OLED (Organic Light Emitting Diode) pixel structure for compensating light emitting nonuniformity and driving method

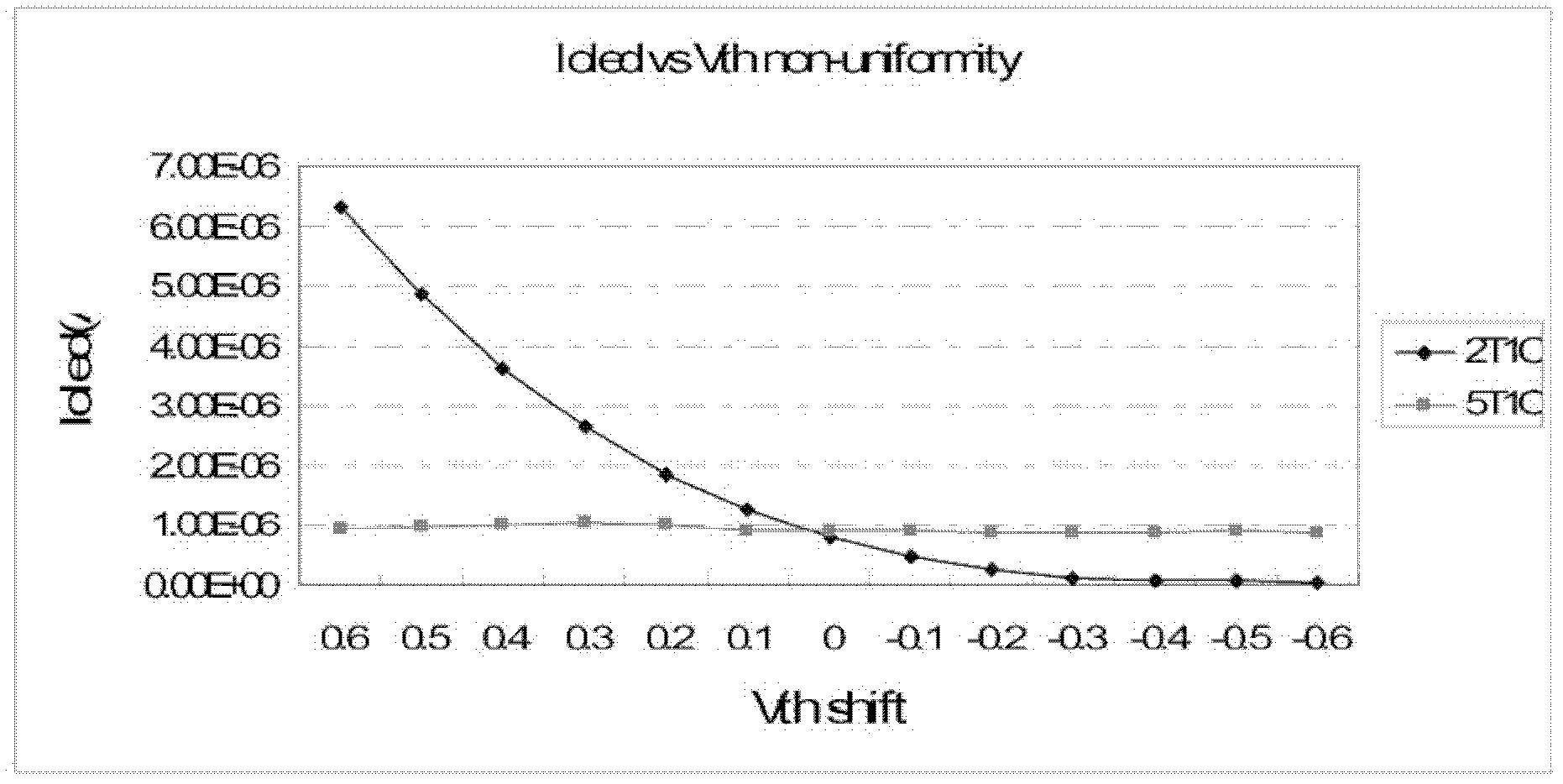

A technology of pixel structure and light-emitting display device, which is applied in the direction of static indicators, instruments, etc., can solve the problems of non-uniform electrical performance, unsuitable for large-size panel application, uneven light emission, etc., and achieve the goal of eliminating non-uniformity of threshold voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

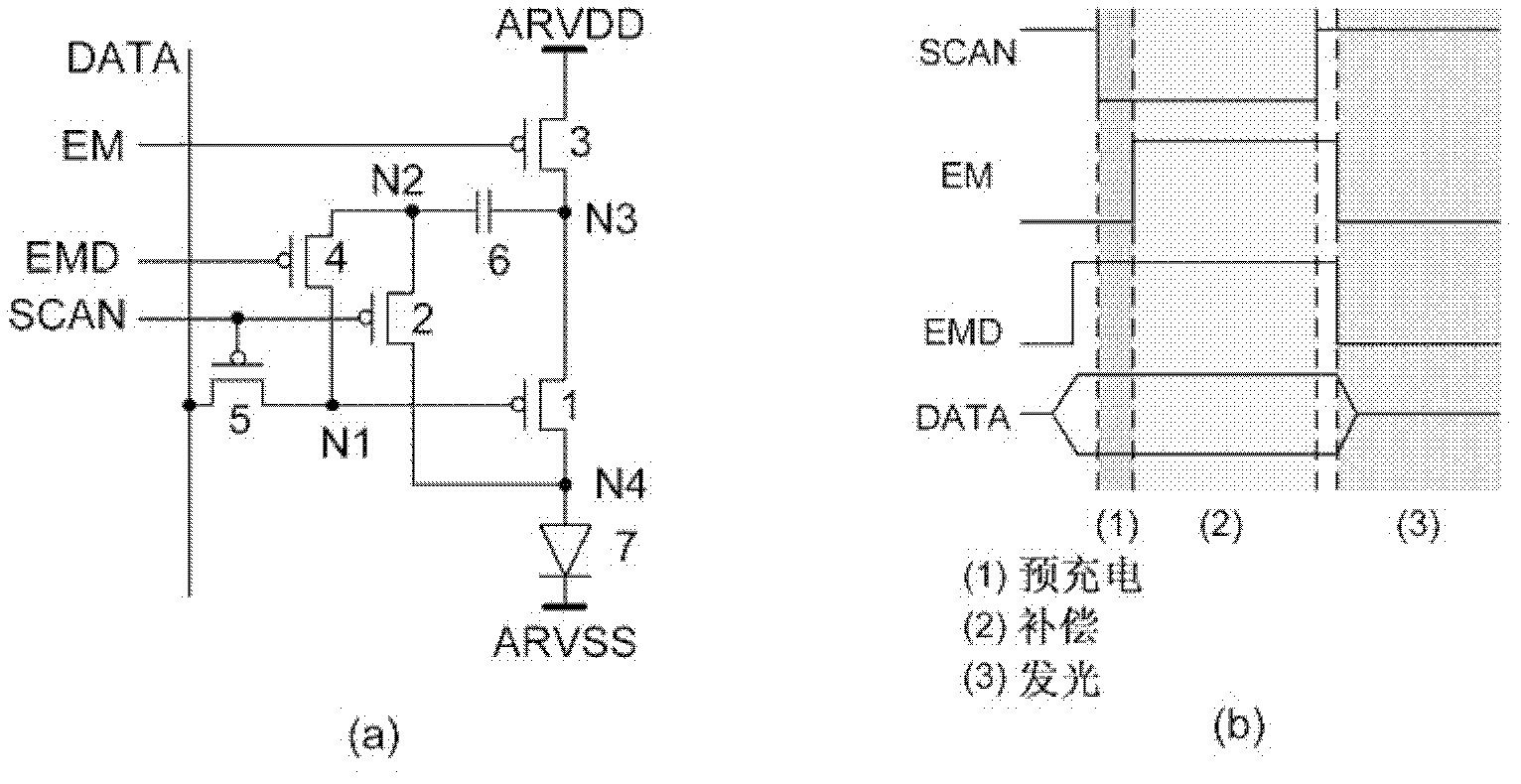

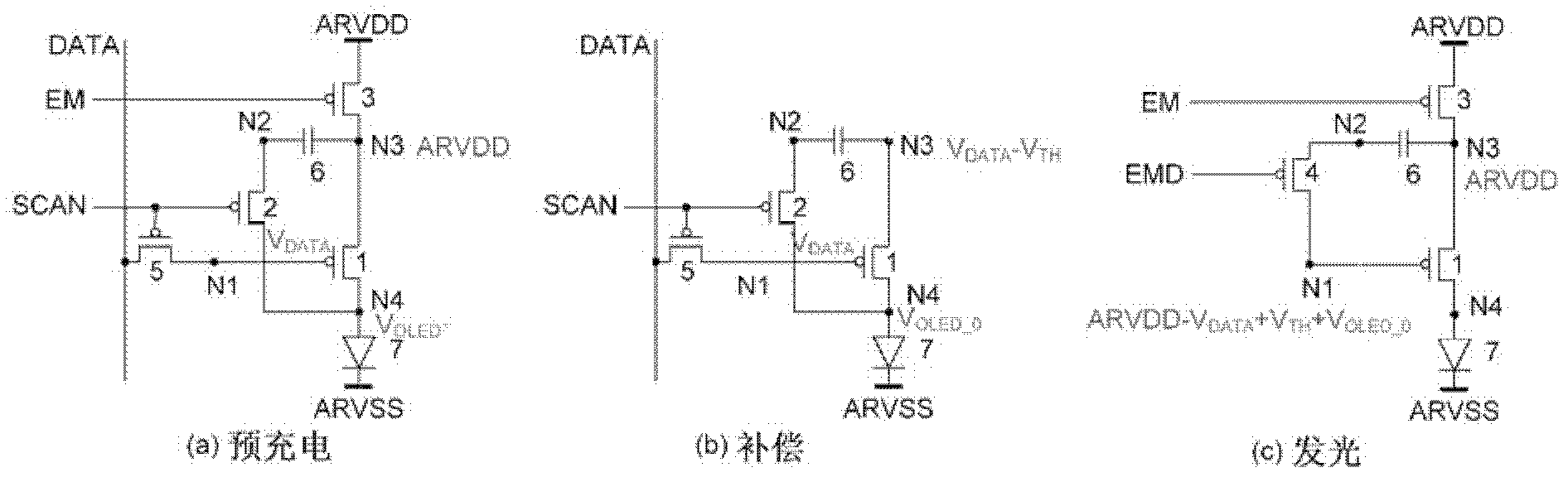

[0034] Such as figure 1 As shown in (a), the pixel circuit structure is composed of P-type TFT transistors 1 to 5, capacitor 6 and OLED 7, ARVDD and ARVSS are the backplane DC positive and negative levels respectively, DATA is the data voltage signal, and SCAN is the row scanning voltage Signals, EM and EMD are control signals, the pixel units in the same row share the SCAN and EM, EMD control signals, and the pixel units in the same column share the DATA data voltage signal. In the pixel circuit structure according to the present invention, the drain of the first TFT 1 is connected to the negative level of the backplane through the OLED device, the source of the first TFT 1 is connected to the drain of the third TFT 3, and the third The source of the thin film transistor 3 is connected to the positive level of the backplane, one end of the capacitor 6 is connected between the first thin film transistor 1 and the third thin film transistor 3 (N3), and the other end of the cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com