Tissue with an insert edge and use of said tissue

A technology of fabric and side warp, applied in the direction of fabric, weaving, loom, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

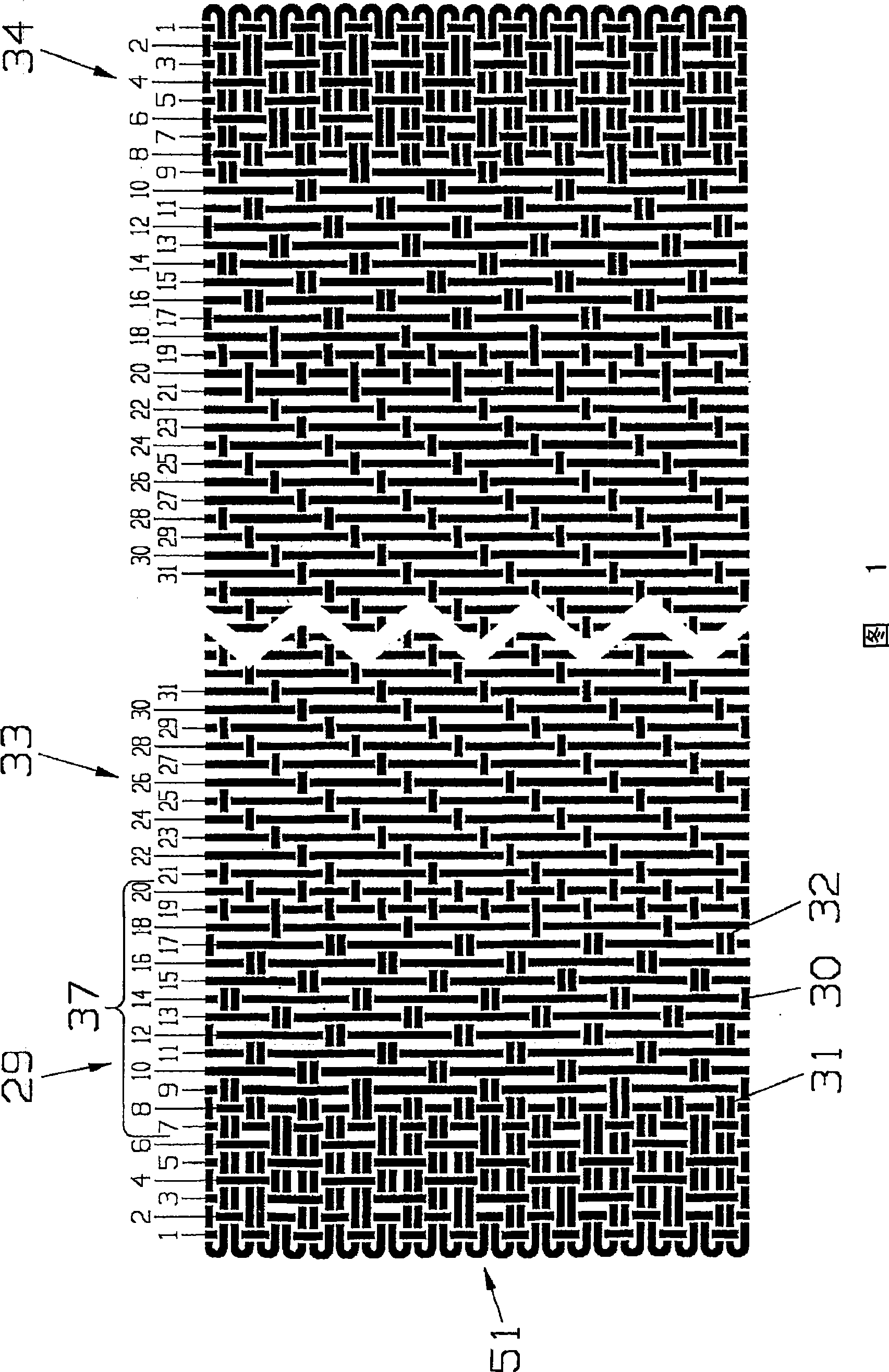

[0065] FIG. 1 shows a fabric according to the invention according to a first embodiment. Here, two sides of the fabric are shown schematically, the fabric having a fabric edge 29 or 34 on each side and a base fabric 33 in between. The white jagged lines interrupting the underlying fabric merely indicate that the right part of the fabric according to the invention shown in FIG. 1 is a mirror image of the left part. Therefore only the left part in FIG. 1 is referred to. Successive reference numerals 1 to 28 schematically show the warp threads in the region of the fabric trim 29 and the warp threads of a part of the underlying fabric. The warp threads 1 to 28 are shown vertically in FIG. 1 , whereas the weft thread 30 is shown horizontally. The weft threads 30 are led back into the fabric trim 29 at the selvedge with the weft thread end sections 31 and are woven there together with the corresponding warp threads 1 to 18 . The weft thread ends 32 are only indicated with the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com