Patents

Literature

82 results about "Ball size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Baseball training system and method

Owner:SHOOT A WAY

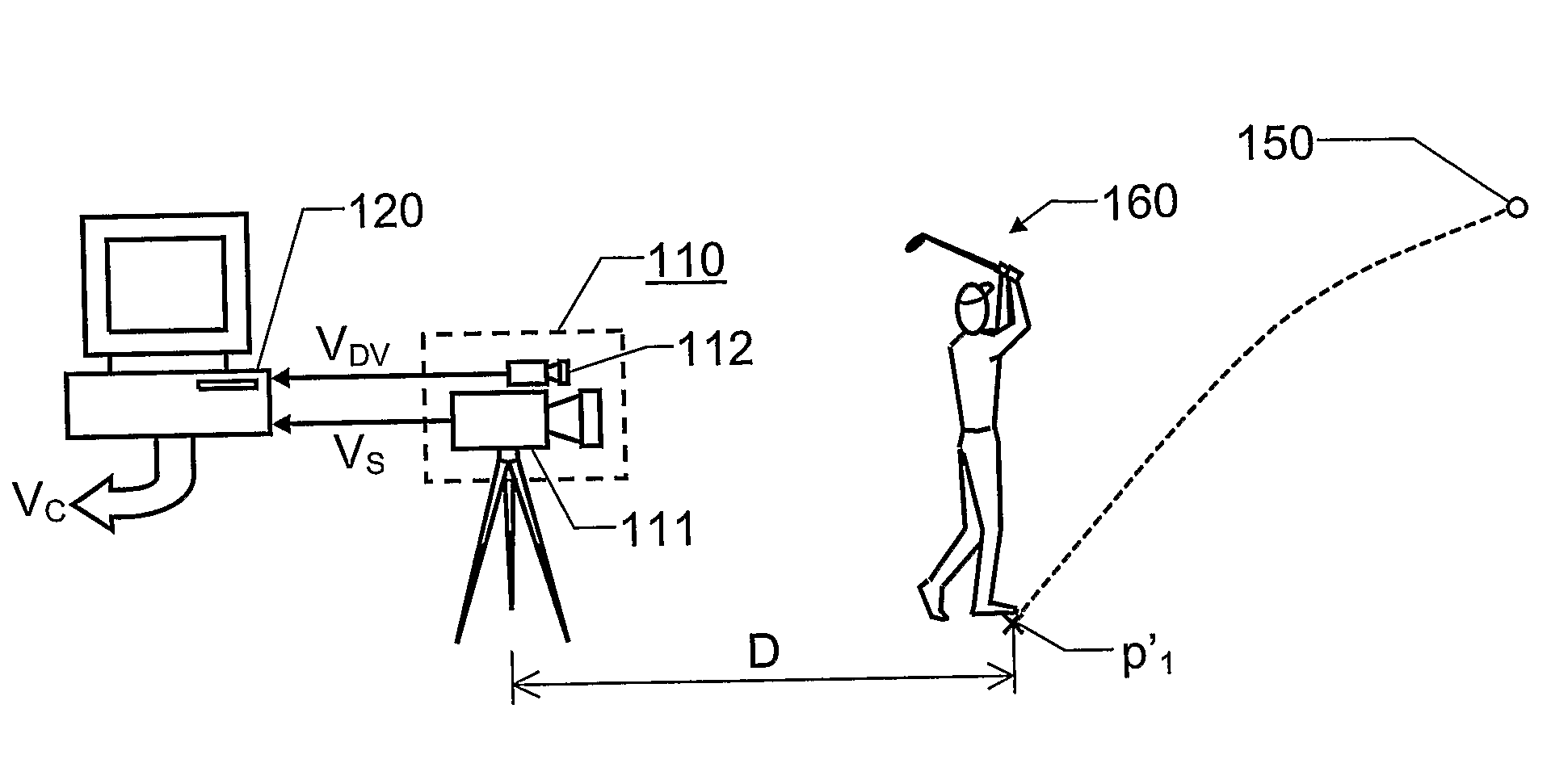

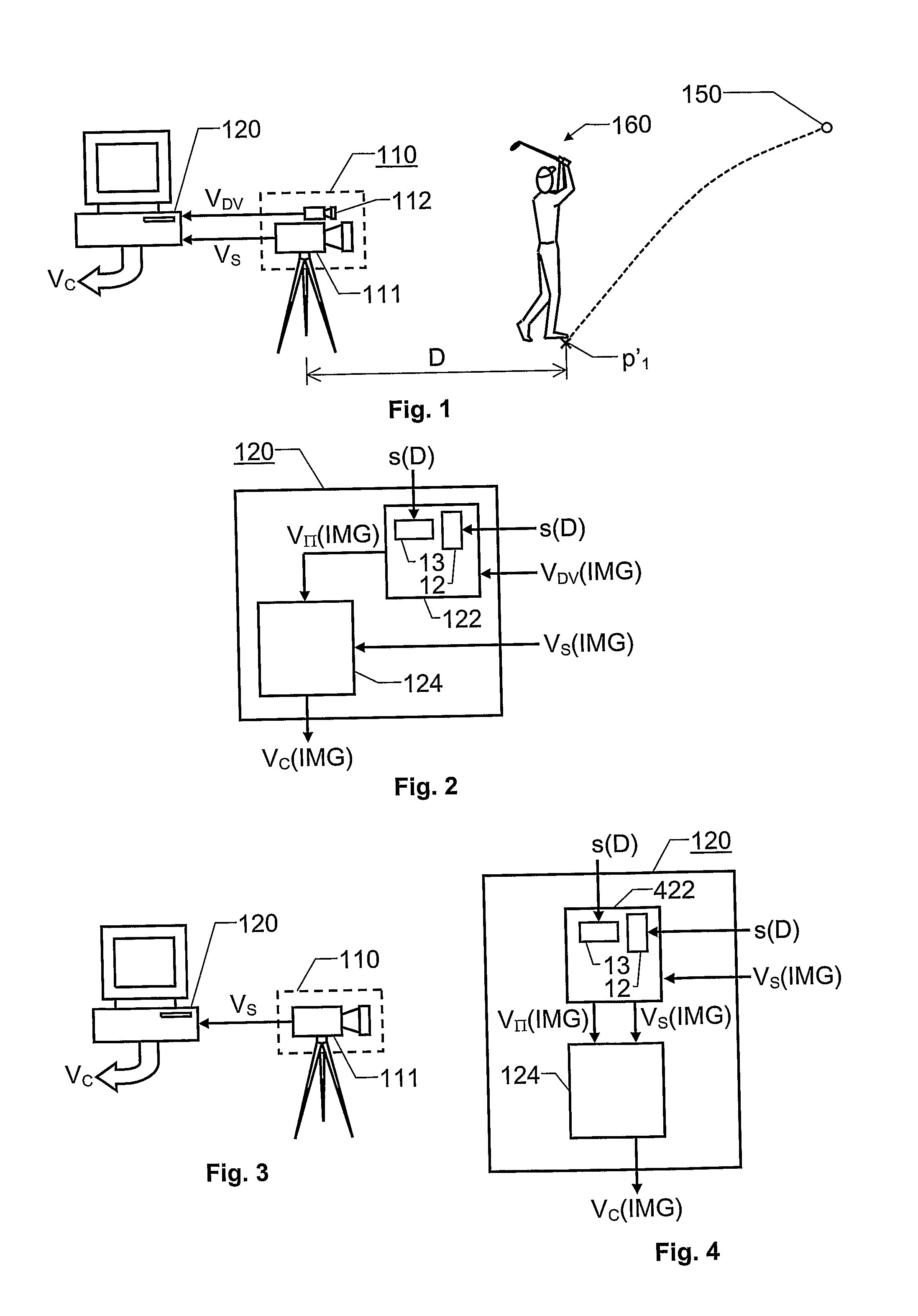

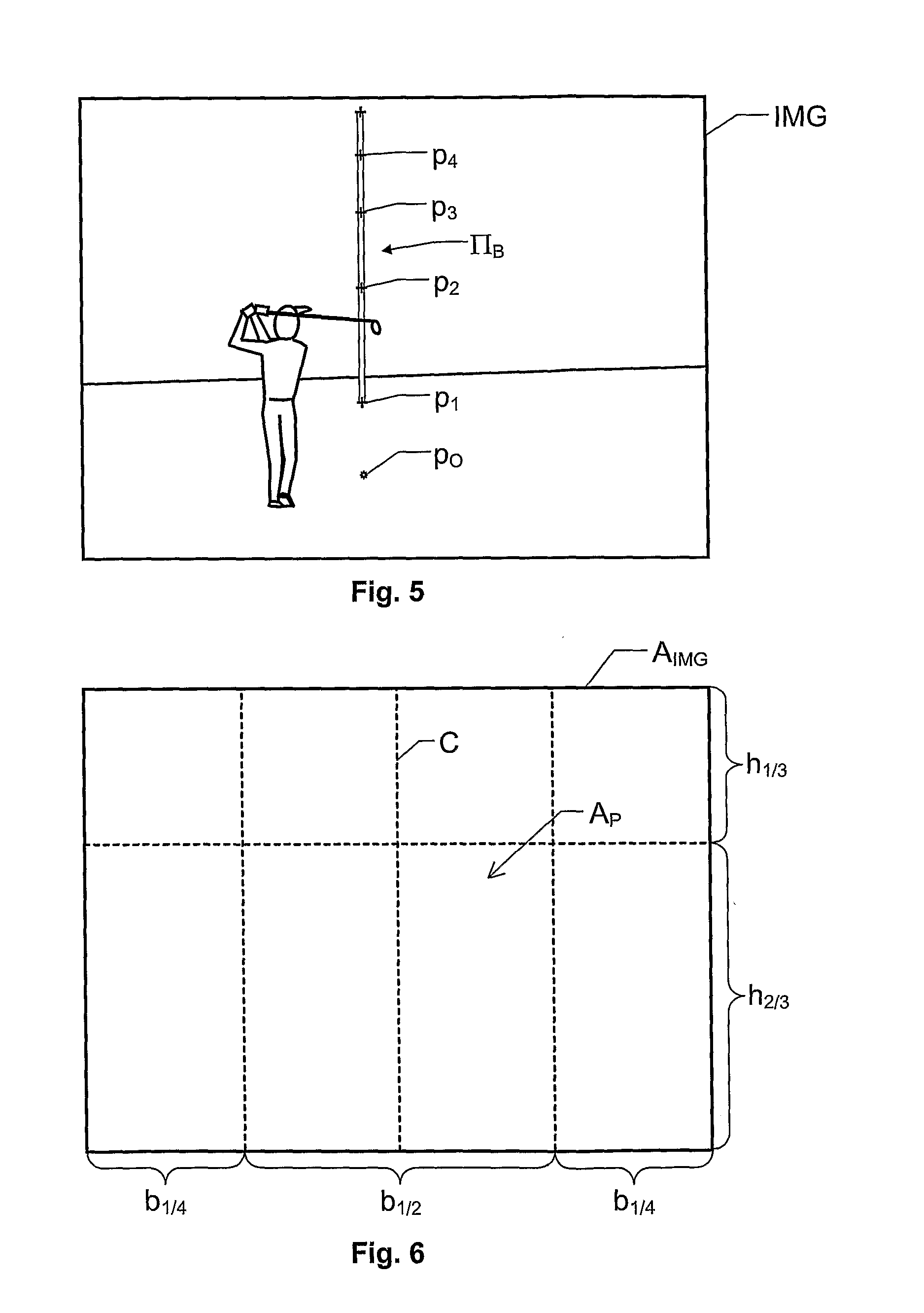

Image Enhancement in Sports Recordings

A video signal representing rapid ball movement is produced from a series of source images. An initial image position for the moving ball is identified by, for each image, producing a difference image between sequential images. In the difference image, image elements representing a contents alteration below a threshold are allocated a first value, and those representing a contents alteration above or equal to the threshold are allocated a second value. A set of candidates is then identified, where each candidate is represented by a group of neighboring image elements that all contain the second value. The group must fulfill a ball size criterion. A ball selection algorithm selects an initial image position from the set of ball candidates. The ball is tracked, and a composite image sequence is generated wherein a synthetic trace representing the path of the moving ball is shown as successively added image data.

Owner:TOPGOLF SWEDEN AB

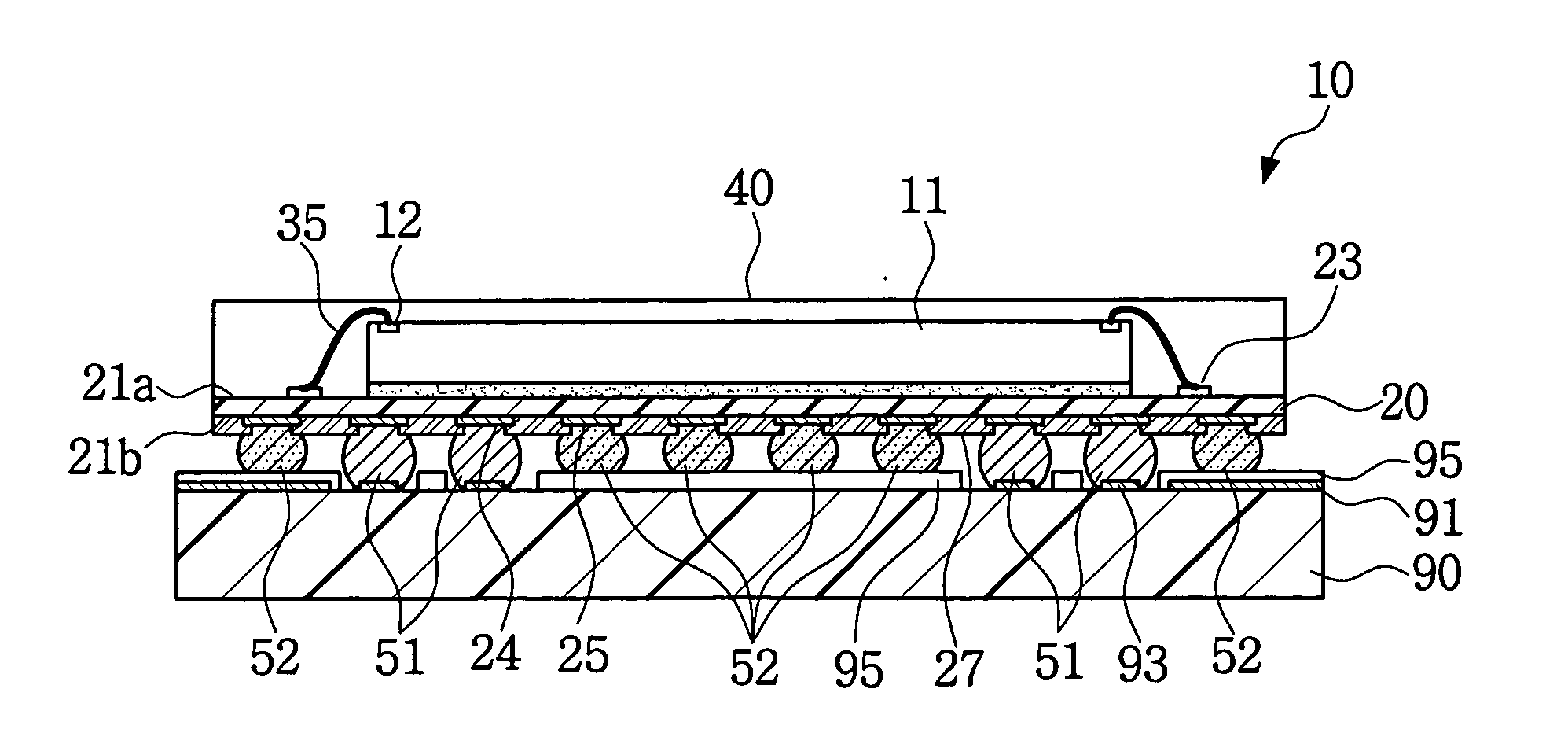

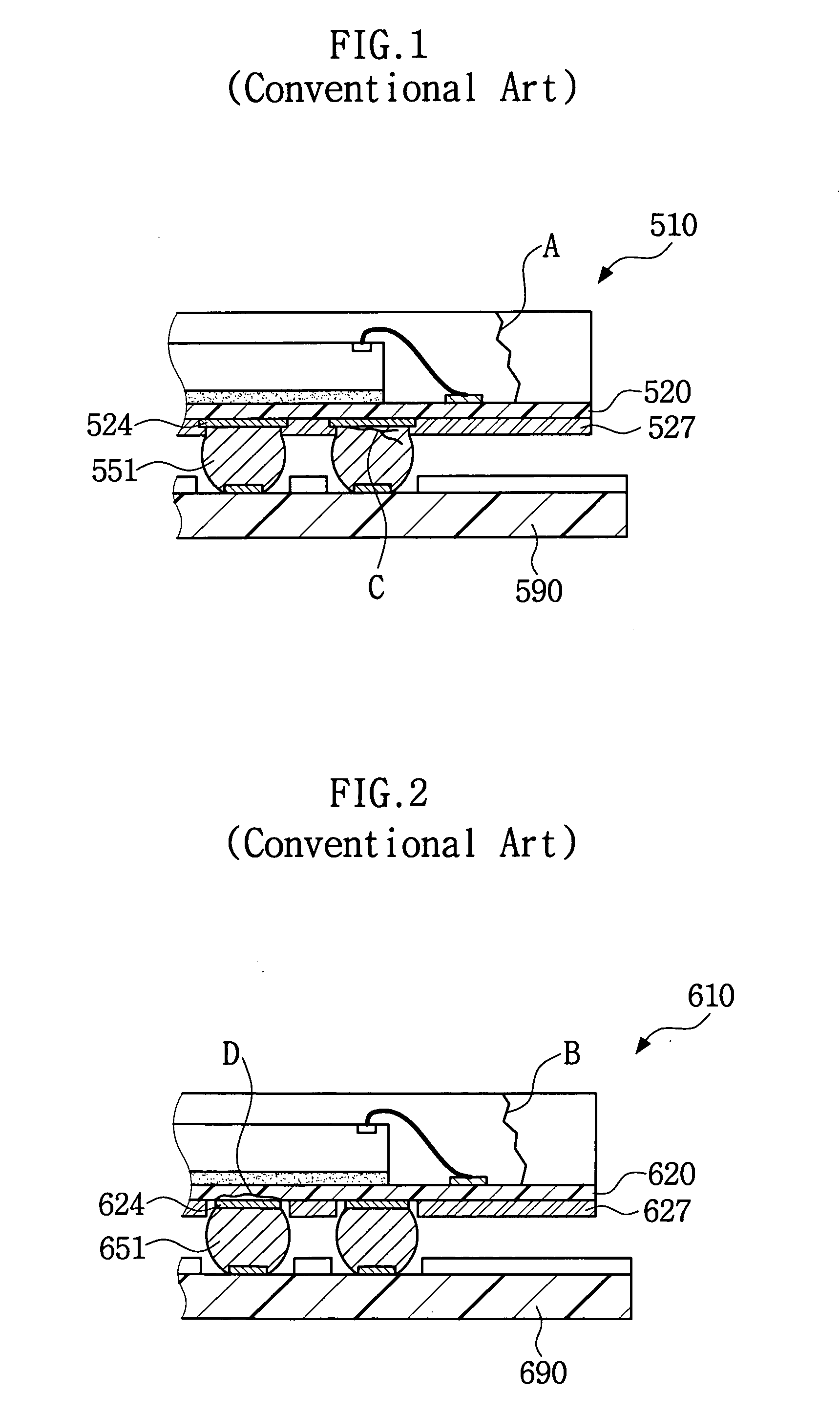

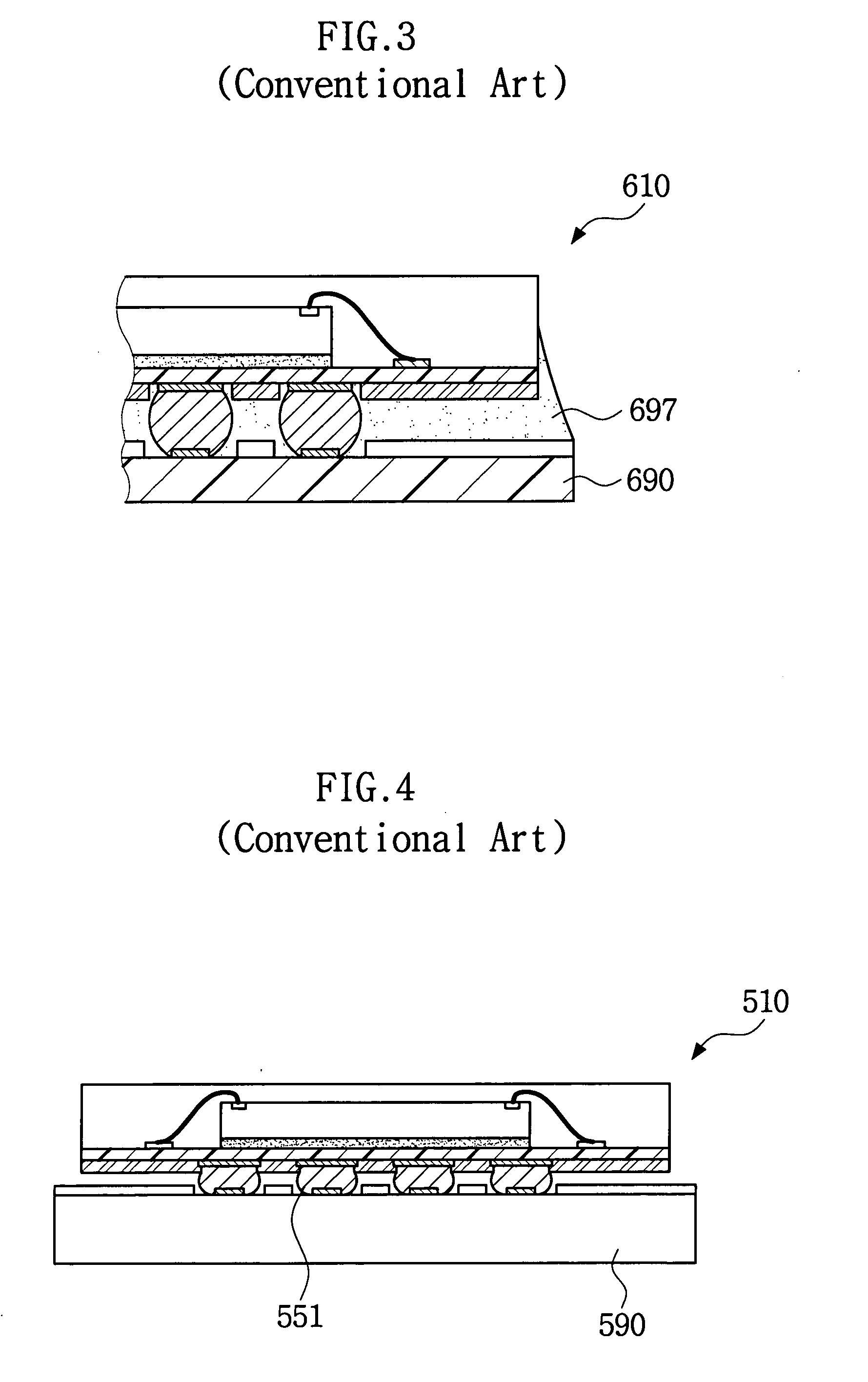

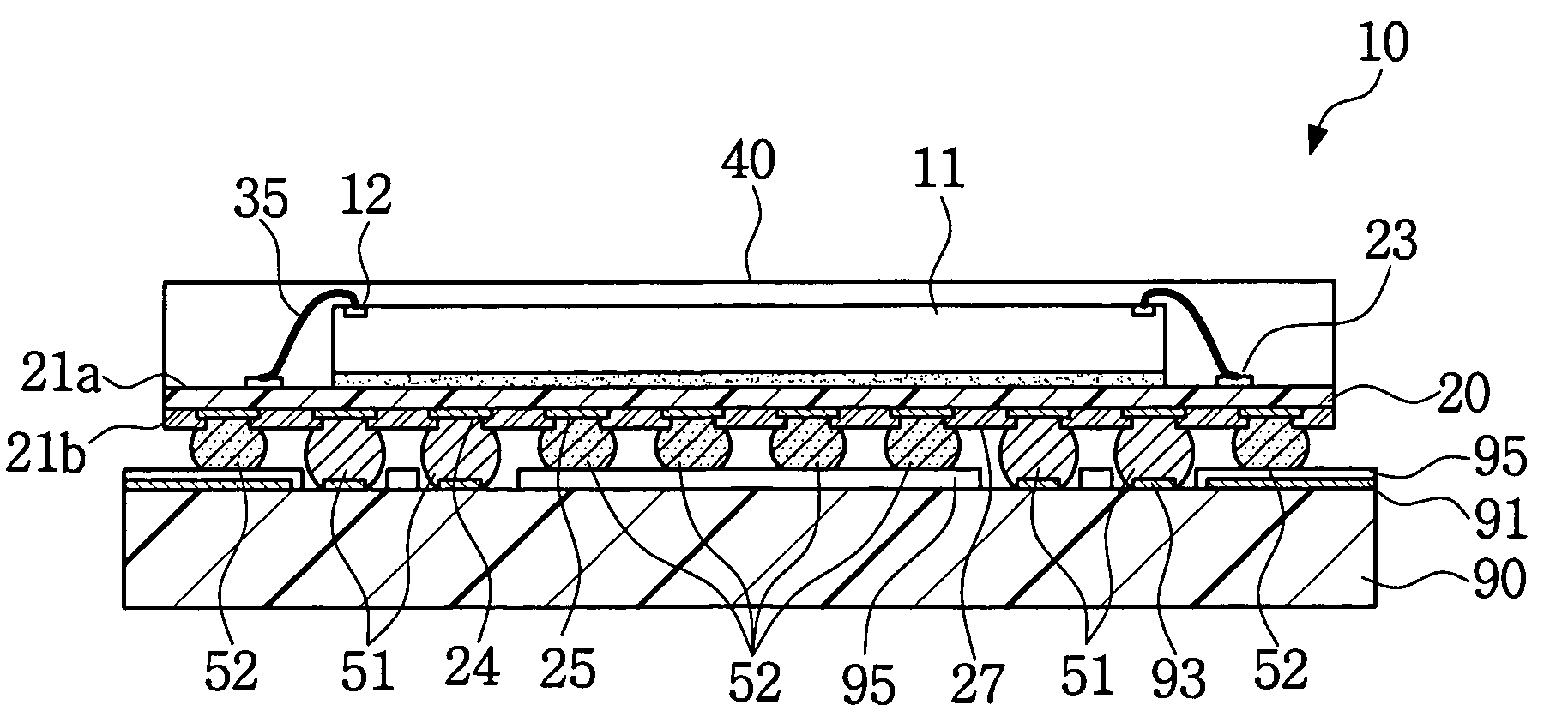

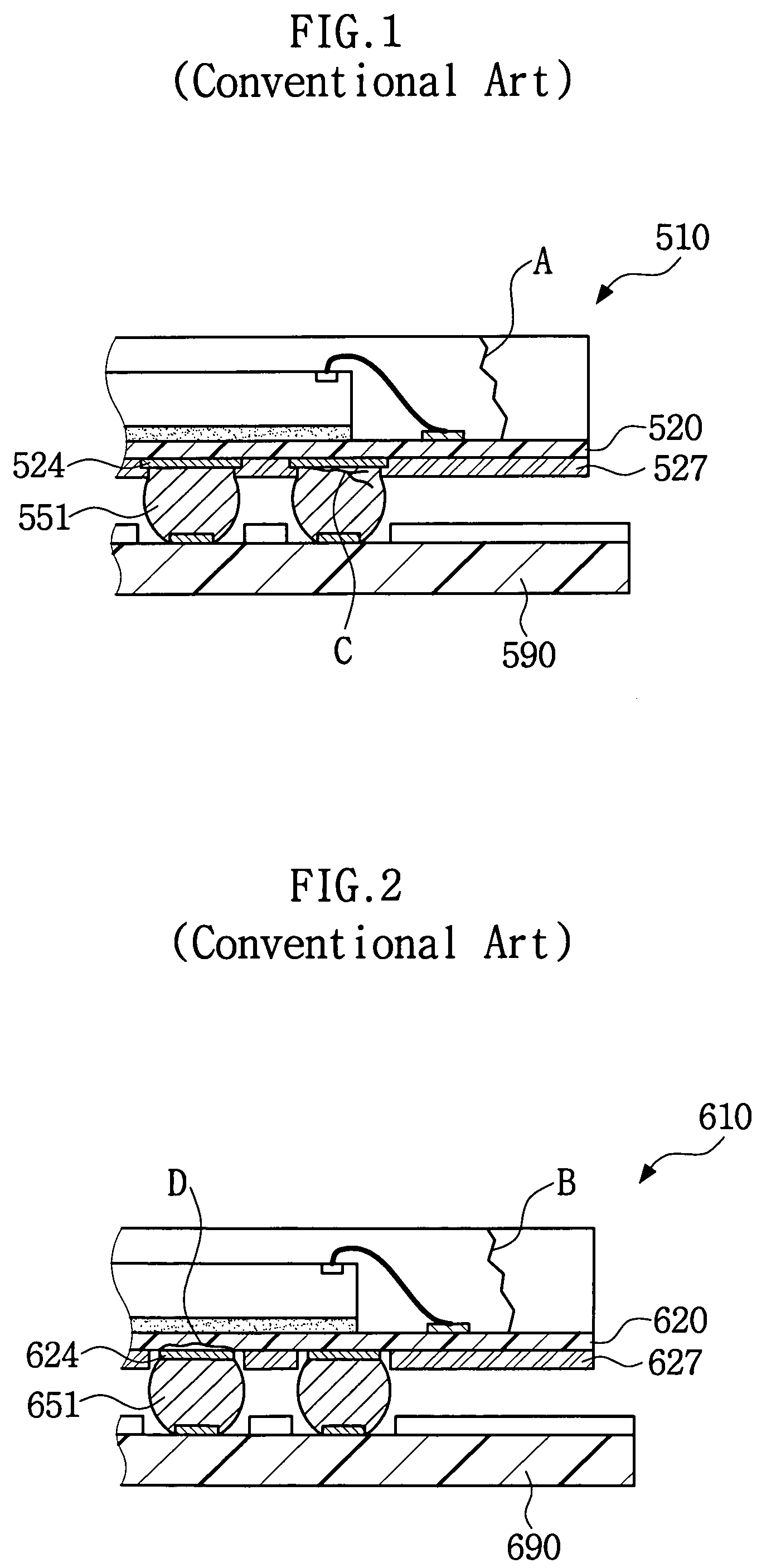

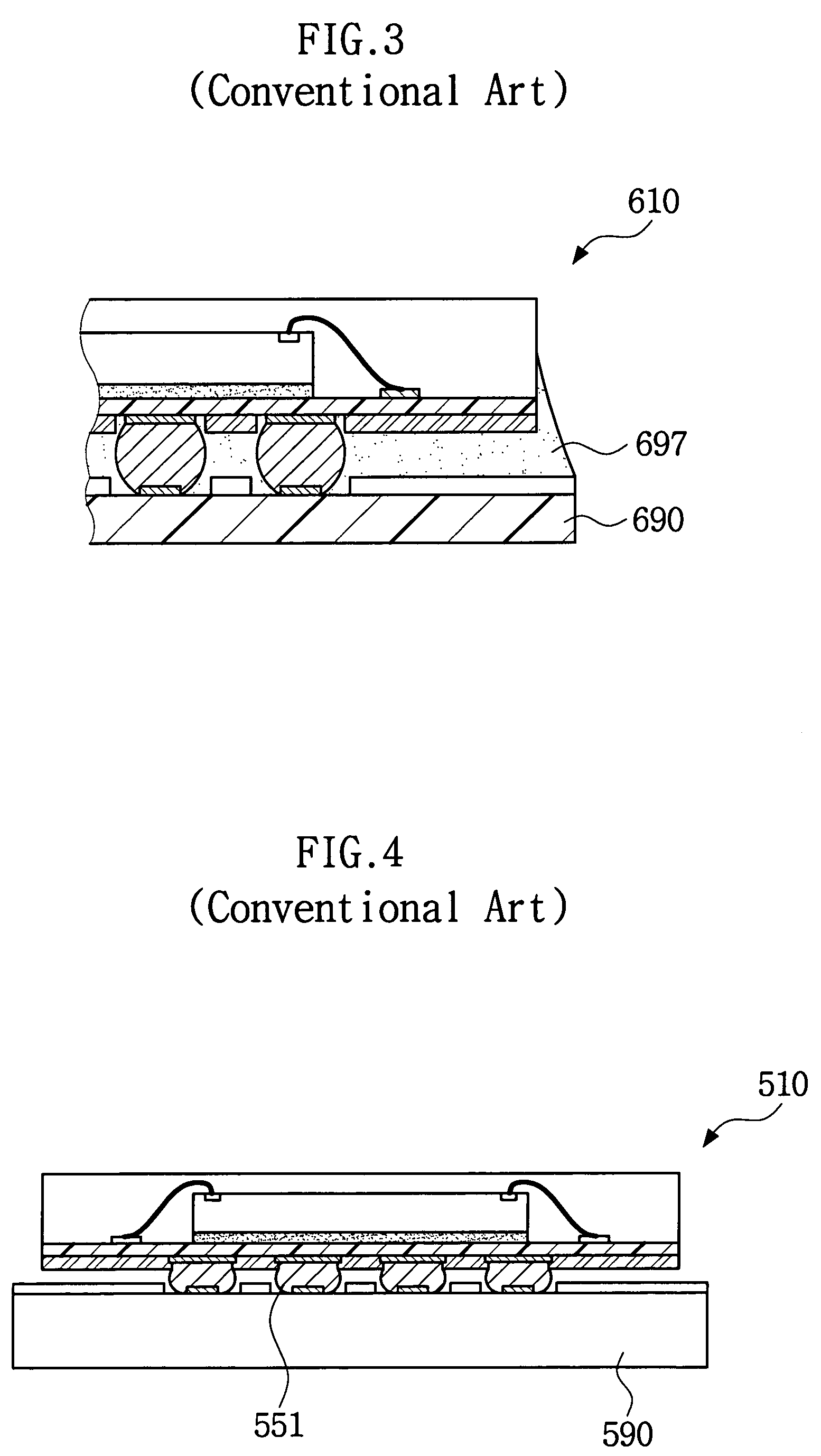

BGA semiconductor chip package and mounting structure thereof

InactiveUS20060231952A1Taller in heightOverhead installationFinal product manufactureSolder ballSemiconductor chip

In example embodiments of the present invention, a structure of a BGA semiconductor chip package includes a substrate having first and second surfaces, a semiconductor chip having a plurality of bonding pads, and mounted on the first surface of the substrate, and plurality of in / out (I / O) solder balls and dummy solder balls provided on the second surface of the substrate, wherein the I / O solder balls are electrically connected to the semiconductor chip and the dummy solder balls are electrically isolated from the semiconductor chip, and the I / O solder balls and the dummy solder balls have the same ball size and ball pitch and are uniformly provided over the second surface of the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

BGA semiconductor chip package and mounting structure thereof

In example embodiments of the present invention, a structure of a BGA semiconductor chip package includes a substrate having first and second surfaces, a semiconductor chip having a plurality of bonding pads, and mounted on the first surface of the substrate, and plurality of in / out (I / O) solder balls and dummy solder balls provided on the second surface of the substrate, wherein the I / O solder balls are electrically connected to the semiconductor chip and the dummy solder balls are electrically isolated from the semiconductor chip, and the I / O solder balls and the dummy solder balls have the same ball size and ball pitch and are uniformly provided over the second surface of the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

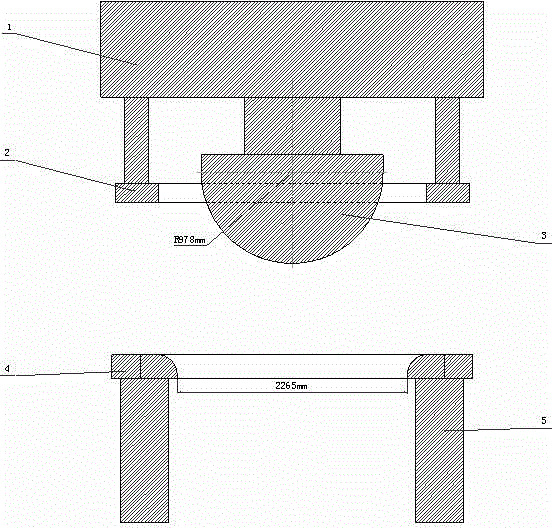

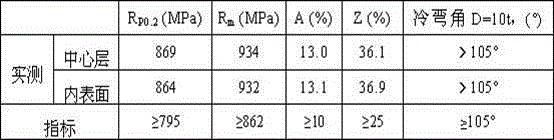

Technology for preparing pressure resisting titanium alloy half ball for bathyscaph manned ball

ActiveCN104923603AAdvantages of dimensional accuracy controlAdvantage under pressureShaping toolsPunchingThick plate

The invention discloses a technology for preparing a pressure resisting titanium alloy half ball for a bathyscaph manned ball. The technology comprises the steps that firstly, a TC4 ELI titanium alloy thick plate for punching is cropped to be round according to the size of a target ball to serve as a plate blank to be punched; secondly, a forming die is designed according to the size of the target ball and a TC4 ELI titanium alloy material expansion coefficient; thirdly, the plate blank to be punched and the surface of the forming die are coated with an anti-oxidation lubrication coating; fourthly, the plate blank to be punched is heated to 850 DEG C to 930 DEG C, and insulating is carried out for 2-4 hours; fifthly, the heated plate blank to be punched is punched on a lower die of the forming die, the temperature drop is strictly controlled in the punching process, and when the temperature of the plate blank to be punched is reduced to be below 700 DEG C, punching is stopped, the plate blank to be punched is returned to a furnace again, secondary punching is carried out, and the process is executed circularly till the plate blank to be punched is punched into the half ball. Compared with multi-scalloped-segment installing and welding, a large number of weld lines can be reduced, and obvious advantages on the ball size precision control, ball pressure bearing and safety performance are achieved.

Owner:BAOJI TITANIUM IND CO LTD +2

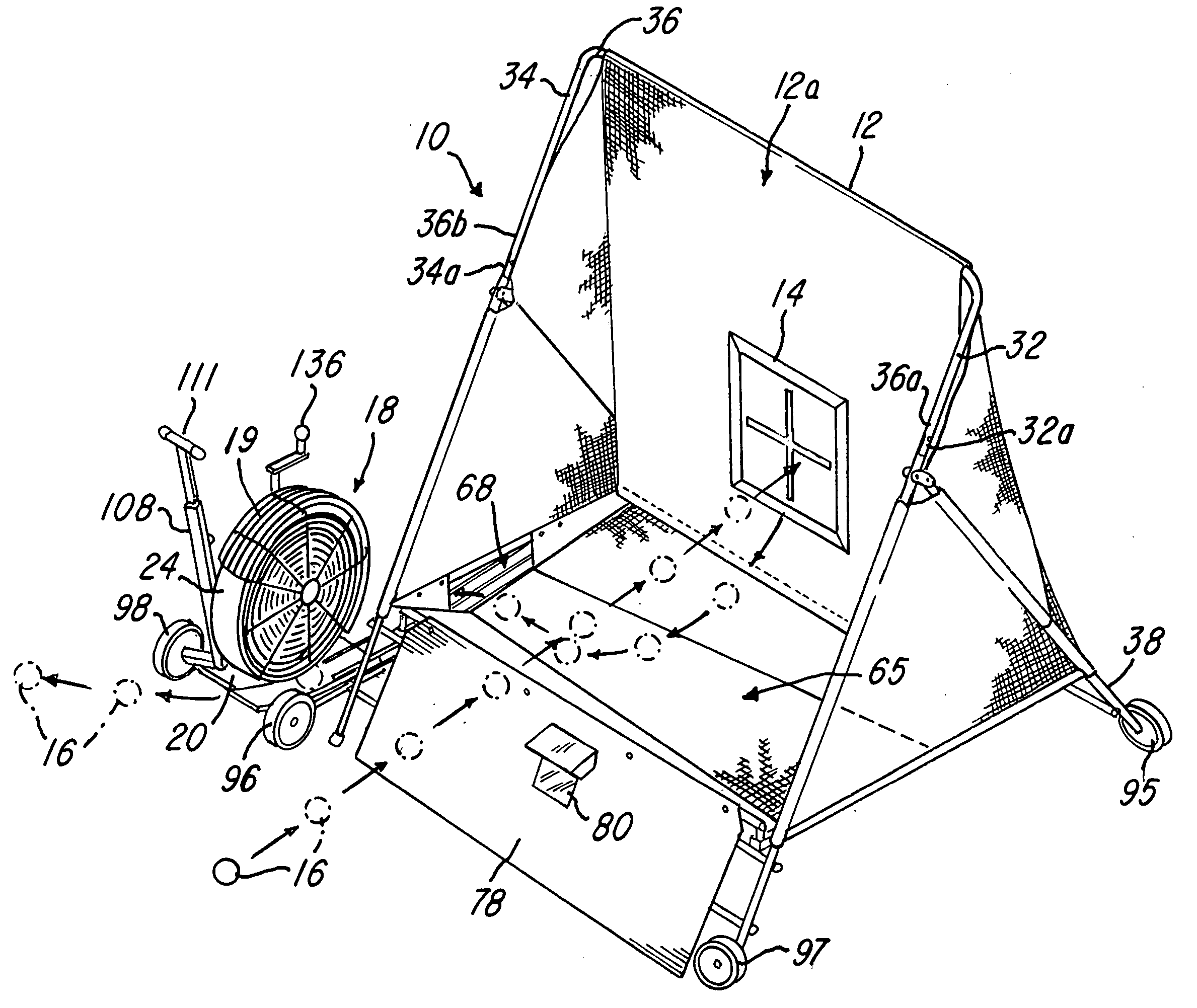

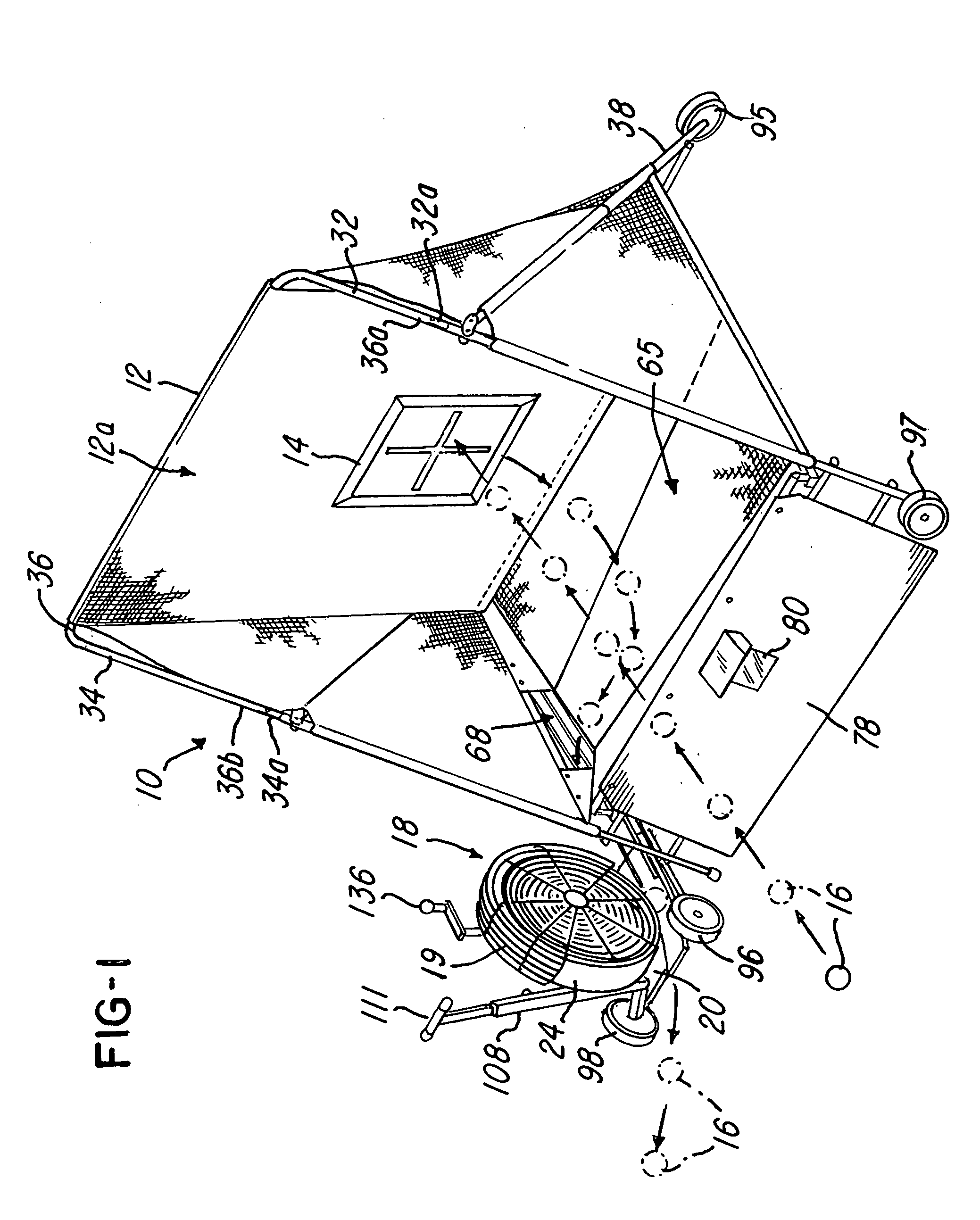

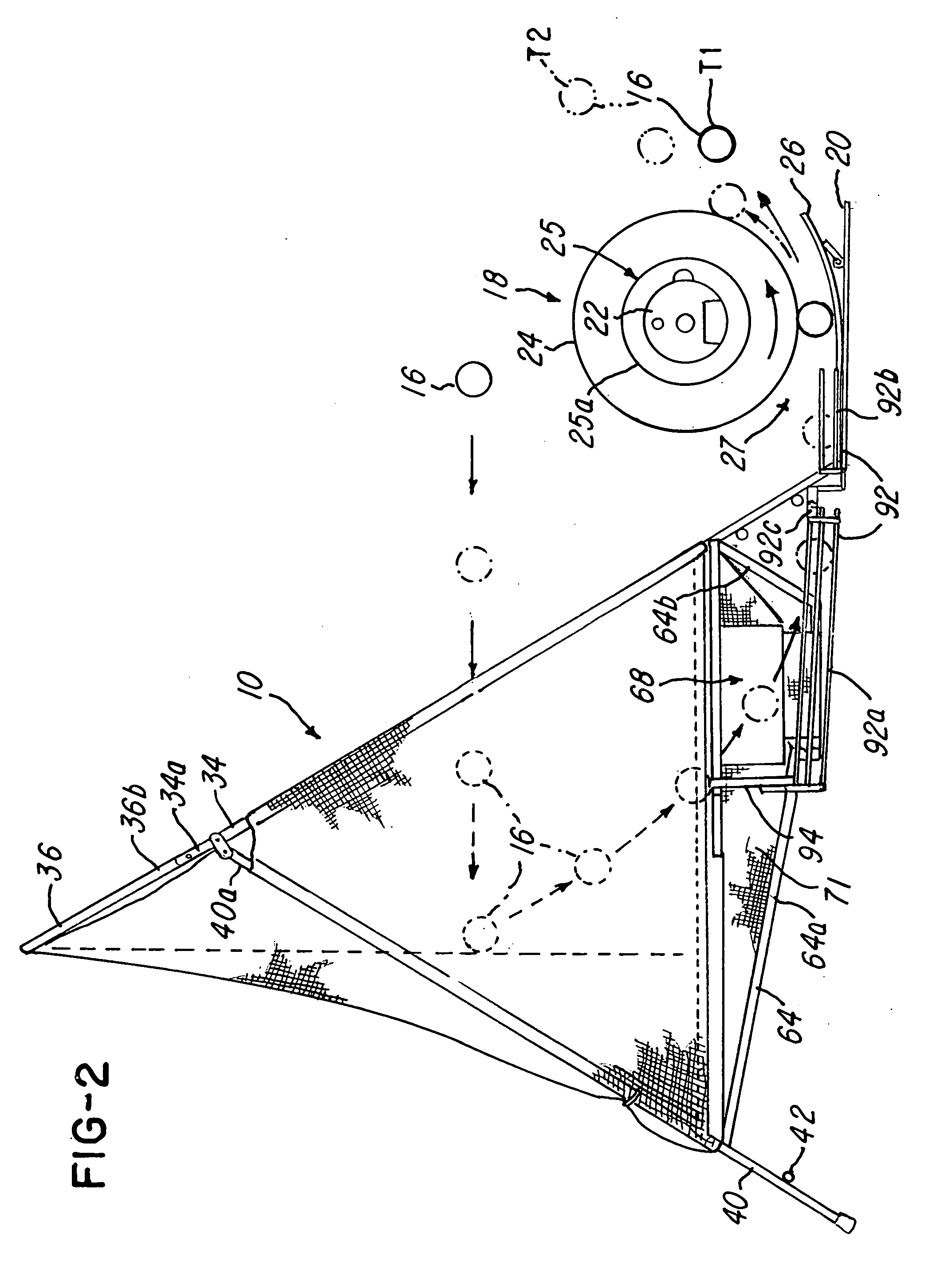

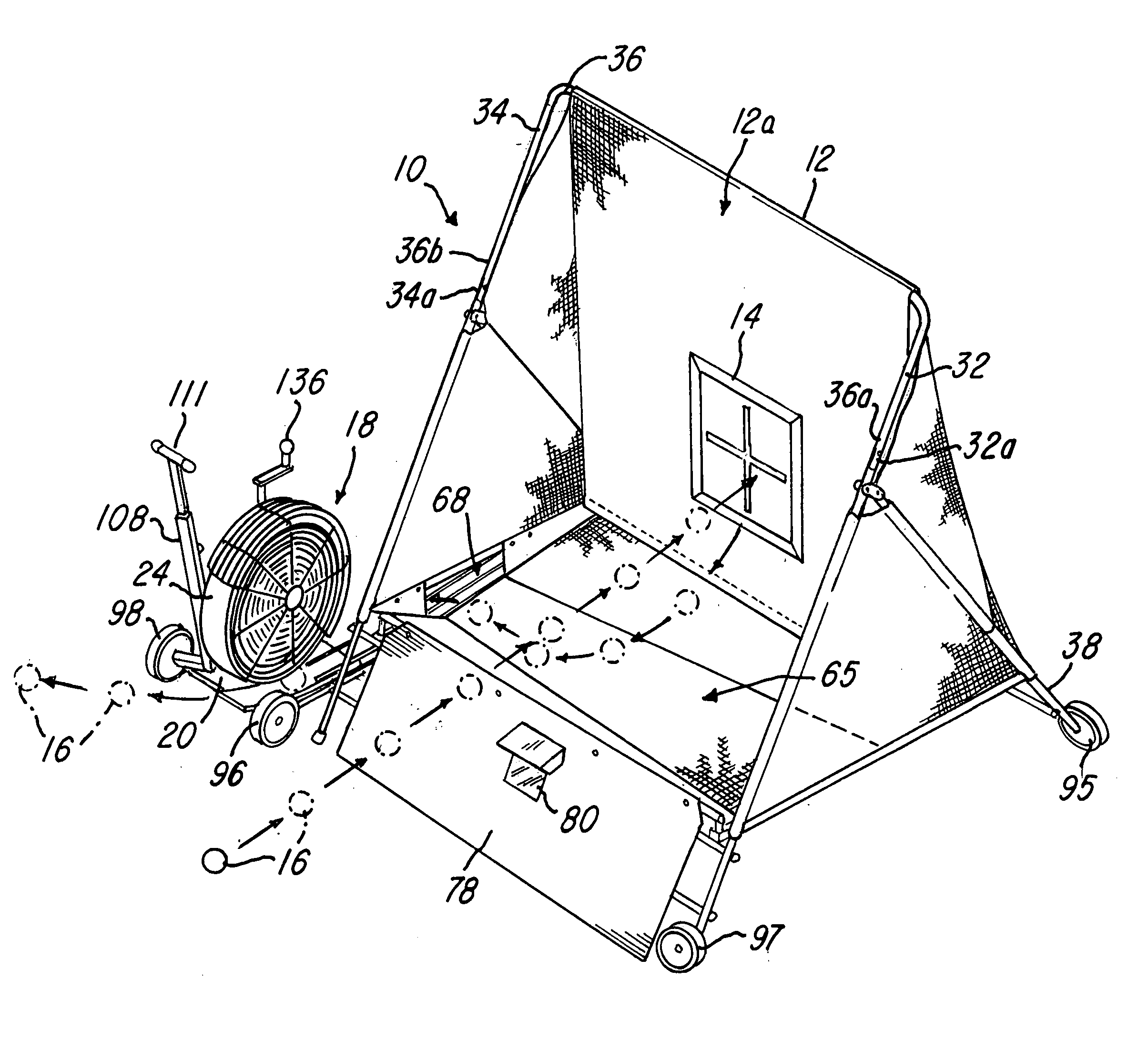

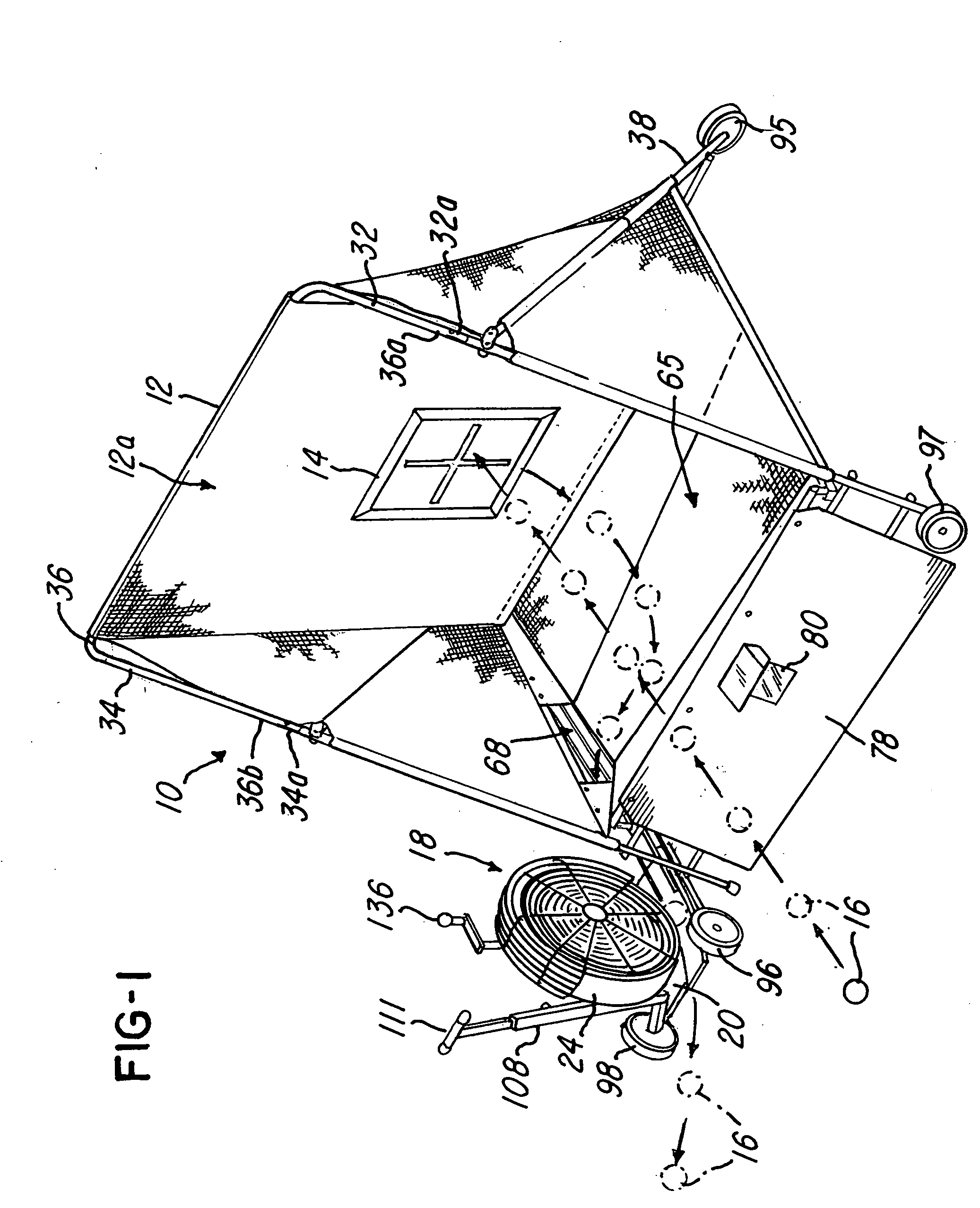

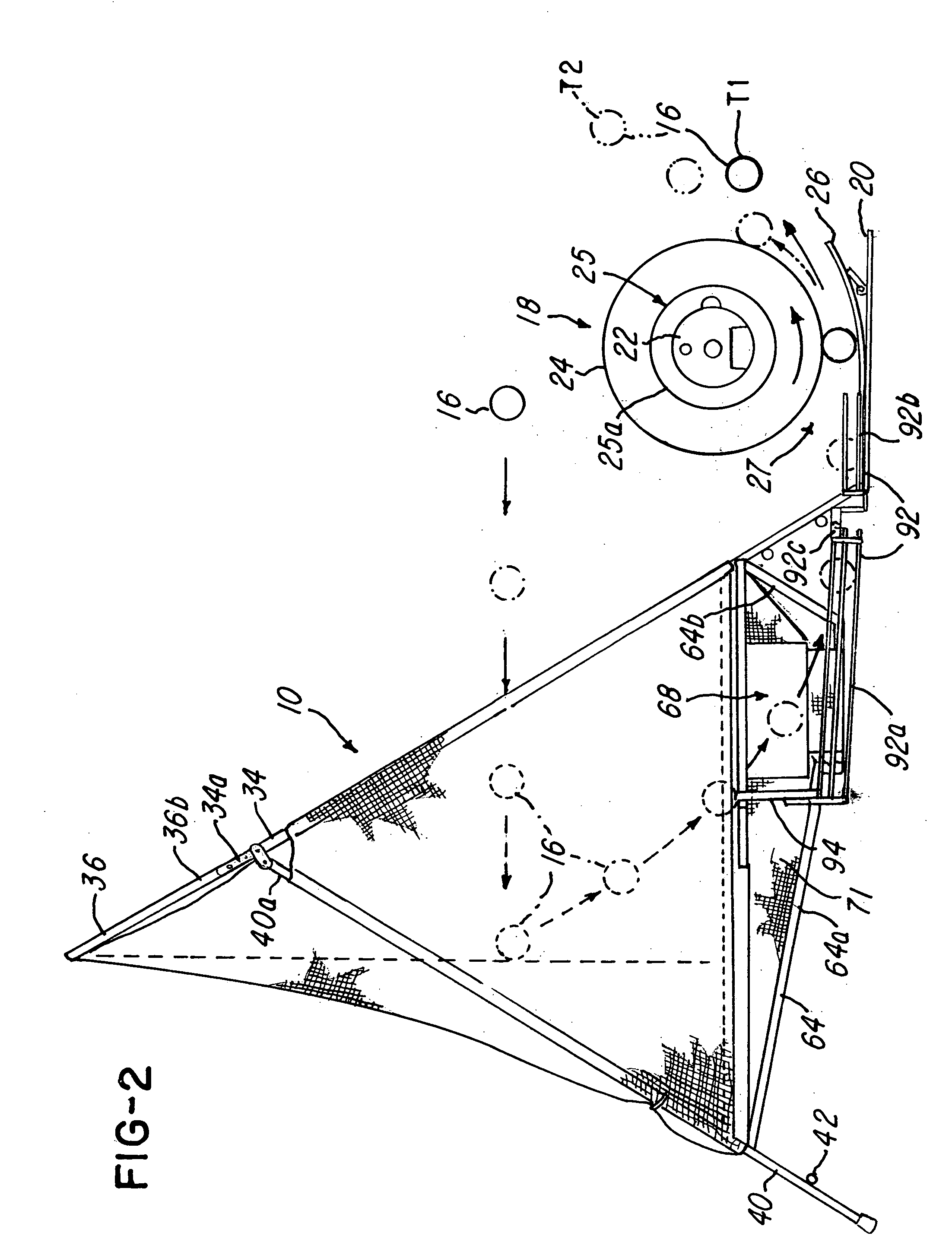

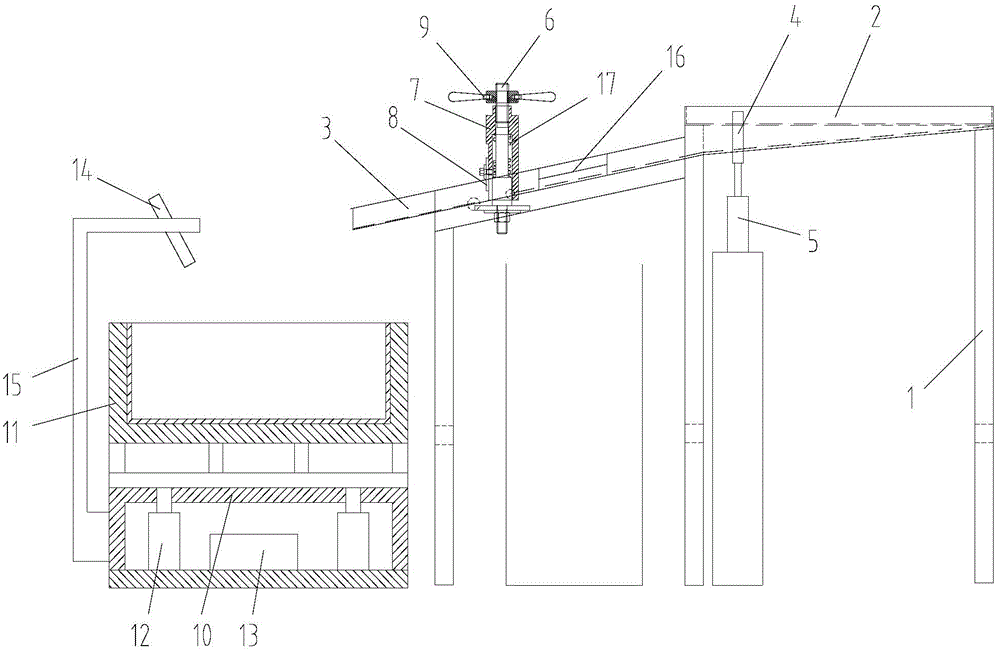

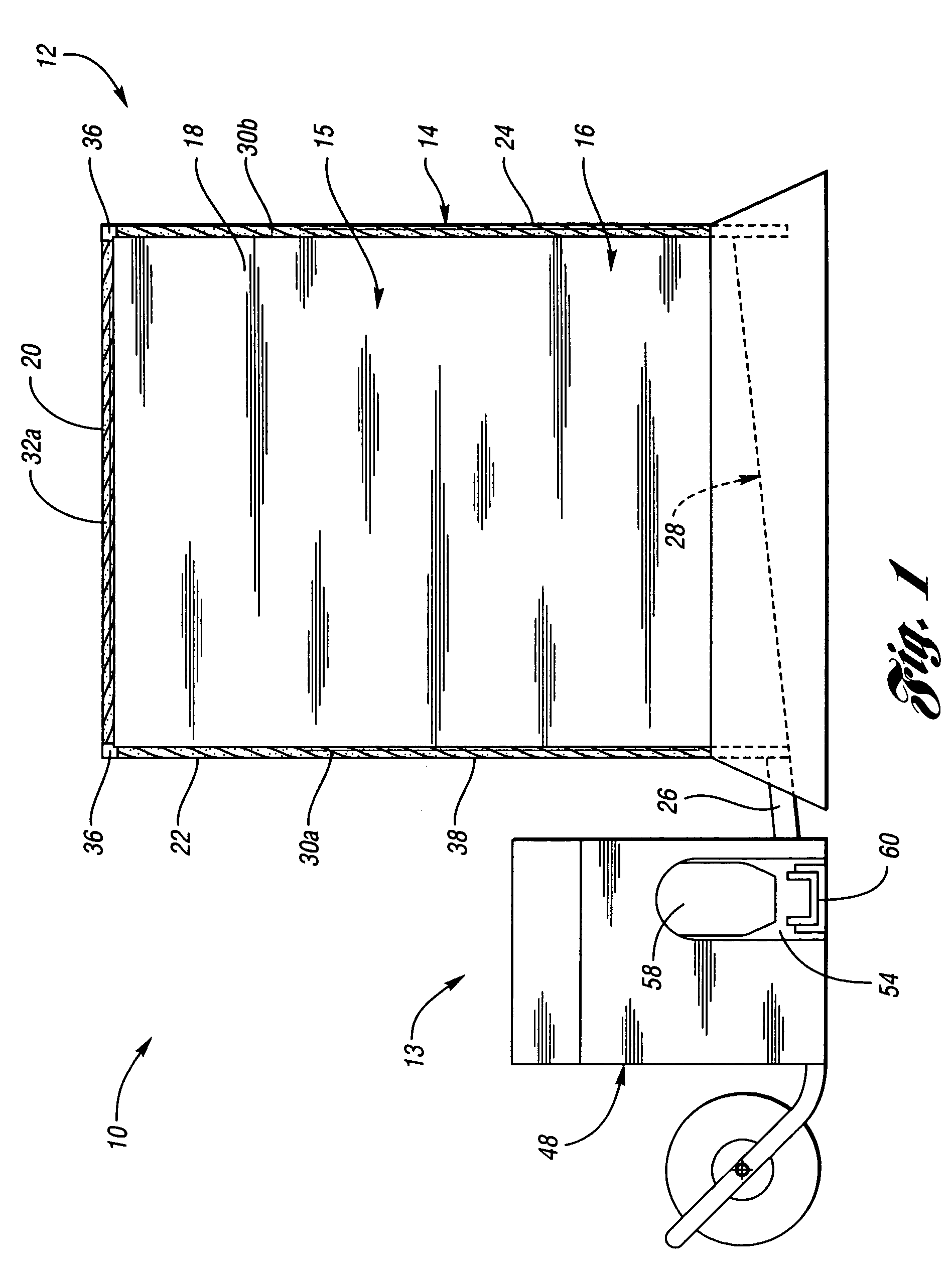

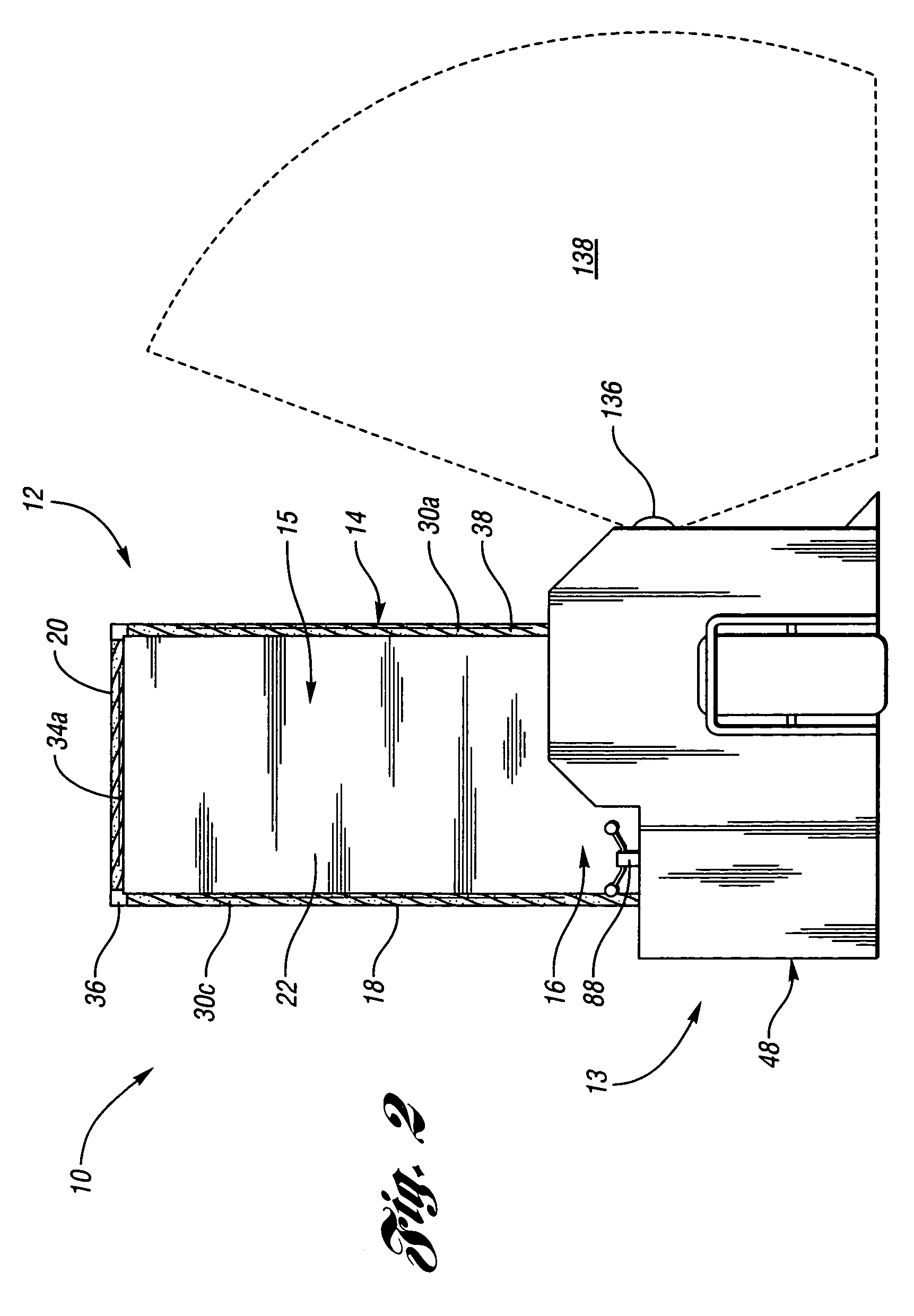

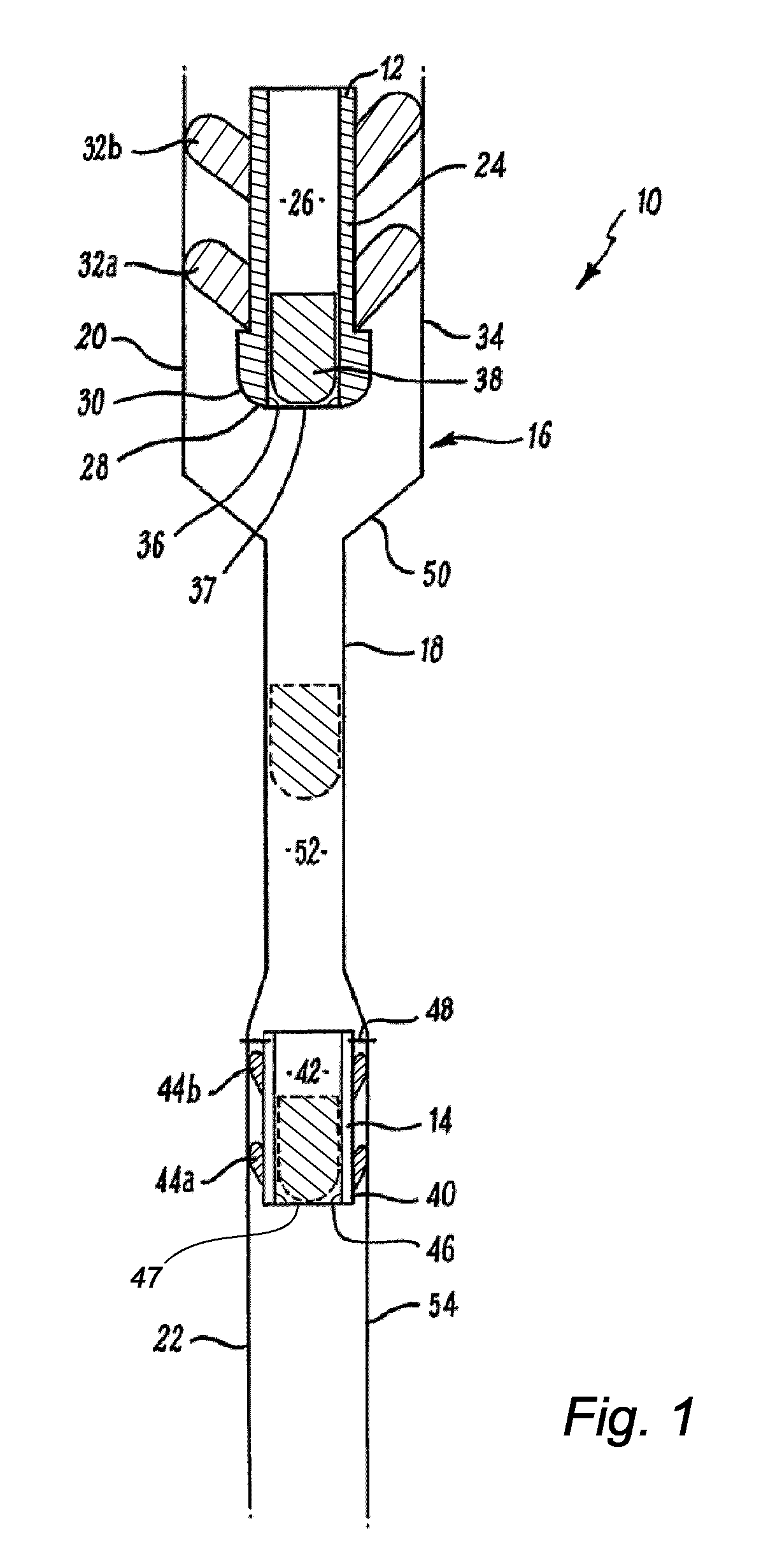

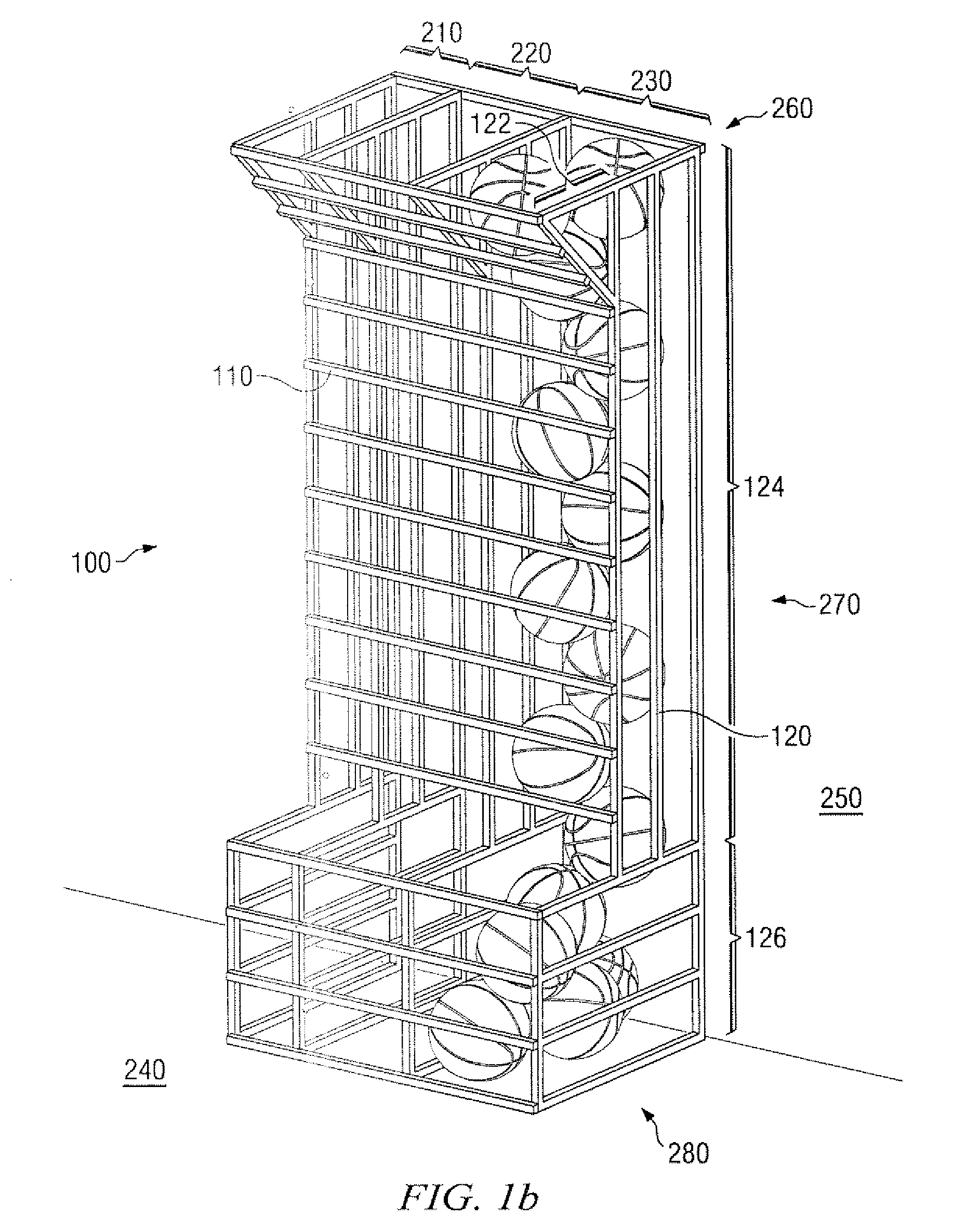

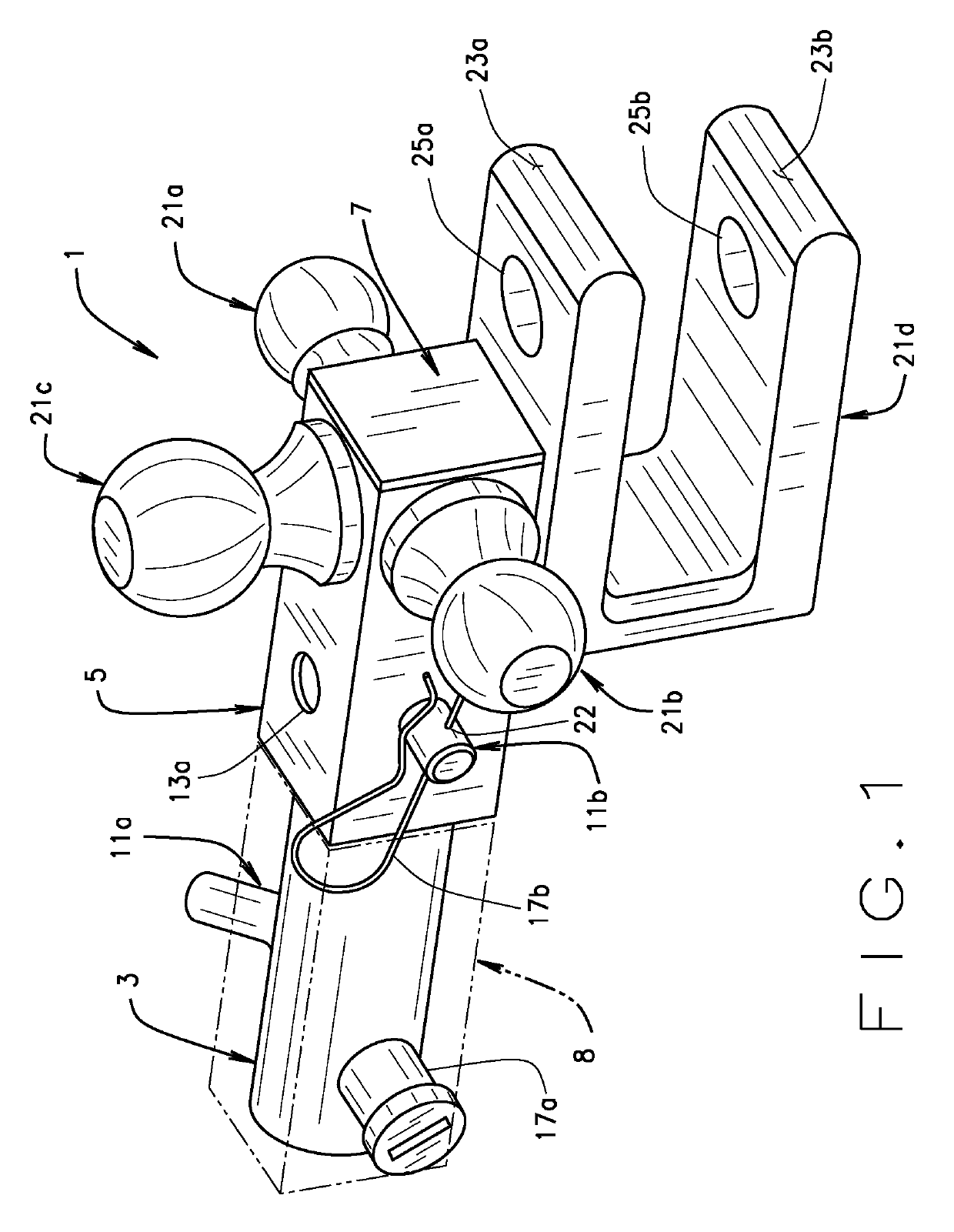

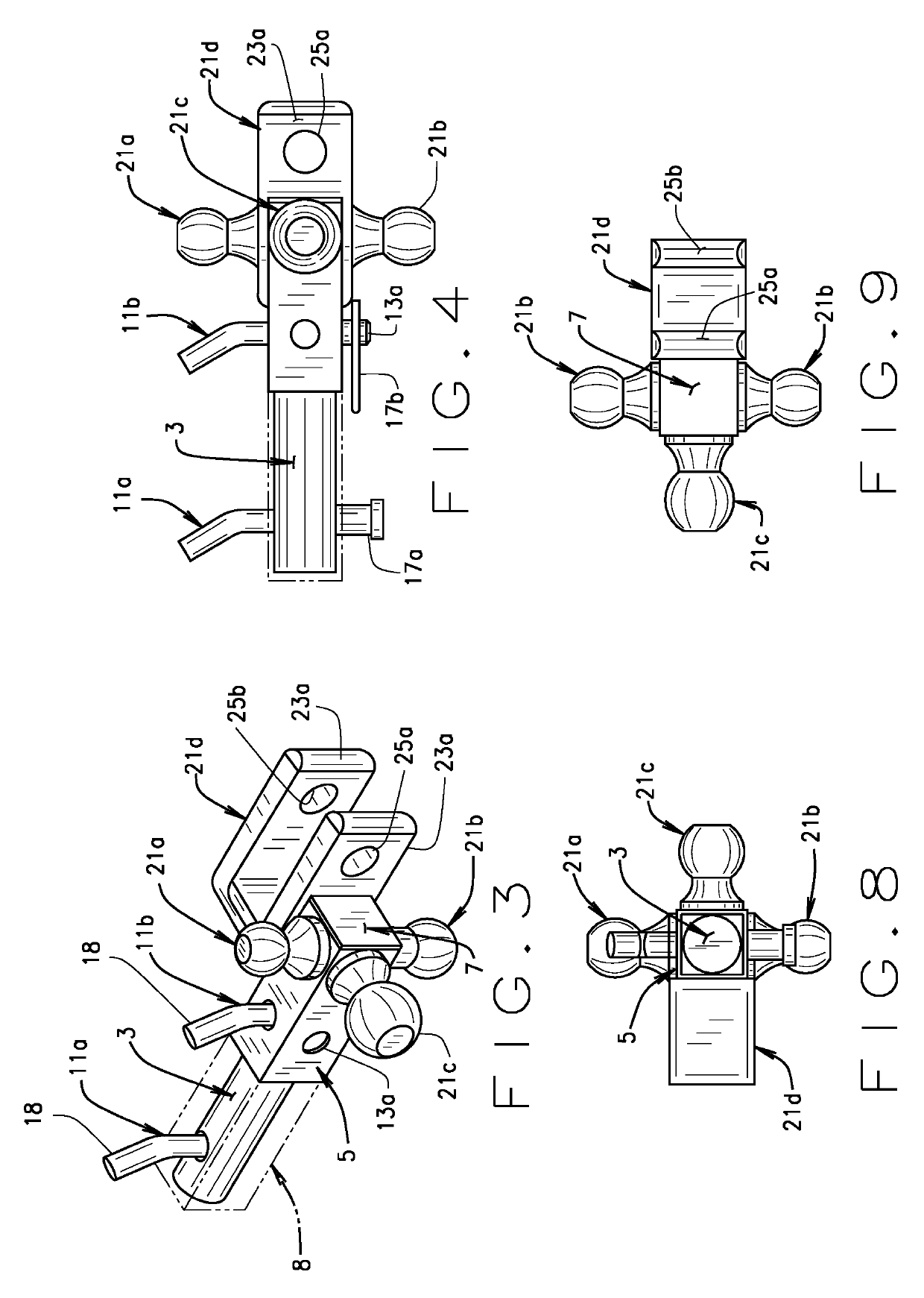

Baseball training system and method

A baseball training system and method for training a player is shown. The baseball system and method includes a collector for collecting thrown balls and directing them to a throwback unit which has multiple adjusters for adjusting various characteristics of a ball being thrown back. The throwback unit can be adjusted to accommodate different ball sizes to change a trajectory of a ball being thrown back by the throwback unit.

Owner:SHOOT A WAY

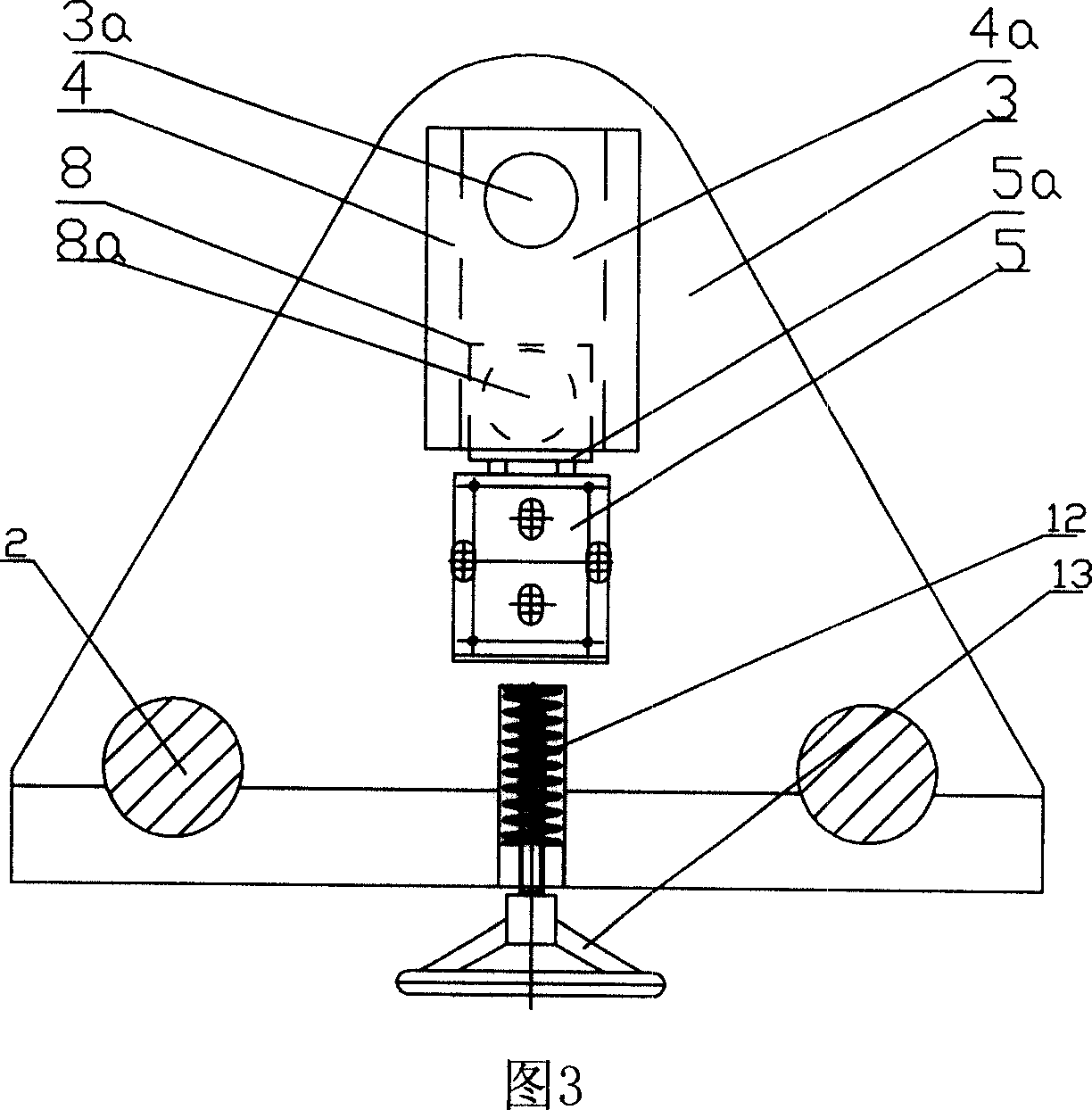

Falling ball impact test machine

InactiveCN1975369APrevent phenomena that affect detection resultsEasy to recycleMaterial strength using single impulsive forceBall impactEngineering

This invention disclosed a testing machine for falling ball impulsion which consists of a column on the base and a platform on the column. The platform was fixed on the column by bolt; there is a grounder channel on the platform, one end connects to a filler and there is a bore on the other end; there are some pulling blocks in the channel. Complicated procedure of placing balls was replaced and the ball size and height were identical in this invention. It works efficiently and precisely.

Owner:重庆信威通信技术有限责任公司

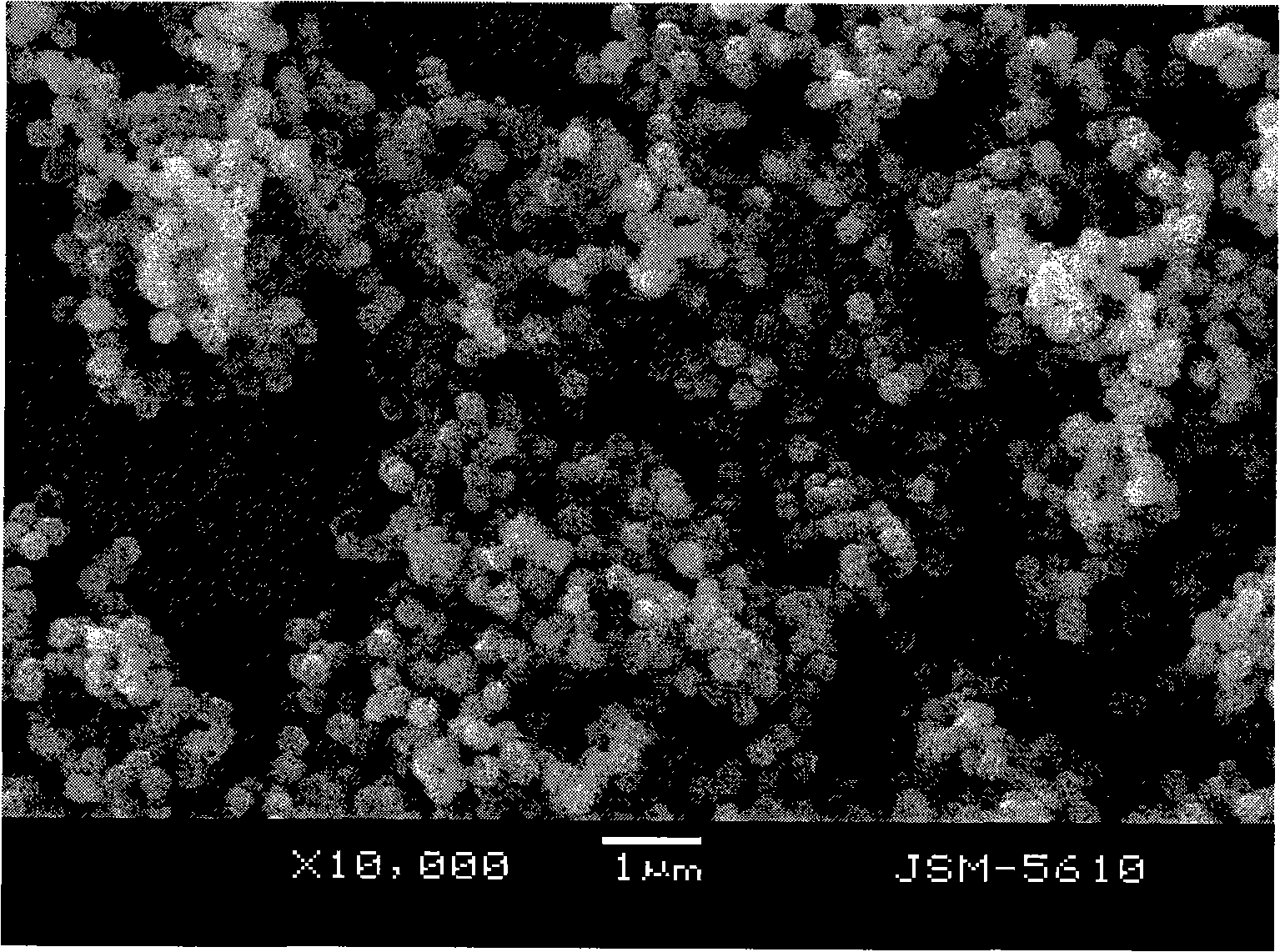

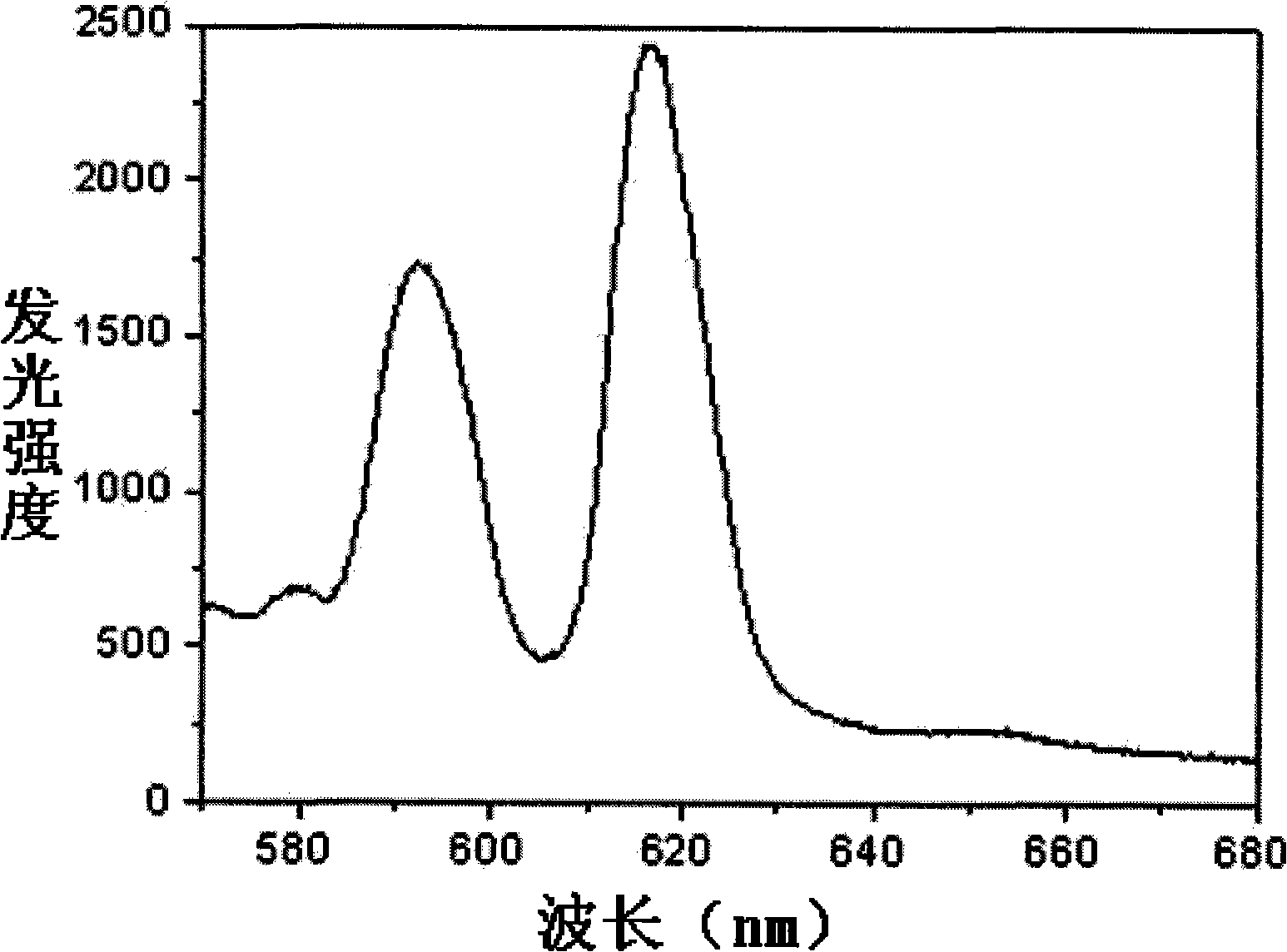

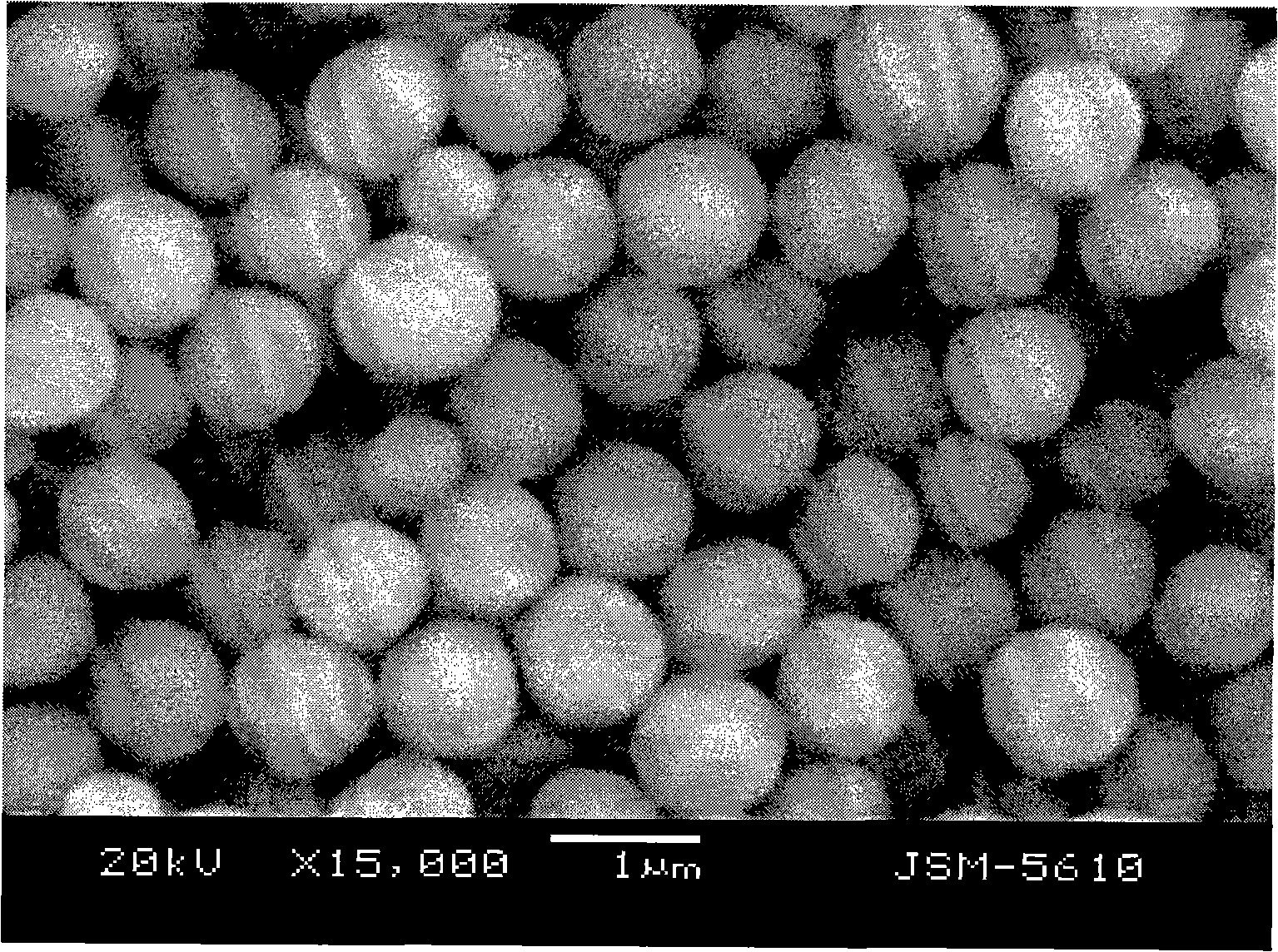

Preparation of europium-doped yttrium borate spherical luminescent material

InactiveCN101298557AUniform sizeGood dispersionLuminescent compositionsSpherical shapedHigh pressure

The invention discloses a preparation method of a spherical luminescent material doped with europium-yttrium borate. Dissolve soluble yttrium salt and europium salt into deionized water to obtain a mixed solution; add borate into the solution to be fully dissolved; the ratio of the total mole number of the borate and the total mole number of the soluble yttrium salt is 1-1.5; add the precipitant into the solution to obtain a colorless and transparent solution. Put the solution into a stainless steel high pressure reactor provided with polytetrafluoroethylene lining; carry out hydrothermal reaction; centrifuge and dry the treated solution to obtain the material. The invention induces the generation of borate salt by decomposing the precipitant under high temperature by a simple hydrothermal method and forms yttrium borate luminescent material doped with europium and having special spherical shape, the molecular formula is YBO3: Eu<3+>. The ball size is uniform with the diameter between 100 nm to 1 Mum, thus having excellent dispersibility, and having a strongest red emission peak at 619 nm, which belongs to the 5 0-72 transition of an europium ion.

Owner:ZHEJIANG SCI-TECH UNIV

Composition and method for improved aluminum hydroxide production

ActiveUS20070172405A1Gallium/indium/thallium compoundsBeryllium compoundsAluminium hydroxideImproved method

An improved method and composition for producing aluminum hydroxide crystals from precipitation liquor, involves the addition of an emulsified crystal growth modifier comprising a C8-C10 fatty acid, precursors, salts or blends thereof. The emulsified crystal growth modifier also facilitates an upward shift in particle size distribution of aluminum hydroxide and an upward shift in oxalate ball size.

Owner:ECOLAB USA INC

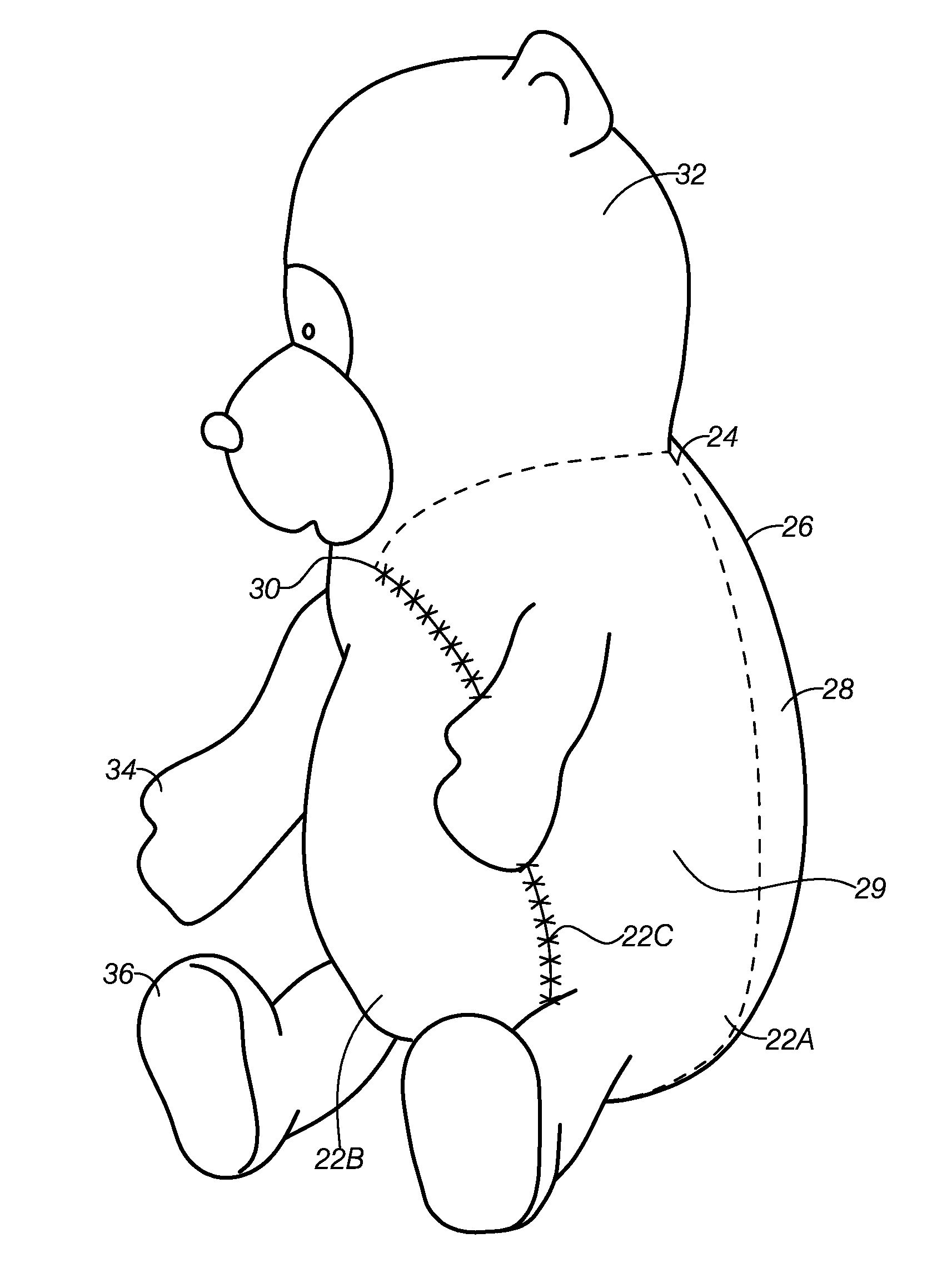

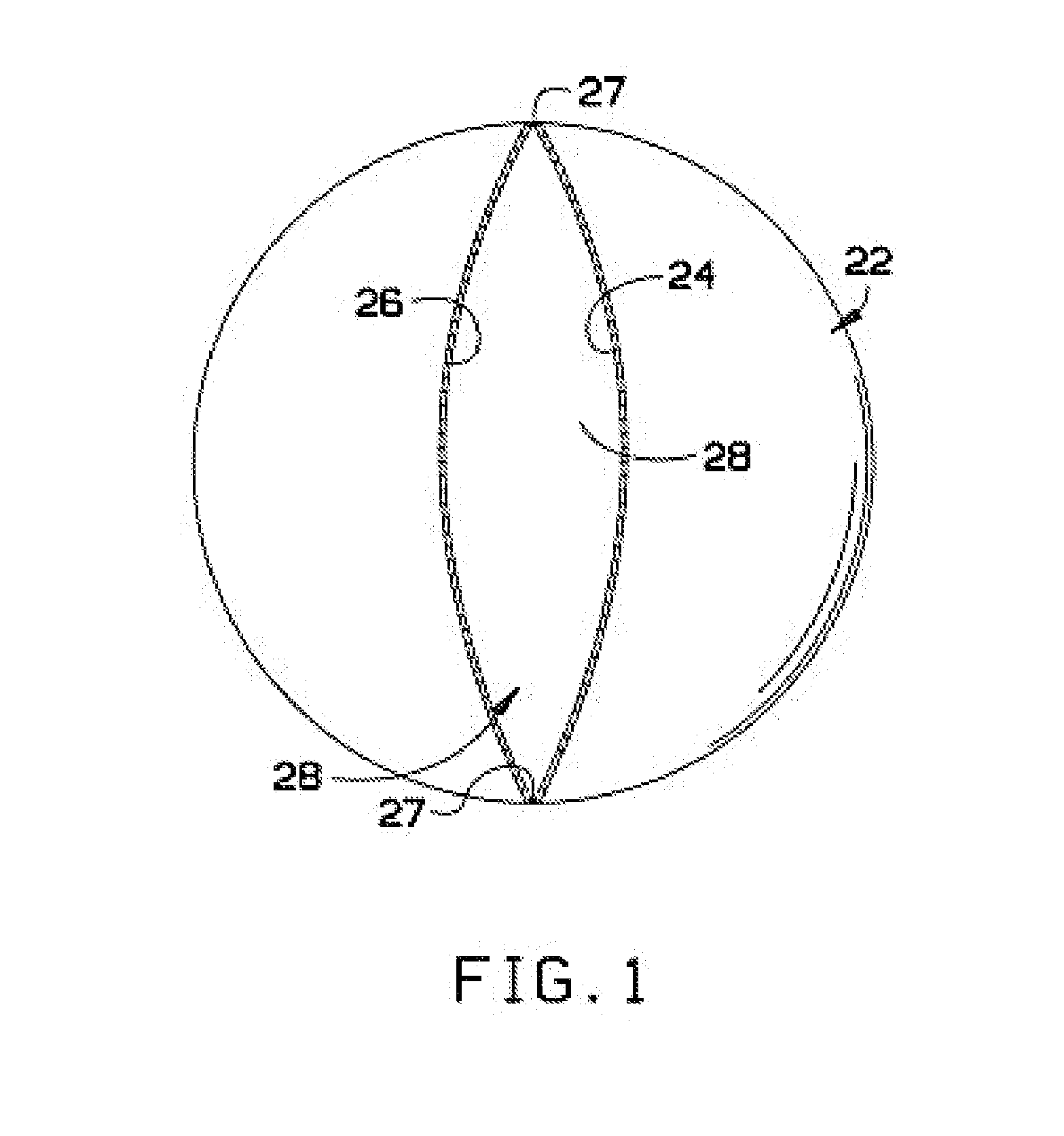

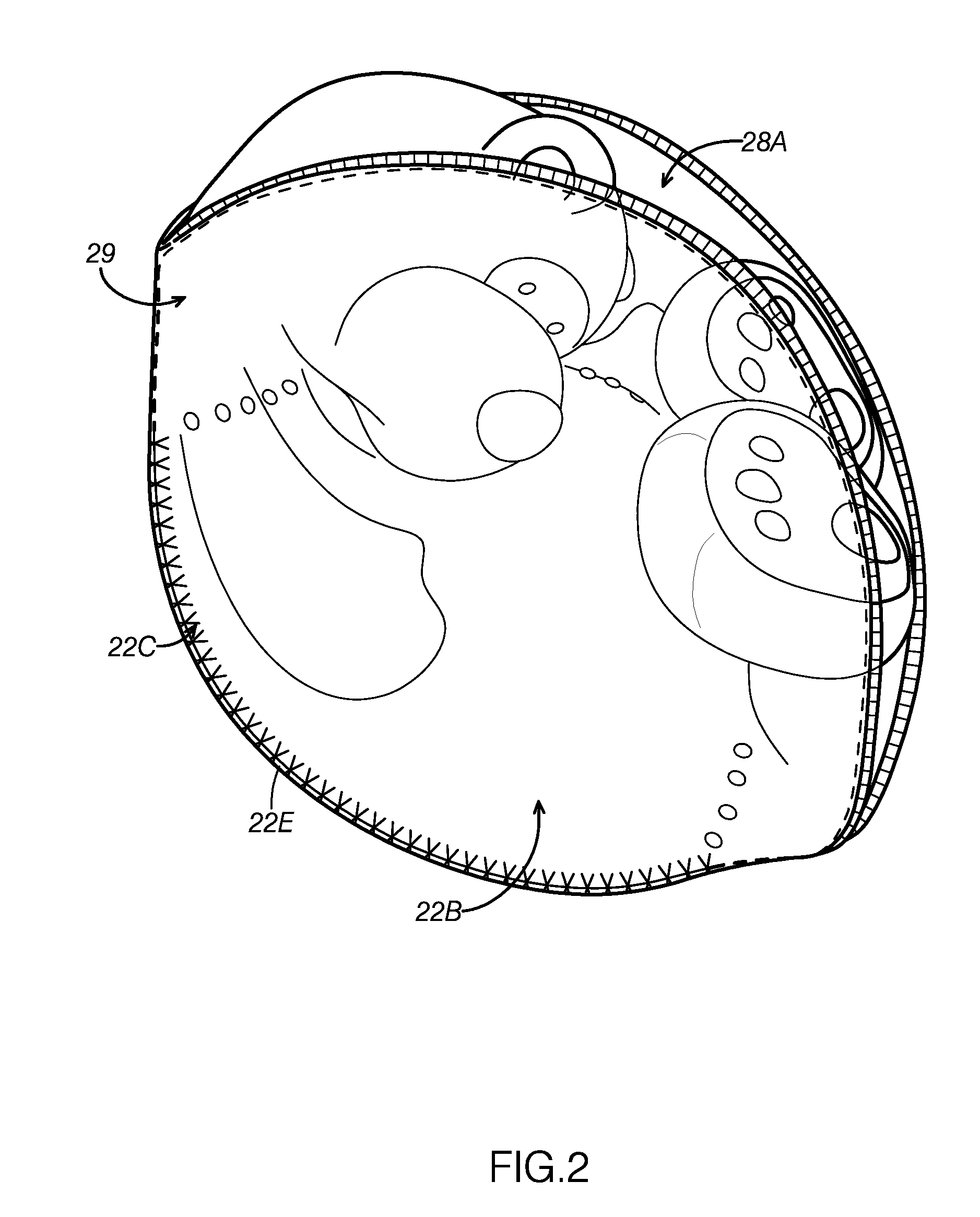

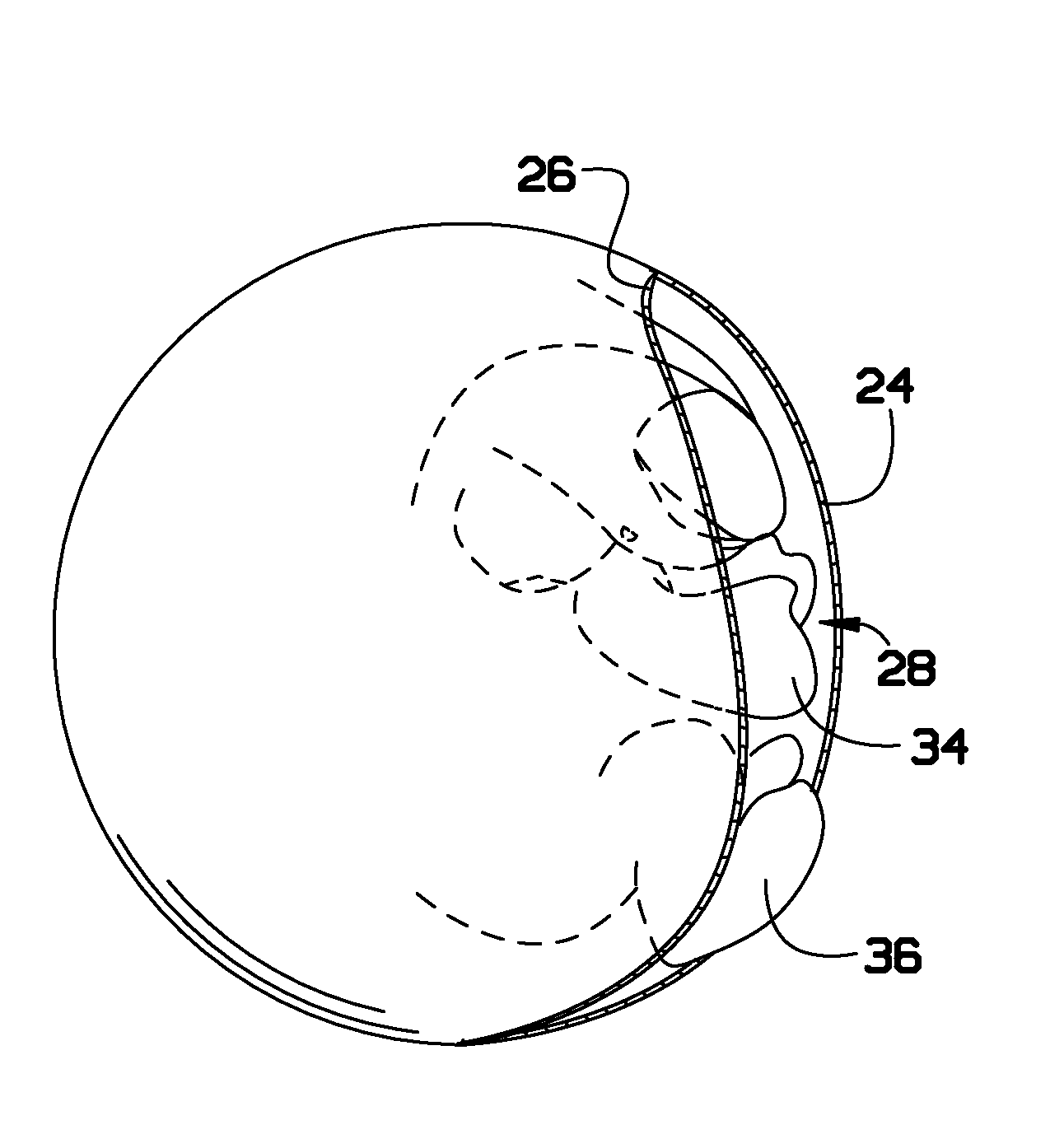

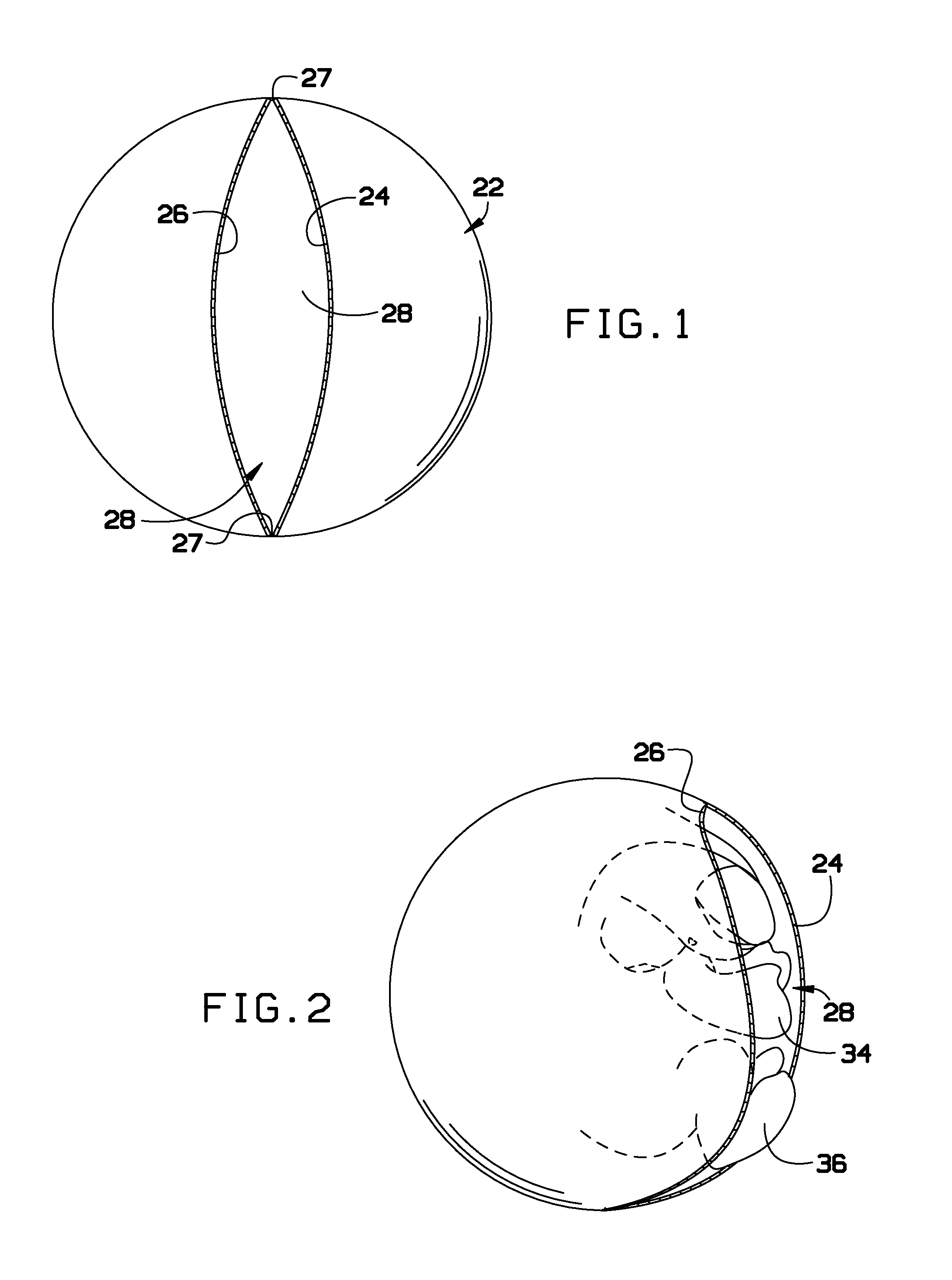

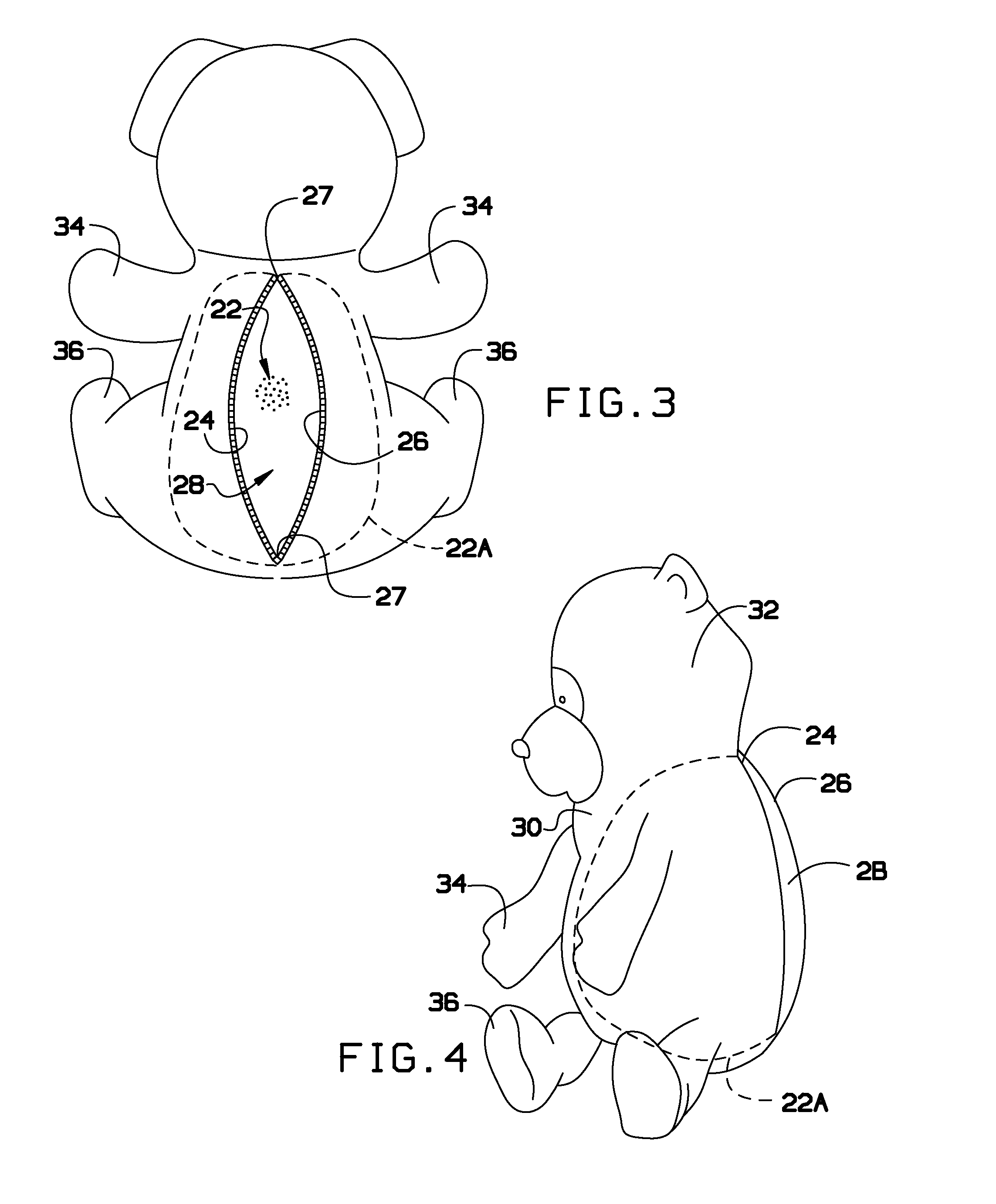

Convertible plush toy with storage

A convertible plush toy can convert between two interconnected reversible shapes. The first shape is that of a plush buddy, such as a teddy bear, that may be reversed into a second, ball shape. The construction and relationship of the ball form to the teddy bear abdomen creates a hidden hollow storage compartment within the plush buddy. The ball size, the abdomen measurements and construction, and the shared opening are designed in such a way to allow the internalized form to support the externalized form, while providing enough independence to avoid distortion of the externalized shape. The ball configuration can be designed in a semi-rigid form, such as with an external plush, internal batting and inner lining, so that the ball retains its shape when externalized and also provides definition to the storage space when internalized.

Owner:REBELLA TIFFANY L +2

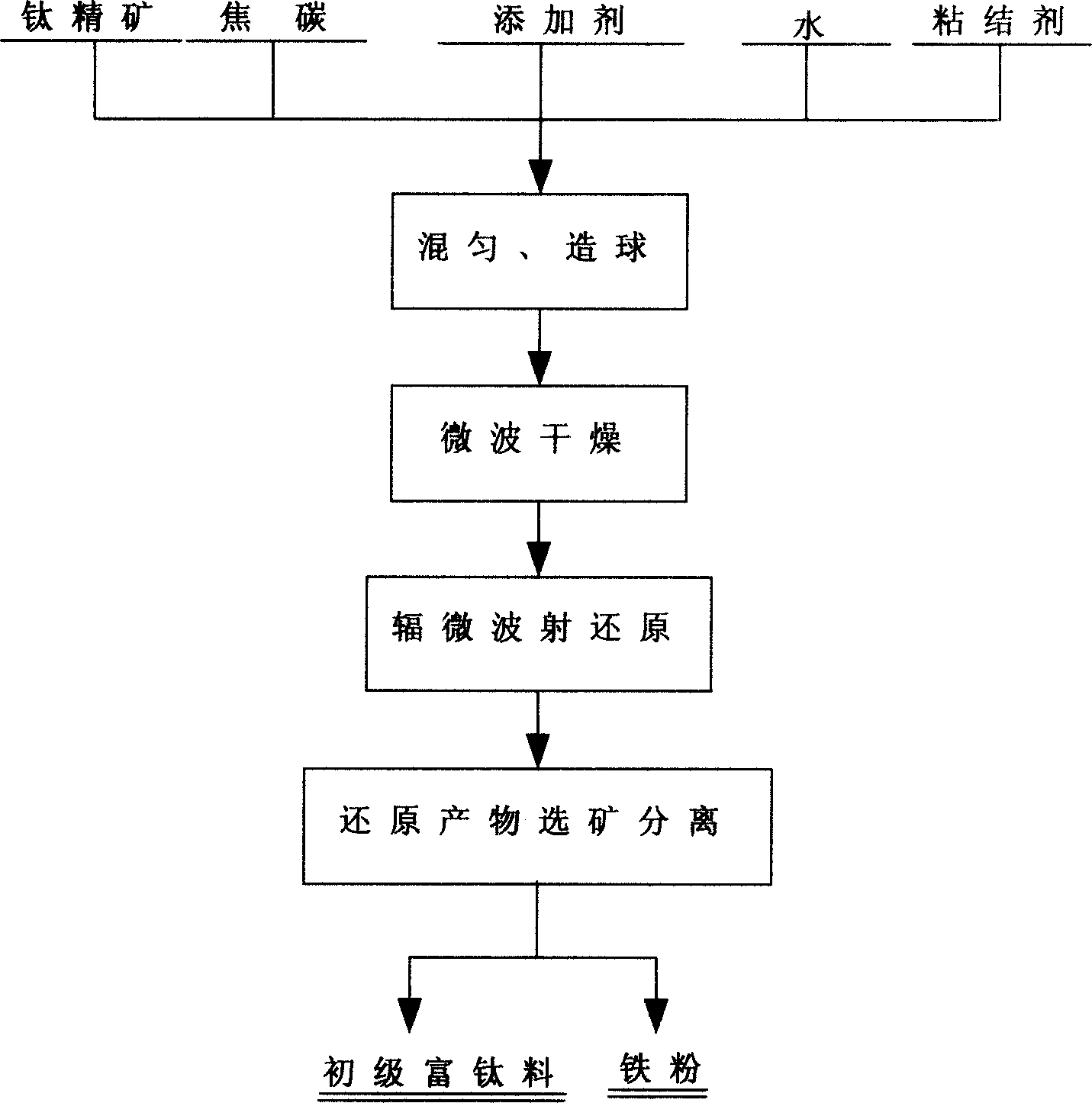

Method for preparing primary titanium-rich material from high calcium-magnesium-titanium headings

The invention relates to a technique refining junior titanium-rich material with high calcium magnesium titanium fine ore. Crash titanium ore of purity 45.00 to 50.00 percent till particles of which the size is smaller than 0.074mm taking 60 to 80 percent weight, then add in with water 8 to 20 percent weight of the ore, adherent sodium silicate 3 to 5 percent, chark 10 to 20 percent, 1 to 5 percent addition sodium sulfate, 1 to 3 percent addition iron powder, 3 to 5 percent addition potassium chloride, making complex balls sized 10 to 15 mm, and acquire junior titanium-rich material after microwave drying, microwave heating and restoring, ore selecting and separating. As the titanium ore is highly wave absorptive, the heating speed is high, and the restore temperature is lowered by 80-120 deg.C, extraneous material calcium and magnesium are of good acid dissolvability which ensures the high purity of the junior titanium-rich material.

Owner:KUNMING UNIV OF SCI & TECH

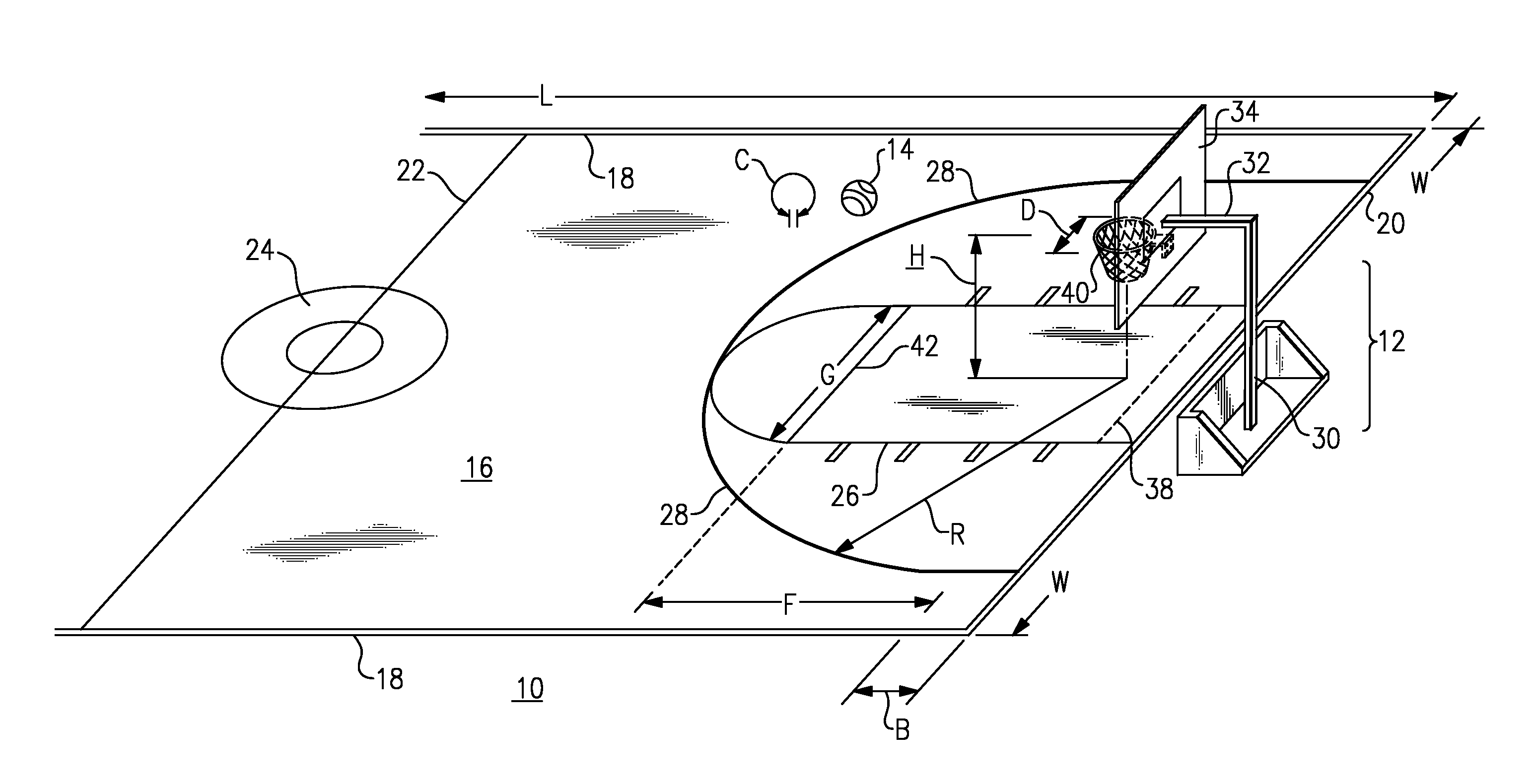

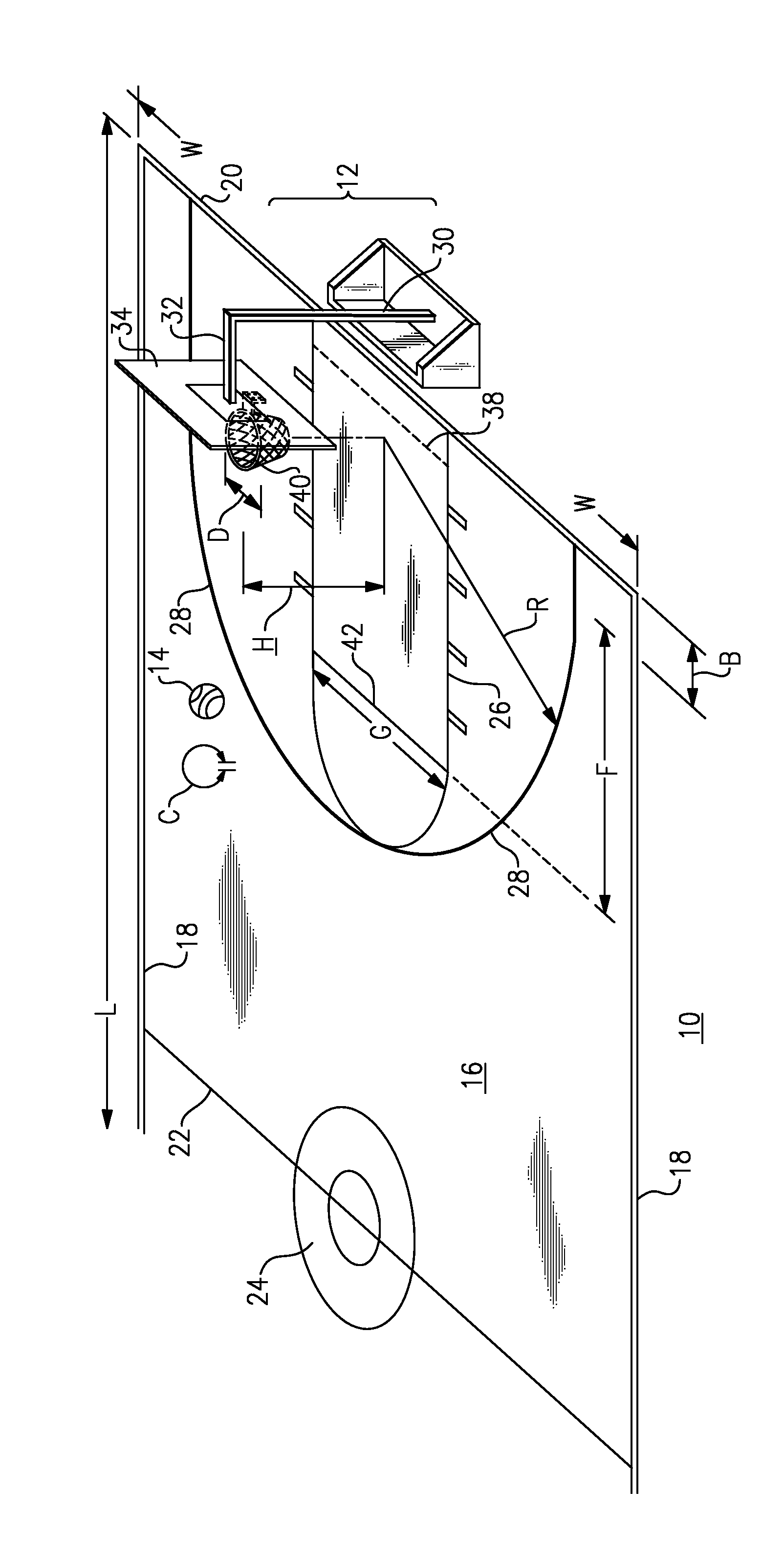

Scale Sports Court and Equipment

InactiveUS20080171620A1Reduce the overall heightReduce the overall diameterBall sportsRacket sportsEngineeringSmall stature

A scale sport playing court or floor and associated equipment are provided for persons of a smaller stature or height than the collegiate or professional players of the standard-size version of the sport. Teams are selected with players' height restricted to a maximum height (e.g., 72 inches) or less. The game is played according to normal rules except that the court size, goal (or net) and ball size are reduced by a scale factor S related to the height of the smaller stature players to the average height of the professional or collegiate players. In a scale basketball game, the court size, hoop diameter, height of the hoop, distance from the free throw line to the backboard, three point arc, and other dimensions are the product of the scale factor S times the standard dimension. The scaling matches the court and equipment to the athleticism of the players.

Owner:FELDMEIER ROBERT H

Automatic steel ball sorting machine

The invention discloses an automatic steel ball sorting machine which comprises a machine frame, a ball storage groove, an extensible ball door device, an oblique sorting groove, a knife foot module and a qualified ball receiving device. The extensible ball door device comprises a ball door and a lifting air cylinder. The sorting knife foot module comprises a screw supporting sleeve, a knife foot and a turning handle. The automatic steel ball sorting machine utilizes the air cylinder to drive the ball door to lift so as to achieve discharging and rolling ball interruption, accordingly the number of the steel ball discharged each time is equal, and the problem that the excessive steel balls roll out of the ball storage groove under the gravity effect and accordingly the balls are clamped by the knife foot portion can be avoided. When the steel balls pass through the knife foot, the distance between the knife foot and the bottom of the sorting groove is adjusted to be equal to the standard ball size, accordingly large balls are intercepted by the knife foot when passing through the knife foot, and standard balls roll into the receiving device through the knife foot. By means of the automatic steel ball sorting machine, all unqualified large balls can be sorted out, and the large balls can be prevented from damaging a refining mill.

Owner:TSUBAKI HOOVER (CHONGQING) CORP LTD

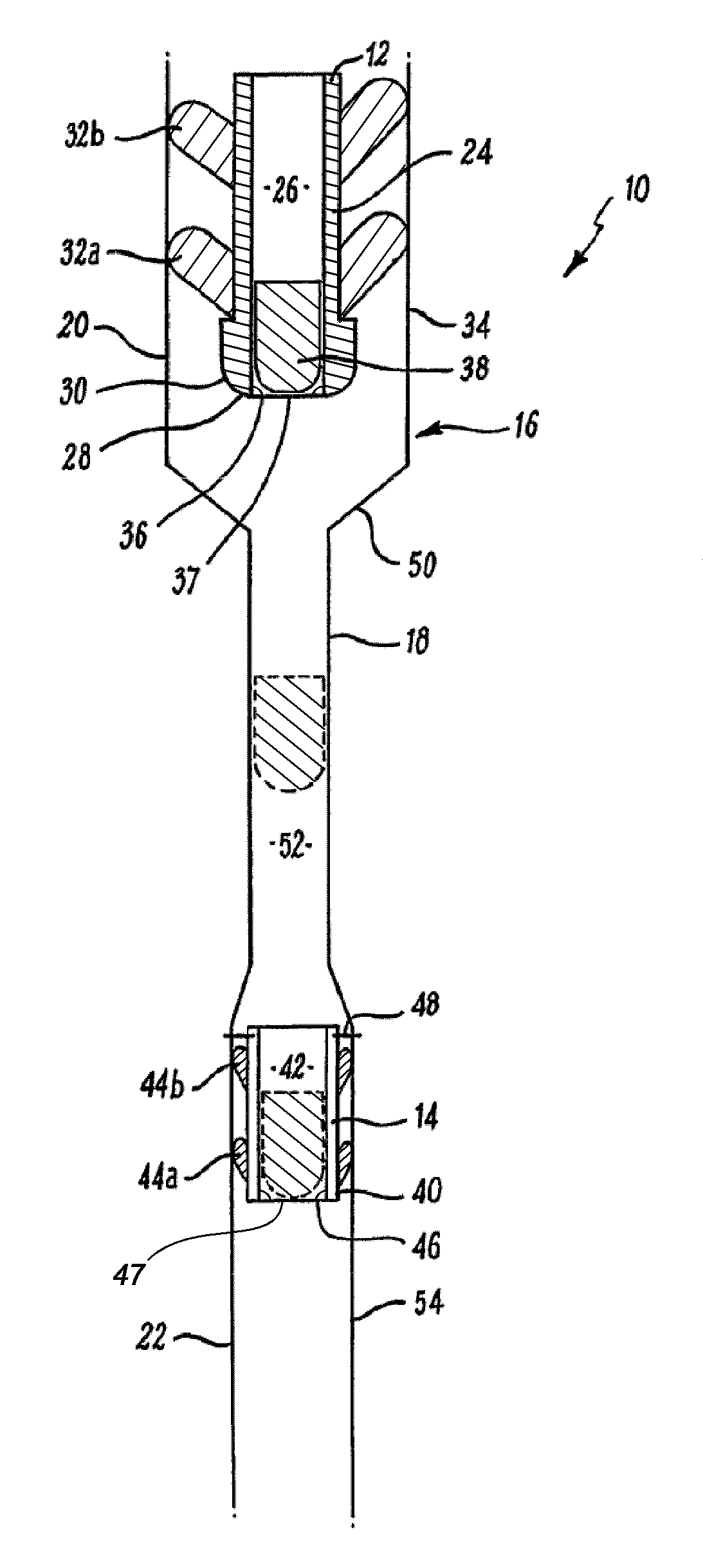

Rotating wheel return mechanism

InactiveUS7137910B2Improve efficiencyReduce riskFiring/trigger mechanismsBall sportsProximity sensorEngineering

A practice machine for receiving a thrown ball and returning it to a user is generally provided with a backstop for stopping the thrown ball, a pan disposed below the backstop for collecting the ball, a ball return adjacent the backstop for expelling the ball, and a trough disposed between the pan and the ball return for feeding the ball from the pan to the ball return. The ball return can adjust between ball sizes and vary the trajectory of expelled balls. Moreover, the ball return can be equipped with safety features including a proximity sensor, audible alerts, speed adjustment and tamper resistant controls. Further, the ball return can alternate between a MANUAL mode and an AUTOMATIC mode. The backstop of the practice machine can be collapsible to permit convenient storage and ease of transportation.

Owner:GRAND SLAM SPORTS

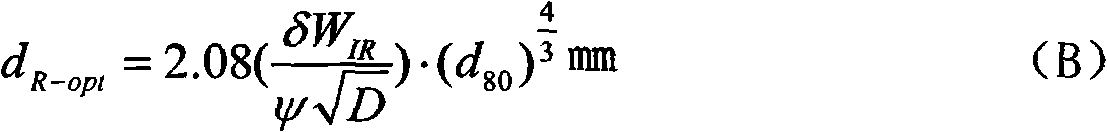

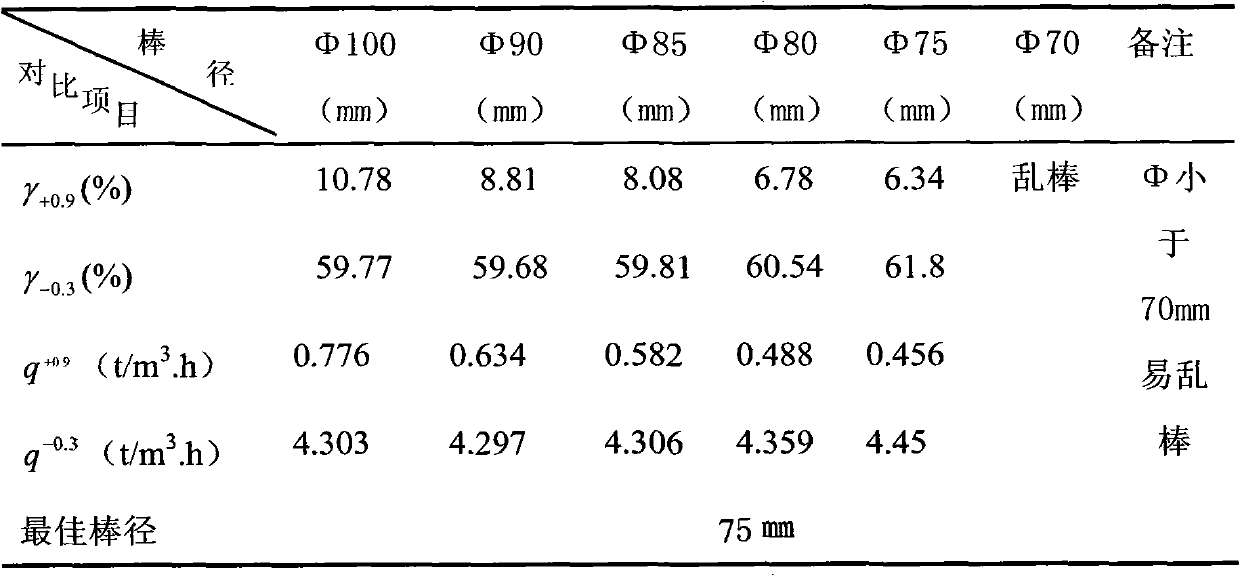

Method for determining rod diameter of rod mill

InactiveCN102172555AEasy way to determineAssays are lengthy and complexGrain treatmentsCompressive strengthBall diameter

The invention relates to a method for determining the rod diameter of a rod mill, belonging to the field of ore grinding and levigating technology. The method provided by the invention comprises the following concrete steps: (1) measuring the uniaxial compressive strength alpha of the ore to be milled, as a mechanical basis for determining the accurate rod diameter; (2) performing screen analysis of particle size for the feeding material of the rod mill, and determining the fraction d'f and average particle size for ensuring the screening rate of 95%; (3) converting the practical working conditions of the rod mill into the working conditions of a ball mill in the same conditions, and calculating the ball diameter in the conditions by using a half-theory formula of ball size (C.G.S system); (4) correcting the calculated ball diameter according to the breaking experience and ore milling characteristics of the steel rod, and calculating the required rod diameter through the formula D(R-opt)=(0.48-0.5)D'b; and (5) performing ore milling contrast test with the rod diameter greater than and less than D(R-opt), and determining the accurate rod diameter of the rod mill according to the ore milling result. Compared with the prior art, the method is simple and convenient, is accurate in calculation result, has low labor intensity of workers and shortens the test period.

Owner:YUNNAN UNIV

Method for fast taking root for transplanted large tree

The present invention relates to an improved large tree transplanting method. The present invention includes determining the root soil ball size based on the bole diameter, treatment of root and embedding specially prepared nutritive oil around the root. The said method makes the transplanted tree fast in taking root and easy to survive.

Owner:戴锁方

Convertible plush toy with storage

A convertible plush toy can convert between two interconnected reversible shapes. The first shape is that of a plush buddy, such as a teddy bear, that may be reversed into a second, ball shape. The construction and relationship of the ball form to the teddy bear abdomen creates a hidden hollow storage compartment within the plush buddy. The ball size, the abdomen measurements and the shared opening are designed in such a way to allow the internalized form to support the externalized form, while providing enough independence to avoid distortion of the externalized shape. The ball configuration can be designed in a semi-rigid form, such as with an external plush, internal batting and inner lining, so that the ball retains its shape when externalized and also provides definition to the storage space when internalized.

Owner:REBELLA GREGORY +2

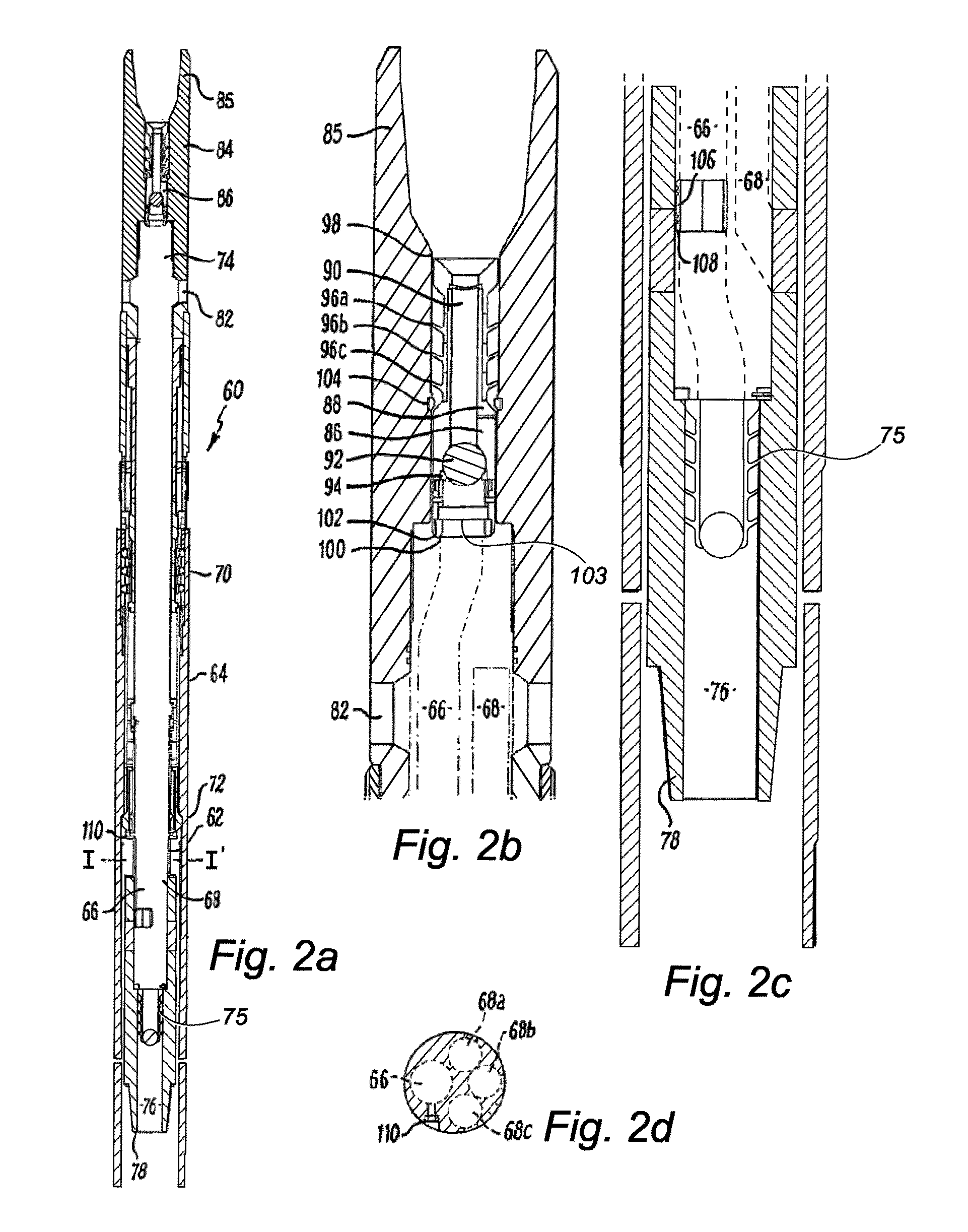

Apparatus and method for use in a well bore

Apparatus for use above and below a restriction in a well bore and a method of operation is described. The apparatus comprises an upper element, such as a wiper, operable in the well bore above the restriction and a lower element, which may be a lower wiper, operable in the well bore below the restriction. A drop ball sized to pass through the restriction is released from the upper element and thereby passes through the restriction to operate the lower element. In one embodiment, the apparatus is incorporated into a running tool, which may be used to hang liners by dimple forming.

Owner:TERCEL IP

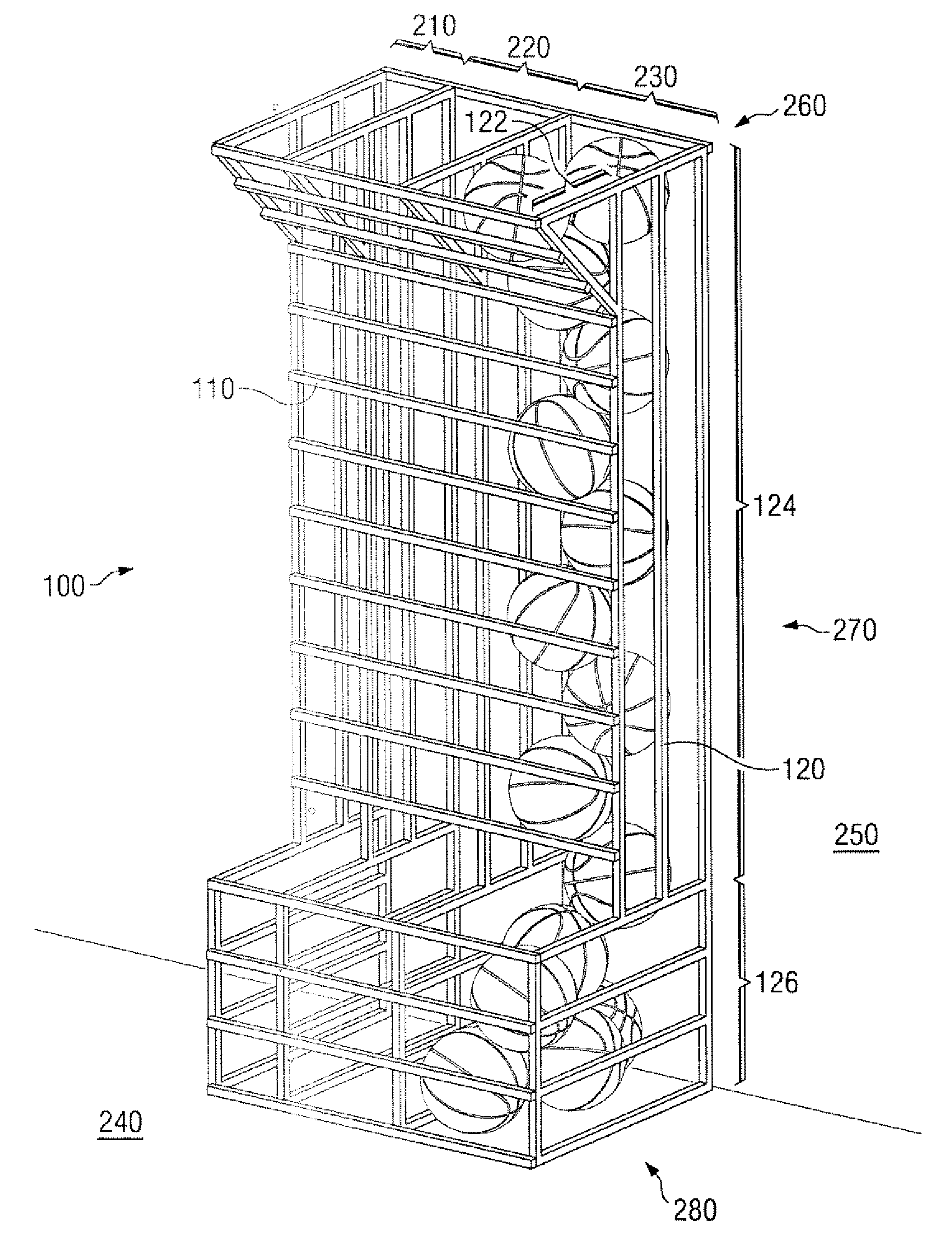

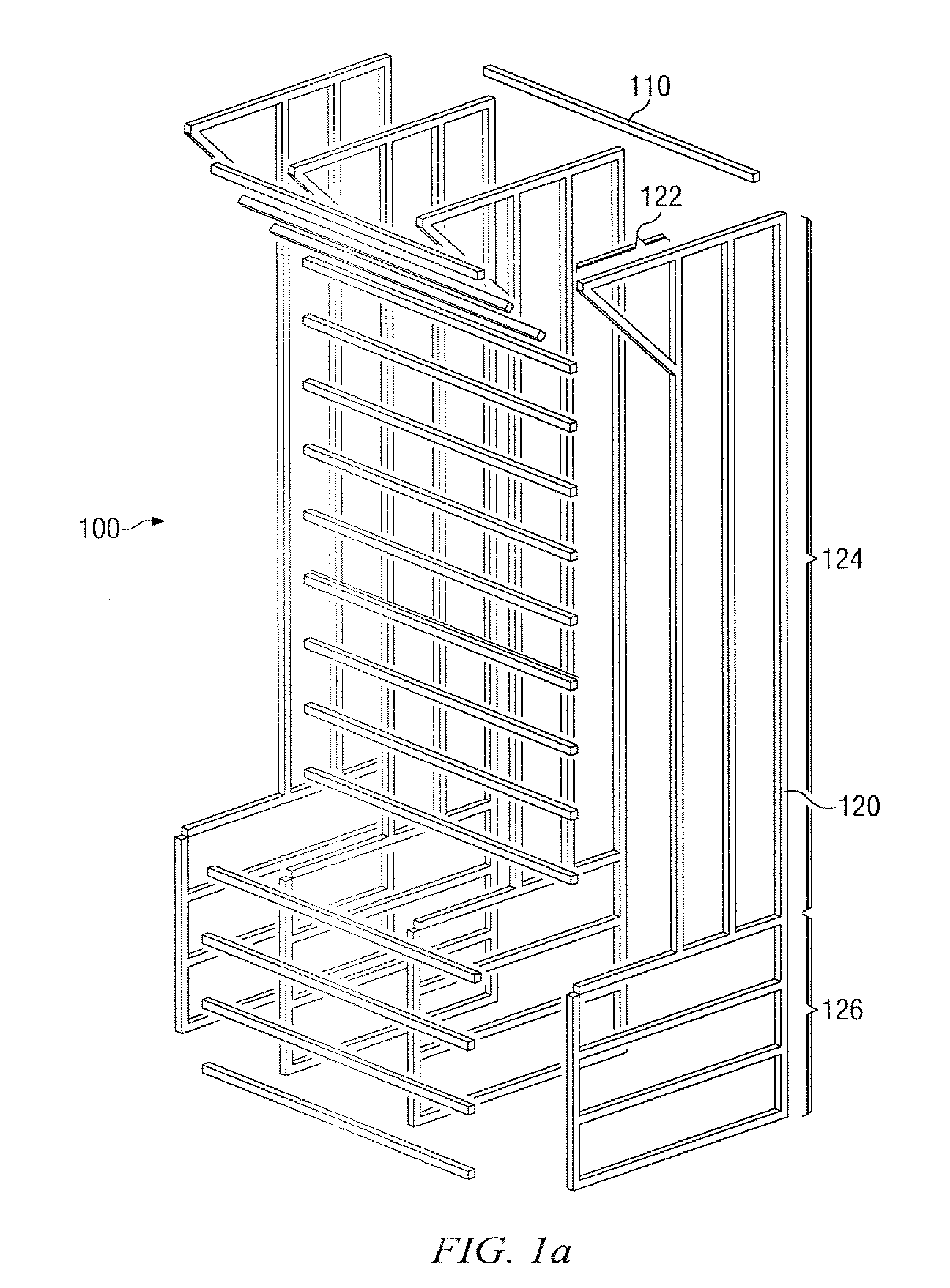

Ball Dispenser for Sports and Athletic Equipment Storage

A ball dispenser having a plurality of connecting members and a plurality of basic sections, each connecting member dimensioned for a particular ball size, and each basic section having a triangular portion, vertical portion, and rectangular portion. When two or more basic sections are integrally connected together by means of varying sized connecting members, a funnel section, column section, and bin section are formed. This allows a number of balls to be placed into the funnel section at the top of the ball dispenser, and to fall one at a time through the column section, and into the bin section. Ball dispenser is designed to be affixed to a wall and to rest on a floor so that the wall and floor provide the back and bottom of the ball dispenser. Additional equipment storage may be affixed to the ball dispenser.

Owner:DI DONATO JO ELLEN

Composition and method for improved aluminum hydroxide production

ActiveUS7976821B2Gallium/indium/thallium compoundsAluminium hydroxide preparationAluminium hydroxideImproved method

An improved method and composition for producing aluminum hydroxide crystals from precipitation liquor, involves the addition of an emulsified crystal growth modifier comprising a C8-C10 fatty acid, precursors, salts or blends thereof. The emulsified crystal growth modifier also facilitates an upward shift in particle size distribution of aluminum hydroxide and an upward shift in oxalate ball size.

Owner:ECOLAB USA INC

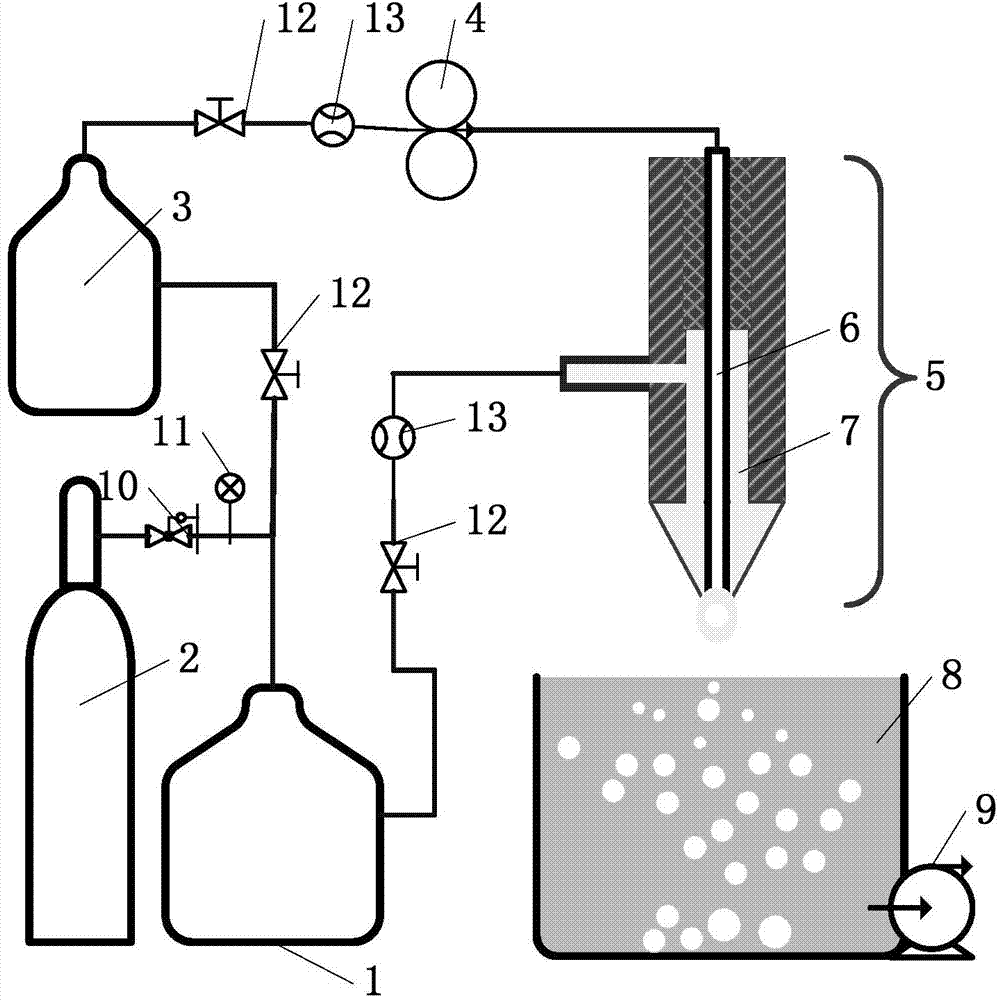

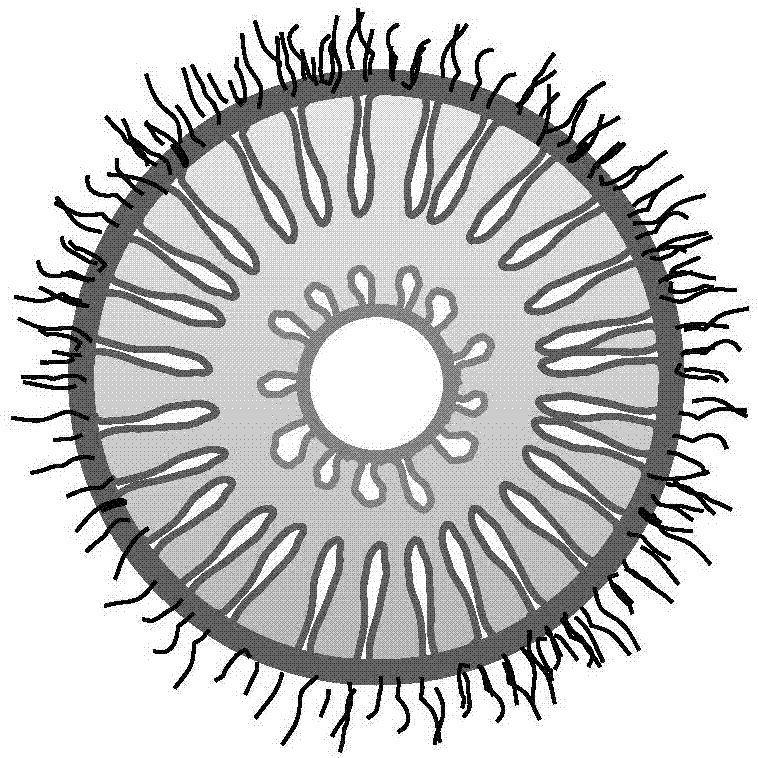

Method for growing carbon nano fibers on ceramic hollow microsphere surface in situ

The invention relates to a method for growing carbon nano fibers on a ceramic hollow microsphere surface in situ, which comprises the steps of precursor slurry preparation, precursor preparation, and sintering carbonization. The method specifically comprises the following steps: synthesizing a carbon nano fiber / ceramic hollow microsphere precursor in situ by utilizing the principle of non-solvent induced phase separation; and carrying out room temperature drying and carbonization sintering treatment on the precursor to finally obtain the carbon nano fiber / ceramic composite material hollow microsphere. Compared with the prior art, the method does not need any metal catalyst or additional carbon source to grow the carbon nano fibers on the external surface and inside of the ceramic ball in situ, and has the advantages of uniform carbon nano fiber dispersion, favorable sphericity of ceramic balls, and controllable ball size and porosity, does not need to consume abundant energies and acid / alkali reagents. The technique is simple and can easily implement mass industrial production.

Owner:SHANGHAI JIAO TONG UNIV +1

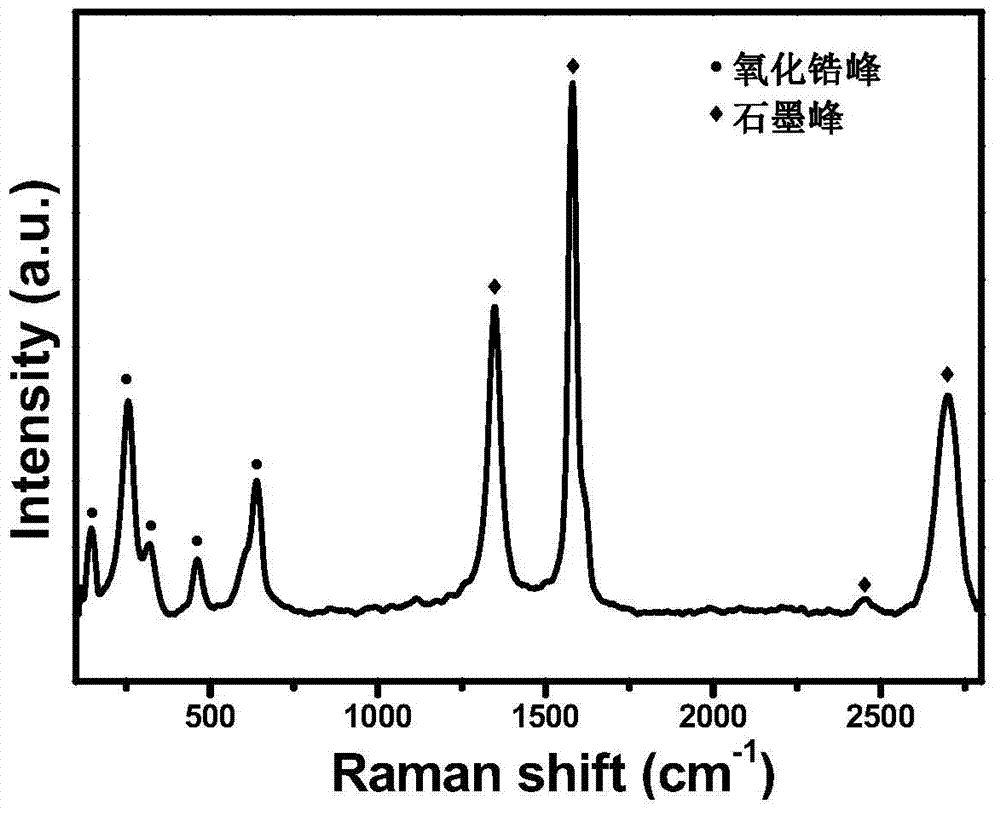

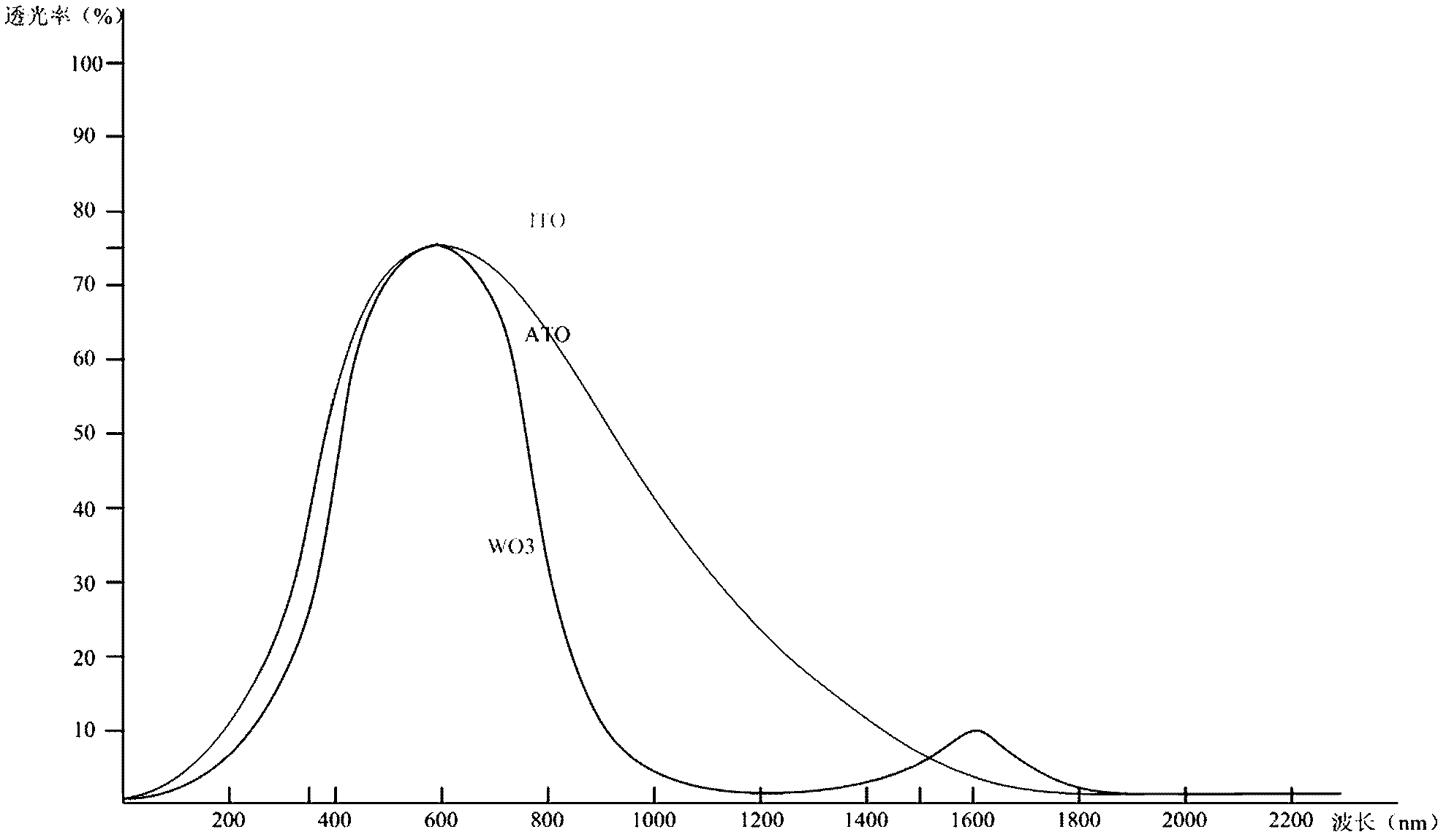

Preparation method of high-performance window film insulation medium

ActiveCN103122155AImprove energy efficiencyStrong transparencyCoatingsThermal insulationTransmittance

The invention discloses a preparation method of high-performance window film insulation medium. The preparation method includes: firstly, selecting blue WO3, ATO and ITO nano-powders according to corresponding conditions, using a planet wet ball-milling disperser and a scientific and reasonable combining-scattering comparison method, and optimally selecting factors such as selection proportion and solid content of different insulation media, selection on mill ball size, control on rotation speed and continuous dispersion time. Therefore, optimal transmittance of visible light, optimal insulation, optimal ultraviolet proofing and optimal performance of high-performance insulation medium are achieved. The high-performance window film insulation medium prepared by the preparation method is high in transparency, thermal insulation and ultraviolet proofing, has high insulation in the near-infrared area of 780nm-900nm, is widely applied to production of high-performance insulation glass and high-performance insulation window films, and has very important social and economic values.

Owner:上海沪正实业有限公司

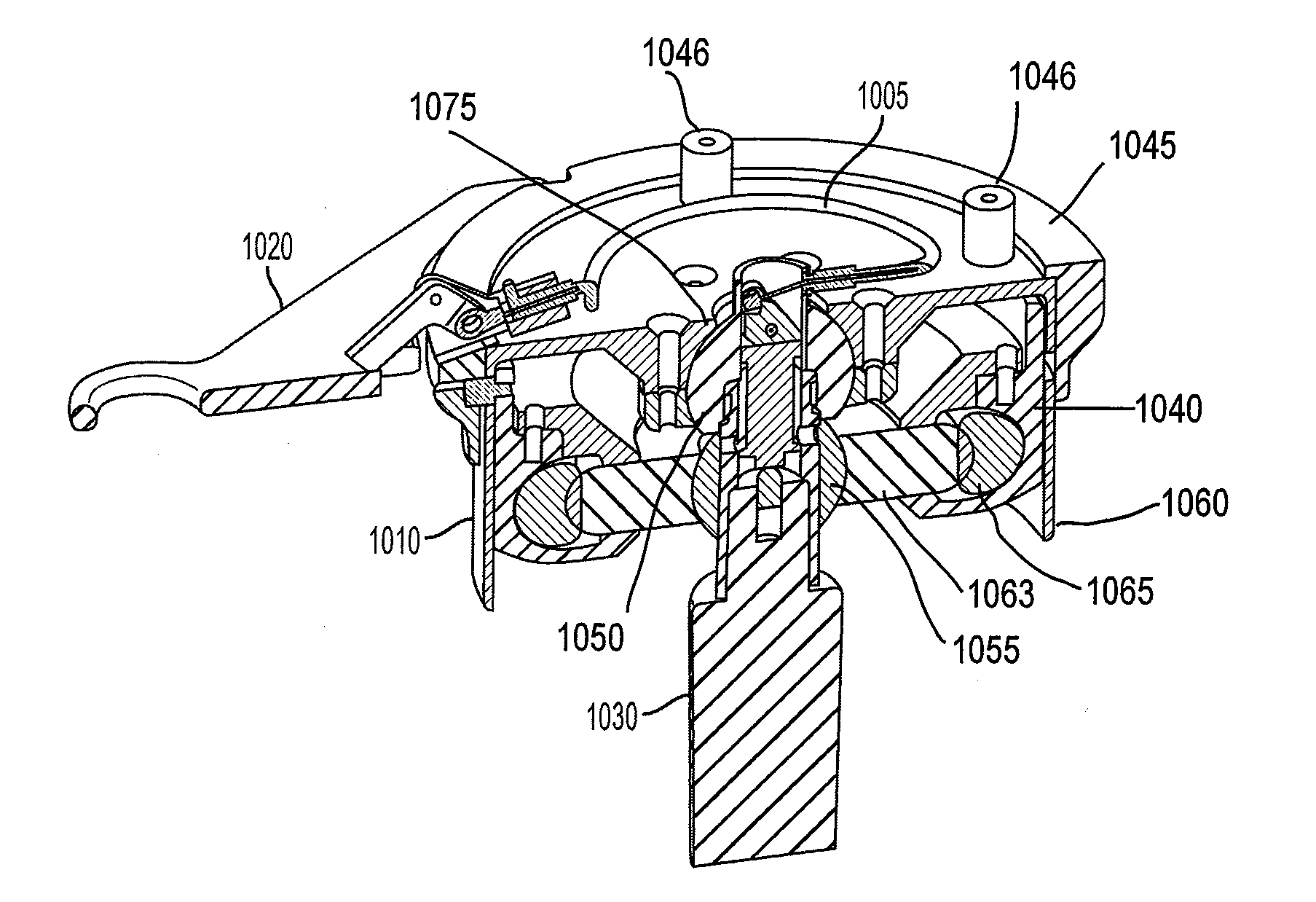

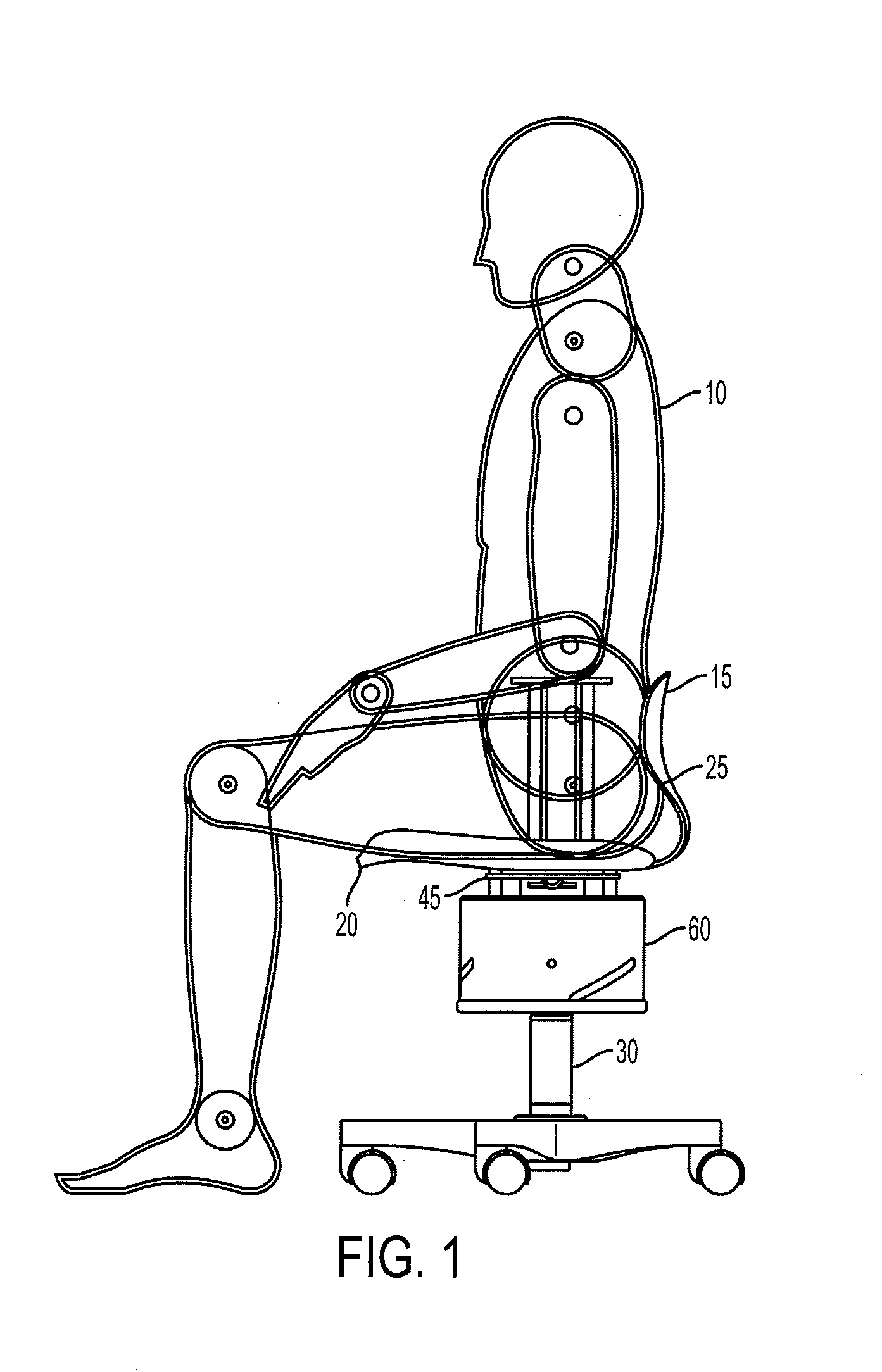

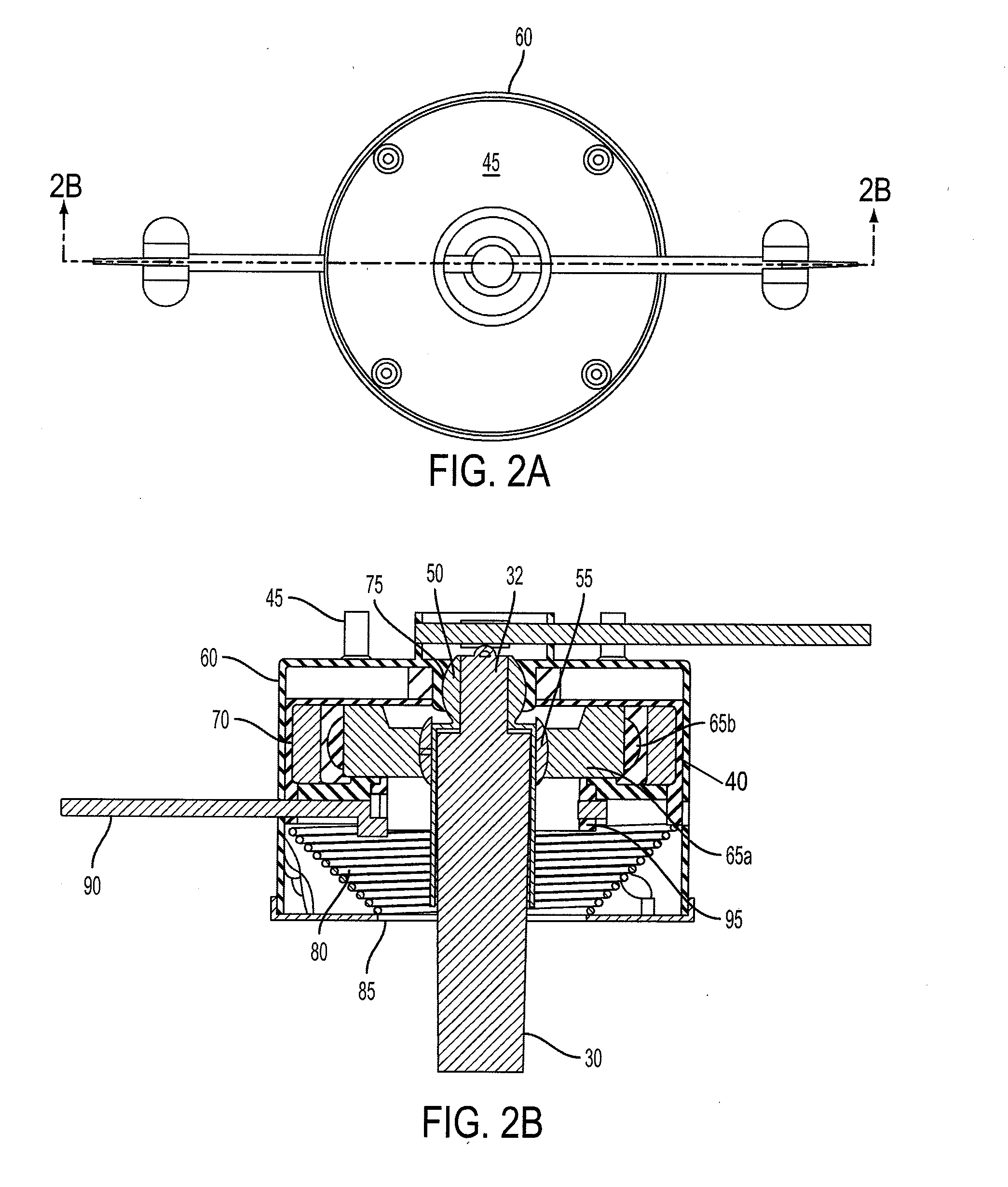

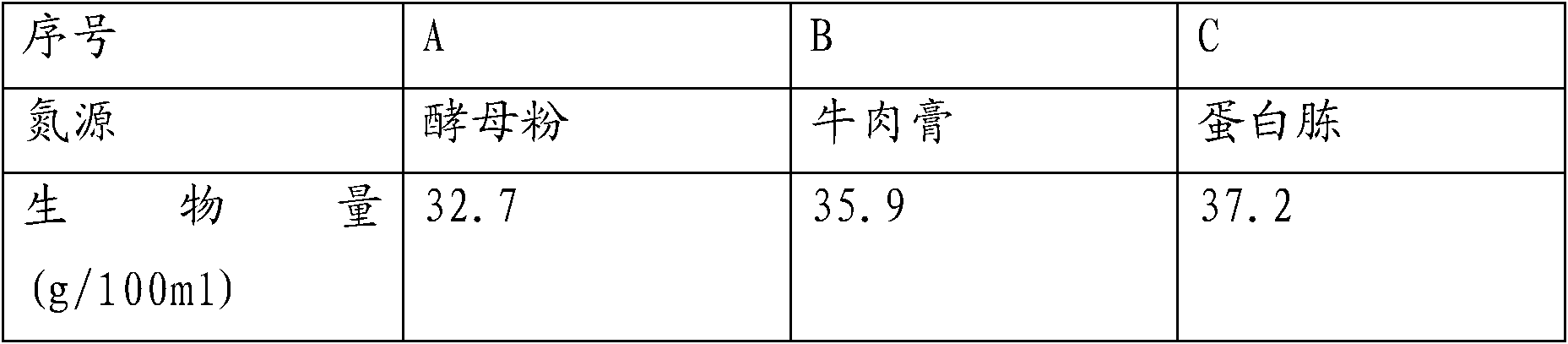

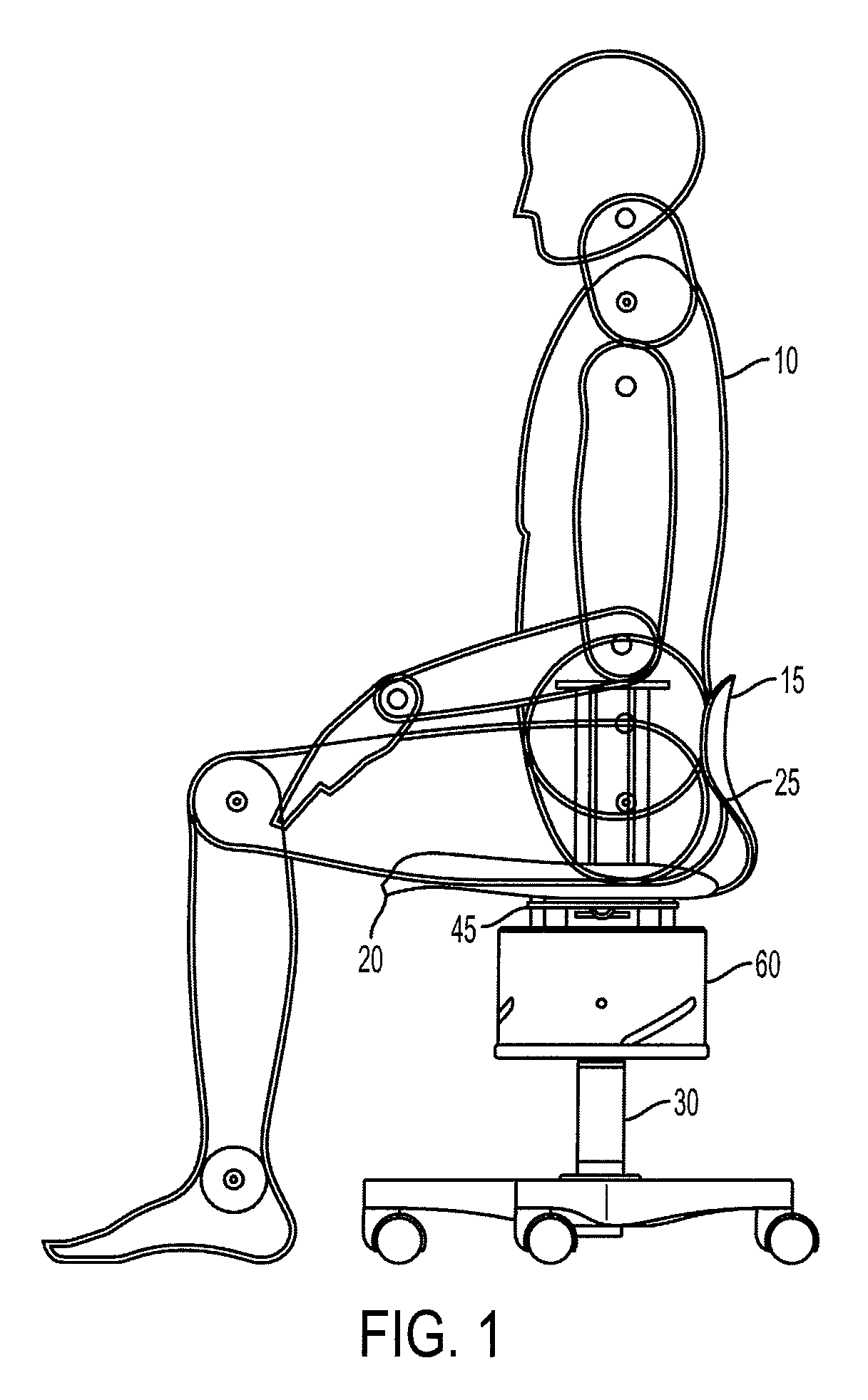

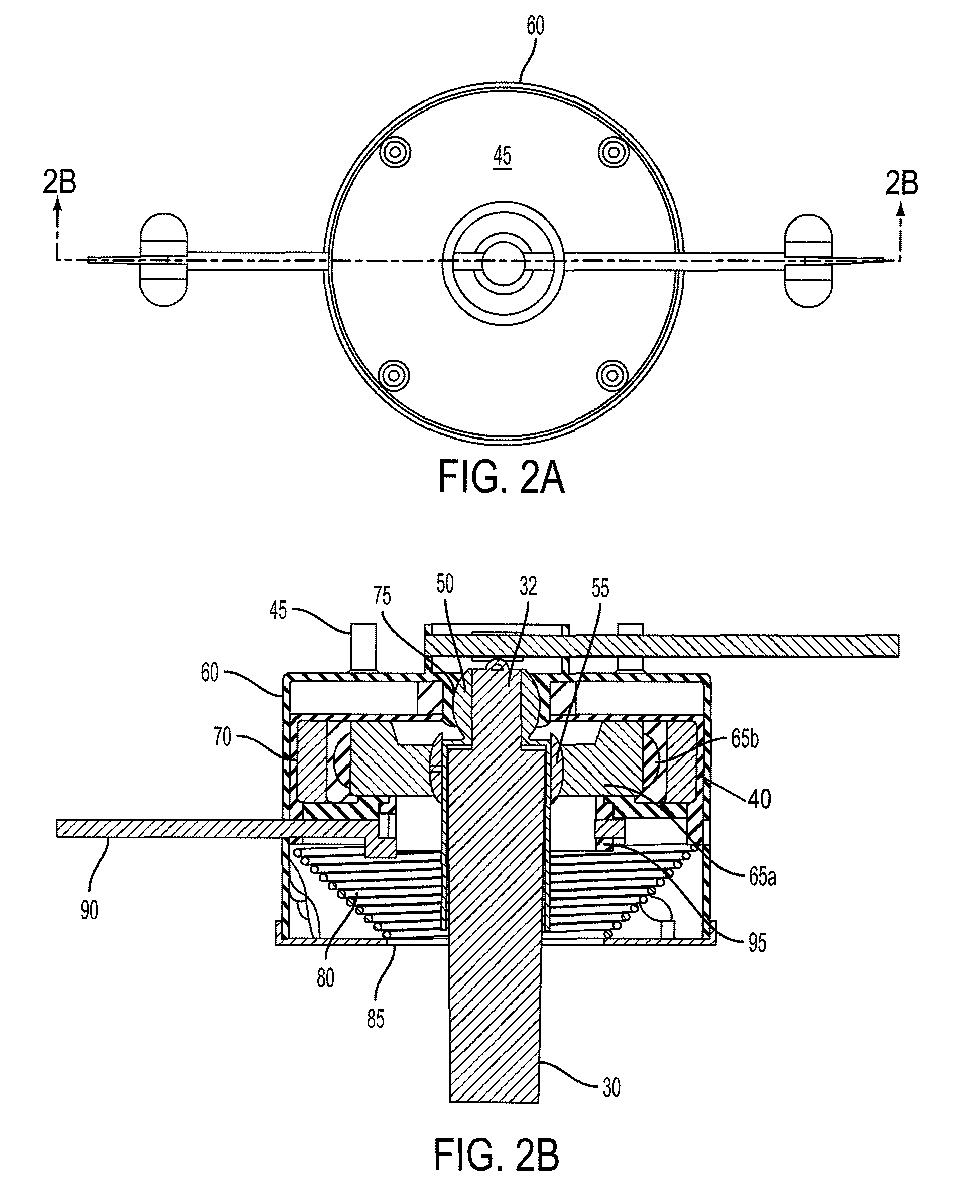

Resistive Support Mechanism

A motion support mechanism, for example for a chair, joined to a mounting surface and to a base for providing resistive support to the mounting surface as the mounting surface undergoes one or both of rotational and tilt movement relative to the base. The motion support mechanism includes a support bearing connected to the mounting surface and to the base which permits one or both of tilting and rotational motion of the mounting surface relative to the base, a pivot ball sized fixedly attached to a portion of the base, and, a resistance cartridge fixedly connected to the mounting surface such that the resistance cartridge undergoes movement relative to the base and applies a resistive force on the base as the mounting surface undergoes one or both of rotational and tilt movement. The resistance cartridge includes a cartridge housing and a resilient member in contact relation with the pivot ball and with a wall of the housing such that the resilient member is compressed by the relative movement between the resistance cartridge and the pivot ball to thereby provide the resistive support to the mounting surface. Preferably, the resistive support also provides a dampening feature, for example by way of the resilient member being formed from a viscoelastic material. A means for varying the resistance applied is provided that permits the distance between the bearing surface and the pivot ball to be varied.

Owner:CORECHAIR

Method of producing magnesium-silicon-calcium fertilizer from submerged arc furnace molten asbestos tailings

ActiveCN108911795AReduce smelting power consumptionRealize deleading processCalcareous fertilisersMolten stateSlag

The invention discloses a method of producing a magnesium-silicon-calcium fertilizer from submerged arc furnace molten asbestos tailings. The method includes: firstly adding asbestos tailings with graphite to a ball mill for ball-milling; controlling the carbon dosage at a mass percent of 2.4%; selecting graphite with a carbon content of 85% for carbon blending; conducting ball-milling on the materials to 100 meshes by the ball mill and then performing discharging; employing a dry ball press machine for ball pressing on the materials to a ball size of 30-100mm; adding the balls into a submerged arc furnace for smelting by a charging system, maintaining a molten state for 30min, and pouring the slag liquid out of the furnace; slowly cooling the slag liquid and then letting the cooled slag liquid enter the ball mill for levigating to 150 meshes, in the discharging process, firstly separating iron, cobalt and nickel by a 0.4T magnetic separator, then subjecting the material to powder sifting by a 150mesh drum screen, and adopting the oversize product as the special tailing for selection of metal chromium; and taking the undersize product as the raw material of medium and trace elementfertilizers, applying the undersize product as powder directly to farmland, or granulating the undersize product and then using the obtained granules as medium and trace element fertilizers.

Owner:北京璞域环保科技有限公司

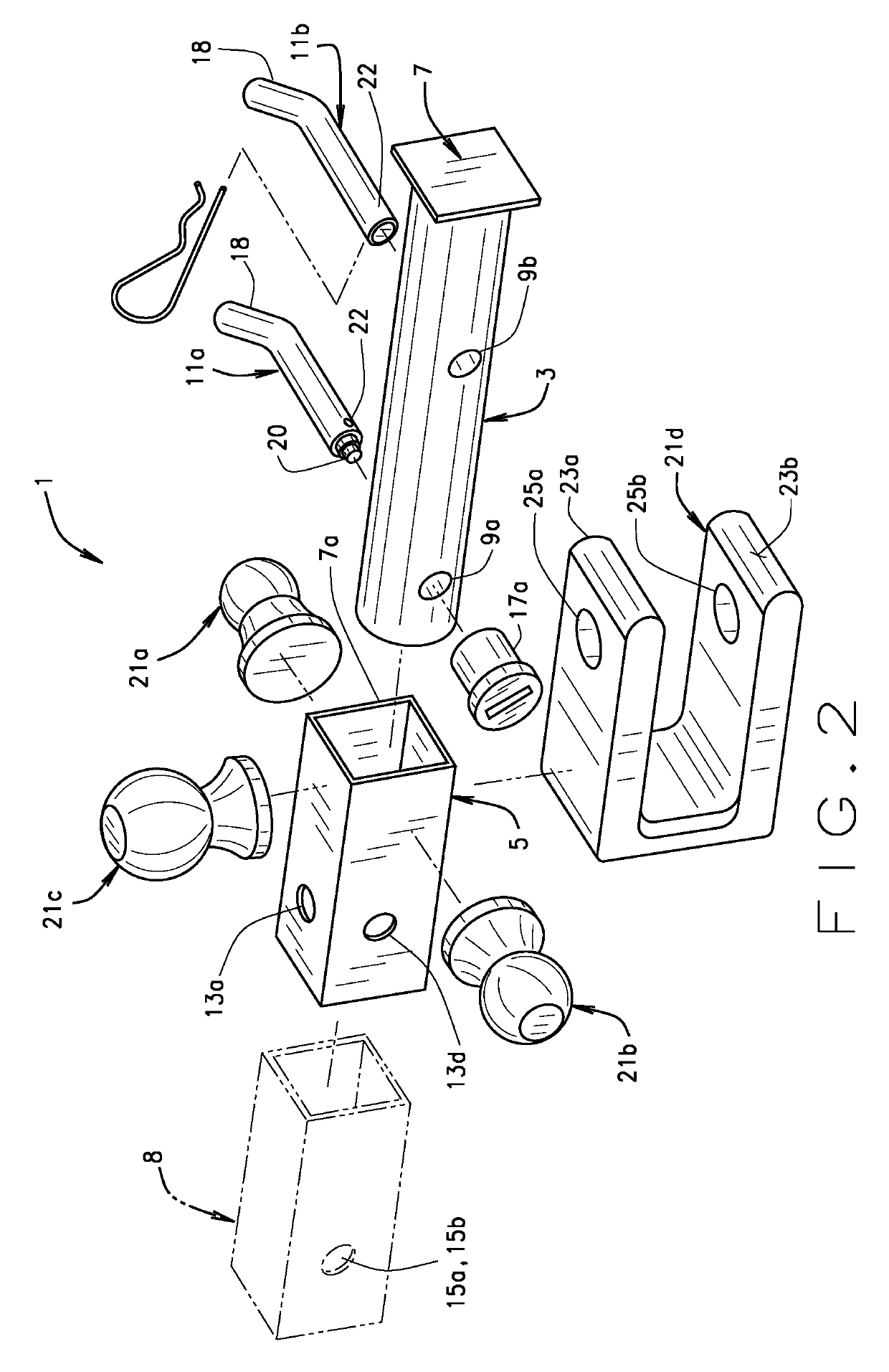

Multiple ball size/clevis hitch

ActiveUS10336145B1Avoid insufficient lengthTowing devicesElectrical and Electronics engineeringBall size

A multiple hitch member assembly is described for connecting a trailer to a tow vehicle where a hitch member is rotatably with respect to a main hitch member that is connected to a hitch receiver on the tow vehicle, where the hitch member carries a plurality of hitch elements (e.g., ball hitches of varying sizes) and where with the main hitch member secured to the hitch receiver the hitch member is rotatable to position a desired hitch element to be connected to a trailer or the like such that the hitch member cannot be removed from the main hitch member.

Owner:THE DELTA CO LLC

Method for processing iron blocks

The invention discloses a method for processing iron blocks. The method comprises the following working procedures: (1) blanking by a punch press; (2) flatting and chamfering the blank subjected to blanking on a meter lathe; (3) cold-extruding the flatted chamfered blank into a green body of the product by the punch press; (4) drilling and chambering the cold-extruded green body of the product by a numerically controlled meter lathe; (5) truning, planning, and chamfering the green body of the product which is processed by the step (4) by the numerically controlled lathe; (6) ball-sizing the green body of the product which is processed by the step (5) by the punch press; (7) truning, planing, and chamfering the green body of the product which is processed by the step (6) by the numerically controlled lathe again; and (8) punching a notch on the green body of the product which is processed by the step (7) by the punch press, and finally forming the iron blocks. The method for processing the iron blocks has the advantages of saving raw materials, having less processing time, improving production efficiency of products, reducing production cost and improving economic benefits.

Owner:CIXI LONGSHAN AUTOMOBILE PART

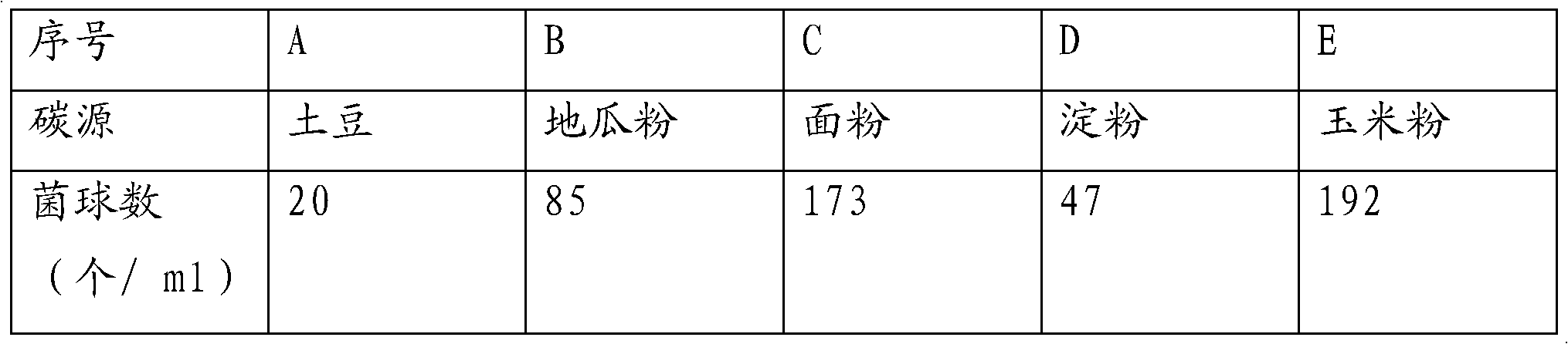

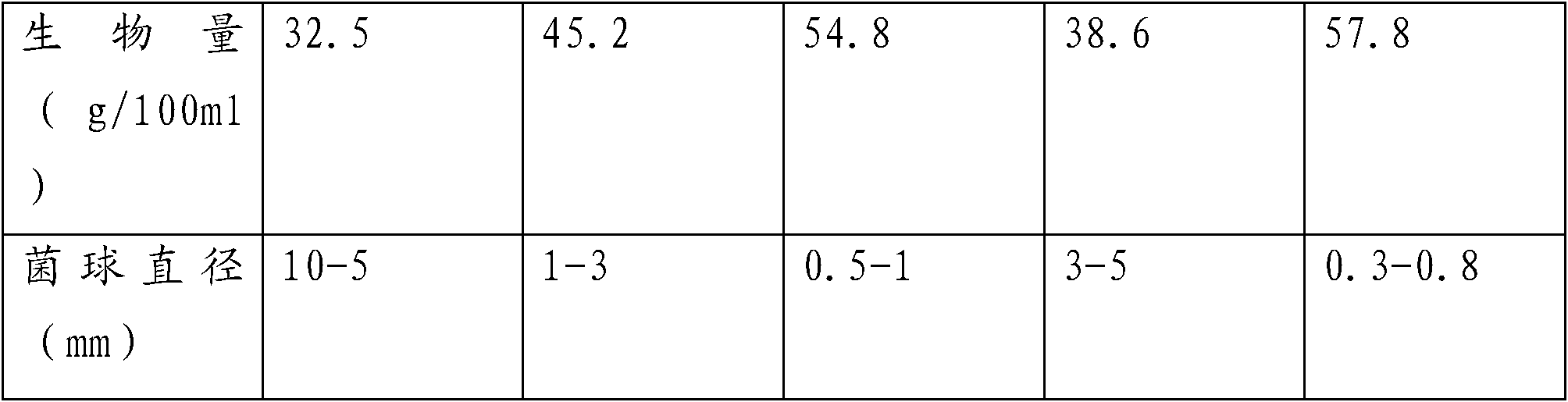

Culture medium and culture method of Fuscoporia punctata first level strain

The invention provides a culture medium formula and a submerged culture method of a Fuscoporia punctata first level strain. The culture medium of Fuscoporia punctata adopts brown sugar and corn flour as a carbon source of a fermentation process, peptone as a nitrogen source of the fermentation process, and a vitamin VB 6 as a fermentation nutrient. A Fuscoporia punctata first level strain obtained through the culture medium of Fuscoporia punctata has the characteristics of the number of bacterium balls of 280 to 300 per milliliter, bacterium ball diameter of 0.5 to 1.5 millimeters, uniform bacterium ball size, clear culture liquid, plenty of the bacterium balls, fine bacterium ball size, compact bacterium ball arrangement, and plenty of mycelia germination points thus is beneficial for a secondary fermentation process. The culture method of a Fuscoporia punctata liquid culture medium has the advantages of simple technology and low energy consumption, thus is applicable to large-scale industrial production.

Owner:三明市三真药业有限公司

Resistive support mechanism

ActiveUS9211013B2Restrict movementStoolsAdjustable chairsElectrical resistance and conductanceEngineering

A motion support mechanism, for example for a chair, joined to a mounting surface and to a base for providing resistive support to the mounting surface as the mounting surface undergoes one or both of rotational and tilt movement relative to the base. The motion support mechanism includes a support bearing connected to the mounting surface and to the base which permits one or both of tilting and rotational motion of the mounting surface relative to the base, a pivot ball sized fixedly attached to a portion of the base, and, a resistance cartridge fixedly connected to the mounting surface such that the resistance cartridge undergoes movement relative to the base and applies a resistive force on the base as the mounting surface undergoes one or both of rotational and tilt movement. The resistance cartridge includes a cartridge housing and a resilient member in contact relation with the pivot ball and with a wall of the housing such that the resilient member is compressed by the relative movement between the resistance cartridge and the pivot ball to thereby provide the resistive support to the mounting surface. Preferably, the resistive support also provides a dampening feature, for example by way of the resilient member being formed from a viscoelastic material. A means for varying the resistance applied is provided that permits the distance between the bearing surface and the pivot ball to be varied.

Owner:CORECHAIR

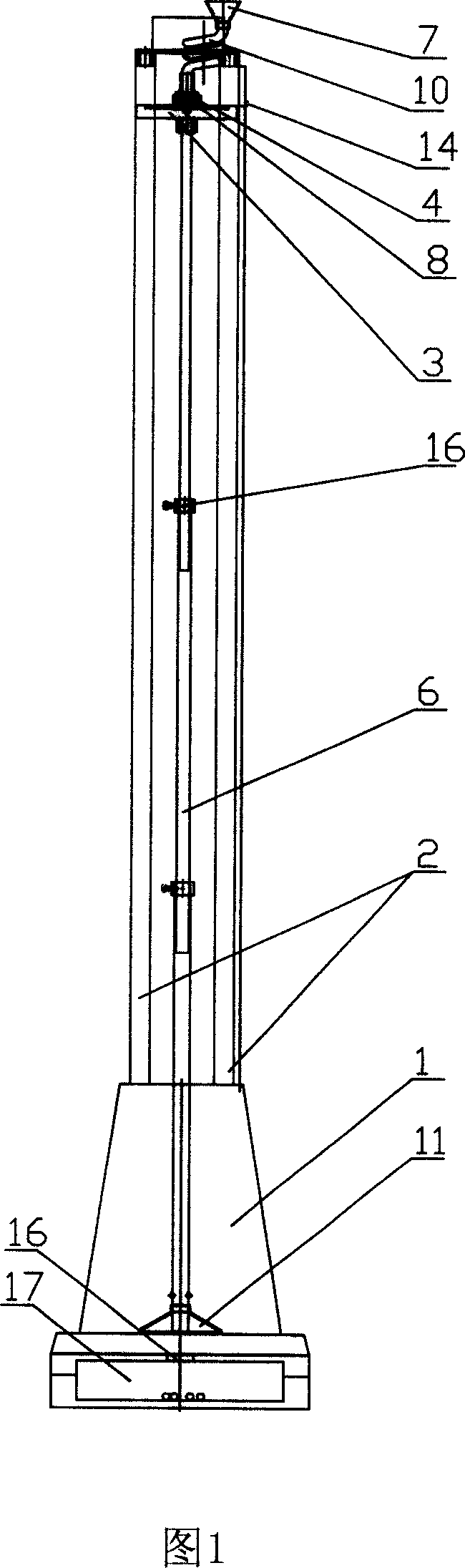

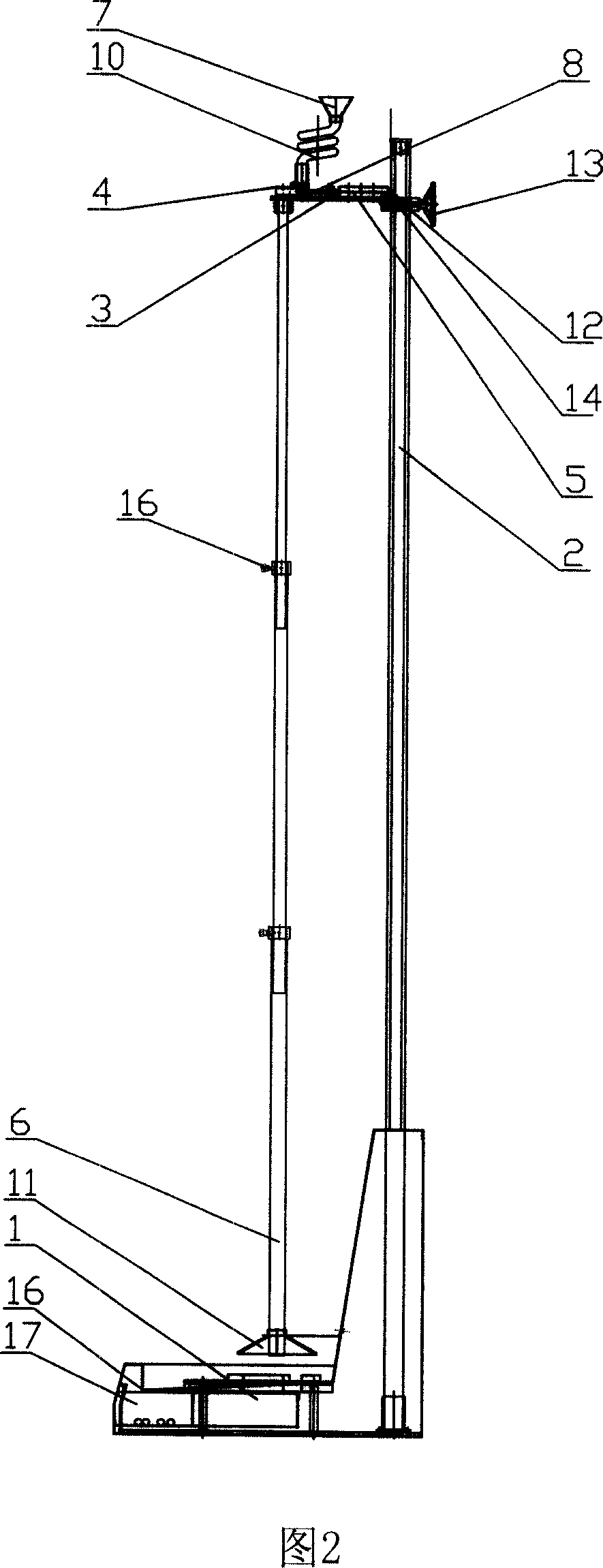

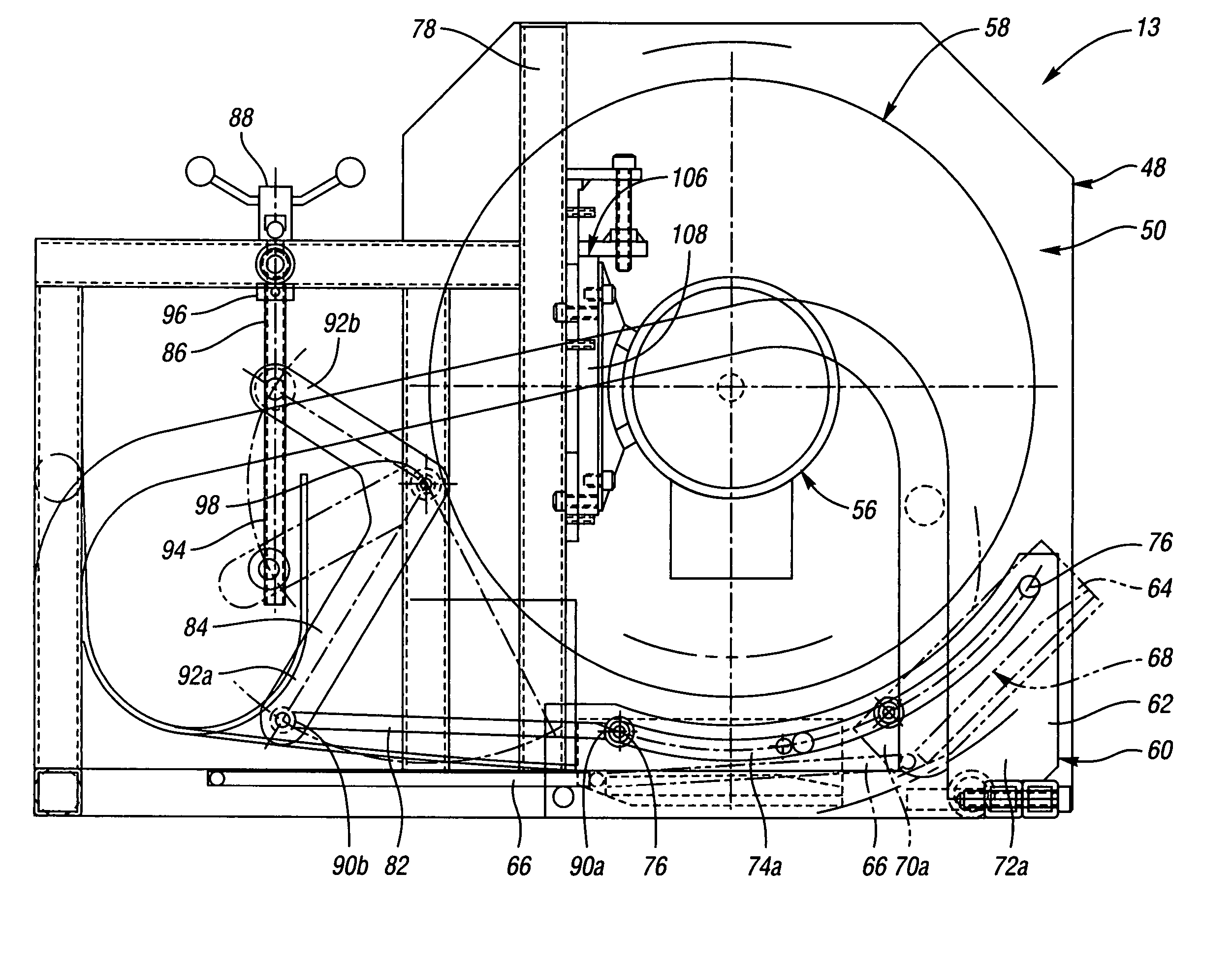

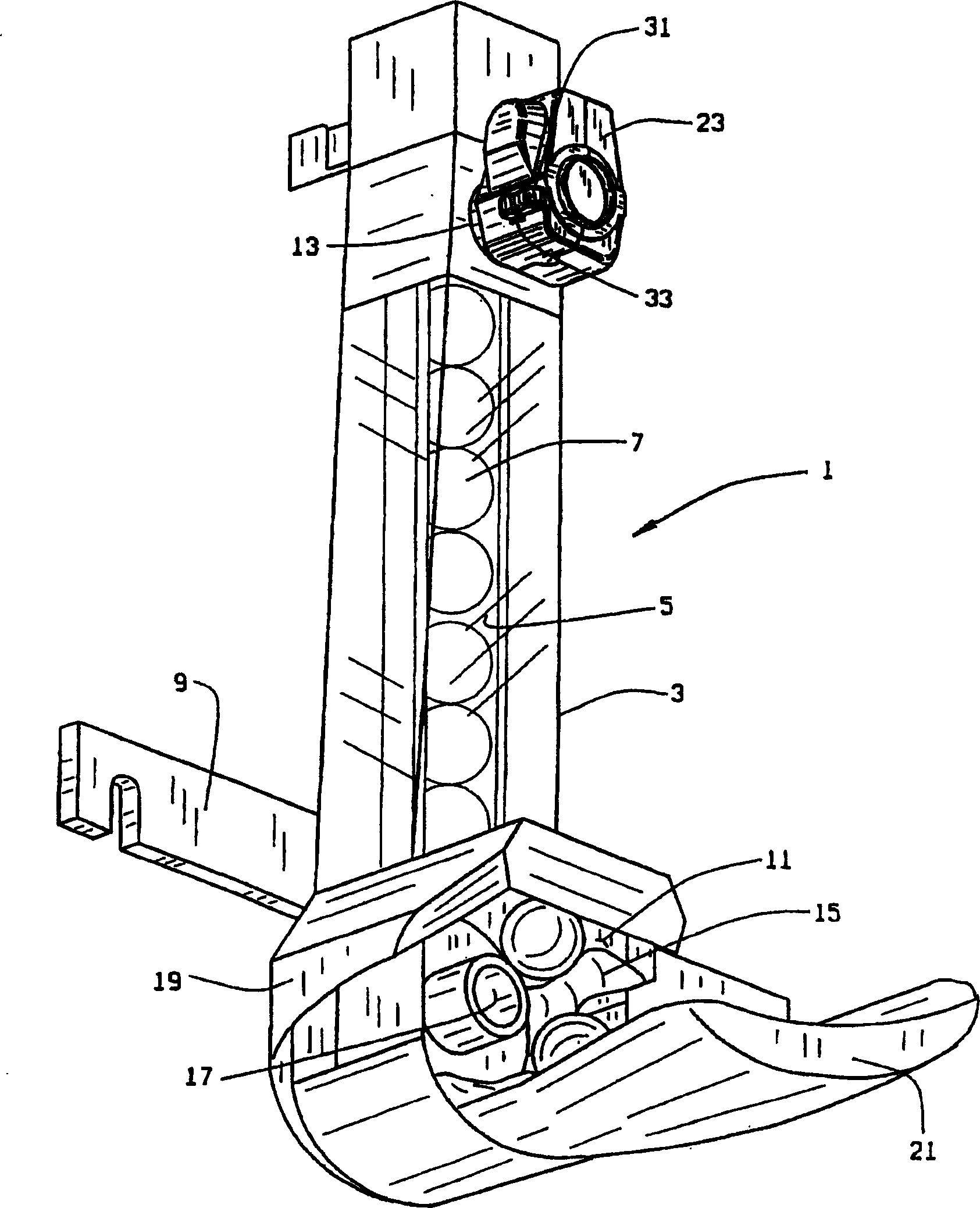

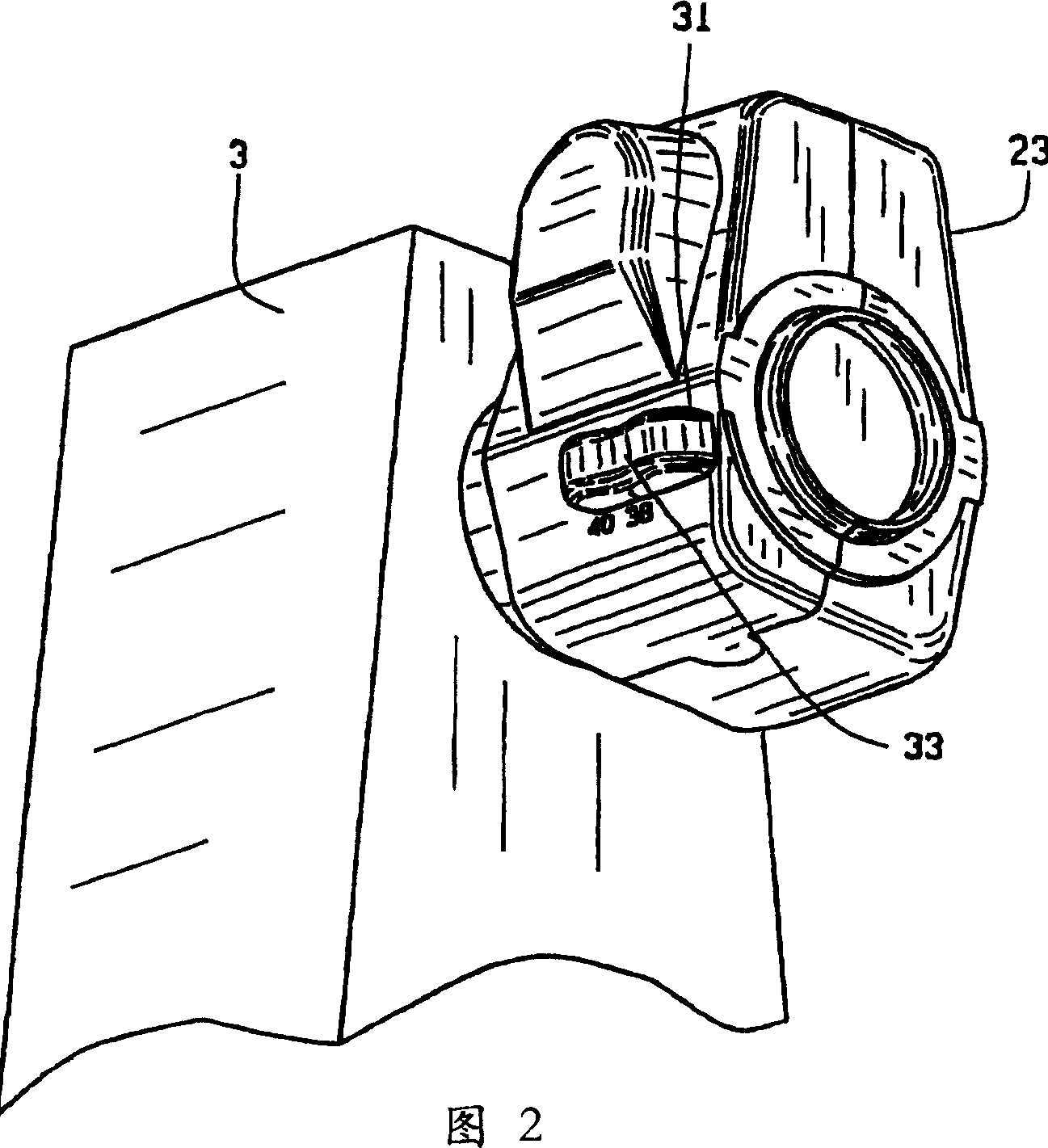

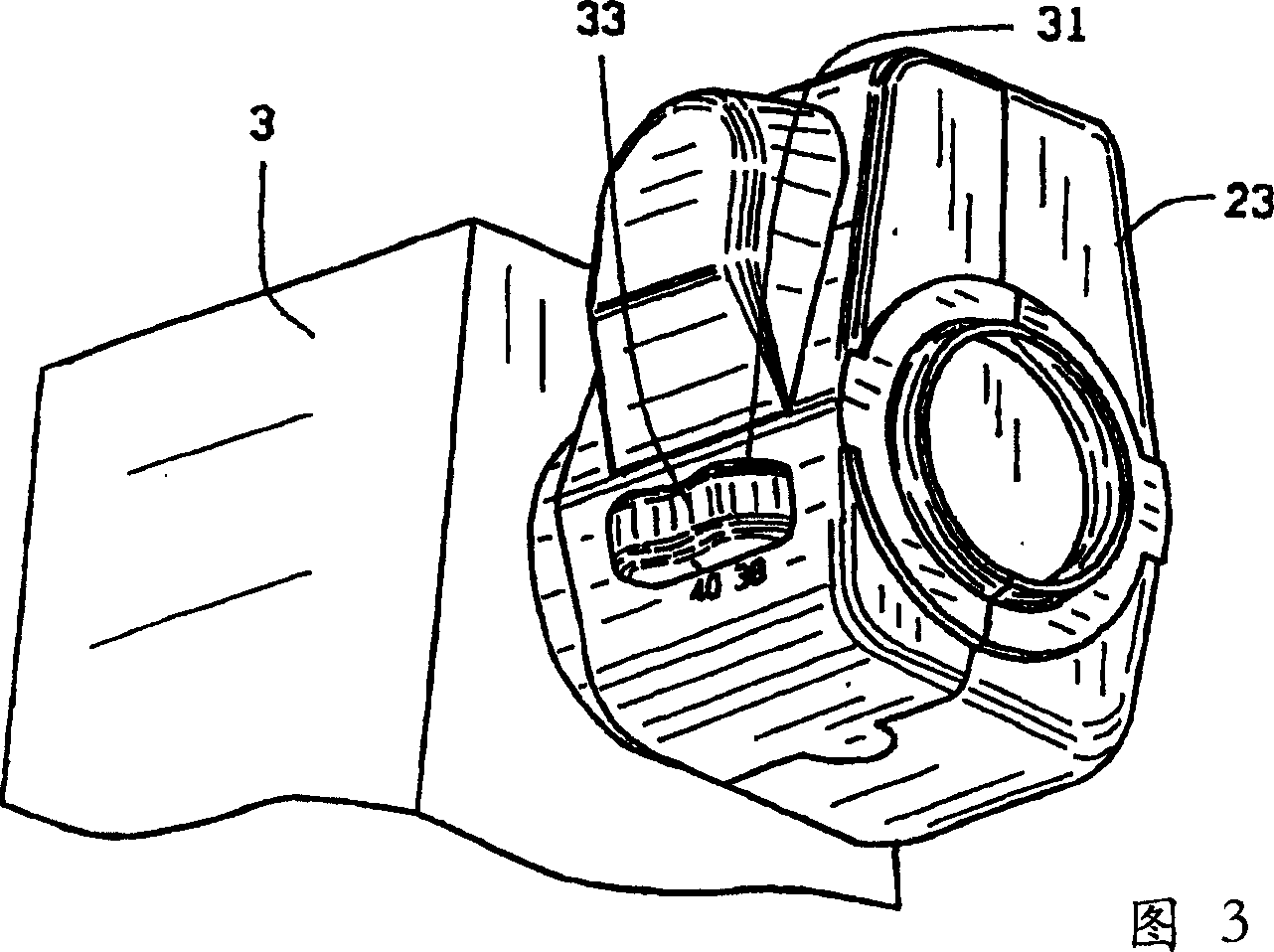

Ball size adjustment mechanism for table tennis robot

The invention discloses an automatic table tennis ball feeding device (1) having a substantially vertically extending housing (3) with a table tennis ball feeding channel (5) comprising a lower table tennis ball inlet (19 ) and the upper table tennis distribution outlet (13). Two ball supply arm bars (15) are installed on the housing near the lower table tennis inlet (19) for upward supply of table tennis balls (7) in the ball supply channel (5) against gravity. The table tennis distribution head (23) is installed on the housing (3) near the top table tennis distribution outlet (13), and is used to send table tennis balls to the players at a selected speed and trajectory. The table tennis distribution head (23) comprises a table tennis size adjustment mechanism (31), so that the table tennis balls of at least two diameters can be selected by the player when one or another of the at least two different table tennis diameters is selected. Selectively pass through the ping pong ball distribution head (23).

Owner:NEWGY IND

Northeast Chinese yew transplanting method in coast saline-alkaline region

InactiveCN105900763AImprove the level of greeningImprove the landscape effectCultivating equipmentsForestryGreeningAqueous solution

The invention relates to a northeast Chinese yew transplanting method in a coast saline-alkaline region. The method comprises the steps of 1) selecting a place that has a shade and a high physical feature where hydrocele is difficult from the middle ten days of March to the middle ten days of April; 2) digging a tree aperture according to the soil ball size of a transplanted nursery stock; 3) mixing well raw soil dug from the tree aperture with turfy soil and river sand in volume ratio of 1:1:1 to obtain plantation soil; 4) filling part backfilling soil, putting the soil ball of the transplanted nursery stock to guarantee that the rhizome junction of the plant is 10cm higher than the ground, then filling the backfilling soil, stamping and compressing; 5) using an aqueous solution that containing 0.3mmp Naphthalene acetic acid, 0.5ppm indole butyric acid and 300ppm calcium nitrate as a root water. <{EN2}>According to the invention, the Chinese yew can be possibly planted in a coast saline-alkaline region, which means a lot for lifting city greening level and landscape effect.

Owner:TIANJIN TEDA GREEN GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com