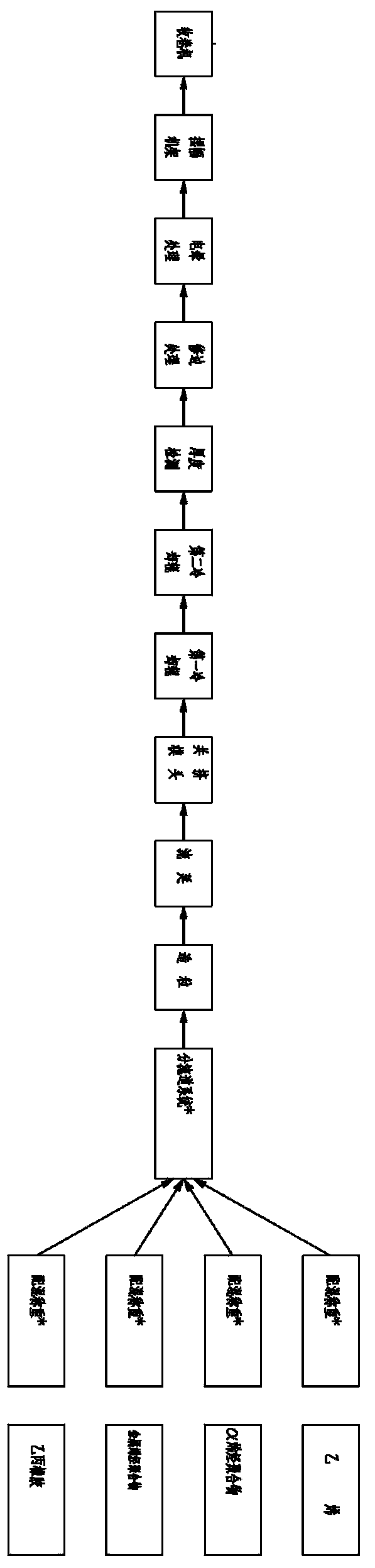

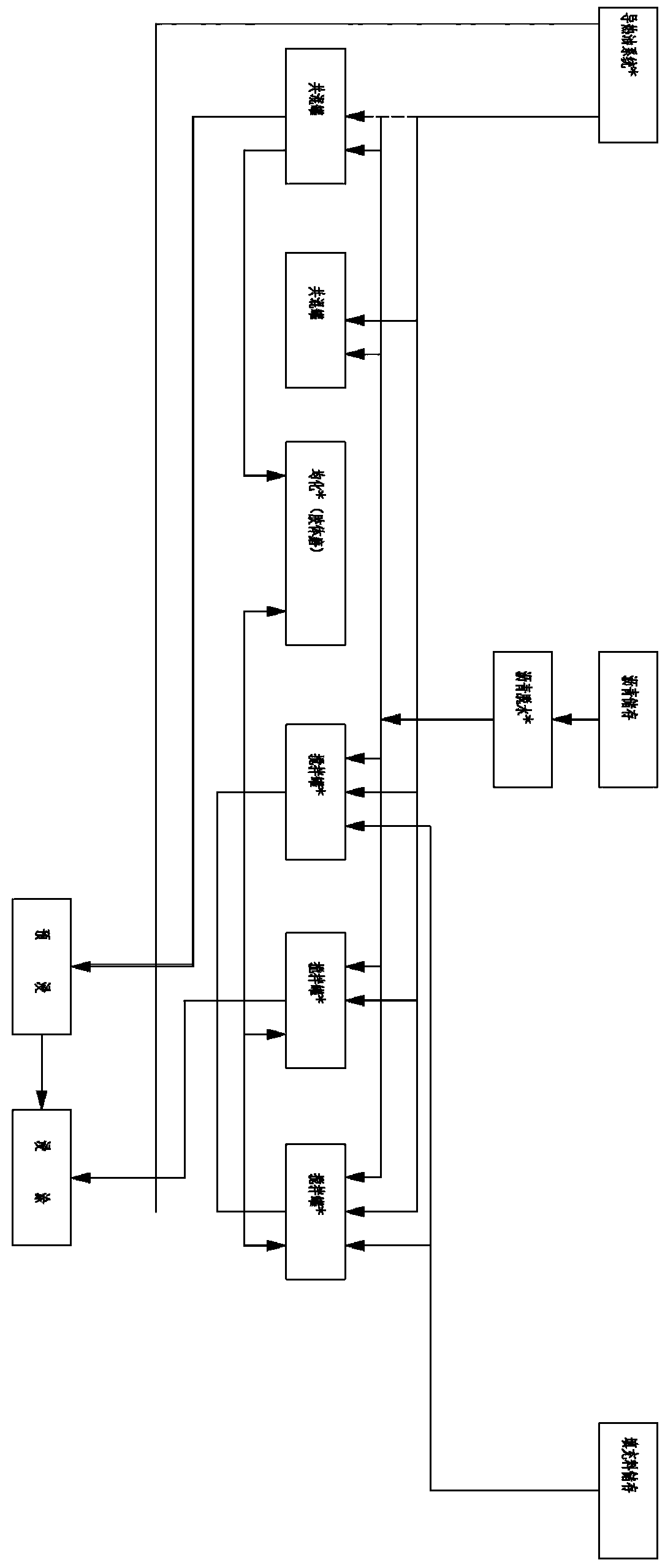

Patents

Literature

129results about How to "Strong heat insulation ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

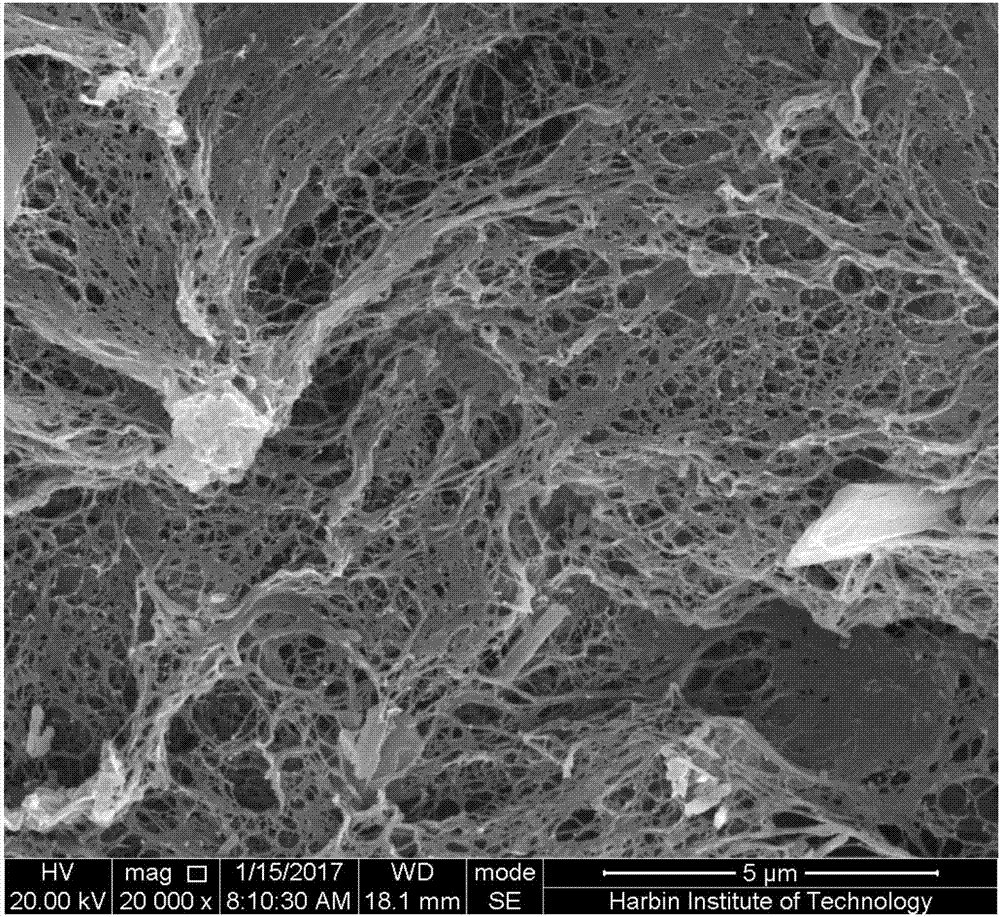

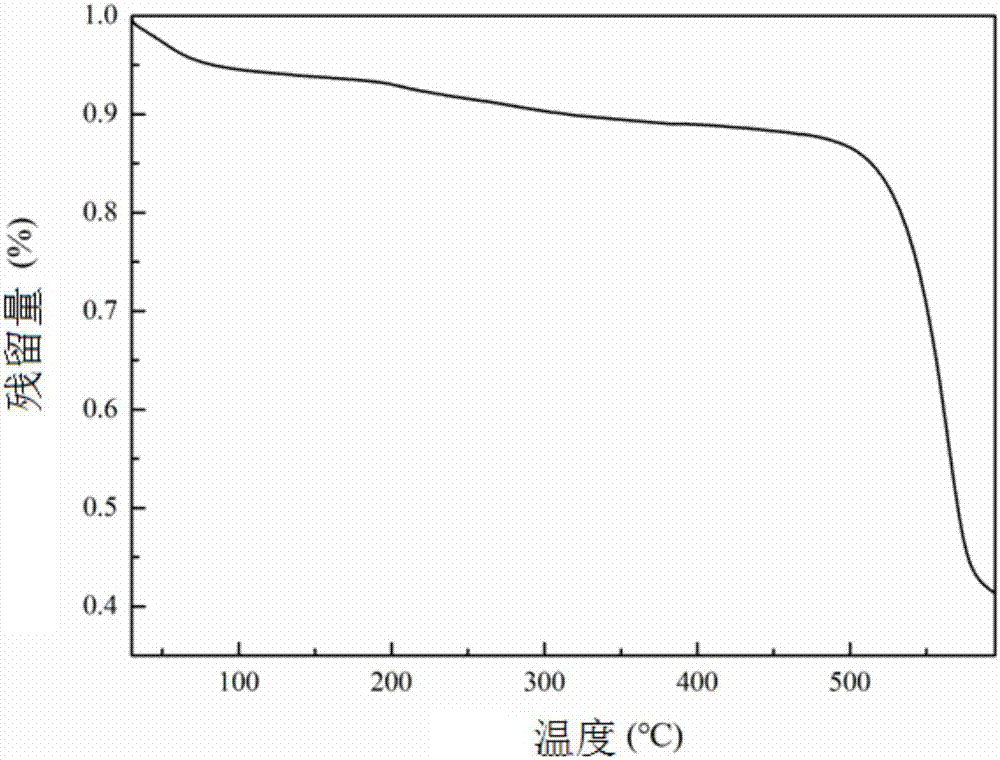

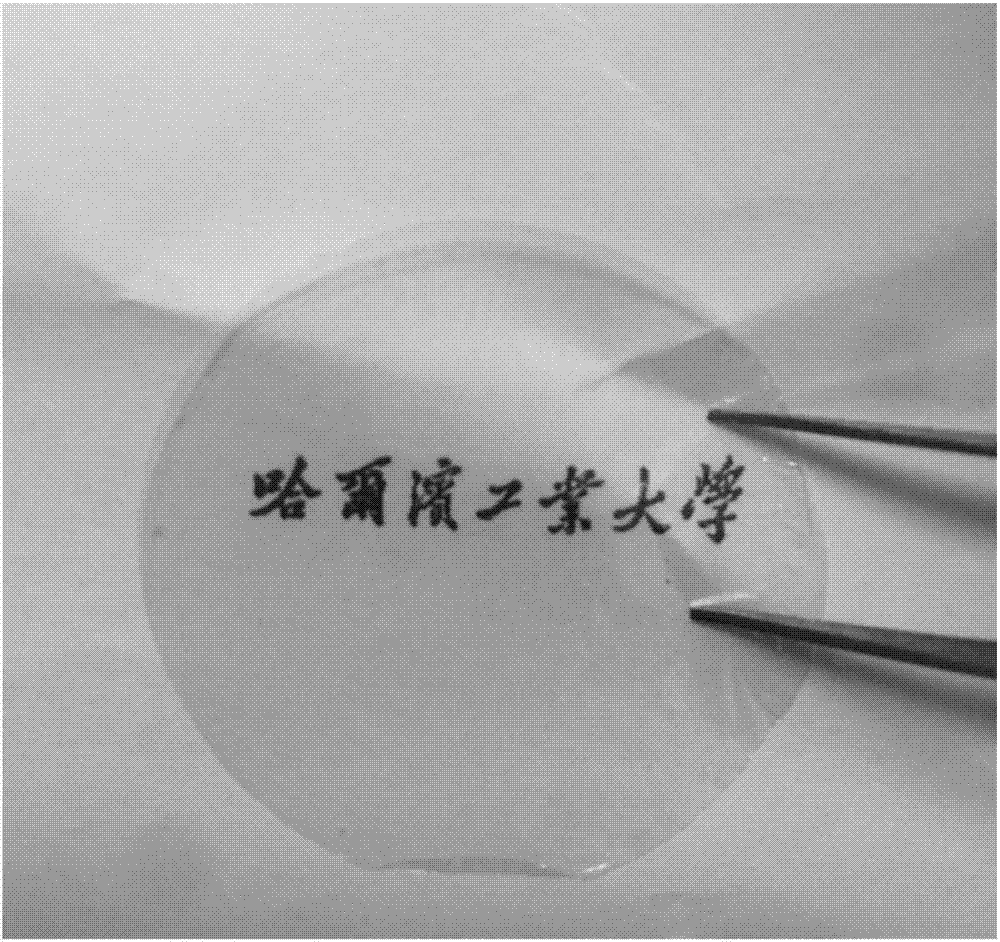

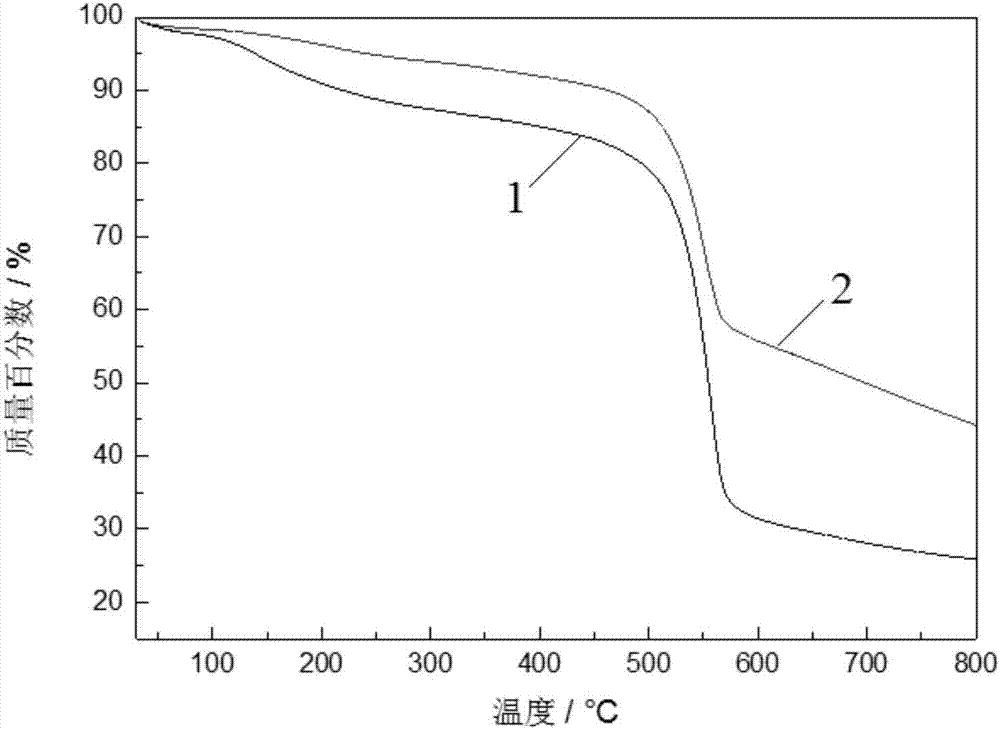

Preparation method of aramid fiber nanofiber aerogel

The invention relates to a preparation method of an aramid fiber nanofiber aerogel, in particular to a preparation method of the aerogel. The invention aims to solve the problems of poor mechanical strength and poor heat resistance of an existing aerogel. The preparation method comprises the steps of (1) extracting; (2) preparing a dark red aramid fiber nanofiber solution; (3) preparing an aramid fiber nanofiber hydrogel; (4) carrying out vacuum filtration and cleaning; (5) freeze drying to obtain the aramid fiber nanofiber aerogel. According to the aramid fiber nanofiber aerogel prepared through the preparation method provided by the invention, the temperature of primary thermal decomposition is 500 DEG C, so that the aramid fiber nanofiber aerogel can be used in a temperature interval ranging from 200 DEG C to 500 DEG C for a long time; the tensile strength of the aramid fiber nanofiber aerogel prepared through the preparation method provided by the invention reaches to 230 MPa. The invention discloses the preparation method of the aramid fiber nanofiber aerogel.

Owner:HARBIN INST OF TECH

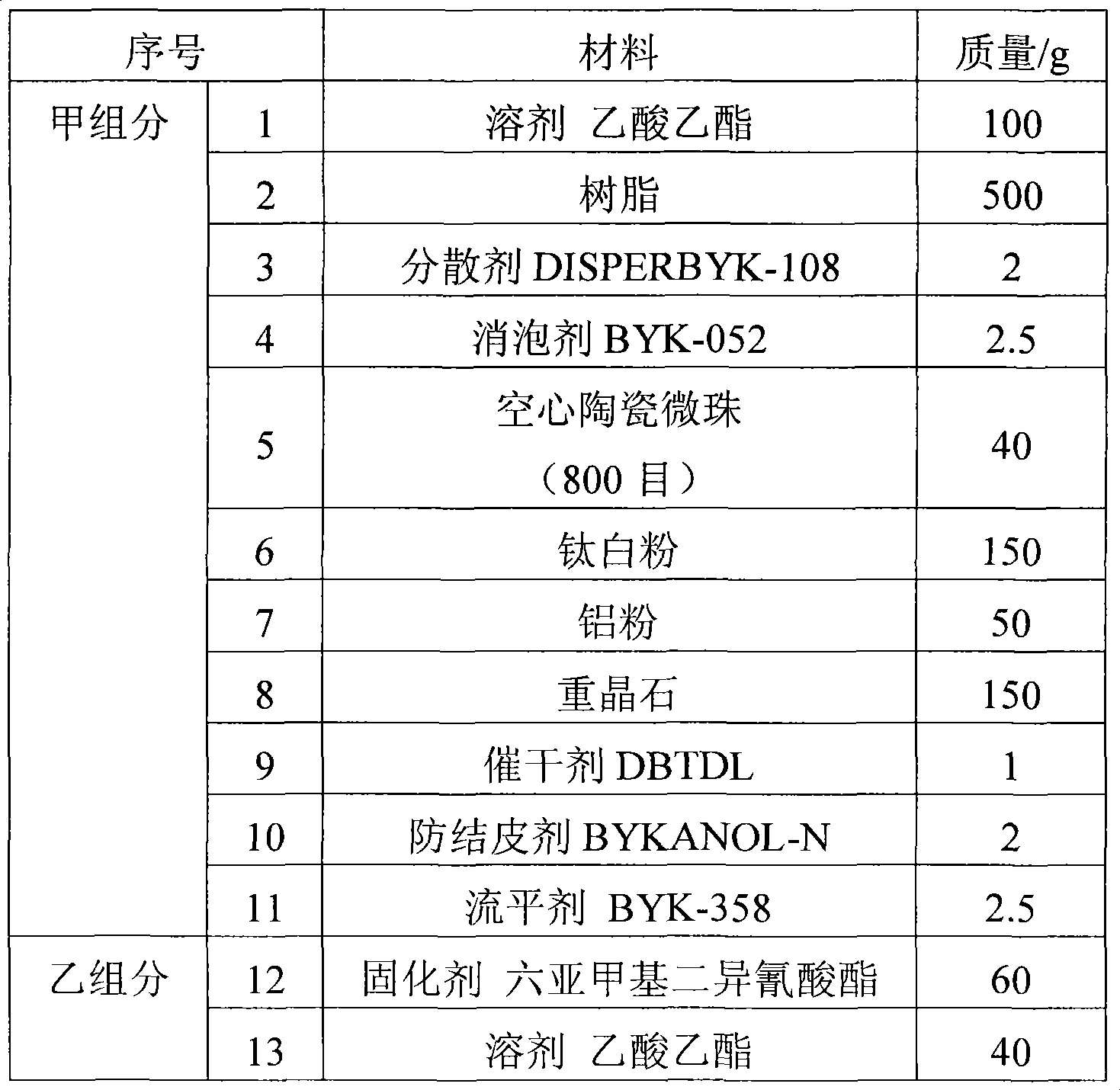

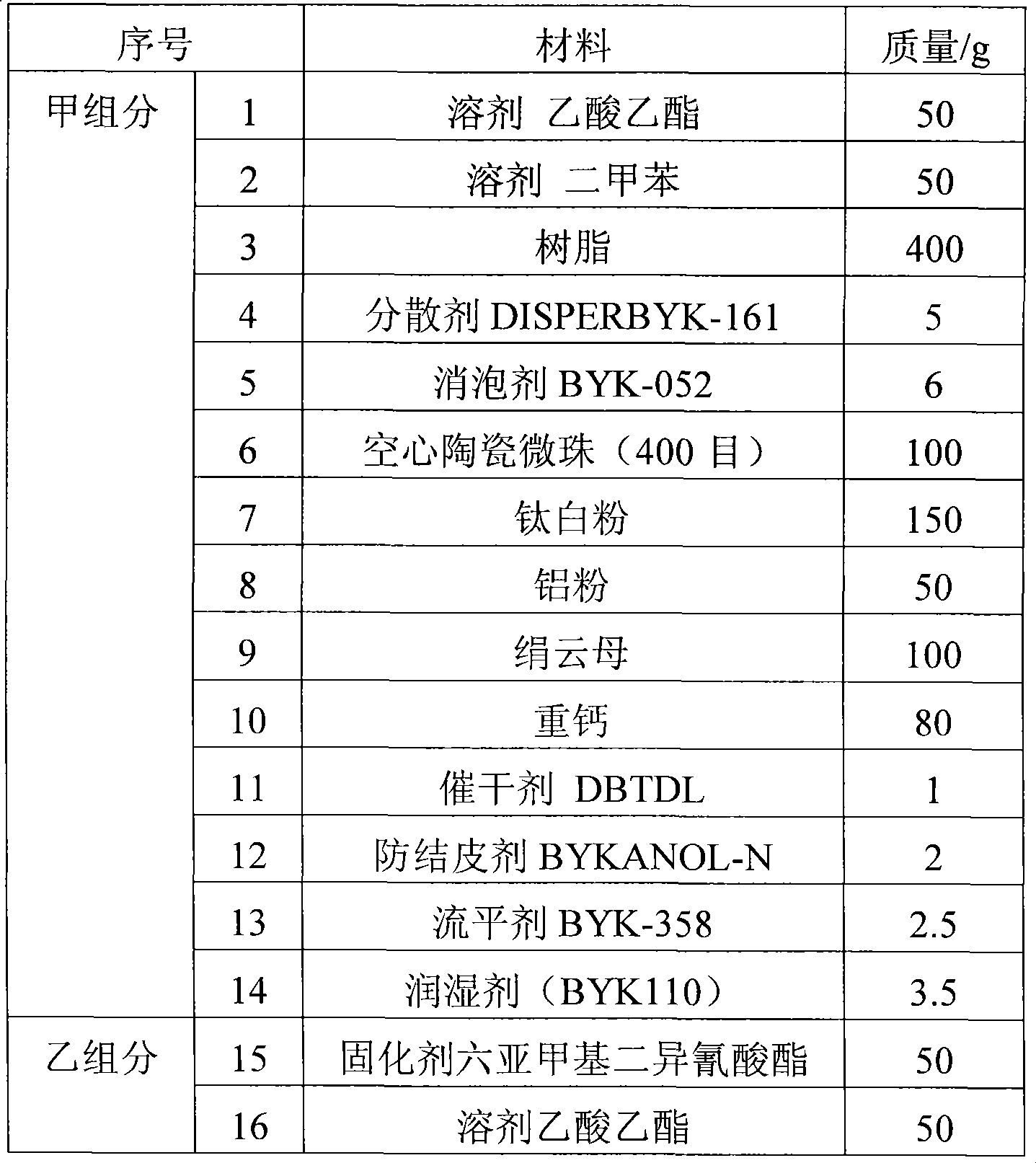

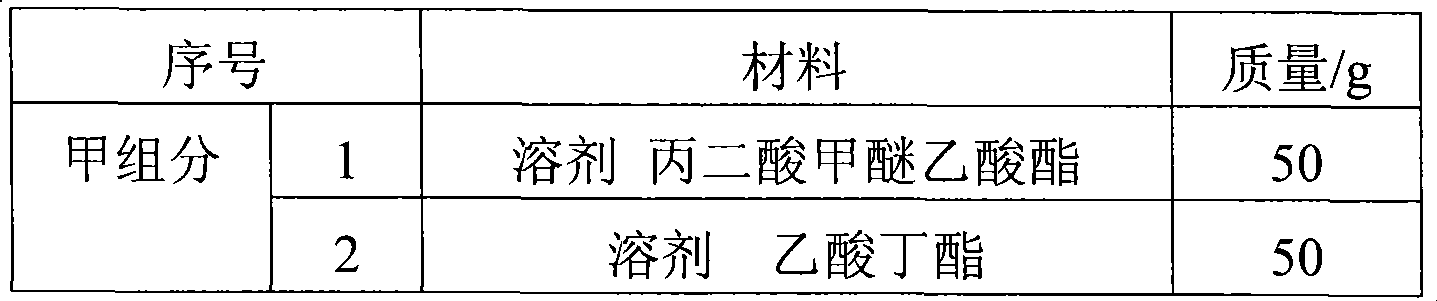

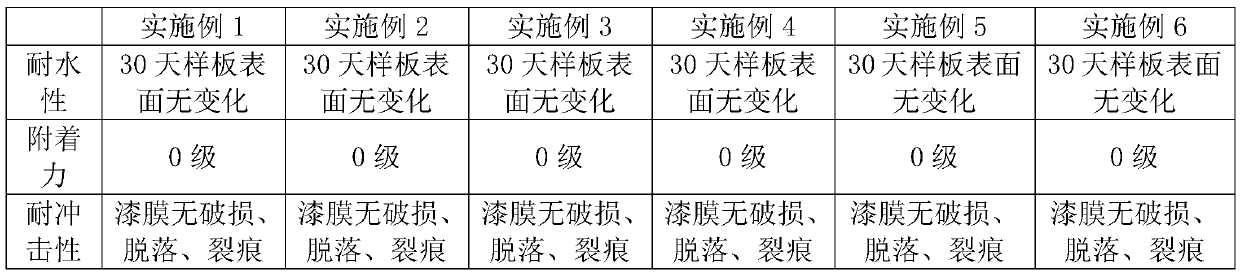

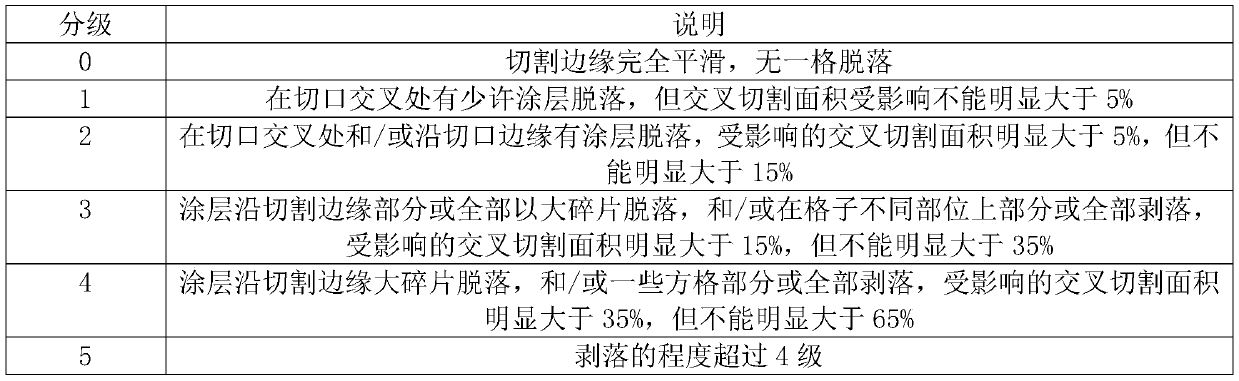

Solvent type heat insulation fluorocarbon exterior wall coating

ActiveCN101423686AWith decorative effectIncreased durabilityReflecting/signal paintsThermal insulationSlurry

The invention discloses a solvent-type fluorocarbon heat insulation and isolation coating which uses hollow glass micro-beads, hollow ceramic micro-beads and the like as heat insulation and isolation materials and uses titanium pigment, aluminium powder (slurry) and the like as reflective materials. The heat conductivity coefficient of the coating is less than 0.055 W / m.K; the reflectivity of sunlight is more than or equal to 0.85; the reflectivity of a hemisphere is more than or equal to 0.85; the time for aging resistance is 2,500 hours; and the coating does not fade or pulverize. The solvent-type fluorocarbon heat insulation and isolation coating belongs to the field of building material, can be applied to the surfaces of outer wall, roof, cement, ceramic tile, glazed tile, decorative tile and other materials. The coating has the function of outer wall decoration, heat insulation, heat isolation and the like.

Owner:CHINA BUILDING MATERIALS ACAD

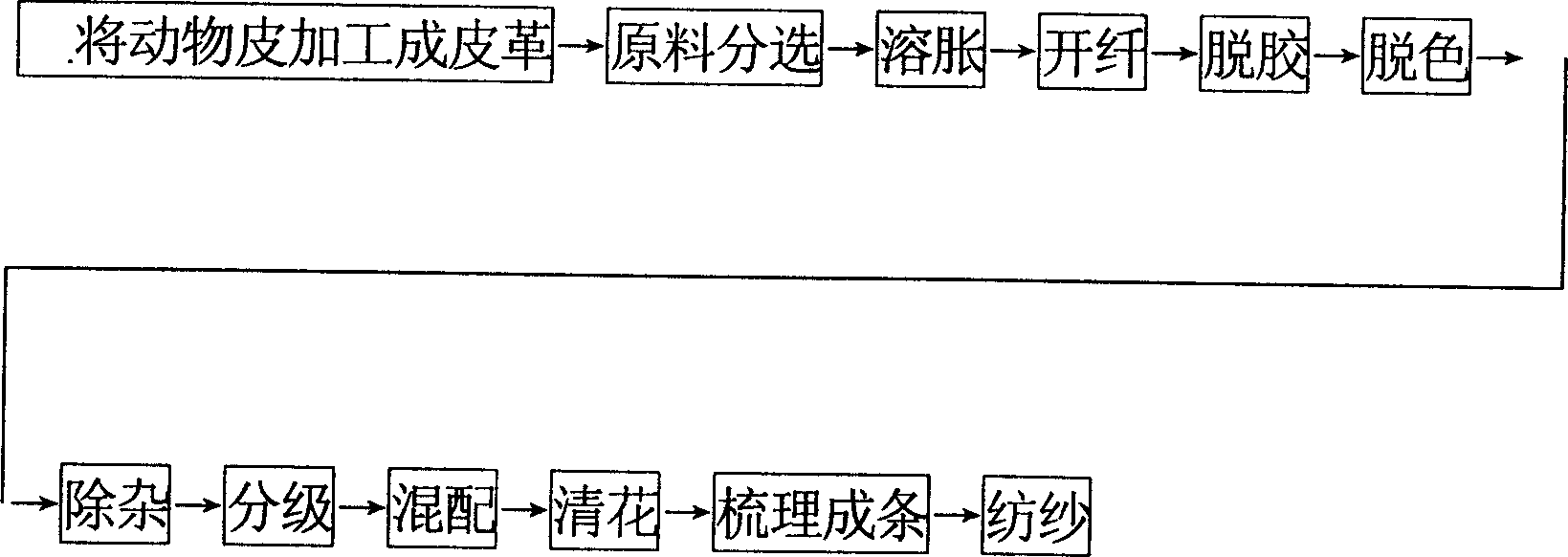

Animal leather yarn and its producing method

The animal leather yarn consists of mechanically opened animal leather fiber in 1-100 wt% and other textile fiber in 0-99 wt%, and the animal leather fiber and other textile fiber in the same weight ratio are crossed and twisted to form the animal leather yarn. Leather processed through traditional leather processing process is further processed through sorting, swelling, opening, deguming, decolorizing, impurity eliminating, grading, mixing, finishing, carding into sliver, twisting and spinning to produce the animal leather yarn. The present invention raises the utilization of leather, expands leather application and, especially, solves the problem of waste leather utilization.

Owner:TIANWEI TEXTILE TECH SHENZHEN

Aluminum silicate fiber refractory felt with good heat insulation performance

ActiveCN107415362AStrong heat insulation abilityAvoid burnsGlass making apparatusLaminationFiberAluminum silicate

The invention specifically discloses an aluminum silicate fiber refractory felt with good heat insulation performance, belonging to the technical field of refractory materials. The aluminum silicate fiber refractory felt is prepared by dipping an aluminum silicate fiber felt in nanometer aerosil slurry, then drying the aluminum silicate fiber felt, separately connecting the two sides of the aluminum silicate fiber felt with refractory layers, then dipping the aluminum silicate fiber felt in the nanometer aerosil slurry again and carrying out drying, wherein the aluminum silicate fiber felt is prepared from modified aluminum silicate fibers through braiding; the modified aluminum silicate fibers are prepared from kaolin powder, alumina, titanium dioxide, a dispersant, nanometer aerosil, polyimide resin, a silane coupling agent, an aluminum phosphate binder and water; and the nanometer aerosil slurry is prepared from diatomite, activated clay, nanometer aerosil and water. The aluminum silicate fiber refractory felt of the invention can form multilayer heat-insulatiing protection, has good heat insulation performance, can meet the demands of equipment for heat preservation and fire resistance and prevents scalding of operators or damage to articles contacting with the felt caused by too high surface temperature of the refractory felt.

Owner:徐州博创建设发展集团有限公司

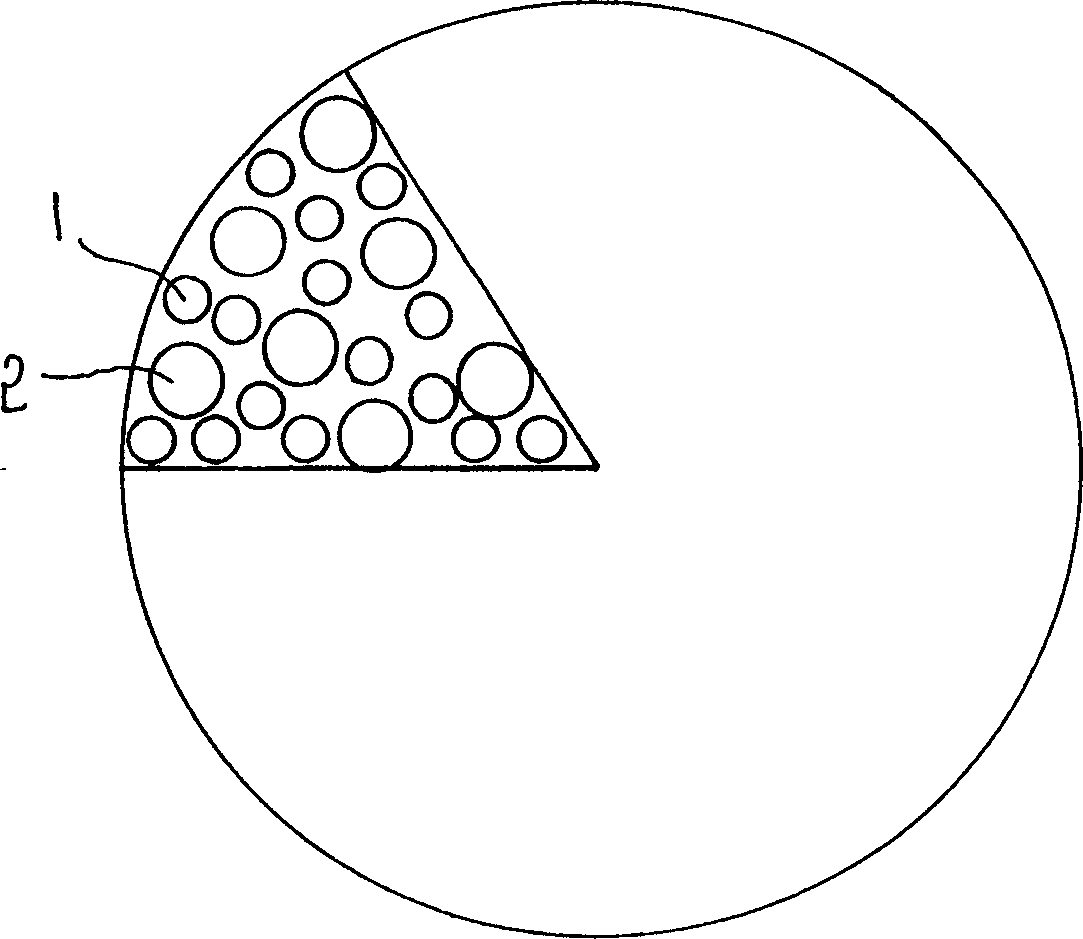

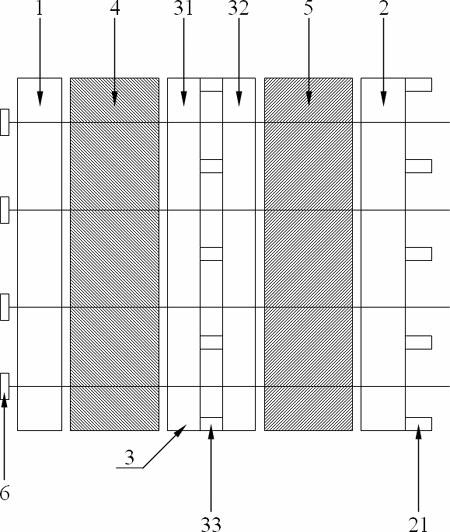

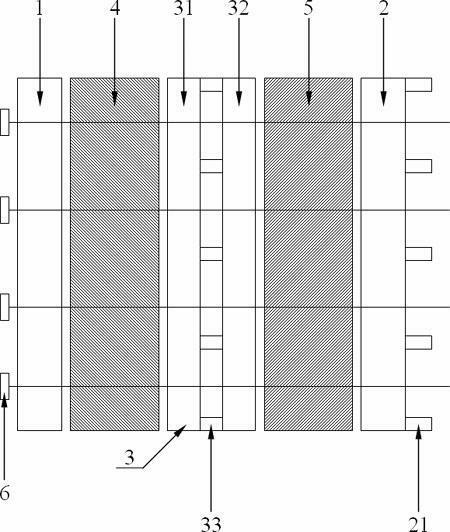

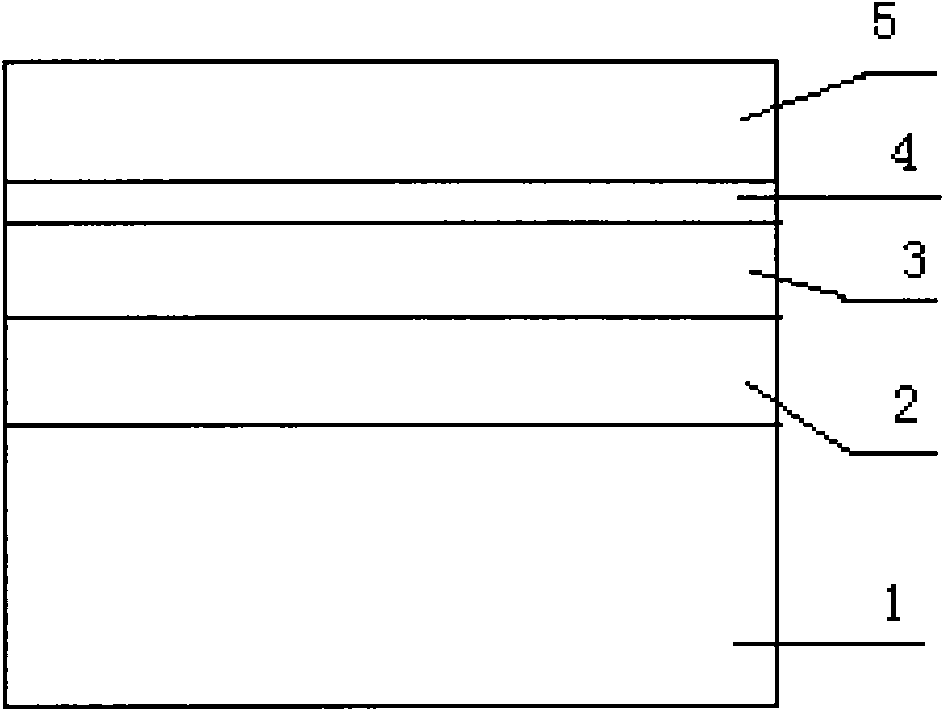

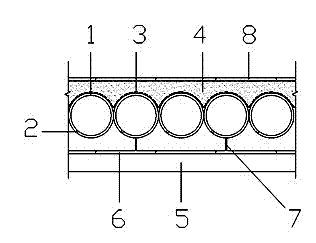

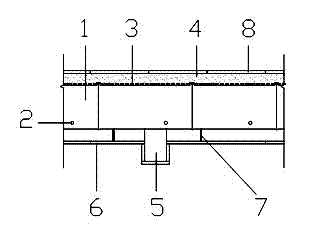

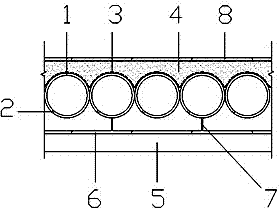

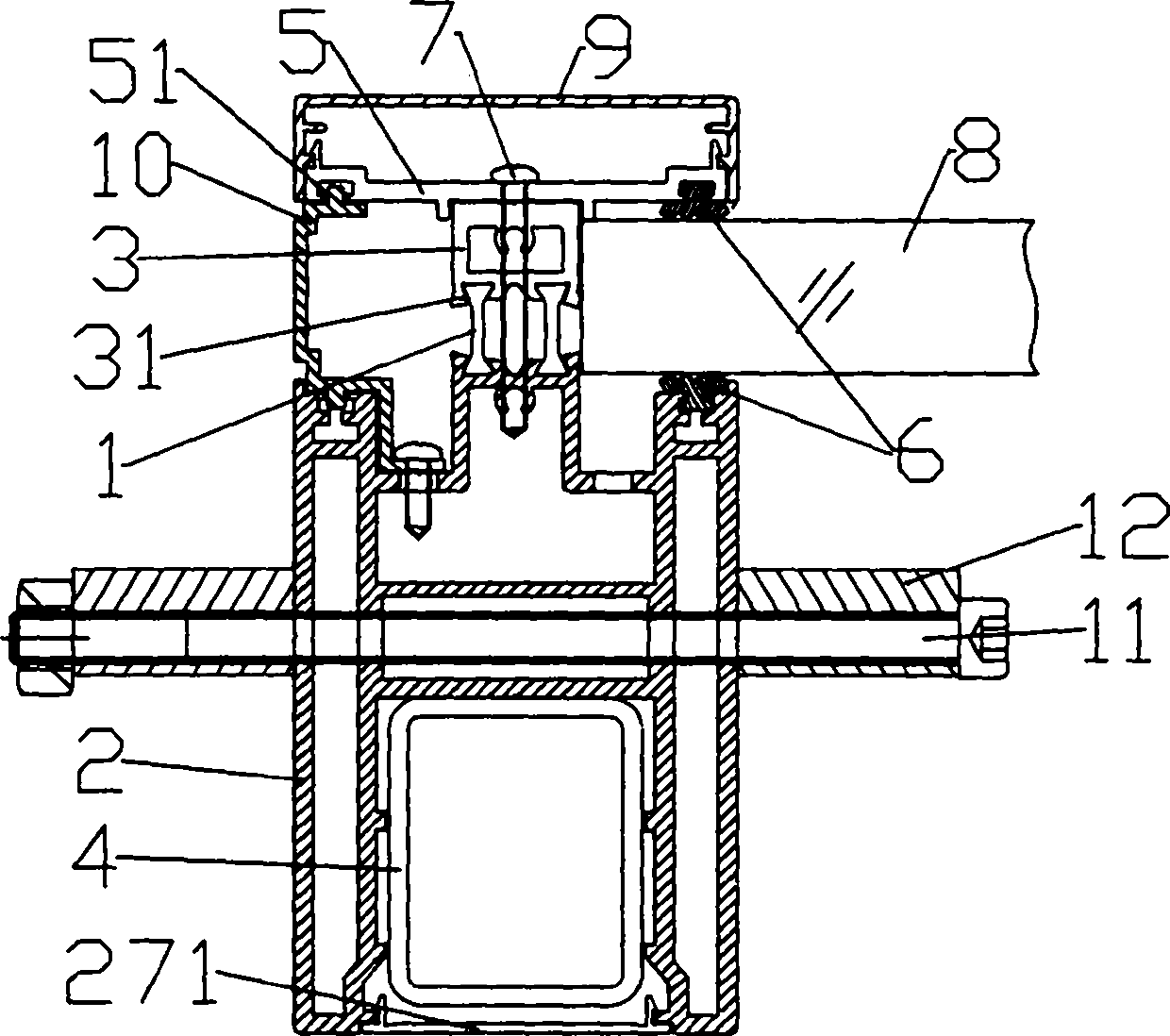

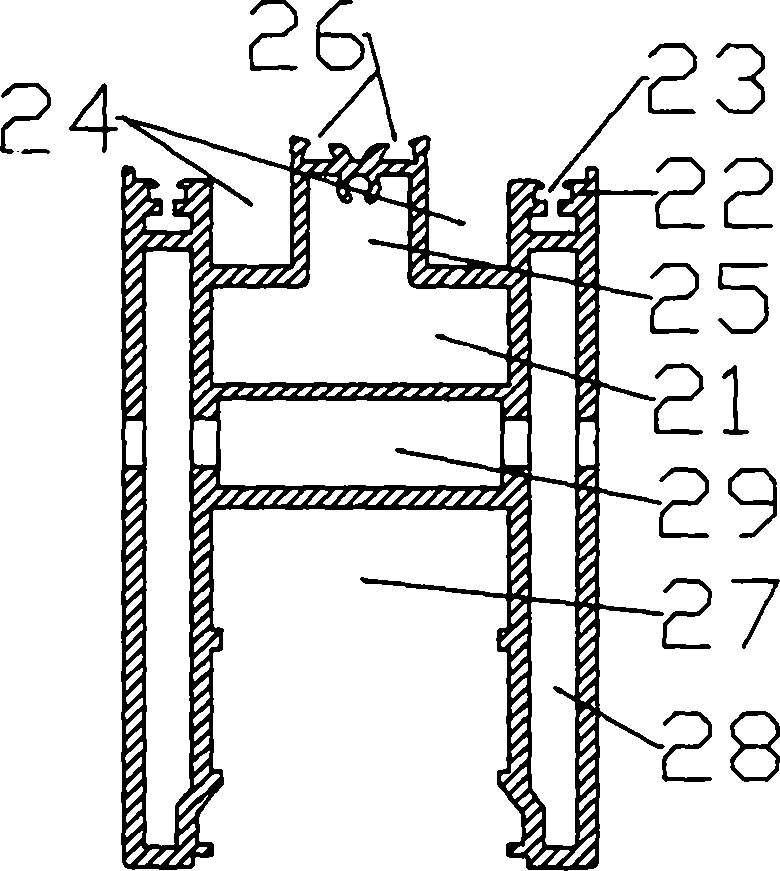

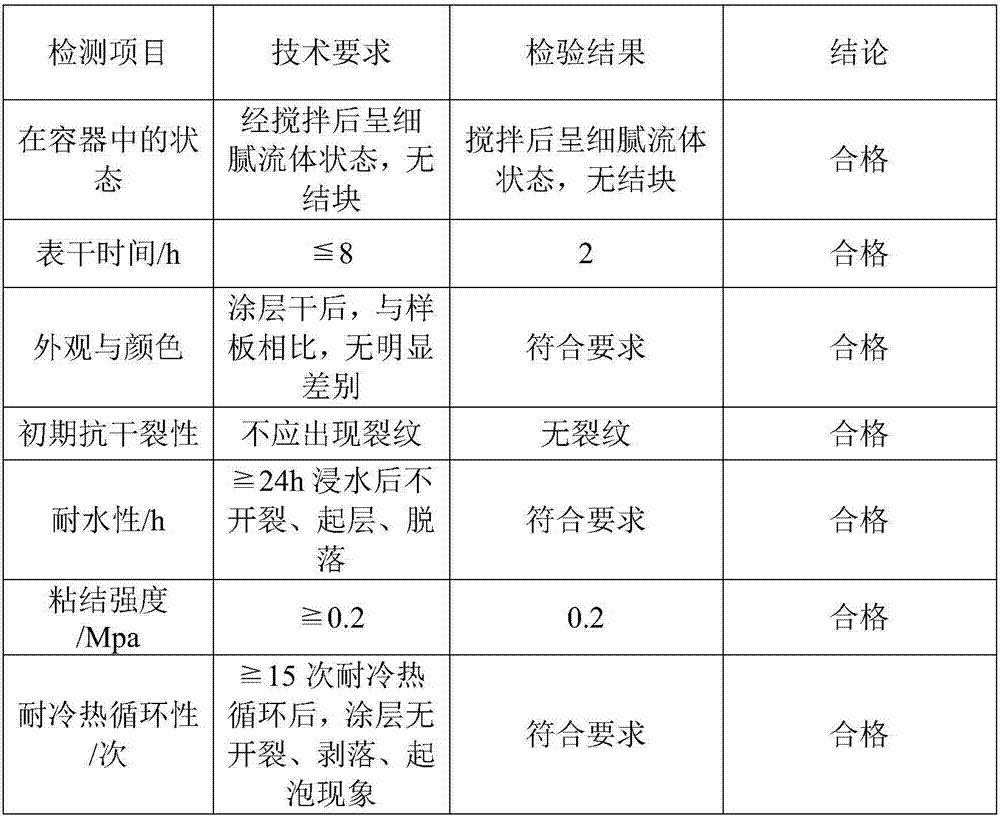

Combined assembly type heat-insulation plate

ActiveCN102619288ASimple structureStrong heat insulation abilityHeat proofingEngineeringInsulation layer

The invention relates to the field of plate type heat-insulation components for keeping warm, in particular to a combined assembly type heat-insulation plate, which comprises an outer support (1) and an inner support (2), and the outer support (1) is arranged on the outer side of the inner support (2). The combined assembly type heat-insulation plate is characterized by further comprising a spacing layer (3), an outer heat-insulation layer (4), an inner heat-insulation layer (5) and a connecting rod (6), the spacing layer (3) is disposed between the outer support (1) and the inner support (2), the outer heat-insulation layer (4) is inlaid in a space between the outer support (1) and the spacing layer (3), the inner heat-insulation layer (5) is inlaid in a space between the inner support (2) and the spacing layer (3), the connecting rod (6) is sequentially connected with and fastens the outer support (1), the outer heat-insulation layer (4), the spacing layer (3), the inner heat-insulation layer (5) and the inner support (2) from outside to inside, and an inner boss (21) is further fixed onto an inner side surface of the inner support (2). The combined assembly type heat-insulation plate is simple in structure, high in heat-insulation effect, fine in warm keeping performance and wide in application range.

Owner:王建军

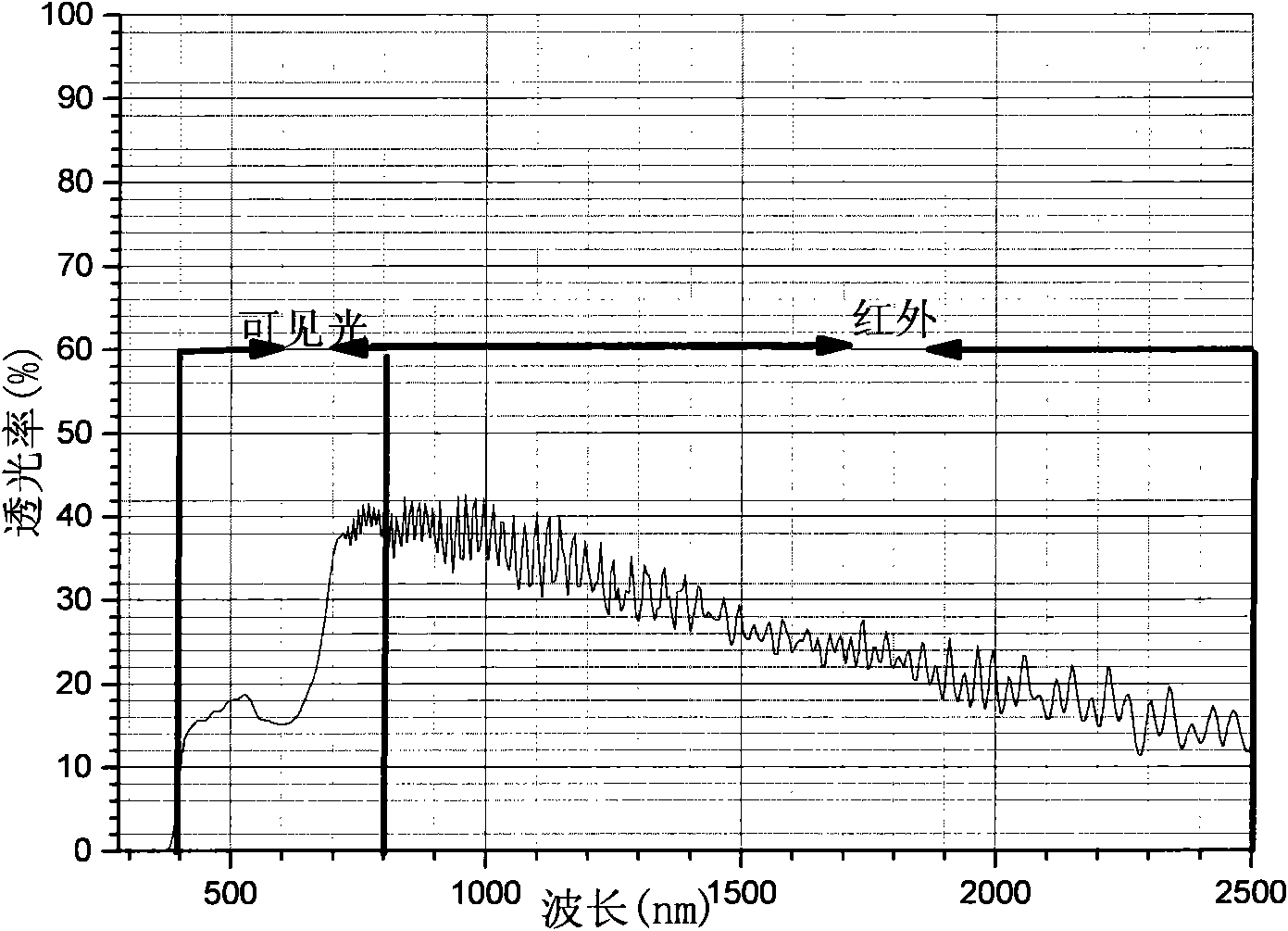

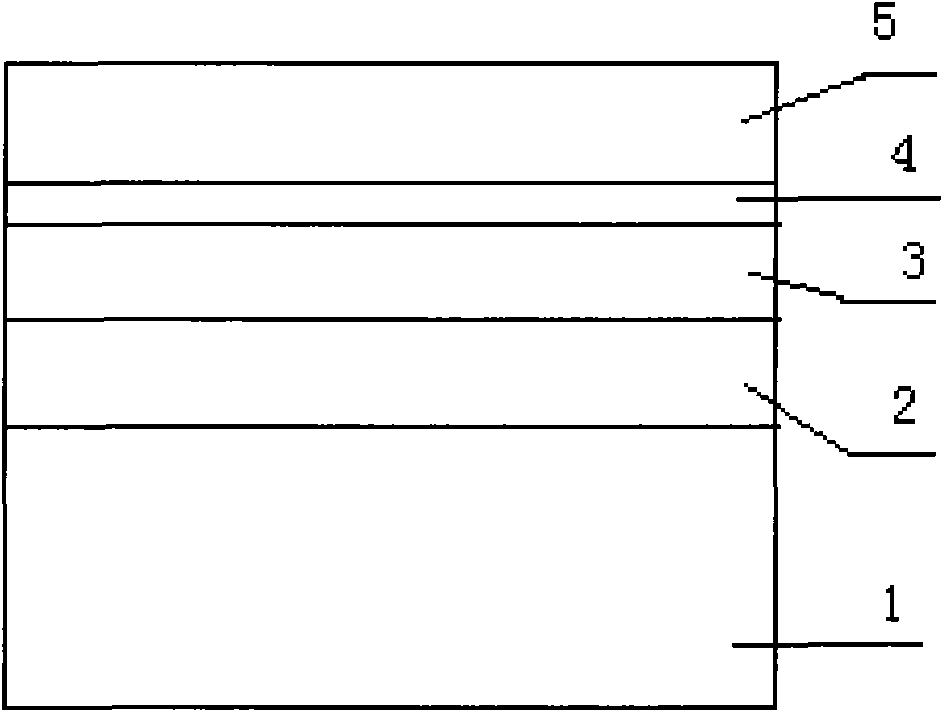

Single silver insulation film based on dielectric layer

InactiveCN101905549AStrong heat insulation abilityHigh visible light transmittanceAntiglare equipmentSynthetic resin layered productsTitanium dioxideTitanium

The invention belongs to the technical field of insulation films and particularly relates to a single silver insulation film based on a dielectric layer. The single silver insulation film based on the dielectric layer is characterized in that a PET substrate is sequentially plated with a dielectric layer, a silver layer, a protective layer and a dielectric layer, the PET substrate is a poly ethylene terephthalate substrate with the thickness of 23-36 mu m, the dielectric layer is made of titanium dioxide with the thickness of 20-40 nm, the silver layer is made of silver with the thickness of 10-15 nm, the protective layer is made of titanium with the thickness of 1-4 nm, and the dielectric layer is made of the titanium dioxide with the thickness of 20-40 nm. The insulation film has the advantages of strong infrared ray reflective power, i.e. insulating capacity, high visible light transmittance, low reflectivity, neutral coloring of colors, natural and soft appearance effect and the like, and is particularly suitable for a vehicle foreside windscreen and the like having high transmittance requirement.

Owner:SOUTHWESTERN INST OF PHYSICS

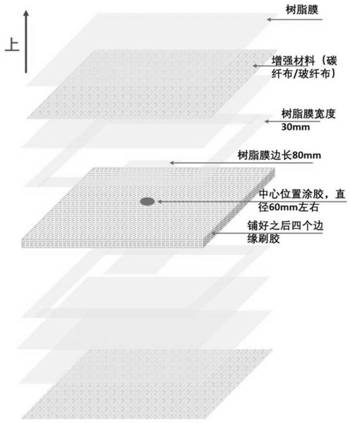

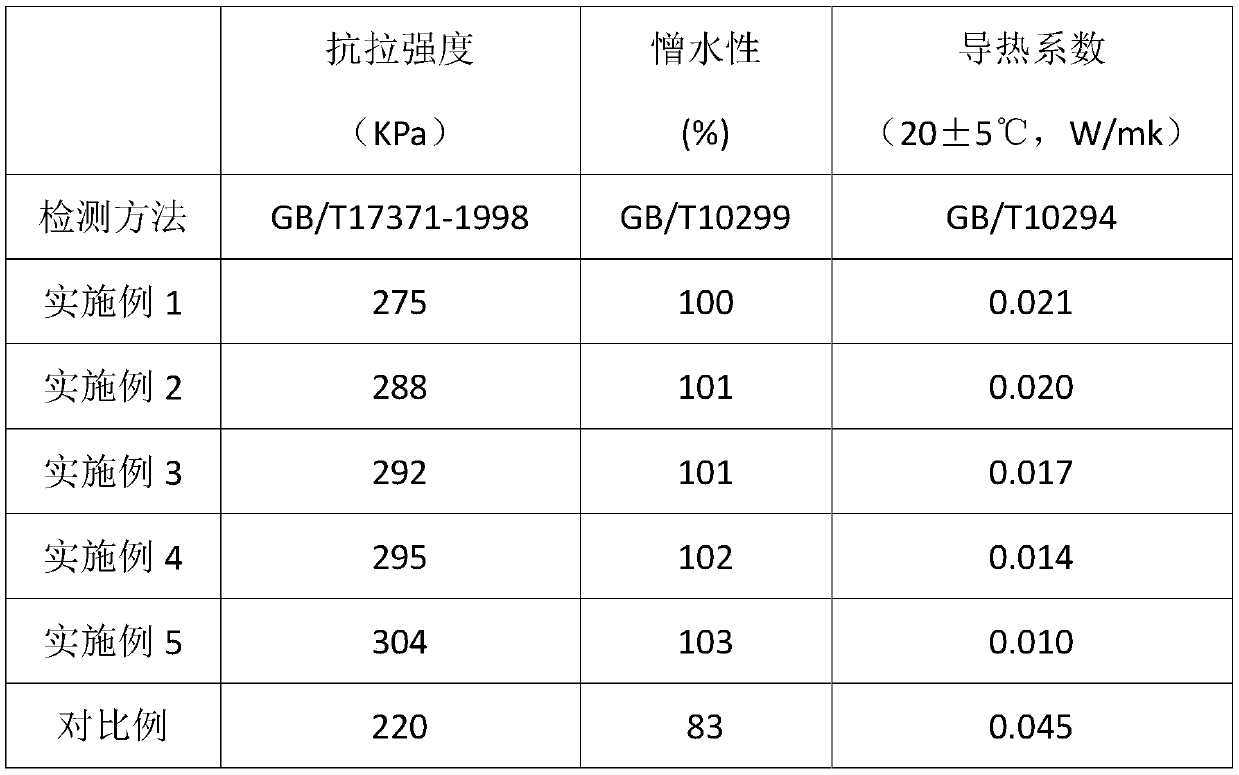

Fireproof insulation board and preparation method thereof

PendingCN112677580AInsulated fitStrong heat insulation abilitySynthetic resin layered productsLaminationThermal insulationAerogel

The invention provides a fireproof thermal insulation board. The fireproof thermal insulation board comprises an aerogel core material layer; reinforcing layers which are compounded on the upper surface and the lower surface of the aerogel core material layer; a resin edge sealing layer which covers the edge of the aerogel core material layer; and a reinforcing layer which is compounded with the aerogel core material layer through flame-retardant resin. Compared with the prior art, the fireproof heat insulation plate provided by the invention takes aerogel as a core material, adopts a specific layer structure, and realizes better overall interaction under a specific connection relationship; a compact, firm and tough composite material skin is formed on the surface of the product, the product is endowed with stronger heat insulation and sound insulation effects while the strength is improved, and a complex plane shape and a complex three-dimensional shape can be processed; moreover, the fireproof heat-insulating plate provided by the invention is provided with the resin edge-sealing layer, so powder leakage at the edge can be avoided, and the whole fireproof heat-insulating plate is more suitable for heat insulation inside precision equipment.

Owner:成都希瑞方晓科技有限公司

Thin type fireproof glass and preparation thereof

InactiveCN101279822AImprove fire performanceGood heat insulationFireproof doorsAmide/imide polymer adhesivesFlat glassWeather resistance

The invention discloses a thin fire-resisting glass and a method for the production thereof. The thin fire-resisting glass of the invention is glued by a flat glass and compounded by pouring fire-proof transparent glue, solidifying and sealing, the compositions of the fire-proof transparent glue (W%) are: gel forming agent of 5 to 15 percent, methylene-bisacrylamide of 10 to 20 percent, initiator of 0.1 to 2.0 percent, sodium chloride of 5 to 15 percent, magnesium chloride of 5 to 30 percent, aluminum phosphate of 5 to 25 percent, boric acid of 0 to 10 percent, ethanolamine of 5 to 25 percent and water of 30 to 50 percent. The fire-resisting glass of the invention is mainly used for fireproof and soundproof building partitioning facilities such as fire-resisting and soundproof doors and fire-resisting and soundproof walls and windows, and has good sound insulation, transmittance, waterproofing and weathering resistance performances, and can meet the requirements of high-grade building fireproof materials with rather high fireproof demand.

Owner:TIANJIN FIRE RES INST

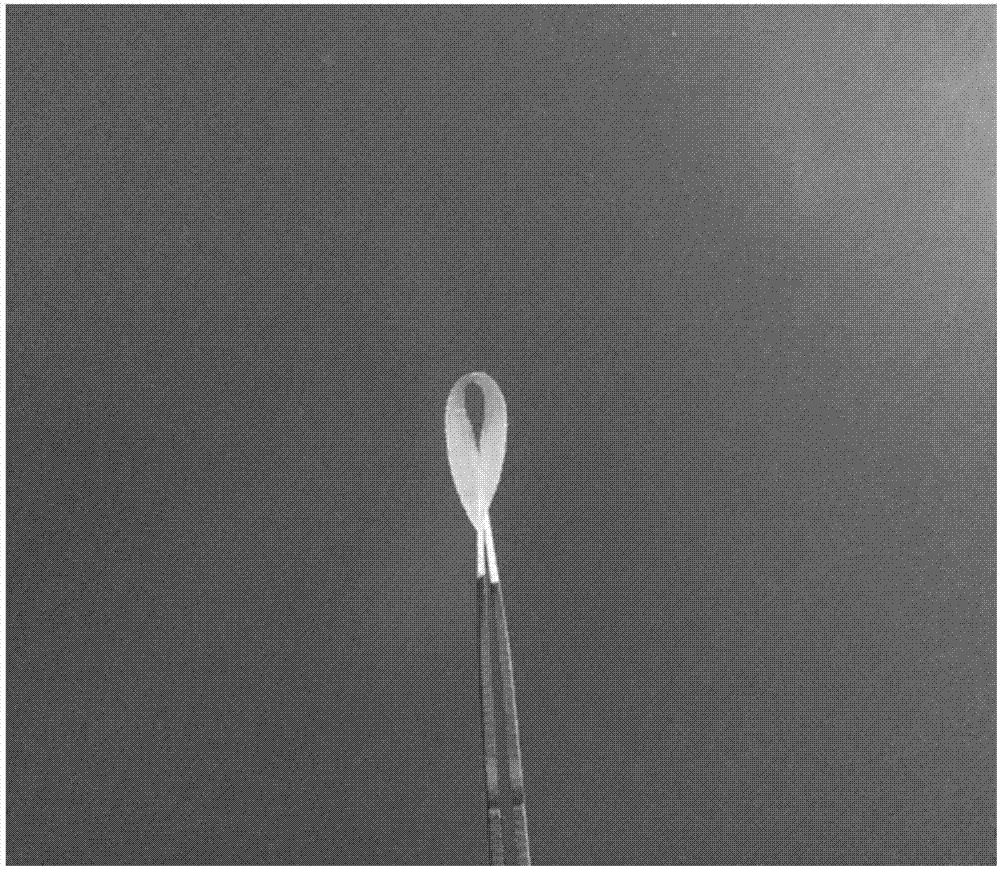

Preparation method of transparent flexible film of POSS (polyhedral oligomeric silsesquioxane) enhanced aramid nanofiber

ActiveCN107022094AHigh mechanical strengthImprove heat resistanceFibre typesChemistryLower intensity

The invention provides a preparation method of a transparent flexible film of POSS (polyhedral oligomeric silsesquioxane) enhanced aramid nanofiber, and relates to a preparation method of a transparent flexible film. The preparation method aims at solving the problems of low intensity and poor thermodynamic property of the existing aramid fiber nanofiber film. The method comprises the following steps of 1, performing extraction; 2, preparing a kermesinus aramid nanofiber solution; 3, preparing POSS dispersion liquid; 4, preparing a POSS hybridized aramid nanofiber solution; 5, preparing hybridized aramid nanofiber hydrogel; 6, performing vacuum pumping and drying to obtain the transparent flexible film of the POSS enhanced aramid nanofiber. The tensile strength of the transparent flexible film of the prepared POSS enhanced aramid nanofiber is greater than 316MPa; the tensile strength of the pure aramid nanofiber film is 202MPa; the tensile strength is improved by about 56.43 percent. The invention provides the preparation method capable of obtaining the transparent flexible film of the prepared POSS enhanced aramid nanofiber.

Owner:HARBIN INST OF TECH

Fireproofing original bamboo floorslab

The invention relates to a fireproofing original bamboo floorslab, belonging to the technical field of building engineering. The fireproofing original bamboo floorslab comprises bamboo rafts, flexible waterproof layers, light clay layers, floor piles, a fireproofing layer, hanging bars and a floor tile layer wood floor surface layer. A plurality of original bamboo are densely arranged on the floor piles to form the bamboo rafts; the flexible waterproof layers are laid on the bamboo rafts; the light clay layers are laid on the flexible waterproof layers; the fireproofing layer is hung below the bamboo rafts through the hanging bars; and each sealed hollow cavity of the original bamboo is provided with a small pressure release hole. Compared with the traditional bamboo floorslab, the fireproofing original bamboo floorslab has the advantages of high bearing capacity, good temperature preserving and sound insulating performance, high fireproofing capacity and the like. The floor tile or wood floor can be laid on the surface of the fireproofing original bamboo floorslab, thus the indoor health sanitary condition can be greatly improved. The bamboo replaces the wood and the steel, thus the living quality of the ethnic people can be improved, the bamboo culture can be revitalized, the forest resources can be protected, and the greenhouse gas emission can be reduced.

Owner:KUNMING UNIV OF SCI & TECH

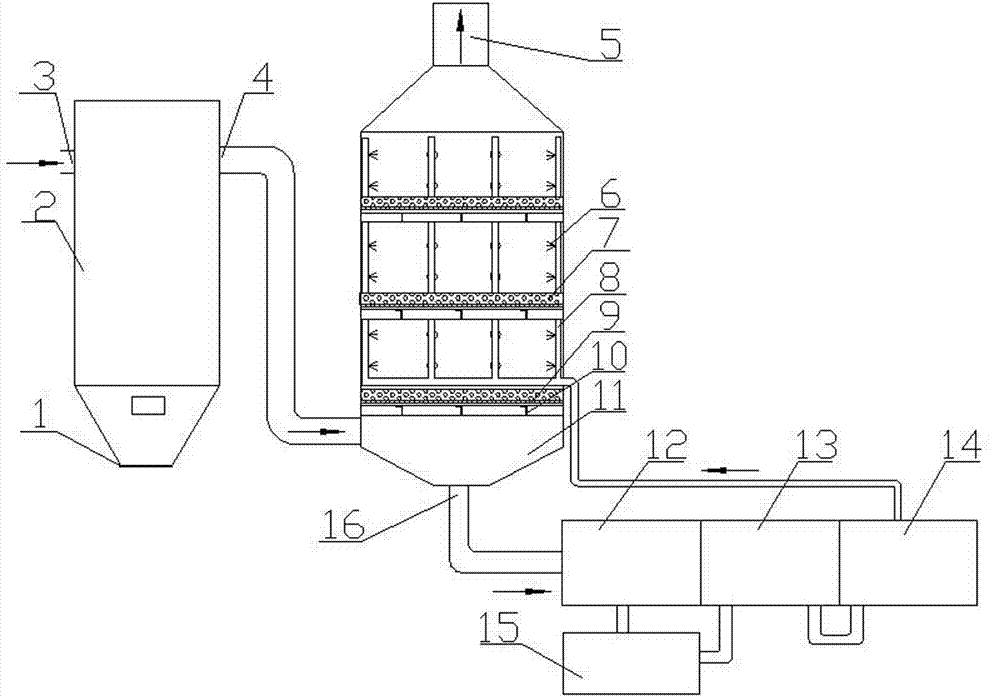

Waste gas purifying spray system

A waste gas purifying spray system includes a waste gas inlet, a cyclone separator and a waste gas outlet. A spray column includes three layers, wherein a filter screen is fixed onto each layer through an angle iron bracket. A plurality of ceramic hollow tubes are irregularly arranged on each filter screen. A plurality of water spray tubes are arranged uniformly from the bottom to the top on inner periphery of the spray column. A plurality of spray nozzles are arranged on the inner side of each spray tube. A first-stage sedimentation tank, a second-stage sedimentation tank, a third-stage sedimentation tank and a fourth-stage sedimentation tank are successively connected to the waste gas outlet through pipelines. The waste gas purifying spray system is simple in structure, is stable in operation and is strong in heat dissipation and insulation. Waste gas can fully make contact with water fog so that the dust removal efficiency can be increased. Meanwhile, the waste gas purifying spray system can remove toxic gases, can achieve toxic-free emission, can form water circulation and can save water resource, so that by means of popularization and application of the system timely, an excellent social and economical benefit can be achieved.

Owner:JINGJIANG XINZHOU ALLOY MATERIALS

Plastic foamed sheet with antistatic and flame-retardant functions and manufacturing technique thereof

The invention relates to an environment-friendly plastic foamed sheet with antistatic and flame-retardant functions and a manufacturing technique thereof. The manufacturing technique comprises the following steps: preparing bamboo carbon powder, kaolin, plastic, antistatic agent, flame retardant and other chemical assistants, banburying, mixing, discharging from a guillotine to obtain a sheet semi-finished product, and foaming to form with a foaming machine. The plastic foamed sheet is prepared from the following raw materials in parts by mass: 5.5-6 parts of plastic, 1.0-1.5 parts of bamboo carbon powder, 1.5-3.5 parts of kaolin, 1.0-2.5 parts of antistatic agent, 1.5-3.5 parts of flame retardant and 0.5-1.0 part of chemical assistants. The manufacturing technique produces the plastic foamed sheet with high-standard antistatic and flame-retardant functions, overcomes the defects and shortcomings in the prior art, has important and profound significance for solving the problems above, and has very wide market potential.

Owner:冼冰

Multi-functional building exterior wall environment-friendly nano-coating and preparation method thereof

The invention discloses a multi-functional building exterior wall environment-friendly nano-coating. The multi-functional building exterior wall environment-friendly nano-coating is prepared from the following components in parts by weight: 20-50 parts of water-based acrylic emulsion, 4-8 parts of butyl acrylate, 1-2 parts of nano TiO2, 1-1.5 parts of pearl mica powder, 0.5-1 part of hollow glass beads, 0.8-1.2 parts of sodium hexametaphosphate, 1.1-1.5 parts of ethoxylated alkylphenol sulfate, 0.5-1 part of propyltrimethoxysilane, 2-3 parts of pH regulator, 2-5 parts of other aids and 10-20 parts of deionized water. The invention further discloses a preparation method of the coating. The coating has the advantages of high coating performance, excellent weather resistance, excellent erosion resistance, high adhesion, non-toxicity and environmental friendliness; moreover, the preparation method is simple, is mild in process conditions, is easy to control, and is low in production cost.

Owner:广东健立科技有限公司

External wall heat-insulation material for constructional engineering and preparation method thereof

InactiveCN109704806ASimple manufacturing methodRaw materials are easy to getCeramicwareFiberMicrosphere

The invention discloses an external wall heat-insulation material for constructional engineering. The external wall heat-insulation material is prepared from the following raw materials in parts by weight: 15 to 20 parts of water-quenched slag, 20 to 30 parts of portland cement, 10 to 15 parts of hollow spherical zirconium oxide, 5 to 10 parts of silicon micro-powder, 10 to 20 parts of glass wool,10 to 20 parts of ceramic fiber cotton, 5 to 10 parts of hollow ceramic microspheres, 3 to 7 parts of expansive soil, 5 to 10 parts of attapulgite, 5 to 10 parts of a functional auxiliary agent basedon PPS-biphenylvinylsiloxy-heptacyclopentyl substituted derivative, 1 to 3 parts of a foaming agent, 1 to 2 parts of polyurethane and 25 to 35 parts of water. The invention further discloses a preparation method of the external wall heat-insulation material for the constructional engineering. The external wall heat-insulation material for the constructional engineering, disclosed by the inventionhas excellent comprehensive performance, remarkable heat-insulation effect and strong flame-retarding performance, heat insulation and coagulation performance.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

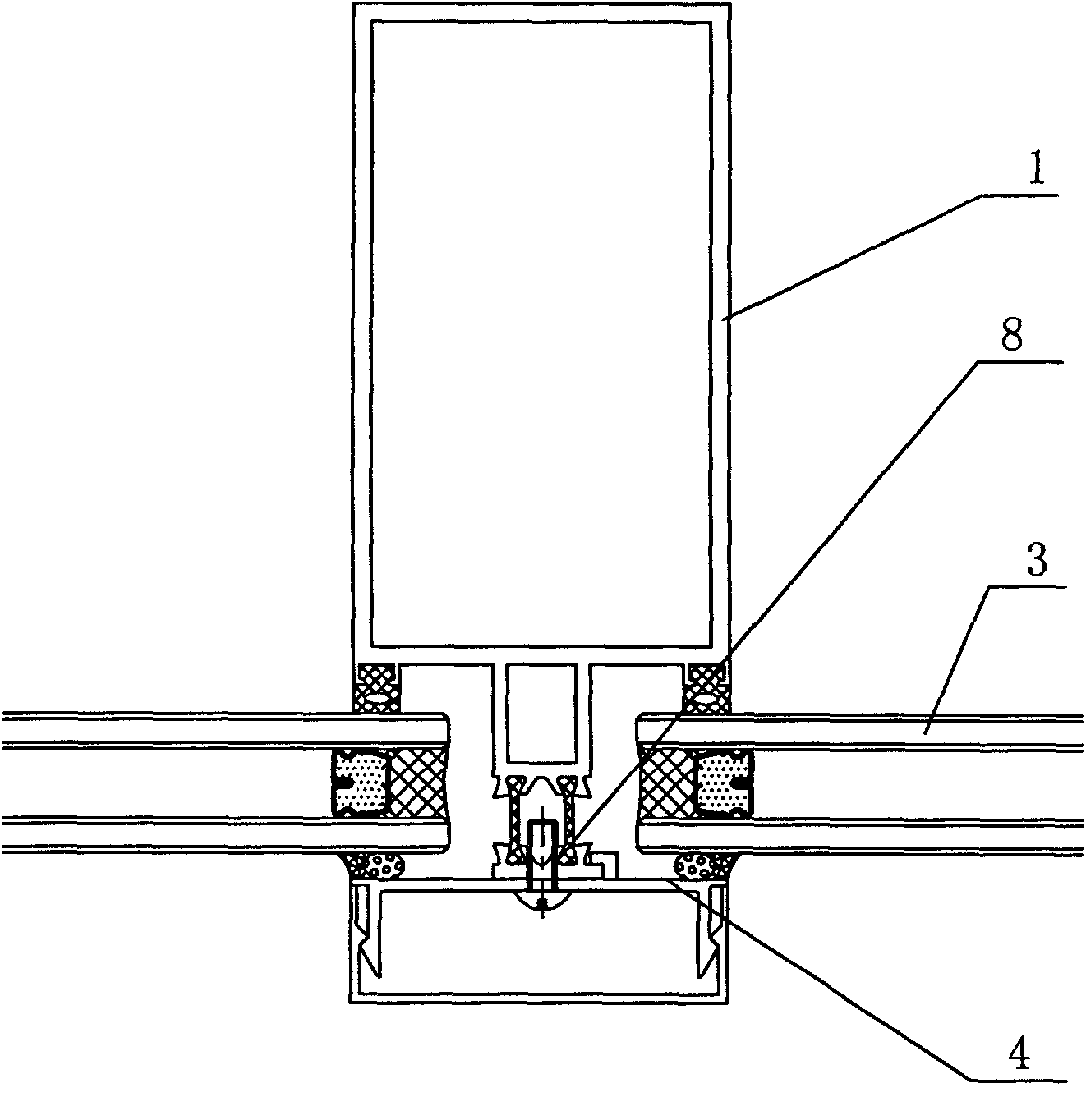

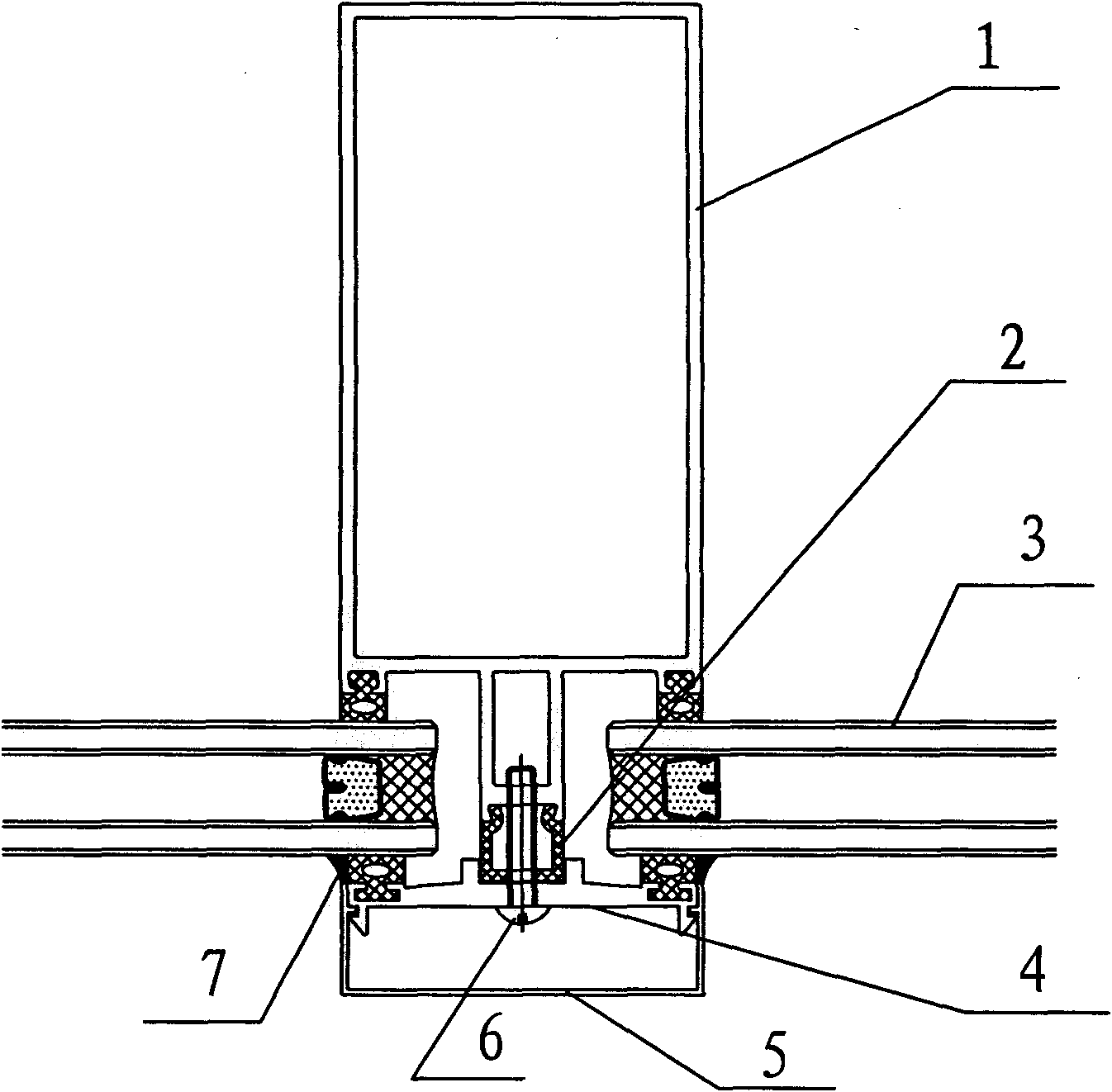

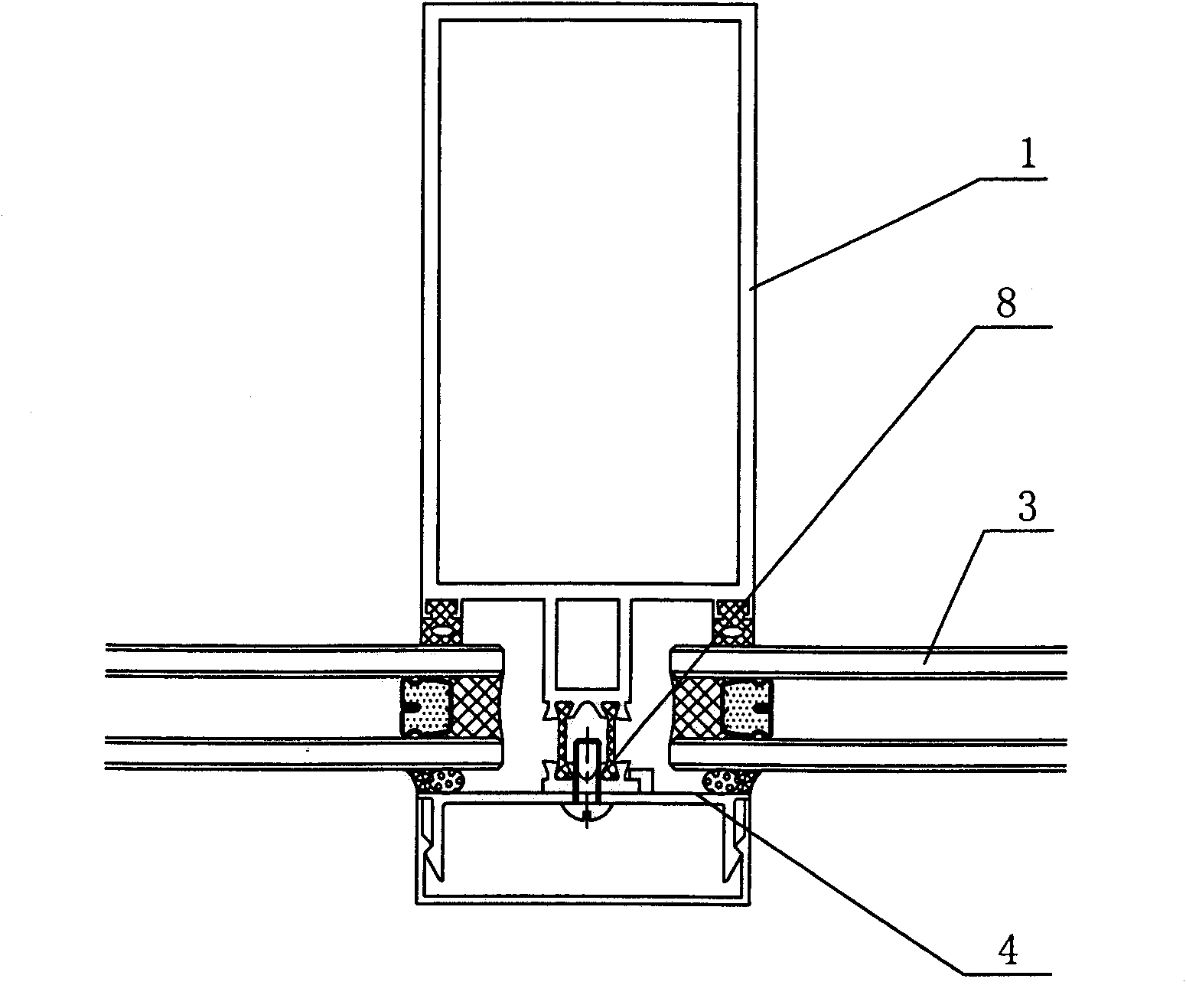

Exposed frame glass curtain wall with Poly vinyl chloride (PVC) heat-insulation block

InactiveCN102213015AStrong heat insulation abilityLow priceWallsHeat proofingEngineeringPoly vinyl chloride

The invention relates to an exposed frame glass curtain wall with a poly vinyl chloride (PVC) heat-insulation block. The exposed frame glass curtain wall comprises a stand column and hollow glass (3). The stand column comprises an aluminum section (1), an inner cover plate (4) of the aluminum section, an outer cover plate (5) of the aluminum section and a screw (6), wherein the inner cover plate (4) of the aluminum section is covered on the aluminum section (1); and the outer cover plate (5) of the aluminum section is covered outside the inner cover plate (4) of the aluminum section. The hollow glass (3) is embedded between the aluminum section (1) and the inner cover plate (4) of the aluminum section through a sealing joint strip (7); the PVC heat-insulation block (2) is embedded between the aluminum section (1) and the inner cover plate (4) of the aluminum section; the PVC block (2) is connected with the aluminum section (1) in a dovetailing mode, and the inner cover plate (4) of the aluminum section, the PVC heat-insulation block (2), and the aluminum section (1) are fixed by inserting the screw (6). The glass curtain wall has high heat-insulation capability and low cost.

Owner:江苏金宇幕墙装饰工程有限公司

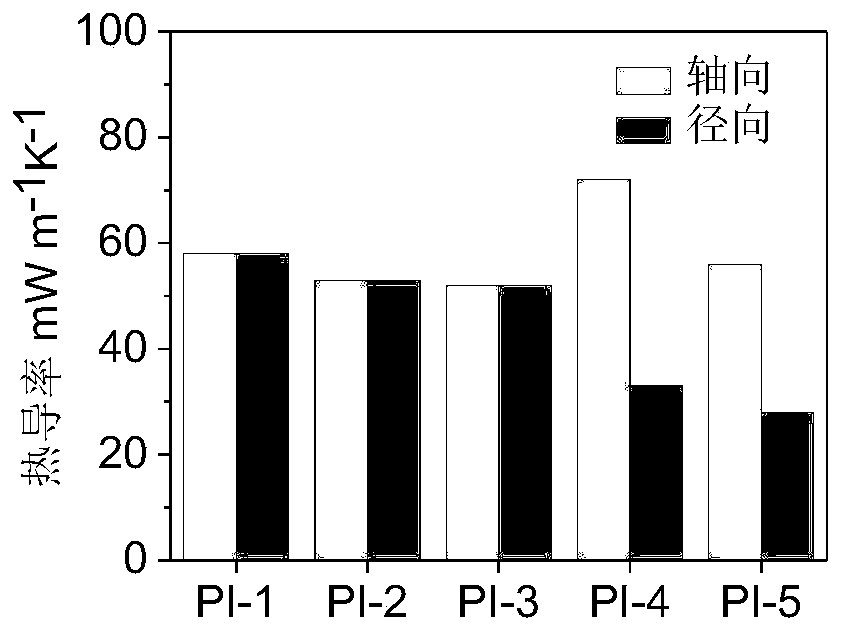

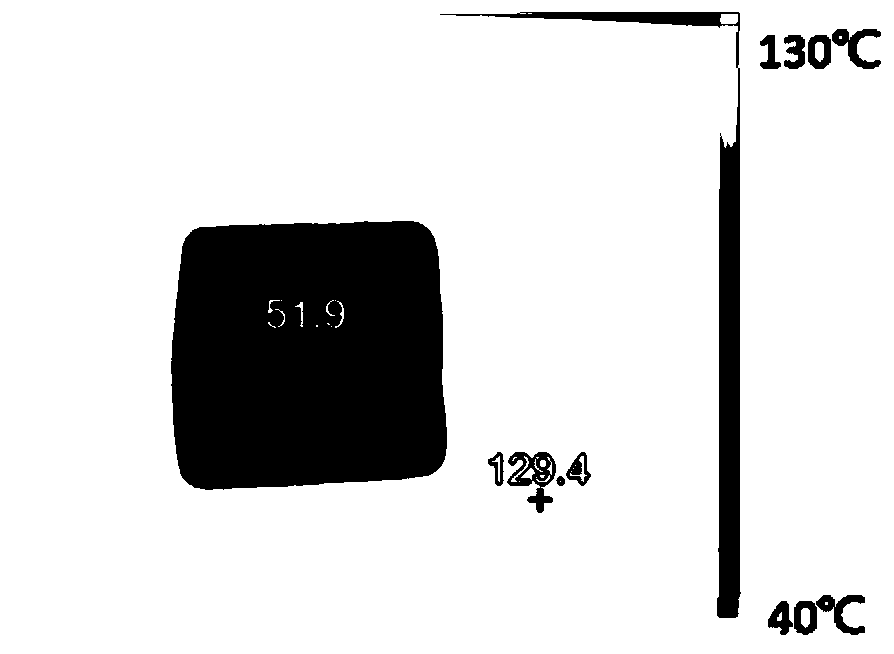

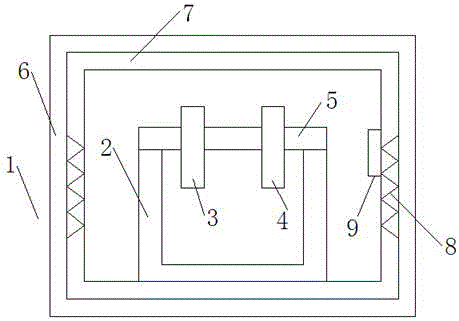

Polyimide aerogel and preparation method thereof

The invention relates to the field of thermal insulation materials and provides a preparation method of polyimide aerogel. The method is characterized by comprising the following steps: step 1, preparing polyamide acid hydrogel; step 2, freezing the polyamide acid hydrogel at low temperature, and performing freeze drying and thermal imidization to obtain the polyimide aerogel. The prepared polyimide aerogel has low density, high strength and high flame retardant capacity, isotropic and anisotropic thermal insulation materials can be obtained, various application scenarios can be met, the preparation process is simple and easy to operate, shorter time is needed, cost is low, environmental protection is realized, toxic solvents are not used, and the potential of large-scale application is provided.

Owner:DONGHUA UNIV

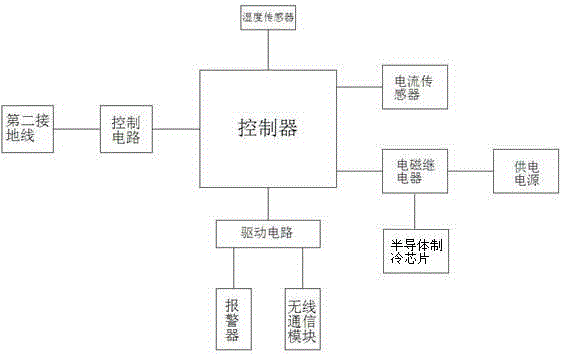

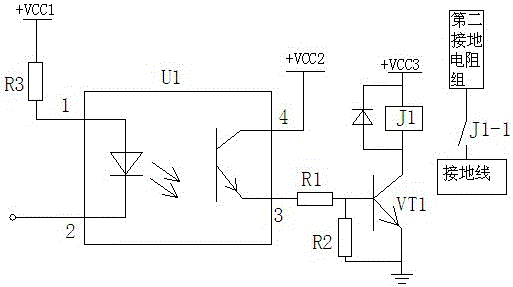

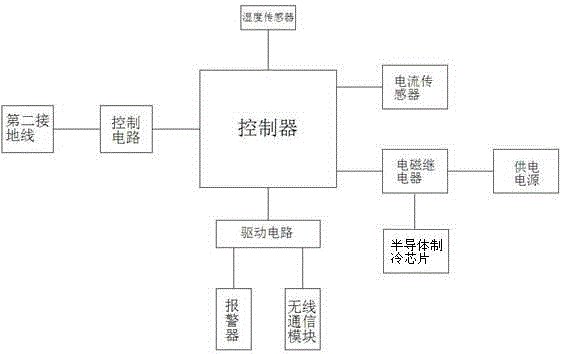

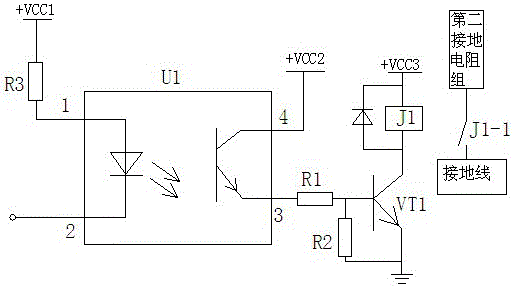

Monitoring system for outdoor cabinet of electric power system

InactiveCN106200514AEffectively fixedPrevent leakageProgramme controlComputer controlElectrical resistance and conductanceElectric power system

The invention relates to a monitoring system for an outdoor cabinet of an electric power system. The monitoring system comprises a background monitoring center and a front-end detecting device installed inside an electric power cabinet, wherein the electric power cabinet is further provided with a bracket therein, the ground resistor is disposed on the bracket, is fixed to the bracket via an insulated block, and is connected with a ground wire, and a current transformer is arranged on the ground wire and is connected with a controller, the controller is connected with an alarm device and a wireless device through a driving circuit, the ground resistor comprises a first ground resistor group and a second ground resistor group, the first ground resistor group is connected with a first ground wire, the second ground resistor group is connected with a second ground wire, and the current transformer is disposed on the first ground wire.

Owner:LIANGSHAN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

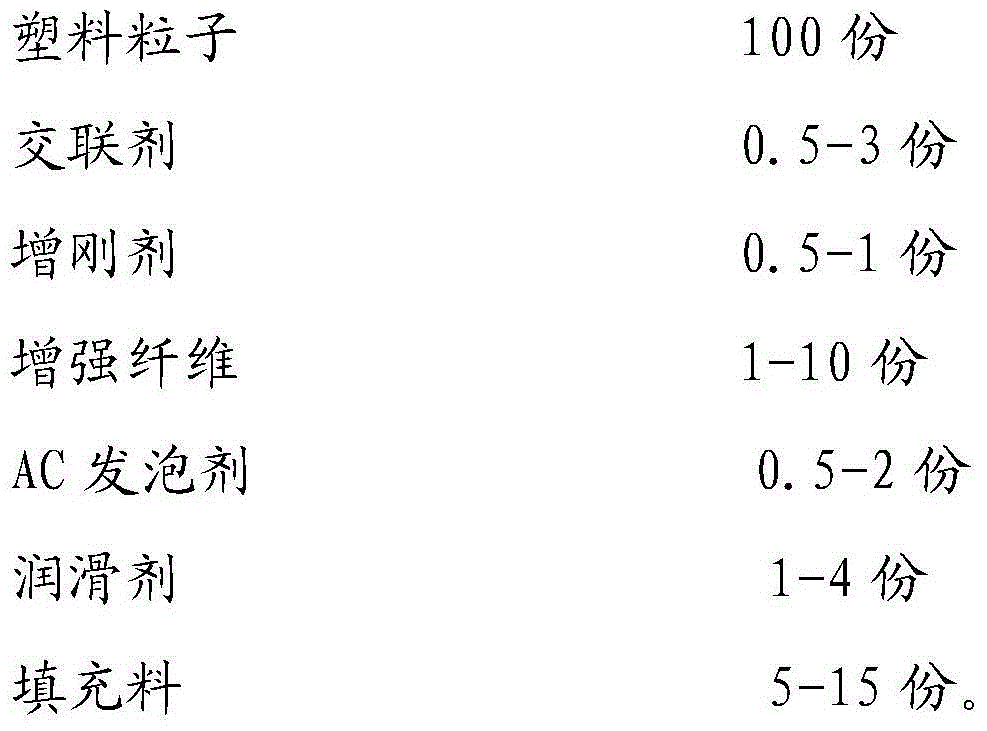

Enhanced door and window auxiliary frame and manufacturing method thereof

The invention discloses an enhanced door and window auxiliary frame. The enhanced door and window auxiliary frame is composed of a micro-foaming sheet material and a steel body embedded inside the micro-foaming sheet material; the micro-foaming sheet material comprises the following compositions: plastic particles, a cross-linking agent, a stiffening agent, reinforced fibers, an AC (Azodicarbonamide) foaming agent and a packing material. By the existence of a large number of bubbles in the micro-foaming material, the enhanced door and window auxiliary frame is low in density, light in weight and high in impact absorption loading capacity; by the steel body embedded inside the micro-foaming sheet material, the enhanced door and window auxiliary frame shows excellent cushioning capacity, and has the advantages of high heat insulation property, good sound insulation effect, acid and alkali resistance and good chemical stability.

Owner:沈建良

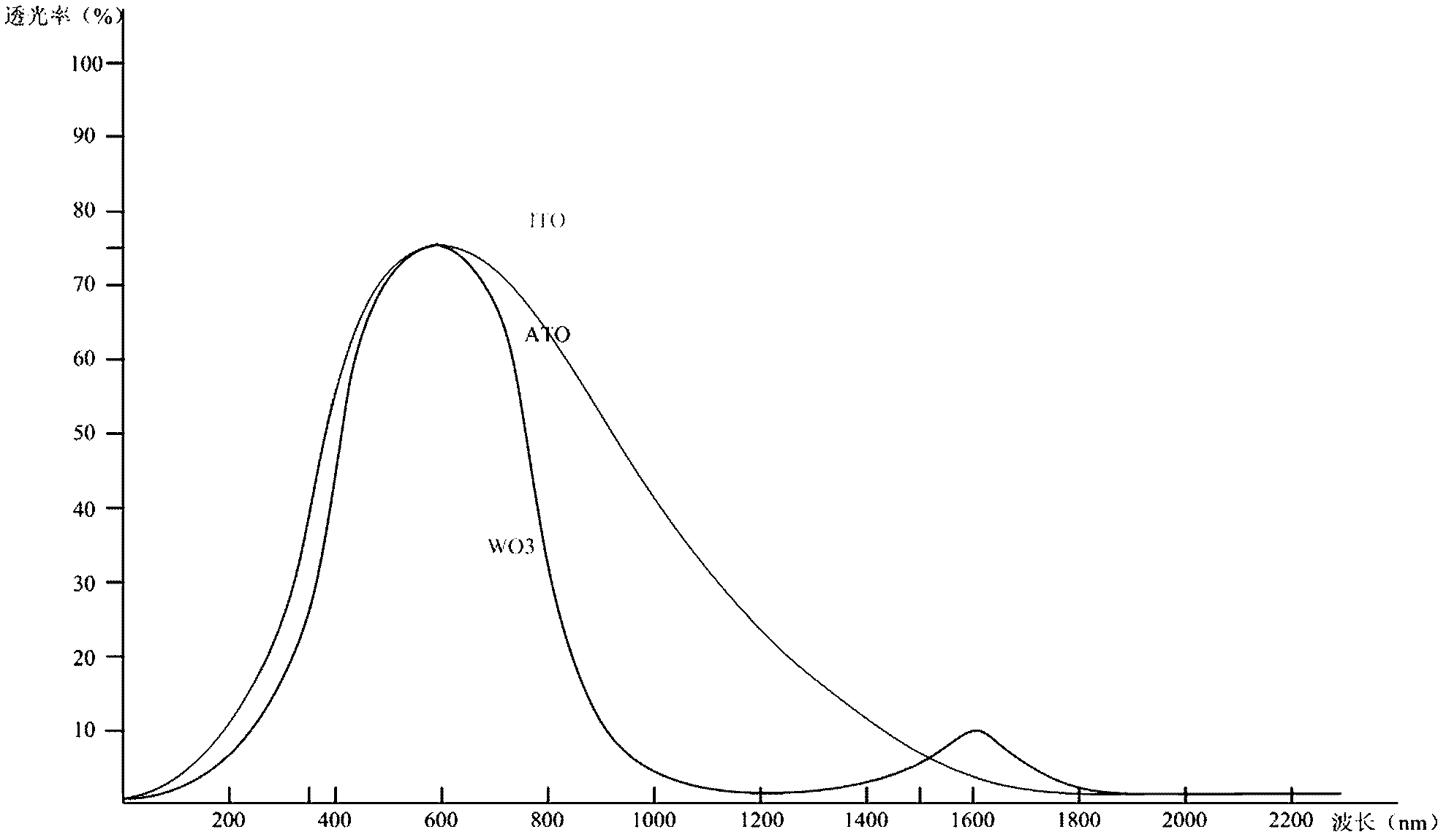

Preparation method of high-performance window film insulation medium

ActiveCN103122155AImprove energy efficiencyStrong transparencyCoatingsThermal insulationTransmittance

The invention discloses a preparation method of high-performance window film insulation medium. The preparation method includes: firstly, selecting blue WO3, ATO and ITO nano-powders according to corresponding conditions, using a planet wet ball-milling disperser and a scientific and reasonable combining-scattering comparison method, and optimally selecting factors such as selection proportion and solid content of different insulation media, selection on mill ball size, control on rotation speed and continuous dispersion time. Therefore, optimal transmittance of visible light, optimal insulation, optimal ultraviolet proofing and optimal performance of high-performance insulation medium are achieved. The high-performance window film insulation medium prepared by the preparation method is high in transparency, thermal insulation and ultraviolet proofing, has high insulation in the near-infrared area of 780nm-900nm, is widely applied to production of high-performance insulation glass and high-performance insulation window films, and has very important social and economic values.

Owner:上海沪正实业有限公司

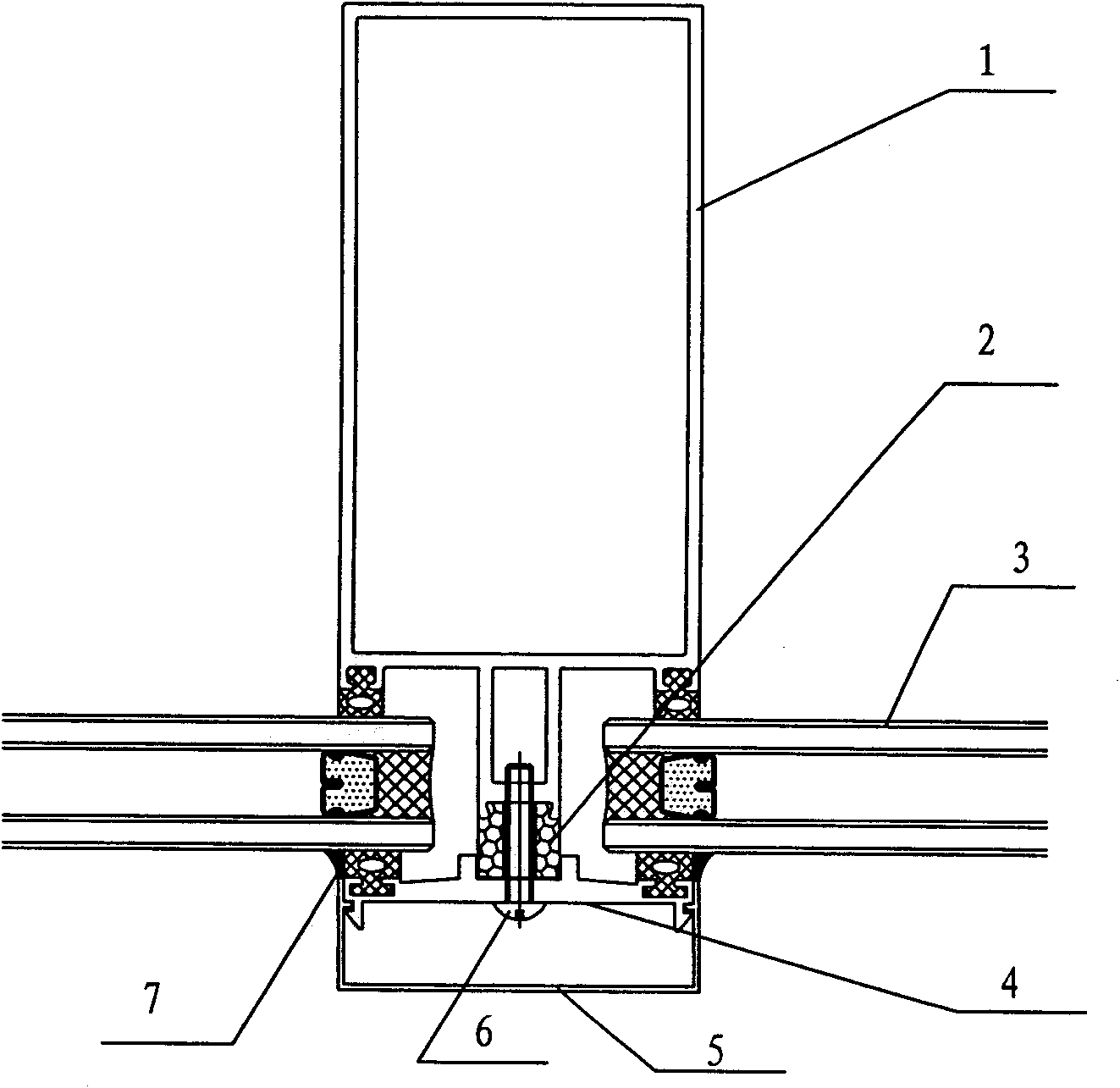

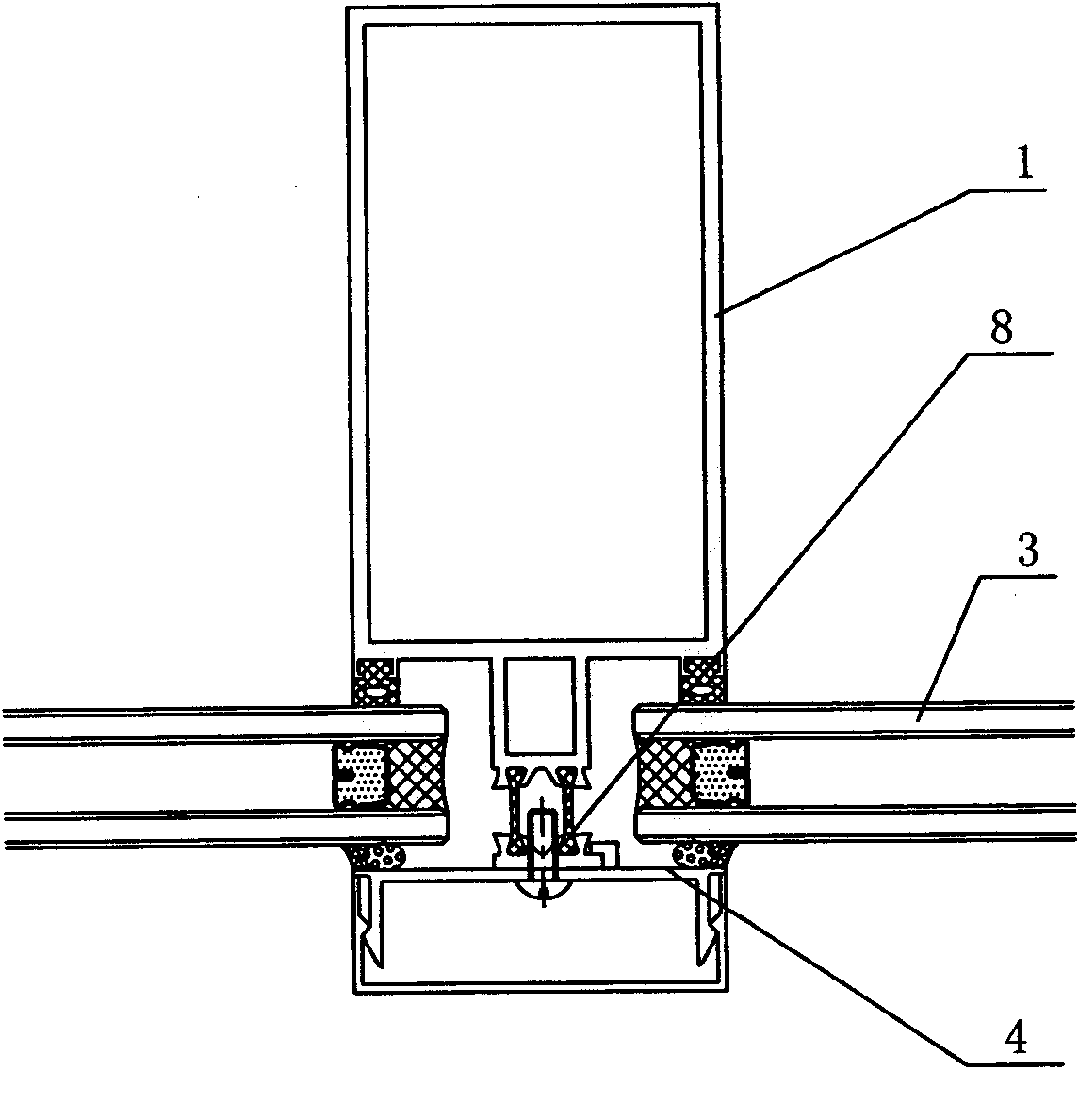

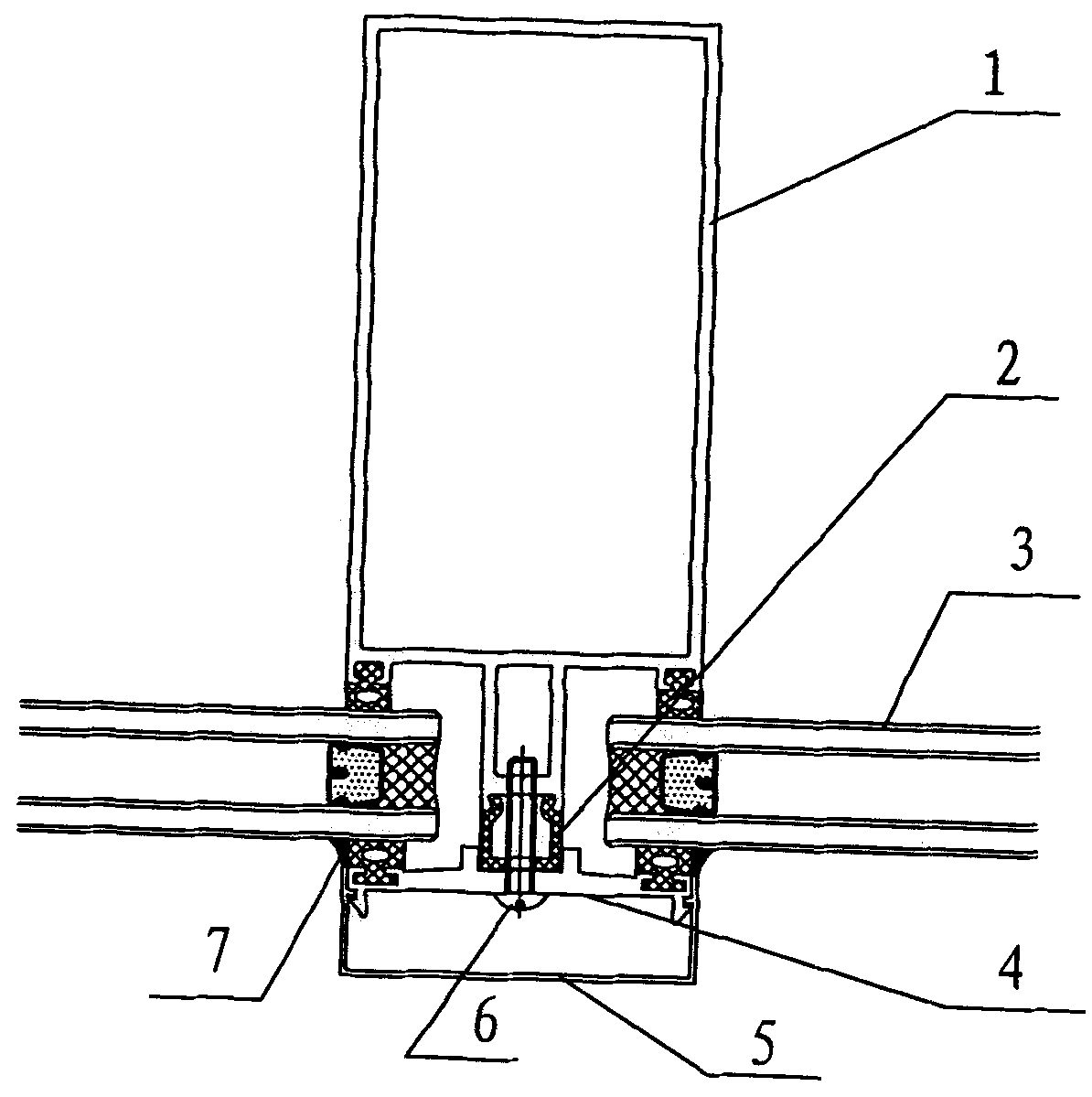

Method for constructing sunlight room roof and sunlight room roof

ActiveCN104196175ASimple structureLow costRoof covering using slabs/sheetsWater leakageThermal insulation

The invention relates to a method for constructing a sunlight room roof. The method includes the following steps that first, main transverse beams and secondary transverse beams are arranged at certain angles and fixedly connected to build a frame for room roof glass, wherein concealed drainage structures are arranged on the main transverse beams and the secondary transverse beams respectively; second, the room roof glass is placed on the frame formed by the main transverse beams and the secondary transverse beams, sealing rubber strips are arranged between the lower side face of the room roof glass and the main transverse beams and between the lower side face of the room roof glass and the secondary transverse beams, sealing rubber strips are arranged between the upper side face of the room roof glass and the main transverse beams, the upper side face of the room roof glass and the main transverse beams are pressed by the sealing rubber strips, flowing water drainage is adopted for the visible positions of the whole sunlight room roof, and seeping water is actively drained to water accumulating grooves in the room roof to be drained out through the concealed drainage structures of the main transverse beams and the concealed drainage structures of the secondary transverse beams. The invention further discloses a structure of the sunlight room roof. Through the method for constructing the sunlight room roof and the sunlight room roof, the problem of water leakage of the sunlight room roof is effectively solved, the sunlight room roof can be waterproof even when no glue is applied to the roof at all, and the sunlight room roof is easy and convenient to machine, assemble and disassemble and high in thermal insulation capacity.

Owner:佛山市淇特科技有限公司

Novel sink head brick and its processing technology

The invention discloses a sink head brick, comprising the following raw materials of: 30wt%+ / -5wt% of cordierite, 20wt%+ / -5wt% of aluminium titanates, 15wt%+ / -5wt% of synthesis mullite, 15wt%+ / -5wt% of wood chip and 20wt%+ / -5wt% of polyester ball. The invention also provides a processing technology of the sink head brick. The sink head brick provided by the invention is characterized in that it has advantages of high-temperature resistance, low heat-conduction coefficient, high insulation, strong heat-insulation performance, light weight, and convenient installation; it can raise casting quality and reduce production cost; it has strong anti-metal liquid erosion capability; it can not be burned; it dose not adhere to sand and contains no binder; it does not react with molten steel and not destroy characteristics of molten steel tissues.

Owner:朱晓明

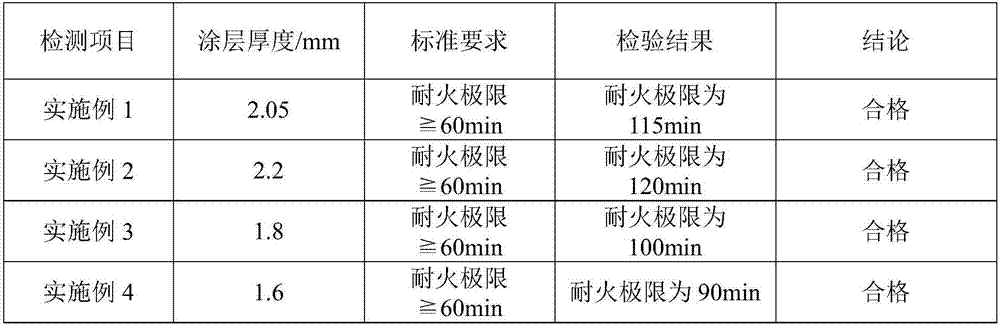

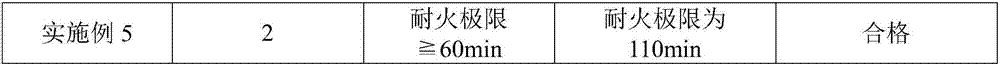

Ultraviolet-resistant radiation-protection aqueous ultra-thin fire resistive coating for steel structure and preparation method thereof

The invention relates to an ultraviolet-resistant radiation-protection aqueous ultra-thin fire resistive coating for a steel structure and a preparation method thereof. On the basis of adopting an ethylene-vinyl acetate emulsion and a polyvinyl acetate emulsion as matrix emulsions, through also adding an ammonium polyphosphate, melamine, dicyandiamide, pentaerythritol, zinc borate, expandable graphite, a light stabilizer and water as raw-material components for the fire resistive coating, the prepared and obtained fire resistive coating is enabled to be not only good in flame resistance, high in heat insulation and excellent in fire resistive performance and but also have advantages of good ultraviolet resistance and anti-radiation performance, good weather resistance and the like; the fire resistive coating provided by the invention is used in the steel structure; the adhesiveness with a matrix is high; the coating has weather-resistant, ultraviolet-resistant, anti-radiation and waterproof functions, and is good in comprehensive performance. The fire resistive coating provided by the invention can be used for an indoor steel structure, and accords with to a GB14907-2002 Fire Resistive Coating for Steel Structure; the fire resistance rating reaches 2h.

Owner:北京茂源防火材料厂

Insulator detection device for outdoor power system

InactiveCN106443255AEffectively fixedPrevent leakageEnvironmental/reliability testsEngineeringGrounding resistance

The invention relates to an insulator detection device for an outdoor power system, and the device comprises an insulating rod, a housing, a lantern ring, an electrode, a contact ring, a composite rod, a rotating disc, a cavity, a Bluetooth generator, a protection resistor, and a circuit board. The device is characterized in that the interior of the housing is provided with a support; the support is provided with a grounding resistor; the grounding resistor is fixed on the support through an insulating block; the grounding resistor is connected with a grounding line; the grounding line is provided with a current transformer which is connected with a controller; the controller is connected with a wireless communication module through a drive circuit and an alarm.

Owner:LIANGSHAN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

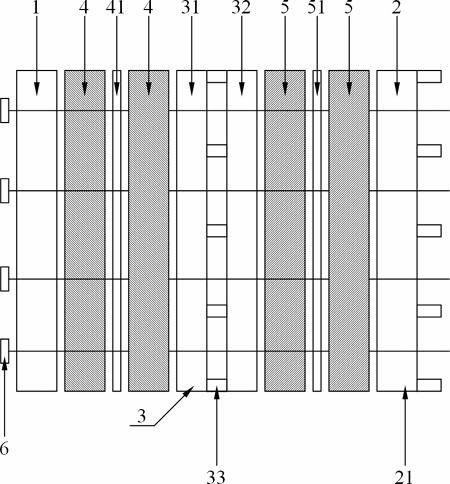

Exposed frame glass curtain wall adopting PVC (polyvinyl chloride) heat insulation bar structure

InactiveCN102213016AStrong heat insulation abilityLow priceWallsHeat proofingPolyvinyl chlorideEngineering

The invention relates to an exposed frame glass curtain wall adopting a PVC (polyvinyl chloride) heat insulation bar structure. The glass curtain wall comprises a vertical column and hollow glass (3), wherein the vertical column comprises an aluminium profile (1), an aluminium profile inner cover plate (4),an aluminium profile outer cover plate (5) and a screw (6); the aluminium profile inner cover plate (4) covers the aluminium profile (1); the aluminium profile outer cover plate (5) covers the aluminium profile inner cover plate (4); and the hollow glass (3) is embedded between the aluminium profile (1) and the aluminium profile inner cover plate (4) by sealing rubber strips (7). The glass curtain wall is characterized in that a PVC heat insulation bar (2) is embedded between the aluminium profile (1) and the aluminium profile inner cover plate (4) and is connected with the aluminium profile (1) in a dovetail manner; and the screw (6) is used for directly penetrating through and fixing the aluminium profile inner cover plate (4), the PVC heat insulation bar (2) and the aluminium profile (1). The glass curtain wall has strong heat insulation capability and lower cost.

Owner:江苏金宇幕墙装饰工程有限公司

Exposed frame glass curtain wall structure adopting PVC (polyvinyl chloride) heat insulation bar

The invention relates to an exposed frame glass curtain wall structure adopting a PVC (polyvinyl chloride) heat insulation bar. The glass curtain wall comprises a vertical column and hollow glass (3), wherein the vertical column comprises an aluminium profile (1), an aluminium profile inner cover plate (4),an aluminium profile outer cover plate (5) and a screw (6); the aluminium profile inner cover plate (4) covers the aluminium profile (1); the aluminium profile outer cover plate (5) covers the aluminium profile inner cover plate (4); and the hollow glass (3) is embedded between the aluminium profile (1) and the aluminium profile inner cover plate (4) by sealing rubber strips (7). The glass curtain wall is characterized in that a PVC heat insulation bar (2) is embedded between the aluminium profile (1) and the aluminium profile inner cover plate (4); and the screw (6) is used for directly penetrating through the aluminium profile inner cover plate (4), the PVC heat insulation bar (2) and the aluminium profile (1) to connect and fix the three materials. The glass curtain wall structure has strong heat insulation capability and lower cost.

Owner:江苏金宇幕墙装饰工程有限公司

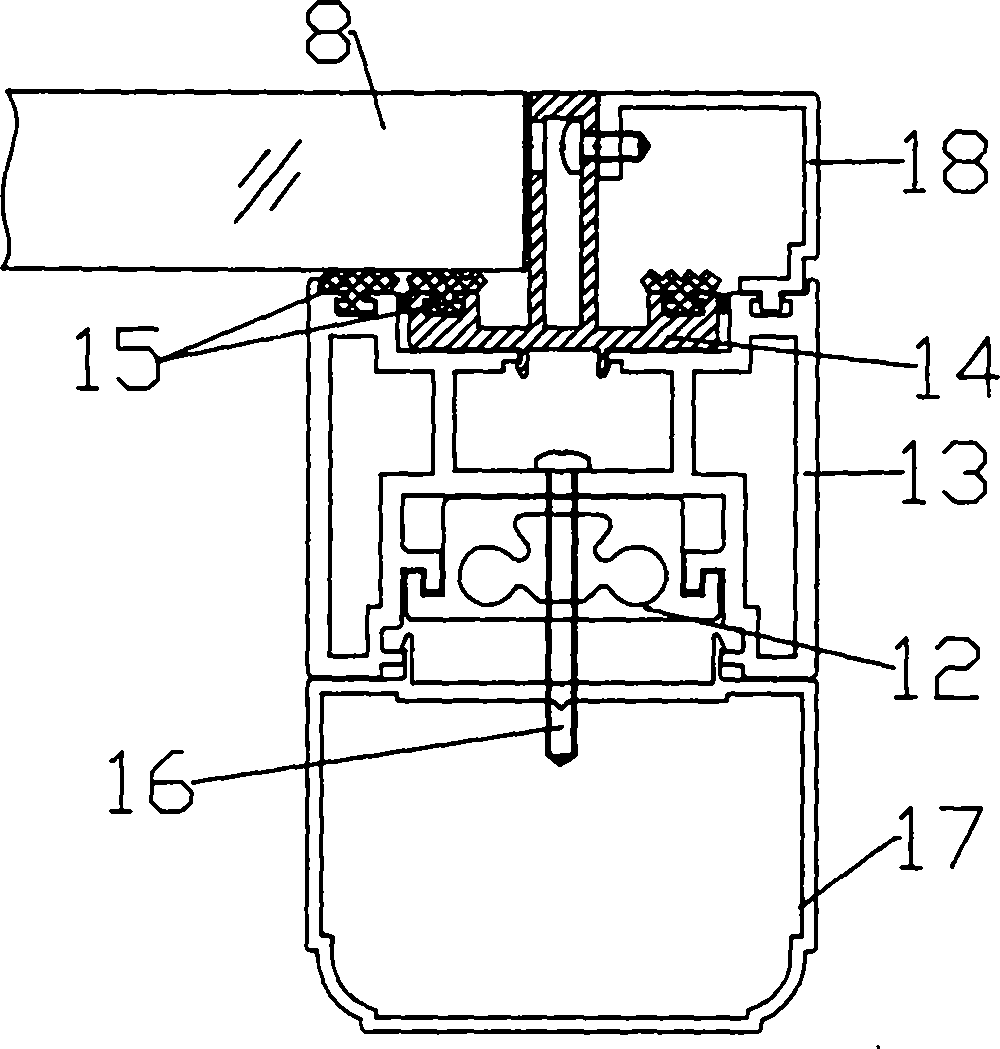

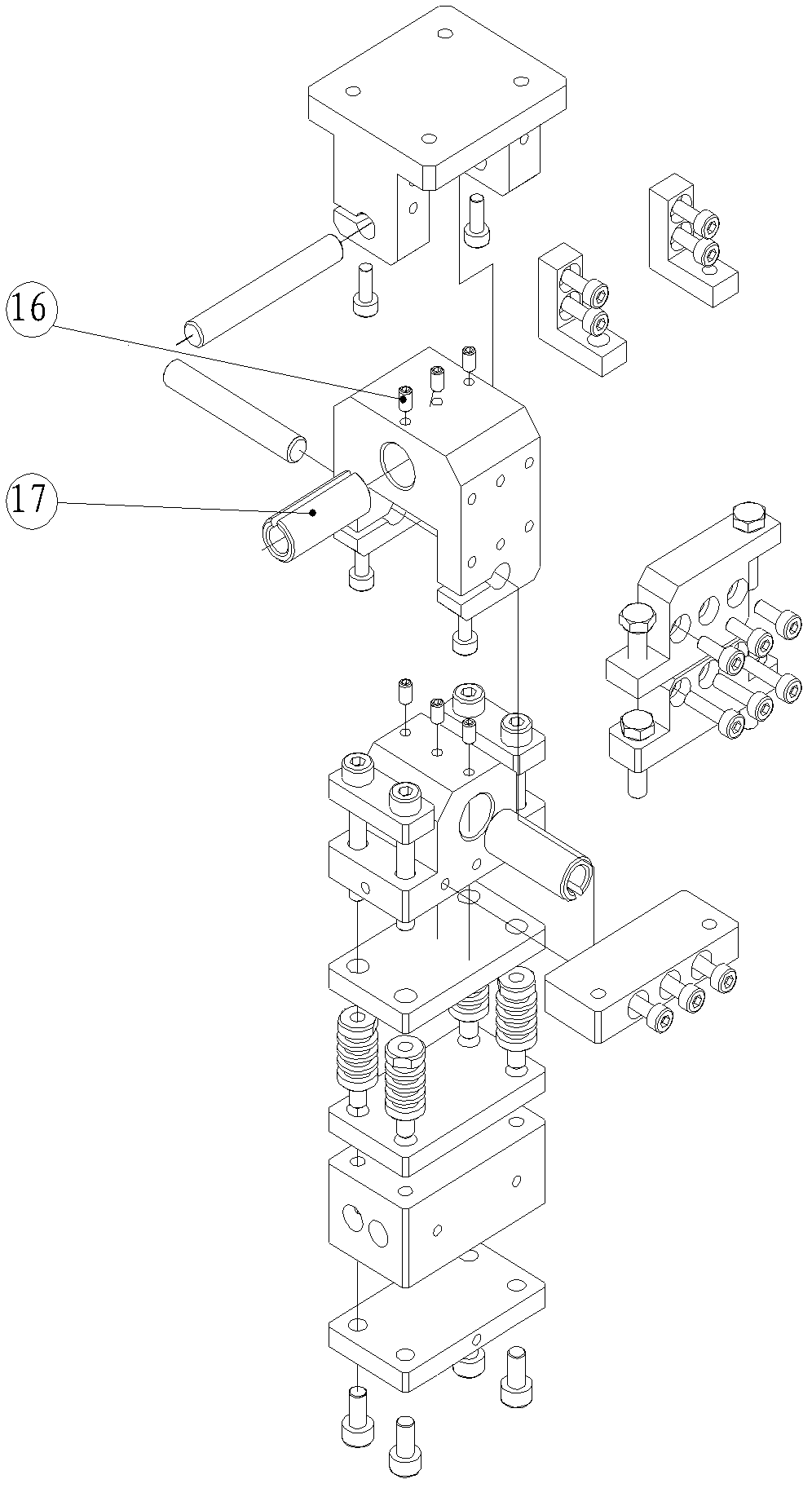

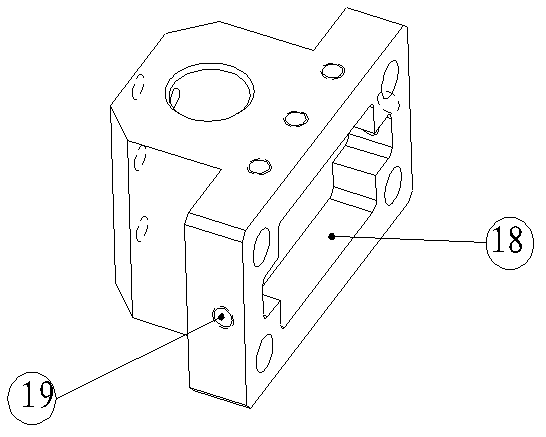

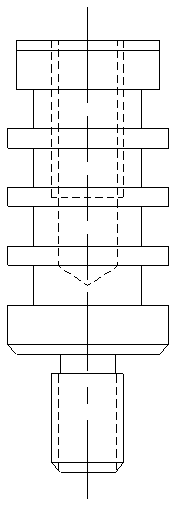

Hot pressing head with adjustable parallelism

InactiveCN102632676AReduce precisionOverall small sizeLaminationLamination apparatusEngineeringCopper

The invention provides a novel hot pressing head with adjustable parallelism, overcomes the shortcomings of a conventional hot pressing head such as inconvenience in the adjustment of parallelism, poor stability and low heat insulation capability in high-frequency pressing and sticking, and realizes the manufacturing of high-precision hot pressing heads under the general machining precision conditions so as to effectively reduce the machining cost and be helpful for improving the overall rigidity of the pressing head and the production speed of equipment. The structure of the novel hot pressing head comprises an X-axis rotating seat 1, a Y-axis rotating seat 9, a heat insulating connecting plate 5, a rotating shaft 2, an X-axis left tensioning block 3, an X-axis right tensioning block 10, an X-axis adjusting seat 12, a Y-axis tensioning block 7, a Y-axis adjusting seat 13, a small heat insulating plate 4, big heat insulating plates 6 and 14, a radiating column 8, a pressing head seat 15, tensioning screws 11, top thread 16 and a copper bush 17. By adjusting the two tensioning screws 11 up and down, the pressing head seat 15 can be adjusted to rotate around an X axis and a Y axis.

Owner:CHANGSHU RES INSTITUE OF NANJING UNIV OF SCI & TECH +1

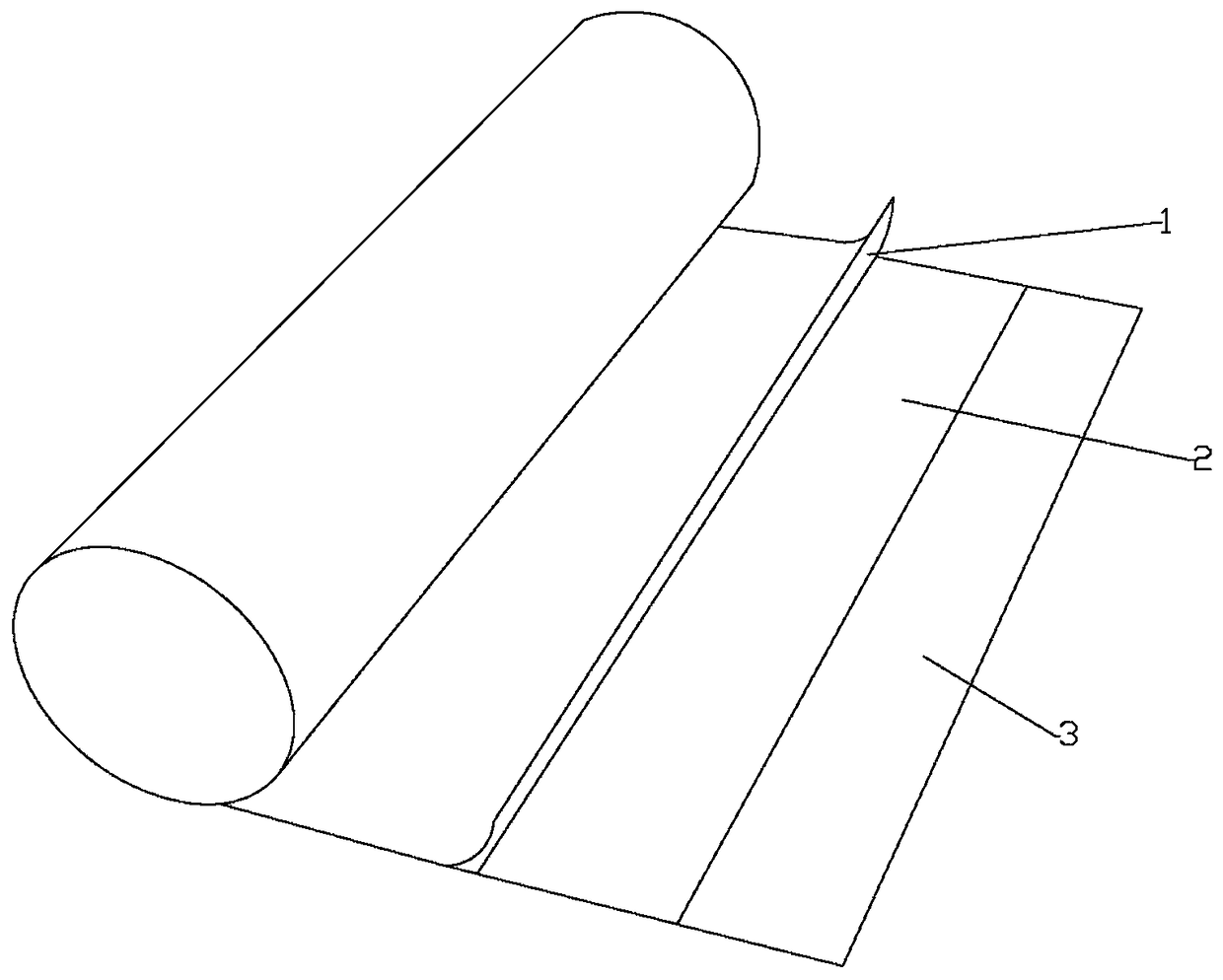

Novel nanoalloy root-system-resistant composite coil and preparation method thereof

PendingCN108276925AStrong root puncture resistanceStrong heat insulation abilityNon-macromolecular adhesive additivesFilm/foil adhesive primer layersPolyolefinTear resistance

The invention relates to the field of waterproof materials for buildings and particularly relates to a novel nanoalloy root-system-resistant composite coil and a preparation method thereof. The novelnanoalloy root-system-resistant composite coil comprises a coil, wherein the coil comprises a composite nanoalloy heat-insulating layer, an asphalt-based waterproof layer and a covering layer which are arranged from top to bottom; the composite nanoalloy heat-insulating layer is a tire body, and is a polyolefin nanoalloy heat-insulating layer; the asphalt-based waterproof layer consists of a rubber polymer and an asphalt-based material; the covering layer is a polyethylene silicon oil anti-sticking isolating film or PE (Polyethylene) crossing powerful film. The preparation method comprises thesteps of: preparing the heat-insulating layer, preparing the asphalt-based waterproof layer, carrying out dip-coating and sticking the film and the like. The novel nanoalloy root-system-resistant composite coil can prevent deformation, is strong in tensile strength, tearing resistance and corrosion resistance and good in heat-insulating property, has a root-resistant system capable of resisting puncture of the plant root system, is strong in bonding force, good in waterproof effect and low in applicable-environment requirement; in addition, the novel nanoalloy root-system-resistant compositecoil is unique in process, good in tire-base property, high in waterproof-layer property, simple in whole structure, excellent in property and strong in practicability.

Owner:驻马店中原世家防水防腐保温建材科技有限公司

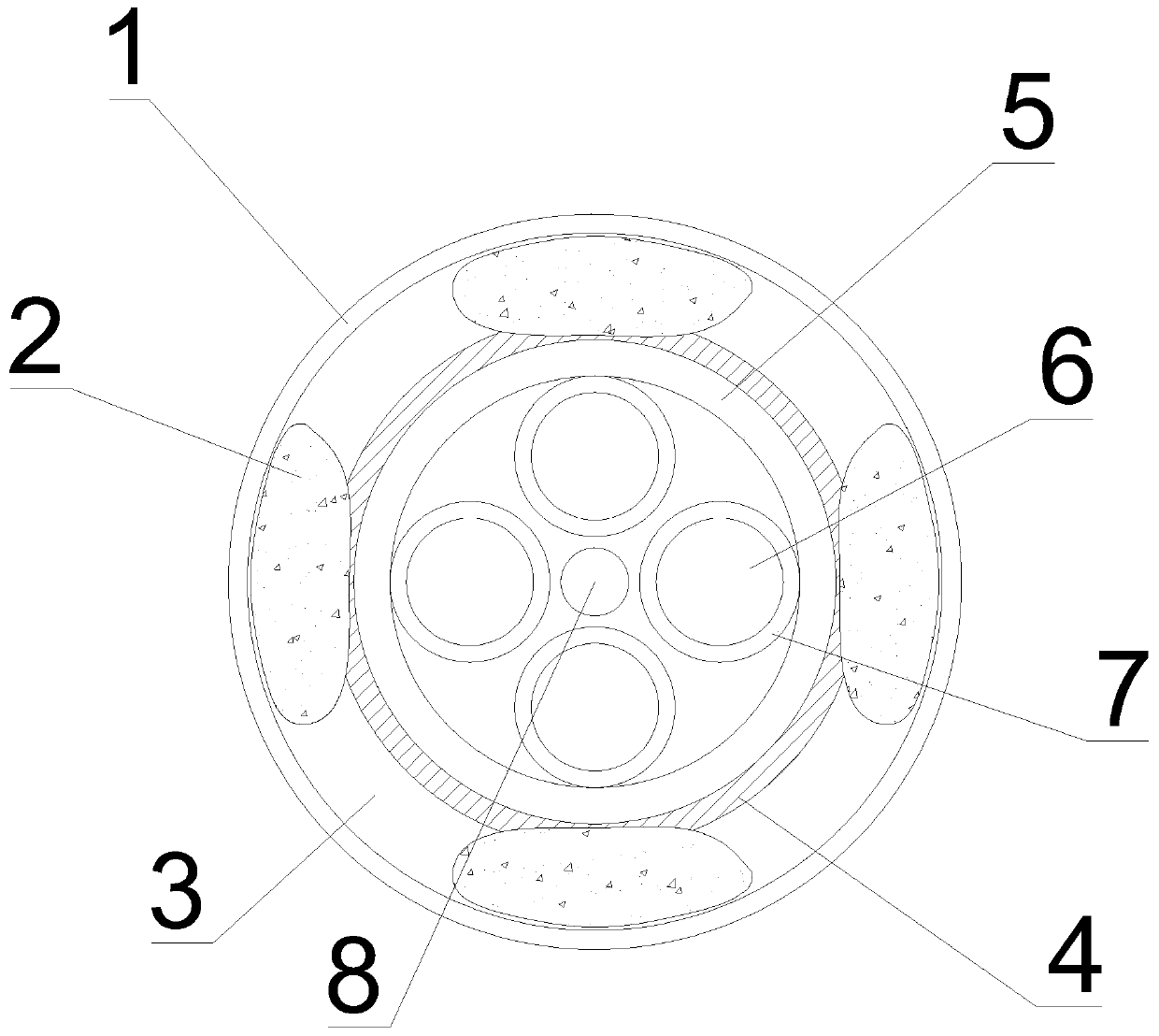

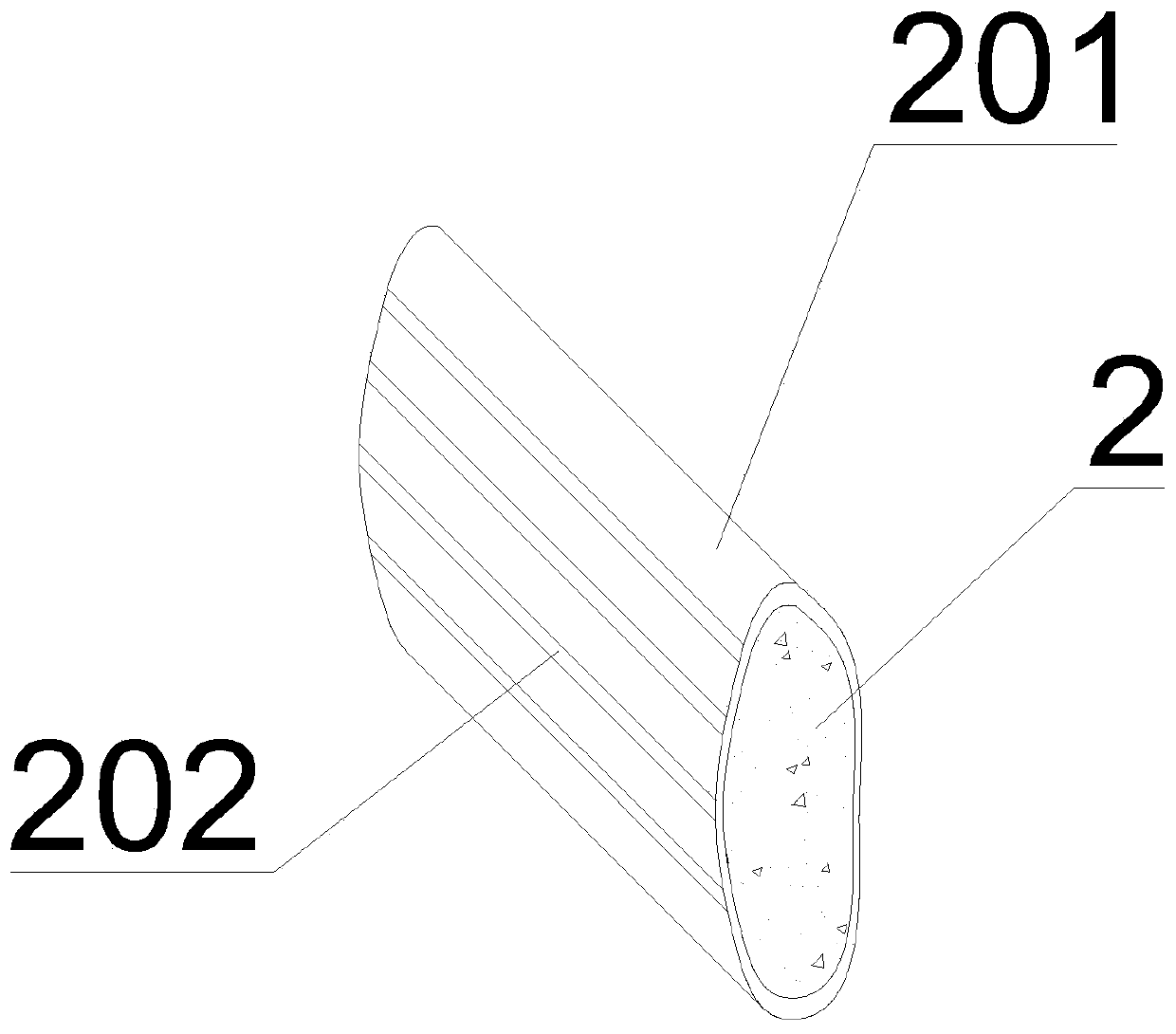

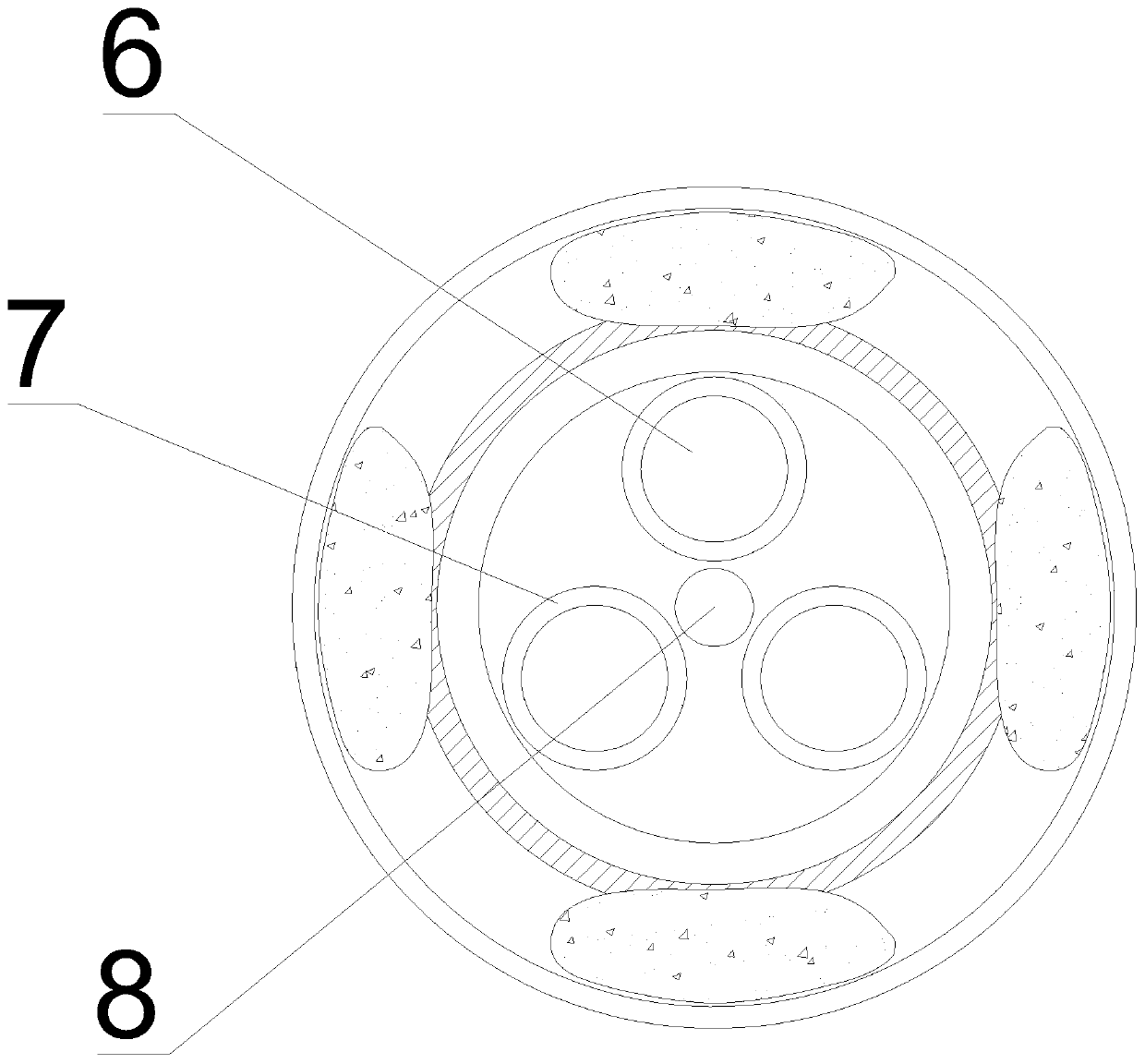

Sheath fire-resistant wire and cable

ActiveCN110444330AImprove fire protectionImprove insulation performanceInsulated cablesFire rescueElectrical conductorThermal insulation

The invention belongs to the technical field of wires and cables, and particularly relates to a sheath fire-resistant wire and cable. Aiming at the problems that the existing traditional fireproof cable cannot meet the current situation, the manufacturing process is complex, the production cost is high, and the practical application is not facilitated. A scheme is proposed as follows: the sheath fireproof wire and cable comprises a supporting framework, conductors, a flame-retardant layer and a sheath; the supporting framework is located at the center of the cable, and the supporting frameworkis an elastic framework; a plurality of conductors are arranged and are uniformly distributed along the supporting framework as the circle center; an insulating layer is arranged on the outside of the conductors; the insulating layer, the conductors and the framework form an inner core of the cable; the outer part of the inner core is provided with a steel wire armor layer, and the outer part ofthe steel wire armor layer is wrapped with an isolation sleeve; a plurality of flame retardant layers are arranged outside the isolation sleeve; a sheath is arranged outside the flame retardant layers; and a hollow cavity is formed among the flame retardant layers, the sheath and the isolation sleeve. The cable is simple in structure, high in thermal insulation effect and high in flame retardancy.

Owner:扬州利家科技有限公司

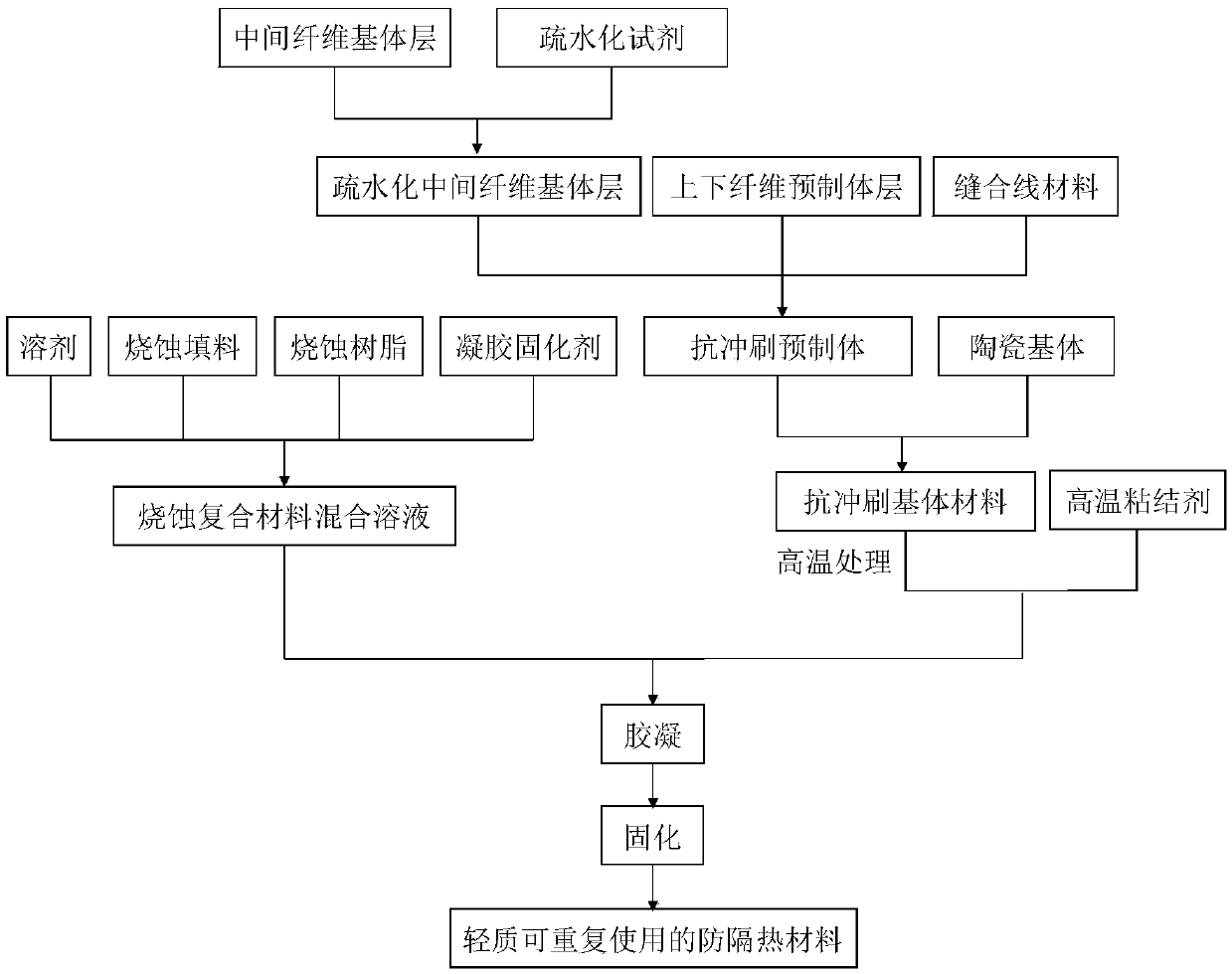

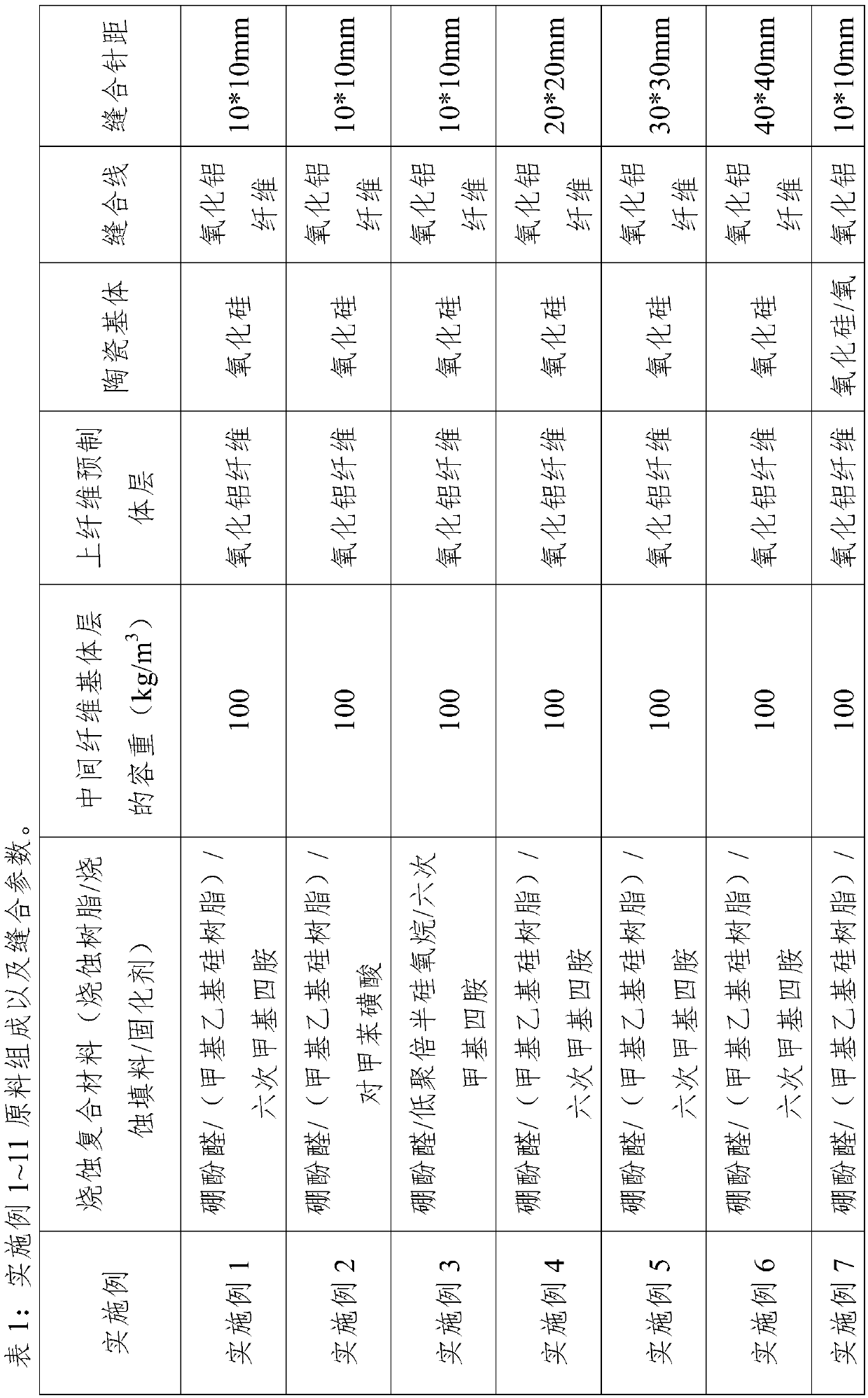

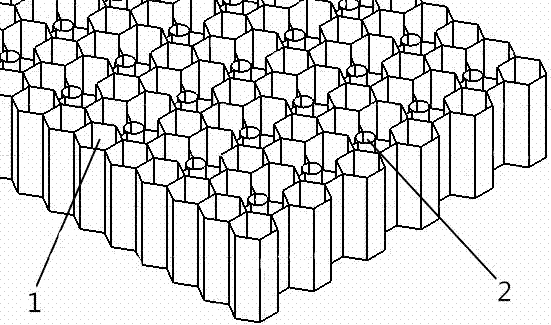

Light reusable thermal insulation material and preparation method thereof

ActiveCN111285699AExcellent ablation and heat insulation functionStrong shape and thermal insulationThermal insulationFiber matrix

The invention relates to a light reusable thermal insulation material and a preparation method thereof. The thermal insulation material comprises an anti-scouring matrix material and an ablative composite material which is compounded with the anti-scouring matrix material and comprises an ablative resin, a gel curing agent and an ablative filler, wherein the anti-scouring matrix material comprisesan anti-scouring prefabricated body and a ceramic base body compounded with the anti-scouring prefabricated body, and the anti-scouring prefabricated body comprises an upper fiber prefabricated bodylayer, a lower fiber prefabricated body layer and a middle fiber base body layer. The method comprises the following steps: combining an upper fiber prefabricated body layer, a lower fiber prefabricated body layer and a middle fiber matrix layer to prepare an anti-scouring prefabricated body, and then compounding the anti-scouring prefabricated body with a ceramic matrix to prepare an anti-scouring matrix material; impregnating the anti-scouring matrix material with an ablative composite material mixed solution; and sequentially carrying out gelatinization and solidification on the anti-scouring matrix material to obtain the thermal insulation material. The thermal insulation material has the advantages of being excellent in ablation thermal insulation performance, high in shape maintaining capacity and capable of being repeatedly used.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

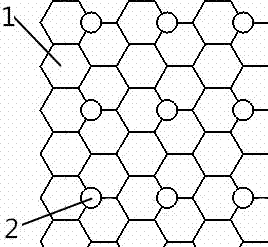

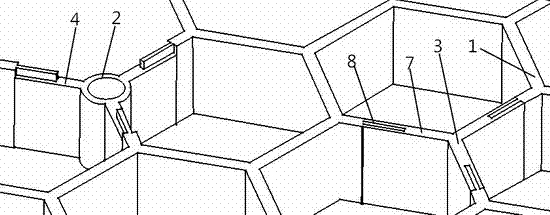

Regular-hexagon honeycomb core with detachable circular noise-reducing structures

InactiveCN107023743ACompressive strengthStrong insulationElongated constructional elementsActive forceHoneycomb structure

The invention discloses a regular-hexagon honeycomb core with detachable circular noise-reducing structures. The regular-hexagon honeycomb core comprises regular-hexagon honeycomb main structures, circular honeycomb structures and Y-shaped aluminum components, wherein the circular honeycomb structures are added among the regular-hexagon honeycomb main structures; part of wall plates at the positions, where the circular honeycomb structures and the Y-shaped aluminum components are mounted, of the regular-hexagon honeycomb main structures are lacking; the extra spaces are suitable for the mounting of the detachable circular honeycomb structures; the radiuses, the heights and the mounting density of the circular honeycomb structures can be adjusted as required; once one circular honeycomb structure is not needed, the circular honeycomb structure can be replaced by one Y-shaped aluminum component; not only the regular-hexagon honeycomb main structures and the circular honeycomb structures but also the regular-hexagon honeycomb main structures and the Y-shaped aluminum components can be fastened by adopting the mutually active force generated from material plasticity deformation; and accordingly, the Y-shaped aluminum components can also be detached.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com