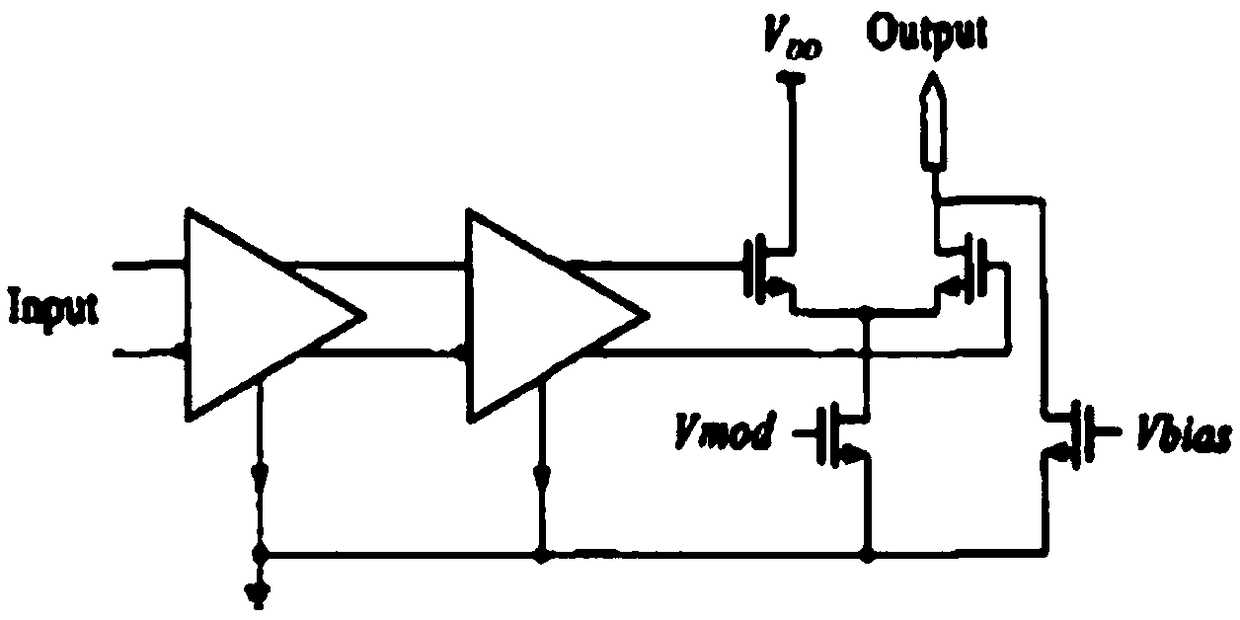

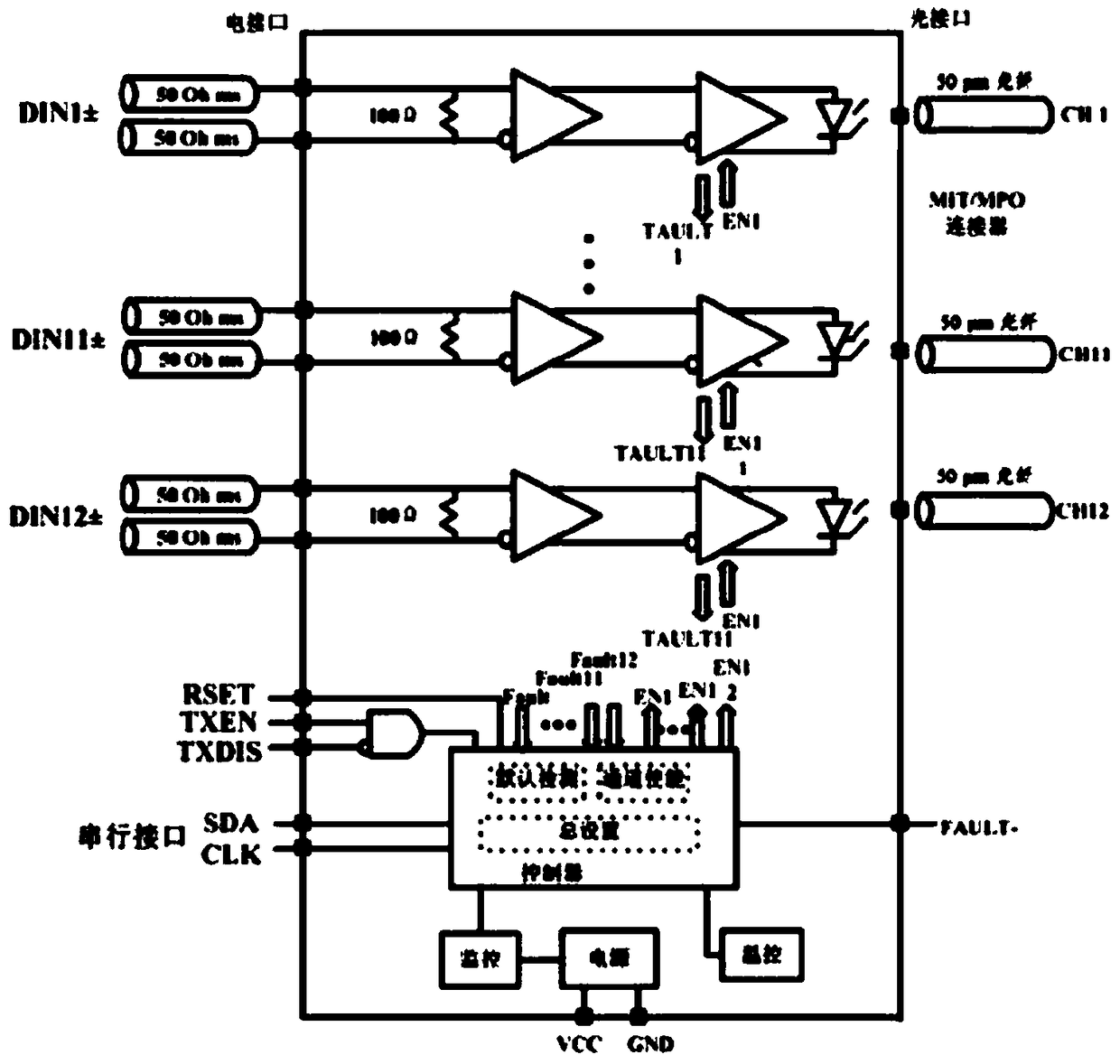

Industrial grade 25G high-speed optical transceiver module

InactiveCN109361464AReduce power consumptionCompensation for degradationElectromagnetic transceiversTransceiverLaser array

The invention discloses an industrial grade 25G high-speed optical transceiver module, comprising a 25G optical emitting module, a single transmission optical fiber and an optical receiving module, wherein two ends of the single transmission optical fiber are respectively connected with the 25G optical emitting module and the optical receiving module through a module connector; the 25G optical emitting module comprises: an electrical connector, a dimensional laser array, an optical fiber module, a module driver, and a power controller; the electrical connector introduces a high-speed digital signal into the 25G optical emitting module, the module driver transmits the signal introduced by the electrical connector to the dimensional laser array after converting the signal into a modulated signal, the dimensional laser array emits a light beam, and the light beam emitted by the dimensional laser array is coupled to the module connector through the optical fiber module. The dimensional laser array in the invention adopts an optical power open-loop mode, which actively reduces the optical power in the interval of 75 to 85 degrees centigrade to avoid deterioration of the eye pattern of the module.

Owner:SHENZHEN OPWAY COMM

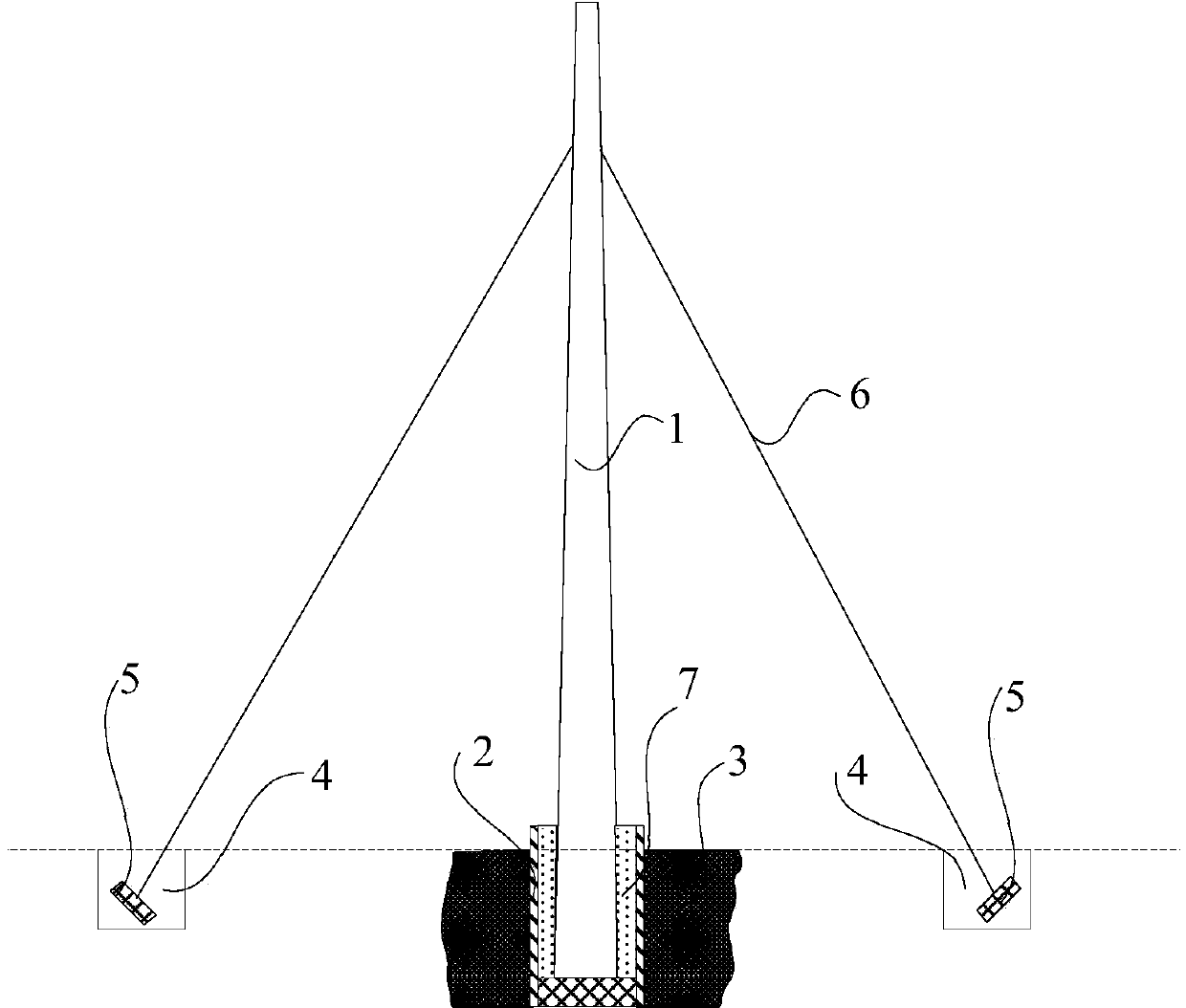

Method for fixing electric pole

InactiveCN105507341AAchieve recyclingAvoid damageFoundation engineeringTowersEngineeringPolyurethane

The invention discloses a fixing method for an electric pole. The fixing method comprises the following steps: preparing the electric pole made of a polyurethane material and a fixed sleeve; excavating an electric pole foundation pint at a position of embedding the electric pole; arranging a fixed sleeve into the electric pole foundation pit, and filling concrete between the outer side wall of the fixed sleeve and the electric pole foundation pit; filling concrete or soil for tamping into the bottom of the fixed sleeve; and putting one end of the electric pole into the fixed sleeve, and filling stuffing between the electric pole and the fixed sleeve. According to the fixing method, the fixed sleeve is firstly fixed in the electric pole foundation pit, then, the electric pole is inserted into the fixed sleeve, and the stuffing is filled between the electric pole and the fixed sleeve for fixing, so that the stuffing is high in anti-pressure ability, and has relatively good adhesive force; under the action of external force, the electric pole can be pulled out from the fixed sleeve, so that detachable connection between the electric pole and the fixed sleeve is realized, the electric pole is recycled, and the production cost is reduced.

Owner:胡广生

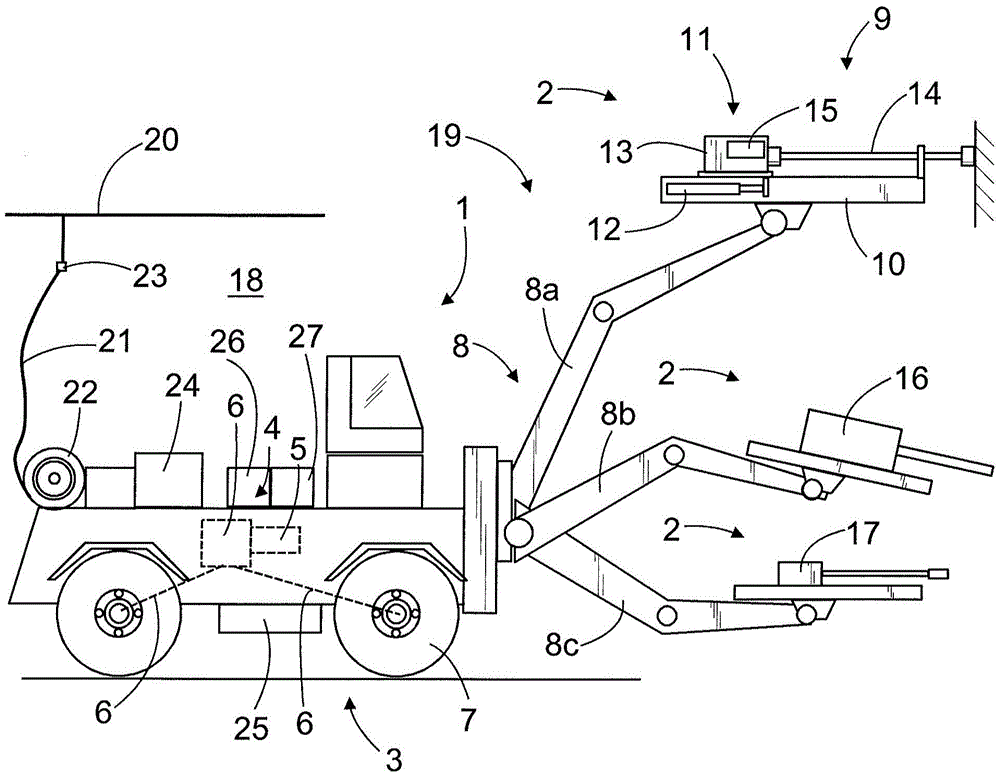

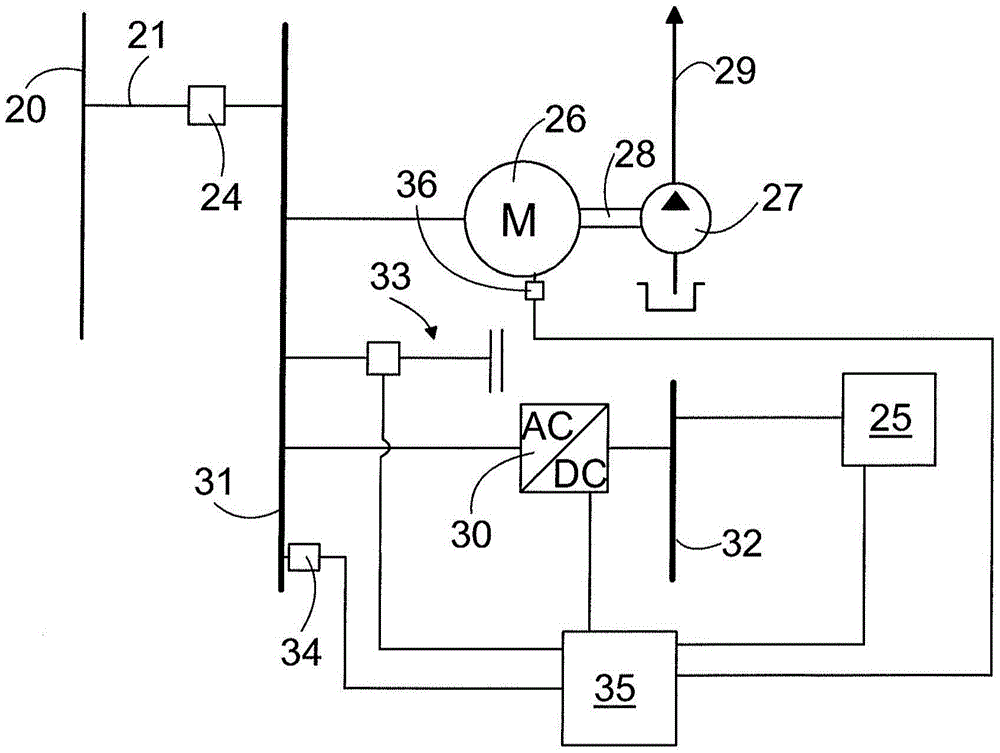

Mining vehicle and method for energy supply thereof

InactiveCN105720664ACompensation costsReduce reactive current compensationBatteries circuit arrangementsAC motor controlCharge currentEnergy supply

The invention relates to a mining vehicle and to a method for an energy supply of the mining vehicle. The mining vehicle comprises at least one mining work device, at least one AC electric motor for powering the at least one mining work device, and an auxiliary energy source. The mining vehicle further comprises a power electronics device that is used for supplying reactive current and for charging or discharging the auxiliary energy source. The amount of the reactive current supplied by the power electronics device and the amount of the effective charging current for charging or discharging the auxiliary energy source are controlled such that the maximum value for the current of the supply cable and the maximum value for the current of the power electronics device are not exceeded.

Owner:SANDVIK MINING & CONSTR OY

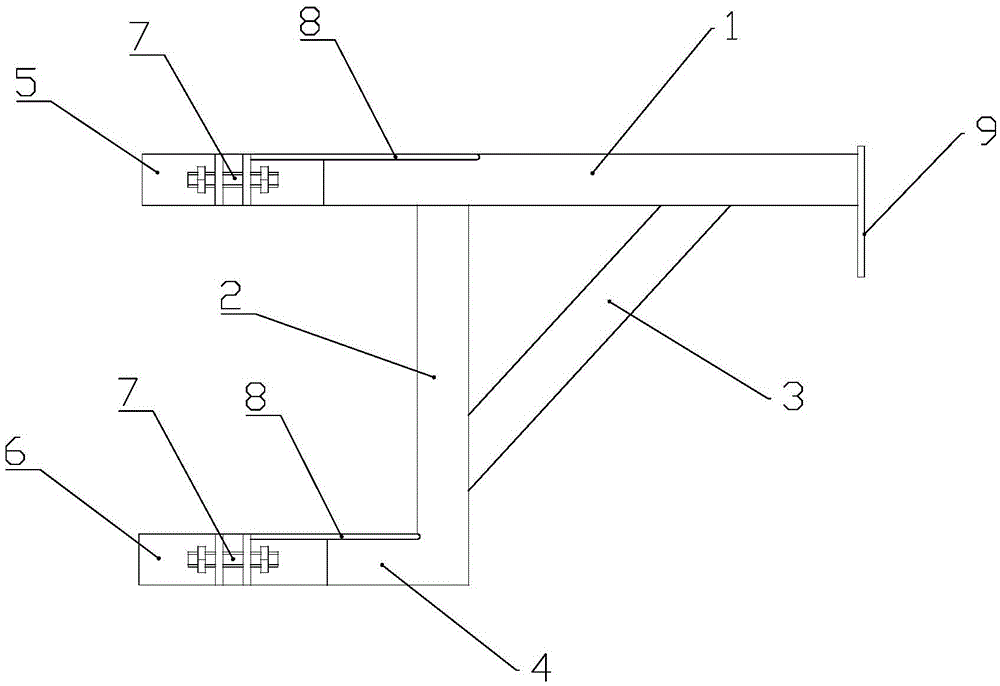

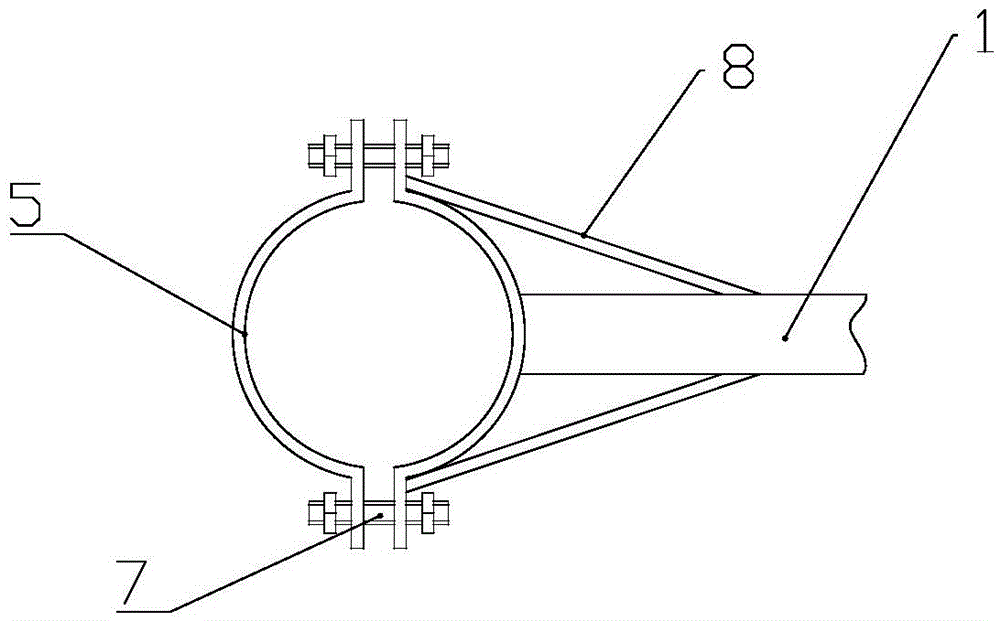

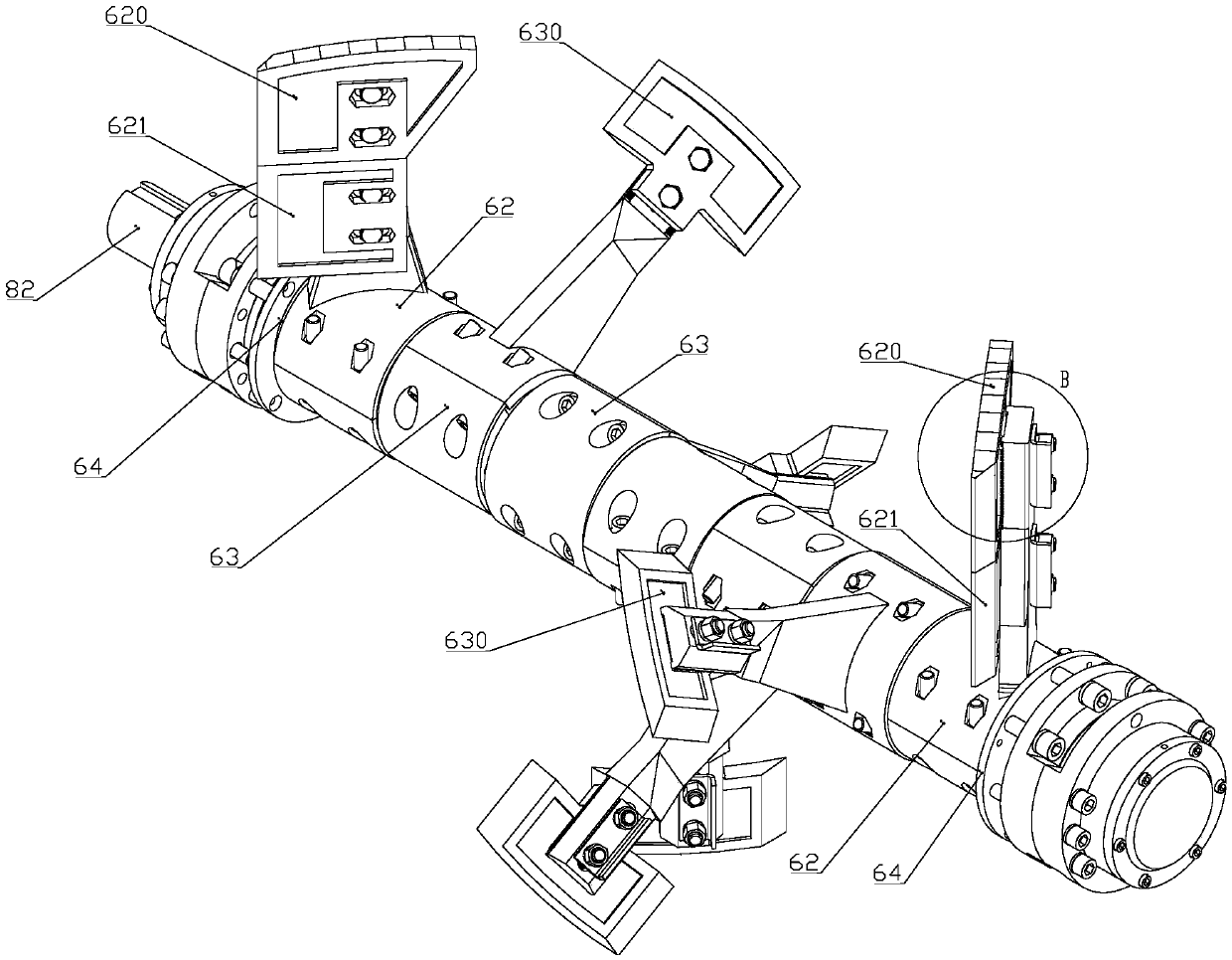

Device for equipment hoisting on overhead power line pole and installation tool thereof

ActiveCN105668446AEasy to fix the switchCompensation for degradationPortable liftingGearing elementsFree formOverhead power line

The invention discloses a device for equipment hoisting on an overhead power line pole and an installation tool thereof, and belongs to the field of power construction. The device comprises at least one cross arm, wherein a pulley fixation device for installing pulleys for hoisting is fixedly connected to one end of the cross arm, a first stay wire hoop is fixedly connected to the other end of the cross arm, and the cross arm is installed on an electric pole through the first stay wire hoop. The installation tool comprises an elastic clamping piece, wherein a plurality of climbing wheels are uniformly distributed at the inner side of the elastic clamping piece, and the climbing wheels rotate to drive the elastic clamping piece to climb the electric pole; and a locking device for locking the first stay wire hoop is installed on the elastic clamping piece through a connection plate. The device is free form the influence of geographical environment, and in particular, avoids the dispute caused due to the entrance of large machinery into the ground, in the countryside, increases the construction efficiency, and reduces the construction expense; and the installation tool completes installation for the device on the premise of no need of manual climbing, and avoids the potential safety hazards brought by manual climbing installation.

Owner:JINING POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

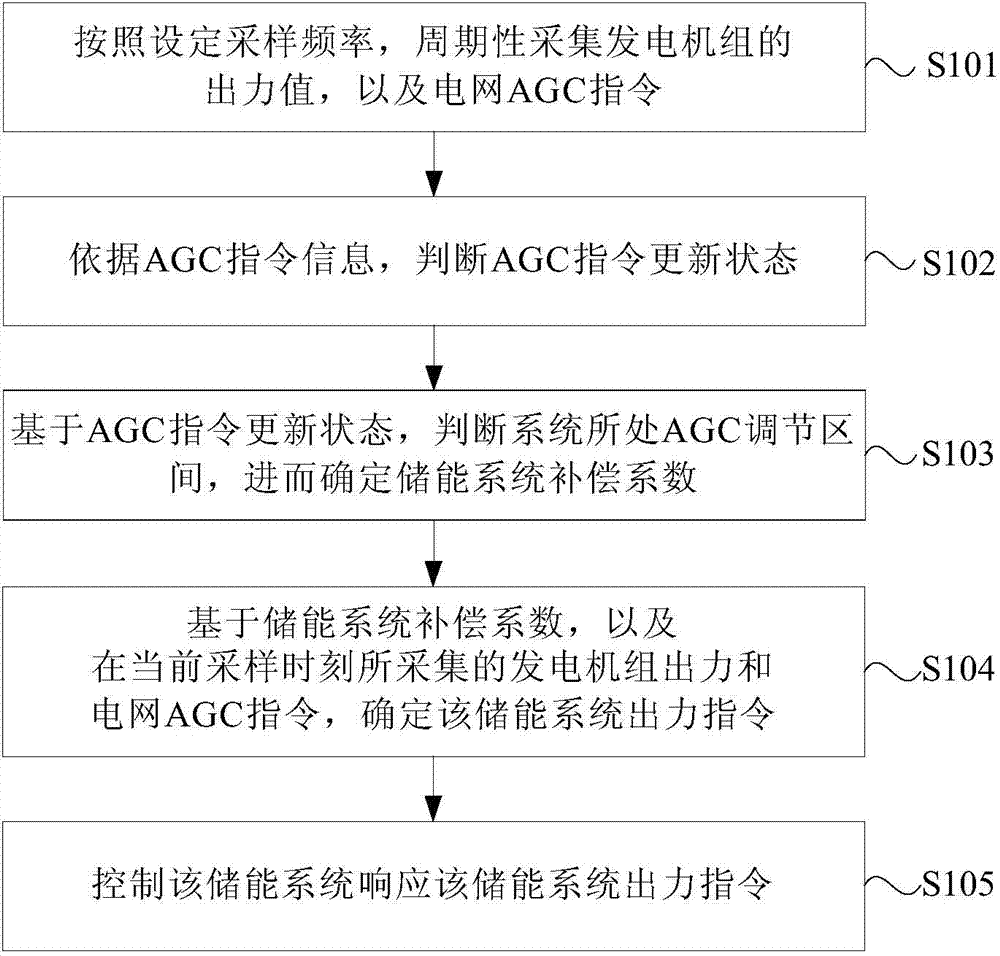

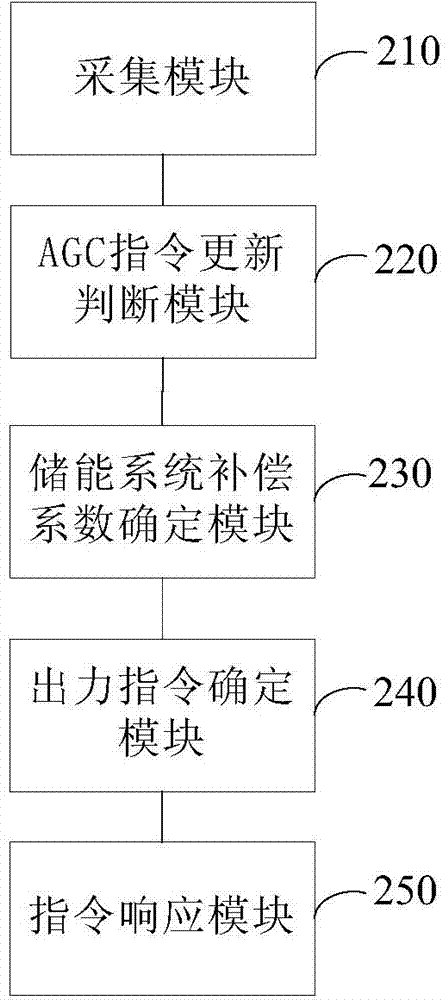

Energy storage system output overshoot suppression control method and device

ActiveCN104767213AImprove responsivenessCompensation for degradationEnergy storageAc network load balancingAutomatic Generation ControlPower grid

The embodiment of the invention discloses an energy storage system output overshoot suppression control method and a device. The method comprises steps: according to a set sampling frequency, generator set output and a power grid AGC (Automatic Generation Control) instruction are acquired periodically; a state is updated according to the AGC instruction, and energy storage system compensation coefficients are determined; on the basis of the energy storage system compensation coefficients and the generator set output and the power grid AGC instruction acquired at the current sampling time, an energy storage system output instruction of the energy storage system is determined, and the energy storage system is controlled to respond to the energy storage system output instruction. Thus, by using the scheme of the invention, during the process during which the energy storage system and the generator set coordinate to respond to the power grid AGC instruction, the energy storage system output overshoot is suppressed, combined output of the generator set and the energy storage system can be more precisely controlled, and effects of a response to the power grid AGC instruction are enhanced.

Owner:北京睿能世纪科技有限公司 +2

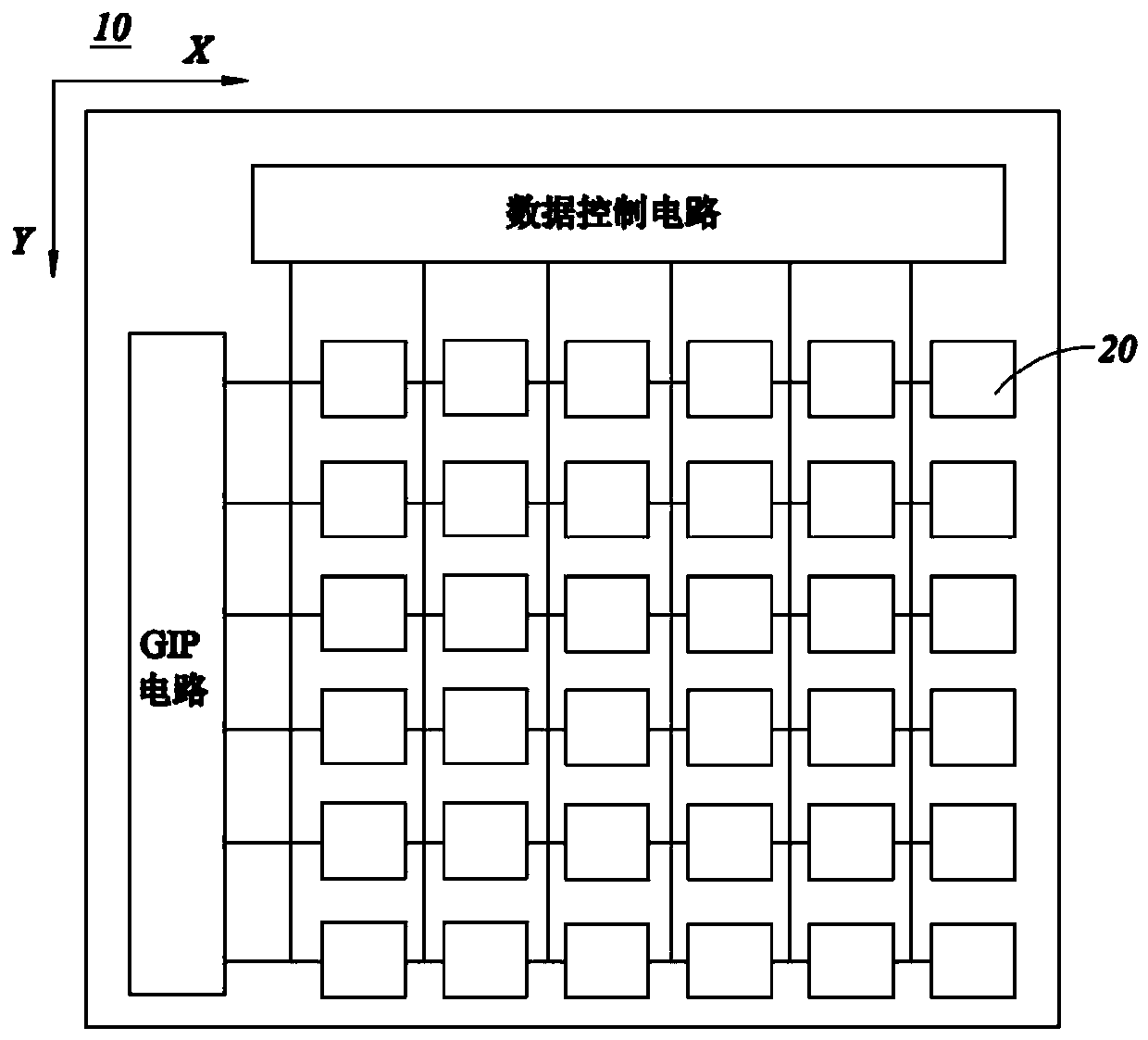

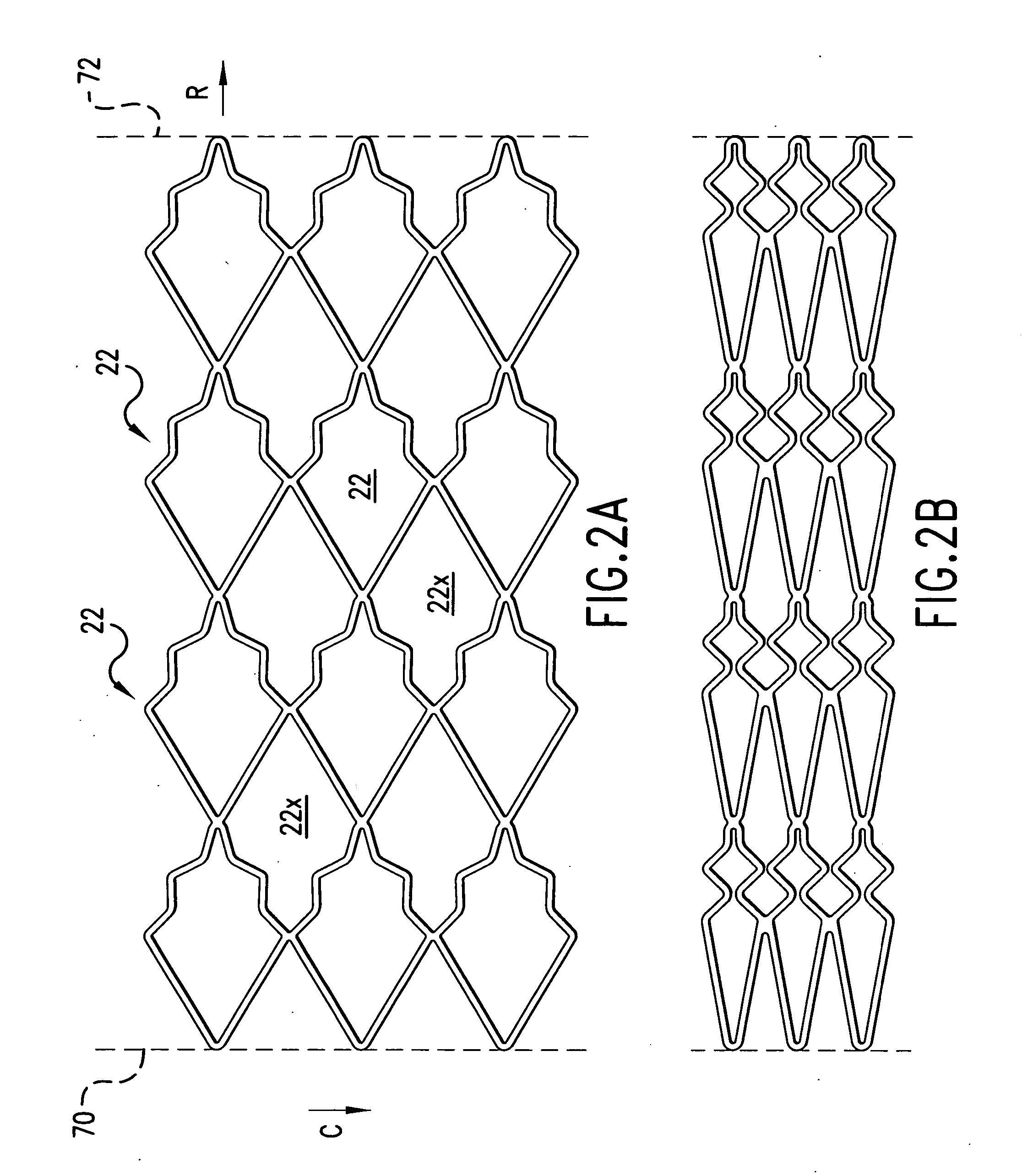

Pixel, driving method, display panel with pixel and display device

ActiveCN109872693AReduce the reduction in brightnessCompensation for degradationStatic indicating devicesAnode voltageEngineering

The invention discloses a pixel, a driving method, a display panel with the pixel and a display device. The pixel comprises an organic light-emitting diode, a driving unit and a compensation unit, thedriving unit is combined to the organic light-emitting diode, and the compensation unit is combined to the data line and the organic light emitting diode, wherein when the pixel is in the compensation time period, the compensation unit is used for obtaining the difference value between the data voltage provided by the data line and the anode voltage of the organic light-emitting diode, the driving unit adjusts the driving current according to the difference value, and the driving current is used for driving the organic light-emitting diode to emit light. According to the present invention, the driving current can be adjusted according to the difference value between the data voltage provided by the data line and the anode voltage of the organic light-emitting diode, so that the driving current rises to compensate the degradation of the organic light-emitting diode, and the reduction of the brightness of the organic light-emitting diode can be reduced.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

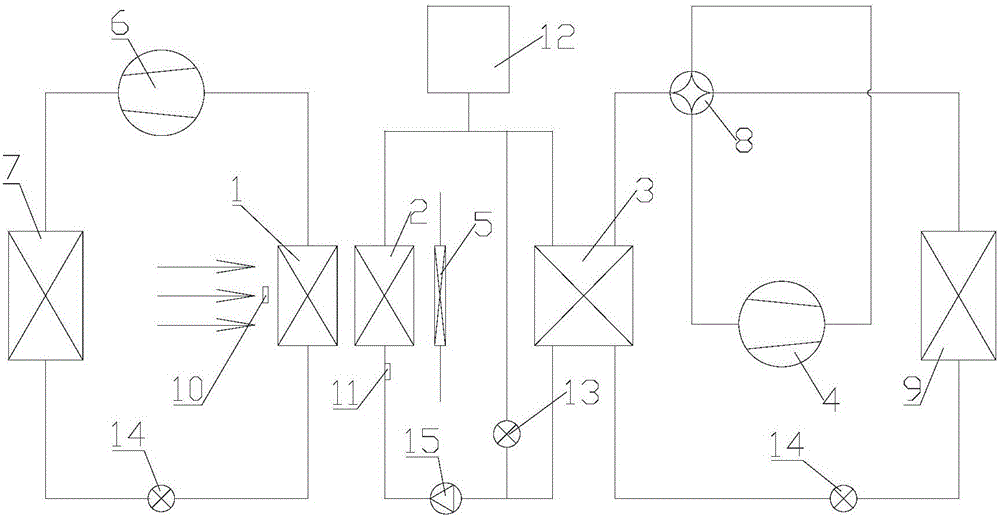

Air conditioning system and control method for same

ActiveCN106152285AAchieving heating/coolingEasy to handleCompressorMechanical apparatusEngineeringAir conditioning

The invention discloses an air conditioning system and a control method for the same. The air-conditioning system comprises: a first refrigerant system including an evaporator; a water system including a first heat exchanger and a second heat exchanger, with the first heat exchanger being arranged at an air-out side of the evaporator and connected to a first heat exchange channel of the second heat exchanger; a second refrigerant system including a compressor A of which an output end is connected to a second heat exchange channel of the second heat exchanger; and a humidifier arranged at an air-out side of the first heat exchanger. The air conditioning system is capable of achieving warming / cooling and / or humidification / dehumidification of air through the use of different combinations of the water system, the second refrigerant system, and the humidifier, thus allowing for fast and accurate processing of temperature and humidity in different operating conditions; therefore, temperature and humidity compensation is decreased, and energy loss is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

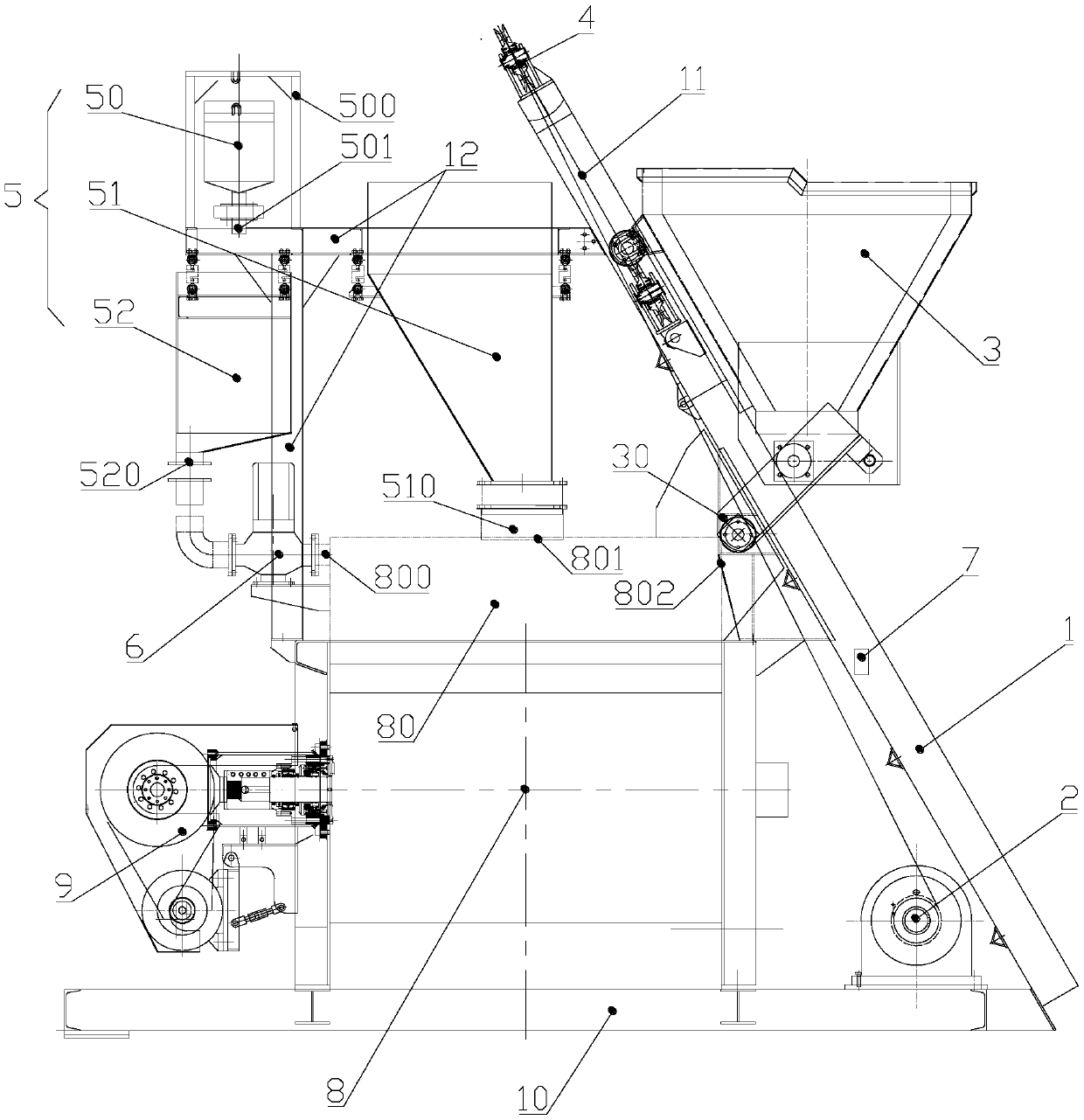

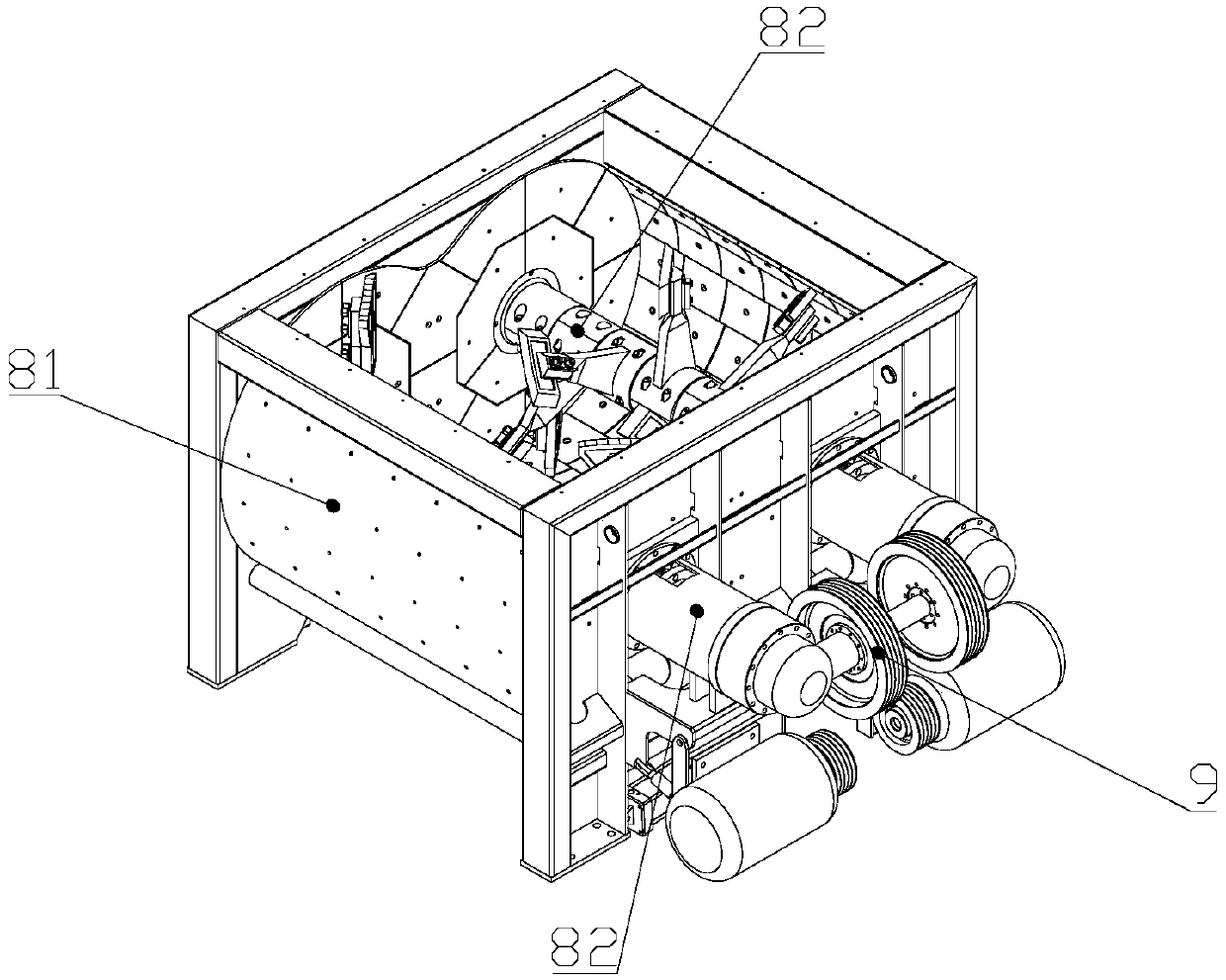

Concrete stirrer high in safety performance

InactiveCN109605573ASimple structureReduce maintenance replacement timesMixing operation control apparatusCement mixing apparatusAutomatic controlEngineering

The invention discloses a concrete stirrer high in safety performance. The concrete stirrer high in safety performance comprises a weighing device, a hopper, a climbing frame, a lifting mechanism anda stirring main machine fixed to a bottom frame; the climbing frame is obliquely arranged in the direction of the stirring main machine and is fixed to the bottom frame; the hopper moves along a trackon the climbing frame through the lifting mechanism; the stirring main machine comprises a stirring tank which is provided with a main machine cover; the top face of the main machine cover is provided with a center feeding port, the side face of the main machine cover is provided with a water inlet, and the side opposite to the side face of the main machine cover is provided with a lateral feeding port; a supporting frame which the weighing device is fixed to is arranged on the two sides of the stirring tank; the weighing device comprises an external adding agent scale, a water weighing hopper and a cement weighing hopper; the water weighing hopper is connected to the water inlet through a water conveying pipe; a liquid outlet of the external adding agent scale supported through a suspending frame is right opposite to an opening of the water weighing hopper; a material outlet of the cement weighing hopper is right opposite to the center feeding port of the main machine cover; and whenthe hopper is lifted to an extreme, an unloading port of the hopper is connected with the lateral feeding port. The concrete stirrer high in safety performance is high in automatic control degree andsafety performance.

Owner:佛山市诺通重工科技有限公司

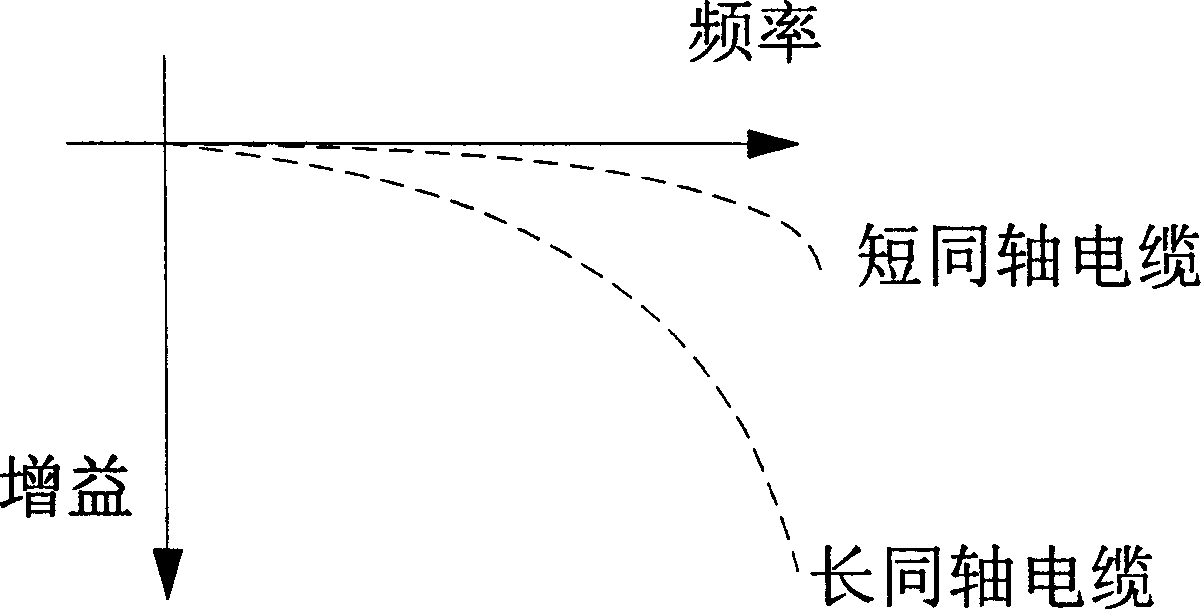

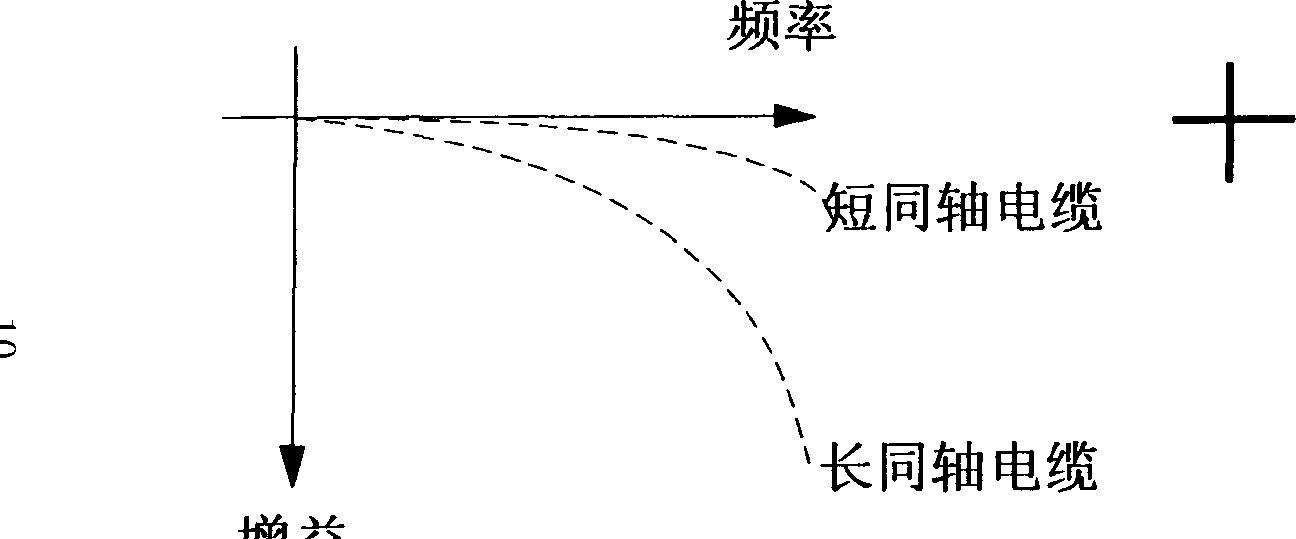

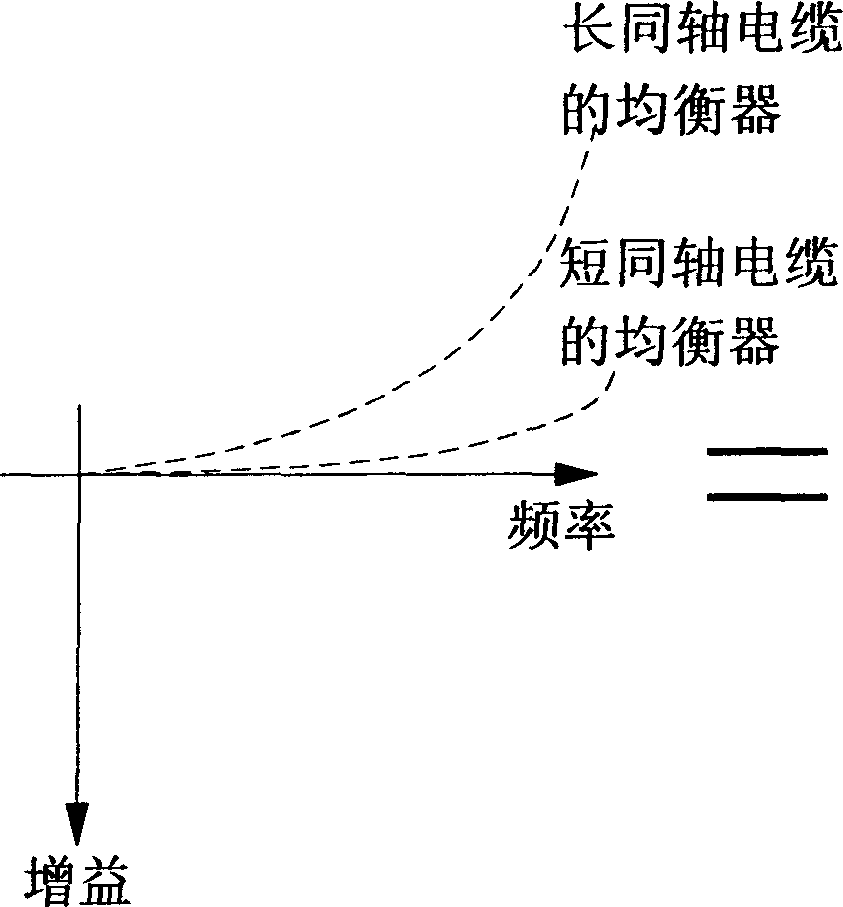

Multi-stage cable equipoise device

ActiveCN1705243ACompensation for degradationLow costTransmission control/equlisationUltrasound attenuationEngineering

The invention relates to a multi-stage cable equipoise device mainly composed by a fixed type gain device being cooperated with an adjustable type gain device. The multi-stage cable equipoise device performs attenuation compensation on a main frequency band of a cable signal by the fixed type gain device, and performs adjustment on different individual frequency bands of the cable signal by the adjustable type gain device. The multi-stage cable equipoise device can has an advantage of elasticity during usage in a condition of low cost because of a design of the fixed type gain device being cooperated with the adjustable type gain device.

Owner:MEDIATEK INC

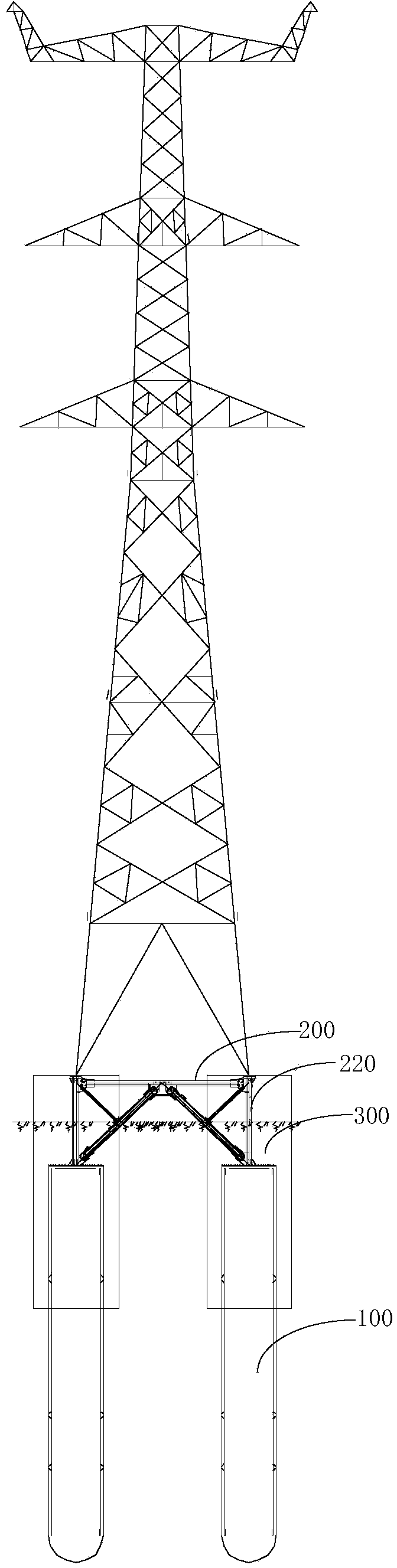

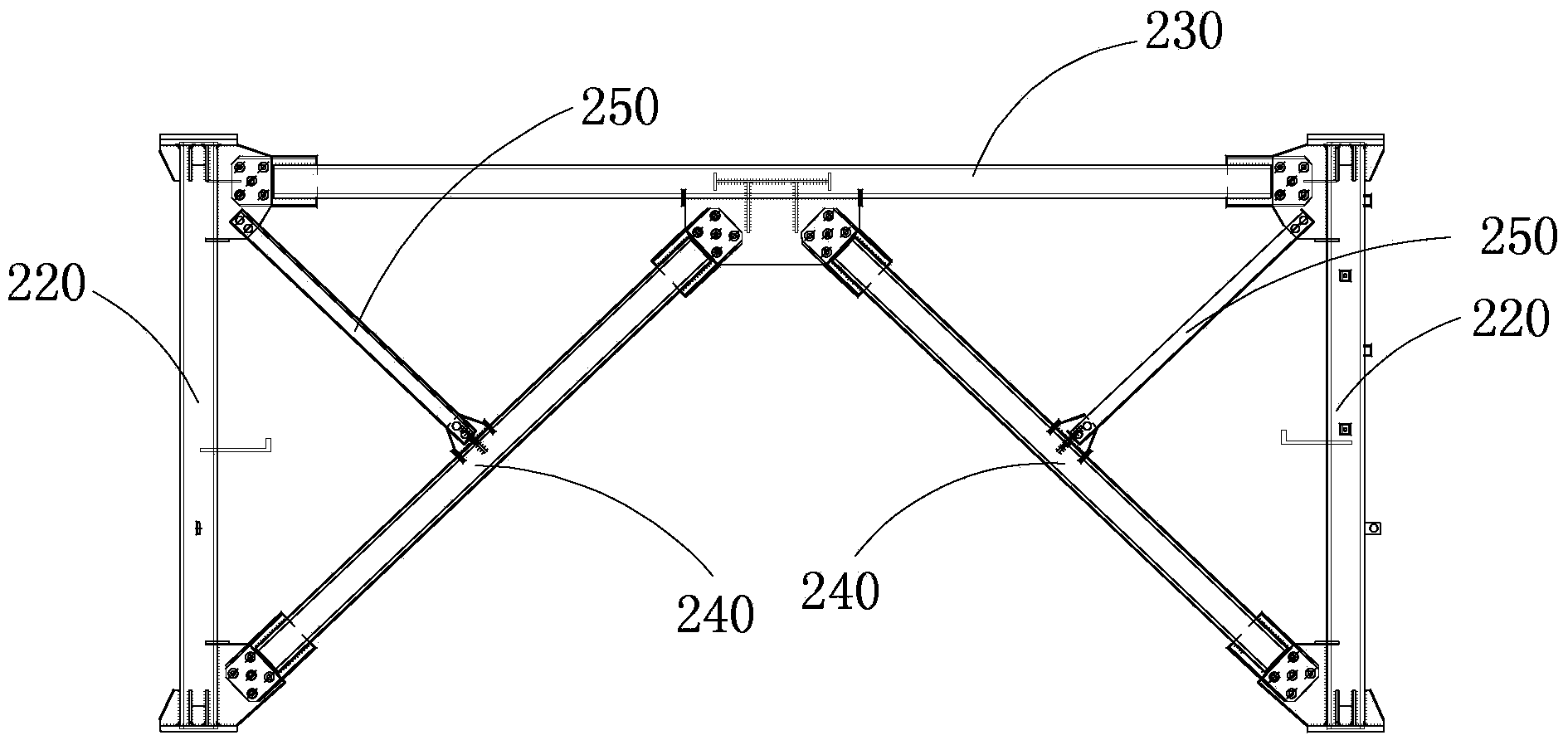

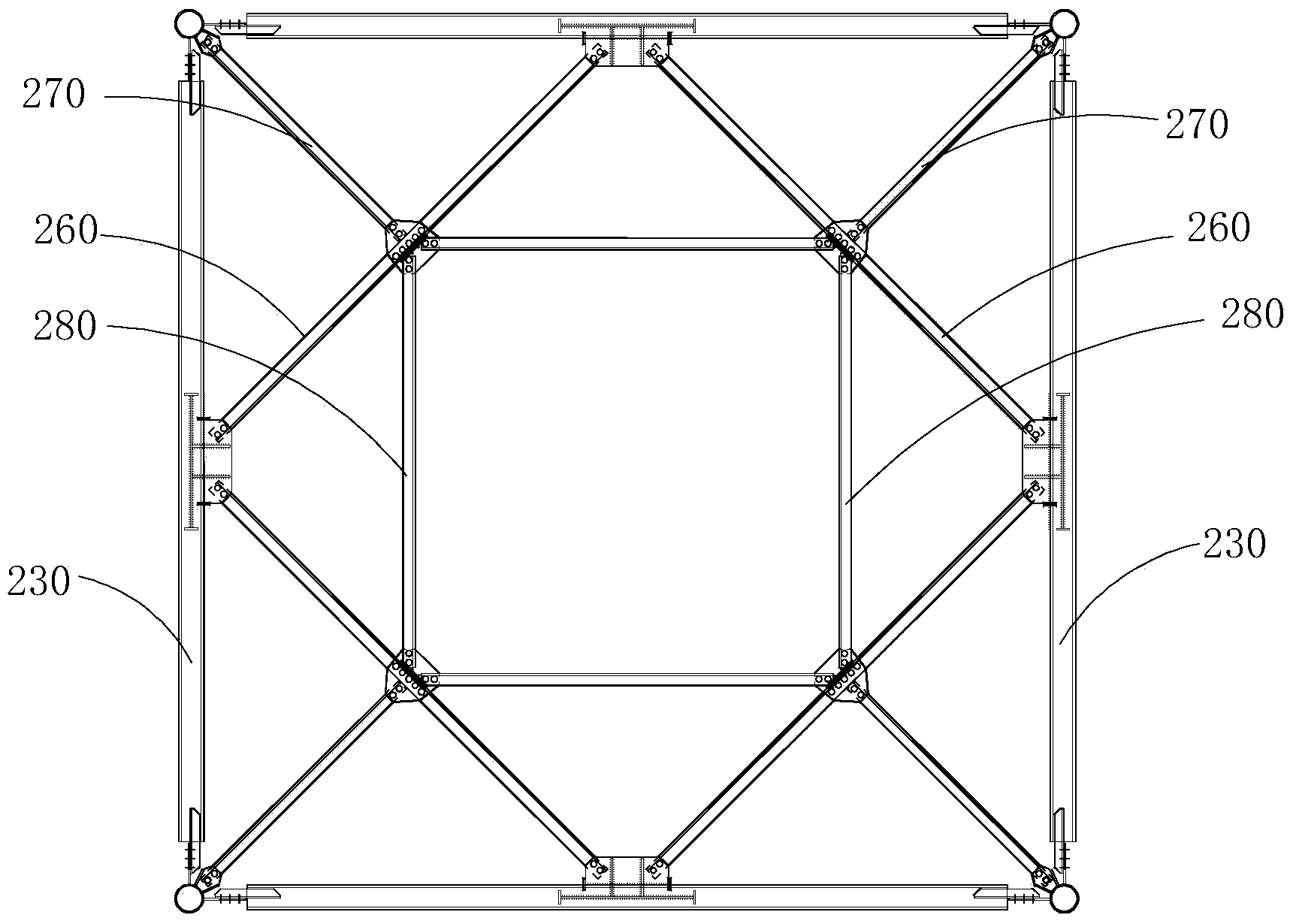

Tower pile foundation exposure lifting structure and construction method

The invention discloses a tower pile foundation exposure lifting structure and a construction method. The tower pile foundation exposure lifting structure comprises pile foundation columns, a supporting truss and exposure columns. The supporting truss comprises a plurality of supporting columns, first transverse rods, first slant rods, first connecting rods, second slant rods and second connecting rods, the supporting columns are matched with the pile foundation columns one by one, the upper ends of the supporting columns are connected with a tower, and the lower ends of the supporting columns are connected with the pile foundation columns. Each exposure column warps the corresponding supporting column and partially wraps the pile foundation column matched with the corresponding supporting column, the upper ends of the exposure columns are flush with the upper ends of the supporting columns, and the lower ends of the exposure columns extend to the pile foundation columns. The tower pile foundation exposure lifting construction method includes the steps of enabling the tower to be separated from the pile foundation columns, enabling the lower ends of the supporting columns of the supporting truss to be fixed on the pile foundation columns, enabling the upper ends of the supporting columns of the supporting truss to be fixed on the tower, and constructing the exposure columns outside the supporting columns and the pile foundation columns. According to the tower pile foundation exposure lifting structure and the construction method, the internal combination is compact, the structure is firm, tower pile foundation exposure can be effectively lifted, and the construction cost is reduced.

Owner:GUANGZHOU ELECTRIC POWER DESIGN INST

Manufacturing method for silicon epitaxial wafer of low-voltage TVS (transient voltage suppressor)

ActiveCN102290337BCompensation for degradationImprove gas phase conditionsSemiconductor/solid-state device manufacturingCooking & bakingHydrogen

Owner:NANJING GUOSHENG ELECTRONICS

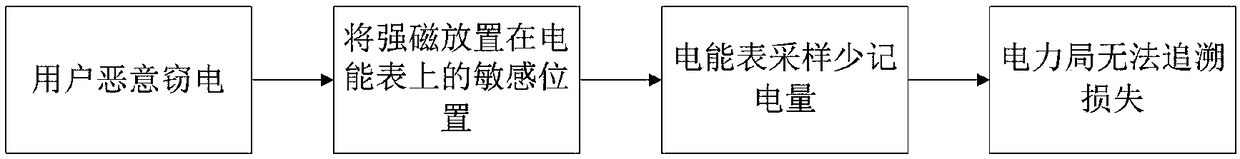

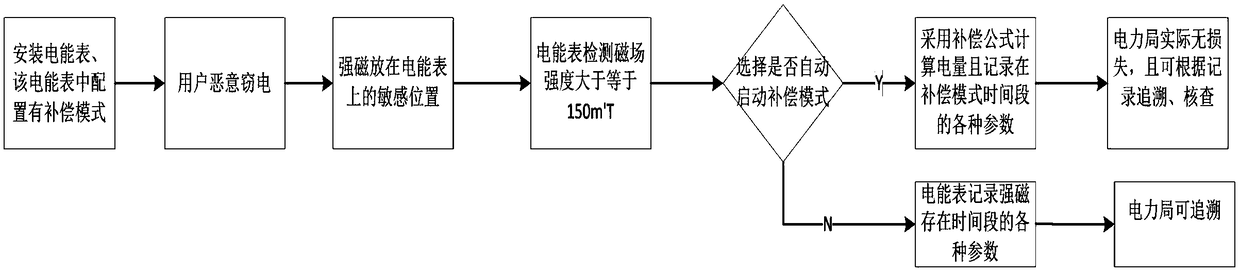

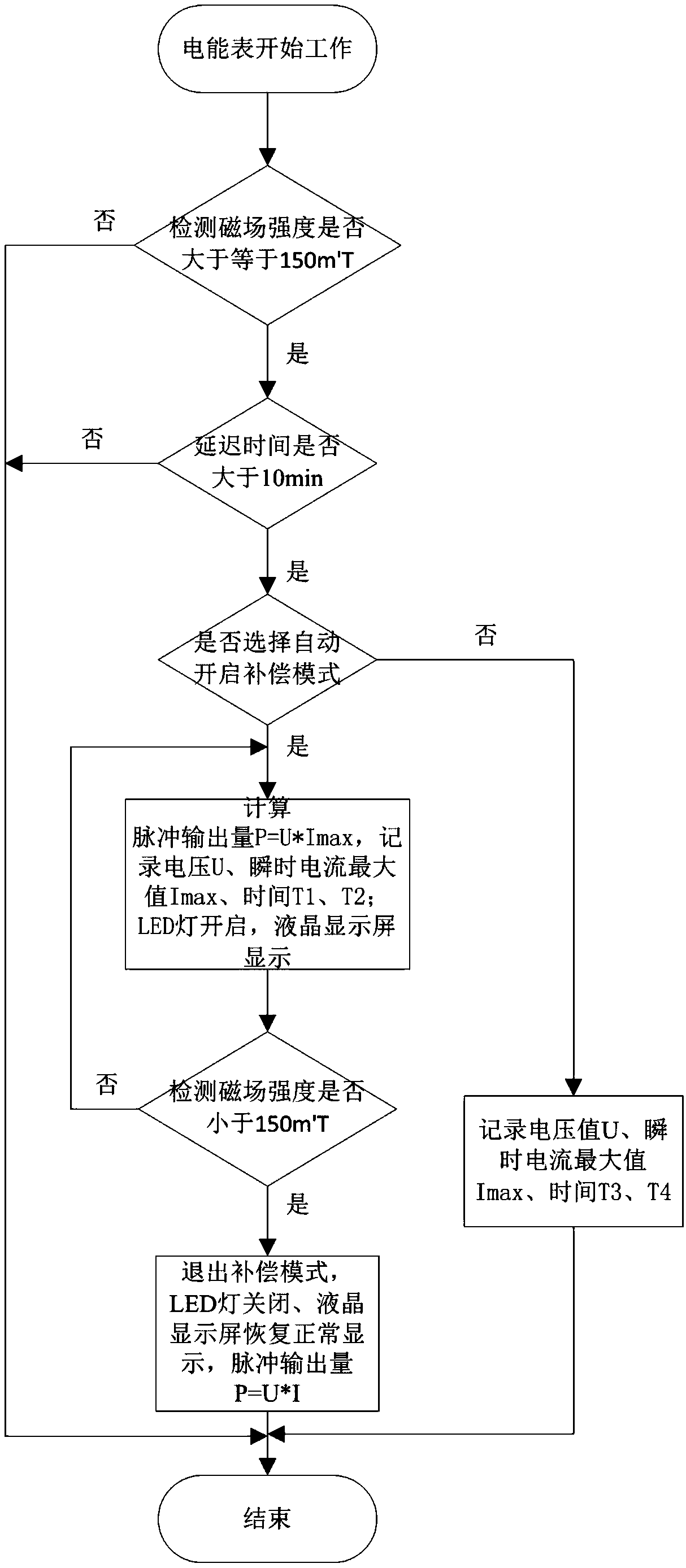

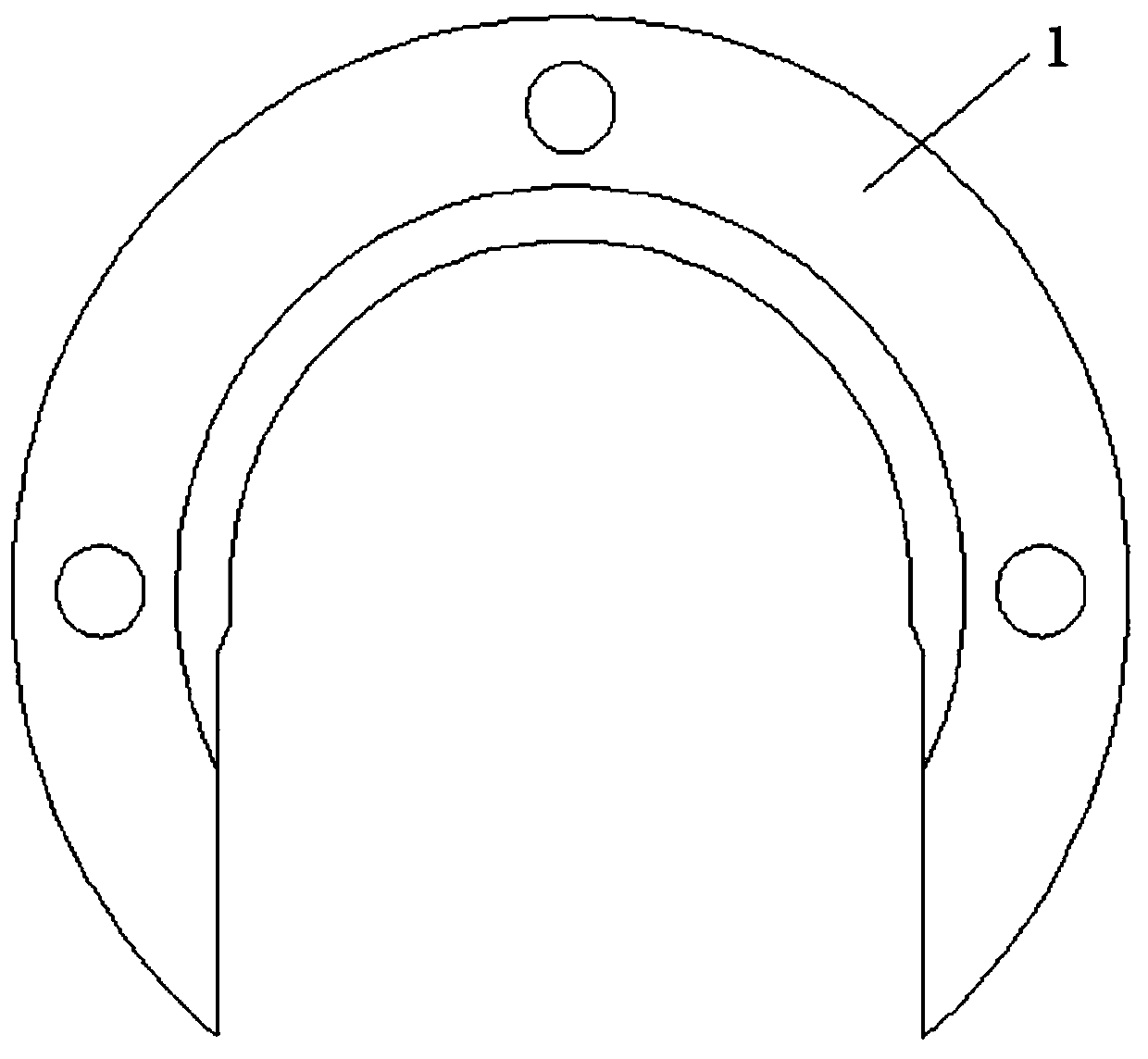

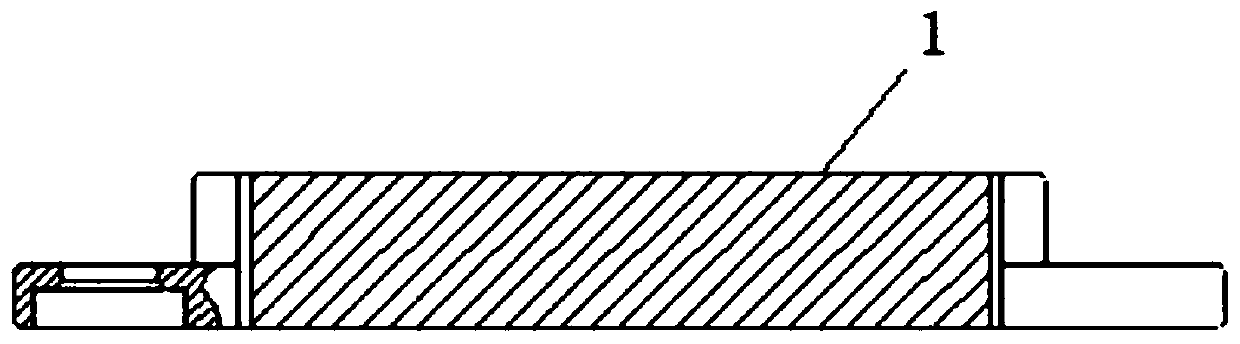

Anti-electric stealing measuring method for electric energy meter

The invention provides an anti-electric stealing measuring method for an electric energy meter. The method comprises the following steps: S1, starting running of the electric energy meter; S2, determining whether a preset electric stealing condition that the magnetic field strength of the electric energy meter is greater than 150m'T is satisfied, proceeding with S3 if so, otherwise returning to the S1; S3, determining whether a preset selection compensation mode is automatically started, proceeding with S4 if so, otherwise proceeding with S6; S4, using a compensation measurement formula P=U*Imax to calculate a pulse output quantity, recording voltage and current parameters, and proceeding with S5; S5, exiting the compensation mode, using a normal measurement formula P=U*I to calculate thepulse output, and proceeding with S7; S6, recording a start time T3 and an end time T4 of the time period that meets the preset electric stealing condition, and recording a current instantaneous maximum value Imax and a voltage value U within T3 and T4; and S7, ending. By providing a compensation mode, the anti-electric stealing measuring method for an electric energy meter can automatically calculate the power loss of the electric energy meter during the electric stealing time period, or record various parameters of the electric energy meter during the electric stealing time period, so as tofacilitate subsequent recovery.

Owner:NINGBO SANXING INTELLIGENT ELECTRIC

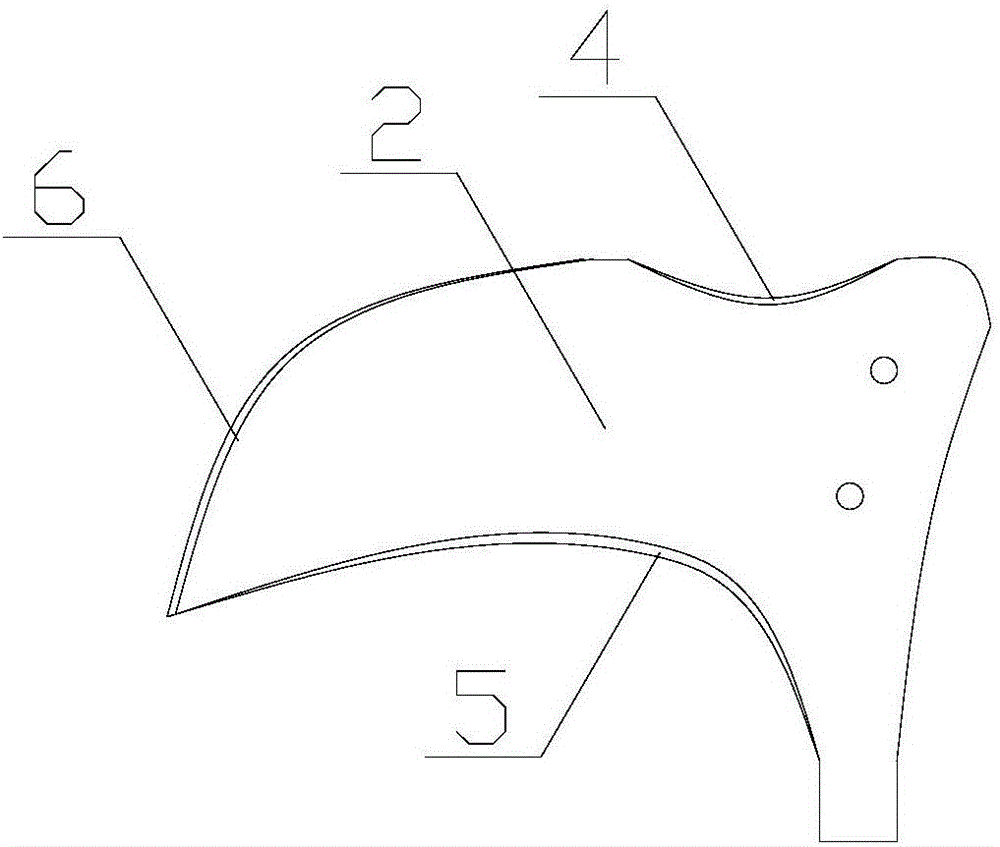

Automobile saddle opening end cover machining method through inner ring surface induction quenching hardening

ActiveCN110777236AHigh hardnessGuaranteed toughnessFurnace typesIncreasing energy efficiencyStructural engineeringInduction hardening

The invention discloses an automobile saddle opening end cover machining method through inner ring surface induction quenching hardening. The method comprises the following steps that 1), a blank is forged for forming; 2), the blank treated in the step 1) is subjected to thermal refining; and 3), the blank treated in the step 2) is machined to be an automobile saddle opening end cover, and finallyscanning induction quenching strengthening is carried out. According to the method, by adopting scanning type induction quenching, quenching strengthening is carried out on the inner surface of the saddle opening end cover, the hardness of the inner surface can be remarkably improved, and meanwhile, the overall toughness of the part is maintained.

Owner:DONGFENG COMML VEHICLE CO LTD

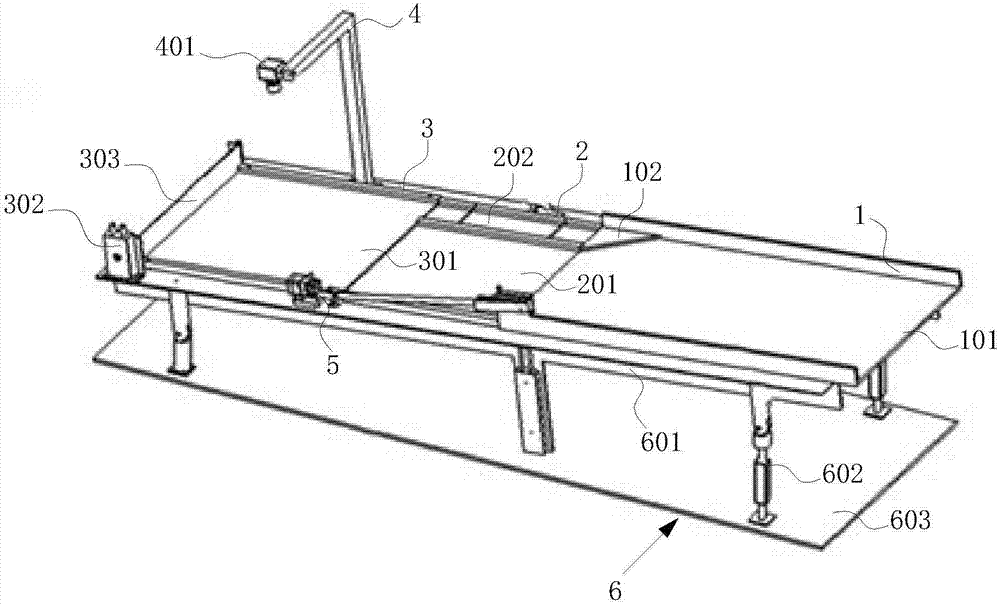

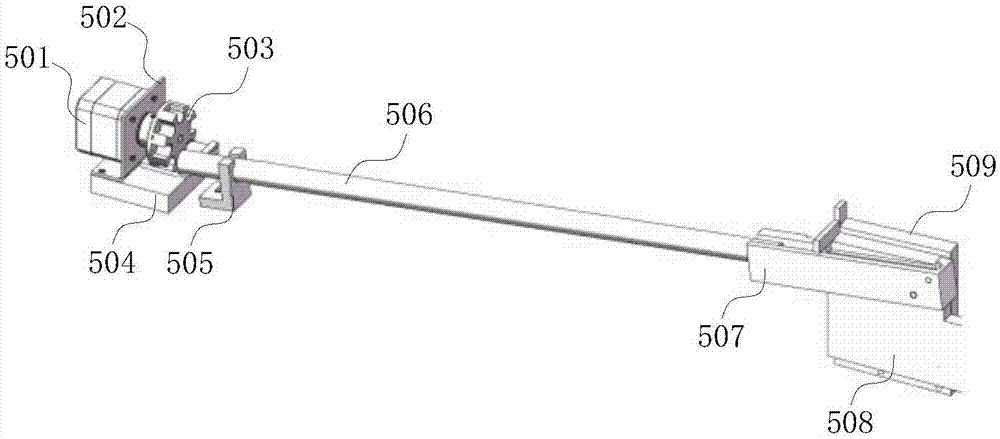

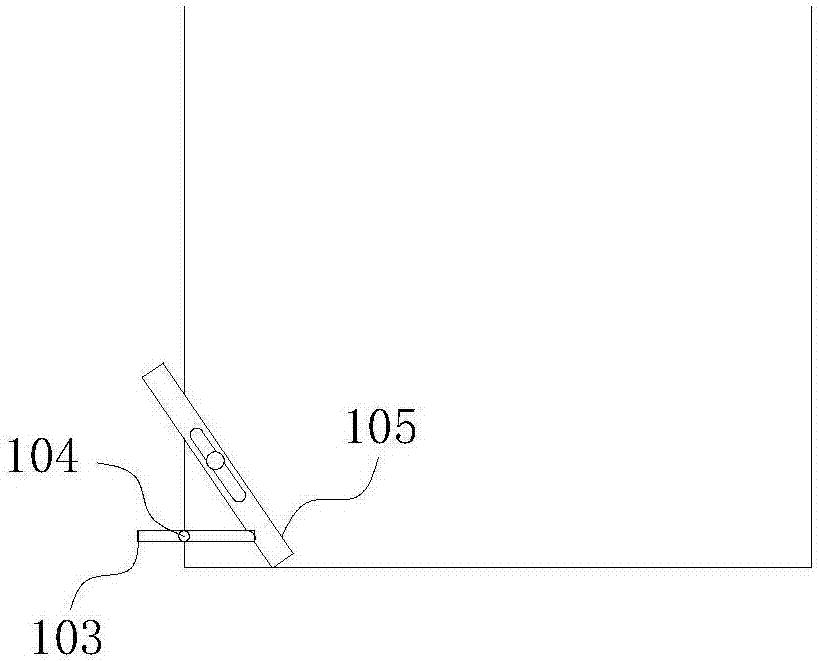

Steel ball precision counting and size identification device and method

ActiveCN107274407ARealize identificationReduce compensationImage enhancementImage analysisComputer control systemEngineering

The invention discloses a steel ball precision counting and size identification device and method and belongs to the steel ball manufacture technical field. The invention aims to solve the problems of low counting precision and incapability of identifying the sizes of steel balls in the prior art. The steel ball precision counting and size identification device of the present invention comprises a material storage unit, a pre-counting unit, a precise counting unit, an image acquisition unit, a computer control system and a single compensation system; the pre-counting unit is arranged at the outlet end of a material storage disk and comprises a pre-counting disk of which two sides are provided with protruding edges, an area adjusting mechanism which adjusts the working area of the pre-counting disk, and a first lifting mechanism which drives the pre-counting disk to move up and down; the precise counting unit is arranged at the outlet end of the pre-counting disk; the image acquisition unit is arranged above the precise counting unit and acquires the images of steel balls on a precise counting disk; the computer control system is connected with the image acquisition unit; the computer control system controls each moving unit to move and performs data processing on the images of the steel balls so as to obtain steel ball quantity and steel ball size information; the single compensation system performs step compensation on the steel balls on the precise counting disk; and the material storage disk, the pre-counting disk and the precise counting disk tilt entirely.

Owner:CHANGCHUN UNIV OF SCI & TECH

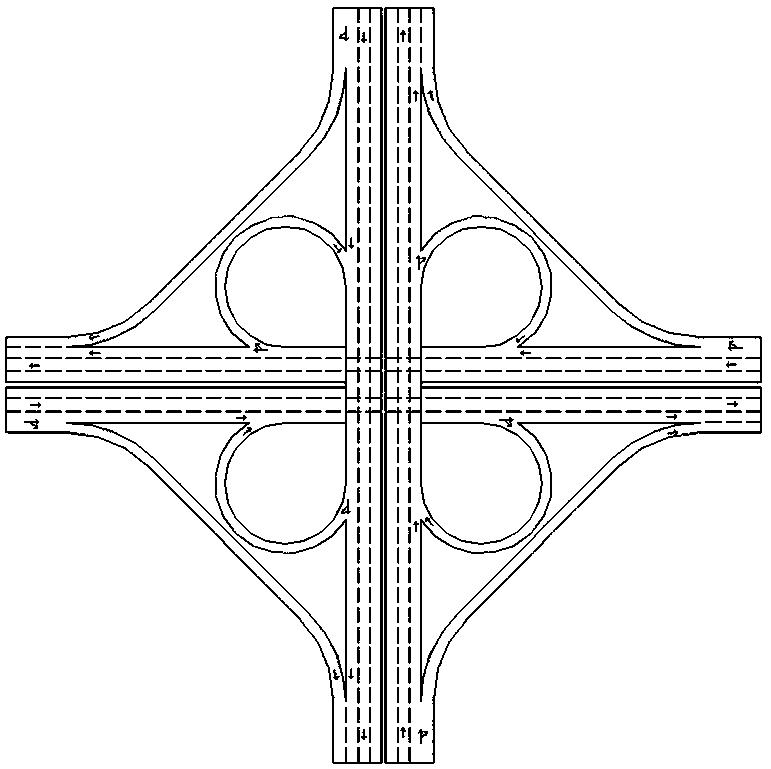

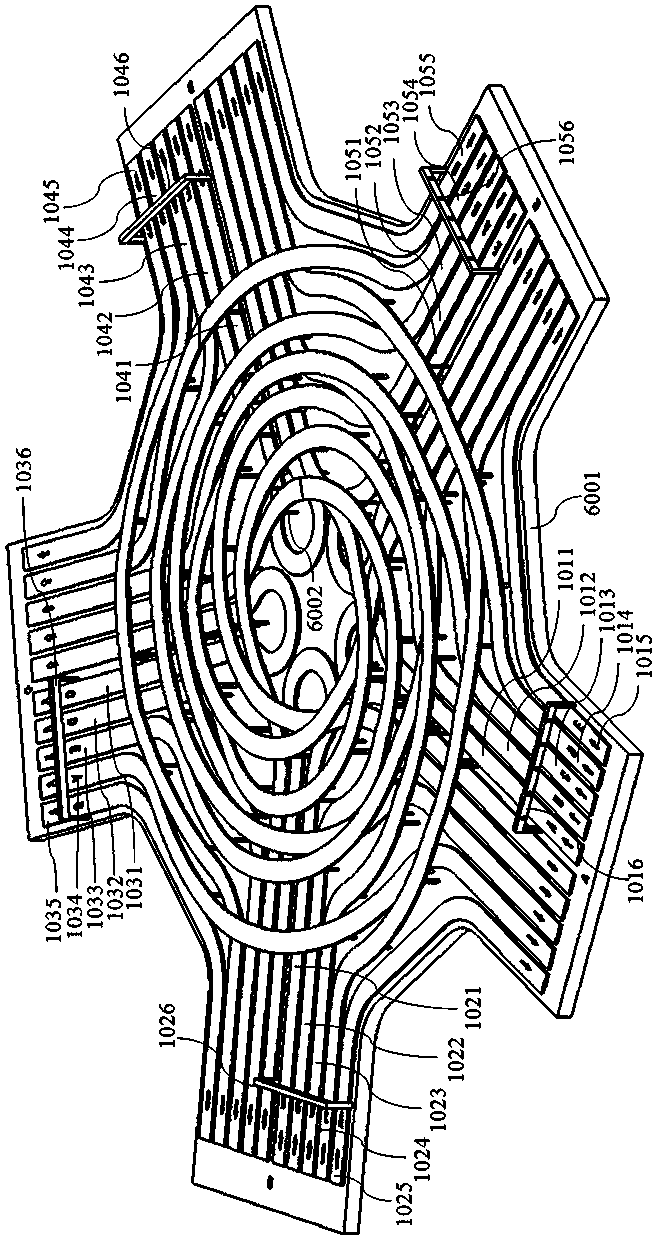

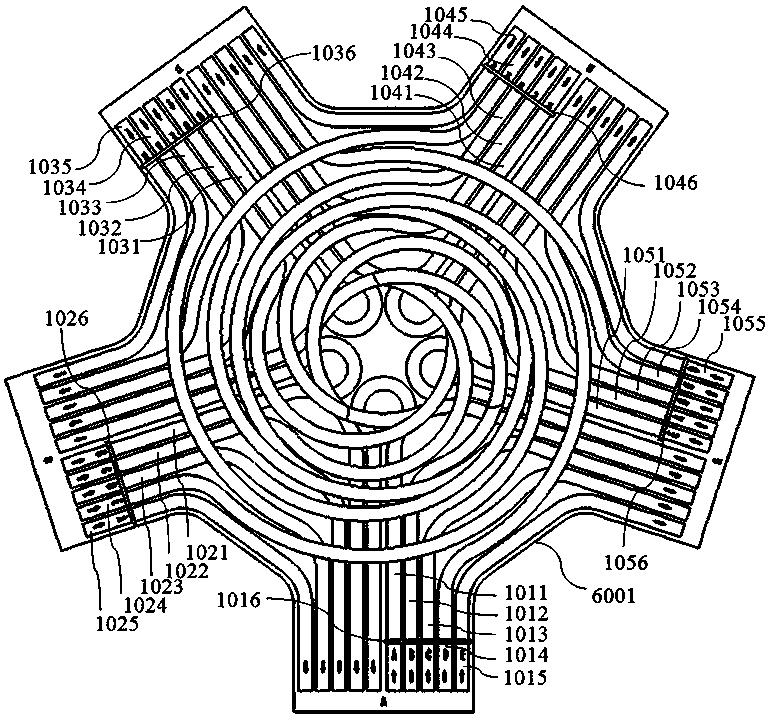

Compact automatic diversion intersection system

The invention discloses a compact automatic diversion intersection system. The system comprises a foundation, a plurality of intersections and a plurality of piers, each intersection comprises a ground turning-around path, a ground turning path and one or more upper and lower diversion paths which are divided into a ground layer and an overhead layer, and all the paths do not interfere with each other to ensure the passing height; land resource occupation is reduced by about two thirds, demolition and compensation are reduced, oil, electricity, time and money are saved, and good economic valueis achieved; rural and suburb cultivated lands are saved, and the social value is high; the driving distance is short, emission is little, and certain environment-friendly value is achieved; all thepaths are special paths, automatic diversion is achieved without forks or lane merging, drivers do not worry about the paths, and good driving experience is achieved; the traffic is fast, the flow islarge, and the system is an effective method for governing urban congestion and reducing traffic accidents; and the compact automatic diversion intersection system can be built in a place where a large flyover cannot be built due to space limitation in the past, so that the system becomes true.

Owner:深圳市华海科技研发有限公司

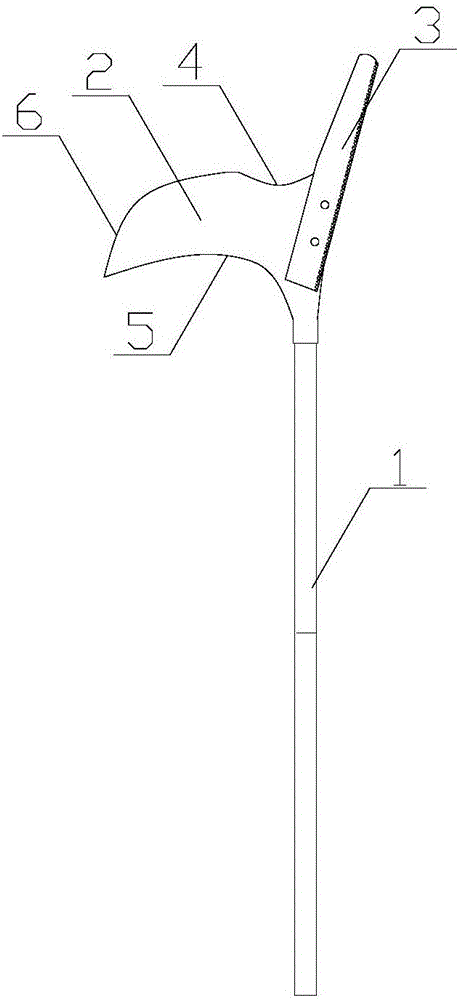

Tool for clearing barriers around aerial cables on ground

InactiveCN106655007AReduce the risk of live operationReduce security risksApparatus for overhead lines/cablesAerial cableEngineering

The invention discloses a tool for clearing barriers around aerial cables on the ground. The tool comprises an insulating rod, a cutter and a saw blade, the cutter is sickle-shaped, a meniscate first cutting blade is arranged at the top of the cutter, a second cutting blade bent inward is arranged below the cutter, an arc-shaped third cutting blade is arranged on a side edge of a front end of the cutter, a tool holder is arranged at a tail end of the cutter, the tool holder is fixed to a top end of the insulating rod, and the saw blade is fixed to the tail end of the cutter. Compared with the prior art, the tool disclosed by the invention has the functions of chopping, cutting, jacking, pulling, hooking and sawing, and requires no tree climbing aerial operation, thereby reducing the risk of electrified operation and greatly reducing the safety risk. No ladder needs to be carried, the tool is convenient to carry and is complete in functions, and an electrician can carry no other felling tools. The operation is simple and understandable, and a large amount of manpower is not required, thereby saving the labor cost. No power cut is required for close electrified branches in general. The compensation caused by cutting a whole tree resulting from that the branches cannot be cut is reduced.

Owner:STATE GRID SICHUAN ELECTRIC POWER

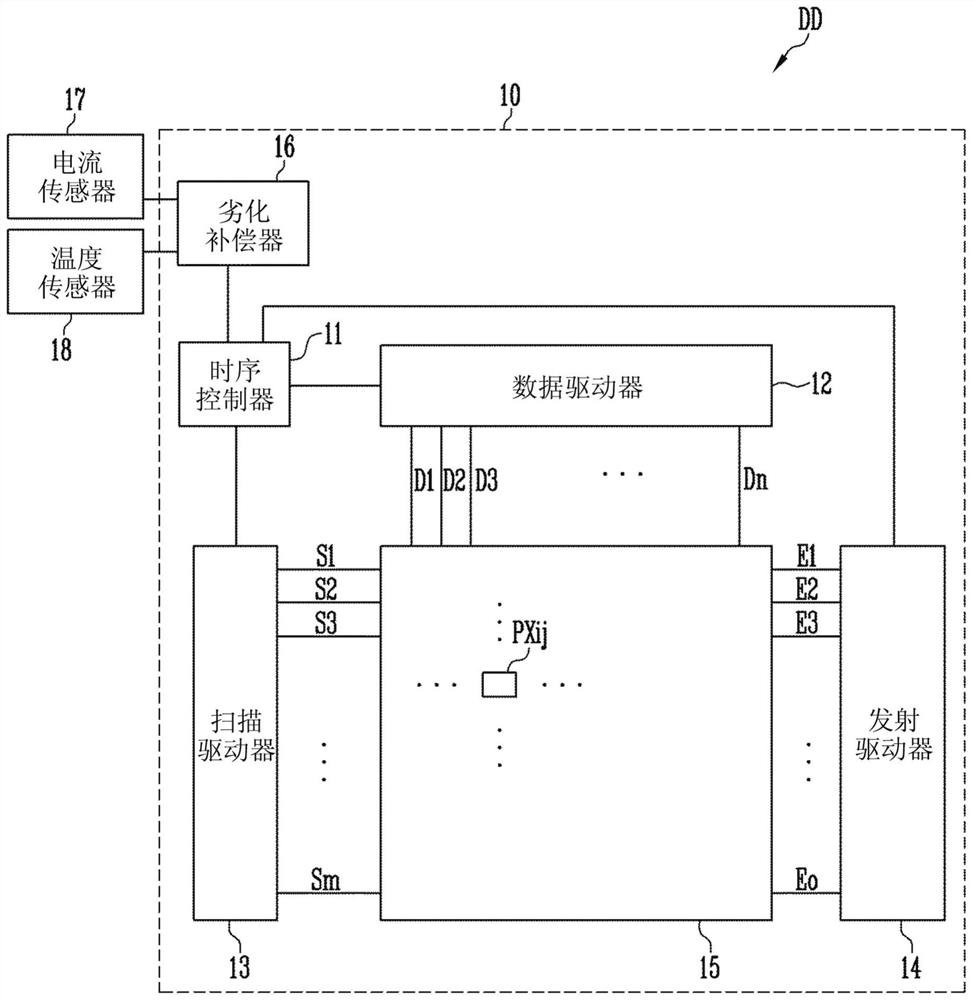

Display device

PendingCN111754931ACompensation for degradationStatic indicating devicesComputer hardwareCurrent transducer

A display device is provided. The display device includes: a display panel including a plurality of pixels configured to receive pixel driving currents; a current sensor configured to measure an entire driving current diverged into the pixel driving currents; and a temperature sensor configured to measure an ambient temperature of the display panel, wherein the display panel includes a degradationcompensator configured to generate output grayscale values for the pixels based on the entire driving current, the ambient temperature, and input grayscale values for the pixels.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com