Steel ball precision counting and size identification device and method

An accurate counting and identification device technology, applied in the field of steel ball manufacturing, can solve problems such as poor counting accuracy and inability to identify the size of steel balls, and achieve the effect of improving efficiency and reducing the number of compensations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

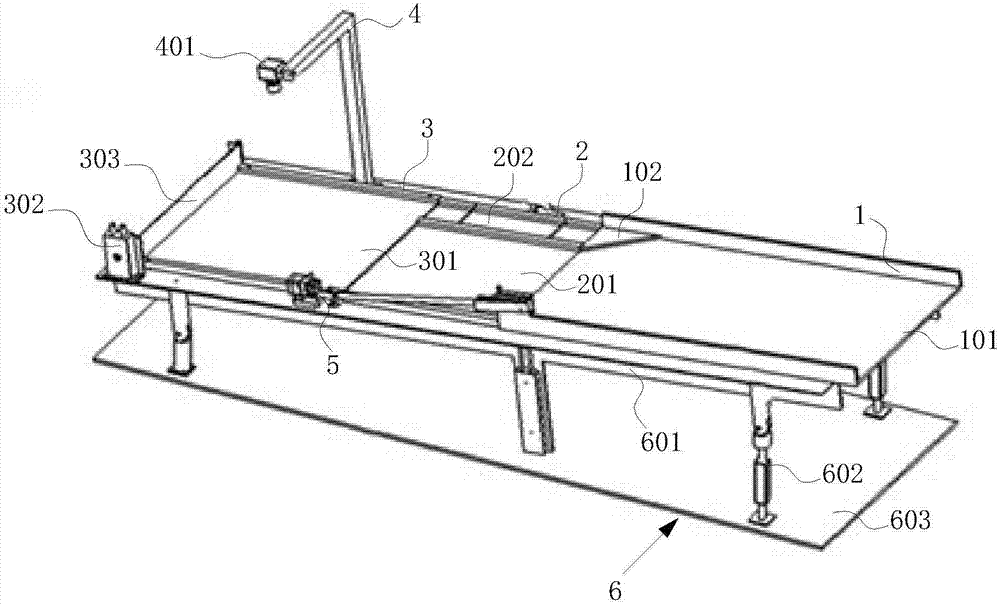

[0059] See attached figure 1 , the steel ball accurate counting and size identification device of the present invention comprises:

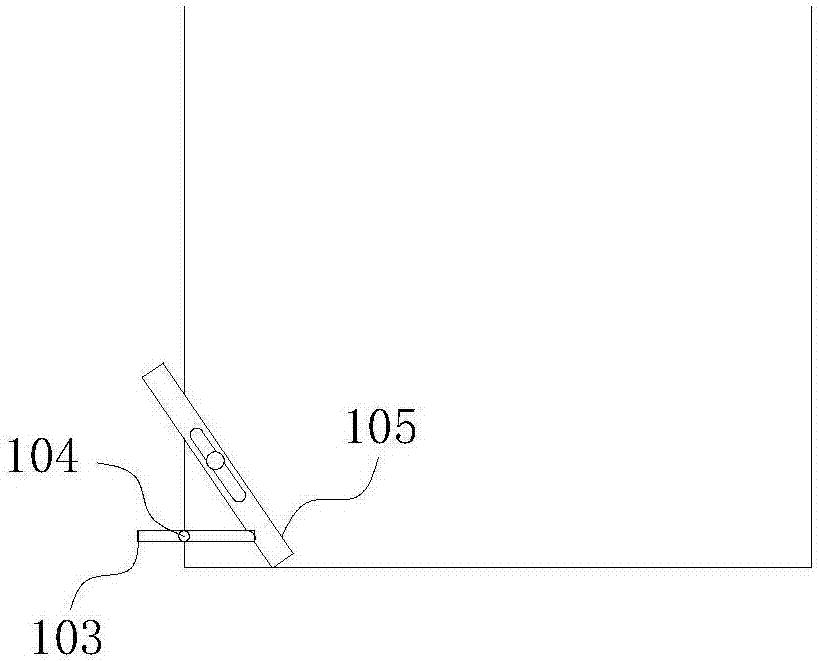

[0060] A storage unit 1, the storage unit 1 includes a storage tray 101 with raised edges on both sides;

[0061] The pre-counting unit 2 arranged at the outlet end of the storage tray 101, the pre-counting unit 2 includes a pre-counting disc 201 with convex edges on both sides, an area adjustment mechanism 202 for adjusting the working area of the pre-counting disc 201 and driving the pre-counting disc 201 The first lifting mechanism that moves up and down;

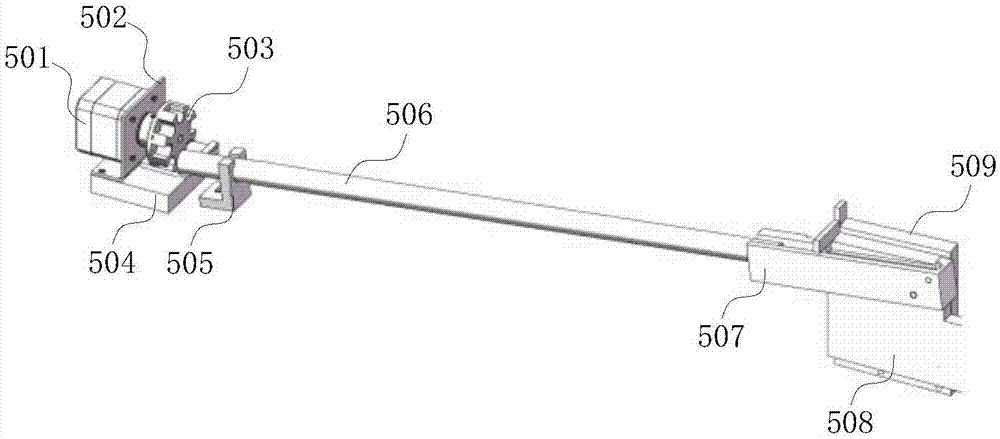

[0062] The fine counting unit 3 arranged at the outlet end of the pre-counting disc 201, the fine counting unit 3 includes a fine counting disc 301 with convex edges on both sides and an outlet mechanism 302 arranged at the outlet end of the fine counting disc 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com