Preparation method of high-performance window film insulation medium

An insulating medium, high-performance technology, applied in the direction of coating, etc., to achieve the effect of super transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

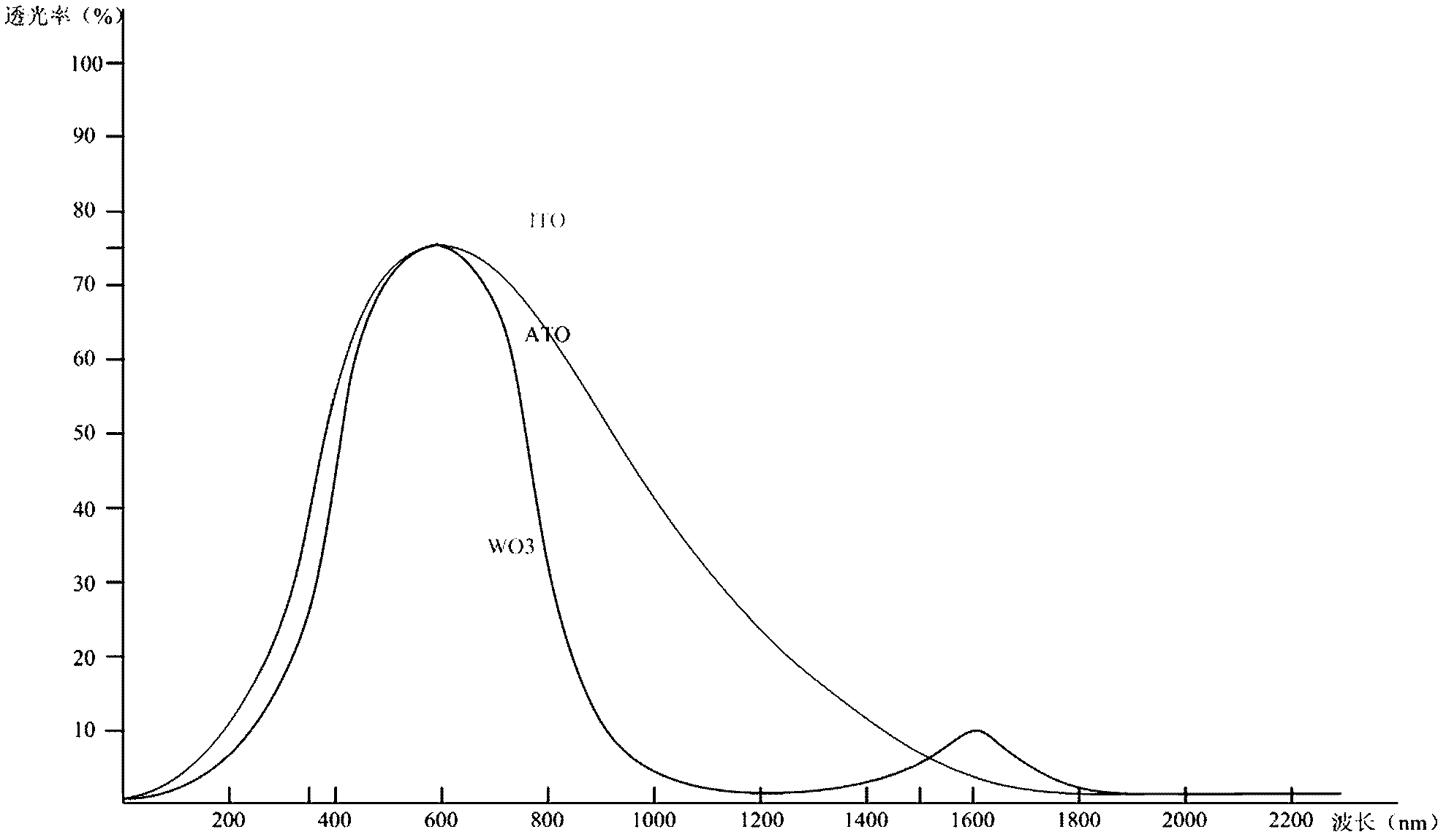

Image

Examples

Embodiment 10

[0017] Embodiment 1.0 (preparation of blue WO with primary particle size not greater than 40nm 3 powder)

[0018] Get respectively successively 1. 50 parts by weight content is the tungstic acid of 99.9% (H 2 WO 4 ); get (2) 5 parts by weight of indium hydroxide In(OH) with a content of 99.9% 3 powder; take ③45 parts by weight of a mixed solvent of methanol and deionized water 1:1, pour ①②③ into the prepared high-speed sand mill disperser in turn, adjust the speed to 12000 rpm, and after 30 minutes, use N, N-dimethylethanolamine to adjust the pH value of the mixed colloid in the high-speed sand mill disperser, and start high-speed dispersion after the pH value is controlled to 5. After continuous dispersion for 4 hours, take out the mixed colloid in the high-speed sand mill disperser and pour it into Al 2 o 3 Put the crucible into the drying box for drying, adjust the temperature to 85 degrees and dry for 5 hours, then increase the temperature to 160 degrees for 4 hours, ...

Embodiment 11

[0019] Embodiment 1.1 (preparation of water-based high-performance thermal insulation medium)

[0020] Weigh the blue WO with a primary particle size not greater than 40nm obtained in ① Example 1.0 3 Powder 160g;

[0021] Weigh 160g of blue ATO powder with a primary particle size not greater than 10nm;

[0022] Weigh 160g of blue ITO powder whose primary particle size is not greater than 20nm;

[0023] Weigh ④ 480g of deionized water;

[0024] Weigh ⑤ aqueous system dispersant, 40g of solution mixed with diethanolamine and triethanolamine in a volume ratio of 1:1;

[0025] Pour ①②③④⑤ into the dispersing bucket of the planetary wet rapid disperser equipped with zirconium balls with a diameter of 0.2mm in turn, adjust the rotating speed to 11000 rpm, open the cover of the dispersing bucket after continuous dispersion for 14 hours, and take out the mixed colloidal nano-slurry , After filtering with a 200-mesh filter cloth, the water-based high-performance heat insulation medi...

Embodiment 12

[0027] Embodiment 1.2 (preparation of oily high-performance thermal insulation medium)

[0028] Weigh the blue WO with a primary particle size not greater than 40nm obtained in ① Example 1.0 3 Powder 160g;

[0029] Weigh 160g of blue ATO powder with a primary particle size not greater than 10nm;

[0030] Weigh 160g of blue ITO powder whose primary particle size is not greater than 20nm;

[0031] Weigh ④ butyl acetate 480g;

[0032] Weigh ⑤ 40g of the oily system dispersant, a solution mixed with JU-110 and BYK2008 at a weight ratio of 1:1.

[0033] Pour ①②③④⑤ into the dispersing barrel of the planetary wet rapid disperser equipped with zirconium balls with a diameter of 0.3mm in sequence, adjust the rotating speed to 12000 rpm, open the cover of the dispersing barrel after continuous dispersion for 16 hours, and take out the mixed colloidal nano-slurry , After filtering with a 200-mesh filter cloth, an oil-based high-performance heat insulation medium with a solid content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com